engine ACURA NSX 1997 Service Manual Online

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 474 of 1503

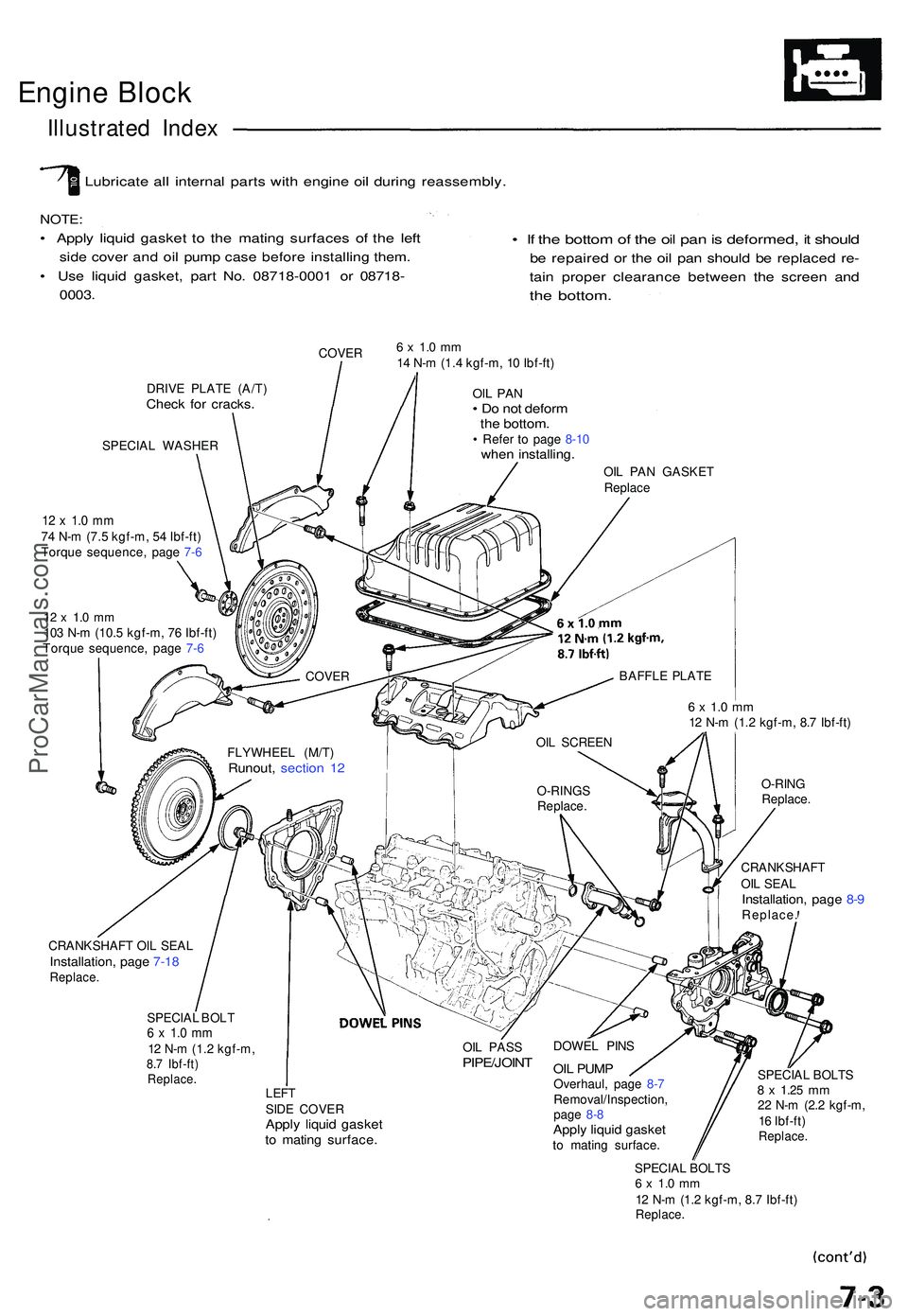

Engine Bloc k

Illustrate d Inde x

Lubricat e al l interna l part s wit h engin e oi l durin g reassembly .

NOTE:

• Appl y liqui d gaske t t o th e matin g surface s o f th e lef t

side cove r an d oi l pum p cas e befor e installin g them .

• Us e liqui d gasket , par t No . 0871 8-000 1 o r 0871 8-

0003 .

• I f th e botto m of th e oi l pa n is deformed , i t shoul d

be repaire d o r th e oi l pa n shoul d b e replace d re -

tain prope r clearanc e betwee n th e scree n an d

the bottom .

COVER

DRIV E PLAT E (A/T )

Check fo r cracks .

SPECIA L WASHER

12 x 1. 0 m m74 N- m (7. 5 kgf-m , 5 4 Ibf-ft )

Torqu e sequence , pag e 7- 6

12 x 1. 0 m m103 N- m (10. 5 kgf-m , 7 6 Ibf-ft )

Torqu e sequence , pag e 7- 6

6 x 1. 0 m m14 N- m (1. 4 kgf-m , 1 0 Ibf-ft )

OIL PA N• D o no t defor mthe bottom .• Refe r t o pag e 8-1 0whe n installing .

OIL PA N GASKE T

Replac e

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

O-RIN G

Replace .

CRANKSHAF T

OI L SEA L

Installation , pag e 8- 9Replace .

CRANKSHAF T OI L SEA L

Installation , pag e 7-1 8Replace .

SPECIAL BOL T6 x 1. 0 m m12 N- m (1. 2 kgf-m ,8.7 Ibf-ft )Replace .

OIL PAS SPIPE/JOIN T

LEFTSIDE COVE RApply liqui d gaske tto matin g surface .

DOWEL PIN S

OIL PUM POverhaul , pag e 8- 7

Removal/Inspection ,

pag e 8- 8

Appl y liqui d gaske tto matin g surface . SPECIA

L BOLT S

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

Replace .

SPECIAL BOLT S6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )Replace .

FLYWHEE L (M/T )Runout , sectio n 1 2

COVE R

OIL SCREE N

O-RING S

Replace .BAFFL

E PLAT E

ProCarManuals.com

Page 475 of 1503

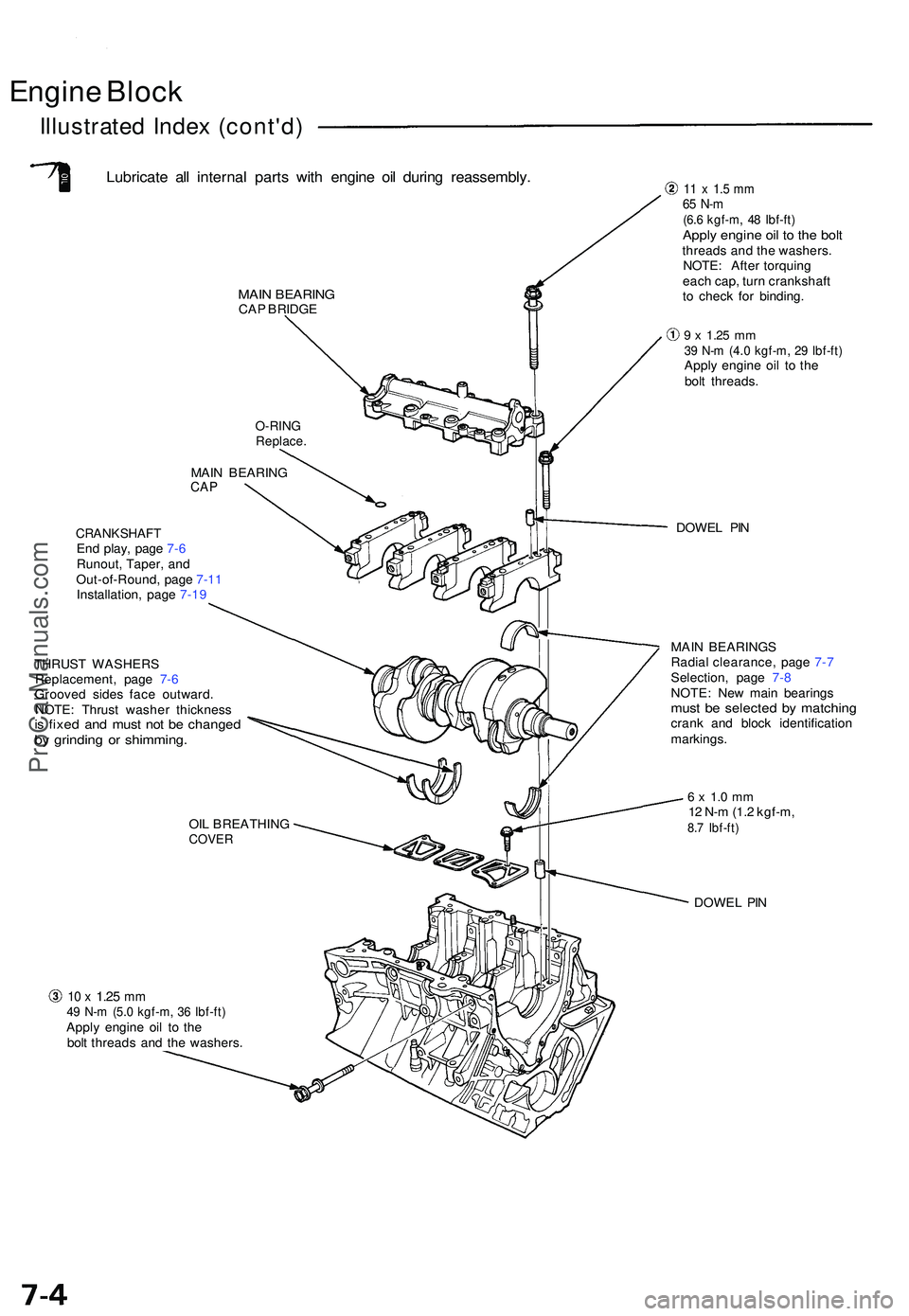

Engine Bloc k

Illustrate d Inde x (cont'd )

Lubricate al l interna l part s wit h engin e oi l durin g reassembly .

MAIN BEARIN GCAP BRIDG E

MAI N BEARIN G

CAP

CRANKSHAF TEnd play , pag e 7- 6

Runout , Taper , an d

Out-of-Round , pag e 7-1 1

Installation , pag e 7-1 9

THRUS T WASHER S

Replacement , pag e 7- 6

Groove d side s fac e outward .

NOTE : Thrus t washe r thicknes s

is fixe d an d mus t no t b e change dby grindin g o r shimming .

10 x 1.2 5 mm49 N- m (5. 0 kgf-m , 3 6 Ibf-ft )Apply engin e oi l t o th e

bol t thread s an d th e washers .

11 x 1. 5 m m65 N- m(6.6 kgf-m , 4 8 Ibf-ft )Apply engin e oi l t o th e bol tthread s an d th e washers .

NOTE : Afte r torquin g

eac h cap , tur n crankshaf t

t o chec k fo r binding .

9 x 1.2 5 mm39 N- m (4. 0 kgf-m , 2 9 Ibf-ft )Apply engin e oi l t o th e

bol t threads .

DOWE L PI N

MAI N BEARING S

Radia l clearance , pag e 7- 7

Selection , pag e 7- 8

NOTE : Ne w mai n bearing s

must b e selecte d b y matchin gcrank an d bloc k identificatio n

markings .

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,8.7 Ibf-ft )

DOWE L PI N

OI

L BREATHIN G

COVER

O-RIN GReplace .

ProCarManuals.com

Page 477 of 1503

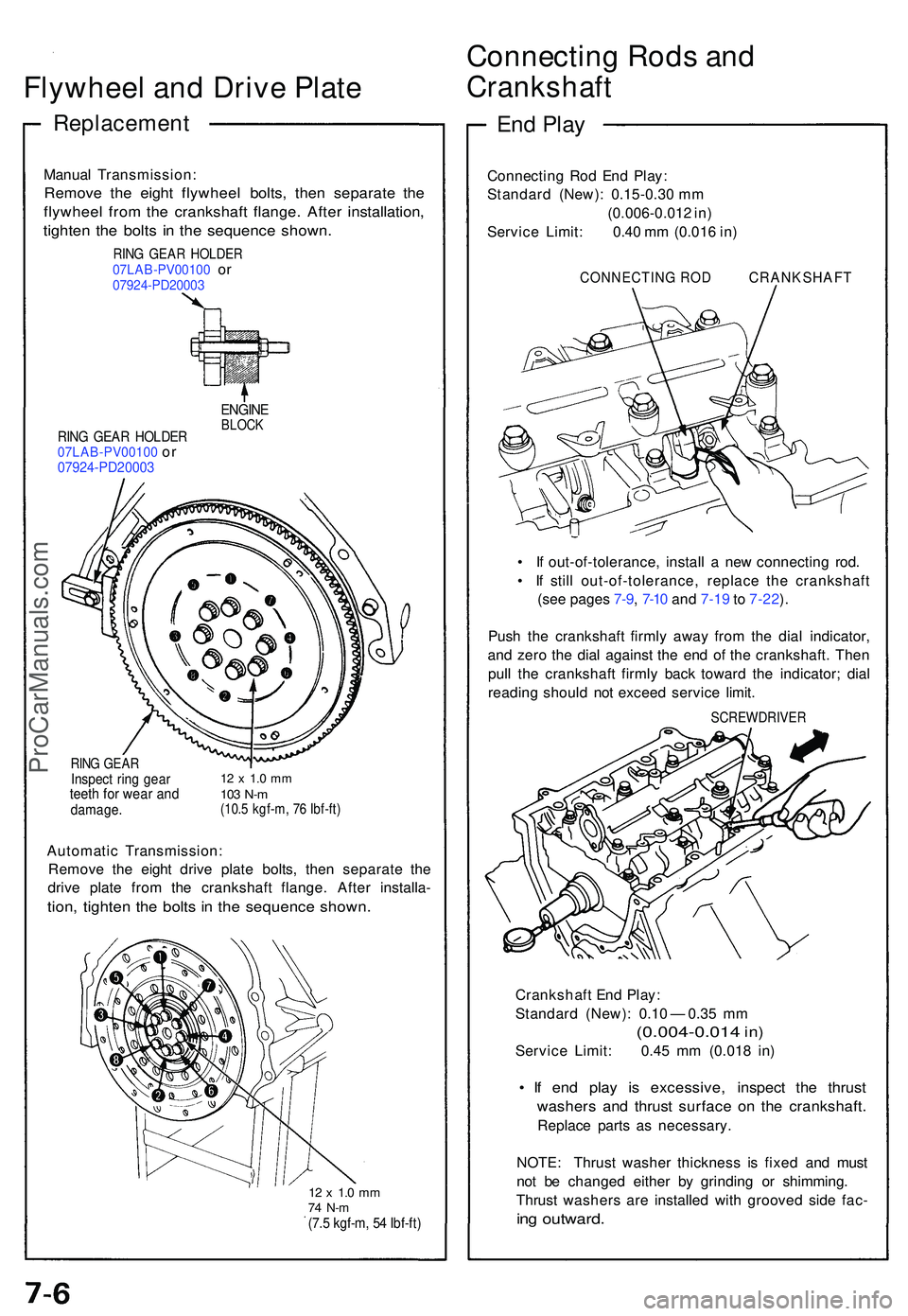

Flywheel an d Driv e Plat e

Replacemen t

Connecting Rod s an d

Crankshaf t

Manual Transmission :

Remove th e eigh t flywhee l bolts , the n separat e th e

flywhee l fro m th e crankshaf t flange . Afte r installation ,

tighten th e bolt s i n th e sequenc e shown .

RING GEA R HOLDE R07LAB-PV0010 0 or07924-PD2000 3

RING GEA R HOLDE R07LAB-PV00100 or07924-PD2000 3

ENGINEBLOCK

RING GEA RInspec t rin g gea rteeth fo r wea r an ddamage .

12 x 1. 0 m m103 N- m(10. 5 kgf-m , 7 6 Ibf-ft )

Automati c Transmission :

Remov e th e eigh t driv e plat e bolts , the n separat e th e

driv e plat e fro m th e crankshaf t flange . Afte r installa -

tion, tighte n th e bolt s i n th e sequenc e shown .

12 x 1. 0 m m74 N- m(7.5 kgf-m , 5 4 Ibf-ft )

End Pla y

Connectin g Ro d En d Play :

Standard (New): 0.15-0.30 mm

(0.006-0.01 2 in )

Servic e Limit : 0.40 m m (0.01 6 in )

CONNECTIN G RO D CRANKSHAF T

• I f out-of-tolerance , instal l a ne w connectin g rod .

• I f stil l out-of-tolerance , replac e th e crankshaf t

(se e page s 7-9 , 7-1 0 an d 7-1 9 to 7-22 ).

Pus h th e crankshaf t firml y awa y fro m th e dia l indicator ,

an d zer o th e dia l agains t th e en d o f th e crankshaft . The n

pul l th e crankshaf t firml y bac k towar d th e indicator ; dia l

readin g shoul d no t excee d servic e limit .

SCREWDRIVE R

Crankshaft En d Play :

Standar d (New) : 0.1 0 — 0.3 5 m m

(0.004-0.01 4 in)

Servic e Limit : 0.4 5 m m (0.01 8 in )

• I f en d pla y i s excessive , inspec t th e thrus t

washer s an d thrus t surfac e o n th e crankshaft .

Replace part s a s necessary .

NOTE : Thrus t washe r thicknes s i s fixe d an d mus t

no t b e change d eithe r b y grindin g o r shimming .

Thrus t washer s ar e installe d wit h groove d sid e fac -

ing outward .

ProCarManuals.com

Page 481 of 1503

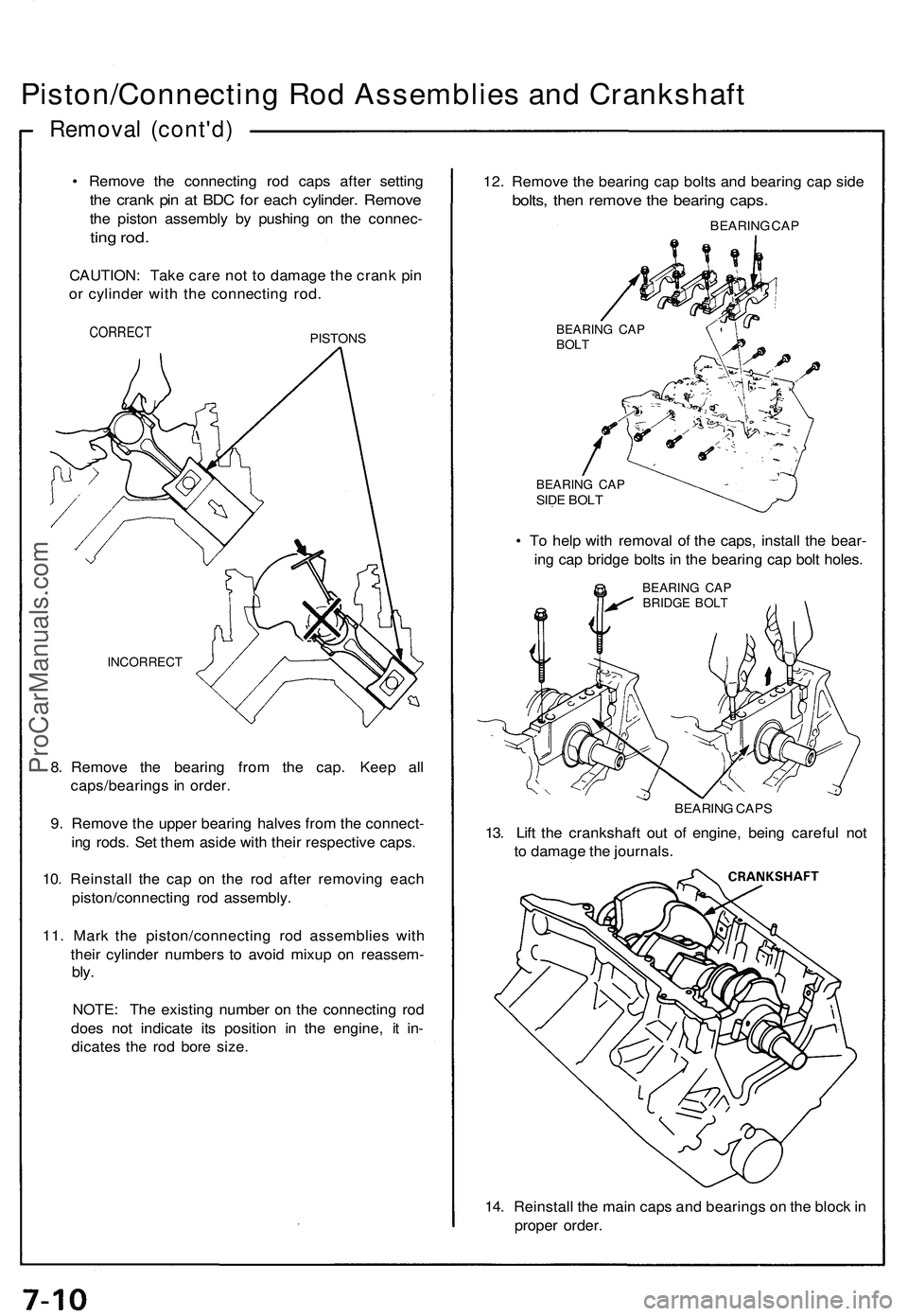

Piston/Connecting Ro d Assemblie s an d Crankshaf t

Removal (cont'd )

• Remov e th e connectin g ro d cap s afte r settin g

the cran k pi n a t BD C fo r eac h cylinder . Remov e

the pisto n assembl y b y pushin g o n th e connec -

ting rod .

CAUTION : Tak e car e no t t o damag e th e cran k pi n

o r cylinde r wit h th e connectin g rod .

CORREC TPISTONS

INCORREC T

8. Remov e th e bearin g fro m th e cap . Kee p al l

caps/bearing s i n order .

9 . Remov e th e uppe r bearin g halve s fro m th e connect -

in g rods . Se t the m asid e wit h thei r respectiv e caps .

10 . Reinstal l th e ca p o n th e ro d afte r removin g eac h

piston/connectin g ro d assembly .

11 . Mar k th e piston/connectin g ro d assemblie s wit h

thei r cylinde r number s t o avoi d mixu p o n reassem -

bly.

NOTE : Th e existin g numbe r o n th e connectin g ro d

doe s no t indicat e it s positio n i n th e engine , i t in -

dicate s th e ro d bor e size . 12

. Remov e th e bearin g ca p bolt s an d bearin g ca p sid e

bolts , the n remov e th e bearin g caps .

BEARIN G CA P

BEARIN G CA PBOL T

BEARIN G CA PSIDE BOL T

• T o hel p wit h remova l o f th e caps , instal l th e bear -

in g ca p bridg e bolt s i n th e bearin g ca p bol t holes .

BEARIN G CA PBRIDG E BOL T

BEARIN G CAP S

13. Lif t th e crankshaf t ou t o f engine , bein g carefu l no t

t o damag e th e journals .

14 . Reinstal l th e mai n cap s an d bearing s o n th e bloc k in

prope r order .

ProCarManuals.com

Page 483 of 1503

Cylinder Bloc k

Inspectio n

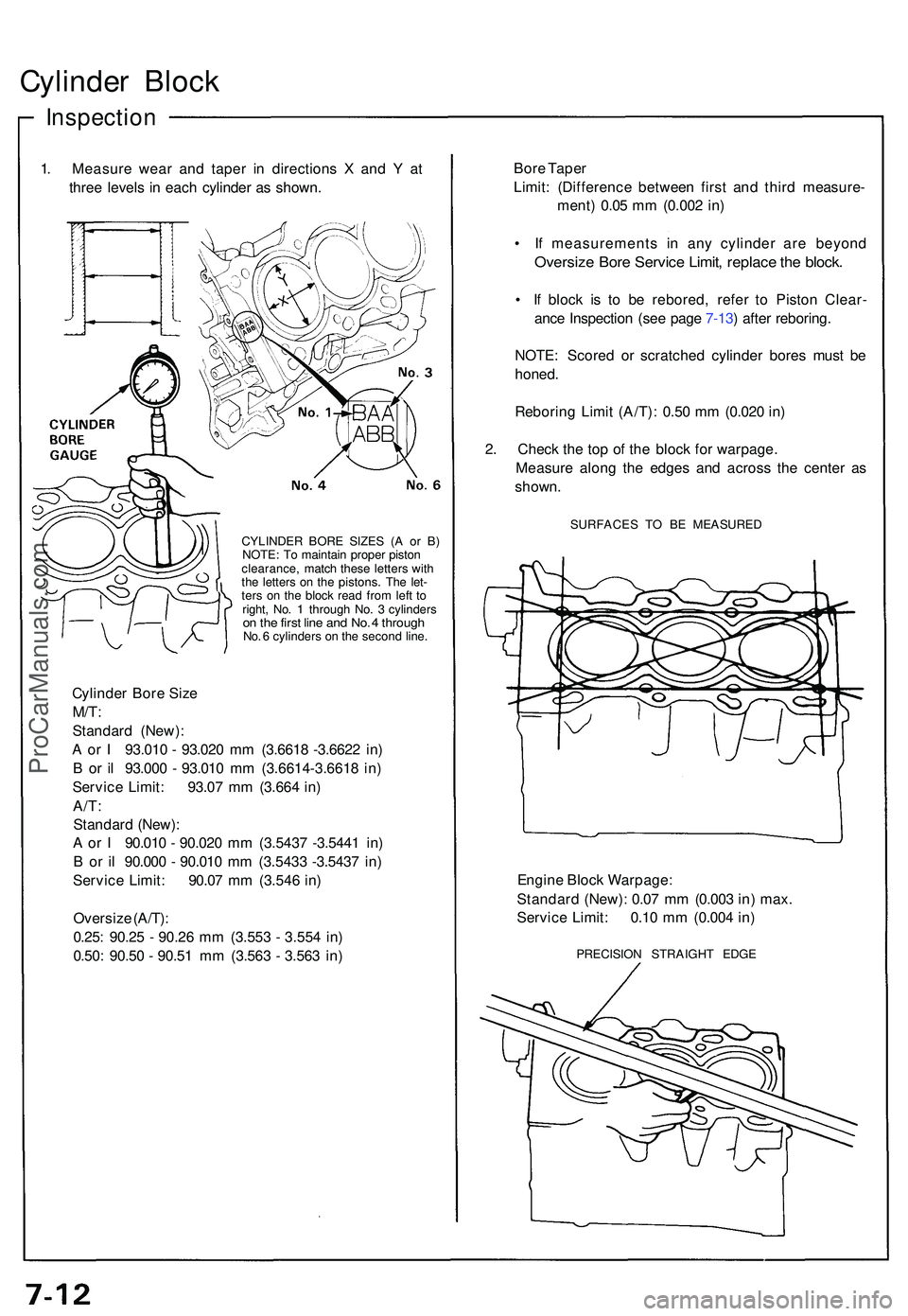

1. Measur e wea r an d tape r i n direction s X an d Y at

thre e level s i n eac h cylinde r a s shown .

CYLINDE R BOR E SIZE S ( A o r B )

NOTE : T o maintai n prope r pisto n

clearance , matc h thes e letter s wit h

th e letter s o n th e pistons . Th e let -

ter s o n th e bloc k rea d fro m lef t t o

right , No . 1 throug h No . 3 cylinder s

on th e firs t lin e an d No . 4 throug hNo. 6 cylinder s o n th e secon d line .

Cylinde r Bor e Siz e

M/T:

Standar d (New) :

A o r I 93.01 0 - 93.02 0 m m (3.661 8 -3.662 2 in )

B o r i l 93.00 0 - 93.01 0 m m (3.6614-3.661 8 in )

Servic e Limit : 93.0 7 m m (3.66 4 in )

A/T :

Standard (New):

A o r I 90.01 0 - 90.02 0 m m (3.543 7 -3.544 1 in )

B o r i l 90.00 0 - 90.01 0 m m (3.543 3 -3.543 7 in )

Servic e Limit : 90.0 7 m m (3.54 6 in )

Oversize (A/T):

0.25: 90.2 5 - 90.2 6 m m (3.55 3 - 3.55 4 in )

0.50 : 90.5 0 - 90.5 1 m m (3.56 3 - 3.56 3 in ) Bor

e Tape r

Limit : (Differenc e betwee n firs t an d thir d measure -

ment ) 0.0 5 m m (0.00 2 in )

• I f measurement s i n an y cylinde r ar e beyon d

Oversize Bor e Servic e Limit , replac e th e block .

• I f bloc k i s t o b e rebored , refe r t o Pisto n Clear -

anc e Inspectio n (se e pag e 7-13 ) afte r reboring .

NOTE : Score d o r scratche d cylinde r bore s mus t b e

honed .

Reborin g Limi t (A/T) : 0.5 0 m m (0.02 0 in )

2 . Chec k th e to p o f th e bloc k fo r warpage .

Measur e alon g th e edge s an d acros s th e cente r a s

shown .

SURFACE S T O B E MEASURE D

Engine Bloc k Warpage :

Standar d (New) : 0.0 7 m m (0.00 3 in ) max .

Servic e Limit : 0.1 0 m m (0.00 4 in )

PRECISIO N STRAIGH T EDG E

ProCarManuals.com

Page 487 of 1503

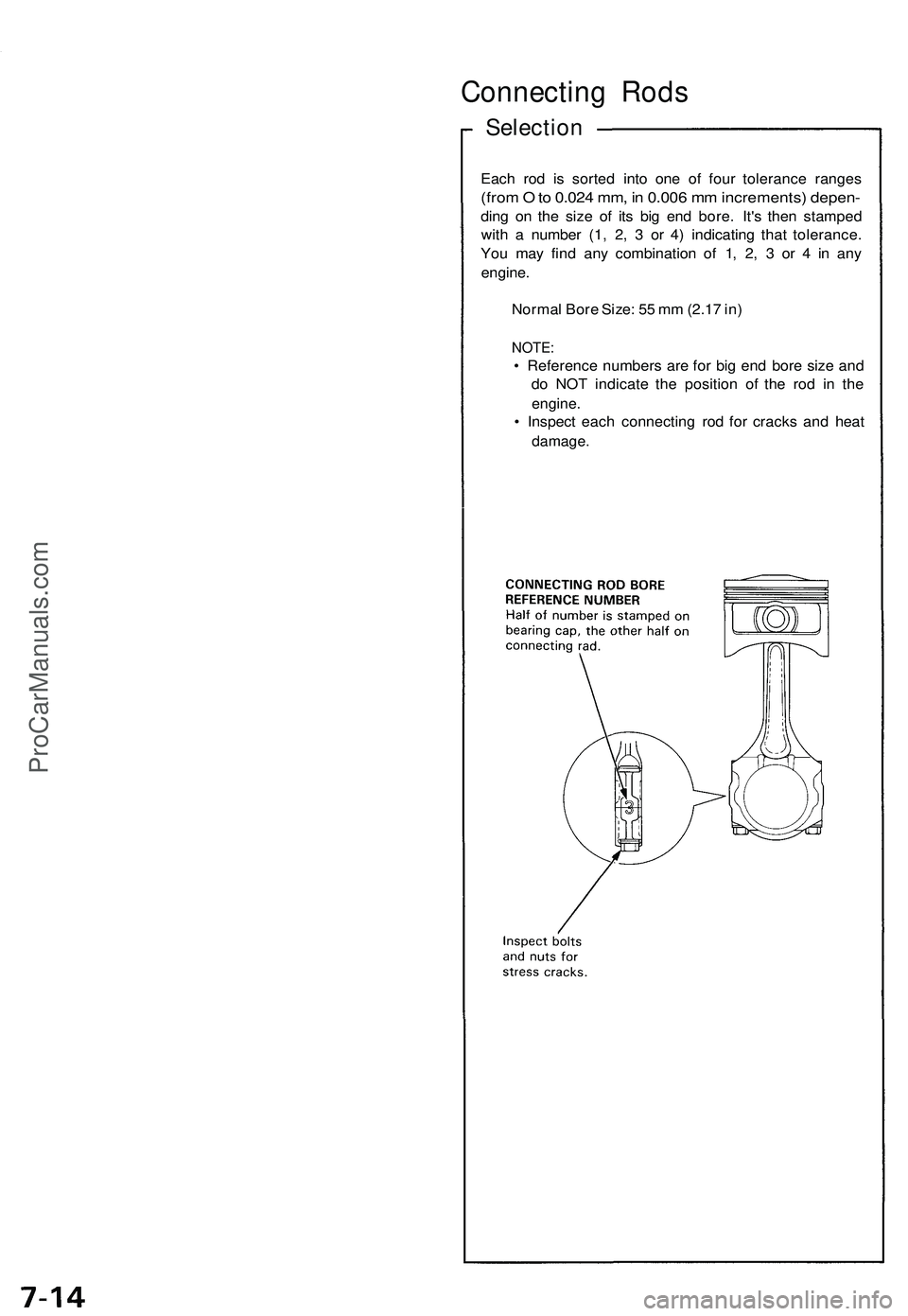

Connecting Rods

Selection

Each rod is sorted into one of four tolerance ranges

(from O to 0.024 mm, in 0.006 mm increments) depen-

ding on the size of its big end bore. It's then stamped

with a number (1, 2, 3 or 4) indicating that tolerance.

You may find any combination of 1, 2, 3 or 4 in any

engine.

Normal Bore Size: 55 mm (2.17 in)

NOTE:

• Reference numbers are for big end bore size and

do NOT indicate the position of the rod in the

engine.

• Inspect each connecting rod for cracks and heat

damage.ProCarManuals.com

Page 488 of 1503

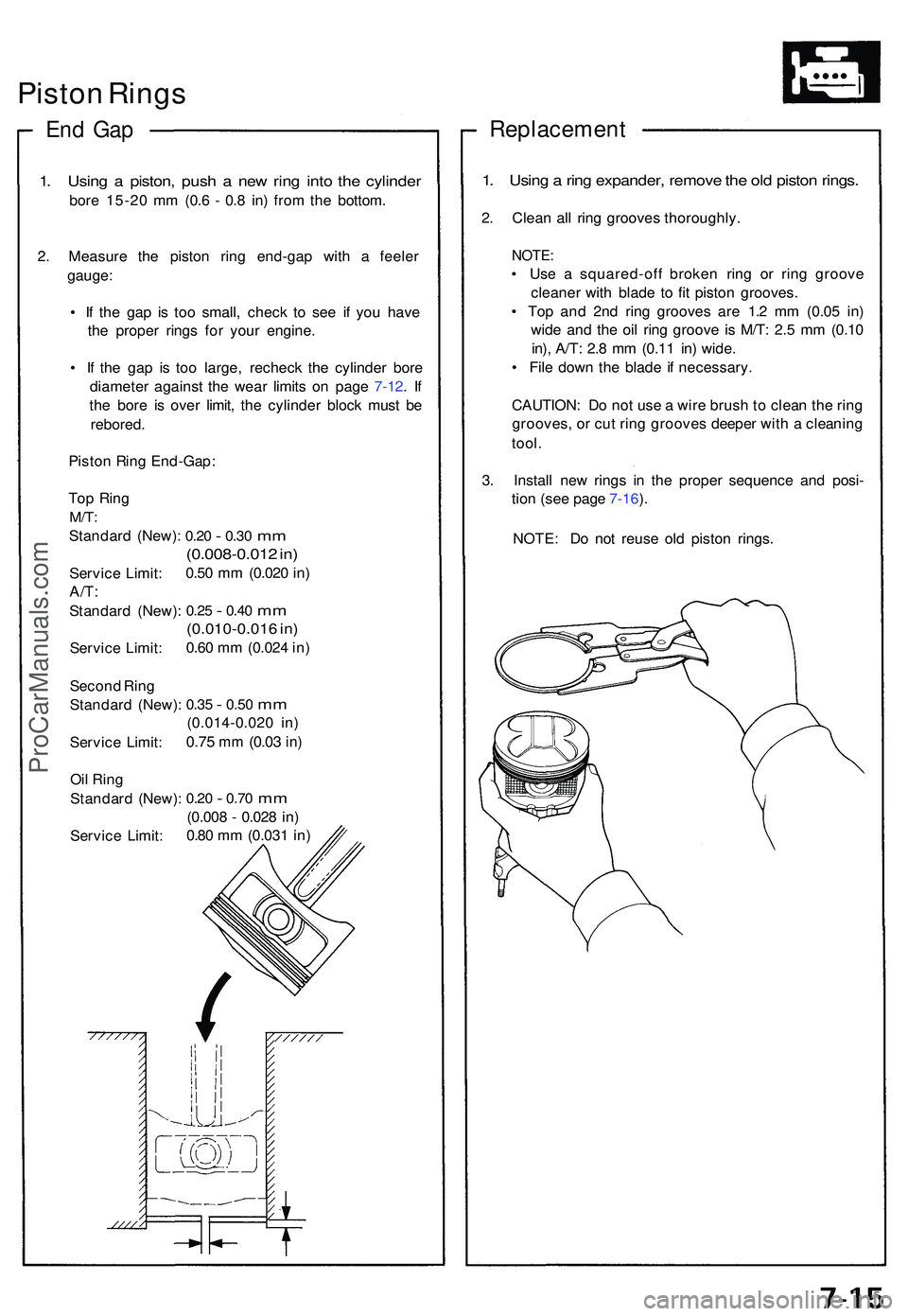

Piston Ring s

End Ga p

1. Usin g a piston , pus h a ne w rin g int o th e cylinde r

bore 15-2 0 m m (0. 6 - 0. 8 in ) fro m th e bottom .

2 . Measur e th e pisto n rin g end-ga p wit h a feele r

gauge :

• I f th e ga p i s to o small , chec k t o se e i f yo u hav e

th e prope r ring s fo r you r engine .

• I f th e ga p i s to o large , rechec k th e cylinde r bor e

diamete r agains t th e wea r limit s o n pag e 7-12 . I f

th e bor e i s ove r limit , th e cylinde r bloc k mus t b e

rebored .

Pisto n Rin g End-Gap :

To p Rin g

M/T:

Standar d (New) :

Servic e Limit :

A/T:

Standar d (New) :

Servic e Limit :

Secon d Rin g

Standar d (New) :

Servic e Limit :

Oi l Rin g

Standar d (New) :

Servic e Limit :

0.20 - 0.3 0 mm

(0.008-0.01 2 in )

0.5 0 m m (0.02 0 in )

0.2 5 - 0.4 0 mm

(0.010-0.01 6 in )

0.6 0 m m (0.02 4 in )

0.3 5 - 0.5 0 mm

(0.014-0.02 0 in )

0.75 mm (0.0 3 in)

0.2 0 - 0.7 0 mm

(0.00 8 - 0.02 8 in )

0.8 0 m m (0.03 1 in )

Replacemen t

1. Usin g a rin g expander , remov e th e ol d pisto n rings .

2. Clea n al l rin g groove s thoroughly .

NOTE:

• Us e a squared-of f broke n rin g o r rin g groov e

cleane r wit h blad e t o fi t pisto n grooves .

• To p an d 2n d rin g groove s ar e 1. 2 m m (0.0 5 in )

wid e an d th e oi l rin g groov e i s M/T : 2. 5 m m (0.1 0

in) , A/T : 2. 8 m m (0.1 1 in ) wide .

• Fil e dow n th e blad e i f necessary .

CAUTION : D o no t us e a wir e brus h to clea n th e rin g

grooves , o r cu t rin g groove s deepe r wit h a cleanin g

tool .

3 . Instal l ne w ring s i n th e prope r sequenc e an d posi -

tio n (se e pag e 7-16 ).

NOTE : D o no t reus e ol d pisto n rings .

ProCarManuals.com

Page 495 of 1503

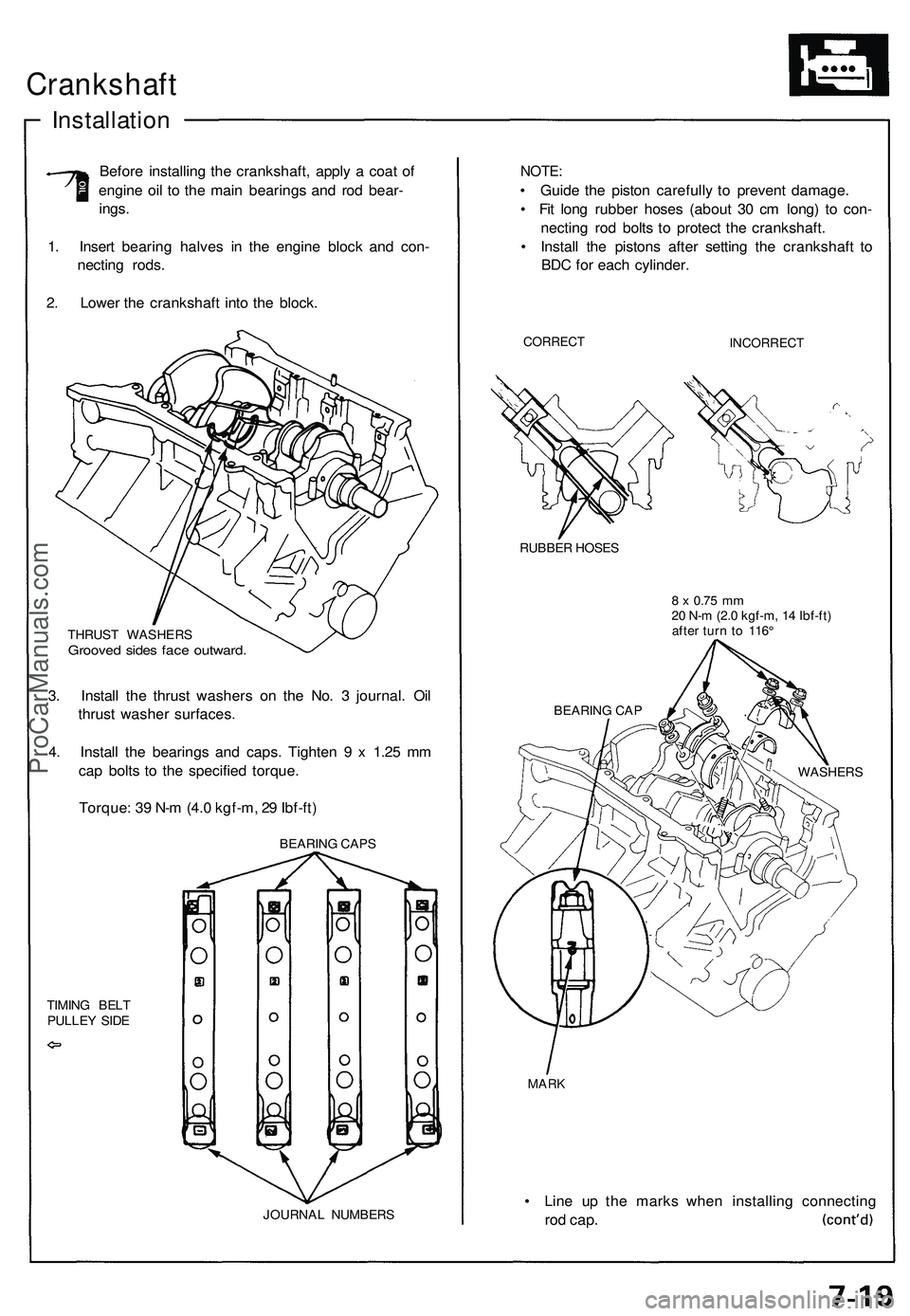

Crankshaft

Installation

Before installing the crankshaft, apply a coat of

engine oil to the main bearings and rod bear-

ings.

1. Insert bearing halves in the engine block and con-

necting rods.

2. Lower the crankshaft into the block.

THRUST WASHERS

Grooved sides face outward.

3. Install the thrust washers on the No. 3 journal. Oil

thrust washer surfaces.

4. Install the bearings and caps. Tighten 9 x 1.25 mm

cap bolts to the specified torque.

Torque: 39 N-m (4.0 kgf-m, 29 Ibf-ft)

TIMING BELT

PULLEY SIDE

JOURNAL NUMBERS

NOTE:

• Guide the piston carefully to prevent damage.

• Fit long rubber hoses (about 30 cm long) to con-

necting rod bolts to protect the crankshaft.

• Install the pistons after setting the crankshaft to

BDC for each cylinder.

CORRECT

INCORRECT

RUBBER HOSES

8 x

0.75

mm

20 N-m (2.0 kgf-m, 14 Ibf-ft)

after turn to 116°

MARK

• Line up the marks when installing connecting

rod

cap.

BEARING CAP

WASHERS

BEARING CAPSProCarManuals.com

Page 496 of 1503

Crankshaft

Installation (cont'd )

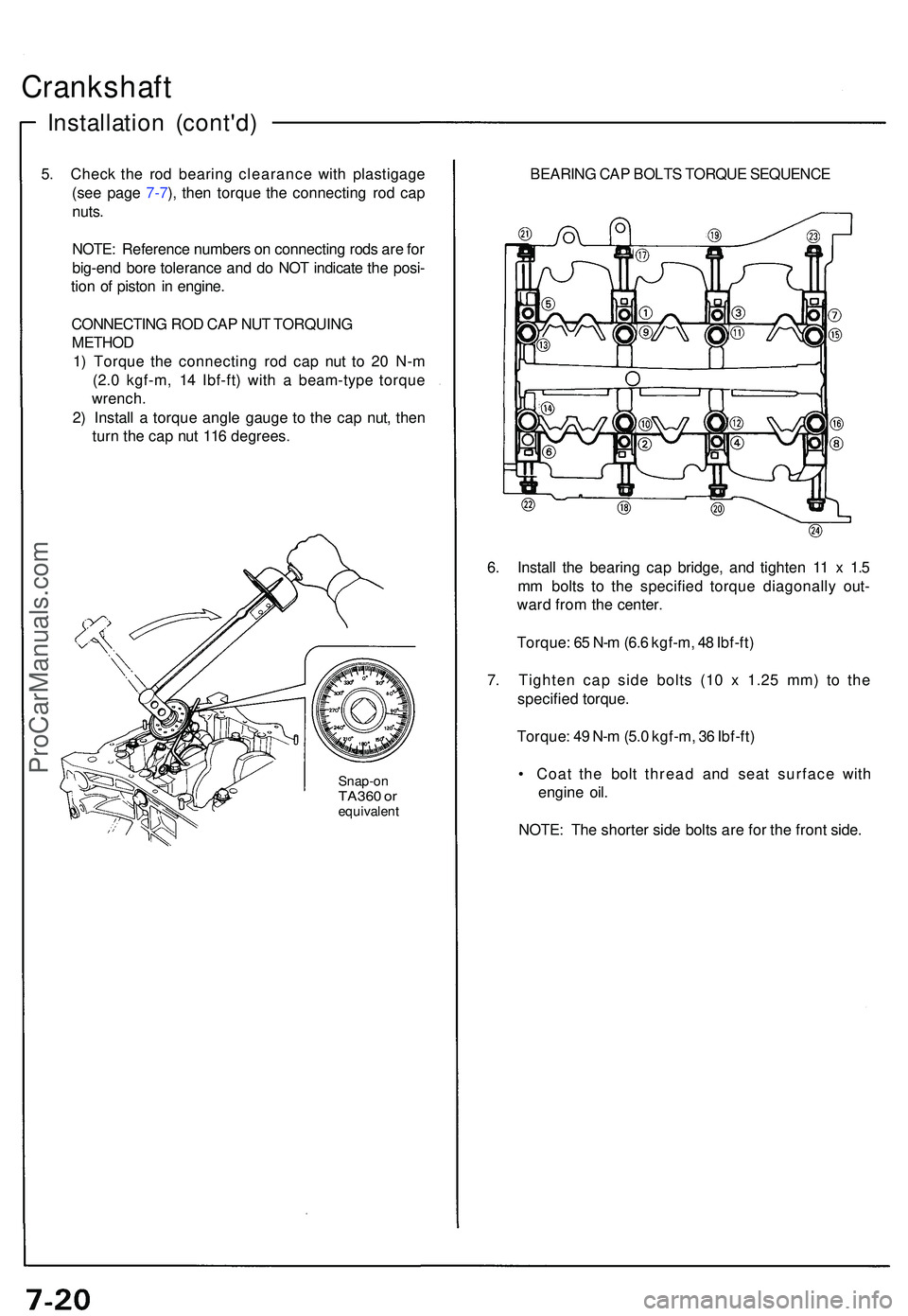

5. Chec k th e ro d bearin g clearanc e wit h plastigag e

(se e pag e 7-7 ), the n torqu e th e connectin g ro d ca p

nuts .

NOTE : Referenc e number s o n connectin g rod s ar e fo r

big-en d bor e toleranc e an d d o NO T indicat e th e posi -

tio n o f pisto n i n engine .

CONNECTIN G RO D CA P NU T TORQUIN G

METHO D

1 ) Torqu e th e connectin g ro d ca p nu t t o 2 0 N- m

(2. 0 kgf-m , 1 4 Ibf-ft ) wit h a beam-typ e torqu e

wrench .

2 ) Instal l a torqu e angl e gaug e t o th e ca p nut , the n

tur n th e ca p nu t 11 6 degrees .

Snap-onTA360 o requivalen t

BEARING CAP BOLTS TORQUE SEQUENCE

6 . Instal l th e bearin g ca p bridge , an d tighte n 1 1 x 1. 5

m m bolt s t o th e specifie d torqu e diagonall y out -

war d fro m th e center .

Torque : 6 5 N- m (6. 6 kgf-m , 4 8 Ibf-ft )

7 . Tighte n ca p sid e bolt s (1 0 x 1.2 5 mm ) t o th e

specifie d torque .

Torque : 4 9 N- m (5. 0 kgf-m , 3 6 Ibf-ft )

• Coa t th e bol t threa d an d sea t surfac e wit h

engin e oil .

NOTE : Th e shorte r sid e bolt s ar e fo r th e fron t side .

ProCarManuals.com

Page 497 of 1503

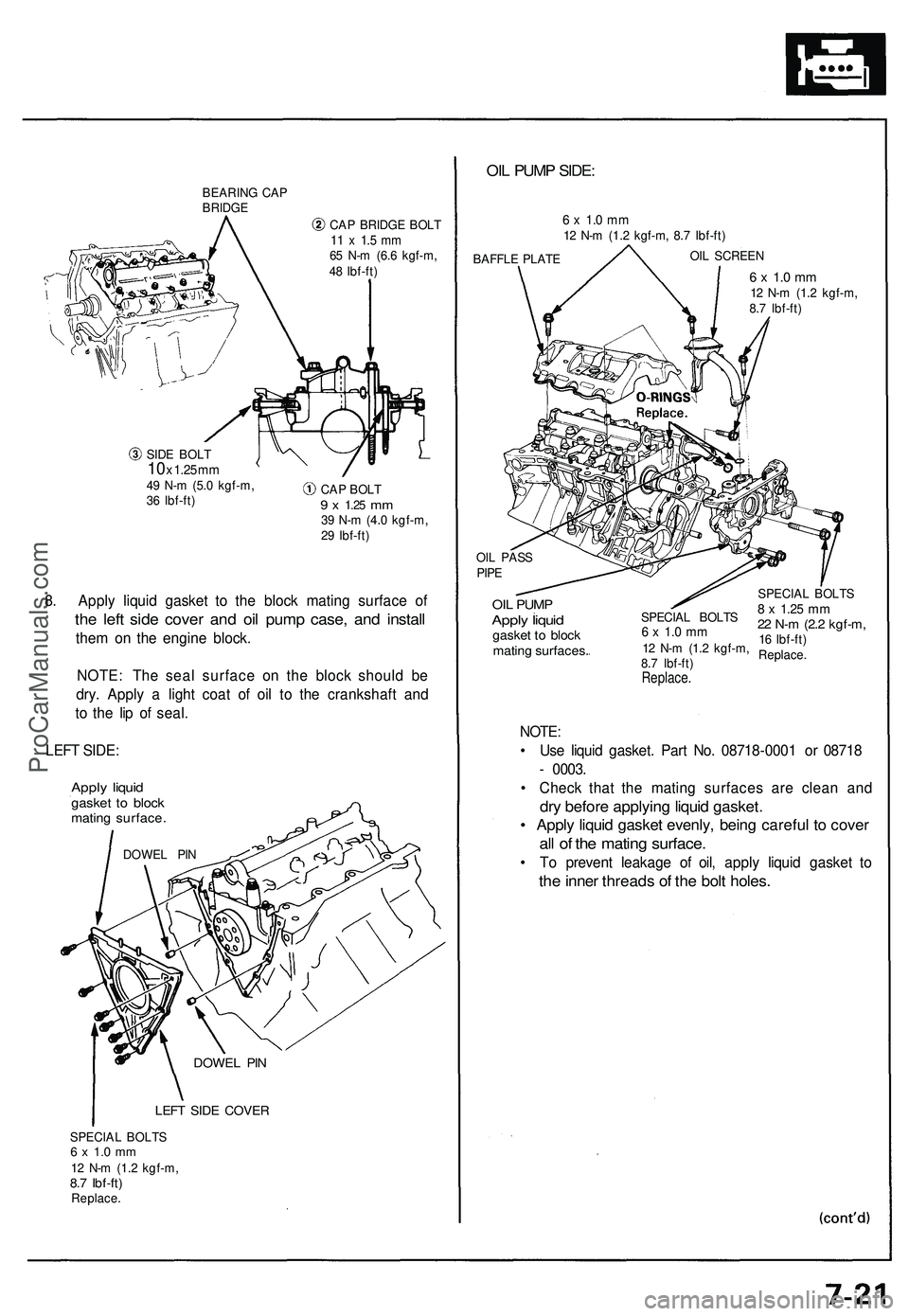

BEARING CA P

BRIDG E

CAP BRIDG E BOL T

11 x 1. 5 m m65 N- m (6. 6 kgf-m ,

4 8 Ibf-ft )

SID E BOL T

10 x 1.2 5 m m49 N- m (5. 0 kgf-m ,

3 6 Ibf-ft ) CA

P BOL T

9 x 1.2 5 mm39 N- m (4. 0 kgf-m ,

2 9 Ibf-ft )

8. Appl y liqui d gaske t t o th e bloc k matin g surfac e o f

the lef t sid e cove r an d oi l pum p case , an d instal l

them o n th e engine block.

NOTE : Th e sea l surfac e o n th e bloc k shoul d b e

dry . Appl y a ligh t coa t o f oi l t o th e crankshaf t an d

t o th e li p o f seal .

LEF T SIDE :

Apply liqui dgaske t t o bloc kmatin g surface .

LEFT SID E COVE R

SPECIA L BOLT S6 x 1. 0 m m12 N- m (1. 2 kgf-m ,8.7 Ibf-ft )Replace .

OIL PUM P SIDE :

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

BAFFL E PLAT E OI

L SCREE N

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

OI L PAS S

PIPE

OIL PUM PApply liqui dgaske t t o bloc k

matin g surfaces .

NOTE:

SPECIA L BOLT S6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

Replace .

SPECIAL BOLT S8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,16 Ibf-ft )

Replace .

• Us e liqui d gasket . Par t No . 0871 8-000 1 o r 0871 8

- 0003 .

• Chec k tha t th e matin g surface s ar e clea n an d

dry befor e applyin g liqui d gasket .

• Appl y liqui d gaske t evenly , bein g carefu l t o cove r

all o f th e matin g surface .

• T o preven t leakag e o f oil , appl y liqui d gaske t t o

th e inne r thread s o f th e bol t holes .

DOWE L PI N

DOWE L PI N

ProCarManuals.com