boot ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 288 of 1640

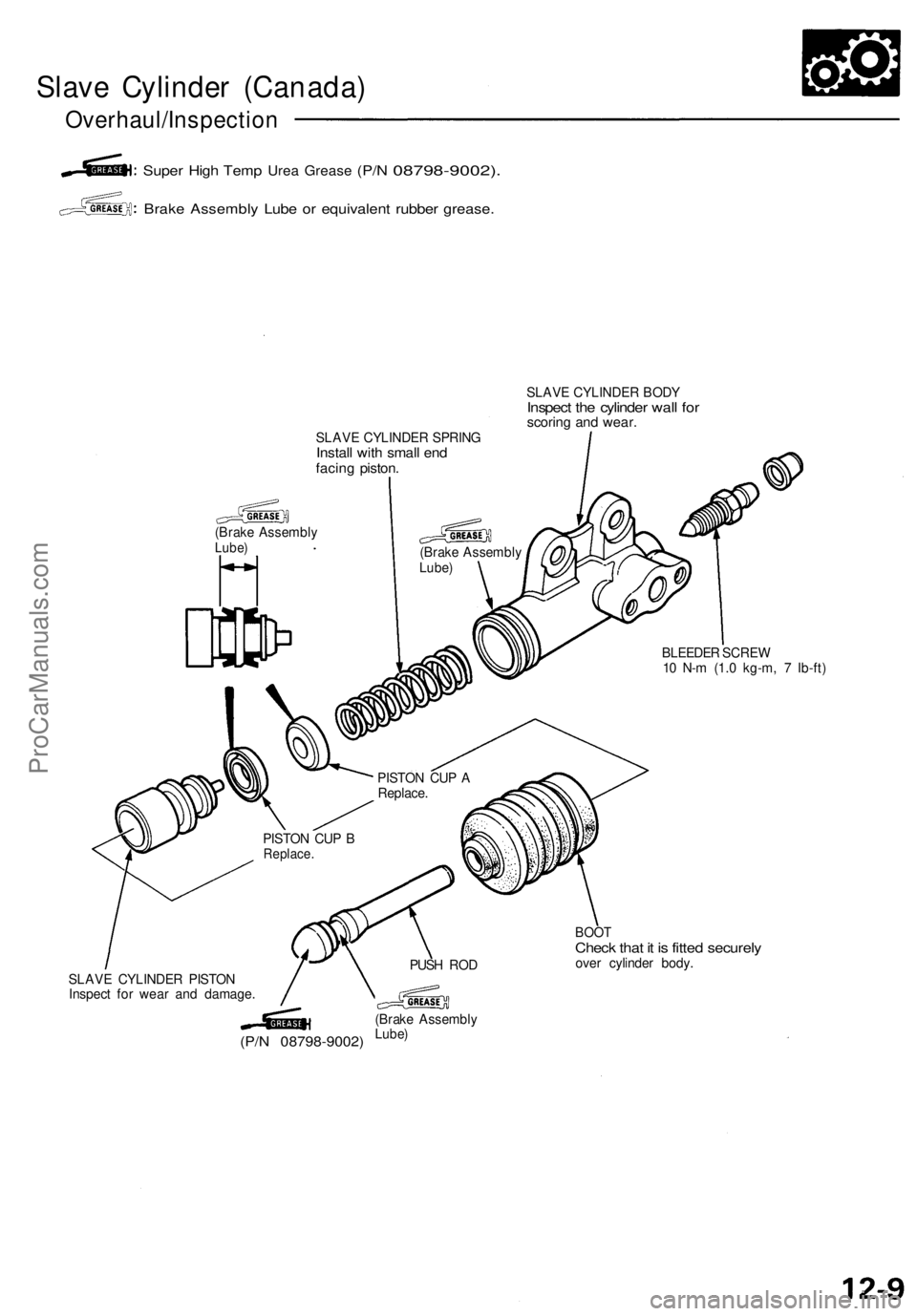

Slave Cylinder (Canada)

Overhaul/Inspection

Super High Temp

Urea

Grease

(P/N

08798-9002).

Brake Assembly Lube or equivalent rubber grease.

SLAVE CYLINDER SPRING

Install with small end

facing piston.

(Brake Assembly

Lube)

SLAVE CYLINDER BODY

Inspect the cylinder wall for

scoring and wear.

(Brake Assembly

Lube)

BLEEDER SCREW

10 N-m (1.0 kg-m, 7 Ib-ft)

SLAVE CYLINDER PISTON

Inspect for wear and damage.

(P/N 08798-9002)

(Brake Assembly

Lube)

BOOT

Check that it is fitted securely

over cylinder body.

PUSH ROD

PISTON CUP B

Replace.

PISTON CUP A

Replace.ProCarManuals.com

Page 387 of 1640

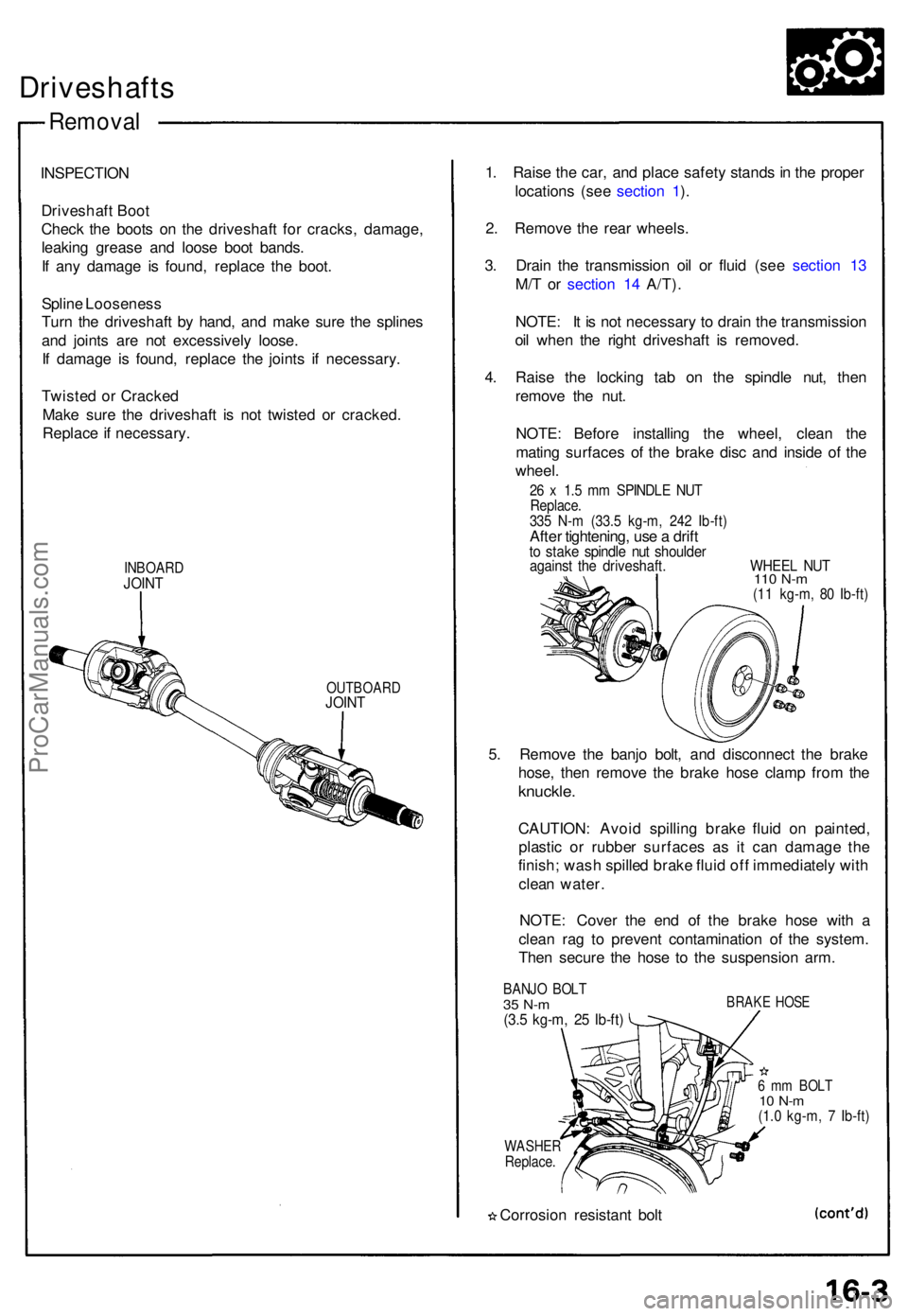

Driveshafts

Removal

INSPECTIO N

Driveshaf t Boo t

Chec k th e boot s o n th e driveshaf t fo r cracks , damage ,

leakin g greas e an d loos e boo t bands .

I f an y damag e i s found , replac e th e boot .

Splin e Loosenes s

Tur n th e driveshaf t b y hand , an d mak e sur e th e spline s

an d joint s ar e no t excessivel y loose .

I f damag e i s found , replac e th e joint s i f necessary .

Twiste d o r Cracke d

Mak e sur e th e driveshaf t i s no t twiste d o r cracked .

Replac e if necessary .

INBOARDJOINT

OUTBOAR DJOINT

1. Rais e th e car , an d plac e safet y stand s in th e prope r

location s (se e sectio n 1 ).

2 . Remov e th e rea r wheels .

3 . Drai n th e transmissio n oi l o r flui d (se e sectio n 1 3

M/ T o r sectio n 1 4 A/T) .

NOTE : I t i s no t necessar y t o drai n th e transmissio n

oi l whe n th e righ t driveshaf t i s removed .

4 . Rais e th e lockin g ta b o n th e spindl e nut , the n

remov e th e nut .

NOTE : Befor e installin g th e wheel , clea n th e

matin g surface s of the brak e dis c an d insid e of the

wheel .

26 x 1. 5 m m SPINDL E NU TReplace .335 N- m (33. 5 kg-m , 24 2 Ib-ft )After tightening , us e a drif tto stak e spindl e nu t shoulde ragainst th e driveshaft . WHEE L NU T110 N- m(11 kg-m , 8 0 Ib-ft )

5. Remov e th e banj o bolt , an d disconnec t th e brak e

hose , the n remov e th e brak e hos e clam p fro m th e

knuckle .

CAUTION : Avoi d spillin g brak e flui d o n painted ,

plasti c o r rubbe r surface s a s i t ca n damag e th e

finish ; was h spille d brak e flui d of f immediatel y wit h

clea n water .

NOTE : Cove r th e en d o f th e brak e hos e wit h a

clea n ra g t o preven t contaminatio n of the system.

The n secur e th e hos e t o th e suspensio n arm .

BANJ O BOL T35 N- m(3.5 kg-m , 2 5 Ib-ft )

BRAK E HOS E

WASHE RReplace.

Corrosio n resistan t bol t

6 m m BOL T10 N- m(1.0 kg-m , 7 Ib-ft )

ProCarManuals.com

Page 390 of 1640

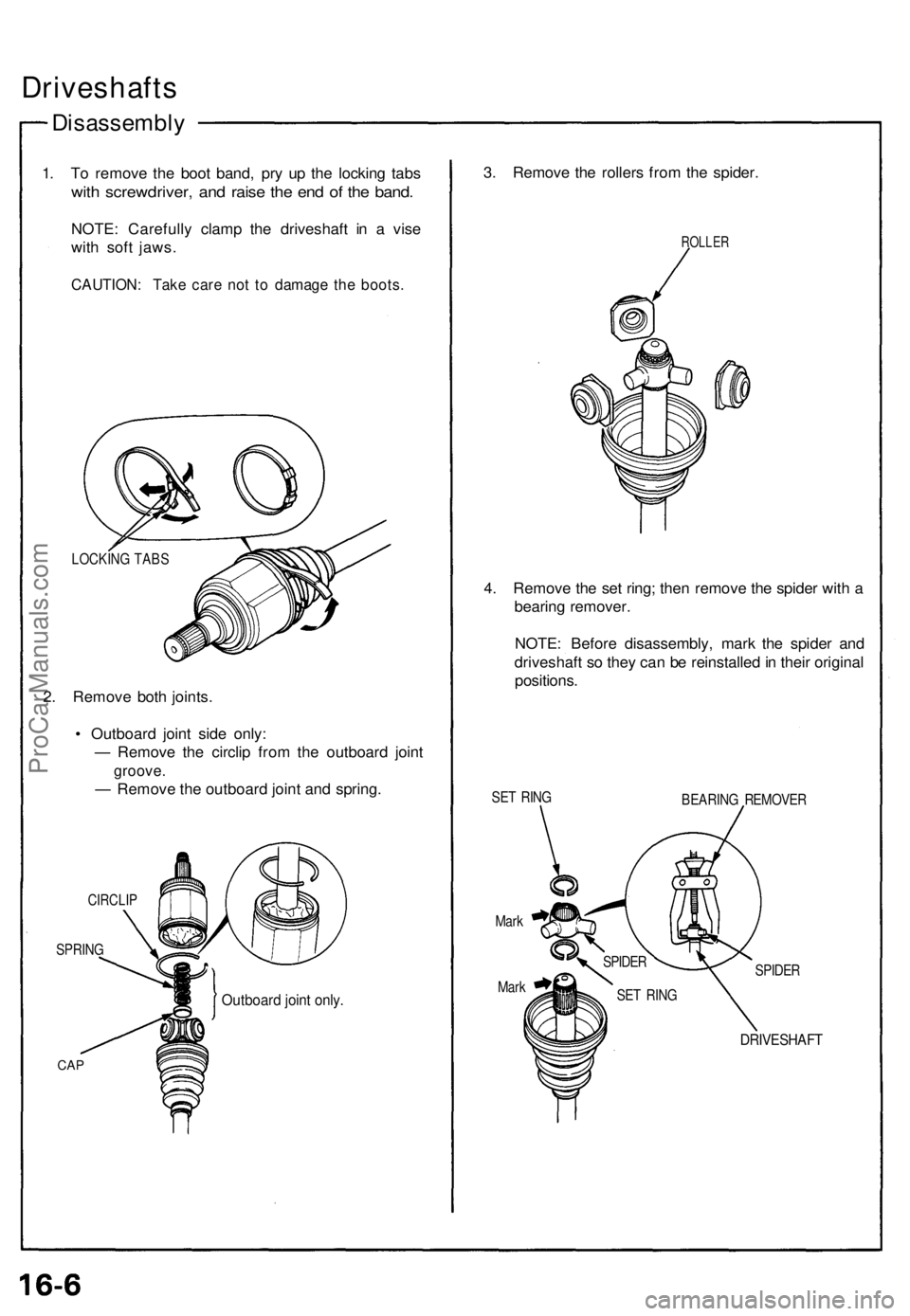

Driveshafts

Disassembly

1. To remove the boot band, pry up the locking tabs

with screwdriver, and raise the end of the band.

NOTE: Carefully clamp the driveshaft in a vise

with soft jaws.

CAUTION: Take care not to damage the boots.

LOCKING TABS

2. Remove both joints.

• Outboard joint side only:

— Remove the circlip from the outboard joint

groove.

— Remove the outboard joint and spring.

CIRCLIP

SPRING

CAP

Outboard joint only.

3. Remove the rollers from the spider.

ROLLER

4. Remove the set ring; then remove the spider with a

bearing remover.

NOTE: Before disassembly, mark the spider and

driveshaft so they can be reinstalled in their original

positions.

SET RING

BEARING REMOVER

Mark

Mark

SPIDER

DRIVESHAFT

SPIDER

SET RINGProCarManuals.com

Page 391 of 1640

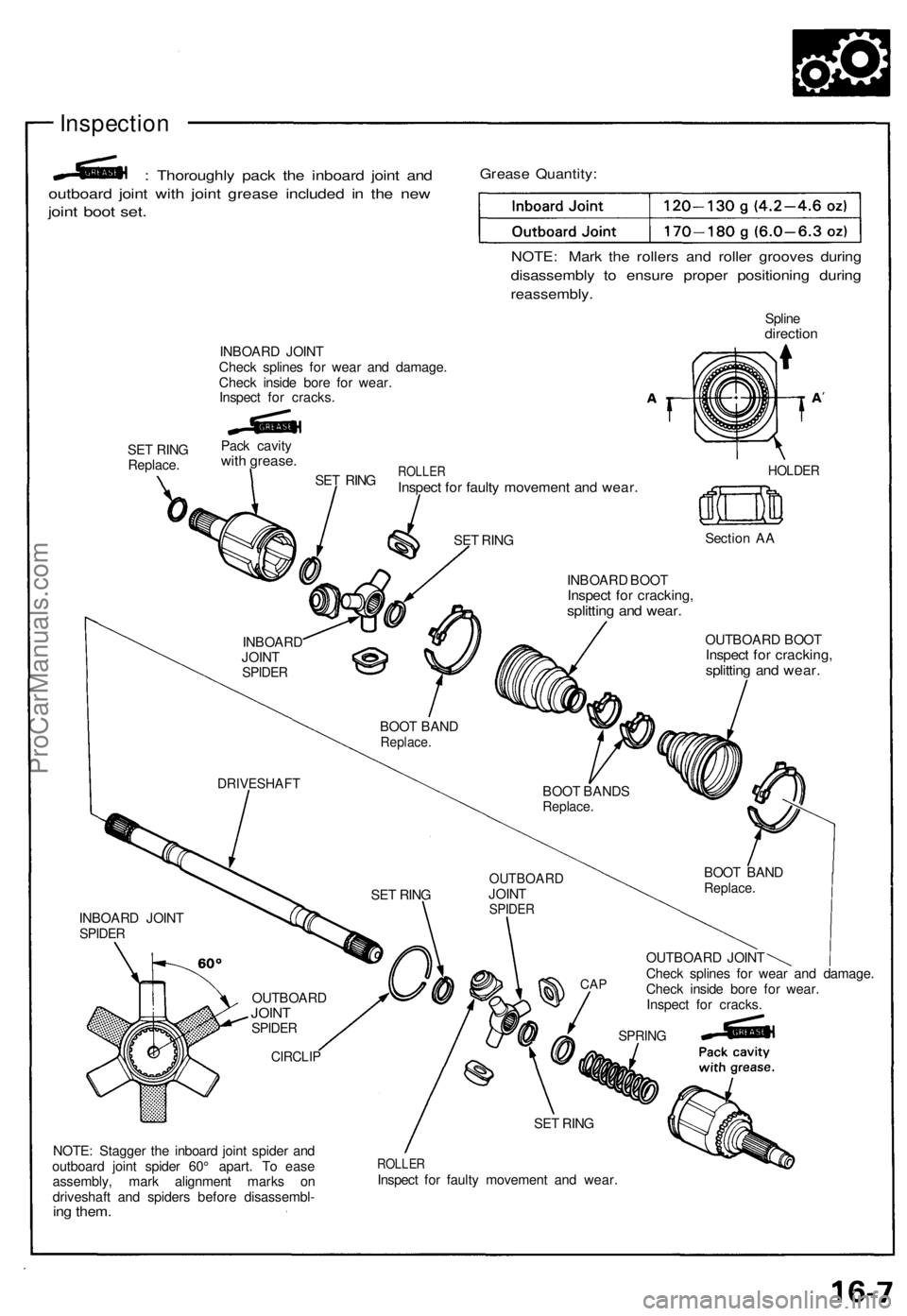

Inspection

: Thoroughly pack the inboard joint and

outboard joint with joint grease included in the new

joint boot set.

Grease Quantity:

NOTE: Mark the rollers and roller grooves during

disassembly to ensure proper positioning during

reassembly.

Spline

direction

INBOARD JOINT

Check splines for wear and damage.

Check inside bore for wear.

Inspect for cracks.

SET RING

Replace.

Pack cavity

with grease.

SET RING

ROLLER

Inspect for faulty movement and wear.

HOLDER

Section AA

INBOARD BOOT

Inspect for cracking,

splitting and wear.

OUTBOARD BOOT

Inspect for cracking,

splitting and wear.

OUTBOARD JOINT

Check splines for wear and damage.

Check inside bore for wear.

Inspect for cracks.

NOTE: Stagger the inboard joint spider and

outboard joint spider 60° apart. To ease

assembly, mark alignment marks on

driveshaft and spiders before disassembl-

ing them.

ROLLER

Inspect for faulty movement and wear.

DRIVESHAFT

SET RING

OUTBOARD

JOINT

SPIDER

CAP

SPRING

SET RING

CIRCLIP

OUTBOARD

JOINT

SPIDER

INBOARD JOINT

SPIDER

BOOT BAND

Replace.

BOOT BANDS

Replace.

BOOT BAND

Replace.

INBOARD

JOINT

SPIDER

SET RINGProCarManuals.com

Page 392 of 1640

Driveshafts

Reassembl y

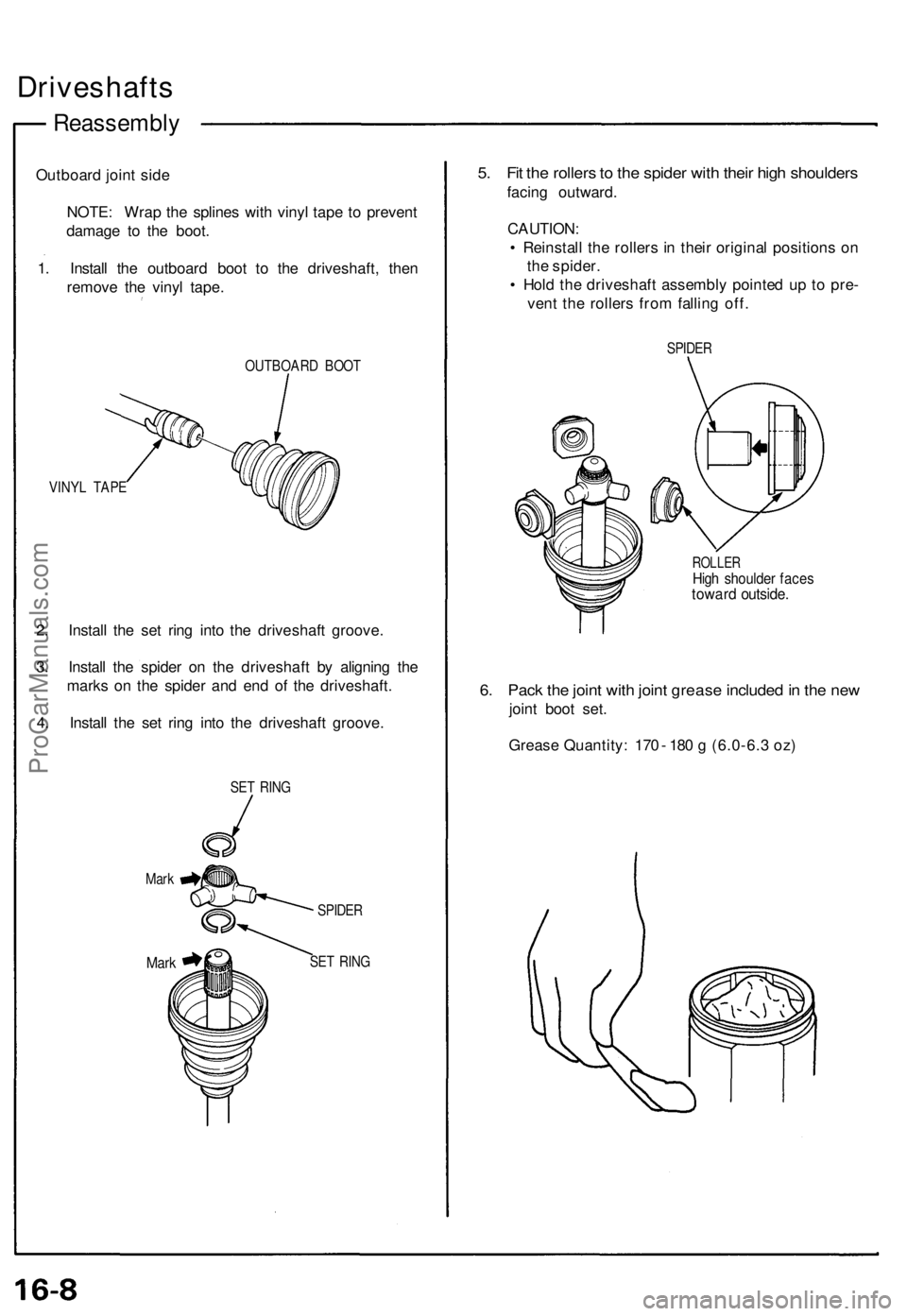

Outboard join t sid e

NOTE : Wra p th e spline s wit h viny l tap e t o preven t

damag e t o th e boot .

1 . Instal l th e outboar d boo t t o th e driveshaft , the n

remov e th e viny l tape .

OUTBOAR D BOO T

VINY L TAP E

2. Instal l th e se t rin g int o th e driveshaf t groove .

3 . Instal l th e spide r o n th e driveshaf t b y alignin g th e

mark s o n th e spide r an d en d o f th e driveshaft .

4 . Instal l th e se t rin g int o th e driveshaf t groove .

SET RIN G

Mar k

Mark

SPIDE R

SE T RIN G

5. Fi t th e roller s to th e spide r wit h thei r hig h shoulder s

facing outward .

CAUTION :

• Reinstal l th e roller s in thei r origina l position s o n

th e spider .

• Hol d th e driveshaf t assembl y pointe d u p t o pre -

ven t th e roller s fro m fallin g off .

SPIDE R

ROLLE RHigh shoulde r face stowar d outside .

6. Pac k th e join t wit h join t greas e include d in th e ne w

join t boo t set .

Greas e Quantity : 17 0 - 18 0 g (6.0-6. 3 oz)

ProCarManuals.com

Page 393 of 1640

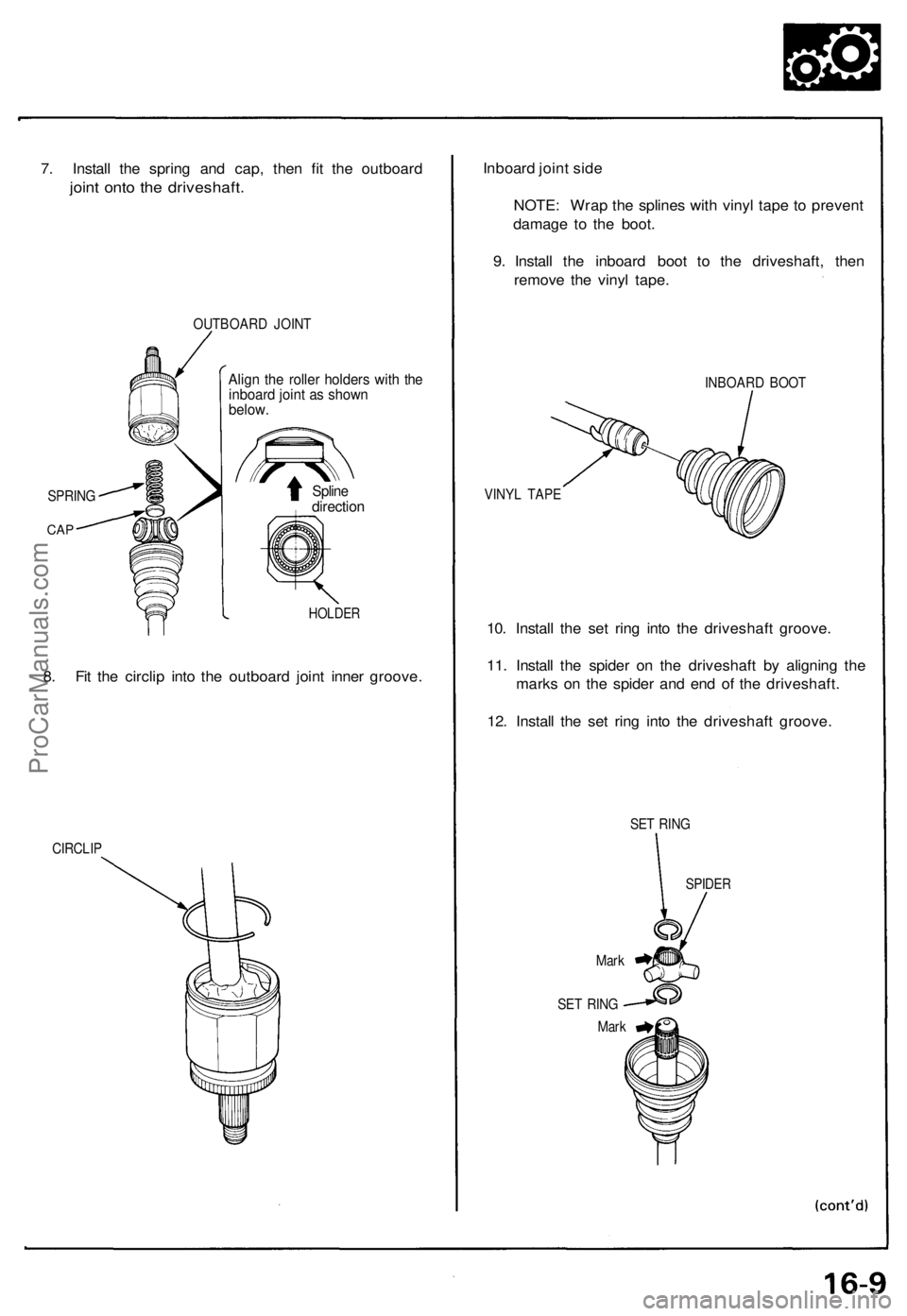

7. Install the spring and cap, then fit the outboard

joint onto the driveshaft.

OUTBOARD JOINT

Align the roller holders with the

inboard joint as shown

below.

Spline

direction

HOLDER

8. Fit the circlip into the outboard joint inner groove.

CIRCLIP

Inboard joint side

NOTE: Wrap the splines with vinyl tape to prevent

damage to the boot.

9. Install the inboard boot to the driveshaft, then

remove the vinyl tape.

INBOARD BOOT

VINYL TAPE

10. Install the set ring into the driveshaft groove.

11. Install the spider on the driveshaft by aligning the

marks on the spider and end of the driveshaft.

12. Install the set ring into the driveshaft groove.

SET RING

Mark

SET RING

Mark

SPIDER

SPRING

CAPProCarManuals.com

Page 394 of 1640

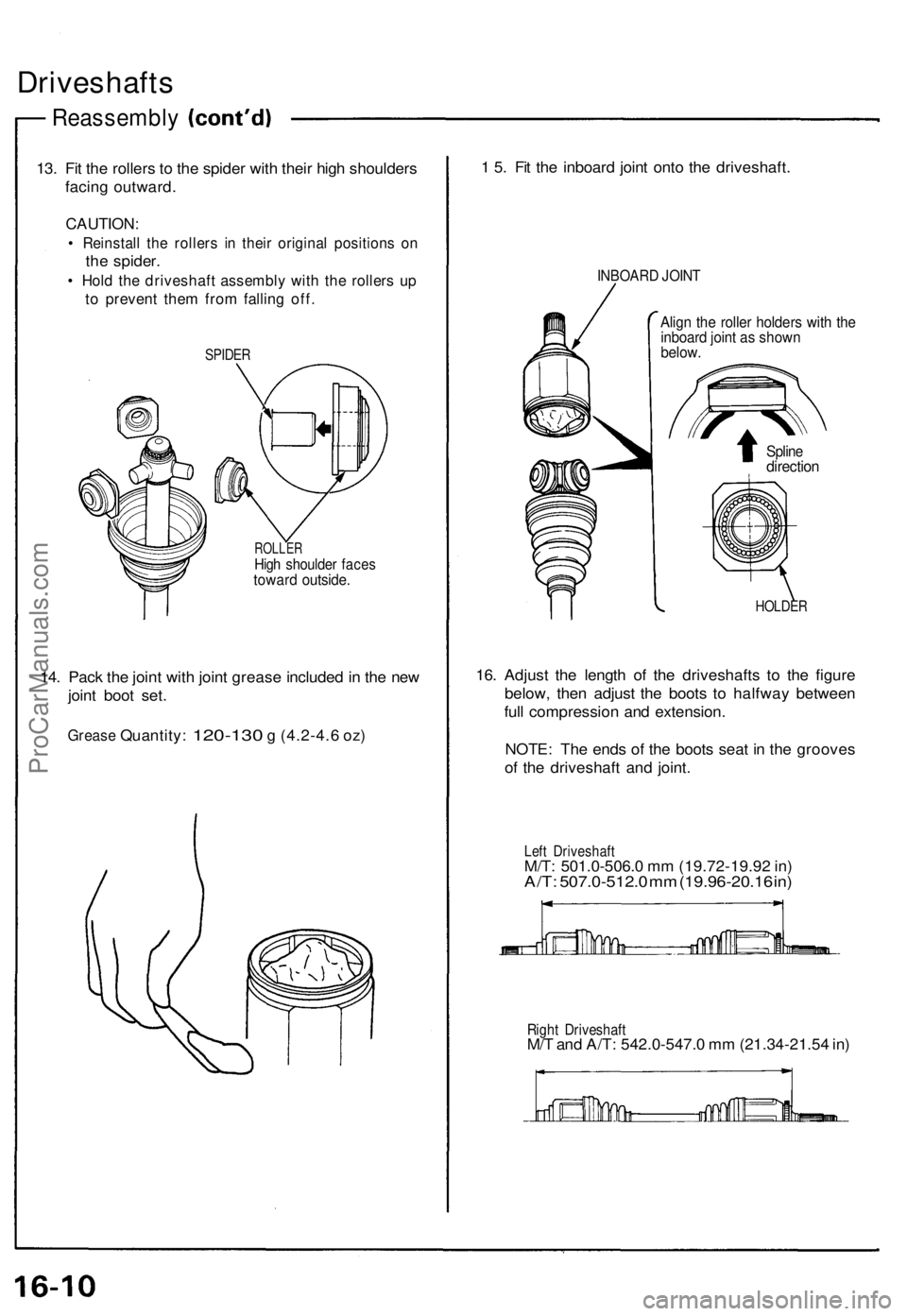

Driveshafts

Reassembl y

13. Fi t th e roller s t o th e spide r wit h thei r hig h shoulder s

facin g outward .

CAUTION :

• Reinstal l th e roller s i n thei r origina l position s o n

the spider .

• Hol d th e driveshaf t assembl y wit h th e roller s u p

to preven t the m fro m fallin g off .

SPIDE R

ROLLE RHigh shoulde r face stowar d outside .

14. Pac k th e join t wit h join t greas e include d in th e ne w

join t boo t set .

Greas e Quantity : 120-130 g (4.2-4. 6 oz)

1 5 . Fi t th e inboar d join t ont o th e driveshaft .

INBOARD JOIN T

Align th e rolle r holder s wit h th einboar d join t a s show nbelow.

HOLDE R

16. Adjus t th e lengt h o f th e driveshaft s t o th e figur e

below , the n adjus t th e boot s t o halfwa y betwee n

ful l compressio n an d extension .

NOTE : Th e end s o f th e boot s sea t i n th e groove s

o f th e driveshaf t an d joint .

Left Driveshaf tM/T: 501.0-506. 0 m m (19.72-19.9 2 in )A/T : 507.0-512. 0 m m (19.96-20.1 6 in )

Righ t Driveshaf tM/T an d A/T : 542.0-547. 0 m m (21.34-21.5 4 in )

Splin edirectio n

ProCarManuals.com

Page 395 of 1640

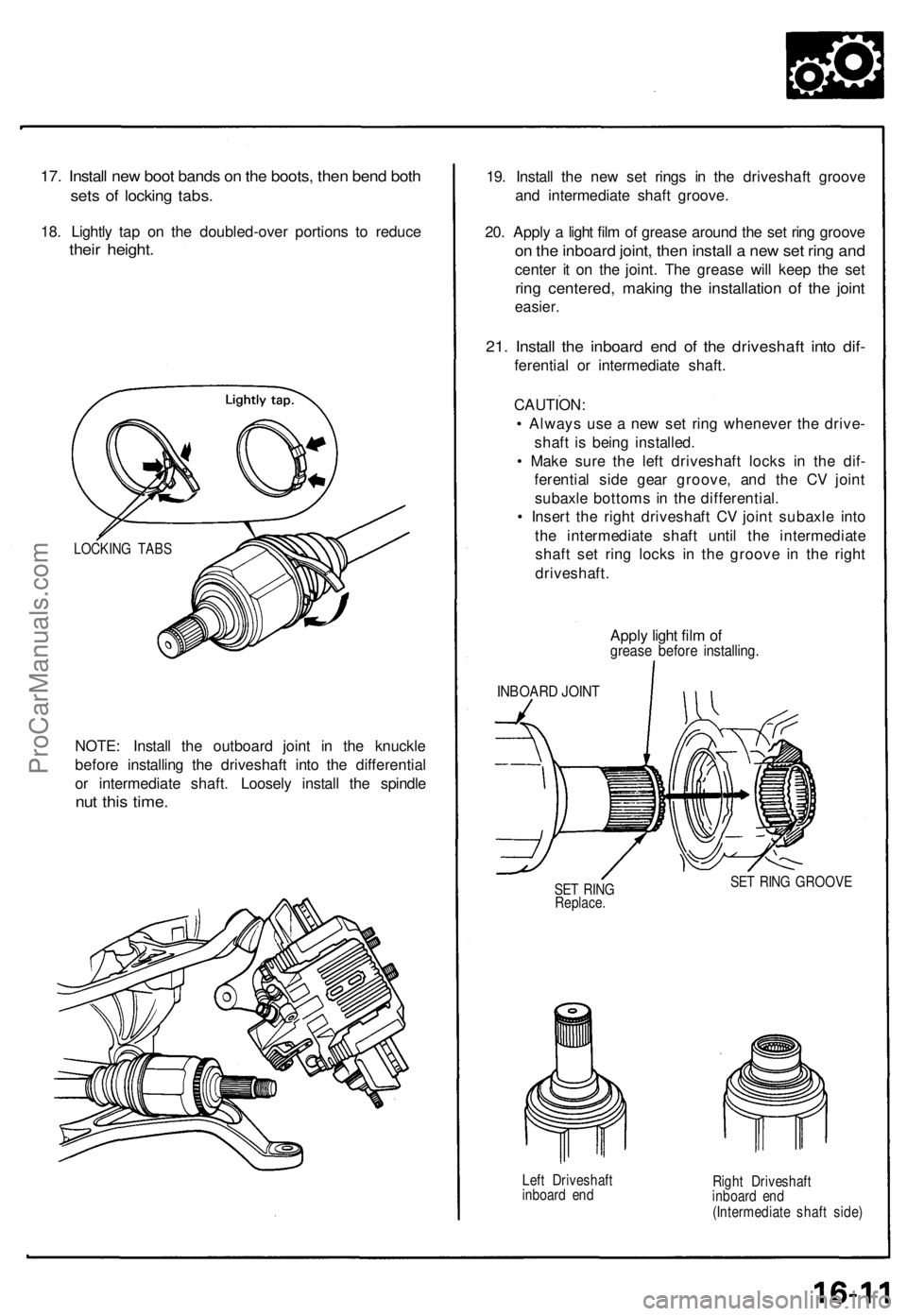

17. Install new boot bands on the boots, then bend both

sets of locking tabs.

18. Lightly tap on the doubled-over portions to reduce

their height.

NOTE: Install the outboard joint in the knuckle

before installing the driveshaft into the differential

or intermediate shaft. Loosely install the spindle

nut this time.

19. Install the new set rings in the driveshaft groove

and intermediate shaft groove.

20. Apply a light film of grease around the set ring groove

on the inboard joint, then install a new set ring and

center it on the joint. The grease will keep the set

ring centered, making the installation of the joint

easier.

21. Install the inboard end of the driveshaft into dif-

ferential or intermediate shaft.

CAUTION:

• Always use a new set ring whenever the drive-

shaft is being installed.

• Make sure the left driveshaft locks in the dif-

ferential side gear groove, and the CV joint

subaxle bottoms in the differential.

• Insert the right driveshaft CV joint subaxle into

the intermediate shaft until the intermediate

shaft set ring locks in the groove in the right

driveshaft.

Apply light film of

grease before installing.

INBOARD JOINT

SET RING

Replace.

SET RING GROOVE

Left Driveshaft

inboard end

Right Driveshaft

inboard end

(Intermediate shaft side)

LOCKING TABSProCarManuals.com

Page 437 of 1640

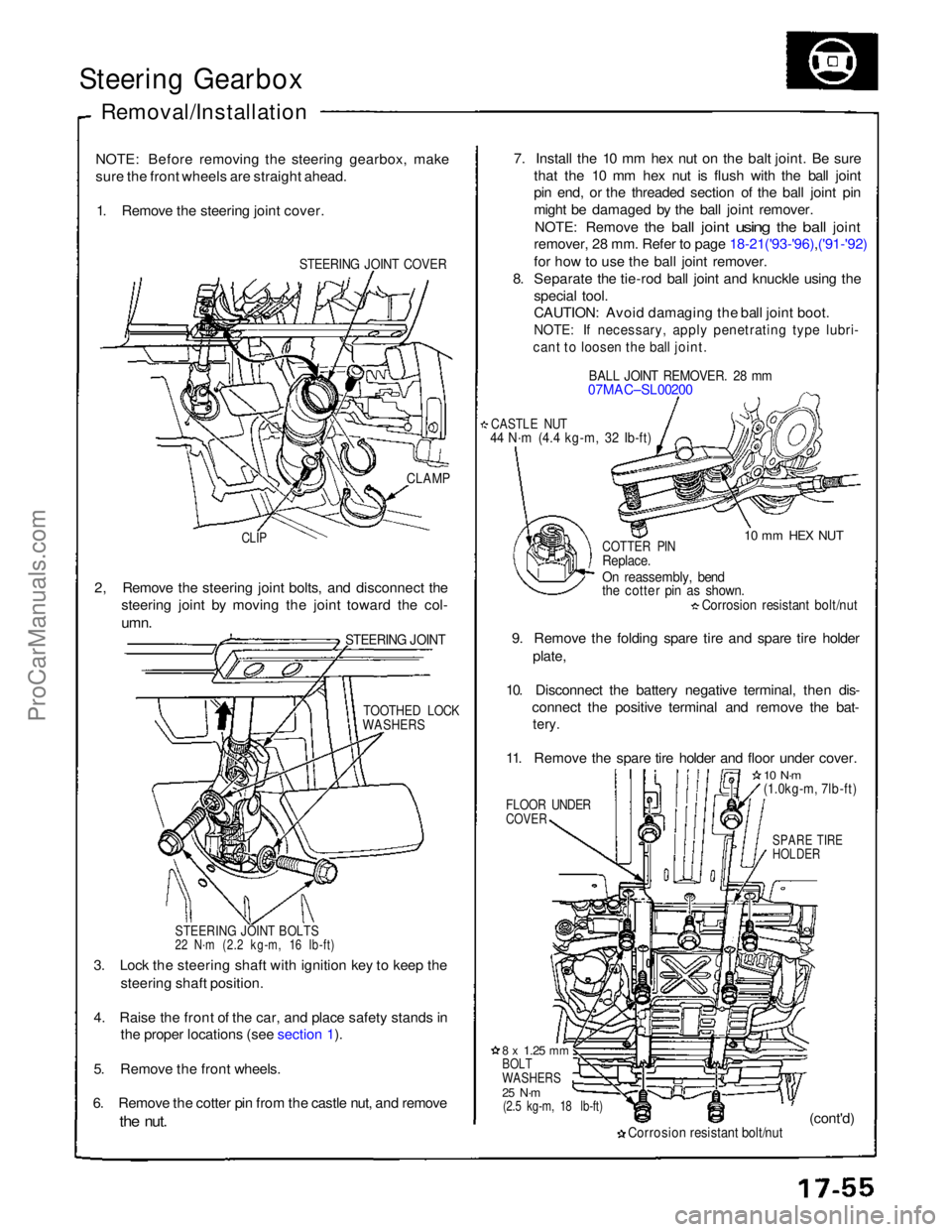

Steering Gearbox

Removal/Installation

NOTE: Before removing the steering gearbox, make

sure the front wheels are straight ahead. 1. Remove the steering joint cover.

STEERING JOINT COVER

7. Install the 10 mm hex nut on the balt joint. Be sure

that the 10 mm hex nut is flush with the ball joint

pin end, or the threaded section of the ball joint pin

might be damaged by the ball joint remover.

NOTE: Remove

the

ball

joint

using

the

ball

joint

remover, 28 mm. Refer to page 18-21('93-'96),('91-'92)

for how to use the ball joint remover.

8. Separate the tie-rod ball joint and knuckle using the

special tool.

CAUTION: Avoid damaging the ball joint boot.

NOTE: If necessary, apply penetrating type lubri-

cant to loosen the ball joint.

BALL JOINT REMOVER. 28 mm

07MAC–SL00200

CASTLE NUT

44 N·m (4.4 kg-m, 32 Ib-ft)

10 mm HEX NUT

CLAMP

CLIP

COTTER PIN

Replace.

On reassembly, bend

the cotter pin as shown.

Corrosion resistant bolt/nut

9. Remove the folding spare tire and spare tire holder plate,

10. Disconnect the battery negative terminal, then dis- connect the positive terminal and remove the bat-

tery.

11. Remove the spare tire holder and floor under cover.

FLOOR UNDER

COVER

10 N·m

(1.0kg-m, 7lb-ft)

SPARE TIRE

HOLDER

2, Remove the steering joint bolts, and disconnect the

steering joint by moving the joint toward the col-

umn.

STEERING JOINT

TOOTHED LOCK

WASHERS

STEERING JOINT BOLTS

22 N·m (2.2 kg-m, 16 Ib-ft)

3. Lock the steering shaft with ignition key to keep the steering shaft position.

4. Raise the front of the car, and place safety stands in the proper locations (see section 1).

5. Remove the front wheels.

6. Remove the cotter pin from the castle nut, and remove

the

nut.

8 x

1.25

mm

BOLT

WASHERS

25 N·m

(2.5 kg-m, 18 lb-ft)

Corrosion resistant bolt/nut

(cont'd)ProCarManuals.com

Page 441 of 1640

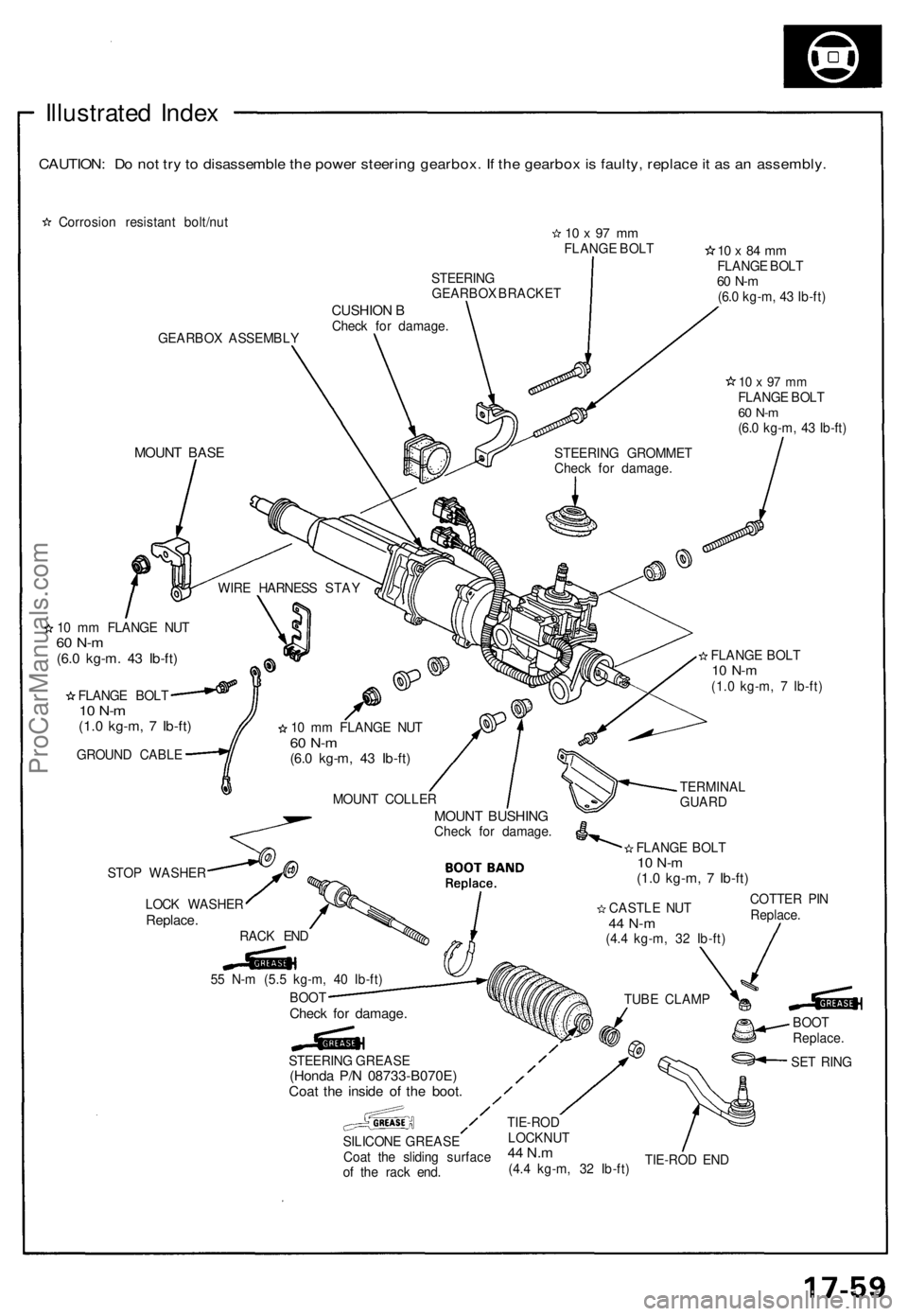

Illustrated Inde x

CAUTION : D o no t tr y to disassembl e th e powe r steerin g gearbox . I f th e gearbo x is faulty , replac e it a s a n assembly .

Corrosion resistan t bolt/nu t10 x 97 m mFLANG E BOL T

GEARBO X ASSEMBL Y STEERIN

G

GEARBO X BRACKE T

CUSHION BChec k fo r damage .

10 x 84 m mFLANG E BOL T60 N- m(6.0 kg-m , 4 3 Ib-ft )

10 x 97 m mFLANG E BOL T60 N- m(6.0 kg-m , 4 3 Ib-ft )

MOUN T BAS E

10 m m FLANG E NU T60 N- m(6.0 kg-m . 4 3 Ib-ft )

FLANG E BOL T10 N- m(1.0 kg-m , 7 Ib-ft )

GROUN D CABL E

STO P WASHE R

LOC K WASHE R

Replace.RACK EN D

TIE-ROD EN D

STEERIN

G GROMME T

Chec k fo r damage .

WIR E HARNES S STA Y

1 0 m m FLANG E NU T

60 N- m(6.0 kg-m , 4 3 Ib-ft )

FLANG E BOL T10 N- m(1.0 kg-m , 7 Ib-ft )

MOUN T COLLE R

MOUNT BUSHIN GCheck fo r damage .

FLANGE BOL T

10 N- m(1.0 kg-m , 7 Ib-ft )

TERMINA L

GUAR D

COTTE R PI N

Replace .

CASTL

E NU T

44 N- m(4.4 kg-m , 3 2 Ib-ft )

TUB E CLAM P

BOOT

Replace .

SE T RIN G

STEERIN

G GREAS E

(Honda P/ N 08733-B070E )Coat th e insid e o f th e boot .

SILICON E GREAS E

Coa t th e slidin g surfac e

o f th e rac k end .

TIE-RO DLOCKNU T44 N.m(4.4 kg-m , 3 2 Ib-ft )

5

5 N- m (5. 5 kg-m , 4 0 Ib-ft )

BOO T

Chec k fo r damage .

ProCarManuals.com