power steering ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 369 of 1503

3-14

Design Specification

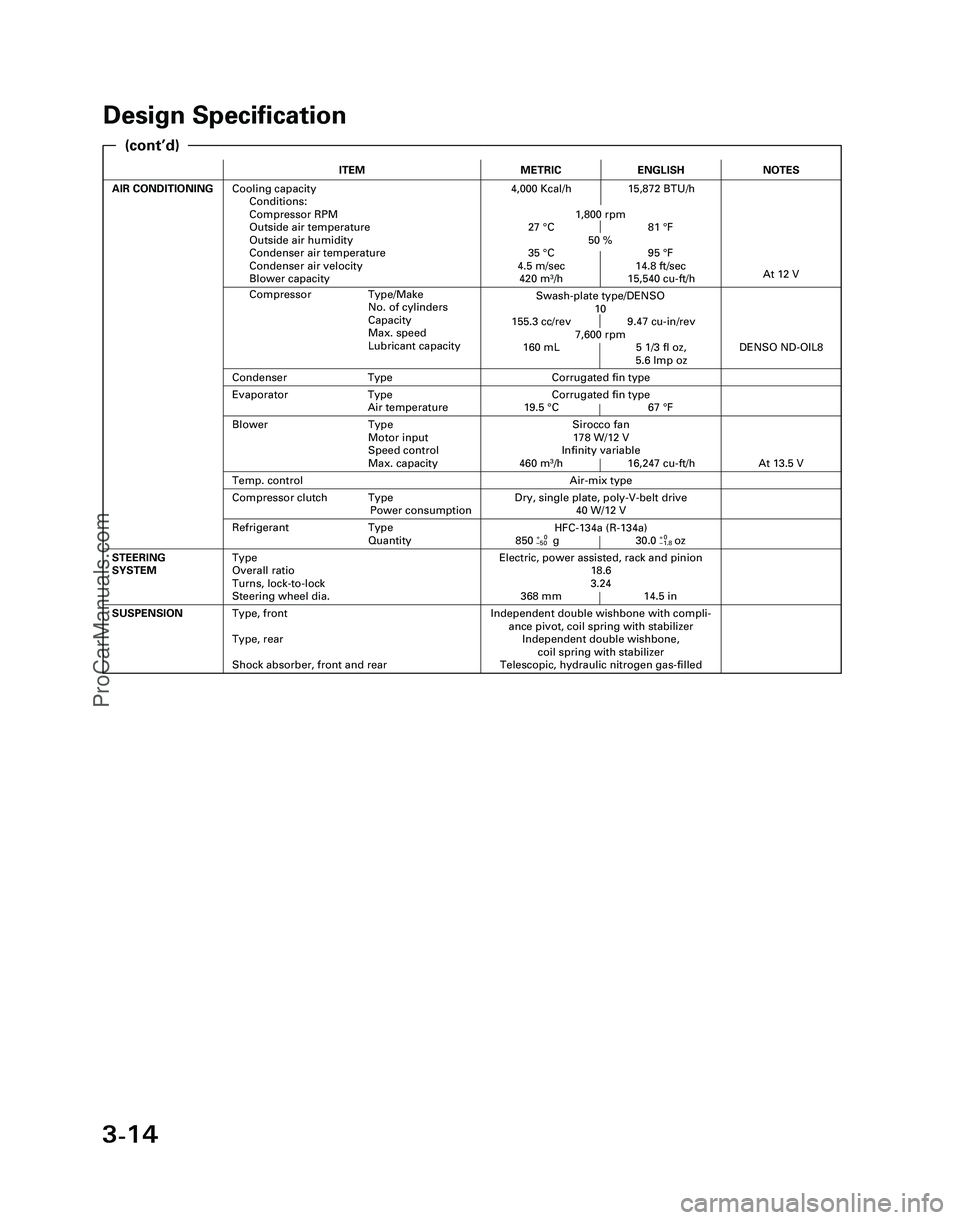

ITEMMETRICENGLISH

AIR CONDITIONINGCooling capacity

Conditions:

Compressor RPM

Outside air temperature

Outside air humidity

Condenser air temperature

Condenser air velocity

Blower capacity4,000 Kcal/h 15,872 BTU/h

1,800 rpm

27 °C 81 °F

50 %

35 °C 95 °F

4.5 m/sec 14.8 ft/sec

420 m

3/h 15,540 cu-ft/h

Independent double wishbone with compli-

ance pivot, coil spring with stabilizer

Independent double wishbone,

coil spring with stabilizer

Telescopic, hydraulic nitrogen gas-filledSUSPENSIONType, front

Type, rear

Shock absorber, front and rear

Evaporator Type

Air temperatureCorrugated fin type

19.5 °C 67 °F

Compressor Type/Make

No. of cylinders

Capacity

Max. speed

Lubricant capacity

NOTES

Swash-plate type/DENSO

10

155.3 cc/rev 9.47 cu-in/rev

7,600 rpm

160 mL 5 1/3 fl oz,

5.6 lmp oz

At 12 V

Air-mix type

Sirocco fan

178 W/12 V

Infinity variable

460 m

3/h 16,247 cu-ft/h

DENSO ND-OIL8

Condenser TypeCorrugated fin type

Temp. control

Blower Type

Motor input

Speed control

Max. capacity

At 13.5 V

Refrigerant Type

Quantity

Dry, single plate, poly-V-belt drive

40 W/12 VCompressor clutch Type

Power consumption

Electric, power assisted, rack and pinion

18.6

3.24

368 mm 14.5 inSTEERING

SYSTEMType

Overall ratio

Turns, lock-to-lock

Steering wheel dia.

HFC-134a (R-134a)

850+0g 30.0+0oz–50–1.8

(cont’d)

*04-NSX (61SW004)SEC03(01-16) 9/22/04 1:49 PM Page 3-14

ProCarManuals.com

Page 371 of 1503

4-2

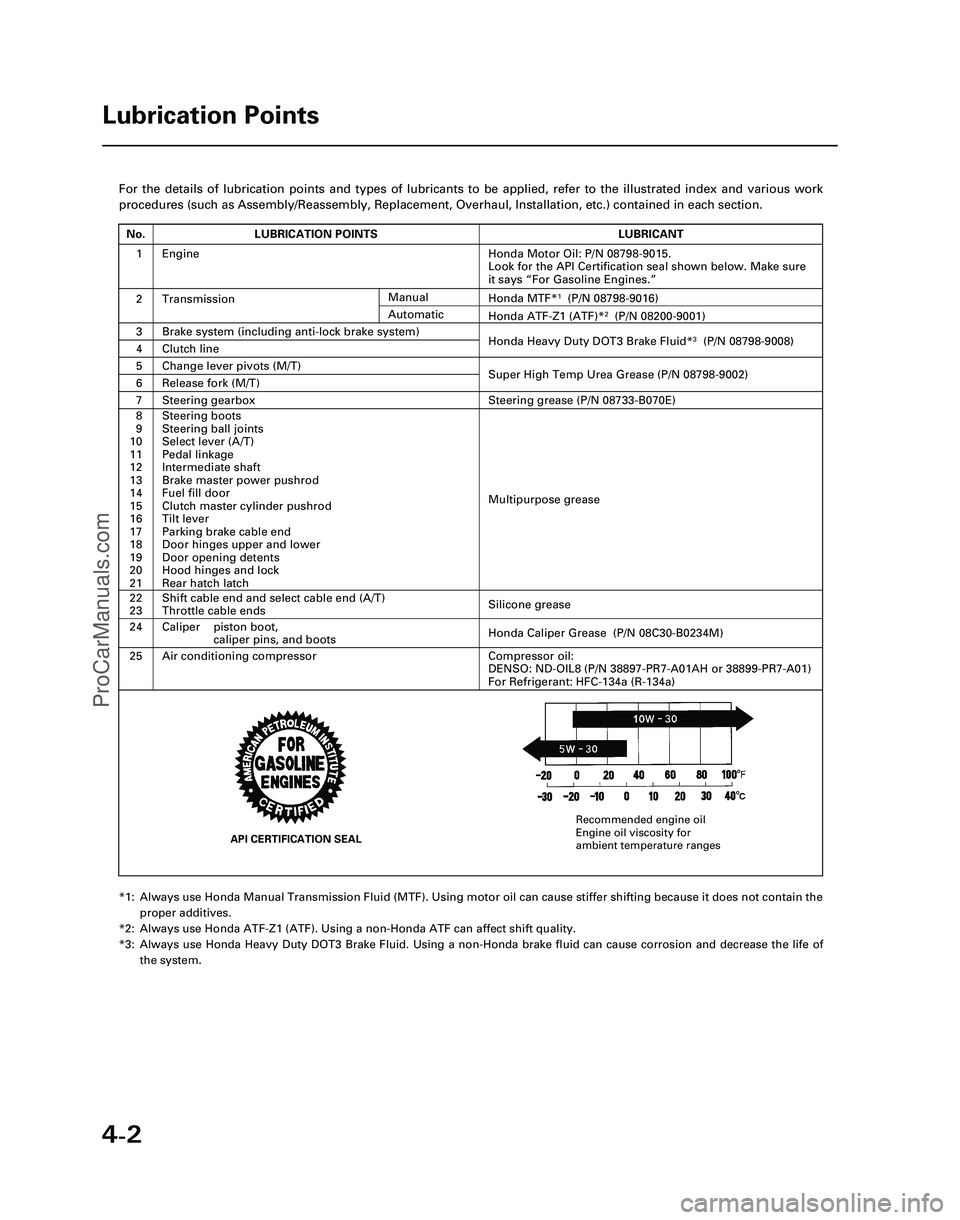

For the details of lubrication points and types of lubricants to be appl\

ied, refer to the illustrated index and various work

procedures (such as Assembly/Reassembly, Replacement, Overhaul, Install\

ation, etc.) contained in each section.

*1: Always use Honda Manual Transmission Fluid (MTF). Using motor oil can \

cause stiffer shifting because it does not contain theproper additives.

*2: Always use Honda ATF-Z1 (ATF). Using a non-Honda ATF can affect shift \

quality.

*3: Always use Honda Heavy Duty DOT3 Brake Fluid. Using a non-Honda brake fl\

uid can cause corrosion and decrease the life of the system.

Lubrication Points

No.LUBRICATION POINTSLUBRICANT

1Honda Motor Oil: P/N 08798-9015.

Look for the API Certification seal shown below. Make sure

it says “For Gasoline Engines.”

2TransmissionHonda MTF*1(P/N 08798-9016)

3Brake system (including anti-lock brake system)Honda Heavy Duty DOT3 Brake Fluid*3(P/N 08798-9008)4Clutch line

5Change lever pivots (M/T)Super High Temp Urea Grease (P/N 08798-9002)6Release fork (M/T)

8

9

10

11

12

13

14

15

16

17

18

19

20

21Steering boots

Steering ball joints

Select lever (A/T)

Pedal linkage

Intermediate shaft

Brake master power pushrod

Fuel fill door

Clutch master cylinder pushrod

Tilt lever

Parking brake cable end

Door hinges upper and lower

Door opening detents

Hood hinges and lock

Rear hatch latch

Multipurpose grease

24

22

23

Caliper piston boot, caliper pins, and boots

Shift cable end and select cable end (A/T)

Throttle cable ends

Honda Caliper Grease (P/N 08C30-B0234M)

Silicone grease

25Air conditioning compressorCompressor oil:

DENSO: ND-OIL8 (P/N 38897-PR7-A01AH or 38899-PR7-A01)

For Refrigerant: HFC-134a (R-134a)

Manual

Honda ATF-Z1 (ATF)*2(P/N 08200-9001)Automatic

7Steering gearboxSteering grease (P/N 08733-B070E)

Engine

API CERTIFICATION SEAL

Recommended engine oil

Engine oil viscosity for

ambient temperature ranges

*05-NSX (61SW004)SEC04(01-10) 9/22/04 1:49 PM Page 4-2

ProCarManuals.com

Page 896 of 1503

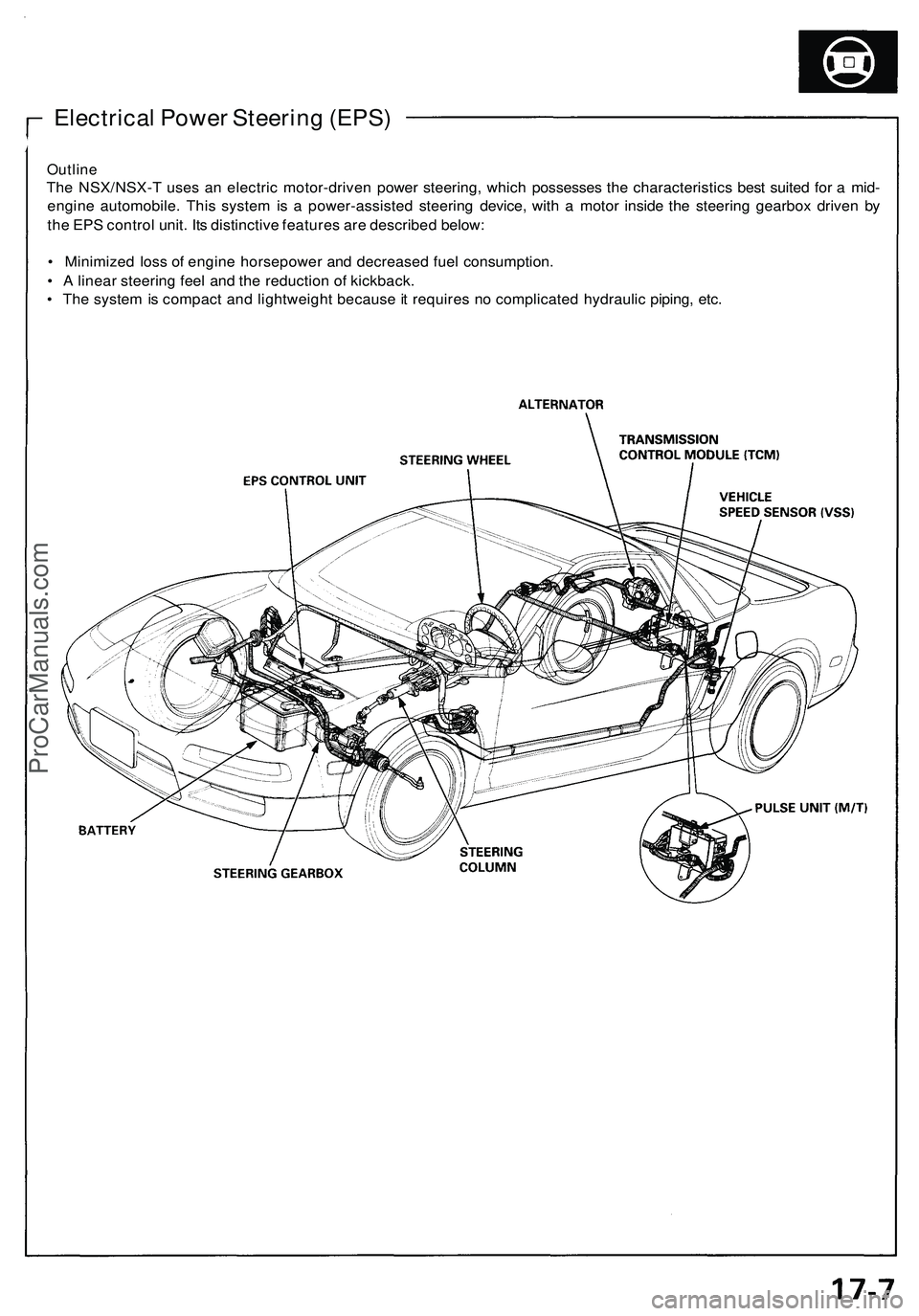

Electrical Powe r Steerin g (EPS )

Outlin e

The NSX/NSX- T use s a n electri c motor-drive n powe r steering , whic h possesse s th e characteristic s bes t suite d fo r a mid -

engin e automobile . Thi s syste m is a power-assiste d steerin g device , wit h a moto r insid e th e steerin g gearbo x drive n b y

th e EP S contro l unit . It s distinctiv e feature s ar e describe d below :

• Minimize d los s o f engin e horsepowe r an d decrease d fue l consumption .

• A linea r steerin g fee l an d th e reductio n o f kickback .

• Th e syste m is compac t an d lightweigh t becaus e it require s n o complicate d hydrauli c piping , etc .

ProCarManuals.com

Page 902 of 1503

Self-Diagnosis Function

The EPS control unit monitors the system inputs and outputs, and the driving current of the motor. If there is a problem in

the system, the control unit turns the system off by actuating the relay. Power assist stops and normal manual steering

operation resumes. The control unit also turns the EPS indicator light on to alert the driver, and memorizes the problem in

the form of a code. Connecting the terminals of the service check connector with the SCS service connector (special tool)

enables the EPS indicator light to blink the problem code when the ignition switch is turned on (II).

Unloader Control

If the steering wheel is turned fully and held in the full-lock position, the steering torque reaches the maximum point, and

an over-current flows to the motor. The control unit detects this and reduces the current flow to the motor.

Average Moving Current Control

The electric current flow to the motor is estimated from the current values detected by the current sensor, and the average

current is obtained at two second intervals. The motor driving current is suppressed when the average current value

exceeds a predetermined marginal value. The control unit regulates the motor current during continuous loading to sup-

press any excessive temperature rise in the motor.ProCarManuals.com

Page 903 of 1503

System Description

Function and Operation (cont'd)

The power module in the EPS control unit consists of a driving circuit, current sensor, field effect transistor (FET) bridge

circuit, and two relays. It receives control signals from the central processing unit (CPU) and controls the driving current of

the motor. The driving circuit controls the rotational direction and speed of the motor by driving the FET bridge circuit

with a pulse width modulation (PWM) method on receipt of an input of driving signals from the CPU.

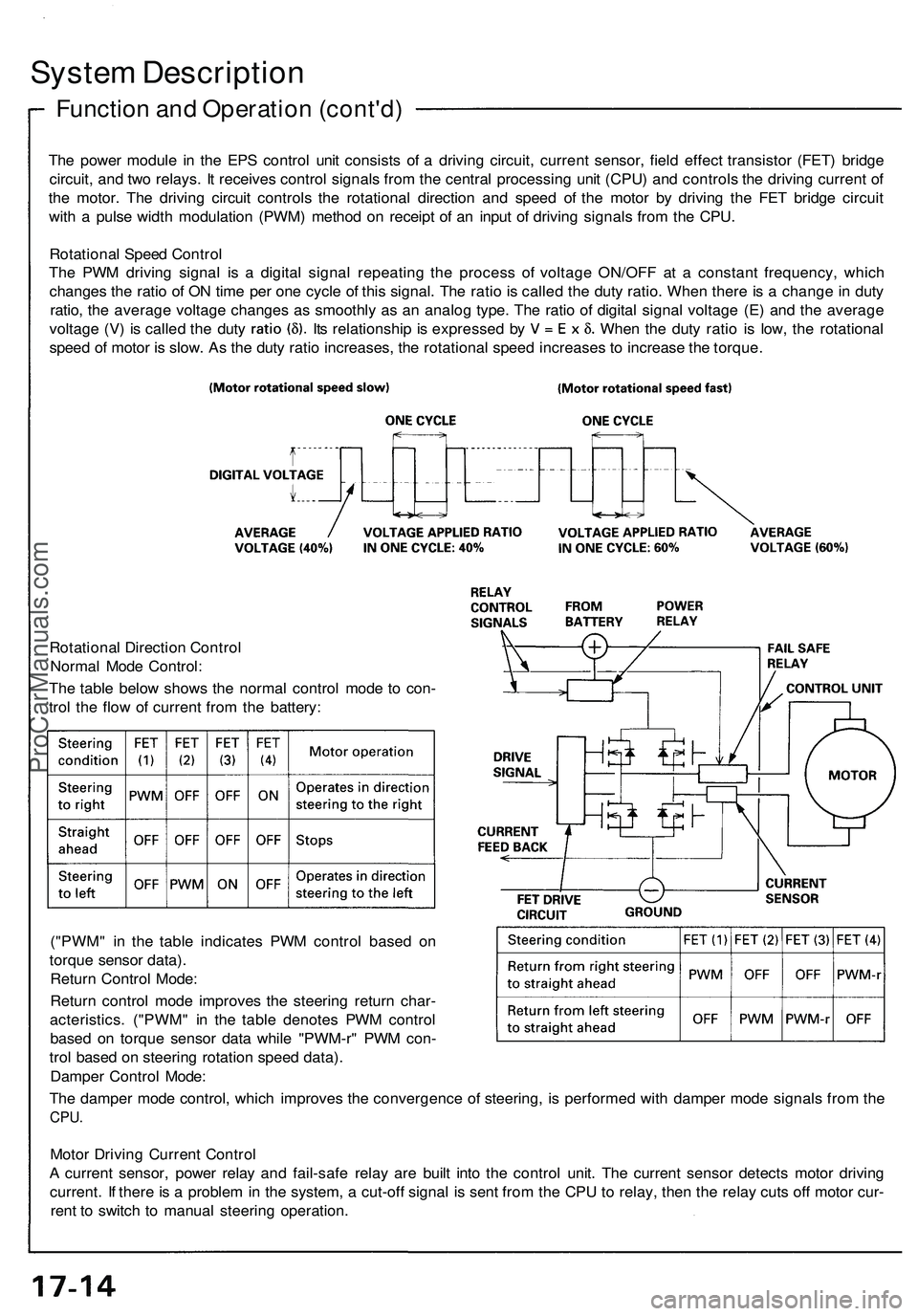

Rotational Speed Control

The PWM driving signal is a digital signal repeating the process of voltage ON/OFF at a constant frequency, which

changes the ratio of ON time per one cycle of this signal. The ratio is called the duty ratio. When there is a change in duty

ratio, the average voltage changes as smoothly as an analog type. The ratio of digital signal voltage (E) and the average

voltage (V) is called the duty Its relationship is expressed by When the duty ratio is low, the rotational

speed of motor is slow. As the duty ratio increases, the rotational speed increases to increase the torque.

Rotational Direction Control

Normal Mode Control:

The table below shows the normal control mode to con-

trol the flow of current from the battery:

("PWM" in the table indicates PWM control based on

torque sensor data).

Return Control Mode:

Return control mode improves the steering return char-

acteristics. ("PWM" in the table denotes PWM control

based on torque sensor data while "PWM-r" PWM con-

trol based on steering rotation speed data).

Damper Control Mode:

The damper mode control, which improves the convergence of steering, is performed with damper mode signals from the

CPU.

Motor Driving Current Control

A current sensor, power relay and fail-safe relay are built into the control unit. The current sensor detects motor driving

current. If there is a problem in the system, a cut-off signal is sent from the CPU to relay, then the relay cuts off motor cur-

rent to switch to manual steering operation.ProCarManuals.com

Page 904 of 1503

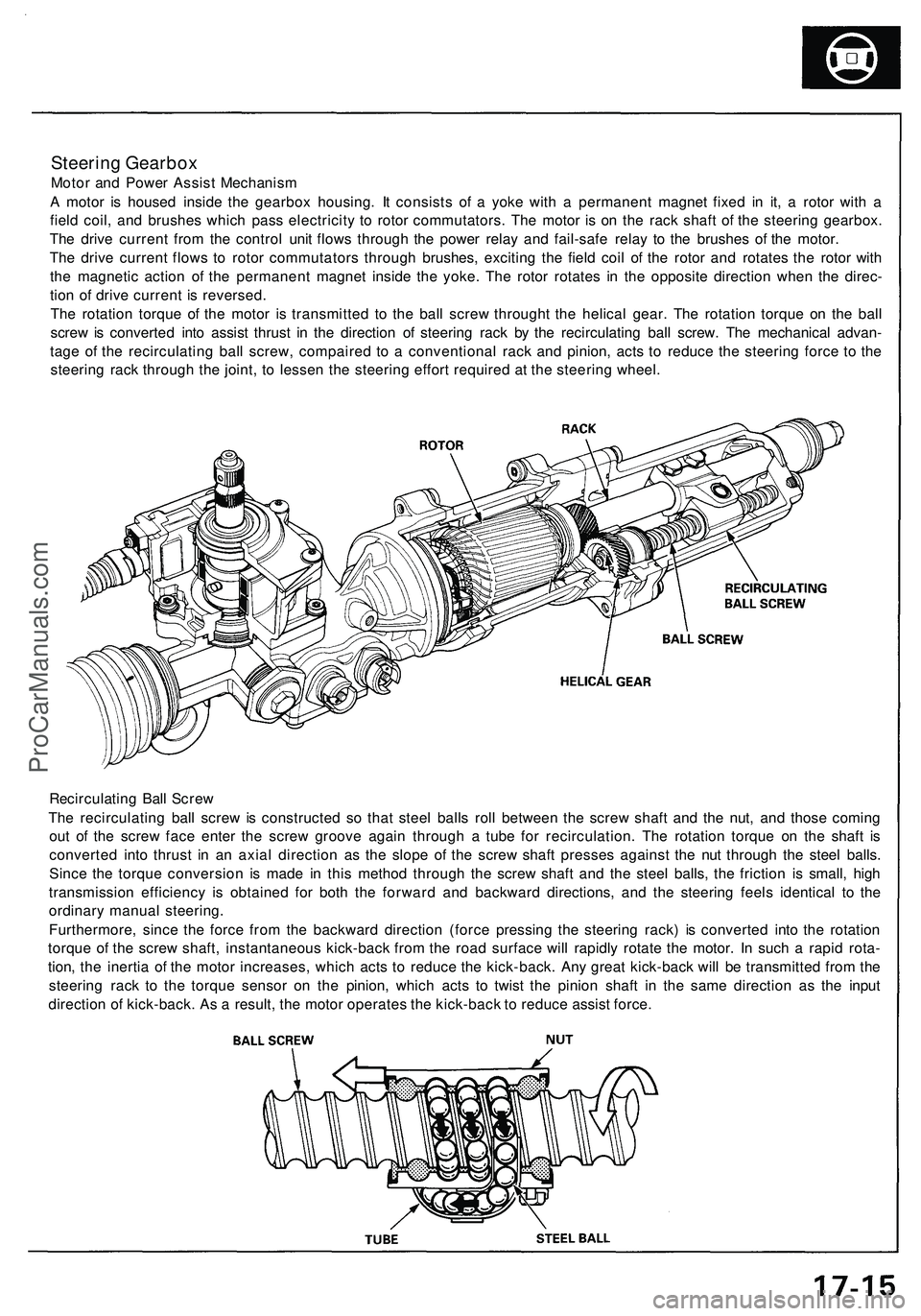

Steering Gearbox

Motor and Power Assist Mechanism

A motor is housed inside the gearbox housing. It consists of a yoke with a permanent magnet fixed in it, a rotor with a

field coil, and brushes which pass electricity to rotor commutators. The motor is on the rack shaft of the steering gearbox.

The drive current from the control unit flows through the power relay and fail-safe relay to the brushes of the motor.

The drive current flows to rotor commutators through brushes, exciting the field coil of the rotor and rotates the rotor with

the magnetic action of the permanent magnet inside the yoke. The rotor rotates in the opposite direction when the direc-

tion of drive current is reversed.

The rotation torque of the motor is transmitted to the ball screw throught the helical gear. The rotation torque on the ball

screw is converted into assist thrust in the direction of steering rack by the recirculating ball screw. The mechanical advan-

tage of the recirculating ball screw, compaired to a conventional rack and pinion, acts to reduce the steering force to the

steering rack through the joint, to lessen the steering effort required at the steering wheel.

Recirculating Ball Screw

The recirculating ball screw is constructed so that steel balls roll between the screw shaft and the nut, and those coming

out of the screw face enter the screw groove again through a tube for recirculation. The rotation torque on the shaft is

converted into thrust in an axial direction as the slope of the screw shaft presses against the nut through the steel balls.

Since the torque conversion is made in this method through the screw shaft and the steel balls, the friction is small, high

transmission efficiency is obtained for both the forward and backward directions, and the steering feels identical to the

ordinary manual steering.

Furthermore, since the force from the backward direction (force pressing the steering rack) is converted into the rotation

torque of the screw shaft, instantaneous kick-back from the road surface will rapidly rotate the motor. In such a rapid rota-

tion, the inertia of the motor increases, which acts to reduce the kick-back. Any great kick-back will be transmitted from the

steering rack to the torque sensor on the pinion, which acts to twist the pinion shaft in the same direction as the input

direction of kick-back. As a result, the motor operates the kick-back to reduce assist force.ProCarManuals.com

Page 909 of 1503

Troubleshooting Precautions

EPS Indicator Light

Under normal conditions, the EPS indicator light in the gauge assembly comes on when the ignition switch is turned to

the ON (II) position, then goes off after the engine is started. This indicates that the bulb and its circuits are operating cor-

rectly. If there is any trouble in the system, the EPS indicator light turns on during driving, and the power steering assist is

turned off. When the EPS indicator light comes on, the control unit memorizes the DTC. In this case, the control unit does

not activate the EPS system after the engine starts again but it keeps the EPS indicator light on.

Diagnostic Trouble Code (DTC)

• The lowest DTC is indicated first.

• The DTCs continue blinking until the ignition switch is turned off.

• The DTCs are erased from the control unit when the EPS control unit VBU power supply or connector is disconnected.

• The EPS system can be reset and the control unit's memory can be erased by disconnecting the CLOCK (7.5 A) fuse for

more than ten seconds.

Self-diagnosis:

The CPU (central processing unit) controls the following when it detects a problem during self-diagnosis:

1. Turns the EPS indicator light ON to alert the driver.

2. Power assist stops, and normal manual steering operation resumes (except DTC 33).

3. The EPS control unit memorizes the diagnostic trouble code (DTC).

4. After the DTC is stored in the control unit, the CPU stops self-diagnosis.

Troubleshooting:

• Before starting the troubleshooting, clear the DTC by disconnecting the CLOCK (7.5 A) fuse for ten seconds or more,

and test-drive the car. Check that the symptom of the trouble appears again, and then troubleshoot.

• When both EPS indicator light and A/T "D" indicator light come on, perform the A/T troubleshooting first.

• When the customer's reported problem cannot be verified in the car, ask the customer about the conditions when the

EPS indicator light came ON, then test-drive the car under those conditions, if possible. If the EPS indicator light does

not come ON during the test, check for loose connections or poor contacts at the connectors by wiggling the harness,

etc.

• The connector terminal numbers are viewed from the wire side for the female terminals and from the terminal side for

the male terminals.

• After the repair, test-drive the car and check that the EPS indicator light does not come ON again during the test. (Refer

to the Symptom-to-System Chart for diagnostic period.)ProCarManuals.com

Page 913 of 1503

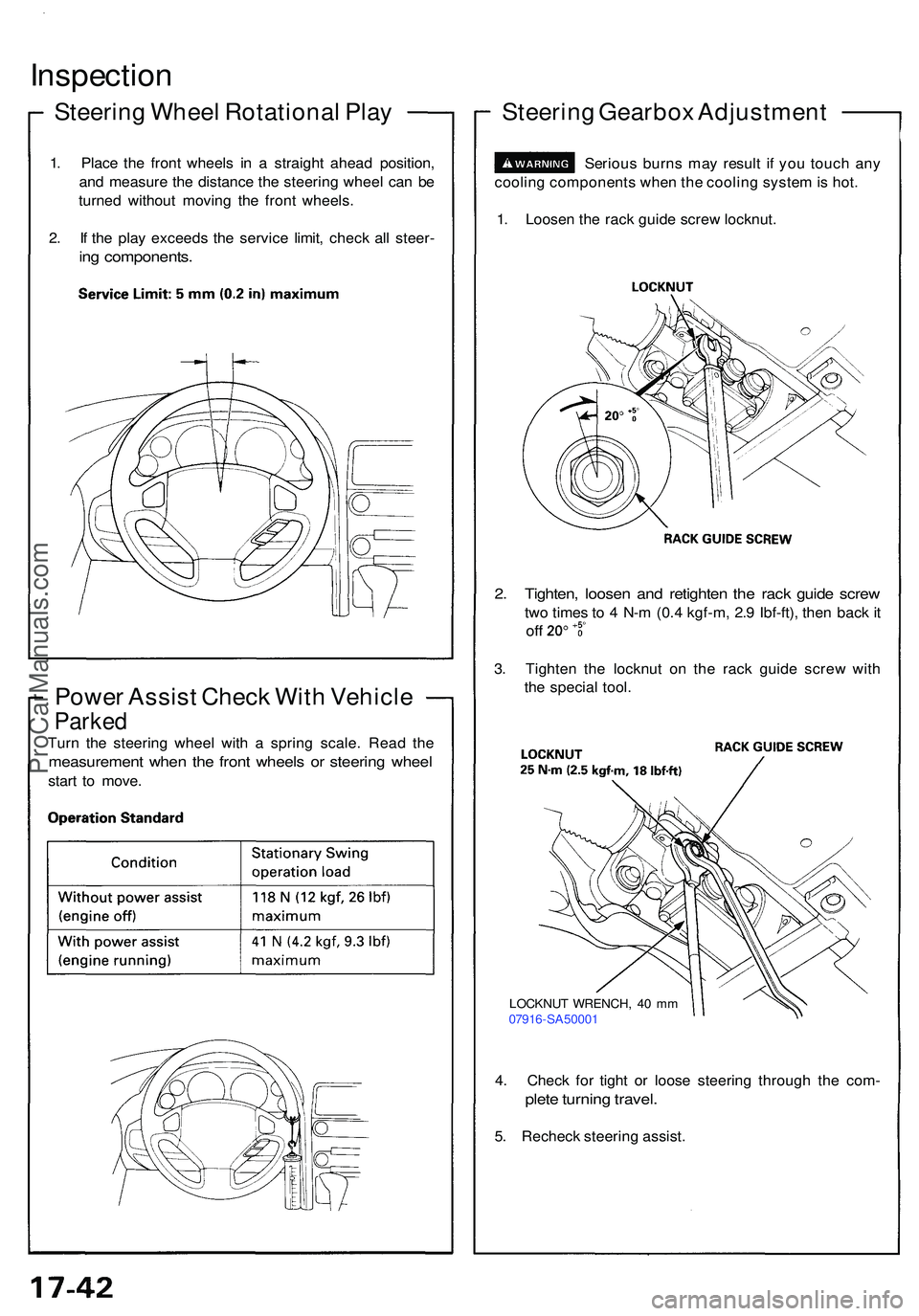

Inspection

Steering Whee l Rotationa l Pla y

1. Plac e th e fron t wheel s i n a straigh t ahea d position ,

an d measur e th e distanc e th e steerin g whee l ca n b e

turne d withou t movin g th e fron t wheels .

2 . I f th e pla y exceed s th e servic e limit , chec k al l steer -

ing components .

Power Assis t Chec k Wit h Vehicl e

Parked

Turn th e steerin g whee l wit h a sprin g scale . Rea d th e

measuremen t whe n th e fron t wheel s o r steerin g whee l

start t o move .

Steerin g Gearbo x Adjustmen t

1. Loose n th e rac k guid e scre w locknut .

Seriou

s burn s ma y resul t i f yo u touc h an y

coolin g component s whe n th e coolin g syste m is hot .

2. Tighten , loose n an d retighte n th e rac k guid e scre w

two time s t o 4 N- m (0. 4 kgf-m , 2. 9 Ibf-ft) , the n bac k i t

of f

3. Tighte n th e locknu t o n th e rac k guid e scre w wit h

th e specia l tool .

4 . Chec k fo r tigh t o r loos e steerin g throug h th e com -

plete turnin g travel .

5. Rechec k steerin g assist .

LOCKNU T WRENCH , 4 0 m m

0791 6-SA5000 1

ProCarManuals.com

Page 1045 of 1503

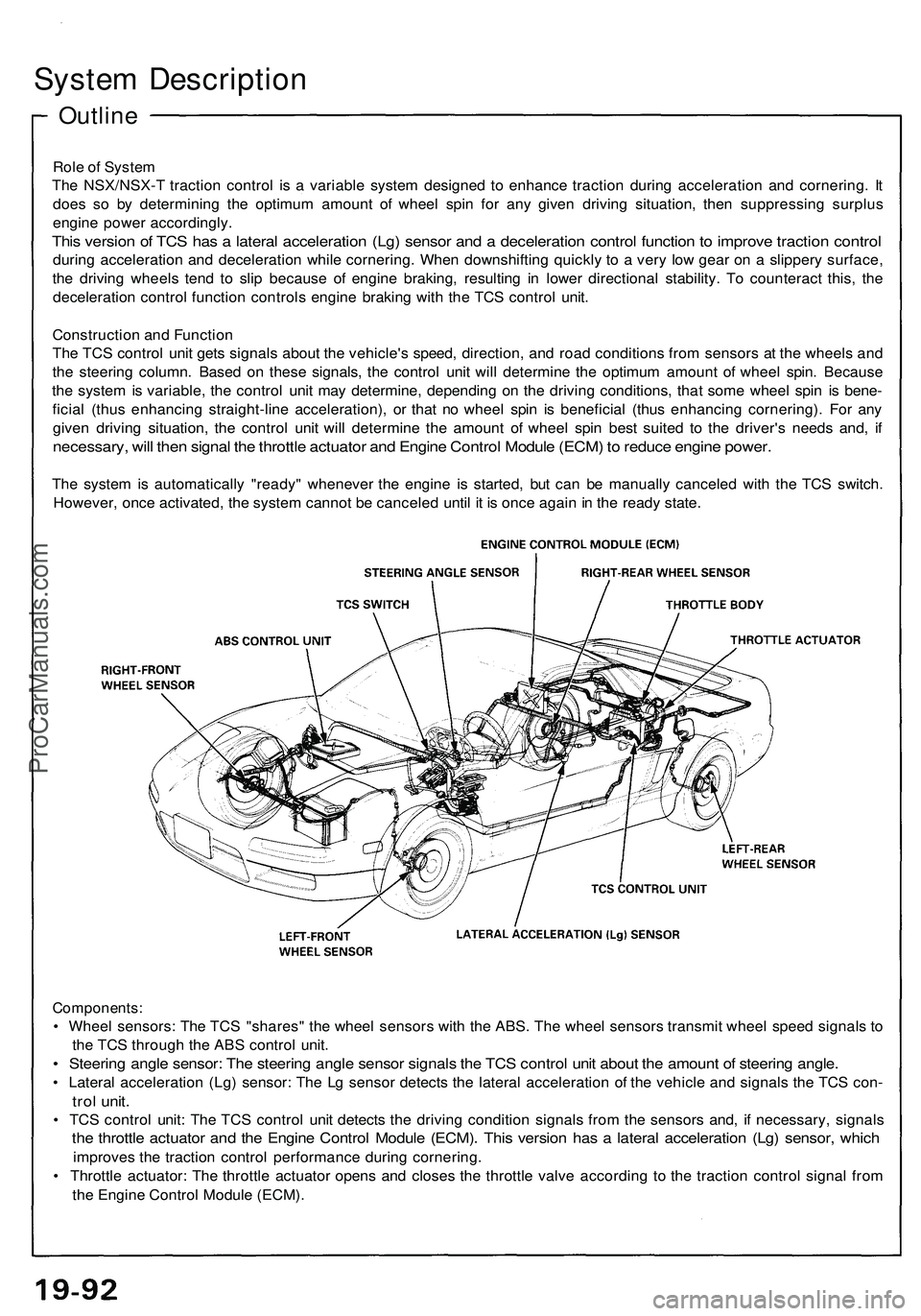

Outline

System Description

Role of System

The NSX/NSX-T traction control is a variable system designed to enhance traction during acceleration and cornering. It

does so by determining the optimum amount of wheel spin for any given driving situation, then suppressing surplus

engine power accordingly.

This version of TCS has a lateral acceleration (Lg) sensor and a deceleration control function to improve traction control

during acceleration and deceleration while cornering. When downshifting quickly to a very low gear on a slippery surface,

the driving wheels tend to slip because of engine braking, resulting in lower directional stability. To counteract this, the

deceleration control function controls engine braking with the TCS control unit.

Construction and Function

The TCS control unit gets signals about the vehicle's speed, direction, and road conditions from sensors at the wheels and

the steering column. Based on these signals, the control unit will determine the optimum amount of wheel spin. Because

the system is variable, the control unit may determine, depending on the driving conditions, that some wheel spin is bene-

ficial (thus enhancing straight-line acceleration), or that no wheel spin is beneficial (thus enhancing cornering). For any

given driving situation, the control unit will determine the amount of wheel spin best suited to the driver's needs and, if

necessary, will then signal the throttle actuator and Engine Control Module (ECM) to reduce engine power.

The system is automatically "ready" whenever the engine is started, but can be manually canceled with the TCS switch.

However, once activated, the system cannot be canceled until it is once again in the ready state.

Components:

• Wheel sensors: The TCS "shares" the wheel sensors with the ABS. The wheel sensors transmit wheel speed signals to

the TCS through the ABS control unit.

• Steering angle sensor: The steering angle sensor signals the TCS control unit about the amount of steering angle.

• Lateral acceleration (Lg) sensor: The Lg sensor detects the lateral acceleration of the vehicle and signals the TCS con-

trol unit.

• TCS control unit: The TCS control unit detects the driving condition signals from the sensors and, if necessary, signals

the throttle actuator and the Engine Control Module (ECM). This version has a lateral acceleration (Lg) sensor, which

improves the traction control performance during cornering.

• Throttle actuator: The throttle actuator opens and closes the throttle valve according to the traction control signal from

the Engine Control Module (ECM).ProCarManuals.com

Page 1046 of 1503

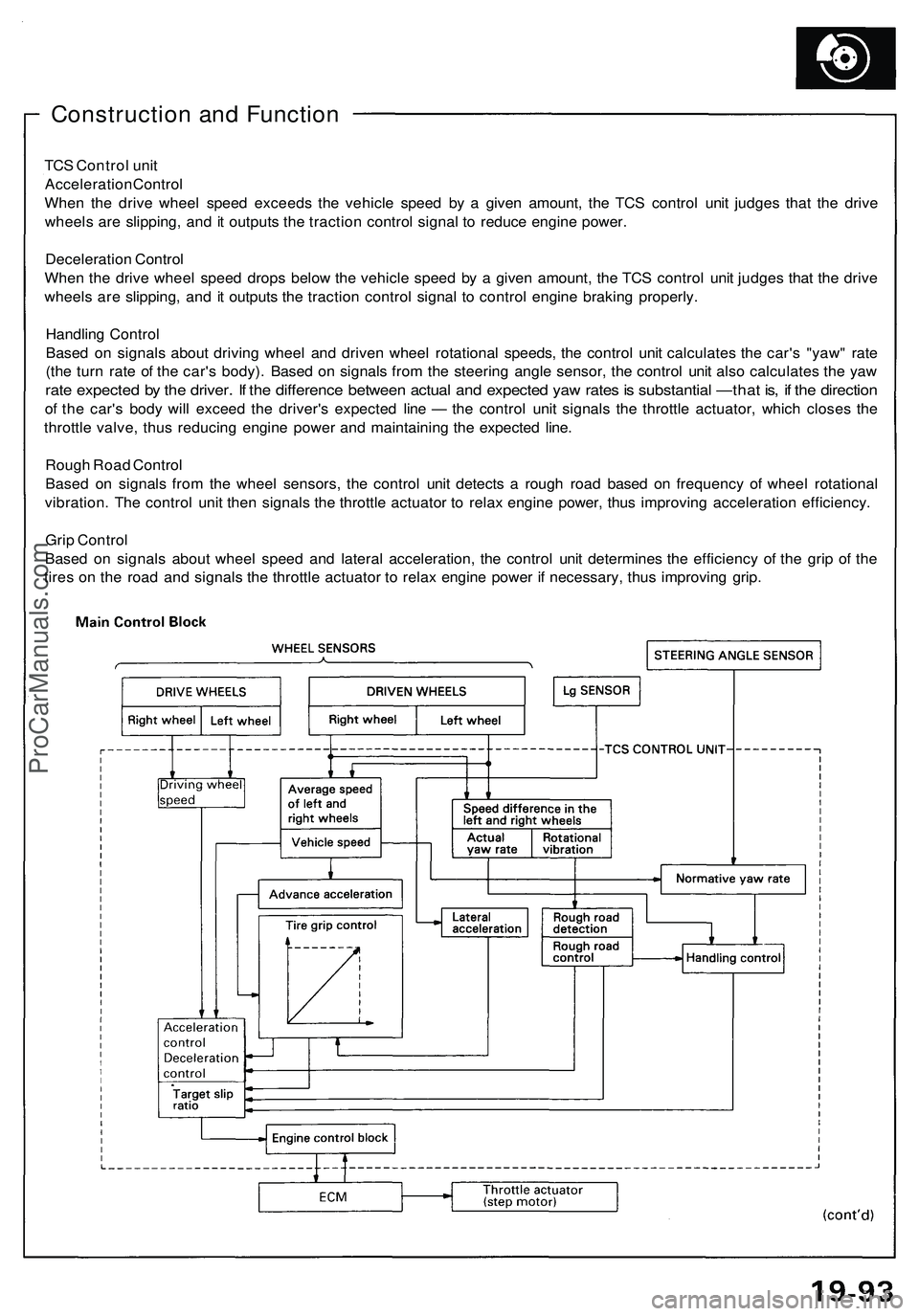

Construction and Function

TCS Control unit

Acceleration Control

When the drive wheel speed exceeds the vehicle speed by a given amount, the TCS control unit judges that the drive

wheels are slipping, and it outputs the traction control signal to reduce engine power.

Deceleration Control

When the drive wheel speed drops below the vehicle speed by a given amount, the TCS control unit judges that the drive

wheels are slipping, and it outputs the traction control signal to control engine braking properly.

Handling Control

Based on signals about driving wheel and driven wheel rotational speeds, the control unit calculates the car's "yaw" rate

(the turn rate of the car's body). Based on signals from the steering angle sensor, the control unit also calculates the yaw

rate expected by the driver. If the difference between actual and expected yaw rates is substantial —that is, if the direction

of the car's body will exceed the driver's expected line — the control unit signals the throttle actuator, which closes the

throttle valve, thus reducing engine power and maintaining the expected line.

Rough Road Control

Based on signals from the wheel sensors, the control unit detects a rough road based on frequency of wheel rotational

vibration. The control unit then signals the throttle actuator to relax engine power, thus improving acceleration efficiency.

Grip Control

Based on signals about wheel speed and lateral acceleration, the control unit determines the efficiency of the grip of the

tires on the road and signals the throttle actuator to relax engine power if necessary, thus improving grip.ProCarManuals.com