check engine ACURA NSX 1997 Service User Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 474 of 1503

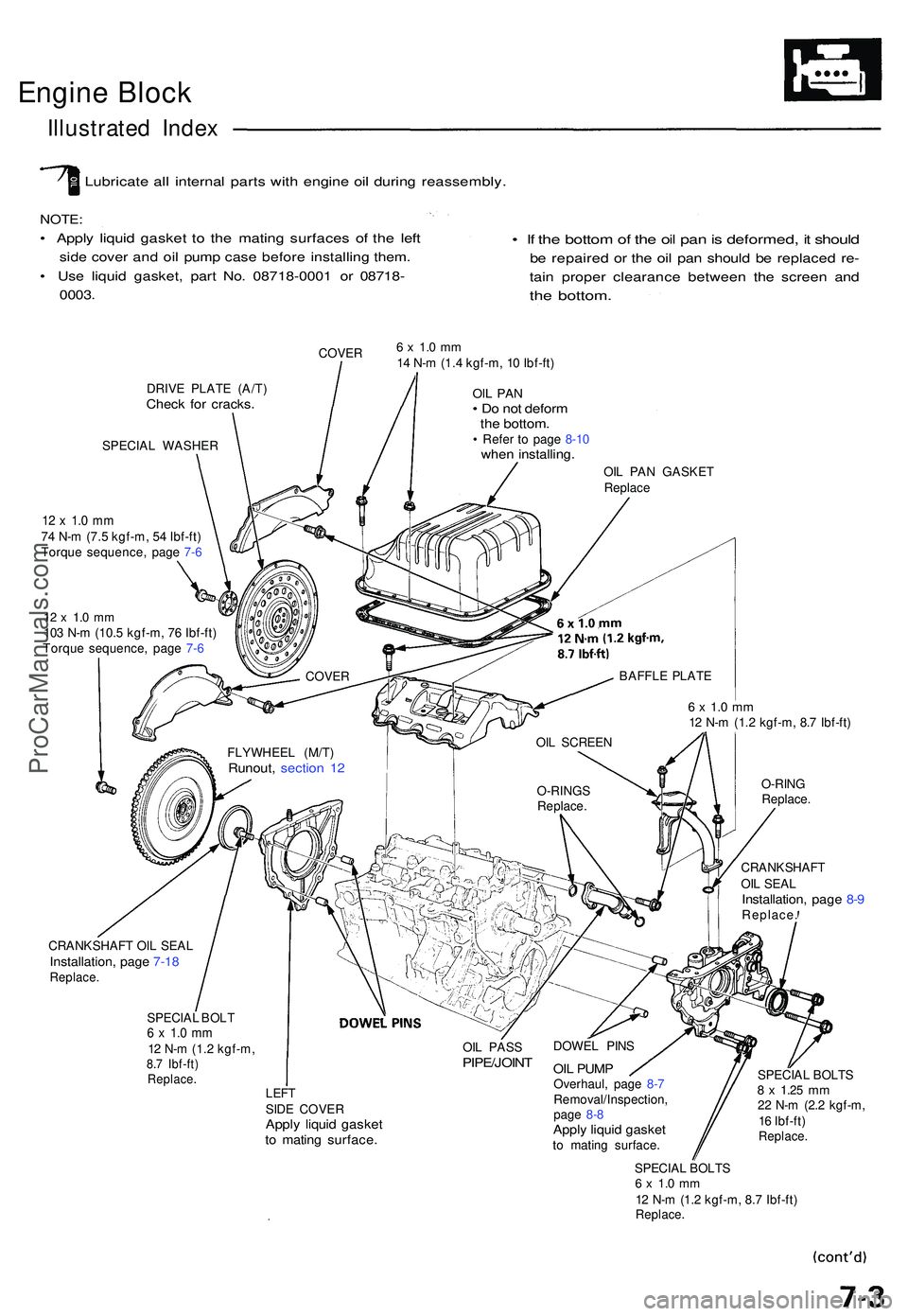

Engine Bloc k

Illustrate d Inde x

Lubricat e al l interna l part s wit h engin e oi l durin g reassembly .

NOTE:

• Appl y liqui d gaske t t o th e matin g surface s o f th e lef t

side cove r an d oi l pum p cas e befor e installin g them .

• Us e liqui d gasket , par t No . 0871 8-000 1 o r 0871 8-

0003 .

• I f th e botto m of th e oi l pa n is deformed , i t shoul d

be repaire d o r th e oi l pa n shoul d b e replace d re -

tain prope r clearanc e betwee n th e scree n an d

the bottom .

COVER

DRIV E PLAT E (A/T )

Check fo r cracks .

SPECIA L WASHER

12 x 1. 0 m m74 N- m (7. 5 kgf-m , 5 4 Ibf-ft )

Torqu e sequence , pag e 7- 6

12 x 1. 0 m m103 N- m (10. 5 kgf-m , 7 6 Ibf-ft )

Torqu e sequence , pag e 7- 6

6 x 1. 0 m m14 N- m (1. 4 kgf-m , 1 0 Ibf-ft )

OIL PA N• D o no t defor mthe bottom .• Refe r t o pag e 8-1 0whe n installing .

OIL PA N GASKE T

Replac e

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

O-RIN G

Replace .

CRANKSHAF T

OI L SEA L

Installation , pag e 8- 9Replace .

CRANKSHAF T OI L SEA L

Installation , pag e 7-1 8Replace .

SPECIAL BOL T6 x 1. 0 m m12 N- m (1. 2 kgf-m ,8.7 Ibf-ft )Replace .

OIL PAS SPIPE/JOIN T

LEFTSIDE COVE RApply liqui d gaske tto matin g surface .

DOWEL PIN S

OIL PUM POverhaul , pag e 8- 7

Removal/Inspection ,

pag e 8- 8

Appl y liqui d gaske tto matin g surface . SPECIA

L BOLT S

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

Replace .

SPECIAL BOLT S6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )Replace .

FLYWHEE L (M/T )Runout , sectio n 1 2

COVE R

OIL SCREE N

O-RING S

Replace .BAFFL

E PLAT E

ProCarManuals.com

Page 501 of 1503

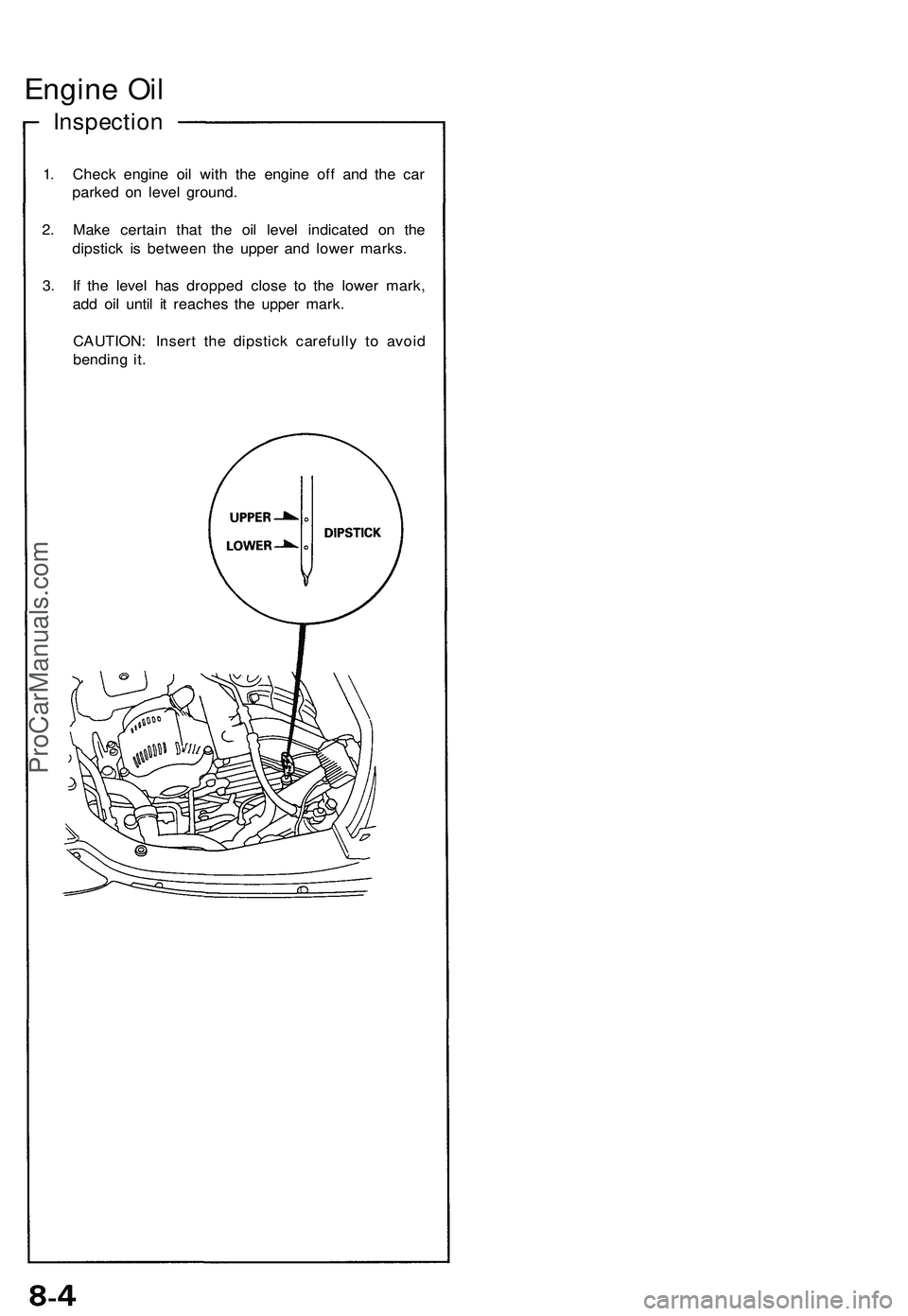

Engine Oil

Inspection

1. Check engine oil with the engine off and the car

parked on level ground.

2. Make certain that the oil level indicated on the

dipstick is between the upper and lower marks.

3. If the level has dropped close to the lower mark,

add oil until it reaches the upper mark.

CAUTION: Insert the dipstick carefully to avoid

bending it.ProCarManuals.com

Page 505 of 1503

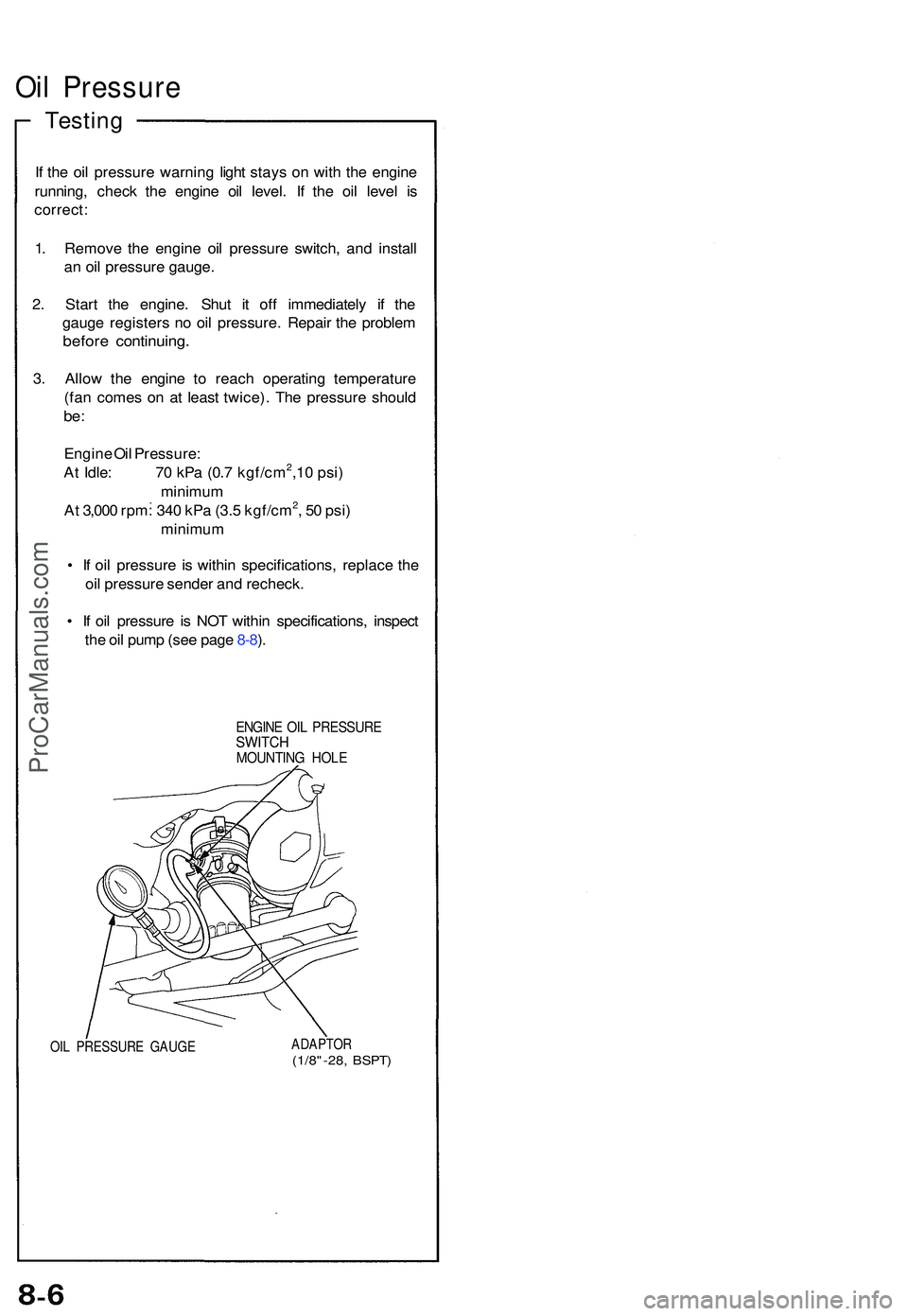

Oil Pressur e

Testing

If th e oi l pressur e warnin g ligh t stay s o n wit h th e engin e

running , chec k th e engin e oi l level . I f th e oi l leve l i s

correct :

1 . Remov e th e engine oil pressur e switch , an d instal l

a n oi l pressur e gauge .

2 . Star t th e engine . Shu t i t of f immediatel y i f th e

gaug e register s n o oi l pressure . Repai r th e proble m

before continuing .

3. Allo w th e engin e t o reac h operatin g temperatur e

(fa n come s o n a t leas t twice) . Th e pressur e shoul d

be:

Engin e Oi l Pressure :

A t Idle : 7 0 kP a (0. 7 kgf/cm2,1 0 psi )

minimu m

A t 3,00 0 rpm : 34 0 kP a (3. 5 kgf/cm

2, 5 0 psi )

minimu m

• I f oi l pressur e i s withi n specifications , replac e th e

oi l pressur e sende r an d recheck .

• I f oi l pressur e i s NO T withi n specifications , inspec t

th e oi l pum p (se e pag e 8-8 ).

ENGIN E OI L PRESSUR ESWITCHMOUNTIN G HOL E

OIL PRESSUR E GAUG EADAPTO R(1/8"-28, BSPT )

ProCarManuals.com

Page 523 of 1503

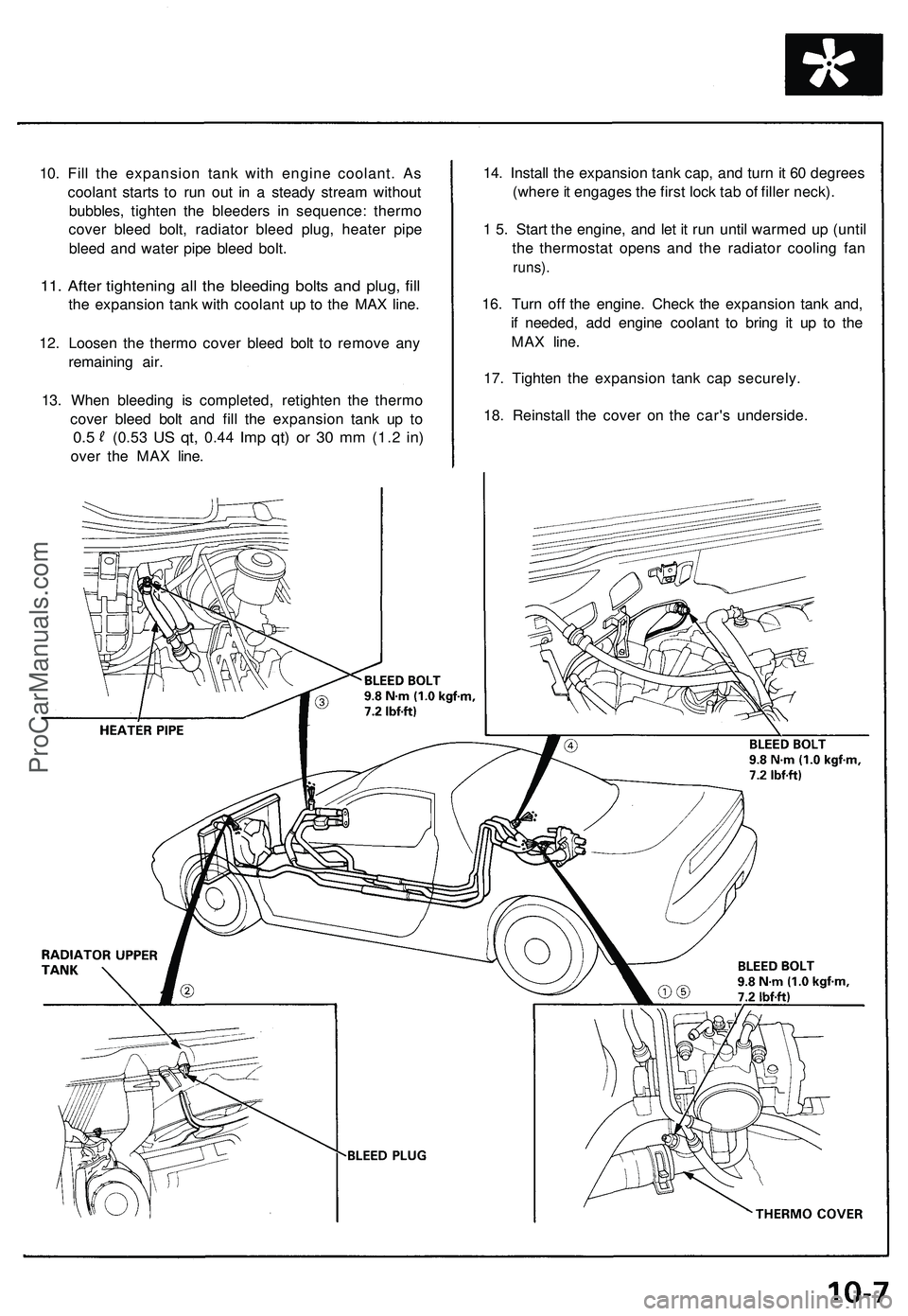

10. Fill the expansion tank with engine coolant. As

coolant starts to run out in a steady stream without

bubbles, tighten the bleeders in sequence: thermo

cover bleed bolt, radiator bleed plug, heater pipe

bleed and water pipe bleed bolt.

11. After tightening all the bleeding bolts and plug, fill

the expansion tank with coolant up to the MAX line.

12. Loosen the thermo cover bleed bolt to remove any

remaining air.

13. When bleeding is completed, retighten the thermo

cover bleed bolt and fill the expansion tank up to

0.5

(0.53

US qt,

0.44

Imp qt) or 30 mm

(1.2

in)

over the MAX line.

14. Install the expansion tank cap, and turn it 60 degrees

(where it engages the first lock tab of filler neck).

1 5. Start the engine, and let it run until warmed up (until

the thermostat opens and the radiator cooling fan

runs).

16. Turn off the engine. Check the expansion tank and,

if needed, add engine coolant to bring it up to the

MAX line.

17. Tighten the expansion tank cap securely.

18. Reinstall the cover on the car's underside.ProCarManuals.com

Page 584 of 1503

Troubleshooting

How to Read Flowcharts

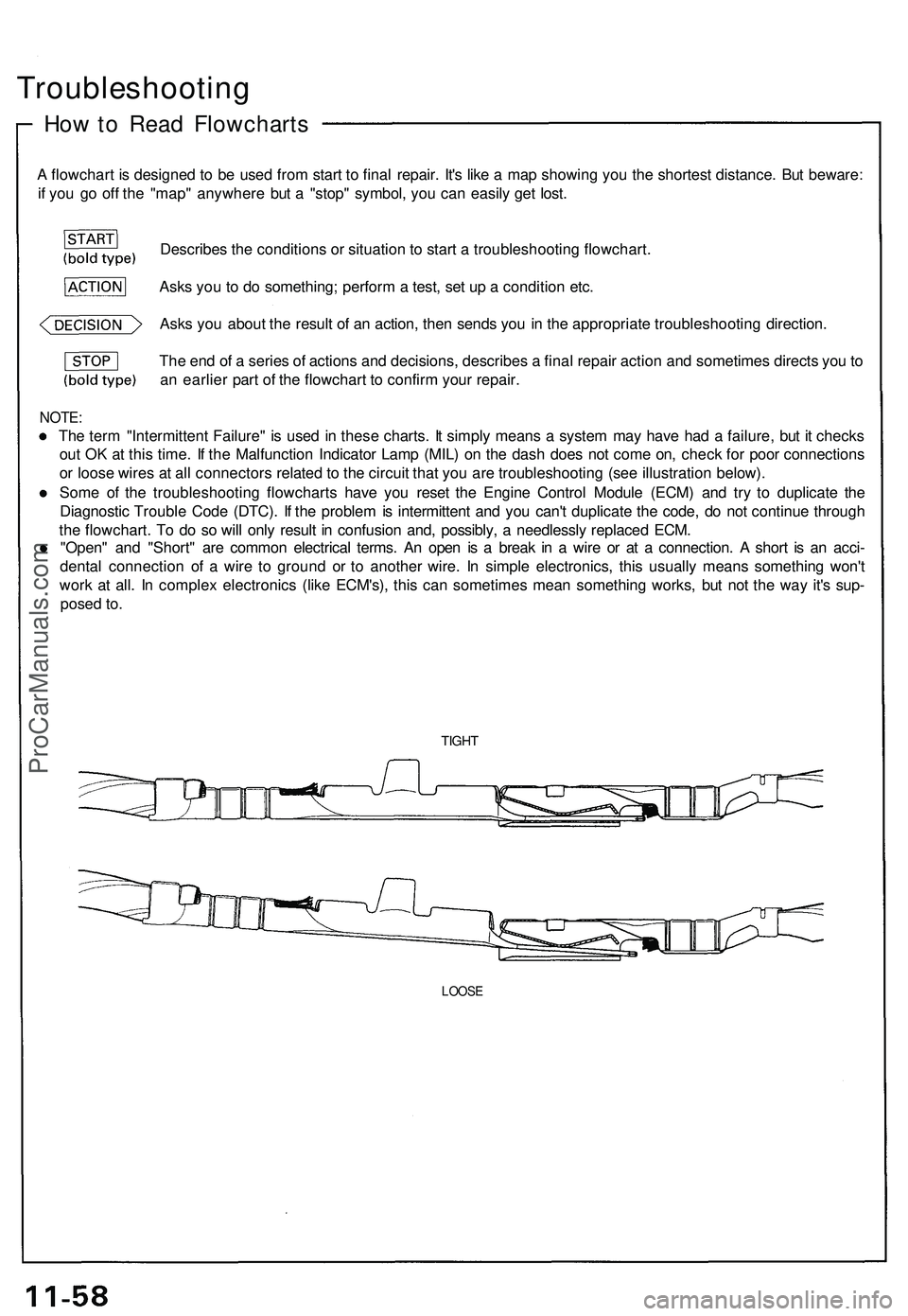

A flowchart is designed to be used from start to final repair. It's like a map showing you the shortest distance. But beware:

if you go off the "map" anywhere but a "stop" symbol, you can easily get lost.

Describes the conditions or situation to start a troubleshooting flowchart.

Asks you to do something; perform a test, set up a condition etc.

Asks you about the result of an action, then sends you in the appropriate troubleshooting direction.

NOTE:

The term "Intermittent Failure" is used in these charts. It simply means a system may have had a failure, but it checks

out OK at this time. If the Malfunction Indicator Lamp (MIL) on the dash does not come on, check for poor connections

or loose wires at all connectors related to the circuit that you are troubleshooting (see illustration below).

Some of the troubleshooting flowcharts have you reset the Engine Control Module (ECM) and try to duplicate the

Diagnostic Trouble Code (DTC). If the problem is intermittent and you can't duplicate the code, do not continue through

the flowchart. To do so will only result in confusion and, possibly, a needlessly replaced ECM.

"Open" and "Short" are common electrical terms. An open is a break in a wire or at a connection. A short is an acci-

dental connection of a wire to ground or to another wire. In simple electronics, this usually means something won't

work at all. In complex electronics (like ECM's), this can sometimes mean something works, but not the way it's sup-

posed to.

TIGHT

LOOSE

The end of a series of actions and decisions, describes a final repair action and sometimes directs you to

an earlier part of the flowchart to confirm your repair.ProCarManuals.com

Page 586 of 1503

PGM-FI System

System Description (cont'd)

3. Fuel Cut-off Control

During deceleration with the throttle valve closed, current to the fuel injectors is cut off to improve fuel economy at

speeds over 1,500 rpm.

Fuel cut-off action also takes place when engine speed exceeds 8,300 rpm, regardless of the position of the throttle

valve, to protect the engine from over-revving.

4. A/C Compressor Clutch Relay

When the ECM receives a demand for cooling from the air conditioning system, it delays the compressor from being

energized, and enriches the mixture to assure smooth translation to the A/C mode.

5. Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant temperature is below 153°F (67°C), the ECM controls the EVAP purge control solenoid valve

which cuts vacuum to the EVAP purge control canister diaphragm.

6. Intake Air Bypass (IAB) Control Solenoid Valve

When the engine speed is below 4,800 rpm, the IAB control solenoid valve is activated by a signal from the ECM. Intake

air then flows through the smaller chamber, and high torque is delivered. To increase air flow at engine speeds higher

than 4,800 rpm, the solenoid valve is deactivated by the ECM, and the intake air flows through the larger chamber.

7. Exhaust Gas Recirculation (EGR) Control Solenoid Valve

When the EGR is required for control of oxides of nitrogen (NOx) emissions, the ECM supplies ground to the EGR

control solenoid valve which supplies regulated vacuum to the EGR valve.

ECM Fail-safe/Back-up Functions

1. Fail-Safe Function

When an abnormality occurs in a signal from a sensor, the ECM ignores that signal and assumes a pre-programmed

valve for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the ECM itself, the fuel injectors are controlled by a back-up circuit independent of the

system in order to permit minimal driving.

3. Self-diagnosis Function [Malfunction Indicator Lamp (MIL)]

When an abnormality occurs in a signal from a sensor, the ECM lights the MIL and stores the diagnostic trouble code

in erasable memory. When the ignition is initially turned on, the ECM supplies ground for the MIL for two seconds to

check the MIL bulb condition.

4. Two Trip Detection Method

To prevent false indications, the Two Trip Detection Method is used for the H02S, fuel metering-related, idle control

system, ECT sensor, EGR system self-diagnostic functions and EVAP control system. When an abnormality occurs,

the ECM stores it in its memory. When the same abnormality recurs after the ignition switch is turned OFF and ON (II)

again, the ECM informs the driver by lighting the MIL.

However, to ease troubleshooting, this function is cancelled when you short the service check connector. The MIL will

then blink immediately when an abnormality occurs.

5. Two (or three) Driving Cycle Detection Method

A "Driving Cycle" consists of starting the engine, beginning closed loop operation, and stopping the engine. If misfir-

ing that increases emissions or EVAP control system malfunction is detected during two consecutive driving cycles,

or TWC deterioration is detected during three consecutive driving cycles, the ECM turns the MIL on.

However,

to

ease

troubleshooting,

this

function

is

cancelled when

you

short

the

service check connector.

The MIL

will

then blink immediately when an abnormality occurs.ProCarManuals.com

Page 603 of 1503

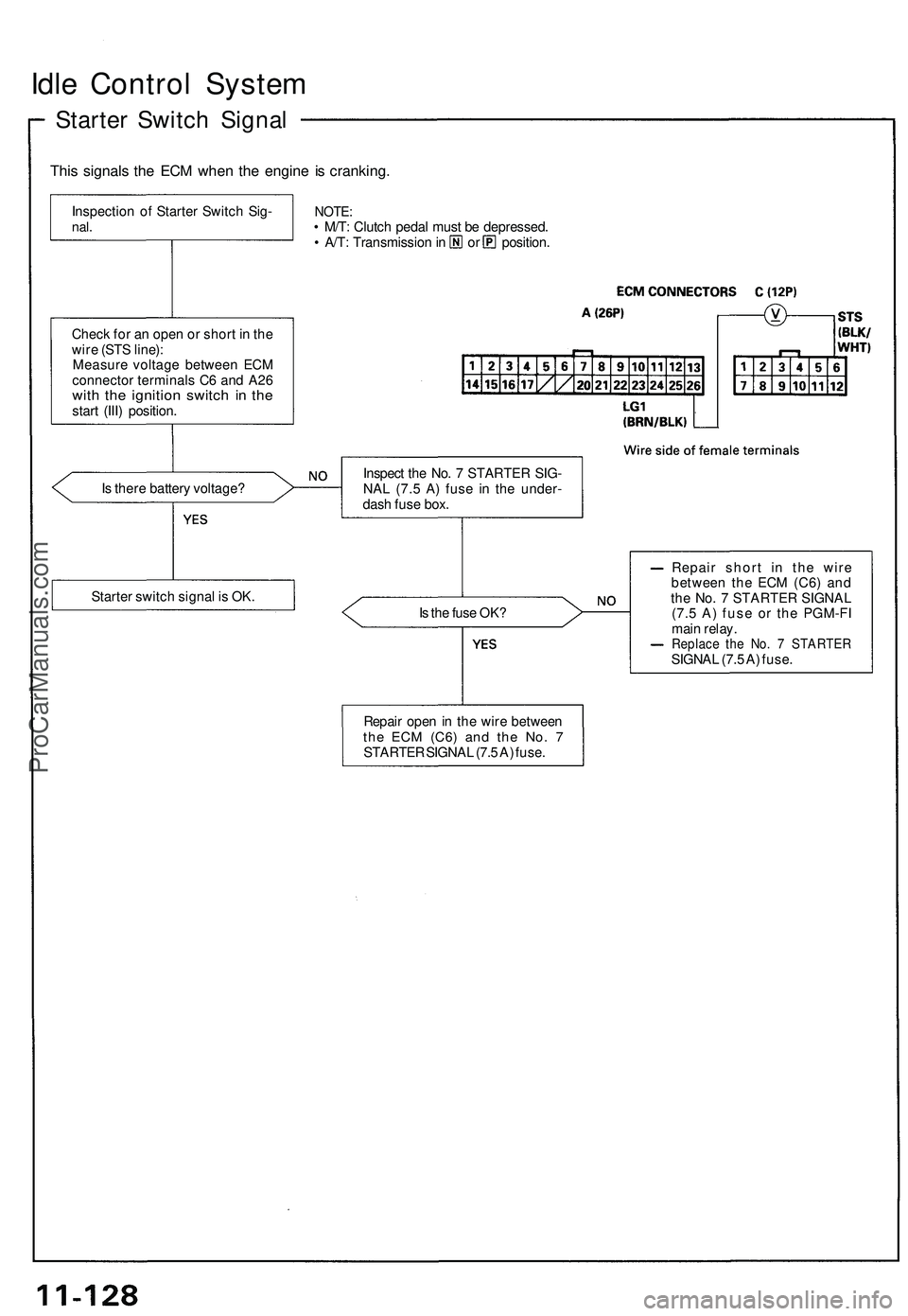

Idle Control System

Starter Switch Signal

This signals the ECM when the engine is cranking.

NOTE:

• M/T: Clutch pedal must be depressed.

• A/T: Transmission in or position.

Is there battery voltage?

Is the fuse OK?

Repair short in the wire

between the ECM (C6) and

the No. 7 STARTER SIGNAL

(7.5 A) fuse or the PGM-FI

main relay.

Replace the No. 7 STARTER

SIGNAL (7.5 A) fuse.

Inspection of Starter Switch Sig-

nal.

Check for an open or short in the

wire (STS line):

Measure voltage between ECM

connector terminals C6 and A26

with the ignition switch in the

start (III) position.

Starter switch signal is OK.

Repair open in the wire between

the ECM

(C6)

and the No. 7

STARTER SIGNAL (7.5 A) fuse.

Inspect the No. 7 STARTER SIG-

NAL (7.5 A) fuse in the under-

dash fuse box.ProCarManuals.com

Page 617 of 1503

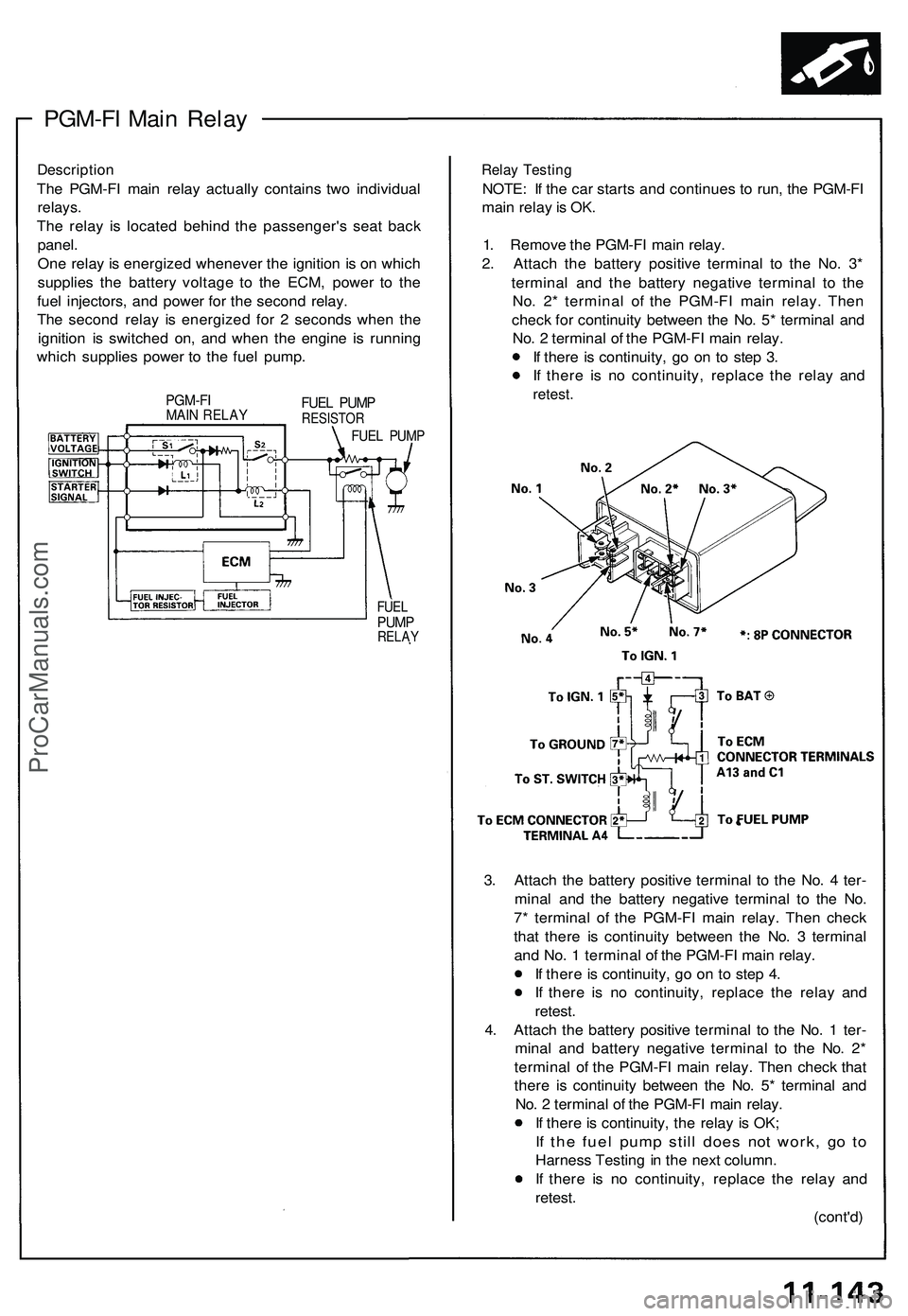

PGM-FI Main Relay

Description

The PGM-FI main relay actually contains two individual

relays.

The relay is located behind the passenger's seat back

panel.

One relay is energized whenever the ignition is on which

supplies the battery voltage to the ECM, power to the

fuel injectors, and power for the second relay.

The second relay is energized for 2 seconds when the

ignition is switched on, and when the engine is running

which supplies power to the fuel pump.

PGM-FI

MAIN RELAY

FUEL PUMP

RESISTOR

FUEL PUMP

FUEL

PUMP

RELAY

Relay Testing

NOTE: If the car starts and continues to run, the PGM-FI

main relay is OK.

1. Remove the PGM-FI main relay.

2. Attach the battery positive terminal to the No. 3*

terminal and the battery negative terminal to the

No. 2* terminal of the PGM-FI main relay. Then

check for continuity between the No. 5* terminal and

No. 2 terminal of the PGM-FI main relay.

If there is continuity, go on to step 3.

If there is no continuity, replace the relay and

retest.

3. Attach the battery positive terminal to the No. 4 ter-

minal and the battery negative terminal to the No.

7* terminal of the PGM-FI main relay. Then check

that there is continuity between the No. 3 terminal

and No. 1 terminal of the PGM-FI main relay.

If there is continuity, go on to step 4.

If there is no continuity, replace the relay and

retest.

4. Attach the battery positive terminal to the No. 1 ter-

minal and battery negative terminal to the No. 2*

terminal of the PGM-FI main relay. Then check that

there is continuity between the No. 5* terminal and

No. 2 terminal of the PGM-FI main relay.

If there is continuity, the relay is OK;

If the fuel pump still does not work, go to

Harness Testing in the next column.

If there is no continuity, replace the relay and

retest.

(cont'd)ProCarManuals.com

Page 628 of 1503

Intake Air System

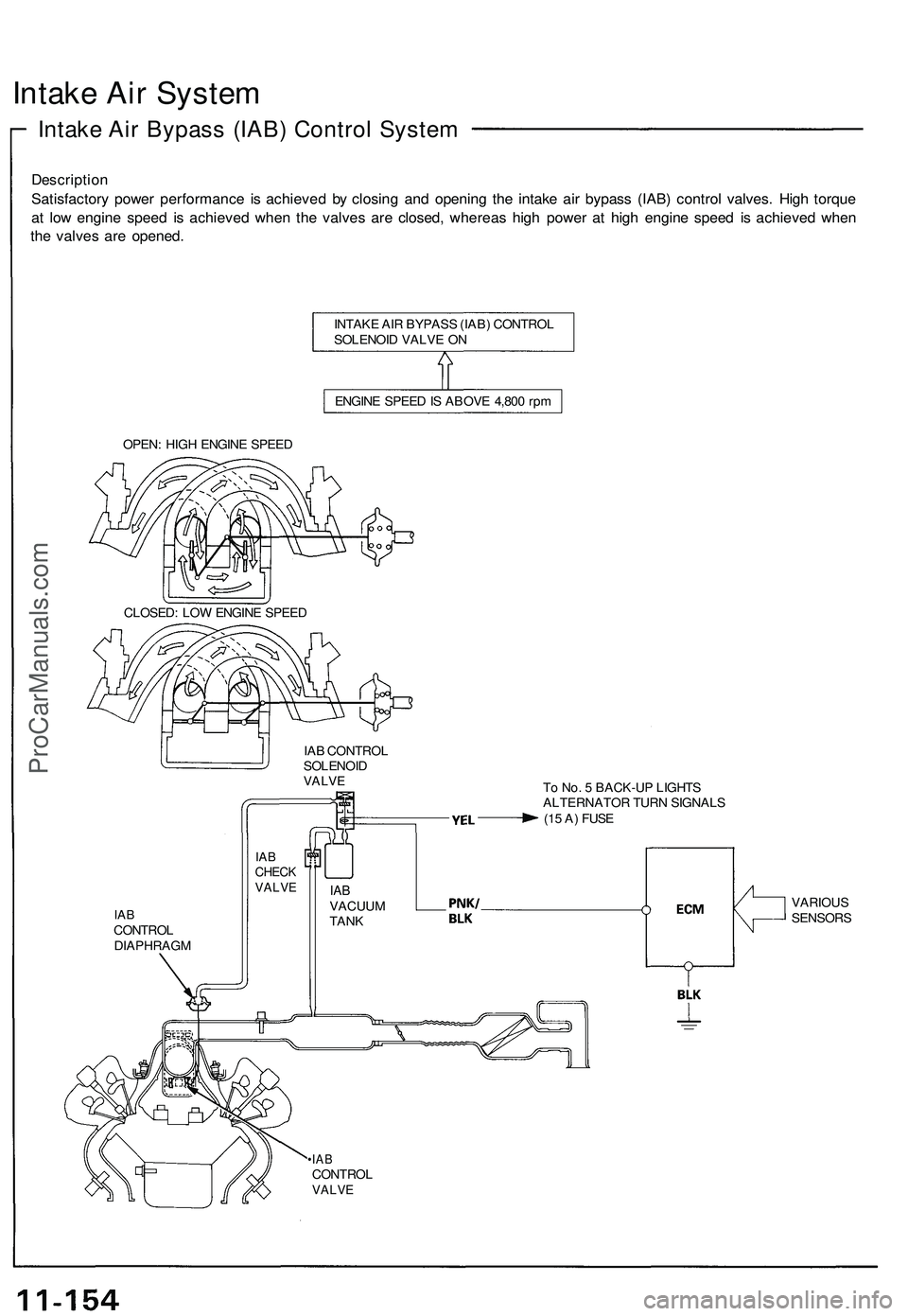

Intake Air Bypass (IAB) Control System

Description

Satisfactory power performance is achieved by closing and opening the intake air bypass (IAB) control valves. High torque

at low engine speed is achieved when the valves are closed, whereas high power at high engine speed is achieved when

the valves are opened.

INTAKE AIR BYPASS (IAB) CONTROL

SOLENOID VALVE ON

ENGINE SPEED IS ABOVE 4,800 rpm

OPEN: HIGH ENGINE SPEED

CLOSED: LOW ENGINE SPEED

IAB CONTROL

SOLENOID

VALVE

To No. 5 BACK-UP LIGHTS

ALTERNATOR TURN SIGNALS

(15 A) FUSE

IAB

CONTROL

DIAPHRAGM

•IAB

CONTROL

VALVE

IAB

CHECK

VALVE

IAB

VACUUM

TANK

VARIOUS

SENSORSProCarManuals.com

Page 635 of 1503

Emission Control System

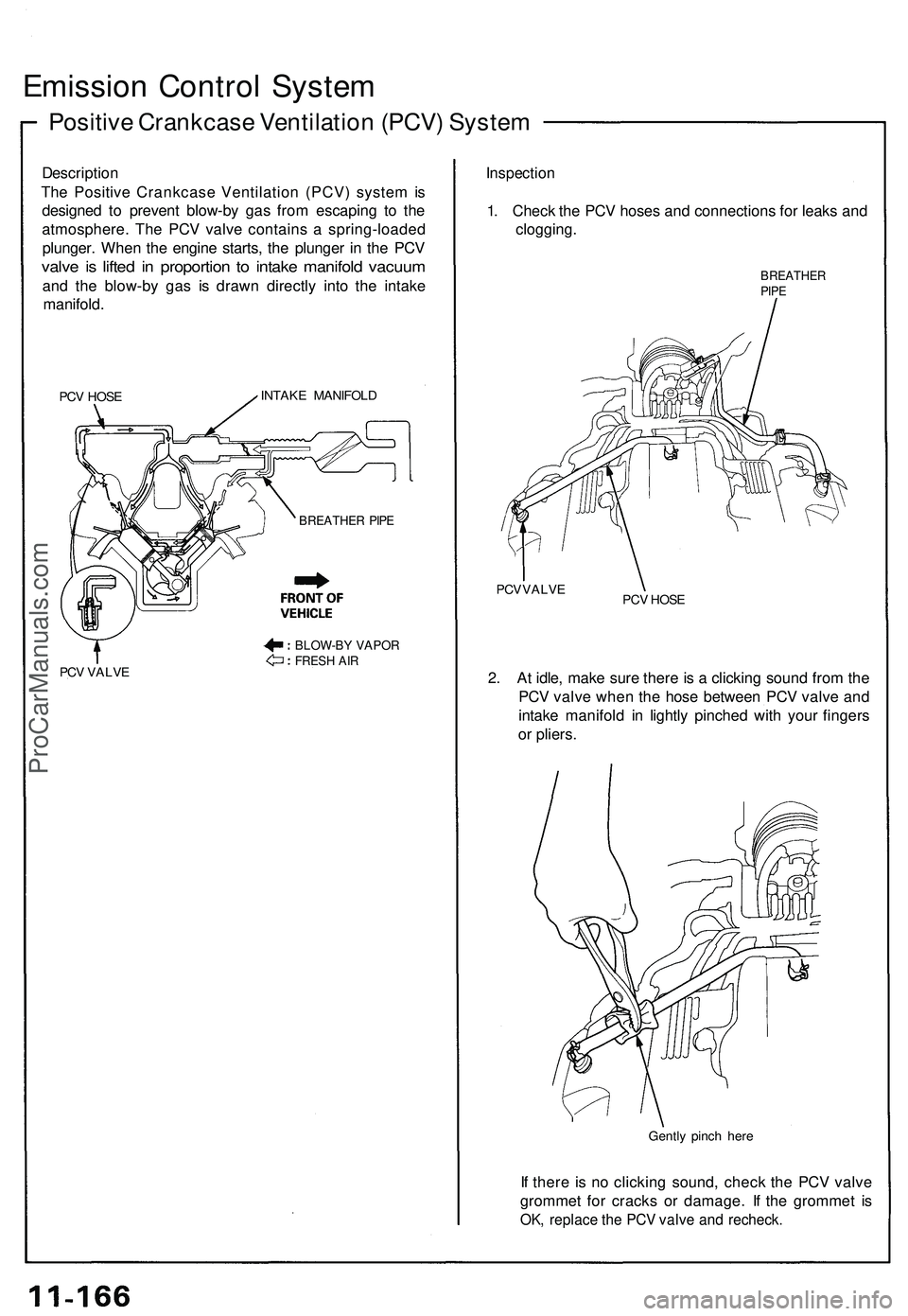

Positive Crankcase Ventilation (PCV) System

Description

The Positive Crankcase Ventilation (PCV) system is

designed to prevent blow-by gas from escaping to the

atmosphere. The PCV valve contains a spring-loaded

plunger. When the engine starts, the plunger in the PCV

valve is lifted in proportion to intake manifold vacuum

and the blow-by gas is drawn directly into the intake

manifold.

PCV HOSE

INTAKE MANIFOLD

PCV VALVE

Inspection

1. Check the PCV hoses and connections for leaks and

clogging.

BREATHER

PIPE

PCV VALVE

PCV HOSE

2. At idle, make sure there is a clicking sound from the

PCV valve when the hose between PCV valve and

intake manifold in lightly pinched with your fingers

or pliers.

Gently pinch here

If there is no clicking sound, check the PCV valve

grommet for cracks or damage. If the grommet is

OK, replace the PCV valve and recheck.

BLOW-BY VAPOR

FRESH AIR

BREATHER PIPEProCarManuals.com