check engine ACURA NSX 1997 Service Owner's Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 707 of 1503

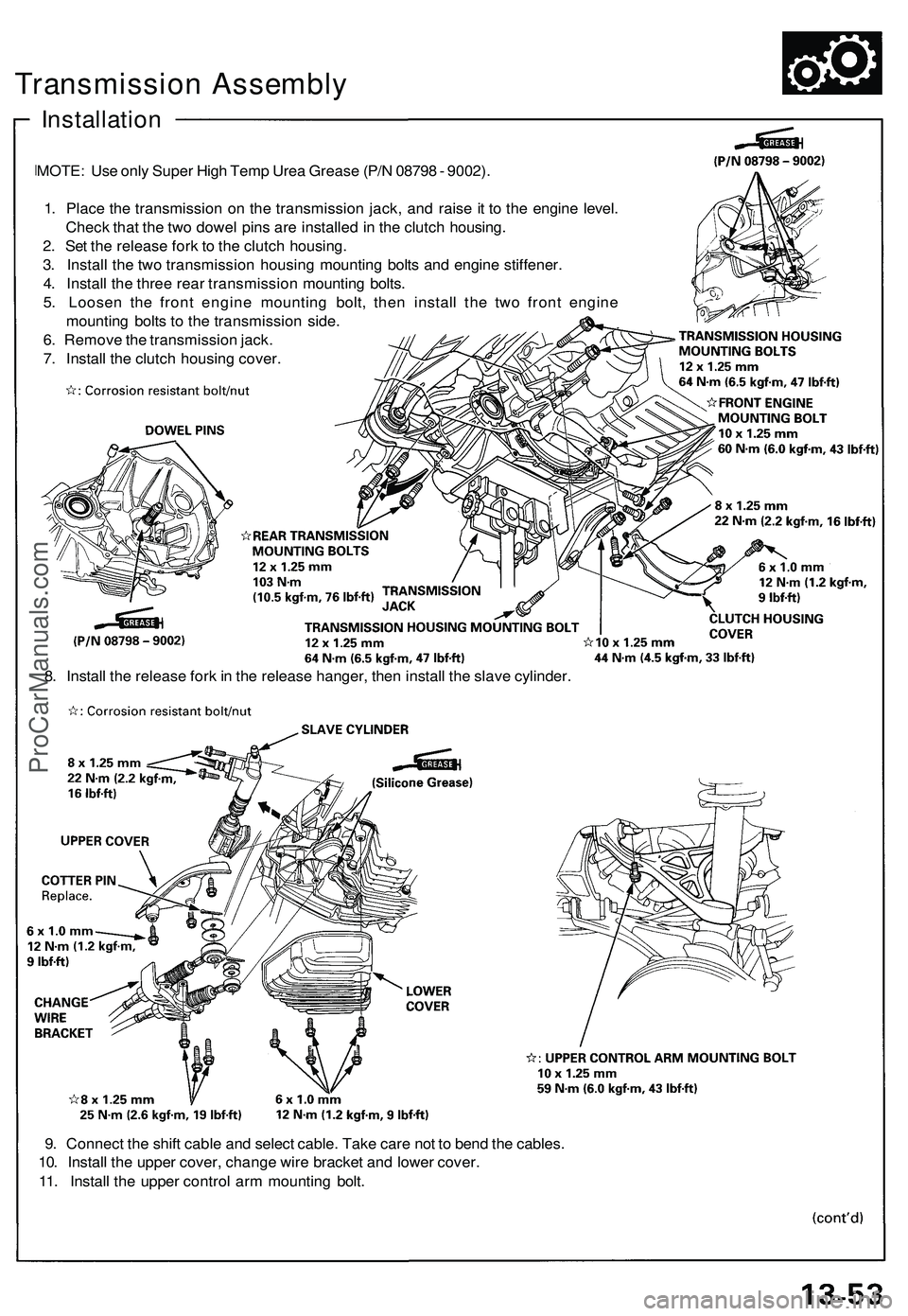

Transmission Assembly

Installation

MOTE: Use only Super High Temp Urea Grease (P/N 08798 - 9002).

1. Place the transmission on the transmission jack, and raise it to the engine level.

Check that the two dowel pins are installed in the clutch housing.

2. Set the release fork to the clutch housing.

3. Install the two transmission housing mounting bolts and engine stiffener.

4. Install the three rear transmission mounting bolts.

5. Loosen the front engine mounting bolt, then install the two front engine

mounting bolts to the transmission side.

6. Remove the transmission jack.

7. Install the clutch housing cover.

8. Install the release fork in the release hanger, then install the slave cylinder.

9. Connect the shift cable and select cable. Take care not to bend the cables.

10. Install the upper cover, change wire bracket and lower cover.

11. Install the upper control arm mounting bolt.ProCarManuals.com

Page 713 of 1503

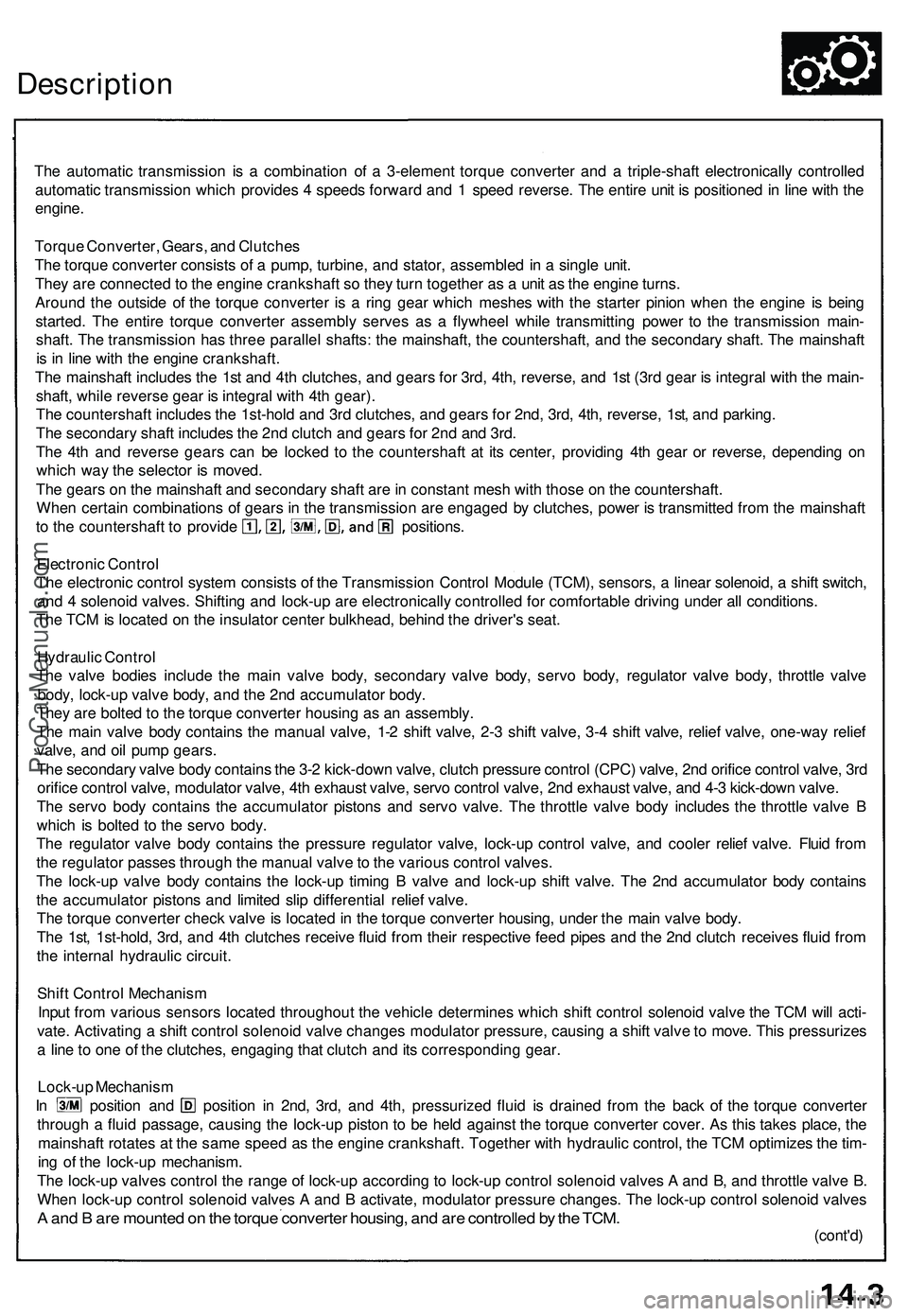

Description

The automatic transmission is a combination of a 3-element torque converter and a triple-shaft electronically controlled

automatic transmission which provides 4 speeds forward and 1 speed reverse. The entire unit is positioned in line with the

engine.

Torque Converter, Gears, and Clutches

The torque converter consists of a pump, turbine, and stator, assembled in a single unit.

They are connected to the engine crankshaft so they turn together as a unit as the engine turns.

Around the outside of the torque converter is a ring gear which meshes with the starter pinion when the engine is being

started. The entire torque converter assembly serves as a flywheel while transmitting power to the transmission main-

shaft. The transmission has three parallel shafts: the mainshaft, the countershaft, and the secondary shaft. The mainshaft

is in line with the engine crankshaft.

The mainshaft includes the 1st and 4th clutches, and gears for 3rd, 4th, reverse, and 1st (3rd gear is integral with the main-

shaft, while reverse gear is integral with 4th gear).

The countershaft includes the 1st-hold and 3rd clutches, and gears for 2nd, 3rd, 4th, reverse, 1st, and parking.

The secondary shaft includes the 2nd clutch and gears for 2nd and 3rd.

The 4th and reverse gears can be locked to the countershaft at its center, providing 4th gear or reverse, depending on

which way the selector is moved.

The gears on the mainshaft and secondary shaft are in constant mesh with those on the countershaft.

When certain combinations of gears in the transmission are engaged by clutches, power is transmitted from the mainshaft

to the countershaft to provide positions.

Electronic Control

The electronic control system consists of the Transmission Control Module (TCM), sensors, a linear solenoid, a shift switch,

and 4 solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located on the insulator center bulkhead, behind the driver's seat.

Hydraulic Control

The valve bodies include the main valve body, secondary valve body, servo body, regulator valve body, throttle valve

body, lock-up valve body, and the 2nd accumulator body.

They are bolted to the torque converter housing as an assembly.

The main valve body contains the manual valve, 1-2 shift valve, 2-3 shift valve, 3-4 shift valve, relief valve, one-way relief

valve, and oil pump gears.

The secondary valve body contains the 3-2 kick-down valve, clutch pressure control (CPC) valve, 2nd orifice control valve, 3rd

orifice control valve, modulator valve, 4th exhaust valve, servo control valve, 2nd exhaust valve, and 4-3 kick-down valve.

The servo body contains the accumulator pistons and servo valve. The throttle valve body includes the throttle valve B

which is bolted to the servo body.

The regulator valve body contains the pressure regulator valve, lock-up control valve, and cooler relief valve. Fluid from

the regulator passes through the manual valve to the various control valves.

The lock-up valve body contains the lock-up timing B valve and lock-up shift valve. The 2nd accumulator body contains

the accumulator pistons and limited slip differential relief valve.

The torque converter check valve is located in the torque converter housing, under the main valve body.

The 1st, 1st-hold, 3rd, and 4th clutches receive fluid from their respective feed pipes and the 2nd clutch receives fluid from

the internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the vehicle determines which shift control solenoid valve the TCM will acti-

vate. Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes

a line to one of the clutches, engaging that clutch and its corresponding gear.

Lock-up Mechanism

In position and position in 2nd, 3rd, and 4th, pressurized fluid is drained from the back of the torque converter

through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes place, the

mainshaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the TCM optimizes the tim-

ing of the lock-up mechanism.

The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and B, and throttle valve B.

When lock-up control solenoid valves A and B activate, modulator pressure changes. The lock-up control solenoid valves

A and B are mounted on the torque converter housing, and are controlled by the TCM.

(cont'd)ProCarManuals.com

Page 738 of 1503

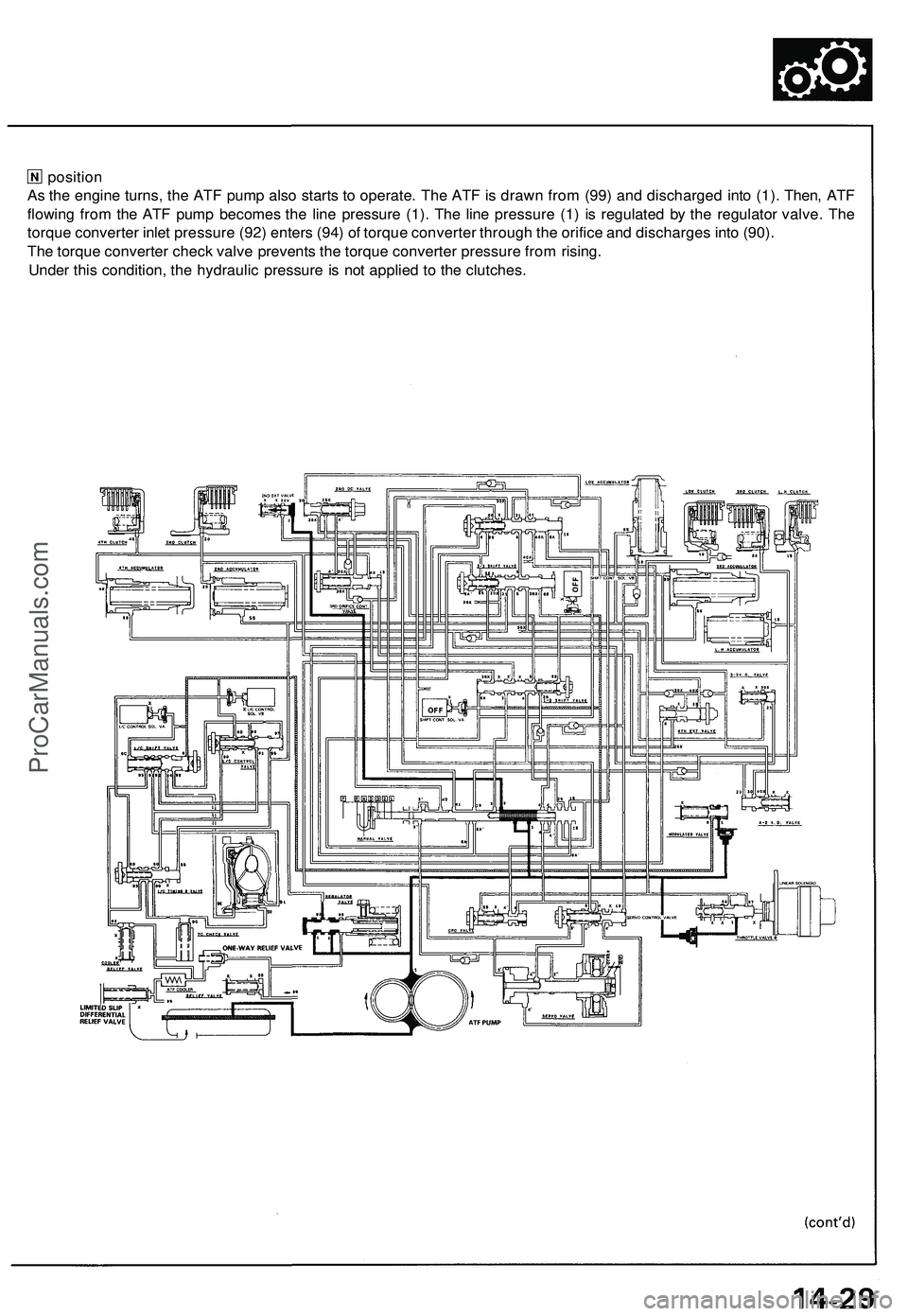

position

As the engine turns, the ATF pump also starts to operate. The ATF is drawn from (99) and discharged into (1). Then, ATF

flowing from the ATF pump becomes the line pressure (1). The line pressure (1) is regulated by the regulator valve. The

torque converter inlet pressure (92) enters (94) of torque converter through the orifice and discharges into (90).

The torque converter check valve prevents the torque converter pressure from rising.

Under this condition, the hydraulic pressure is not applied to the clutches.ProCarManuals.com

Page 771 of 1503

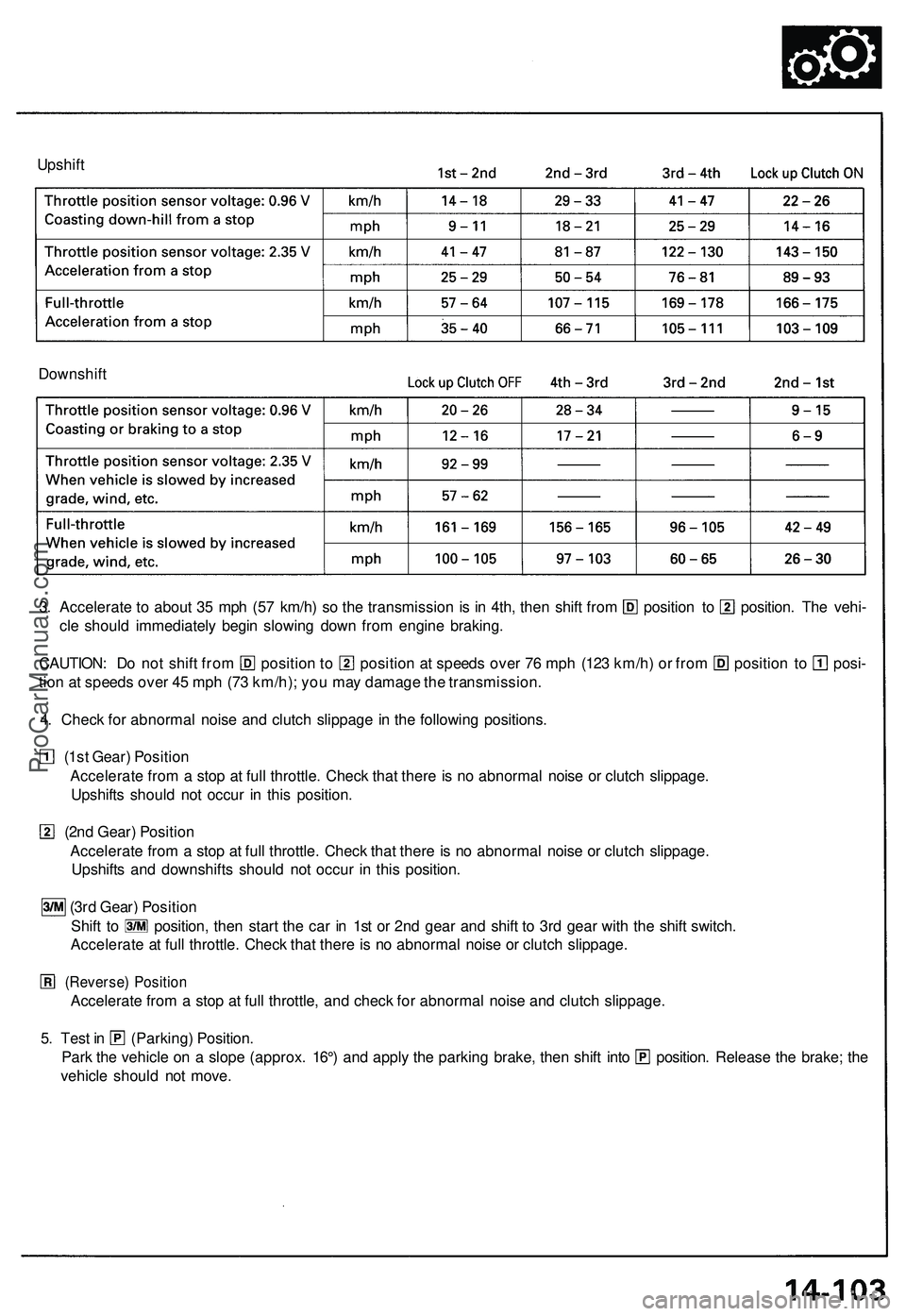

Upshift

Downshift

3. Accelerate to about 35 mph (57 km/h) so the transmission is in 4th, then shift from position to position. The vehi-

cle should immediately begin slowing down from engine braking.

CAUTION: Do not shift from position to position at speeds over 76 mph (123 km/h) or from position to posi-

tion at speeds over 45 mph (73 km/h); you may damage the transmission.

4. Check for abnormal noise and clutch slippage in the following positions.

(1st Gear) Position

Accelerate from a stop at full throttle. Check that there is no abnormal noise or clutch slippage.

Upshifts should not occur in this position.

(2nd Gear) Position

Accelerate from a stop at full throttle. Check that there is no abnormal noise or clutch slippage.

Upshifts and downshifts should not occur in this position.

(3rd Gear) Position

Shift to position, then start the car in 1st or 2nd gear and shift to 3rd gear with the shift switch.

Accelerate at full throttle. Check that there is no abnormal noise or clutch slippage.

(Reverse) Position

Accelerate from a stop at full throttle, and check for abnormal noise and clutch slippage.

5. Test in (Parking) Position.

Park the vehicle on a slope (approx. 16°) and apply the parking brake, then shift into position. Release the brake; the

vehicle should not move.ProCarManuals.com

Page 773 of 1503

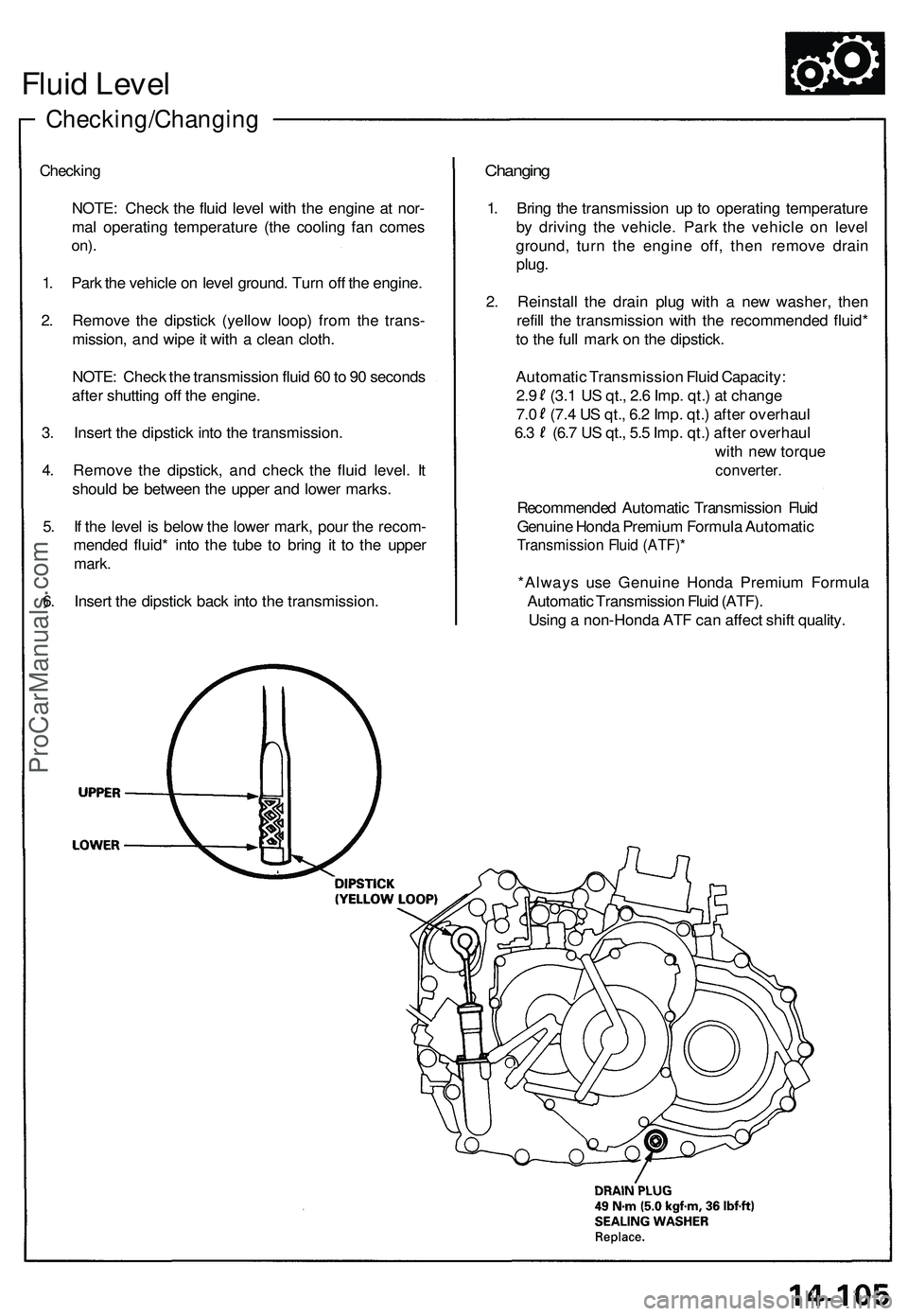

Checking/Changing

Fluid Leve l

Checkin g

NOTE : Chec k th e flui d leve l wit h th e engin e a t nor -

ma l operatin g temperatur e (th e coolin g fa n come s

on).

1. Par k th e vehicl e o n leve l ground . Tur n of f th e engine .

2 . Remov e th e dipstic k (yello w loop ) fro m th e trans -

mission , an d wip e it wit h a clea n cloth .

NOTE : Chec k th e transmissio n flui d 6 0 to 9 0 second s

afte r shuttin g of f th e engine .

3 . Inser t th e dipstic k int o th e transmission .

4 . Remov e th e dipstick , an d chec k th e flui d level . I t

shoul d b e betwee n th e uppe r an d lowe r marks .

5 . I f th e leve l i s belo w th e lowe r mark , pou r th e recom -

mende d fluid * int o th e tub e t o brin g i t t o th e uppe r

mark.

6. Inser t th e dipstic k bac k int o th e transmission .

Changing

1. Brin g th e transmissio n u p t o operatin g temperatur e

b y drivin g th e vehicle . Par k th e vehicl e o n leve l

ground , tur n th e engin e off , the n remov e drai n

plug .

2 . Reinstal l th e drai n plu g wit h a ne w washer , the n

refil l th e transmissio n wit h th e recommende d fluid *

t o th e ful l mar k o n th e dipstick .

Automati c Transmissio n Flui d Capacity :

2. 9 (3. 1 U S qt. , 2. 6 Imp . qt. ) a t chang e

7. 0 (7. 4 U S qt. , 6. 2 Imp . qt. ) afte r overhau l

6.3 (6. 7 U S qt. , 5. 5 Imp . qt. ) afte r overhau l

wit h ne w torqu e

converter .

Recommende d Automati c Transmissio n Fluid

Genuin e Hond a Premiu m Formul a Automati c

Transmissio n Flui d (ATF) *

*Alway s us e Genuin e Hond a Premiu m Formul a

Automati c Transmissio n Flui d (ATF) .

Usin g a non-Hond a AT F ca n affec t shif t quality .

ProCarManuals.com

Page 835 of 1503

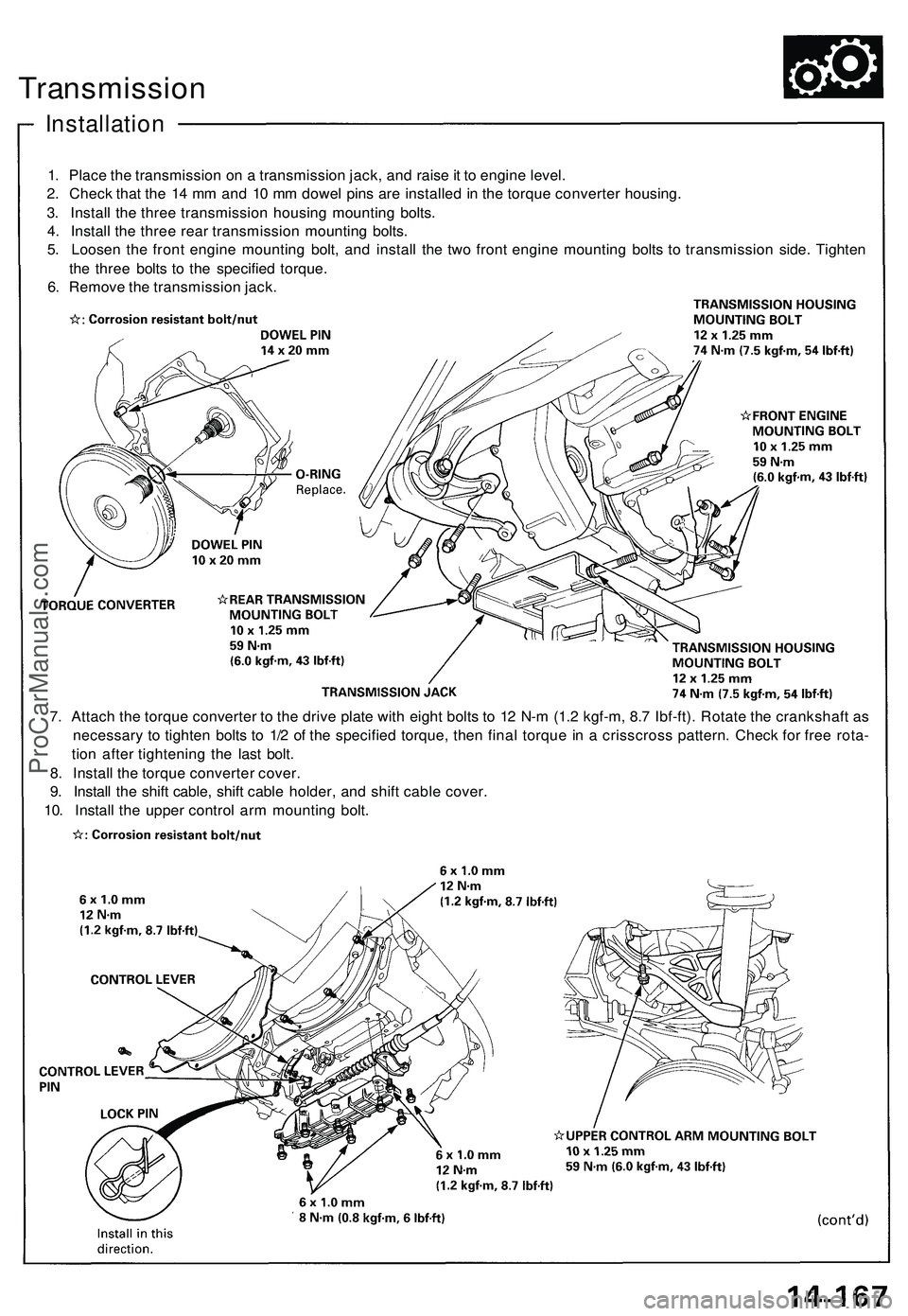

Transmission

Installation

1. Place the transmission on a transmission jack, and raise it to engine level.

2. Check that the 14 mm and 10 mm dowel pins are installed in the torque converter housing.

3. Install the three transmission housing mounting bolts.

4. Install the three rear transmission mounting bolts.

5. Loosen the front engine mounting bolt, and install the two front engine mounting bolts to transmission side. Tighten

the three bolts to the specified torque.

6. Remove the transmission jack.

7. Attach the torque converter to the drive plate with eight bolts to 12 N-m (1.2 kgf-m, 8.7 Ibf-ft). Rotate the crankshaft as

necessary to tighten bolts to 1/2 of the specified torque, then final torque in a crisscross pattern. Check for free rota-

tion after tightening the last bolt.

8. Install the torque converter cover.

9. Install the shift cable, shift cable holder, and shift cable cover.

10. Install the upper control arm mounting bolt.ProCarManuals.com

Page 909 of 1503

Troubleshooting Precautions

EPS Indicator Light

Under normal conditions, the EPS indicator light in the gauge assembly comes on when the ignition switch is turned to

the ON (II) position, then goes off after the engine is started. This indicates that the bulb and its circuits are operating cor-

rectly. If there is any trouble in the system, the EPS indicator light turns on during driving, and the power steering assist is

turned off. When the EPS indicator light comes on, the control unit memorizes the DTC. In this case, the control unit does

not activate the EPS system after the engine starts again but it keeps the EPS indicator light on.

Diagnostic Trouble Code (DTC)

• The lowest DTC is indicated first.

• The DTCs continue blinking until the ignition switch is turned off.

• The DTCs are erased from the control unit when the EPS control unit VBU power supply or connector is disconnected.

• The EPS system can be reset and the control unit's memory can be erased by disconnecting the CLOCK (7.5 A) fuse for

more than ten seconds.

Self-diagnosis:

The CPU (central processing unit) controls the following when it detects a problem during self-diagnosis:

1. Turns the EPS indicator light ON to alert the driver.

2. Power assist stops, and normal manual steering operation resumes (except DTC 33).

3. The EPS control unit memorizes the diagnostic trouble code (DTC).

4. After the DTC is stored in the control unit, the CPU stops self-diagnosis.

Troubleshooting:

• Before starting the troubleshooting, clear the DTC by disconnecting the CLOCK (7.5 A) fuse for ten seconds or more,

and test-drive the car. Check that the symptom of the trouble appears again, and then troubleshoot.

• When both EPS indicator light and A/T "D" indicator light come on, perform the A/T troubleshooting first.

• When the customer's reported problem cannot be verified in the car, ask the customer about the conditions when the

EPS indicator light came ON, then test-drive the car under those conditions, if possible. If the EPS indicator light does

not come ON during the test, check for loose connections or poor contacts at the connectors by wiggling the harness,

etc.

• The connector terminal numbers are viewed from the wire side for the female terminals and from the terminal side for

the male terminals.

• After the repair, test-drive the car and check that the EPS indicator light does not come ON again during the test. (Refer

to the Symptom-to-System Chart for diagnostic period.)ProCarManuals.com

Page 994 of 1503

Tests

Brake Booster

Functional Test

1. With the engine stopped, depress the brake pedal

several times to deplete the vacuum reservoir, then

depress the pedal hard and hold it for 15 seconds. If

the pedal sinks, either the master cylinder is

bypassing internally, or the brake system (master

cylinder, lines, modulator, proportioning valve, or

calipers) is leaking.

2. Start the engine with the pedal depressed. If the

pedal sinks slightly, the vacuum booster is operat-

ing normally, if the pedal height does not vary, the

booster or check valve is faulty.

3. With the engine running, depress the brake pedal

lightly. Apply just enough pressure to hold back

automatic transmission creep. If the brake pedal

sinks more than 10 mm (3/8 in.) in three minutes,

the master cylinder is faulty. A slight change in

pedal height when the A/C compressor cycles on

and off if normal. (The A/C compressor load

changes the vacuum available to the booster.)

Leak Test

1. Depress the brake pedal with the engine running,

then stop the engine. If the pedal height does not

vary while depressed for 30 seconds, the vacuum

booster is OK. If the pedal rises, the booster is

faulty.

2. With the engine stopped, depress the brake pedal

several times using normal pressure. When the

pedal is first depressed, it should be low. On con-

secutive applications, the pedal height should grad-

ually rise. If the pedal position does not vary, check

the booster check valve.

Booster Check Valve Test

1. Disconnect the brake booster vacuum hose at the

booster or at the booster side of the valve.

2. Start the engine and let it idle. There should be vac-

uum. If no vacuum is available, the check valve is

not working properly. Replace the check valve and

retest.ProCarManuals.com

Page 1014 of 1503

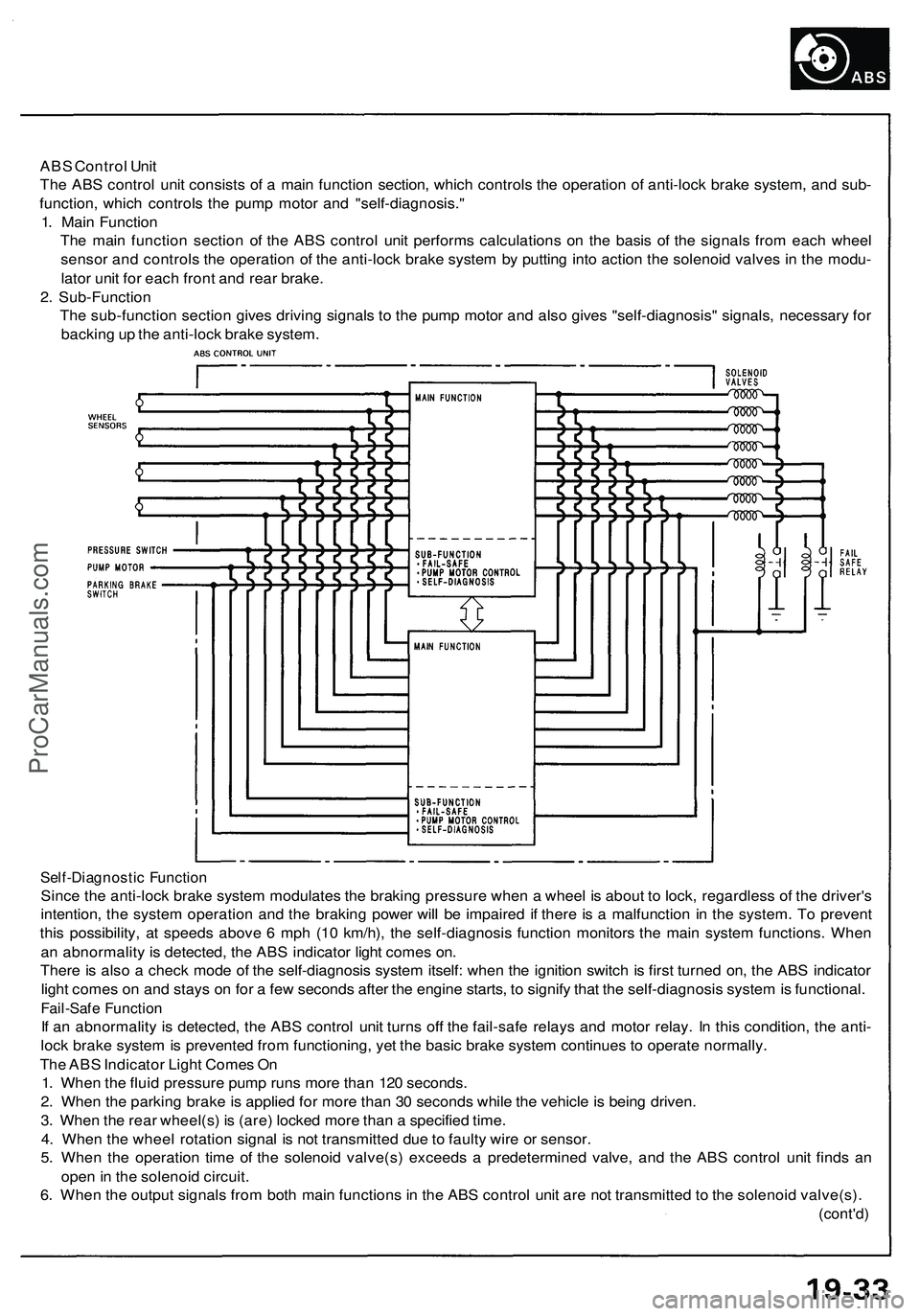

ABS Control Unit

The ABS control unit consists of a main function section, which controls the operation of anti-lock brake system, and sub-

function, which controls the pump motor and "self-diagnosis."

1. Main Function

The main function section of the ABS control unit performs calculations on the basis of the signals from each wheel

sensor and controls the operation of the anti-lock brake system by putting into action the solenoid valves in the modu-

lator unit for each front and rear brake.

2. Sub-Function

The sub-function section gives driving signals to the pump motor and also gives "self-diagnosis" signals, necessary for

backing up the anti-lock brake system.

Self-Diagnostic Function

Since the anti-lock brake system modulates the braking pressure when a wheel is about to lock, regardless of the driver's

intention, the system operation and the braking power will be impaired if there is a malfunction in the system. To prevent

this possibility, at speeds above 6 mph (10 km/h), the self-diagnosis function monitors the main system functions. When

an abnormality is detected, the ABS indicator light comes on.

There is also a check mode of the self-diagnosis system itself: when the ignition switch is first turned on, the ABS indicator

light comes on and stays on for a few seconds after the engine starts, to signify that the self-diagnosis system is functional.

Fail-Safe Function

If an abnormality is detected, the ABS control unit turns off the fail-safe relays and motor relay. In this condition, the anti-

lock brake system is prevented from functioning, yet the basic brake system continues to operate normally.

The ABS Indicator Light Comes On

1. When the fluid pressure pump runs more than 120 seconds.

2. When the parking brake is applied for more than 30 seconds while the vehicle is being driven.

3. When the rear wheel(s) is (are) locked more than a specified time.

4. When the wheel rotation signal is not transmitted due to faulty wire or sensor.

5. When the operation time of the solenoid valve(s) exceeds a predetermined valve, and the ABS control unit finds an

open in the solenoid circuit.

6. When the output signals from both main functions in the ABS control unit are not transmitted to the solenoid valve(s).

(cont'd)ProCarManuals.com

Page 1034 of 1503

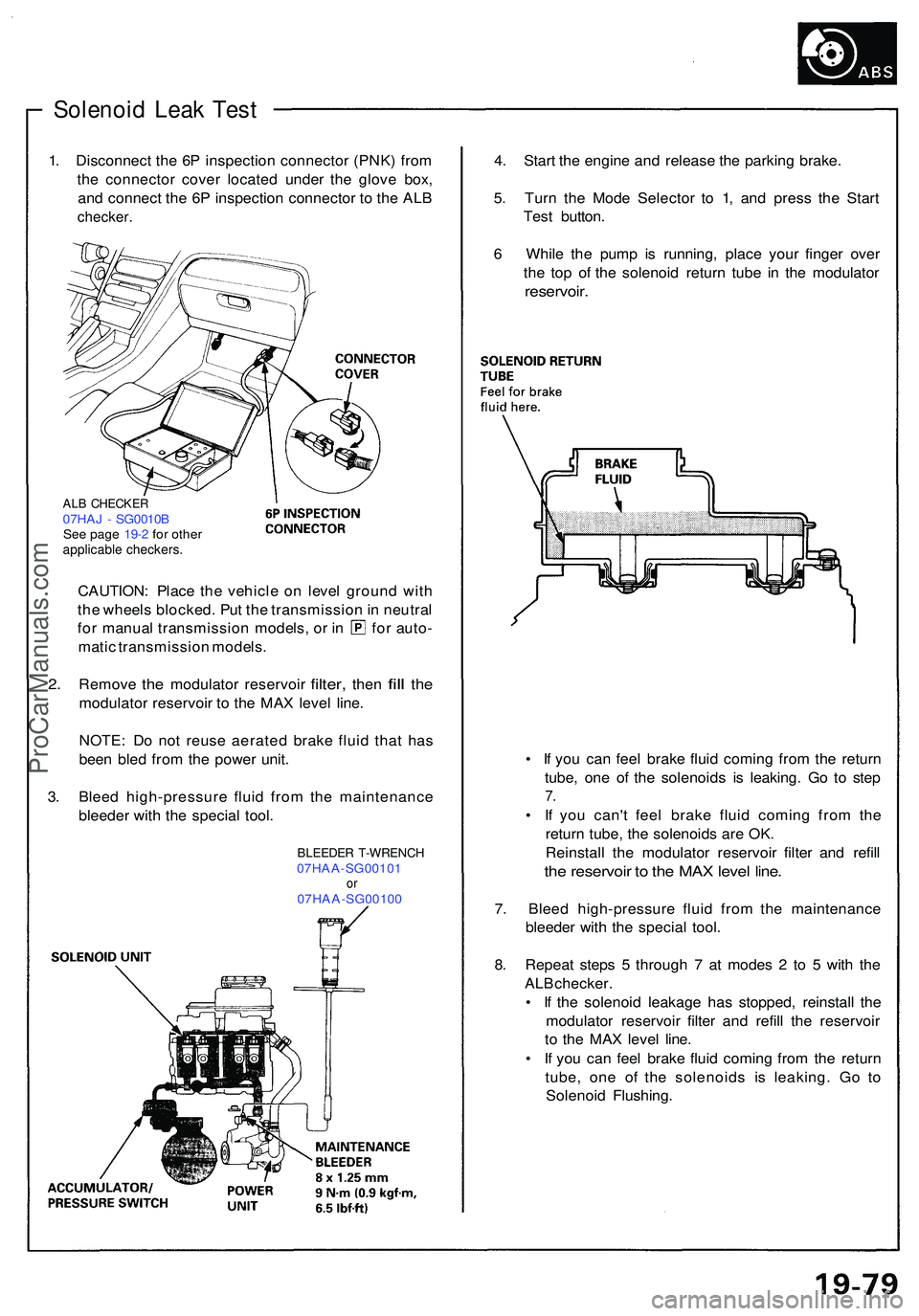

Solenoid Lea k Tes t

1. Disconnec t th e 6 P inspectio n connecto r (PNK ) fro m

th e connecto r cove r locate d unde r th e glov e box ,

an d connec t th e 6 P inspectio n connecto r t o th e AL B

checker .

ALB CHECKE R07HAJ - SG0010 B

Se e pag e 19- 2 fo r othe r

applicabl e checkers .

CAUTION : Plac e th e vehicl e o n leve l groun d wit h

th e wheel s blocked . Pu t th e transmissio n in neutra l

for manua l transmissio n models , o r i n fo r auto -

mati c transmissio n models .

2. Remov e the modulato r reservoi r filter, then fill th e

modulato r reservoi r t o th e MA X leve l line .

NOTE : D o no t reus e aerate d brak e flui d tha t ha s

bee n ble d fro m th e powe r unit .

3 . Blee d high-pressur e flui d fro m th e maintenanc e

bleede r wit h th e specia l tool .

BLEEDE R T-WRENC H07HAA-SG0010 1or07HAA-SG0010 0

• I f yo u ca n fee l brak e flui d comin g fro m th e retur n

tube , on e o f th e solenoid s i s leaking . G o t o ste p

7.

• I f yo u can' t fee l brak e flui d comin g fro m th e

retur n tube , th e solenoid s ar e OK .

Reinstal l th e modulato r reservoi r filte r an d refil l

the reservoi r t o th e MA X leve l line .

7. Blee d high-pressur e flui d fro m th e maintenanc e

bleede r wit h th e specia l tool .

8 . Repea t step s 5 throug h 7 at mode s 2 to 5 wit h th e

AL B checker .

• I f th e solenoi d leakag e ha s stopped , reinstal l th e

modulato r reservoi r filte r an d refil l th e reservoi r

t o th e MA X leve l line .

• I f yo u ca n fee l brak e flui d comin g fro m th e retur n

tube , on e o f th e solenoid s i s leaking . G o t o

Solenoi d Flushing .

4

. Star t th e engine and releas e th e parkin g brake .

5 . Tur n th e Mod e Selecto r t o 1 , an d pres s th e Star t

Tes t button .

6 Whil e th e pum p i s running , plac e you r finge r ove r

th e to p o f th e solenoi d retur n tub e i n th e modulato r

reservoir.

ProCarManuals.com