engine ACURA NSX 1997 Service Workshop Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 367 of 1503

3-2

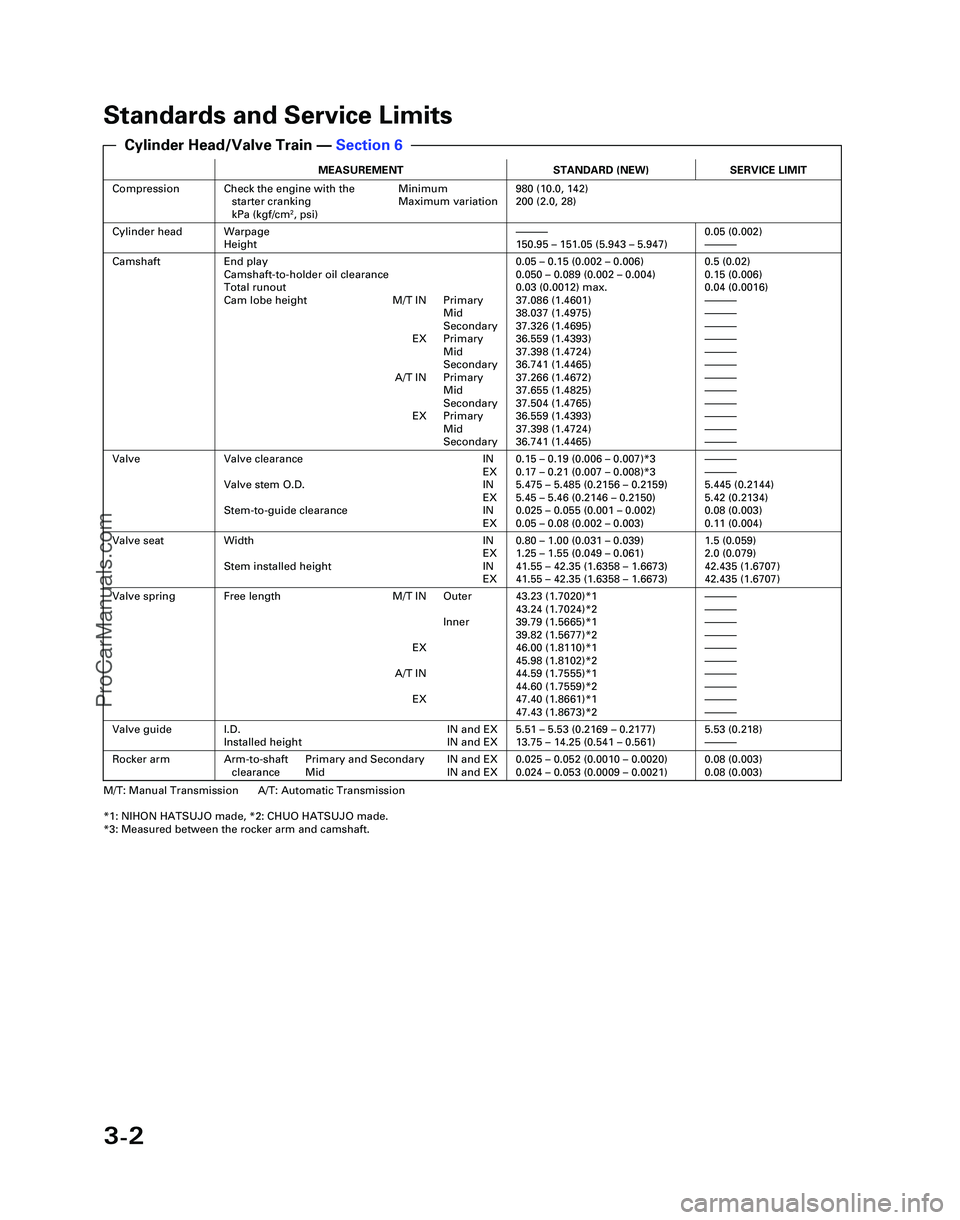

Standards and Service Limits

MEASUREMENTSTANDARD (NEW)SERVICE LIMIT

CompressionCheck the engine with the Minimumstarter cranking Maximum variation

kPa (kgf/cm

2, psi)

980 (10.0, 142)

200 (2.0, 28)

Cylinder headWarpage

Height—150.95 – 151.05 (5.943 – 5.947)0.05 (0.002)—

CamshaftEnd play

Camshaft-to-holder oil clearance

Total runout

Cam lobe height M/T IN Primary Mid

Secondary

EX Primary Mid

Secondary

A/T IN Primary Mid

Secondary

EX Primary Mid

Secondary0.05 – 0.15 (0.002 – 0.006)

0.050 – 0.089 (0.002 – 0.004)

0.03 (0.0012) max.

37.086 (1.4601)

38.037 (1.4975)

37.326 (1.4695)

36.559 (1.4393)

37.398 (1.4724)

36.741 (1.4465)

37.266 (1.4672)

37.655 (1.4825)

37.504 (1.4765)

36.559 (1.4393)

37.398 (1.4724)

36.741 (1.4465)0.5 (0.02)

0.15 (0.006)

0.04 (0.0016)

—

—

—

—

—

—

—

—

—

—

—

—

ValveValve clearance IN EX

Valve stem O.D. IN EX

Stem-to-guide clearance IN EX0.15 – 0.19 (0.006 – 0.007)*3

0.17 – 0.21 (0.007 – 0.008)*3

5.475 – 5.485 (0.2156 – 0.2159)

5.45 – 5.46 (0.2146 – 0.2150)

0.025 – 0.055 (0.001 – 0.002)

0.05 – 0.08 (0.002 – 0.003)—

—

5.445 (0.2144)

5.42 (0.2134)

0.08 (0.003)

0.11 (0.004)

Valve seatWidth INEX

Stem installed height IN EX0.80 – 1.00 (0.031 – 0.039)

1.25 – 1.55 (0.049 – 0.061)

41.55 – 42.35 (1.6358 – 1.6673)

41.55 – 42.35 (1.6358 – 1.6673)1.5 (0.059)

2.0 (0.079)

42.435 (1.6707)

42.435 (1.6707)

Valve springFree length M/T IN Outer

Inner

EX

A/T IN EX43.23 (1.7020)*1

43.24 (1.7024)*2

39.79 (1.5665)*1

39.82 (1.5677)*2

46.00 (1.8110)*1

45.98 (1.8102)*2

44.59 (1.7555)*1

44.60 (1.7559)*2

47.40 (1.8661)*1

47.43 (1.8673)*2—

—

—

—

—

—

—

—

—

—

Valve guideI.D. IN and EX

Installed height IN and EX5.51 – 5.53 (0.2169 – 0.2177)

13.75 – 14.25 (0.541 – 0.561)5.53 (0.218)—

Rocker armArm-to-shaft Primary and Secondary IN and EXclearance Mid IN and EX0.025 – 0.052 (0.0010 – 0.0020)

0.024 – 0.053 (0.0009 – 0.0021)0.08 (0.003)

0.08 (0.003)

M/T: Manual Transmission A/T: Automatic Transmission

*1: NIHON HATSUJO made, *2: CHUO HATSUJO made.

*3: Measured between the rocker arm and camshaft.

Cylinder Head/Valve Train — Section 6

*04-NSX (61SW004)SEC03(01-16) 9/22/04 1:48 PM Page 3-2

ProCarManuals.com

Page 368 of 1503

3-13

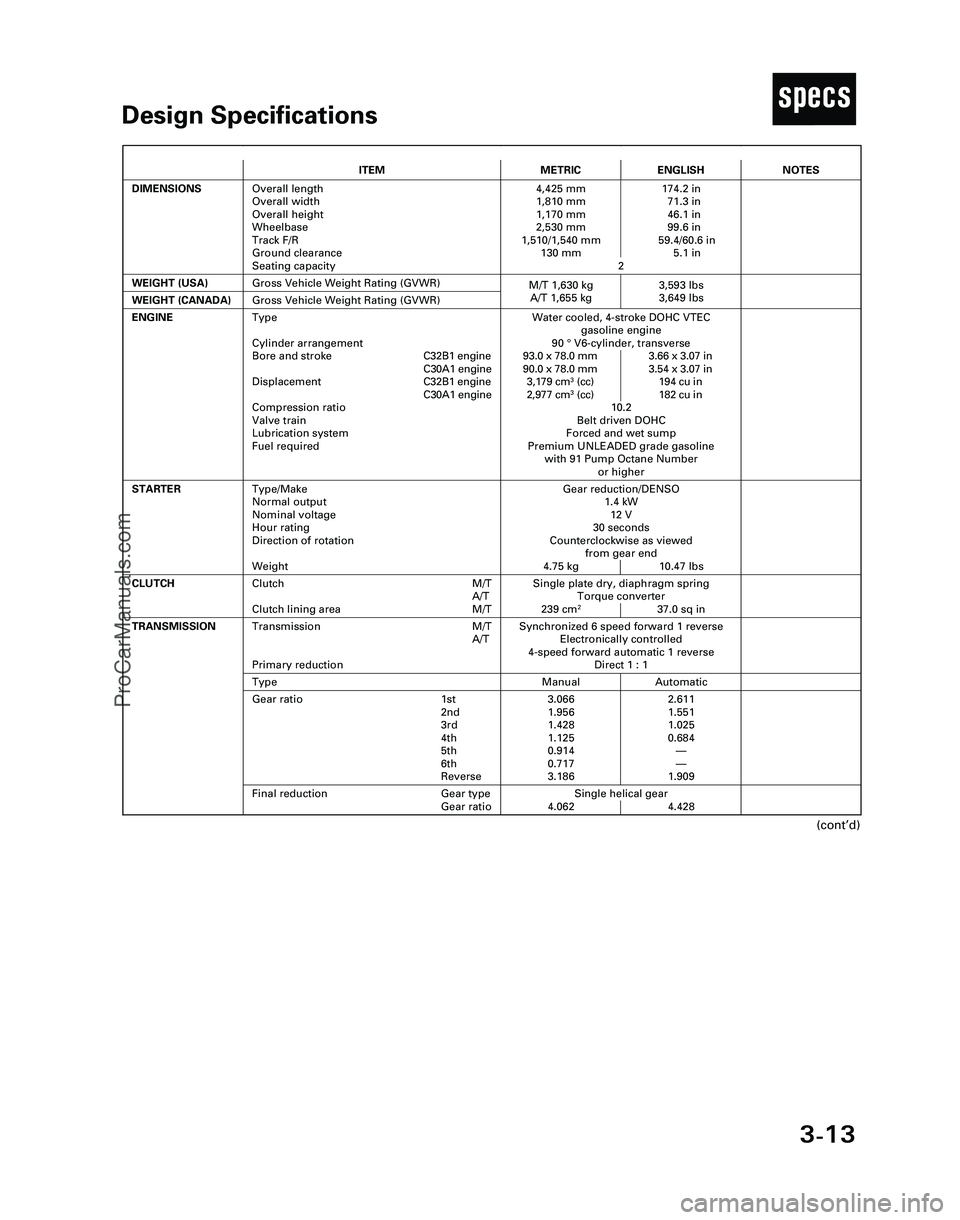

TDesign Specifications

(cont’d)

ITEMMETRICENGLISH

DIMENSIONSOverall length

Overall width

Overall height

Wheelbase

Track F/R

Ground clearance

Seating capacity4,425 mm 174.2 in

1,810 mm 71.3 in

1,170 mm 46.1 in

2,530 mm 99.6 in

1,510/1,540 mm 59.4/60.6 in

130 mm 5.1 in

2

WEIGHT (USA)

Single plate dry, diaphragm spring

Torque converter

239 cm

237.0 sq in

CLUTCHClutch M/T

A/T

Clutch lining area M/T

Gross Vehicle Weight Rating (GVWR)

NOTES

Gear reduction/DENSO

1.4 kW

12 V

30 seconds

Counterclockwise as viewed

from gear end

4.75 kg 10.47 lbs

ENGINEWater cooled, 4-stroke DOHC VTEC

gasoline engine

90 °V6-cylinder, transverse

93.0 x 78.0 mm 3.66 x 3.07 in

90.0 x 78.0 mm 3.54 x 3.07 in

3,179 cm

3(cc) 194 cu in

2,977 cm3(cc) 182 cu in

10.2

Belt driven DOHC

Forced and wet sump

Premium UNLEADED grade gasoline

with 91 Pump Octane Number

or higher

STARTERType/Make

Normal output

Nominal voltage

Hour rating

Direction of rotation

Weight

WEIGHT (CANADA)Gross Vehicle Weight Rating (GVWR)

Synchronized 6 speed forward 1 reverse

Electronically controlled

4-speed forward automatic 1 reverse

Direct 1 : 1Transmission M/T

A/T

Primary reduction

Manual AutomaticType

3.066 2.611

1.956 1.551

1.428 1.025

1.125 0.684

0.914—

0.717—

3.186 1.909Gear ratio 1st

2nd

3rd

4th

5th

6th

Reverse

Single helical gear

4.062 4.428

TRANSMISSION

Final reduction Gear type

Gear ratio

Type

Cylinder arrangement

Bore and strokeC32B1 engine

C30A1 engine

DisplacementC32B1 engine

C30A1 engine

Compression ratio

Valve train

Lubrication system

Fuel required

M/T 1,630 kg 3,593 lbs

A/T 1,655 kg 3,649 lbs

*04-NSX (61SW004)SEC03(01-16) 9/22/04 1:49 PM Page 3-13

ProCarManuals.com

Page 370 of 1503

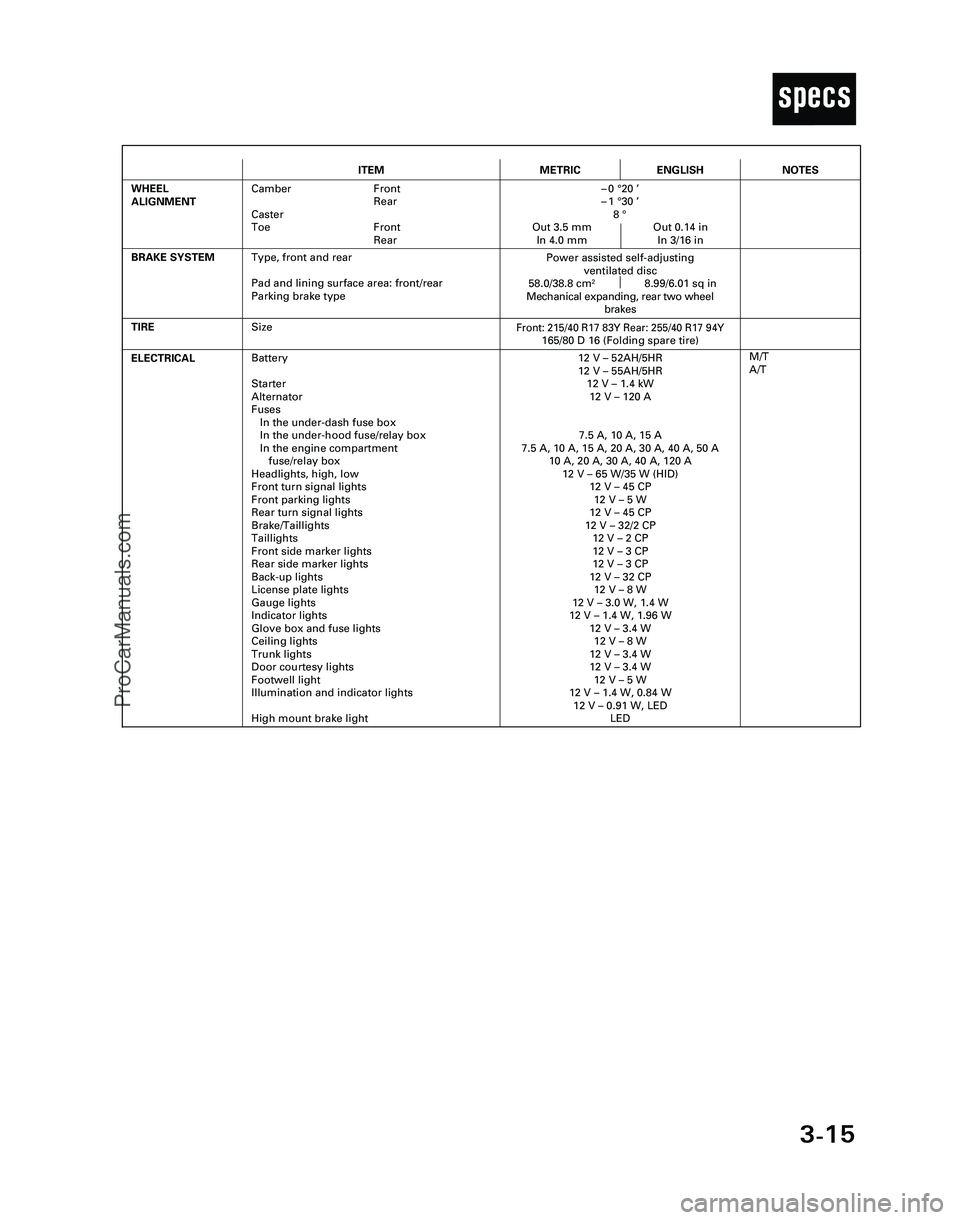

3-15

T

ITEMMETRICENGLISH

ELECTRICALBattery

Starter

Alternator

Fuses

In the under-dash fuse box

In the under-hood fuse/relay box

In the engine compartment

fuse/relay box

Headlights, high, low

Front turn signal lights

Front parking lights

Rear turn signal lights

Brake/Taillights

Taillights

Front side marker lights

Rear side marker lights

Back-up lights

License plate lights

Gauge lights

Indicator lights

Glove box and fuse lights

Ceiling lights

Trunk lights

Door courtesy lights

Footwell light

Illumination and indicator lights

High mount brake light12 V – 52AH/5HR

12 V – 55AH/5HR

12 V – 1.4 kW

12 V – 120 A

7.5 A, 10 A, 15 A

7.5 A, 10 A, 15 A, 20 A, 30 A, 40 A, 50 A

10 A, 20 A, 30 A, 40 A, 120 A

12 V – 65 W/35 W (HID)

12 V – 45 CP

12 V – 5 W

12 V – 45 CP

12 V – 32/2 CP

12 V – 2 CP

12 V – 3 CP

12 V – 3 CP

12 V – 32 CP

12 V – 8 W

12 V – 3.0 W, 1.4 W

12 V – 1.4 W, 1.96 W

12 V – 3.4 W

12 V – 8 W

12 V – 3.4 W

12 V – 3.4 W

12 V – 5 W

12 V – 1.4 W, 0.84 W

12 V – 0.91 W, LED

LED

TIRE

M/T

A/T

BRAKE SYSTEM

Front: 215/40 R17 83Y Rear: 255/40 R17 94Y165/80 D 16 (Folding spare tire)

Power assisted self-adjusting

ventilated disc

58.0/38.8 cm

28.99/6.01 sq in

Mechanical expanding, rear two wheel

brakes

WHEEL

ALIGNMENTCamber Front

Rear

Caster

Toe Front

Rear–0 °20 ’

–1 °30 ’

8 °

Out 3.5 mm Out 0.14 in

In 4.0 mm In 3/16 in

NOTES

Size

Type, front and rear

Pad and lining surface area: front/rear

Parking brake type

*04-NSX (61SW004)SEC03(01-16) 9/22/04 1:49 PM Page 3-15

ProCarManuals.com

Page 371 of 1503

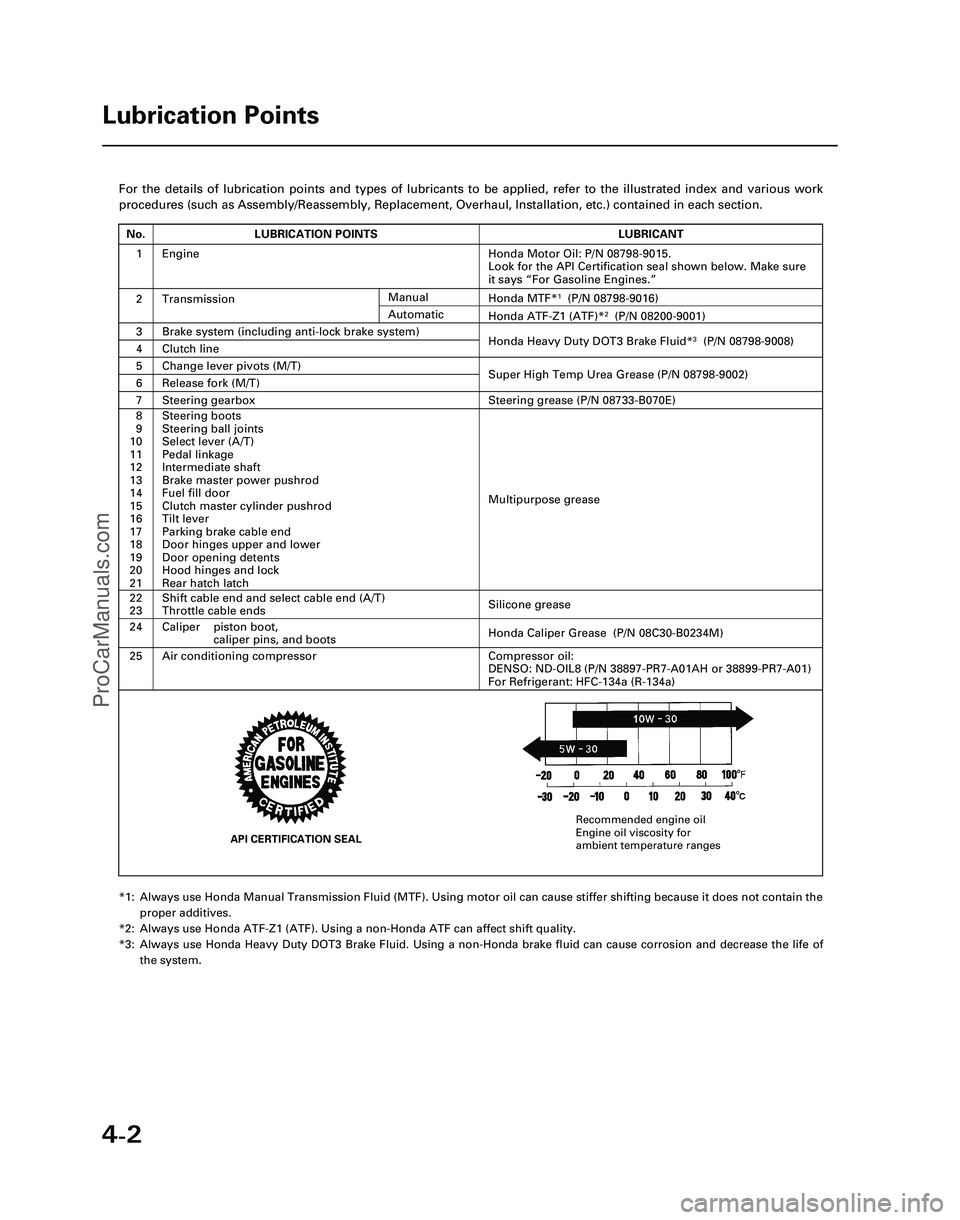

4-2

For the details of lubrication points and types of lubricants to be appl\

ied, refer to the illustrated index and various work

procedures (such as Assembly/Reassembly, Replacement, Overhaul, Install\

ation, etc.) contained in each section.

*1: Always use Honda Manual Transmission Fluid (MTF). Using motor oil can \

cause stiffer shifting because it does not contain theproper additives.

*2: Always use Honda ATF-Z1 (ATF). Using a non-Honda ATF can affect shift \

quality.

*3: Always use Honda Heavy Duty DOT3 Brake Fluid. Using a non-Honda brake fl\

uid can cause corrosion and decrease the life of the system.

Lubrication Points

No.LUBRICATION POINTSLUBRICANT

1Honda Motor Oil: P/N 08798-9015.

Look for the API Certification seal shown below. Make sure

it says “For Gasoline Engines.”

2TransmissionHonda MTF*1(P/N 08798-9016)

3Brake system (including anti-lock brake system)Honda Heavy Duty DOT3 Brake Fluid*3(P/N 08798-9008)4Clutch line

5Change lever pivots (M/T)Super High Temp Urea Grease (P/N 08798-9002)6Release fork (M/T)

8

9

10

11

12

13

14

15

16

17

18

19

20

21Steering boots

Steering ball joints

Select lever (A/T)

Pedal linkage

Intermediate shaft

Brake master power pushrod

Fuel fill door

Clutch master cylinder pushrod

Tilt lever

Parking brake cable end

Door hinges upper and lower

Door opening detents

Hood hinges and lock

Rear hatch latch

Multipurpose grease

24

22

23

Caliper piston boot, caliper pins, and boots

Shift cable end and select cable end (A/T)

Throttle cable ends

Honda Caliper Grease (P/N 08C30-B0234M)

Silicone grease

25Air conditioning compressorCompressor oil:

DENSO: ND-OIL8 (P/N 38897-PR7-A01AH or 38899-PR7-A01)

For Refrigerant: HFC-134a (R-134a)

Manual

Honda ATF-Z1 (ATF)*2(P/N 08200-9001)Automatic

7Steering gearboxSteering grease (P/N 08733-B070E)

Engine

API CERTIFICATION SEAL

Recommended engine oil

Engine oil viscosity for

ambient temperature ranges

*05-NSX (61SW004)SEC04(01-10) 9/22/04 1:49 PM Page 4-2

ProCarManuals.com

Page 374 of 1503

4-5

Y

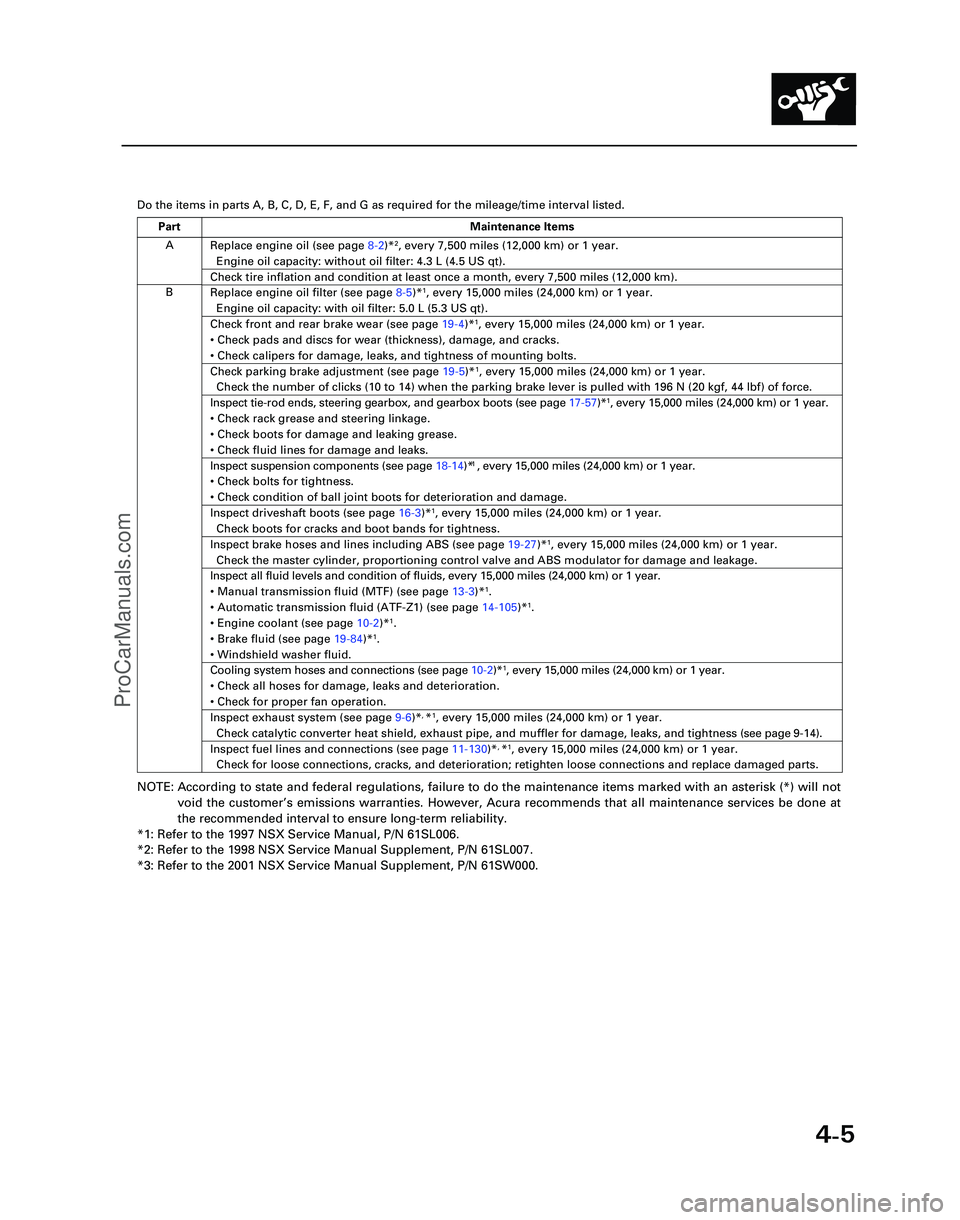

Do the items in parts A, B, C, D, E, F, and G as required for the mileag\

e/time interval listed.

NOTE: According to state and federal regulations, failure to do the maintenanc\

e items marked with an asterisk (*) will not

void the customer ’s emissions warranties. However, Acura recommends that all maintenance s\

ervices be done at

the recommended interval to ensure long-term reliability.

*1: Refer to the 1997 NSX Service Manual, P/N 61SL006.

*2: Refer to the 1998 NSX Service Manual Supplement, P/N 61SL007.

*3: Refer to the 2001 NSX Service Manual Supplement, P/N 61SW000.

A

B Replace engine oil (see page

8-2)*

2, every 7,500 miles (12,000 km) or 1 year.

Engine oil capacity: without oil filter: 4.3 L (4.5 US qt).

Check tire inflation and condition at least once a month, every 7,500 mi\

les (12,000 km).

Replace engine oil filter (see page 8-5)*1, every 15,000 miles (24,000 km) or 1 year.

Engine oil capacity: with oil filter: 5.0 L (5.3 US qt).

Check front and rear brake wear (see page 19-4)*1, every 15,000 miles (24,000 km) or 1 year.

• Check pads and discs for wear (thickness), damage, and cracks.

• Check calipers for damage, leaks, and tightness of mounting bolts.

Check parking brake adjustment (see page 19-5)*1, every 15,000 miles (24,000 km) or 1 year.

Check the number of clicks (10 to 14) when the parking brake lever is pulled with 196 N (20 kgf,\

44 lbf) of force.

Inspect tie-rod ends, steering gearbox, and gearbox boots (see page 17-57)*1, every 15,000 miles (24,000 km) or 1 year.

• Check rack grease and steering linkage.

• Check boots for damage and leaking grease.

• Check fluid lines for damage and leaks.1

• Check bolts for tightness.

• Check condition of ball joint boots for deterioration and damage.

Inspect driveshaft boots (see page 16-3)*1, every 15,000 miles (24,000 km) or 1 year.

Check boots for cracks and boot bands for tightness.

Inspect brake hoses and lines including ABS (see page 19-27)*1, every 15,000 miles (24,000 km) or 1 year.

Check the master cylinder, proportioning control valve and ABS modulator\

for damage and leakage.

Inspect all fluid levels and condition of fluids, every 15,000 miles (2\

4,000 km) or 1 year.

• Manual transmission fluid (MTF) (see page 13-3)*

1.

• Automatic transmission fluid (ATF-Z1) (see page 14-105)*1.

• Engine coolant (see page 10-2)*1.

• Brake fluid (see page 19-84)*1.

• Windshield washer fluid.

Cooling system hoses and connections (see page 10-2)*1, every 15,000 miles (24,000 km) or 1 year.

• Check all hoses for damage, leaks and deterioration.

• Check for proper fan operation.

Inspect exhaust system (see page 9-6)*, *1, every 15,000 miles (24,000 km) or 1 year.

Check catalytic converter heat shield, exhaust pipe, and muffler for dam\

age, leaks, and tightness ( see page 9-14 ).

Inspect fuel lines and connections (see page 11-130)*, *1, every 15,000 miles (24,000 km) or 1 year.

Check for loose connections, cracks, and deterioration; retighten loose \

connections and replace damaged parts.

Part Maintenance Items

*05-NSX (61SW004)SEC04(01-10) 9/22/04 1:49 PM Page 4-5

Inspect suspension components (see page 18-14)* , every 15,000 miles (24,000 km) or 1 year.

ProCarManuals.com

Page 375 of 1503

4-6

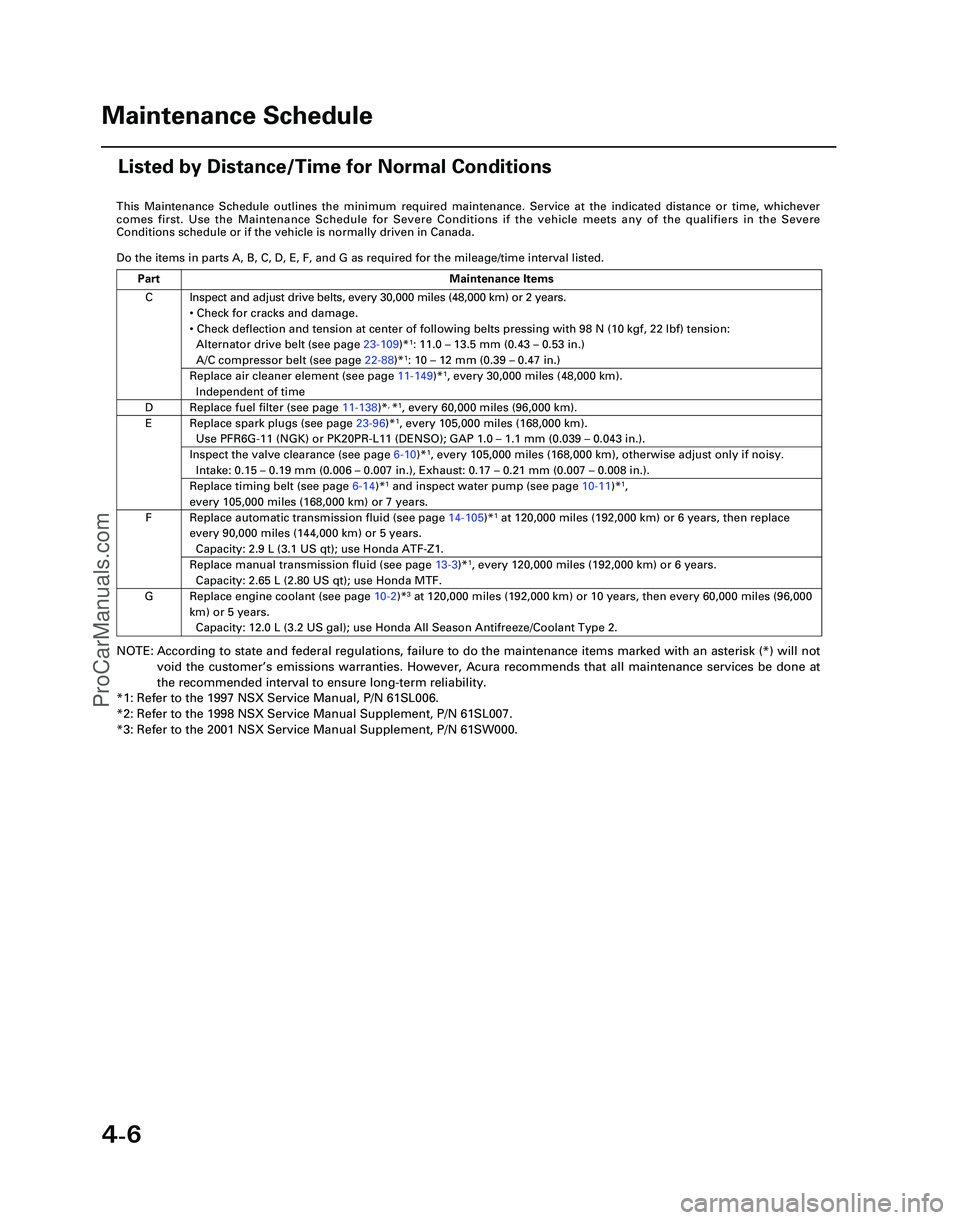

This Maintenance Schedule outlines the minimum required maintenance. Ser\

vice at the indicated distance or time, whichever

comes first. Use the Maintenance Schedule for Severe Conditions if the v\

ehicle meets any of the qualifiers in the Severe

Conditions schedule or if the vehicle is normally driven in Canada.

Do the items in parts A, B, C, D, E, F, and G as required for the mileag\

e/time interval listed.

NOTE: According to state and federal regulations, failure to do the maintenanc\

e items marked with an asterisk (*) will not

void the customer ’s emissions warranties. However, Acura recommends that all maintenance s\

ervices be done at

the recommended interval to ensure long-term reliability.

*1: Refer to the 1997 NSX Service Manual, P/N 61SL006.

*2: Refer to the 1998 NSX Service Manual Supplement, P/N 61SL007.

*3: Refer to the 2001 NSX Service Manual Supplement, P/N 61SW000.

C

D

E

F

G Inspect and adjust drive belts, every 30,000 miles (48,000 km) or 2 ye\

ars.

•

Check for cracks and damage.

• Check deflection and tension at center of following belts pressing with\

98 N (10 kgf, 22 lbf) tension:

Alternator drive belt (see page 23-109)*

1: 11.0 – 13.5 mm (0.43 – 0.53 in.)

A/C compressor belt (see page 22-88)*1: 10 – 12 mm (0.39 – 0.47 in.)

Replace air cleaner element (see page 11-149)*1, every 30,000 miles (48,000 km).

Independent of time

Replace fuel filter (see page 11-138)*, *1, every 60,000 miles (96,000 km).

Replace spark plugs (see page 23-96)*1, every 105,000 miles (168,000 km).

Use PFR6G-11 (NGK) or PK20PR-L11 (DENSO); GAP 1.0 – 1.1 mm (0.039 – 0.043 in.).

Inspect the valve clearance (see page 6-10)*1, every 105,000 miles (168,000 km), otherwise adjust only if noisy.

Intake: 0.15 – 0.19 mm (0.006 – 0.007 in.), Exhaust: 0.17 – 0.21 mm (0.007 – 0.008 in.).

Replace timing belt (see page 6-14)*1 and inspect water pump (see page 10-11)*1,

every 105,000 miles (168,000 km) or 7 years.

Replace automatic transmission fluid (see page 14-105)*1 at 120,000 miles (192,000 km) or 6 years, then replace

every 90,000 miles (144,000 km) or 5 years.

Capacity: 2.9 L (3.1 US qt); use Honda ATF-Z1.

Replace manual transmission fluid (see page 13-3)*1, every 120,000 miles (192,000 km) or 6 years.

Capacity: 2.65 L (2.80 US qt); use Honda MTF.

Replace engine coolant (see page 10-2 )*3 at 120,000 miles (192,000 km) or 10 years, then every 60,000 miles (9\

6,000

km) or 5 years. Capacity: 12.0 L (3.2 US gal); use Honda All Season Antifreeze/Coolant\

Type 2.

Part Maintenance Items

Maintenance Schedule

Listed by Distance/Time for Normal Conditions

*05-NSX (61SW004)SEC04(01-10) 9/22/04 1:49 PM Page 4-6

ProCarManuals.com

Page 376 of 1503

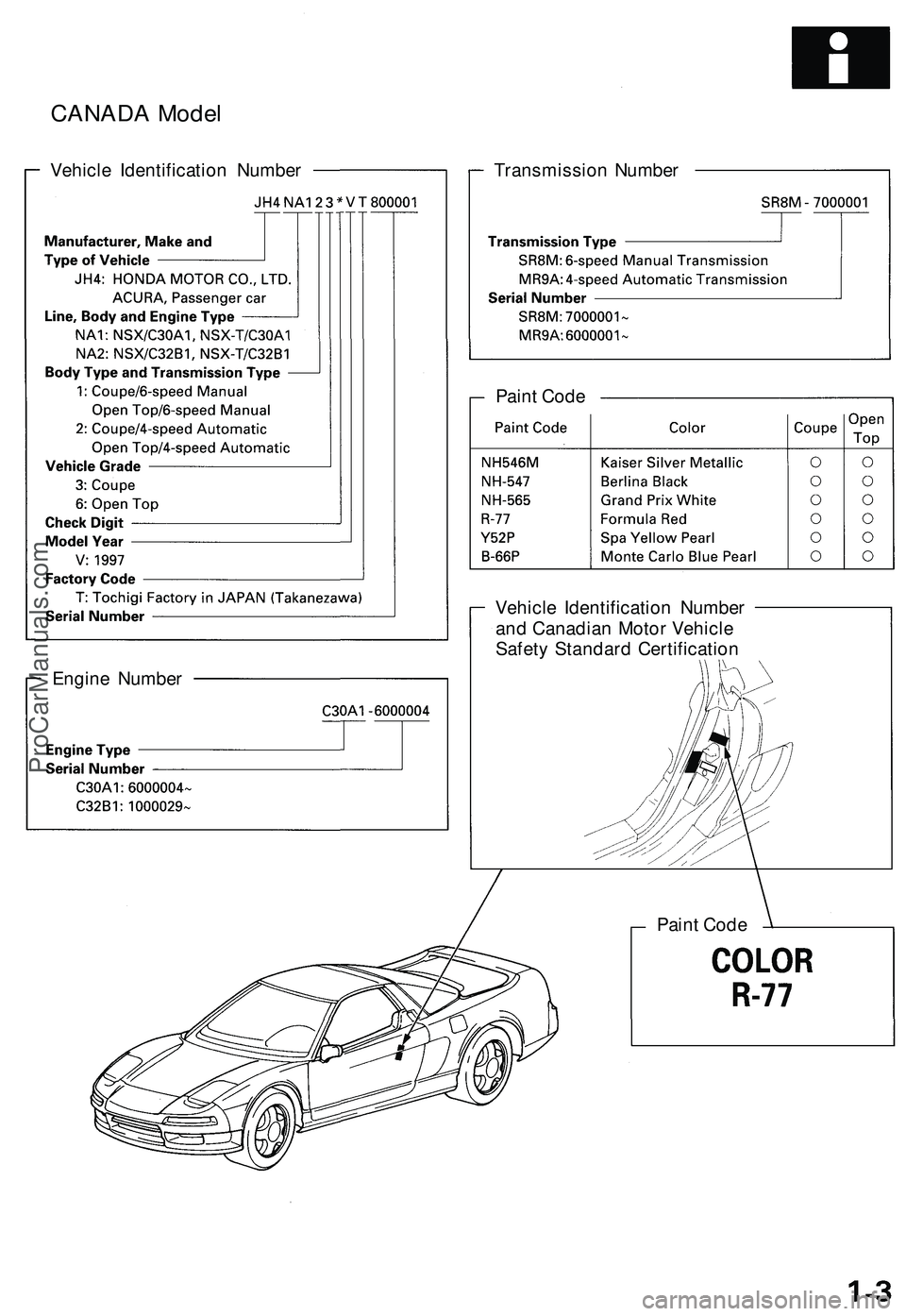

CANADA Model

Vehicle Identification Number

Transmission Number

Paint Code

Vehicle Identification Number

and Canadian Motor Vehicle

Safety Standard Certification

Paint Code

Engine NumberProCarManuals.com

Page 381 of 1503

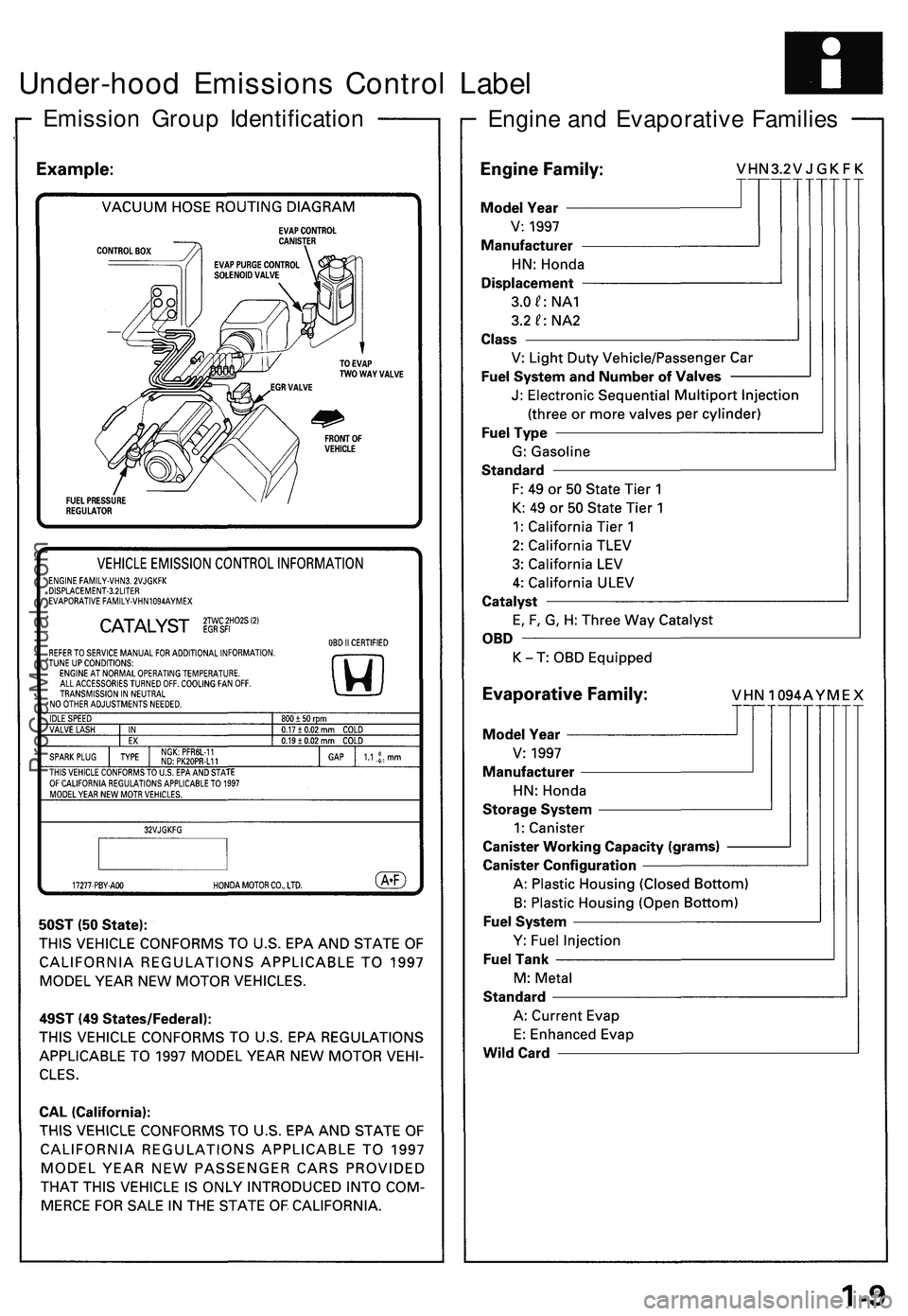

Under-hood Emissions Control Label

Emission Group Identification

Engine and Evaporative FamiliesProCarManuals.com

Page 384 of 1503

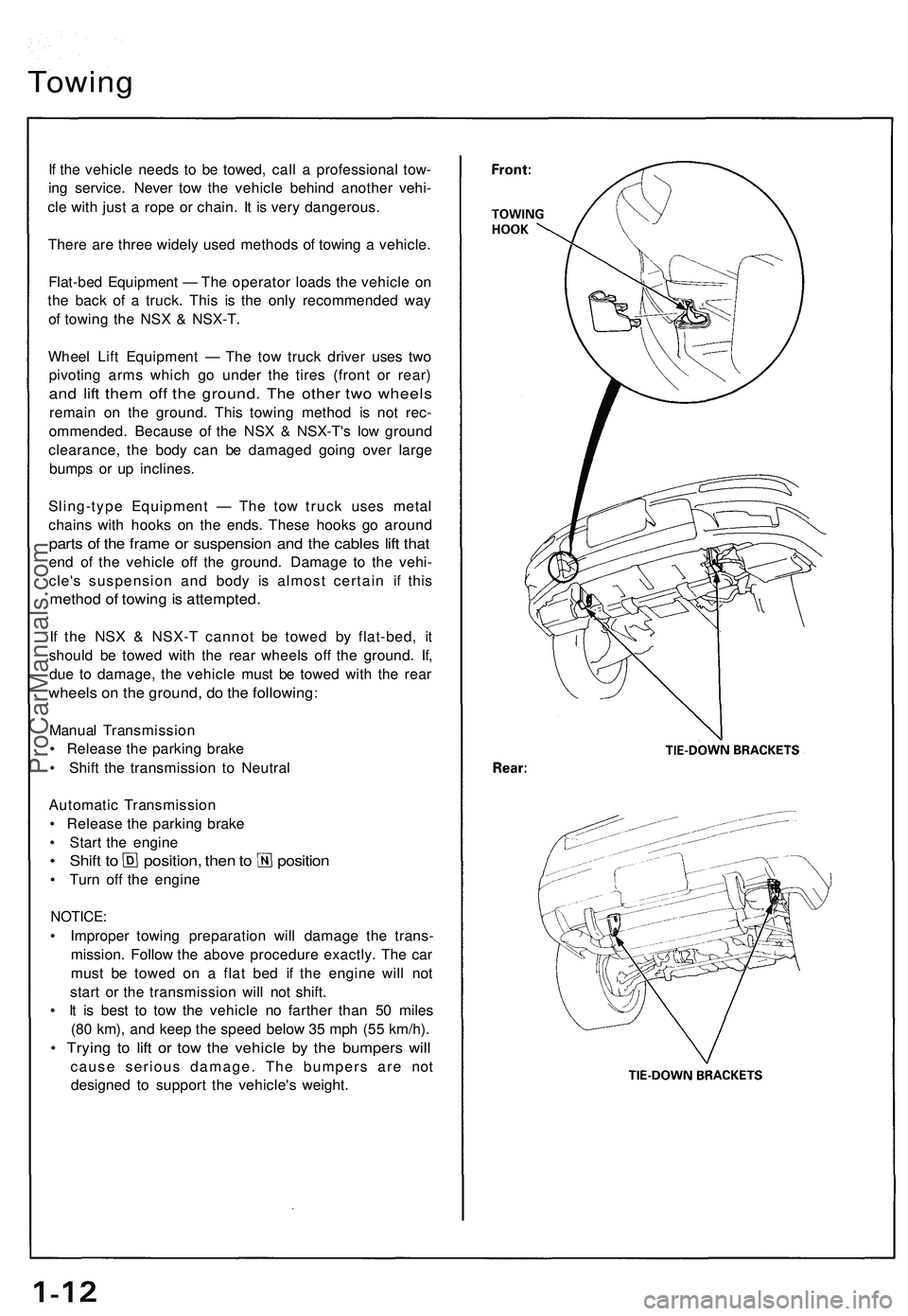

Towing

If the vehicle needs to be towed, call a professional tow-

ing service. Never tow the vehicle behind another vehi-

cle with just a rope or chain. It is very dangerous.

There are three widely used methods of towing a vehicle.

Flat-bed Equipment — The operator loads the vehicle on

the back of a truck. This is the only recommended way

of towing the NSX & NSX-T.

Wheel Lift Equipment — The tow truck driver uses two

pivoting arms which go under the tires (front or rear)

and lift them off the ground. The other two wheels

remain on the ground. This towing method is not rec-

ommended. Because of the NSX & NSX-T's low ground

clearance, the body can be damaged going over large

bumps or up inclines.

Sling-type Equipment — The tow truck uses metal

chains with hooks on the ends. These hooks go around

parts of the frame or suspension and the cables lift that

end of the vehicle off the ground. Damage to the vehi-

cle's suspension and body is almost certain if this

method of towing is attempted.

If the NSX & NSX-T cannot be towed by flat-bed, it

should be towed with the rear wheels off the ground. If,

due to damage, the vehicle must be towed with the rear

wheels on the ground, do the following:

Manual Transmission

• Release the parking brake

• Shift the transmission to Neutral

Automatic Transmission

• Release the parking brake

• Start the engine

• Shift to position, then to position

• Turn off the engine

NOTICE:

• Improper towing preparation will damage the trans-

mission. Follow the above procedure exactly. The car

must be towed on a flat bed if the engine will not

start or the transmission will not shift.

• It is best to tow the vehicle no farther than 50 miles

(80 km), and keep the speed below 35 mph (55 km/h).

• Trying to lift or tow the vehicle by the bumpers will

cause serious damage. The bumpers are not

designed to support the vehicle's weight.ProCarManuals.com

Page 385 of 1503

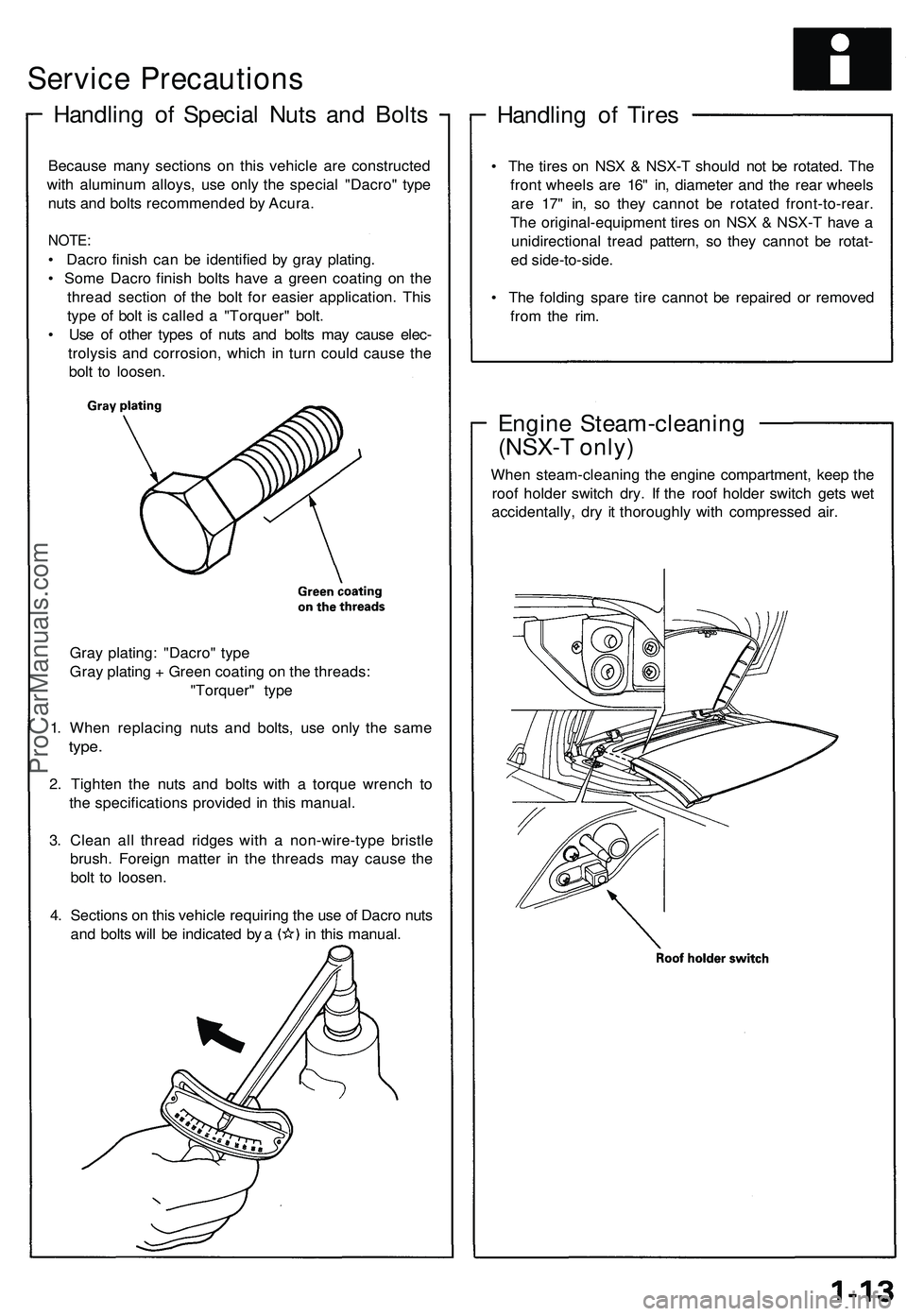

Service Precautions

Handling of Special Nuts and Bolts

Handling of Tires

• The tires on NSX & NSX-T should not be rotated. The

front wheels are 16" in, diameter and the rear wheels

are 17" in, so they cannot be rotated front-to-rear.

The original-equipment tires on NSX & NSX-T have a

unidirectional tread pattern, so they cannot be rotat-

ed side-to-side.

• The folding spare tire cannot be repaired or removed

from the rim.

Engine Steam-cleaning

(NSX-T only)

When steam-cleaning the engine compartment, keep the

roof holder switch dry. If the roof holder switch gets wet

accidentally, dry it thoroughly with compressed air.

Because many sections on this vehicle are constructed

with aluminum alloys, use only the special "Dacro" type

nuts and bolts recommended by Acura.

NOTE:

• Dacro finish can be identified by gray plating.

• Some Dacro finish bolts have a green coating on the

thread section of the bolt for easier application. This

type of bolt is called a "Torquer" bolt.

• Use of other types of nuts and bolts may cause elec-

trolysis and corrosion, which in turn could cause the

bolt to loosen.

Gray plating: "Dacro" type

Gray plating + Green coating on the threads:

"Torquer" type

1. When replacing nuts and bolts, use only the same

type.

2. Tighten the nuts and bolts with a torque wrench to

the specifications provided in this manual.

3. Clean all thread ridges with a non-wire-type bristle

brush. Foreign matter in the threads may cause the

bolt to loosen.

4. Sections on this vehicle requiring the use of Dacro nuts

and bolts will be indicated by a in this manual.ProCarManuals.com