engine ACURA NSX 1997 Service Owners Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 500 of 1503

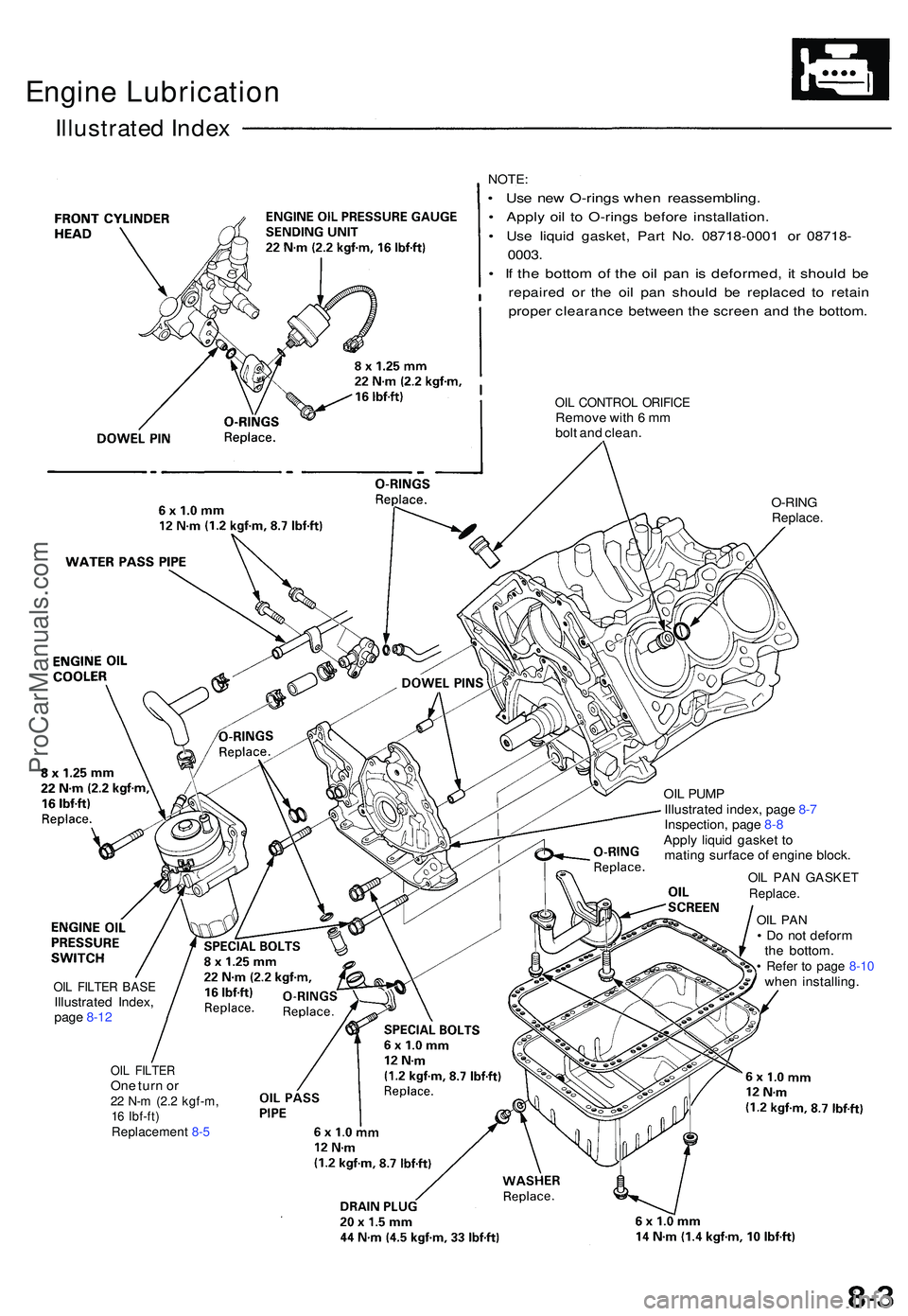

Engine Lubricatio n

Illustrated Index

NOTE:

• Us e ne w O-ring s whe n reassembling .

• Appl y oi l t o O-ring s befor e installation .

• Us e liqui d gasket , Par t No . 0871 8-000 1 o r 0871 8-

0003 .

• I f th e botto m o f th e oi l pa n i s deformed , i t shoul d b e

repaire d o r th e oi l pa n shoul d b e replace d t o retai n

prope r clearanc e betwee n th e scree n an d th e bottom .

OIL CONTRO L ORIFIC ERemove wit h 6 m m

bol t an d clean .

O-RIN GReplace .

OIL FILTE R BAS EIllustrate d Index ,

pag e 8-1 2

OIL FILTE ROne tur n o r22 N- m (2. 2 kgf-m ,16 Ibf-ft )Replacemen t 8- 5

OI L PUM P

Illustrate d index , pag e 8- 7

Inspection , pag e 8 -8

Appl y liqui d gaske t t o

matin g surfac e o f engin e block .

OIL PA N GASKE TReplace.

OIL PA N• D o no t defor m

th e bottom .

• Refe r t o pag e 8-1 0whe n installing .

ProCarManuals.com

Page 501 of 1503

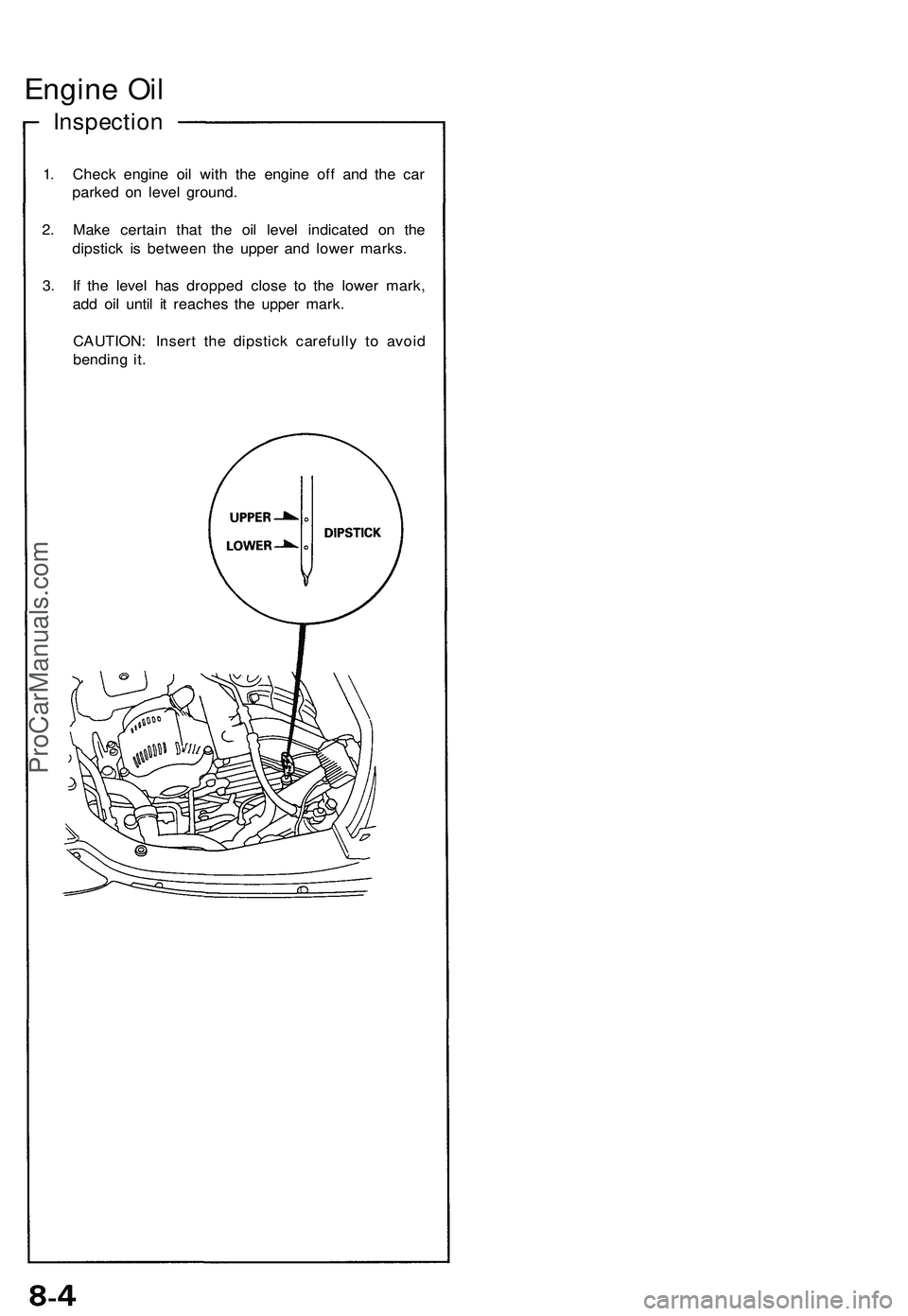

Engine Oil

Inspection

1. Check engine oil with the engine off and the car

parked on level ground.

2. Make certain that the oil level indicated on the

dipstick is between the upper and lower marks.

3. If the level has dropped close to the lower mark,

add oil until it reaches the upper mark.

CAUTION: Insert the dipstick carefully to avoid

bending it.ProCarManuals.com

Page 502 of 1503

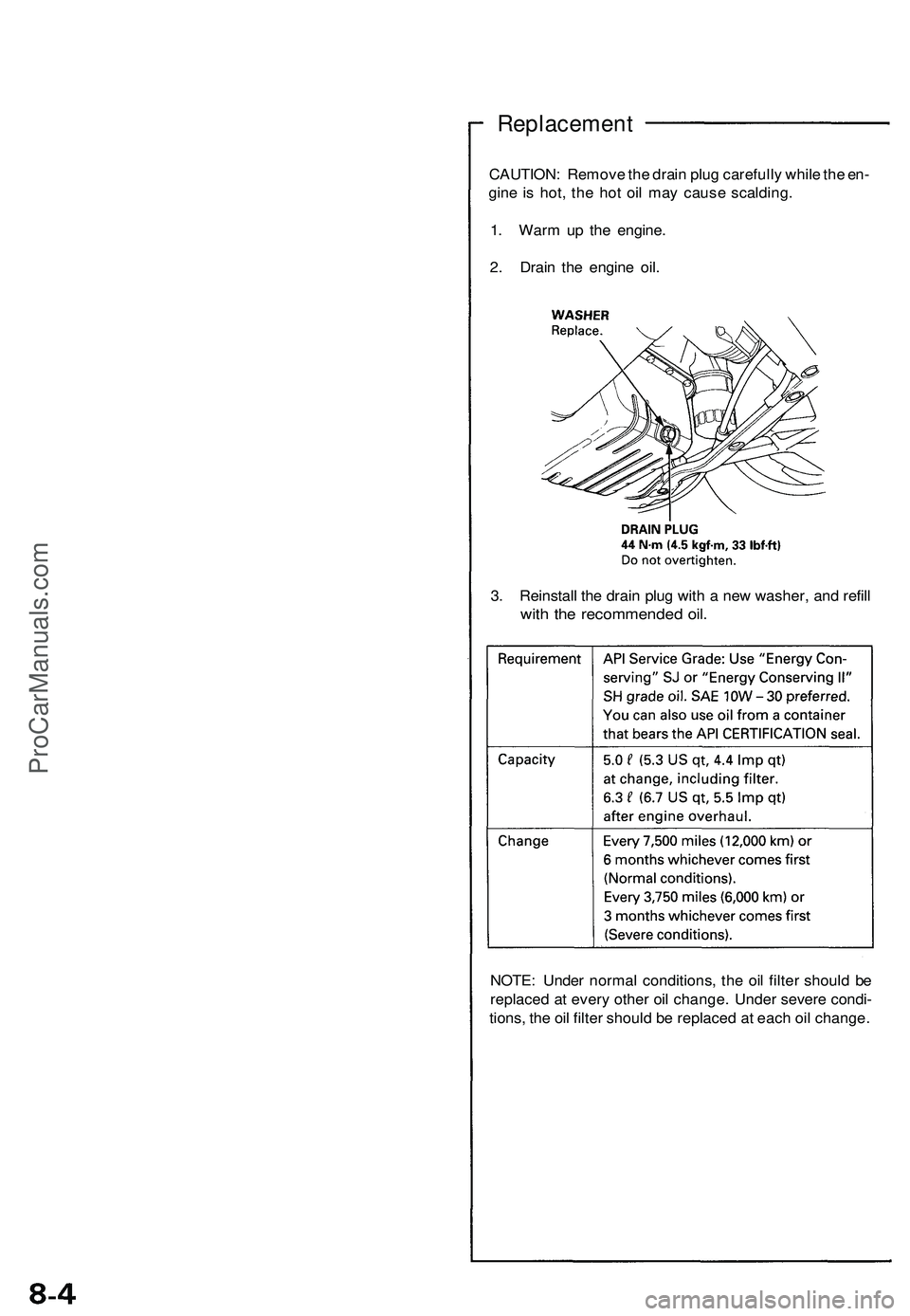

Replacement

CAUTION: Remove the drain plug carefully while the en-

gine is hot, the hot oil may cause scalding.

1. Warm up the engine.

2. Drain the engine oil.

3. Reinstall the drain plug with a new washer, and refill

with the recommended oil.

NOTE: Under normal conditions, the oil filter should be

replaced at every other oil change. Under severe condi-

tions, the oil filter should be replaced at each oil change.ProCarManuals.com

Page 504 of 1503

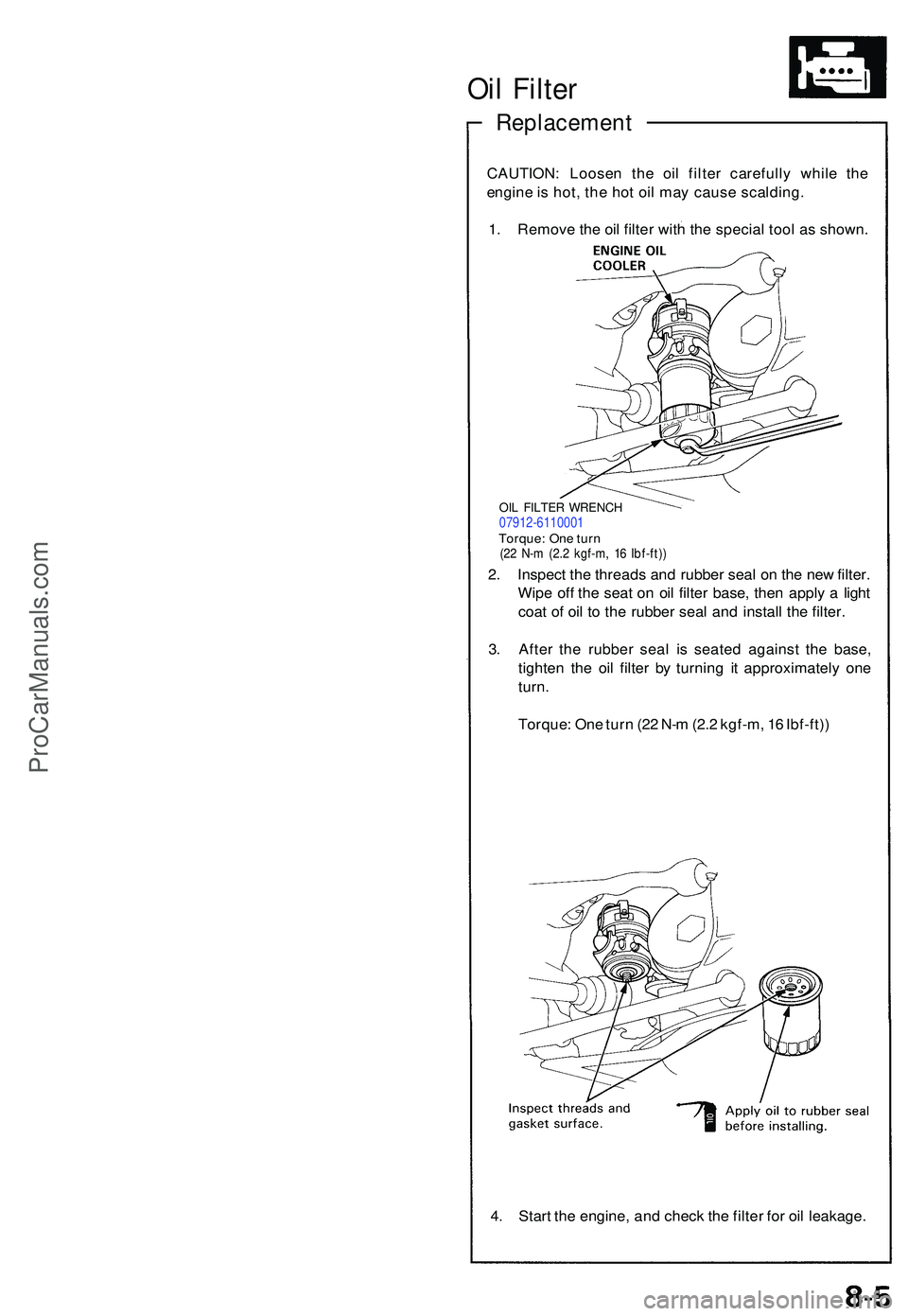

Oil Filte r

Replacemen t

CAUTION: Loose n th e oi l filte r carefull y whil e th e

engin e is hot , the hot oi l ma y cause scalding .

1 . Remov e th e oi l filte r wit h th e specia l too l a s shown .

OIL FILTE R WRENC H07912-611000 1Torque: On e tur n(22 N- m (2. 2 kgf-m , 1 6 Ibf-ft) )

2. Inspec t th e thread s an d rubbe r sea l o n th e ne w filter .

Wip e of f th e sea t o n oi l filte r base , the n appl y a ligh t

coa t o f oi l t o th e rubber seal an d instal l th e filter .

3 . Afte r th e rubbe r sea l i s seate d agains t th e base ,

tighte n th e oi l filte r b y turnin g i t approximatel y on e

turn .

Torque : On e tur n (2 2 N- m (2. 2 kgf-m , 1 6 Ibf-ft) )

4 . Star t th e engine , an d chec k th e filte r fo r oi l leakage .

ProCarManuals.com

Page 505 of 1503

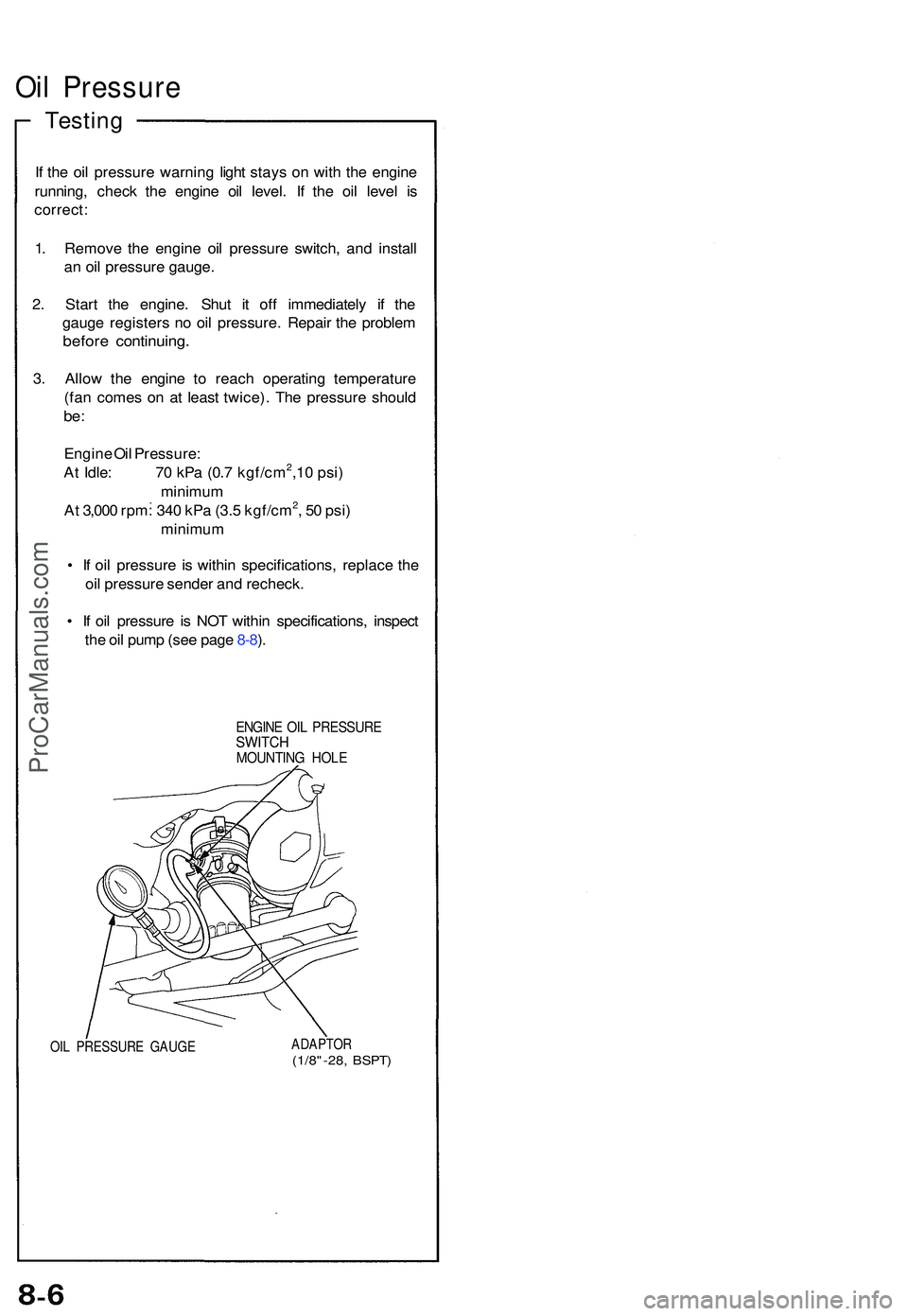

Oil Pressur e

Testing

If th e oi l pressur e warnin g ligh t stay s o n wit h th e engin e

running , chec k th e engin e oi l level . I f th e oi l leve l i s

correct :

1 . Remov e th e engine oil pressur e switch , an d instal l

a n oi l pressur e gauge .

2 . Star t th e engine . Shu t i t of f immediatel y i f th e

gaug e register s n o oi l pressure . Repai r th e proble m

before continuing .

3. Allo w th e engin e t o reac h operatin g temperatur e

(fa n come s o n a t leas t twice) . Th e pressur e shoul d

be:

Engin e Oi l Pressure :

A t Idle : 7 0 kP a (0. 7 kgf/cm2,1 0 psi )

minimu m

A t 3,00 0 rpm : 34 0 kP a (3. 5 kgf/cm

2, 5 0 psi )

minimu m

• I f oi l pressur e i s withi n specifications , replac e th e

oi l pressur e sende r an d recheck .

• I f oi l pressur e i s NO T withi n specifications , inspec t

th e oi l pum p (se e pag e 8-8 ).

ENGIN E OI L PRESSUR ESWITCHMOUNTIN G HOL E

OIL PRESSUR E GAUG EADAPTO R(1/8"-28, BSPT )

ProCarManuals.com

Page 507 of 1503

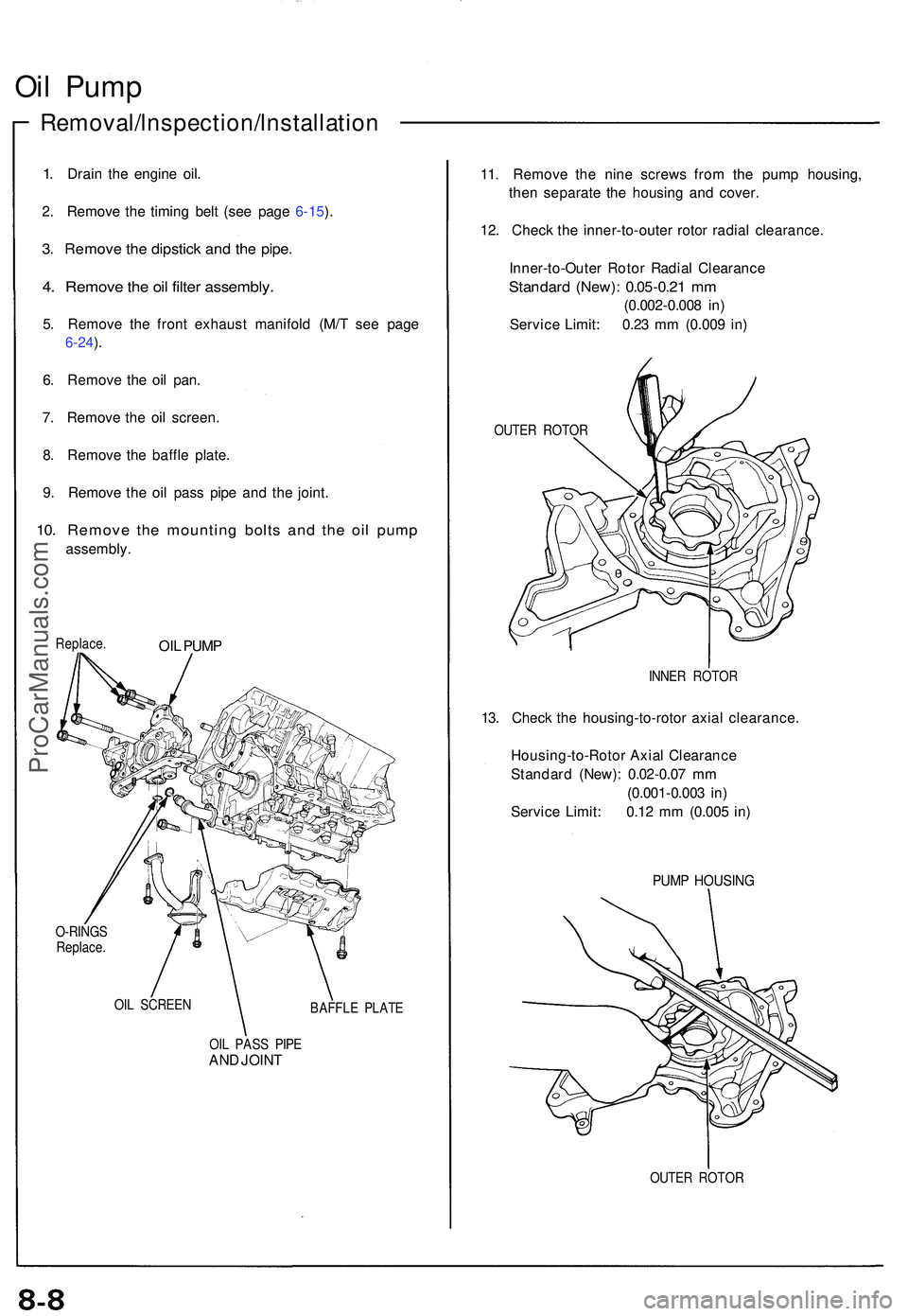

Oil Pum p

Removal/lnspection/lnstallatio n

1. Drai n th e engine oil.

2 . Remov e th e timin g bel t (se e pag e 6-15 ).

3 . Remov e th e dipstic k an d th e pipe .

4. Remov e th e oi l filte r assembly .

5. Remov e th e fron t exhaus t manifol d (M/ T se e pag e

6-24).

6 . Remov e th e oi l pan .

7 . Remov e th e oi l screen .

8 . Remov e th e baffl e plate .

9 . Remov e th e oi l pas s pip e an d th e joint .

10. Remov e th e mountin g bolt s an d th e oi l pum p

assembly . 11

. Remov e th e nin e screw s fro m th e pum p housing ,

the n separat e th e housin g an d cover .

12 . Chec k th e inner-to-oute r roto r radia l clearance .

Inner-to-Oute r Roto r Radia l Clearanc e

Standard (New) : 0.0 5-0.2 1 m m

(0.00 2-0.00 8 in )

Servic e Limit : 0.2 3 m m (0.00 9 in )

Replace .OIL PUM P

O-RING S

Replace .

OI L SCREE N

BAFFLE PLAT E

OI L PAS S PIP E

AND JOIN T

OUTE R ROTO R

13. Chec k th e housing-to-roto r axia l clearance .

Housing-to-Roto r Axia l Clearanc e

Standar d (New) : 0.0 2-0.0 7 m m

(0.00 1-0.00 3 in )

Servic e Limit : 0.1 2 m m (0.00 5 in )

OUTE R ROTO R

PUMP HOUSIN G

INNER ROTO R

ProCarManuals.com

Page 518 of 1503

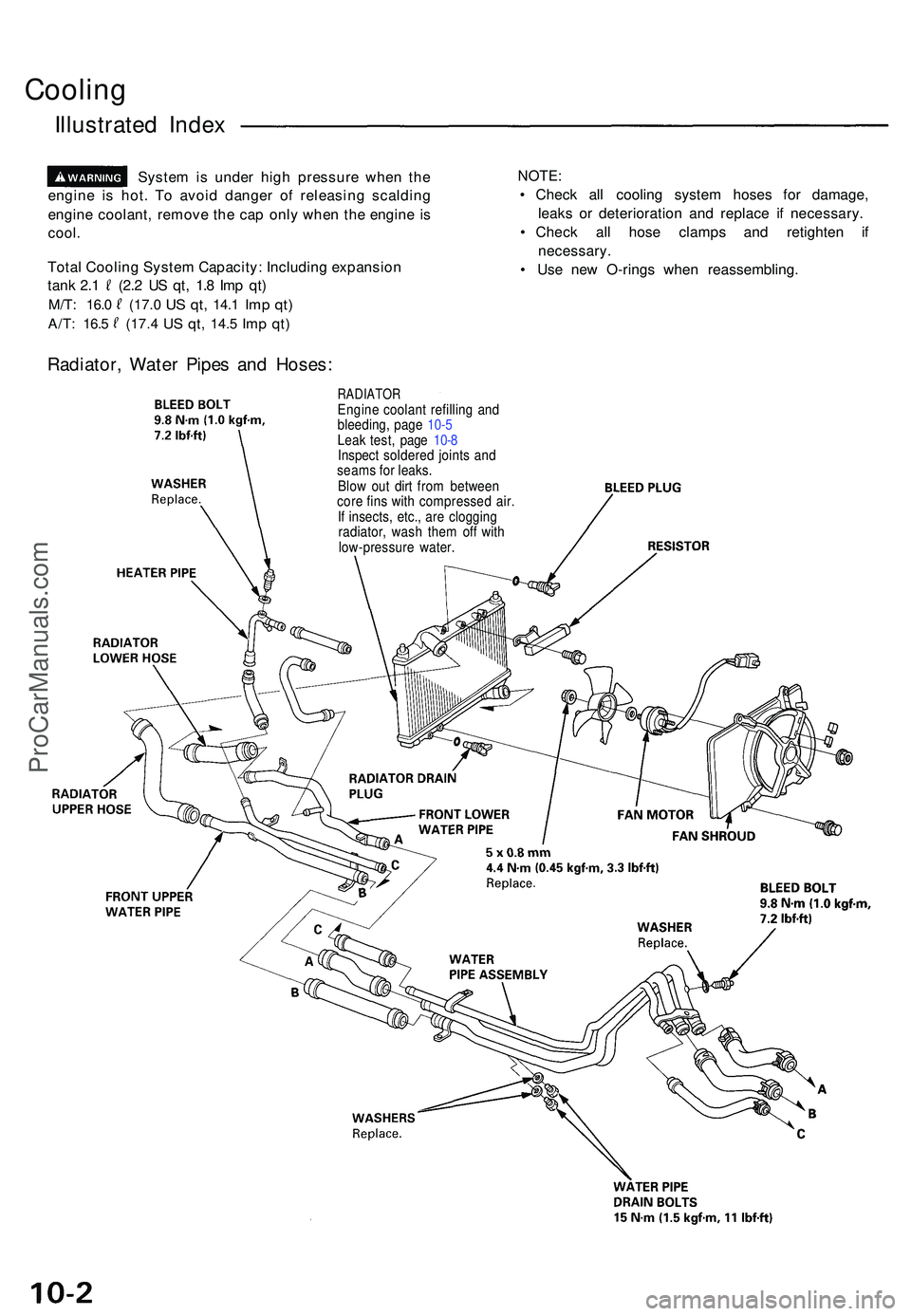

Cooling

Illustrate d Inde x

Syste m is unde r hig h pressur e whe n th e

engin e i s hot . T o avoi d dange r o f releasin g scaldin g

engin e coolant , remov e th e ca p onl y whe n th e engin e i s

cool .

Tota l Coolin g Syste m Capacity : Includin g expansio n

tank 2. 1 (2. 2 U S qt , 1. 8 Im p qt )

M/T : 16. 0 (17. 0 US qt , 14. 1 Imp qt )

A/T : 16. 5 (17. 4 US qt , 14. 5 Imp qt )

NOTE :

• Chec k al l coolin g syste m hose s fo r damage ,

leak s o r deterioratio n an d replac e i f necessary .

• Chec k al l hos e clamp s an d retighte n i f

necessary .

• Us e ne w O-ring s whe n reassembling .

RADIATOREngine coolan t refillin g an d

bleeding , pag e 10- 5

Leak test , pag e 10- 8

Inspec t soldere d joint s an d

seam s fo r leaks .

Blo w ou t dir t fro m betwee n

cor e fin s wit h compresse d air .

I f insects , etc. , ar e cloggin g

radiator , was h the m of f wit h

low-pressur e water .

Radiator , Wate r Pipe s an d Hoses :

ProCarManuals.com

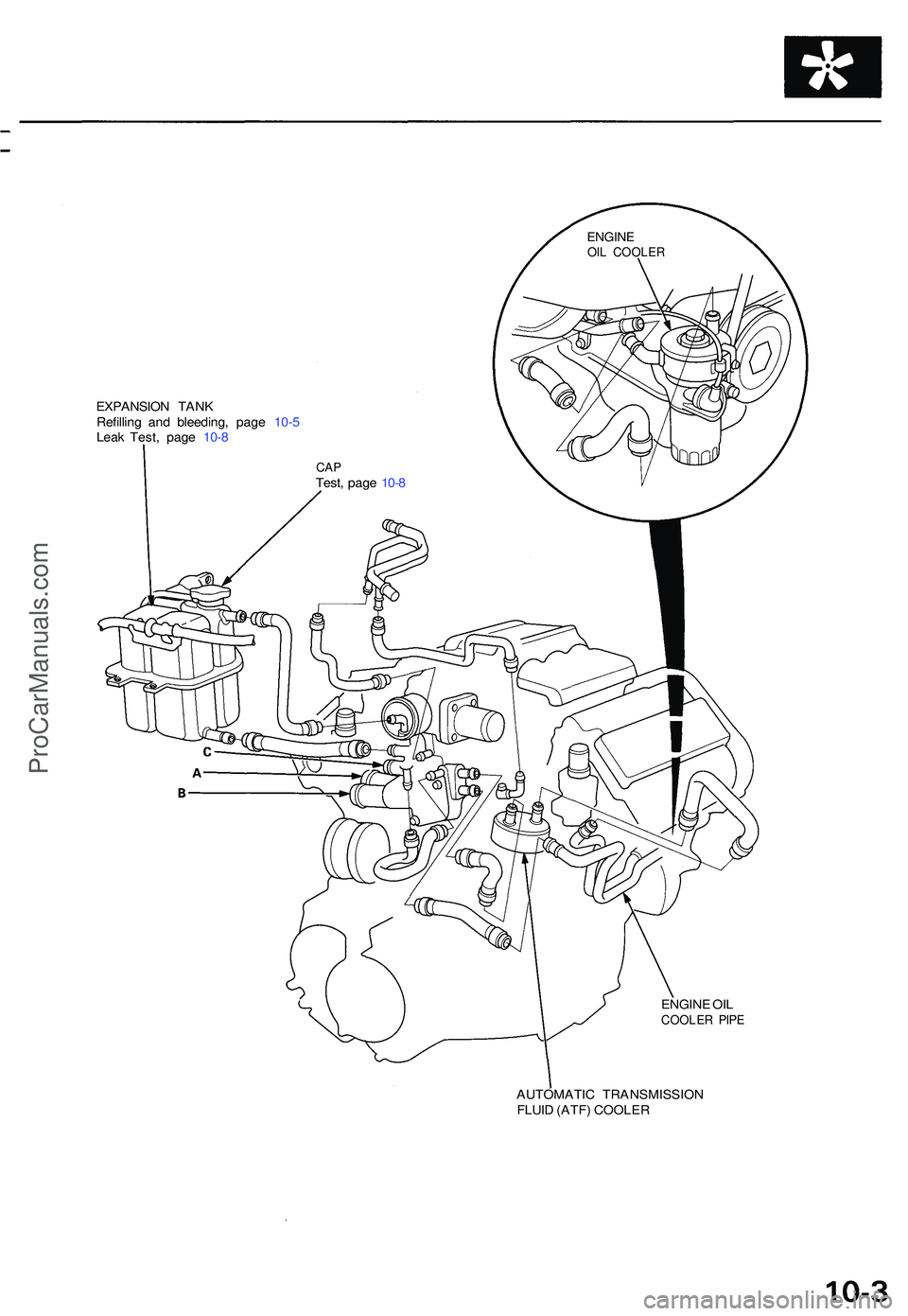

Page 519 of 1503

EXPANSION TAN K

Refillin g an d bleeding , pag e 10- 5

Lea k Test , pag e 10- 8

ENGINE OI L

COOLE R PIP E

AUTOMATI C TRANSMISSIO N

FLUI D (ATF ) COOLE R

CAPTest , pag e 10- 8

ENGIN EOIL COOLE R

ProCarManuals.com

Page 521 of 1503

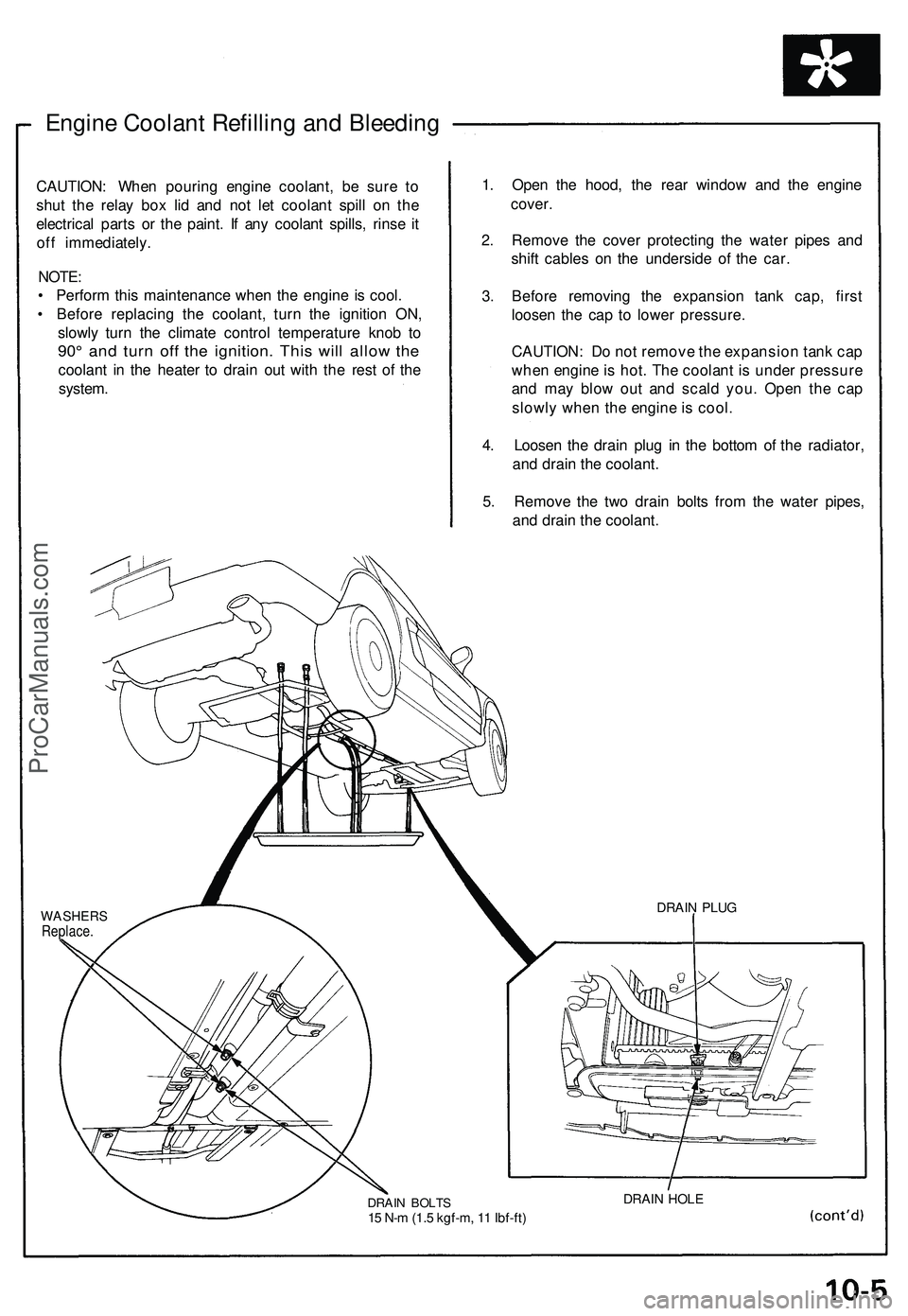

Engine Coolant Refilling and Bleeding

CAUTION: When pouring engine coolant, be sure to

shut the relay box lid and not let coolant spill on the

electrical parts or the paint. If any coolant spills, rinse it

off immediately.

NOTE:

• Perform this maintenance when the engine is cool.

• Before replacing the coolant, turn the ignition ON,

slowly turn the climate control temperature knob to

90° and turn off the ignition. This will allow the

coolant in the heater to drain out with the rest of the

system.

1. Open the hood, the rear window and the engine

cover.

2. Remove the cover protecting the water pipes and

shift cables on the underside of the car.

3. Before removing the expansion tank cap, first

loosen the cap to lower pressure.

CAUTION: Do not remove the expansion tank cap

when engine is hot. The coolant is under pressure

and may blow out and scald you. Open the cap

slowly when the engine is cool.

4. Loosen the drain plug in the bottom of the radiator,

and drain the coolant.

5. Remove the two drain bolts from the water pipes,

and drain the coolant.

WASHERS

Replace.

DRAIN BOLTS

15 N-m (1.5 kgf-m, 11 Ibf-ft)

DRAIN HOLE

DRAIN PLUGProCarManuals.com

Page 522 of 1503

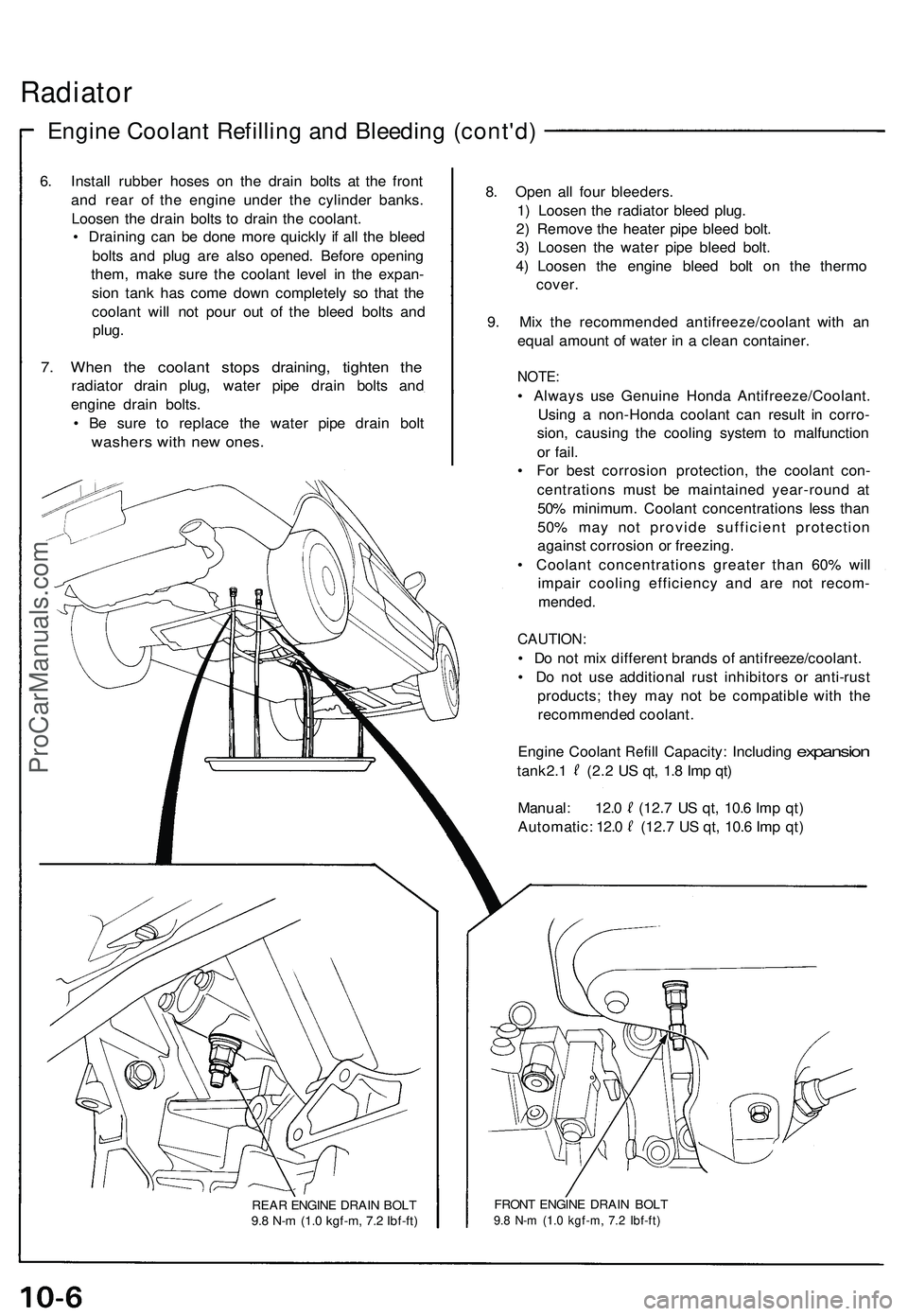

Radiator

Engine Coolan t Refillin g an d Bleedin g (cont'd)

6. Instal l rubbe r hose s o n th e drai n bolt s a t th e fron t

an d rea r o f th e engin e unde r th e cylinde r banks .

Loose n th e drai n bolt s t o drai n th e coolant .

• Drainin g ca n b e don e mor e quickl y i f al l th e blee d

bolt s an d plu g ar e als o opened . Befor e openin g

them , mak e sur e th e coolan t leve l i n th e expan -

sio n tan k ha s com e dow n completel y s o tha t th e

coolan t wil l no t pou r ou t o f th e blee d bolt s an d

plug .

7. Whe n th e coolan t stop s draining , tighte n th e

radiato r drai n plug , wate r pip e drai n bolt s an d

engin e drai n bolts .

• B e sur e t o replac e th e wate r pip e drai n bol t

washer s wit h ne w ones .

REAR ENGIN E DRAI N BOL T

9. 8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

8. Ope n al l fou r bleeders .

1 ) Loose n th e radiato r blee d plug .

2 ) Remov e th e heate r pip e blee d bolt .

3 ) Loose n th e wate r pip e blee d bolt .

4 ) Loose n th e engin e blee d bol t o n th e therm o

cover .

9 . Mi x th e recommende d antifreeze/coolan t wit h a n

equa l amoun t o f wate r i n a clea n container .

NOTE:

• Alway s us e Genuin e Hond a Antifreeze/Coolant .

Usin g a non-Hond a coolan t ca n resul t i n corro -

sion , causin g th e coolin g syste m to malfunctio n

o r fail .

• Fo r bes t corrosio n protection , th e coolan t con -

centration s mus t b e maintaine d year-roun d a t

50 % minimum . Coolan t concentration s les s tha n

50 % ma y no t provid e sufficien t protectio n

agains t corrosio n o r freezing .

• Coolan t concentration s greate r tha n 60 % wil l

impai r coolin g efficienc y an d ar e no t recom -

mended .

CAUTION :

• D o no t mi x differen t brand s o f antifreeze/coolant .

• D o no t us e additiona l rus t inhibitor s o r anti-rus t

products ; the y ma y no t b e compatibl e wit h th e

recommende d coolant .

Engin e Coolan t

Refill Capacity : Includin g expansion

tank 2. 1 (2. 2 U S qt , 1. 8 Im p qt )

Manual : 12. 0 (12. 7 U S qt , 10. 6 Im p qt )

Automatic : 12. 0 (12. 7 U S qt , 10. 6 Im p qt )

FRON T ENGIN E DRAI N BOL T9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

ProCarManuals.com