check engine ACURA NSX 1997 Service Owner's Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 1039 of 1503

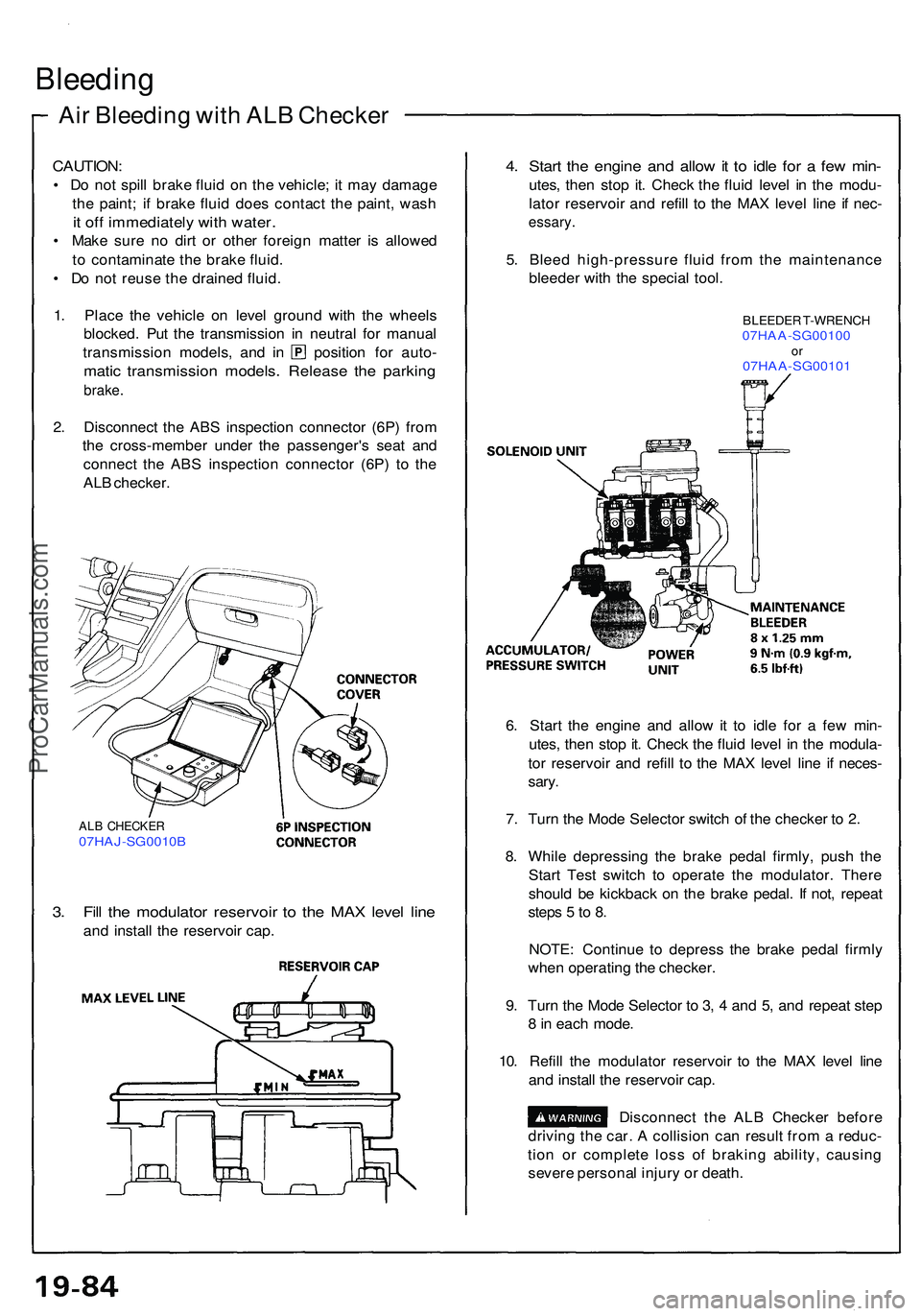

Air Bleedin g wit h AL B Checke r

Bleeding

CAUTION :

• D o no t spil l brak e flui d o n th e vehicle ; i t ma y damag e

th e paint ; i f brak e flui d doe s contac t th e paint , was h

it of f immediatel y wit h water .

• Mak e sur e n o dir t o r othe r foreig n matte r i s allowe d

t o contaminat e th e brak e fluid .

• D o no t reus e th e draine d fluid .

1 . Plac e th e vehicl e o n leve l groun d wit h th e wheel s

blocked . Pu t th e transmissio n i n neutra l fo r manua l

transmissio n models , an d i n positio n fo r auto -

matic transmissio n models . Releas e th e parkin g

brake.

2. Disconnec t th e AB S inspectio n connecto r (6P ) fro m

th e cross-membe r unde r th e passenger' s sea t an d

connec t th e AB S inspectio n connecto r (6P ) t o th e

AL B checker .

4. Star t th e engin e an d allo w it t o idl e fo r a fe w min -

utes, the n sto p it . Chec k th e flui d leve l i n th e modu -

lato r reservoi r an d refil l t o th e MA X leve l lin e i f nec -

essary .

5. Blee d high-pressur e flui d fro m th e maintenanc e

bleede r wit h th e specia l tool .

BLEEDE R T-WRENC H07HAA-SG0010 0or07HAA-SG0010 1

6. Star t th e engine and allo w it t o idl e fo r a fe w min -

utes , the n sto p it . Chec k th e flui d leve l i n th e modula -

to r reservoi r an d refil l t o th e MA X leve l lin e i f neces -

sary .

7 . Tur n th e Mod e Selecto r switc h o f th e checke r t o 2 .

8 . Whil e depressin g th e brak e peda l firmly , pus h th e

Star t Tes t switc h t o operat e th e modulator . Ther e

shoul d b e kickbac k o n th e brak e pedal . I f not , repea t

step s 5 to 8 .

NOTE : Continu e t o depres s th e brak e peda l firml y

whe n operatin g th e checker .

9 . Tur n th e Mod e Selecto r t o 3 , 4 an d 5 , an d repea t ste p

8 in eac h mode .

10 . Refil l th e modulato r reservoi r t o th e MA X leve l lin e

an d instal l th e reservoi r cap .

Disconnec t th e AL B Checke r befor e

drivin g th e car . A collisio n ca n resul t fro m a reduc -

tio n o r complete loss o f brakin g ability , causin g

sever e persona l injur y o r death .

ALB CHECKE R07HAJ-SG0010 B

3. Fil l th e modulato r reservoi r t o th e MA X leve l lin e

and instal l th e reservoi r cap .

ProCarManuals.com

Page 1052 of 1503

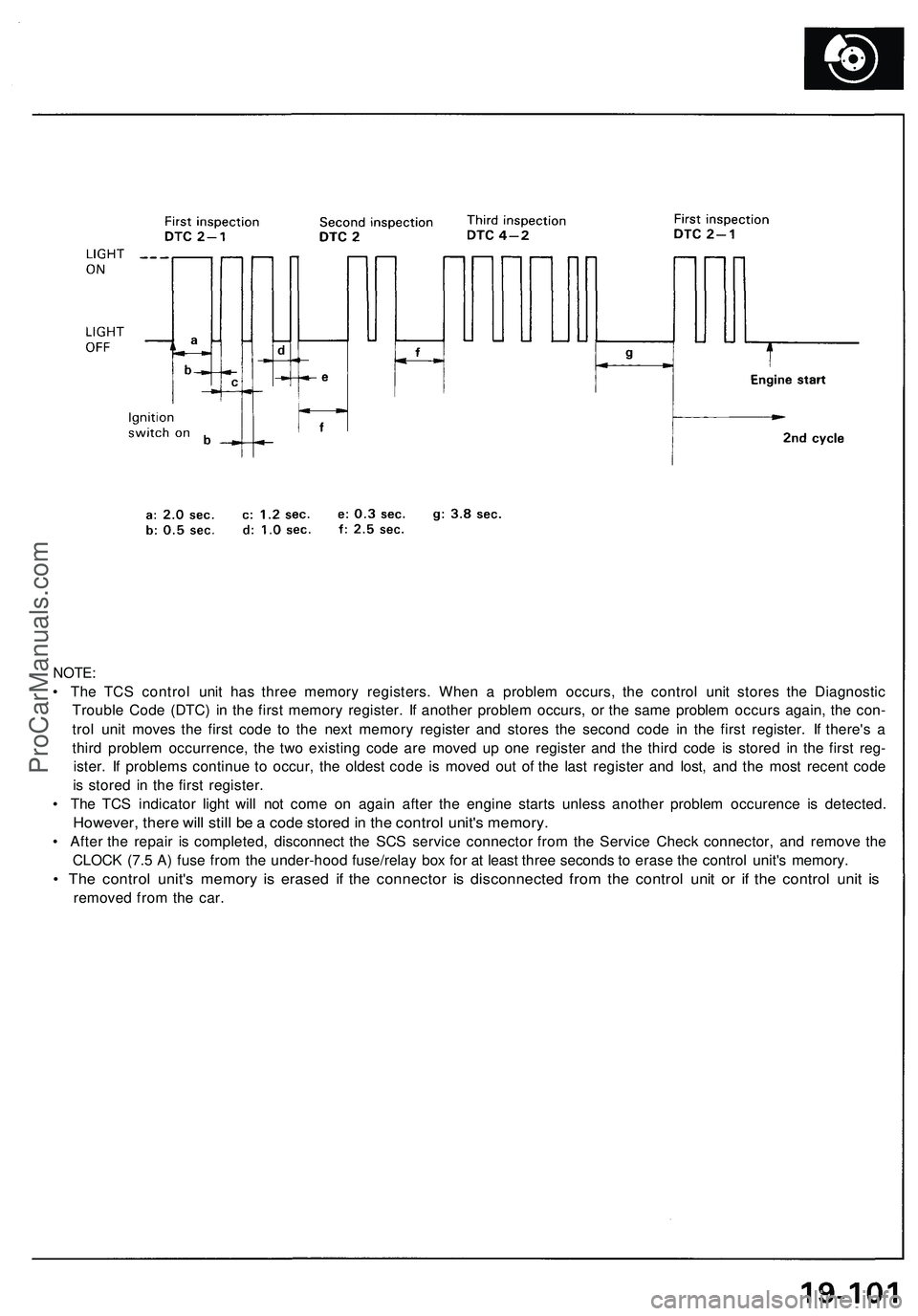

NOTE:

• The TCS control unit has three memory registers. When a problem occurs, the control unit stores the Diagnostic

Trouble Code (DTC) in the first memory register. If another problem occurs, or the same problem occurs again, the con-

trol unit moves the first code to the next memory register and stores the second code in the first register. If there's a

third problem occurrence, the two existing code are moved up one register and the third code is stored in the first reg-

ister. If problems continue to occur, the oldest code is moved out of the last register and lost, and the most recent code

is stored in the first register.

• The TCS indicator light will not come on again after the engine starts unless another problem occurence is detected.

However, there will still be a code stored in the control unit's memory.

• After the repair is completed, disconnect the SCS service connector from the Service Check connector, and remove the

CLOCK (7.5 A) fuse from the under-hood fuse/relay box for at least three seconds to erase the control unit's memory.

• The control unit's memory is erased if the connector is disconnected from the control unit or if the control unit is

removed from the car.ProCarManuals.com

Page 1056 of 1503

Steering angl e senso r syste m chec k

1 . Star t th e engine .

2 . Pus h th e TC S switc h thre e time s withi n thre e seconds .

NOTE : Alway s maintai n th e sam e numbe r o f rota -

tions .

3 . Tur n th e steerin g whee l slowl y fro m lef t t o righ t mor e

tha n 1. 5 turns .

NOTE :

• Star t checkin g afte r th e steerin g whee l move s a t

leas t 1. 5 turn s fro m righ t t o left .

• Tur n th e steerin g whee l slowly , n o faste r tha n

on e tur n in fou r seconds .

4 . Pus h th e TC S switc h twic e withi n thre e seconds .

NOTE : Alway s maintai n th e sam e numbe r o f rota -

tions .

5 . Retur n th e steerin g whee l t o th e lef t sid e slowly , an d

chec k th e numbe r o f time s th e TC S indicato r ligh t

flashe s afte r th e whee l ha s move d approximatel y

on e turn .

NOTE :

• Star t th e chec k fro m th e beginnin g whe n th e steer -

in g whee l move s a t leas t on e tur n fro m lef t t o

right .

• Tur n th e steerin g whee l slowly , n o faste r tha n on e

tur n in fou r seconds .

Standar d numbe r o f time s th e TC S indicato r ligh t

flashes :

Manual Transmission : 5 time s

Automati c Transmission : 2 time s

6 . I f ther e is a n abnormality , chec k th e troubleshootin g

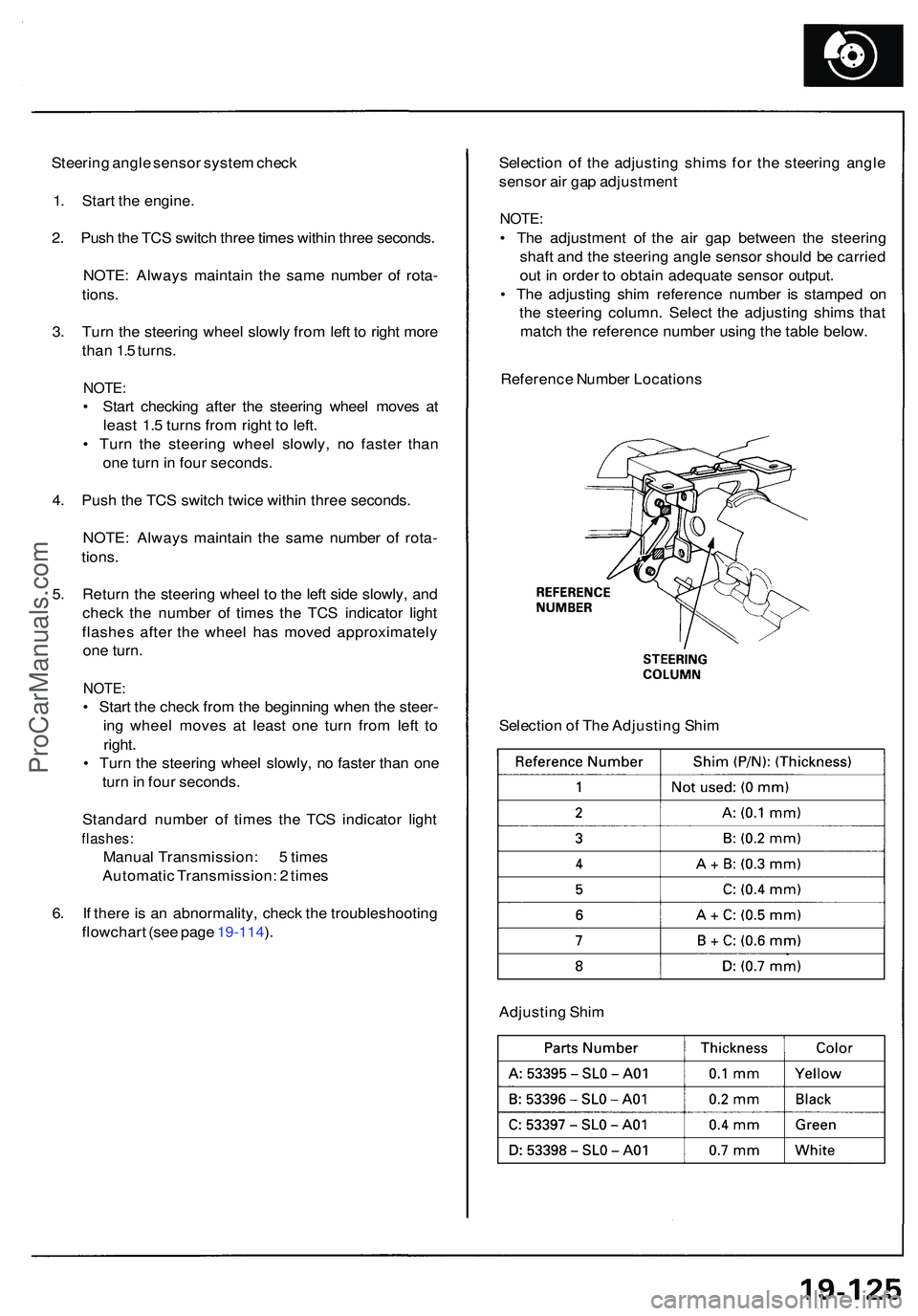

flowchar t (se e pag e 19-114 ). Selectio

n o f th e adjustin g shim s fo r th e steerin g angl e

senso r ai r ga p adjustmen t

NOTE:

• Th e adjustmen t o f th e ai r ga p betwee n th e steerin g

shaf t an d th e steerin g angl e senso r shoul d b e carrie d

ou t i n orde r t o obtai n adequat e senso r output .

• Th e adjustin g shi m referenc e numbe r i s stampe d o n

th e steerin g column . Selec t th e adjustin g shim s tha t

matc h th e referenc e numbe r usin g th e tabl e below .

Referenc e Numbe r Location s

Selectio n o f Th e Adjustin g Shi m

Adjustin g Shi m

ProCarManuals.com

Page 1121 of 1503

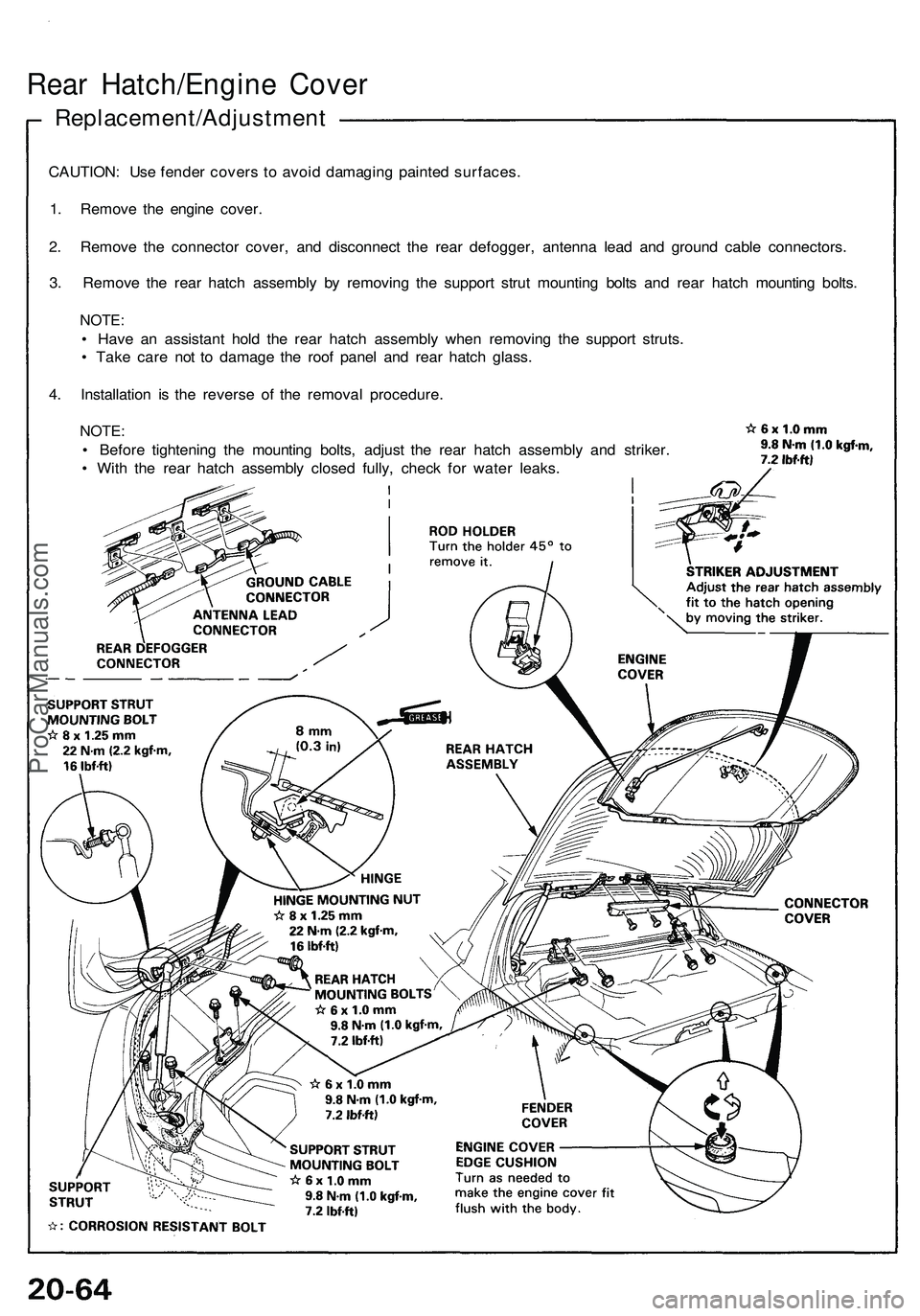

Rear Hatch/Engine Cover

Replacement/Adjustment

CAUTION: Use fender covers to avoid damaging painted surfaces.

1. Remove the engine cover.

2. Remove the connector cover, and disconnect the rear defogger, antenna lead and ground cable connectors.

3. Remove the rear hatch assembly by removing the support strut mounting bolts and rear hatch mounting bolts.

NOTE:

• Have an assistant hold the rear hatch assembly when removing the support struts.

• Take care not to damage the roof panel and rear hatch glass.

4. Installation is the reverse of the removal procedure.

NOTE:

• Before tightening the mounting bolts, adjust the rear hatch assembly and striker.

• With the rear hatch assembly closed fully, check for water leaks.ProCarManuals.com

Page 1187 of 1503

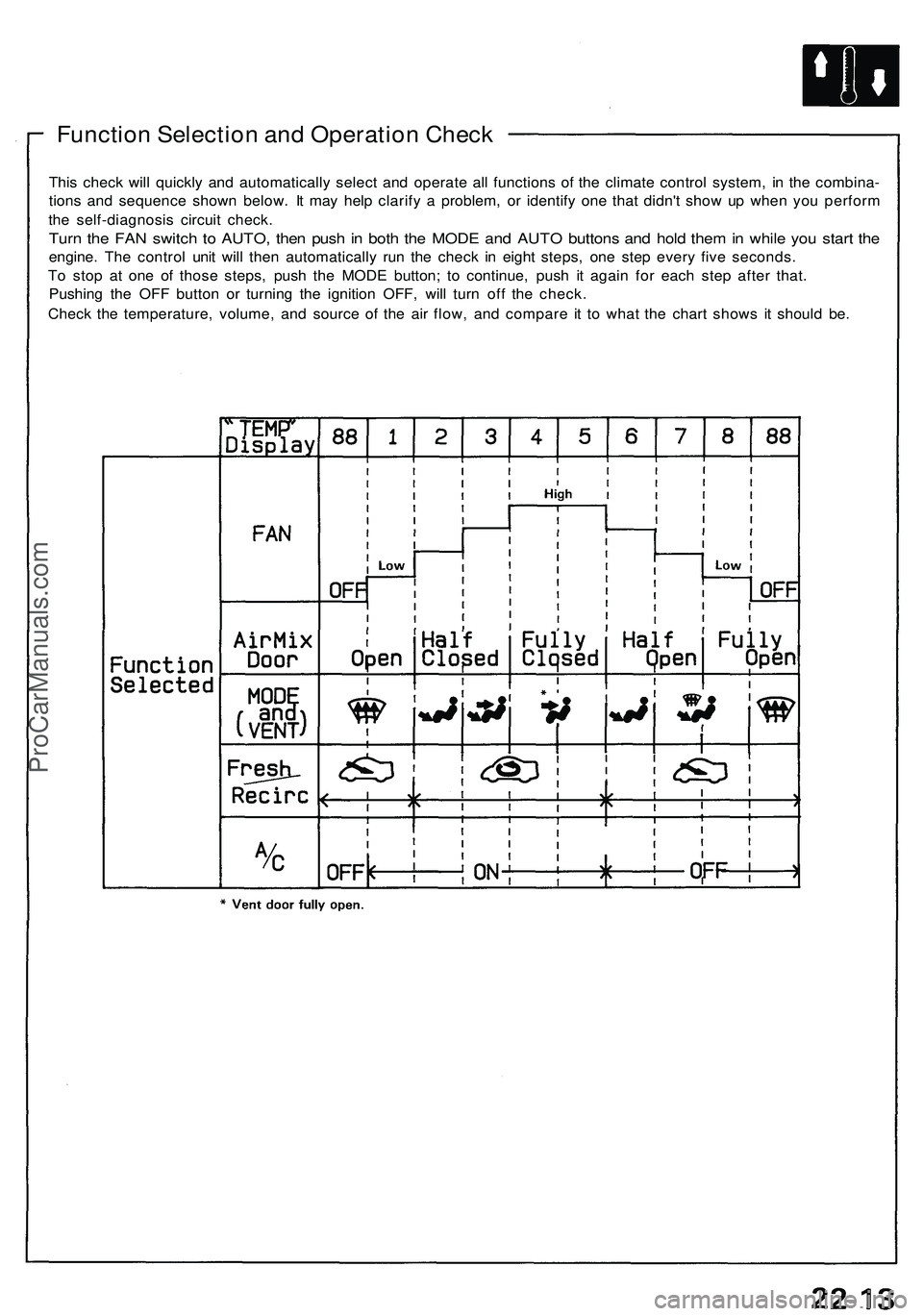

Function Selection and Operation Check

This check will quickly and automatically select and operate all functions of the climate control system, in the combina-

tions and sequence shown below. It may help clarify a problem, or identify one that didn't show up when you perform

the self-diagnosis circuit check.

Turn the FAN switch to AUTO, then push in both the MODE and AUTO buttons and hold them in while you start the

engine. The control unit will then automatically run the check in eight steps, one step every five seconds.

To stop at one of those steps, push the MODE button; to continue, push it again for each step after that.

Pushing the OFF button or turning the ignition OFF, will turn off the check.

Check the temperature, volume, and source of the air flow, and compare it to what the chart shows it should be.ProCarManuals.com

Page 1231 of 1503

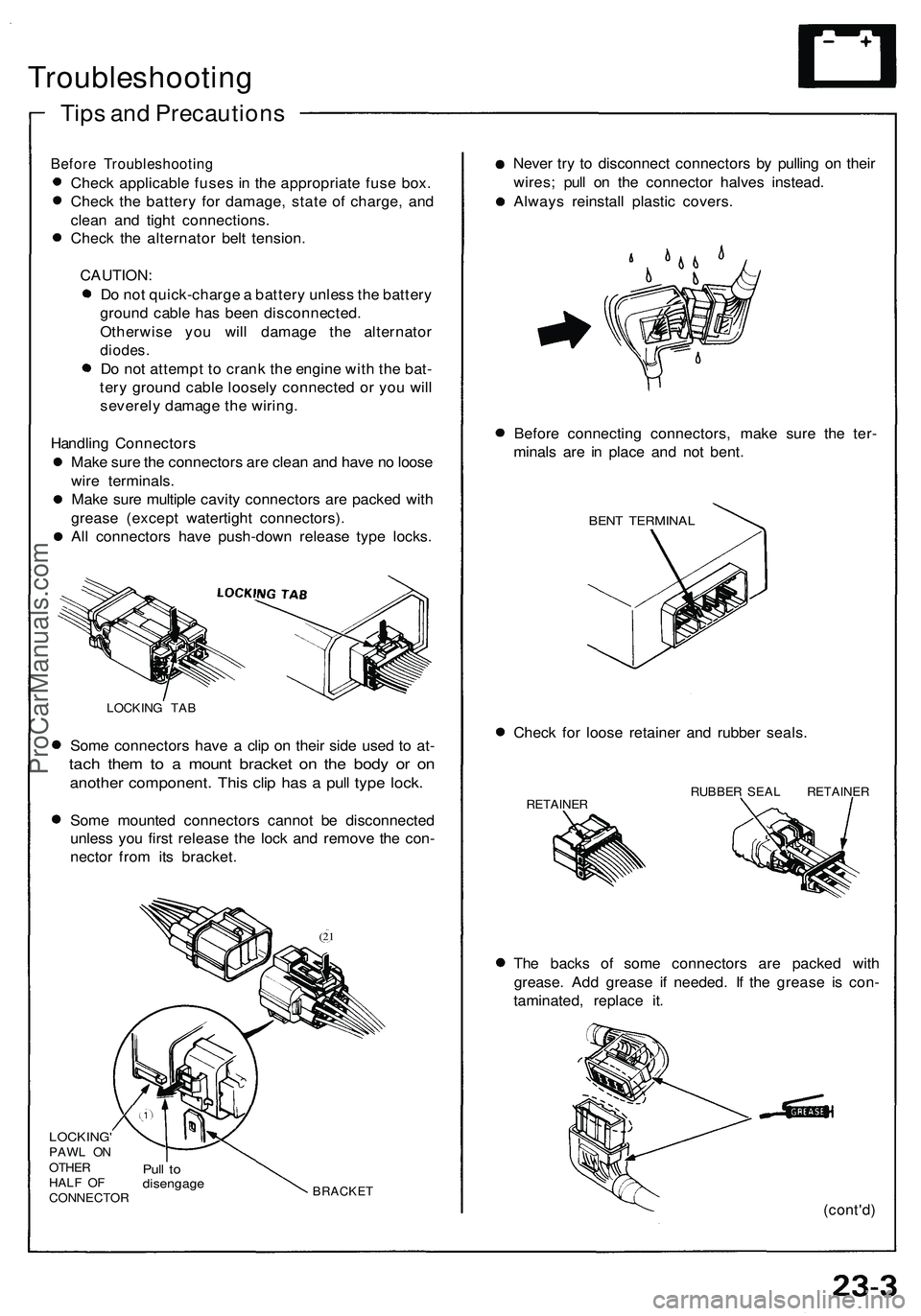

Troubleshooting

Tips and Precautions

Before Troubleshooting

Check applicable fuses in the appropriate fuse box.

Check the battery for damage, state of charge, and

clean and tight connections.

Check the alternator belt tension.

CAUTION:

Do not quick-charge a battery unless the battery

ground cable has been disconnected.

Otherwise you will damage the alternator

diodes.

Do not attempt to crank the engine with the bat-

tery ground cable loosely connected or you will

severely damage the wiring.

Handling Connectors

Make sure the connectors are clean and have no loose

wire terminals.

Make sure multiple cavity connectors are packed with

grease (except watertight connectors).

All connectors have push-down release type locks.

LOCKING TAB

Some connectors have a clip on their side used to at-

tach them to a mount bracket on the body or on

another component. This clip has a pull type lock.

Some mounted connectors cannot be disconnected

unless you first release the lock and remove the con-

nector from its bracket.

(21

LOCKING'

PAWL ON

OTHER

HALF OF

CONNECTOR

Pull to

disengage

BRACKET

Never try to disconnect connectors by pulling on their

wires; pull on the connector halves instead.

Always reinstall plastic covers.

Before connecting connectors, make sure the ter-

minals are in place and not bent.

BENT TERMINAL

Check for loose retainer and rubber seals.

RETAINER

RUBBER SEAL RETAINER

The backs of some connectors are packed with

grease. Add grease if needed. If the grease is con-

taminated, replace it.

(cont'd)ProCarManuals.com

Page 1251 of 1503

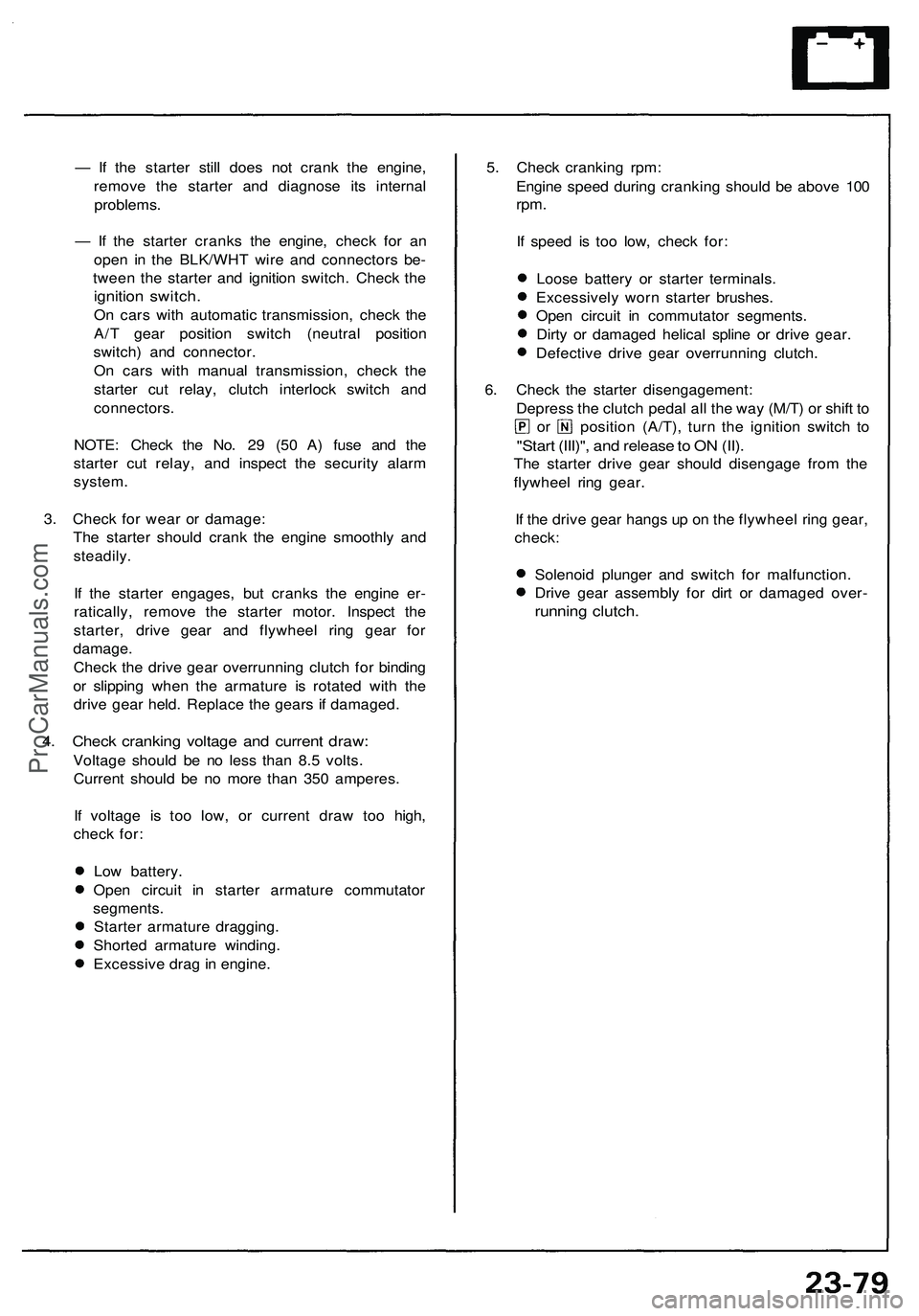

— If the starter still does not crank the engine,

remove the starter and diagnose its internal

problems.

— If the starter cranks the engine, check for an

open in the BLK/WHT wire and connectors be-

tween the starter and ignition switch. Check the

ignition switch.

On cars with automatic transmission, check the

A/T gear position switch (neutral position

switch) and connector.

On cars with manual transmission, check the

starter cut relay, clutch interlock switch and

connectors.

NOTE: Check the No. 29 (50 A) fuse and the

starter cut relay, and inspect the security alarm

system.

3. Check for wear or damage:

The starter should crank the engine smoothly and

steadily.

If the starter engages, but cranks the engine er-

ratically, remove the starter motor. Inspect the

starter, drive gear and flywheel ring gear for

damage.

Check the drive gear overrunning clutch for binding

or slipping when the armature is rotated with the

drive gear held. Replace the gears if damaged.

4. Check cranking voltage and current draw:

Voltage should be no less than 8.5 volts.

Current should be no more than 350 amperes.

If voltage is too low, or current draw too high,

check for:

Low battery.

Open circuit in starter armature commutator

segments.

Starter armature dragging.

Shorted armature winding.

Excessive drag in engine.

5. Check cranking rpm:

Engine speed during cranking should be above 100

rpm.

If speed is too low, check for:

Loose battery or starter terminals.

Excessively worn starter brushes.

Open circuit in commutator segments.

Dirty or damaged helical spline or drive gear.

Defective drive gear overrunning clutch.

6. Check the starter disengagement:

Depress the clutch pedal all the way (M/T) or shift to

or position (A/T), turn the ignition switch to

"Start (III)", and release to ON (II).

The starter drive gear should disengage from the

flywheel ring gear.

If the drive gear hangs up on the flywheel ring gear,

check:

Solenoid plunger and switch for malfunction.

Drive gear assembly for dirt or damaged over-

running clutch.ProCarManuals.com

Page 1253 of 1503

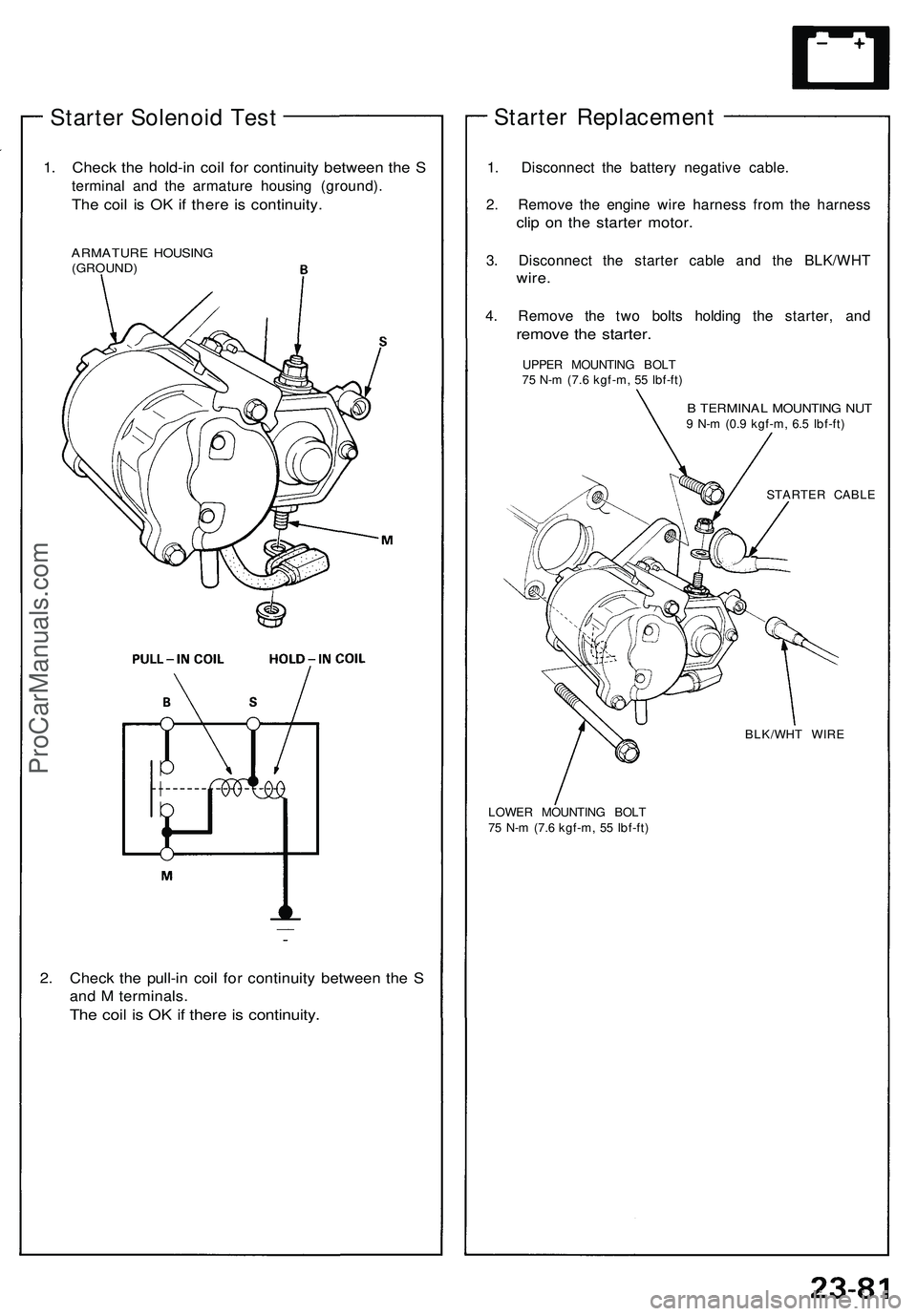

Starter Solenoid Test

1. Check the hold-in coil for continuity between the S

terminal and the armature housing (ground).

The coil is OK if there is continuity.

ARMATURE HOUSING

(GROUND)

2. Check the pull-in coil for continuity between the S

and M terminals.

The coil is OK if there is continuity.

Starter Replacement

1. Disconnect the battery negative cable.

2. Remove the engine wire harness from the harness

clip on the starter motor.

3. Disconnect the starter cable and the BLK/WHT

wire.

4. Remove the two bolts holding the starter, and

remove the starter.

UPPER MOUNTING BOLT

75 N-m (7.6 kgf-m, 55 Ibf-ft)

B TERMINAL MOUNTING NUT

9 N-m (0.9 kgf-m, 6.5 Ibf-ft)

STARTER CABLE

LOWER MOUNTING BOLT

75 N-m (7.6 kgf-m, 55 Ibf-ft)

BLK/WHT WIREProCarManuals.com

Page 1287 of 1503

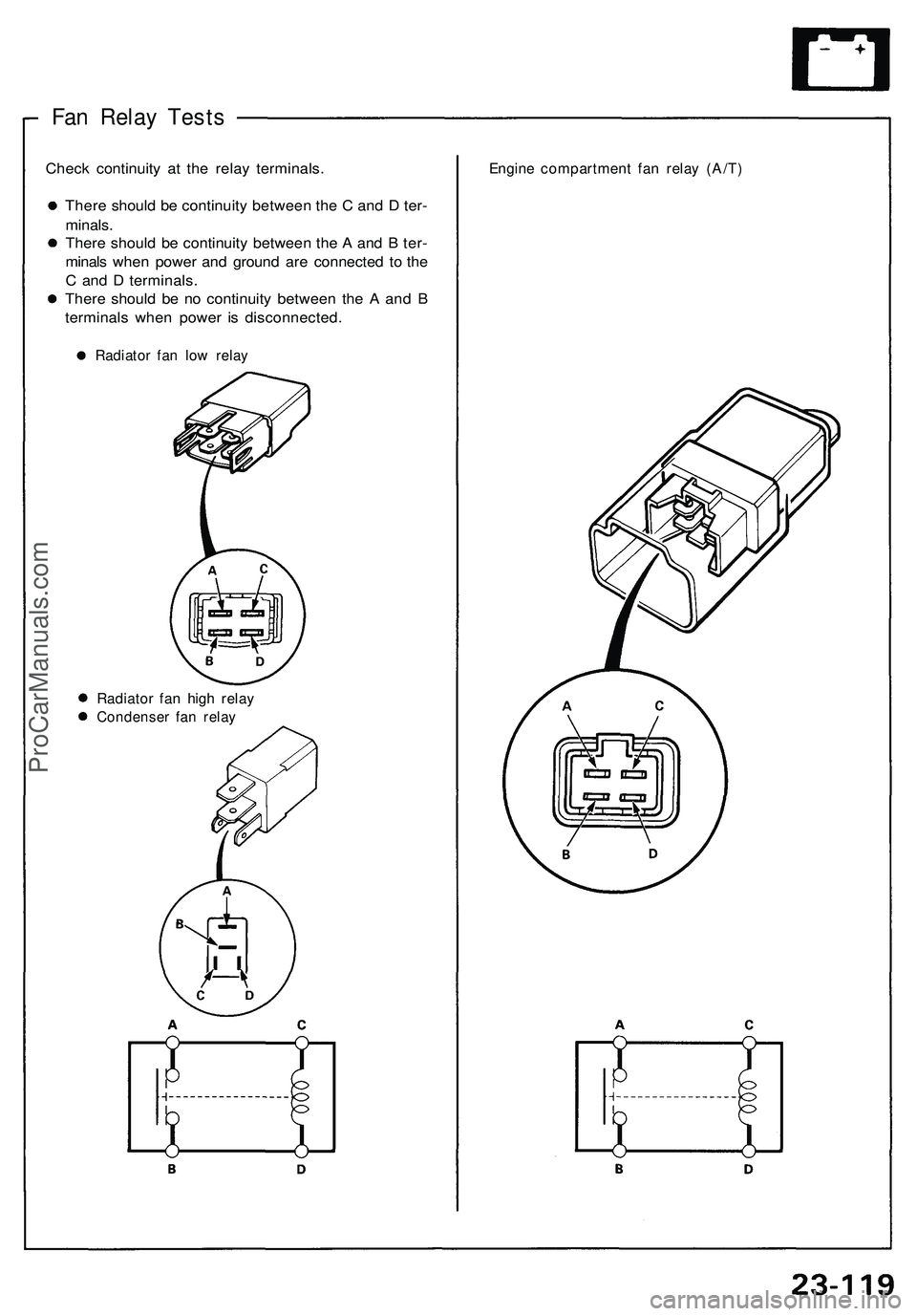

Fan Relay Tests

Check continuity at the relay terminals.

There should be continuity between the C and D ter-

minals.

There should be continuity between the A and B ter-

minals when power and ground are connected to the

C and D terminals.

There should be no continuity between the A and B

terminals when power is disconnected.

Radiator fan low relay

Engine compartment fan relay (A/T)

Radiator fan high relay

Condenser fan relayProCarManuals.com

Page 1323 of 1503

Rear Window Defogger Timer System:

Terminal Test condition

Test: Desired result

Possible cause if result is not obtained

A8

A9

A5

WHT/RED

A10

Under all conditions

Under all conditions

Ignition switch ON (II)

Defogger switch

pushed

Ignition switch ON (II)

Check for continuity to ground:

There should be continuity.

Check for voltage to ground:

There should be battery voltage.

Check for voltage to ground:

There should be battery voltage.

Check for continuity to ground:

There should be continuity as the

switch is pushed.

Attach to ground: The rear window

defogger should work and the

defogger switch indicator light

should come on.

• Poor ground (G401, G402, G403)

• An open in the wire

• Blown No. 34 (15 A) fuse

• An open in the wire

• Blown No. 5 (15 A) fuse

• An open in the wire

• Faulty defogger switch

• Poor ground (G401, G402, G403)

• An open in the wire

• Blown No. 4 (15 A) fuse

• Faulty defogger relay

• Blown bulb

• An open in the wire

Oil Pressure Indicator System:

Terminal Test condition

Test: Desired result

Possible cause if result is not obtained

A8

A9

A5 '

WHT/BLU2

YEL/RED

Under all conditions

Under all conditions

Ignition switch ON (II)

Engine running

Ignition switch OFF

Ignition switch ON (II)

Start the engine.

Check for continuity to ground:

There should be continuity.

Check for voltage to ground:

There should be battery voltage.

Check for voltage to ground:

There should be battery voltage.

Check for voltage to ground:

There should be battery voltage.

Check for continuity to ground:

There should be continuity.

Check indicator light operation.

If the light does not come on, attach

the YEL/RED terminal to ground: The

light should come on as the ignition

switch is turned ON (II).

Check for voltage to ground:

There should be battery voltage.

• Poor ground (G401, G402, G403)

• An open in the wire

• Blown No. 34 (15 A) fuse

• An open in the wire

• Blown No. 5 (15 A) fuse

• An open in the wire

• Faulty charging system

• An open in the wire

• Faulty engine oil pressure switch

• An open in the wire

• Blown bulb

• An open in the wire

• Insufficient oil

• Improper lubrication

• Faulty engine oil pressure switch

(cont'd)ProCarManuals.com