air conditioning ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 1 of 1503

General Info

Specifications

Maintenance

Engine

Cooling

Fuel and Emissions

*Transaxle

SteeringSuspension

*Brakes (Including ABS)

*Body

*Heating, Ventilation and

Air Conditioning

*Body Electrical

*Engine Electrical

*SRS

1997-200 5 NSX Main Menu

As sections w/ * include SRS components,

special precautions are required when servicing.

ProCarManuals.com

Page 369 of 1503

3-14

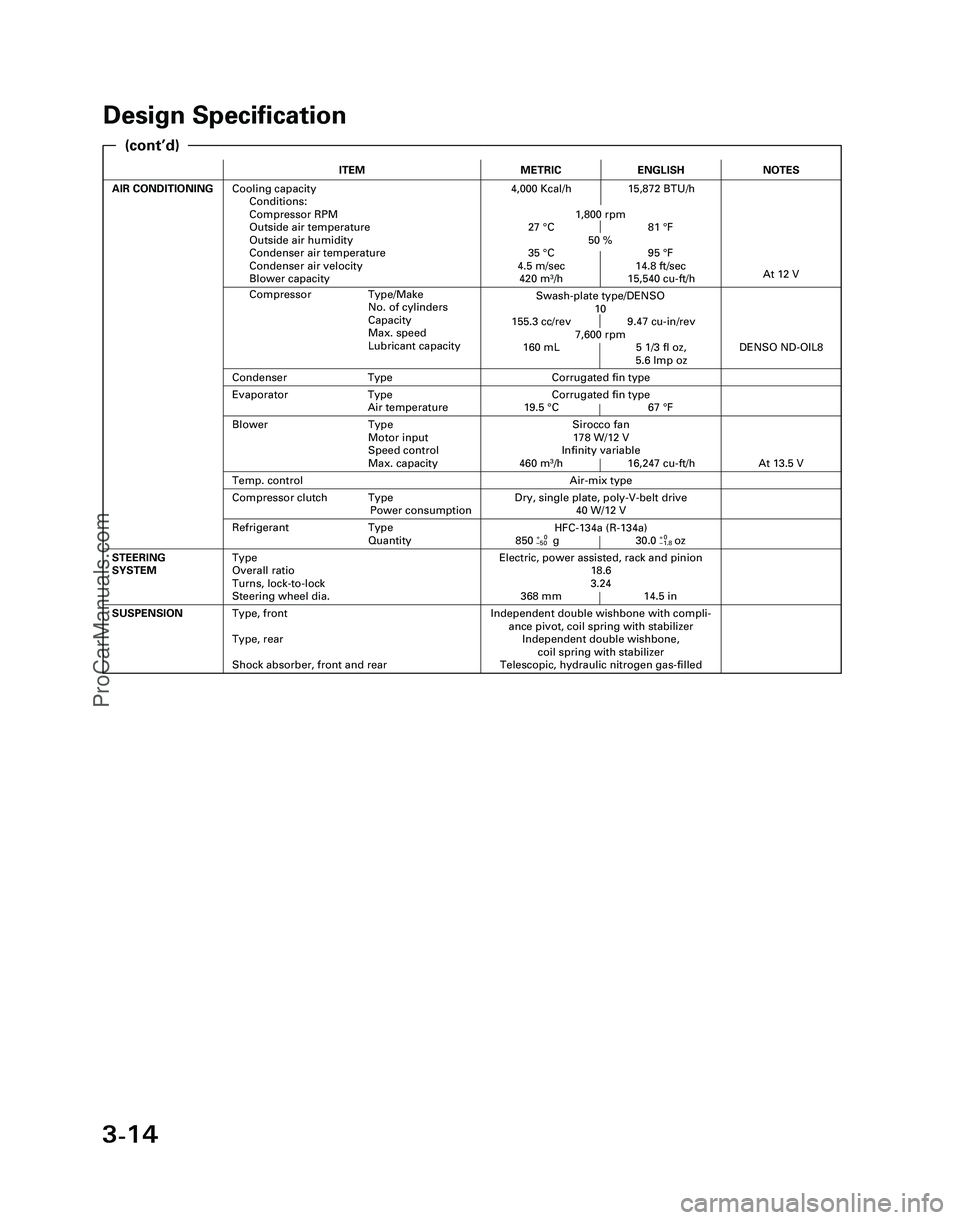

Design Specification

ITEMMETRICENGLISH

AIR CONDITIONINGCooling capacity

Conditions:

Compressor RPM

Outside air temperature

Outside air humidity

Condenser air temperature

Condenser air velocity

Blower capacity4,000 Kcal/h 15,872 BTU/h

1,800 rpm

27 °C 81 °F

50 %

35 °C 95 °F

4.5 m/sec 14.8 ft/sec

420 m

3/h 15,540 cu-ft/h

Independent double wishbone with compli-

ance pivot, coil spring with stabilizer

Independent double wishbone,

coil spring with stabilizer

Telescopic, hydraulic nitrogen gas-filledSUSPENSIONType, front

Type, rear

Shock absorber, front and rear

Evaporator Type

Air temperatureCorrugated fin type

19.5 °C 67 °F

Compressor Type/Make

No. of cylinders

Capacity

Max. speed

Lubricant capacity

NOTES

Swash-plate type/DENSO

10

155.3 cc/rev 9.47 cu-in/rev

7,600 rpm

160 mL 5 1/3 fl oz,

5.6 lmp oz

At 12 V

Air-mix type

Sirocco fan

178 W/12 V

Infinity variable

460 m

3/h 16,247 cu-ft/h

DENSO ND-OIL8

Condenser TypeCorrugated fin type

Temp. control

Blower Type

Motor input

Speed control

Max. capacity

At 13.5 V

Refrigerant Type

Quantity

Dry, single plate, poly-V-belt drive

40 W/12 VCompressor clutch Type

Power consumption

Electric, power assisted, rack and pinion

18.6

3.24

368 mm 14.5 inSTEERING

SYSTEMType

Overall ratio

Turns, lock-to-lock

Steering wheel dia.

HFC-134a (R-134a)

850+0g 30.0+0oz–50–1.8

(cont’d)

*04-NSX (61SW004)SEC03(01-16) 9/22/04 1:49 PM Page 3-14

ProCarManuals.com

Page 371 of 1503

4-2

For the details of lubrication points and types of lubricants to be appl\

ied, refer to the illustrated index and various work

procedures (such as Assembly/Reassembly, Replacement, Overhaul, Install\

ation, etc.) contained in each section.

*1: Always use Honda Manual Transmission Fluid (MTF). Using motor oil can \

cause stiffer shifting because it does not contain theproper additives.

*2: Always use Honda ATF-Z1 (ATF). Using a non-Honda ATF can affect shift \

quality.

*3: Always use Honda Heavy Duty DOT3 Brake Fluid. Using a non-Honda brake fl\

uid can cause corrosion and decrease the life of the system.

Lubrication Points

No.LUBRICATION POINTSLUBRICANT

1Honda Motor Oil: P/N 08798-9015.

Look for the API Certification seal shown below. Make sure

it says “For Gasoline Engines.”

2TransmissionHonda MTF*1(P/N 08798-9016)

3Brake system (including anti-lock brake system)Honda Heavy Duty DOT3 Brake Fluid*3(P/N 08798-9008)4Clutch line

5Change lever pivots (M/T)Super High Temp Urea Grease (P/N 08798-9002)6Release fork (M/T)

8

9

10

11

12

13

14

15

16

17

18

19

20

21Steering boots

Steering ball joints

Select lever (A/T)

Pedal linkage

Intermediate shaft

Brake master power pushrod

Fuel fill door

Clutch master cylinder pushrod

Tilt lever

Parking brake cable end

Door hinges upper and lower

Door opening detents

Hood hinges and lock

Rear hatch latch

Multipurpose grease

24

22

23

Caliper piston boot, caliper pins, and boots

Shift cable end and select cable end (A/T)

Throttle cable ends

Honda Caliper Grease (P/N 08C30-B0234M)

Silicone grease

25Air conditioning compressorCompressor oil:

DENSO: ND-OIL8 (P/N 38897-PR7-A01AH or 38899-PR7-A01)

For Refrigerant: HFC-134a (R-134a)

Manual

Honda ATF-Z1 (ATF)*2(P/N 08200-9001)Automatic

7Steering gearboxSteering grease (P/N 08733-B070E)

Engine

API CERTIFICATION SEAL

Recommended engine oil

Engine oil viscosity for

ambient temperature ranges

*05-NSX (61SW004)SEC04(01-10) 9/22/04 1:49 PM Page 4-2

ProCarManuals.com

Page 586 of 1503

PGM-FI System

System Description (cont'd)

3. Fuel Cut-off Control

During deceleration with the throttle valve closed, current to the fuel injectors is cut off to improve fuel economy at

speeds over 1,500 rpm.

Fuel cut-off action also takes place when engine speed exceeds 8,300 rpm, regardless of the position of the throttle

valve, to protect the engine from over-revving.

4. A/C Compressor Clutch Relay

When the ECM receives a demand for cooling from the air conditioning system, it delays the compressor from being

energized, and enriches the mixture to assure smooth translation to the A/C mode.

5. Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant temperature is below 153°F (67°C), the ECM controls the EVAP purge control solenoid valve

which cuts vacuum to the EVAP purge control canister diaphragm.

6. Intake Air Bypass (IAB) Control Solenoid Valve

When the engine speed is below 4,800 rpm, the IAB control solenoid valve is activated by a signal from the ECM. Intake

air then flows through the smaller chamber, and high torque is delivered. To increase air flow at engine speeds higher

than 4,800 rpm, the solenoid valve is deactivated by the ECM, and the intake air flows through the larger chamber.

7. Exhaust Gas Recirculation (EGR) Control Solenoid Valve

When the EGR is required for control of oxides of nitrogen (NOx) emissions, the ECM supplies ground to the EGR

control solenoid valve which supplies regulated vacuum to the EGR valve.

ECM Fail-safe/Back-up Functions

1. Fail-Safe Function

When an abnormality occurs in a signal from a sensor, the ECM ignores that signal and assumes a pre-programmed

valve for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the ECM itself, the fuel injectors are controlled by a back-up circuit independent of the

system in order to permit minimal driving.

3. Self-diagnosis Function [Malfunction Indicator Lamp (MIL)]

When an abnormality occurs in a signal from a sensor, the ECM lights the MIL and stores the diagnostic trouble code

in erasable memory. When the ignition is initially turned on, the ECM supplies ground for the MIL for two seconds to

check the MIL bulb condition.

4. Two Trip Detection Method

To prevent false indications, the Two Trip Detection Method is used for the H02S, fuel metering-related, idle control

system, ECT sensor, EGR system self-diagnostic functions and EVAP control system. When an abnormality occurs,

the ECM stores it in its memory. When the same abnormality recurs after the ignition switch is turned OFF and ON (II)

again, the ECM informs the driver by lighting the MIL.

However, to ease troubleshooting, this function is cancelled when you short the service check connector. The MIL will

then blink immediately when an abnormality occurs.

5. Two (or three) Driving Cycle Detection Method

A "Driving Cycle" consists of starting the engine, beginning closed loop operation, and stopping the engine. If misfir-

ing that increases emissions or EVAP control system malfunction is detected during two consecutive driving cycles,

or TWC deterioration is detected during three consecutive driving cycles, the ECM turns the MIL on.

However,

to

ease

troubleshooting,

this

function

is

cancelled when

you

short

the

service check connector.

The MIL

will

then blink immediately when an abnormality occurs.ProCarManuals.com

Page 1207 of 1503

A/C System Service

Performance Test

The performance test will help determine if the air con-

ditioning system is operating within specifications.

Only use service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioning system.

CAUTION: Exposure to air conditioner refrigerant

and lubricant vapor or mist can irritate eyes, nose

and throat. Avoid breathing the air conditioner

refrigerant and lubricant vapor or mist.

If accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioning sys-

tem should not be pressure tested or leak tested with

compressed air.

Some mixtures of air and R-134a have

been shown to be combustible at elevated pressures

and can result in fire or explosion causing injury or

property damage. Never use compressed air to pres-

sure test R-134a service equipment or vehicle air

conditioning systems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

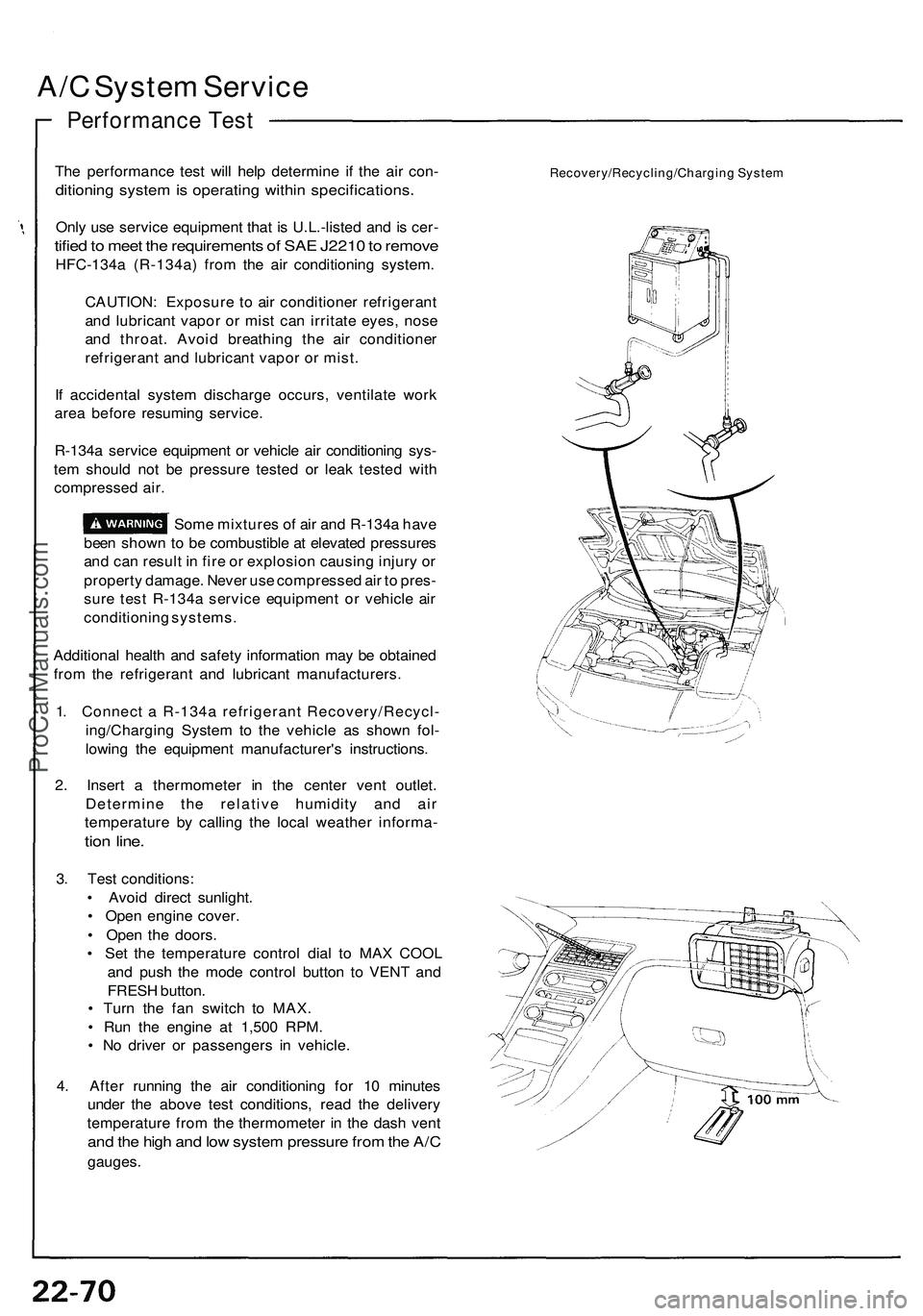

1. Connect a R-134a refrigerant Recovery/Recycl-

ing/Charging System to the vehicle as shown fol-

lowing the equipment manufacturer's instructions.

2. Insert a thermometer in the center vent outlet.

Determine the relative humidity and air

temperature by calling the local weather informa-

tion line.

3. Test conditions:

• Avoid direct sunlight.

• Open engine cover.

• Open the doors.

• Set the temperature control dial to MAX COOL

and push the mode control button to VENT and

FRESH button.

• Turn the fan switch to MAX.

• Run the engine at 1,500 RPM.

• No driver or passengers in vehicle.

4. After running the air conditioning for 10 minutes

under the above test conditions, read the delivery

temperature from the thermometer in the dash vent

and the high and low system pressure from the A/C

gauges.

Recovery/Recycling/Charging SystemProCarManuals.com

Page 1227 of 1503

A/C System Service

Evacuation

Only use service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioning system.

CAUTION: Exposure to air conditioner refrigerant

and lubricant vapor or mist can irritate eyes, nose

and throat. Avoid breathing the air conditioner

refrigerant and lubricant vapor or mist.

If accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioning sys-

tem should not be pressure tested or leak tested with

compressed air.

Some mixtures of air and R-134a have

been shown to be combustible at elevated pressures

and can result in fire or explosion causing injury or

property damage. Never use compressed air to pres-

sure test R-134a service equipment or vehicle air

conditioning systems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

1. When an A/C System has been opened to the at-

mosphere, such as during installation or repair, it

must be evacuated using a R-134a refrigerant

Recovery/Recycling/Charging System. (If the

system has been open for several days, the

receiver/dryer should be replaced).

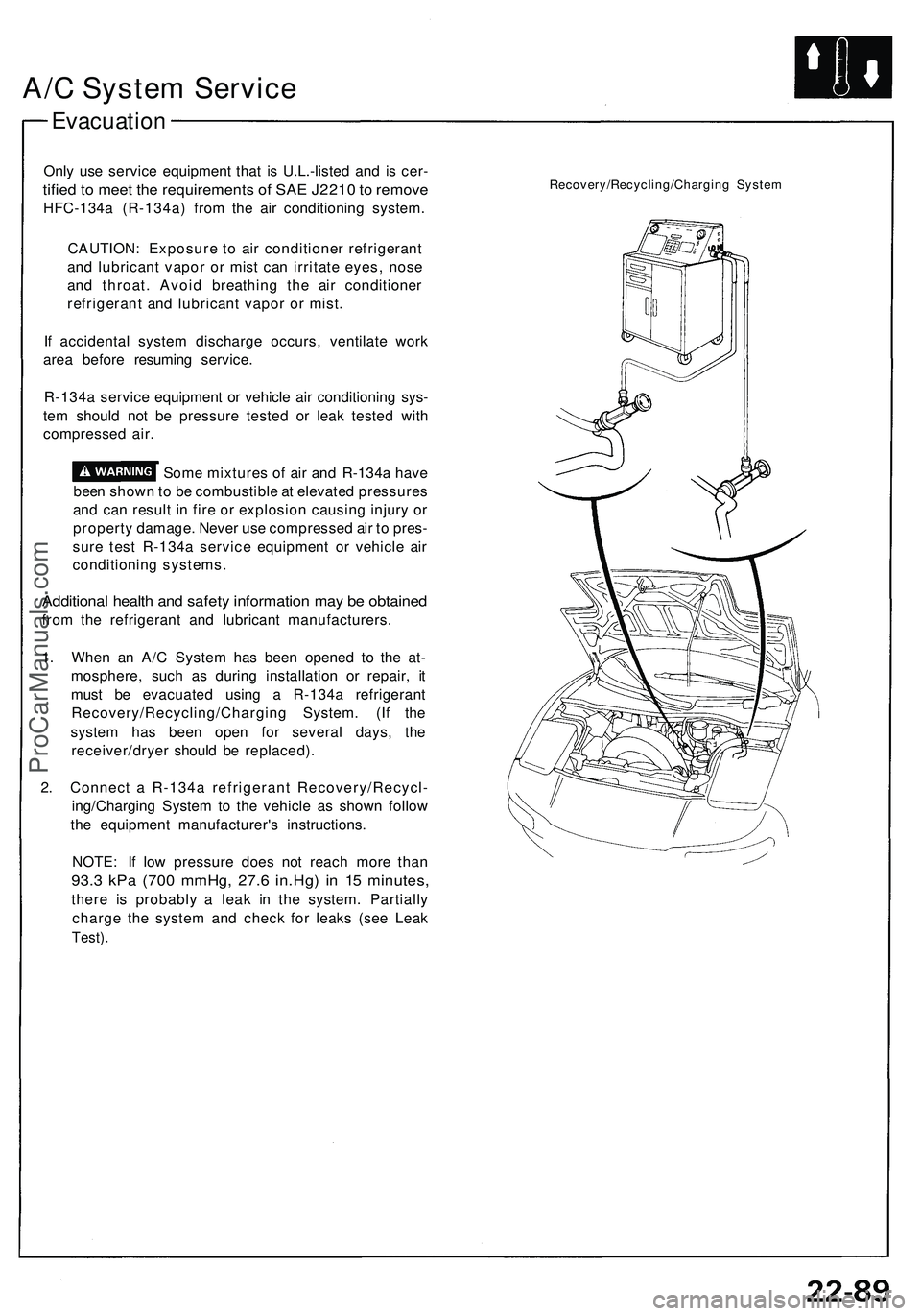

2. Connect a R-134a refrigerant Recovery/Recycl-

ing/Charging System to the vehicle as shown follow

the equipment manufacturer's instructions.

NOTE: If low pressure does not reach more than

93.3 kPa (700 mmHg, 27.6 in.Hg) in 15 minutes,

there is probably a leak in the system. Partially

charge the system and check for leaks (see Leak

Test).

Recovery/Recycling/Charging SystemProCarManuals.com