change wheel ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 477 of 1503

Flywheel an d Driv e Plat e

Replacemen t

Connecting Rod s an d

Crankshaf t

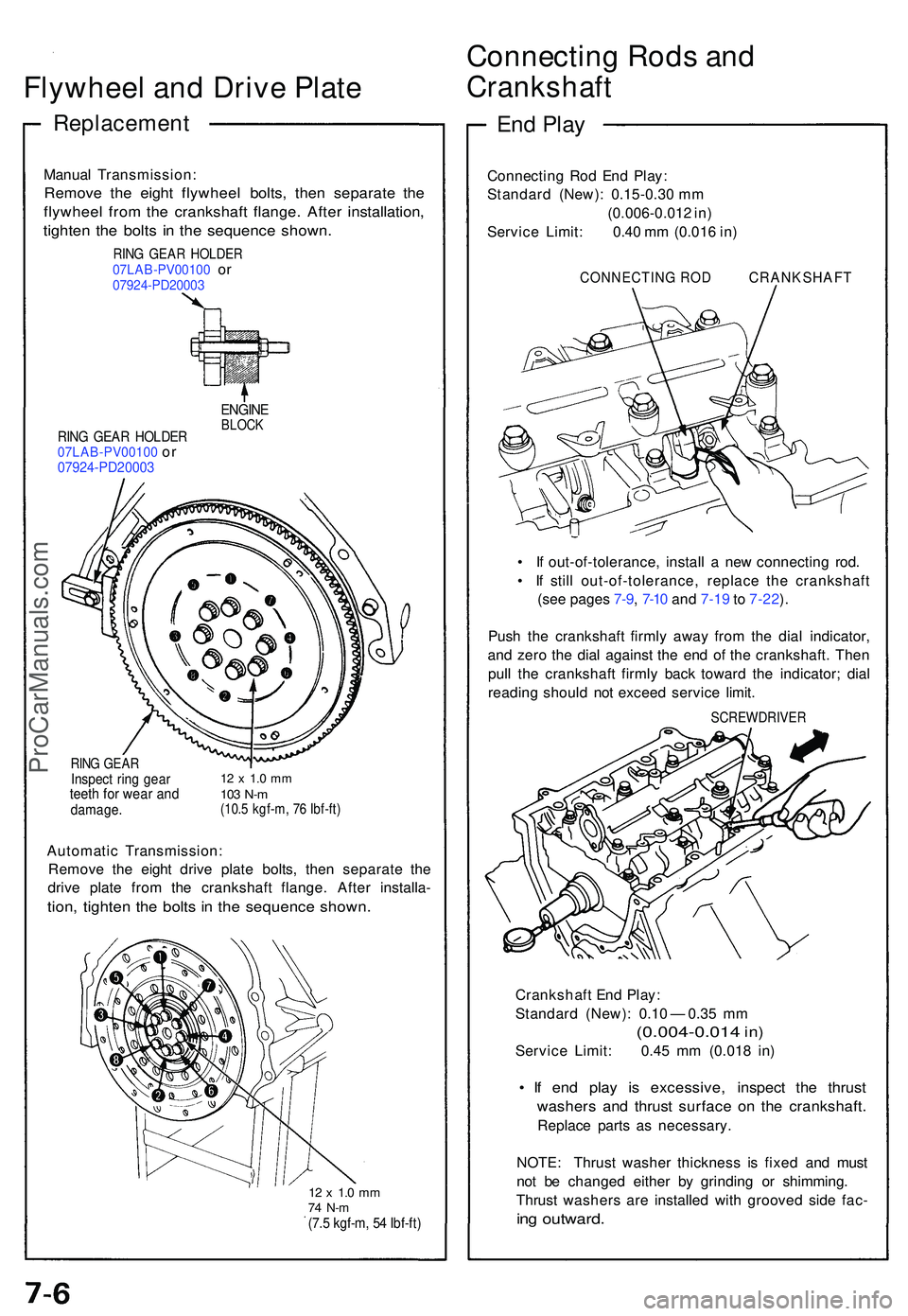

Manual Transmission :

Remove th e eigh t flywhee l bolts , the n separat e th e

flywhee l fro m th e crankshaf t flange . Afte r installation ,

tighten th e bolt s i n th e sequenc e shown .

RING GEA R HOLDE R07LAB-PV0010 0 or07924-PD2000 3

RING GEA R HOLDE R07LAB-PV00100 or07924-PD2000 3

ENGINEBLOCK

RING GEA RInspec t rin g gea rteeth fo r wea r an ddamage .

12 x 1. 0 m m103 N- m(10. 5 kgf-m , 7 6 Ibf-ft )

Automati c Transmission :

Remov e th e eigh t driv e plat e bolts , the n separat e th e

driv e plat e fro m th e crankshaf t flange . Afte r installa -

tion, tighte n th e bolt s i n th e sequenc e shown .

12 x 1. 0 m m74 N- m(7.5 kgf-m , 5 4 Ibf-ft )

End Pla y

Connectin g Ro d En d Play :

Standard (New): 0.15-0.30 mm

(0.006-0.01 2 in )

Servic e Limit : 0.40 m m (0.01 6 in )

CONNECTIN G RO D CRANKSHAF T

• I f out-of-tolerance , instal l a ne w connectin g rod .

• I f stil l out-of-tolerance , replac e th e crankshaf t

(se e page s 7-9 , 7-1 0 an d 7-1 9 to 7-22 ).

Pus h th e crankshaf t firml y awa y fro m th e dia l indicator ,

an d zer o th e dia l agains t th e en d o f th e crankshaft . The n

pul l th e crankshaf t firml y bac k towar d th e indicator ; dia l

readin g shoul d no t excee d servic e limit .

SCREWDRIVE R

Crankshaft En d Play :

Standar d (New) : 0.1 0 — 0.3 5 m m

(0.004-0.01 4 in)

Servic e Limit : 0.4 5 m m (0.01 8 in )

• I f en d pla y i s excessive , inspec t th e thrus t

washer s an d thrus t surfac e o n th e crankshaft .

Replace part s a s necessary .

NOTE : Thrus t washe r thicknes s i s fixe d an d mus t

no t b e change d eithe r b y grindin g o r shimming .

Thrus t washer s ar e installe d wit h groove d sid e fac -

ing outward .

ProCarManuals.com

Page 640 of 1503

Description

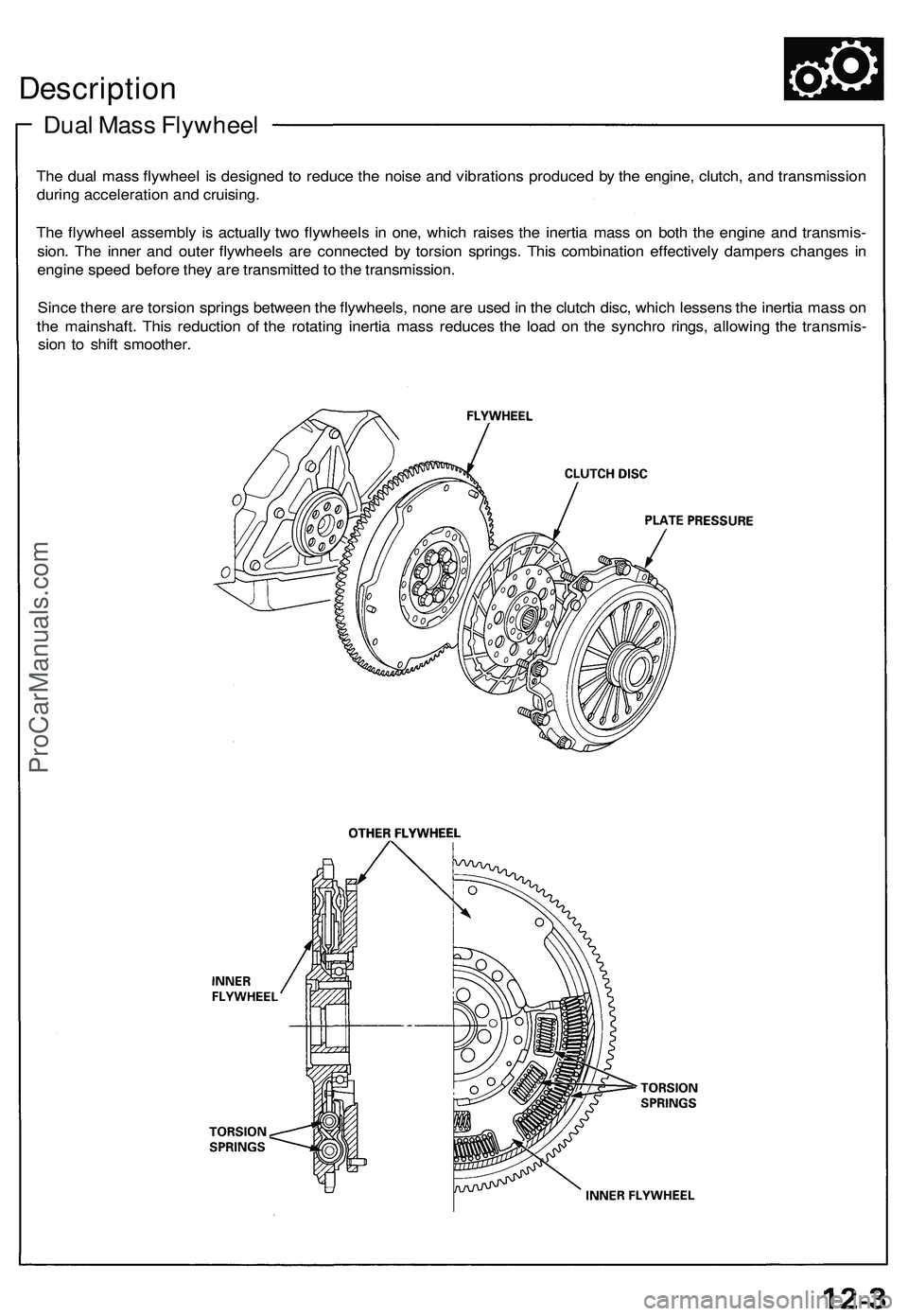

Dual Mas s Flywhee l

The dua l mas s flywhee l i s designe d t o reduc e th e nois e an d vibration s produce d b y th e engine , clutch , an d transmissio n

durin g acceleratio n an d cruising .

Th e flywhee l assembl y i s actuall y tw o flywheel s i n one , whic h raise s th e inerti a mas s o n bot h th e engin e an d transmis -

sion . Th e inne r an d oute r flywheel s ar e connecte d b y torsio n springs . Thi s combinatio n effectivel y damper s change s i n

engin e spee d befor e the y ar e transmitte d to th e transmission .

Sinc e ther e ar e torsio n spring s betwee n th e flywheels , non e ar e use d in th e clutc h disc , whic h lessen s th e inerti a mas s o n

th e mainshaft . Thi s reductio n o f th e rotatin g inerti a mas s reduce s th e loa d o n th e synchr o rings , allowin g th e transmis -

sio n t o shif t smoother .

ProCarManuals.com

Page 713 of 1503

Description

The automatic transmission is a combination of a 3-element torque converter and a triple-shaft electronically controlled

automatic transmission which provides 4 speeds forward and 1 speed reverse. The entire unit is positioned in line with the

engine.

Torque Converter, Gears, and Clutches

The torque converter consists of a pump, turbine, and stator, assembled in a single unit.

They are connected to the engine crankshaft so they turn together as a unit as the engine turns.

Around the outside of the torque converter is a ring gear which meshes with the starter pinion when the engine is being

started. The entire torque converter assembly serves as a flywheel while transmitting power to the transmission main-

shaft. The transmission has three parallel shafts: the mainshaft, the countershaft, and the secondary shaft. The mainshaft

is in line with the engine crankshaft.

The mainshaft includes the 1st and 4th clutches, and gears for 3rd, 4th, reverse, and 1st (3rd gear is integral with the main-

shaft, while reverse gear is integral with 4th gear).

The countershaft includes the 1st-hold and 3rd clutches, and gears for 2nd, 3rd, 4th, reverse, 1st, and parking.

The secondary shaft includes the 2nd clutch and gears for 2nd and 3rd.

The 4th and reverse gears can be locked to the countershaft at its center, providing 4th gear or reverse, depending on

which way the selector is moved.

The gears on the mainshaft and secondary shaft are in constant mesh with those on the countershaft.

When certain combinations of gears in the transmission are engaged by clutches, power is transmitted from the mainshaft

to the countershaft to provide positions.

Electronic Control

The electronic control system consists of the Transmission Control Module (TCM), sensors, a linear solenoid, a shift switch,

and 4 solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located on the insulator center bulkhead, behind the driver's seat.

Hydraulic Control

The valve bodies include the main valve body, secondary valve body, servo body, regulator valve body, throttle valve

body, lock-up valve body, and the 2nd accumulator body.

They are bolted to the torque converter housing as an assembly.

The main valve body contains the manual valve, 1-2 shift valve, 2-3 shift valve, 3-4 shift valve, relief valve, one-way relief

valve, and oil pump gears.

The secondary valve body contains the 3-2 kick-down valve, clutch pressure control (CPC) valve, 2nd orifice control valve, 3rd

orifice control valve, modulator valve, 4th exhaust valve, servo control valve, 2nd exhaust valve, and 4-3 kick-down valve.

The servo body contains the accumulator pistons and servo valve. The throttle valve body includes the throttle valve B

which is bolted to the servo body.

The regulator valve body contains the pressure regulator valve, lock-up control valve, and cooler relief valve. Fluid from

the regulator passes through the manual valve to the various control valves.

The lock-up valve body contains the lock-up timing B valve and lock-up shift valve. The 2nd accumulator body contains

the accumulator pistons and limited slip differential relief valve.

The torque converter check valve is located in the torque converter housing, under the main valve body.

The 1st, 1st-hold, 3rd, and 4th clutches receive fluid from their respective feed pipes and the 2nd clutch receives fluid from

the internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the vehicle determines which shift control solenoid valve the TCM will acti-

vate. Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes

a line to one of the clutches, engaging that clutch and its corresponding gear.

Lock-up Mechanism

In position and position in 2nd, 3rd, and 4th, pressurized fluid is drained from the back of the torque converter

through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes place, the

mainshaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the TCM optimizes the tim-

ing of the lock-up mechanism.

The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and B, and throttle valve B.

When lock-up control solenoid valves A and B activate, modulator pressure changes. The lock-up control solenoid valves

A and B are mounted on the torque converter housing, and are controlled by the TCM.

(cont'd)ProCarManuals.com

Page 899 of 1503

System Description

Function and Operation

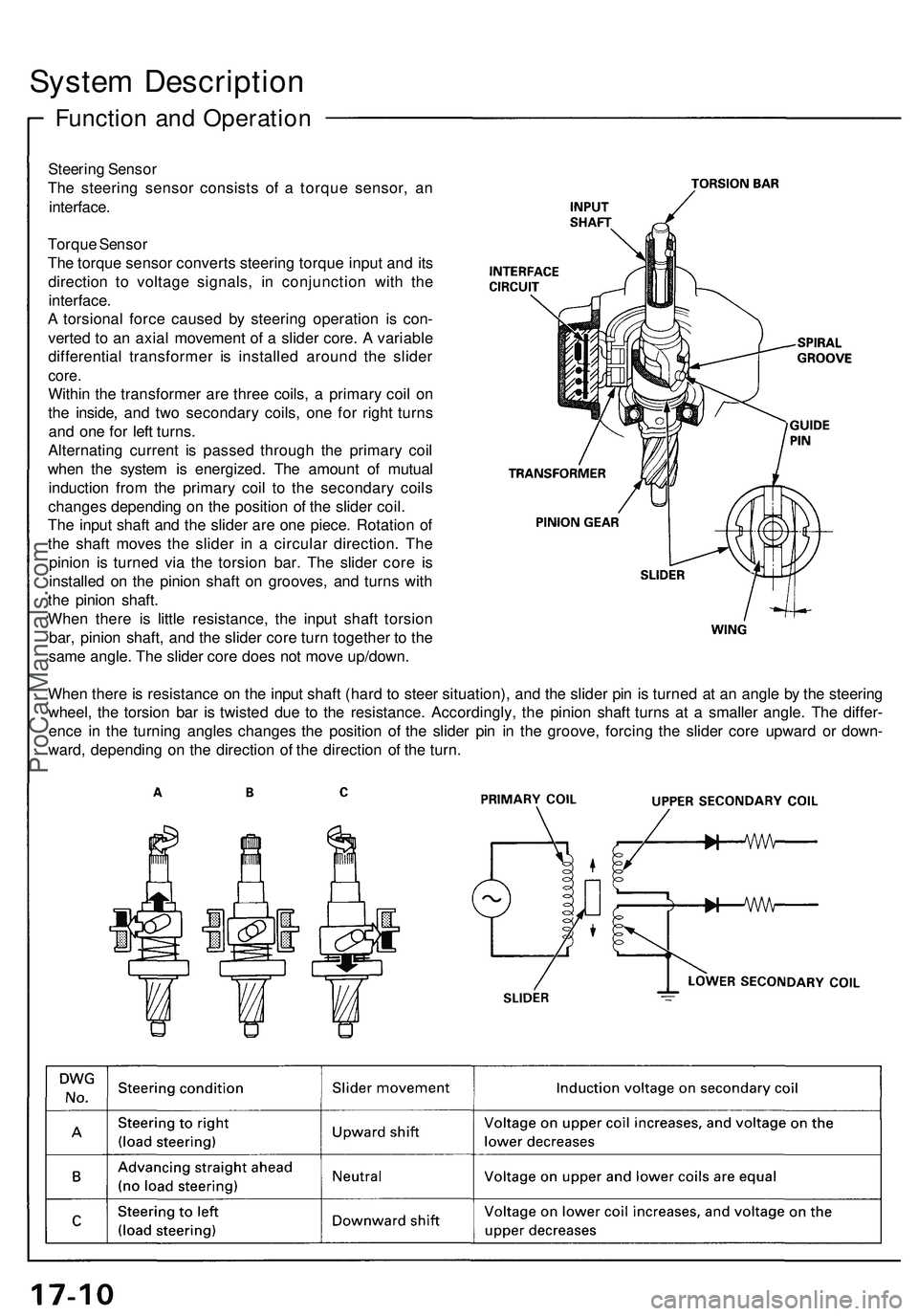

Steering Sensor

The steering sensor consists of a torque sensor, an

interface.

Torque Sensor

The torque sensor converts steering torque input and its

direction to voltage signals, in conjunction with the

interface.

A torsional force caused by steering operation is con-

verted to an axial movement of a slider core. A variable

differential transformer is installed around the slider

core.

Within the transformer are three coils, a primary coil on

the inside, and two secondary coils, one for right turns

and one for left turns.

Alternating current is passed through the primary coil

when the system is energized. The amount of mutual

induction from the primary coil to the secondary coils

changes depending on the position of the slider coil.

The input shaft and the slider are one piece. Rotation of

the shaft moves the slider in a circular direction. The

pinion is turned via the torsion bar. The slider core is

installed on the pinion shaft on grooves, and turns with

the pinion shaft.

When there is little resistance, the input shaft torsion

bar, pinion shaft, and the slider core turn together to the

same angle. The slider core does not move up/down.

When there is resistance on the input shaft (hard to steer situation), and the slider pin is turned at an angle by the steering

wheel, the torsion bar is twisted due to the resistance. Accordingly, the pinion shaft turns at a smaller angle. The differ-

ence in the turning angles changes the position of the slider pin in the groove, forcing the slider core upward or down-

ward, depending on the direction of the direction of the turn.ProCarManuals.com

Page 938 of 1503

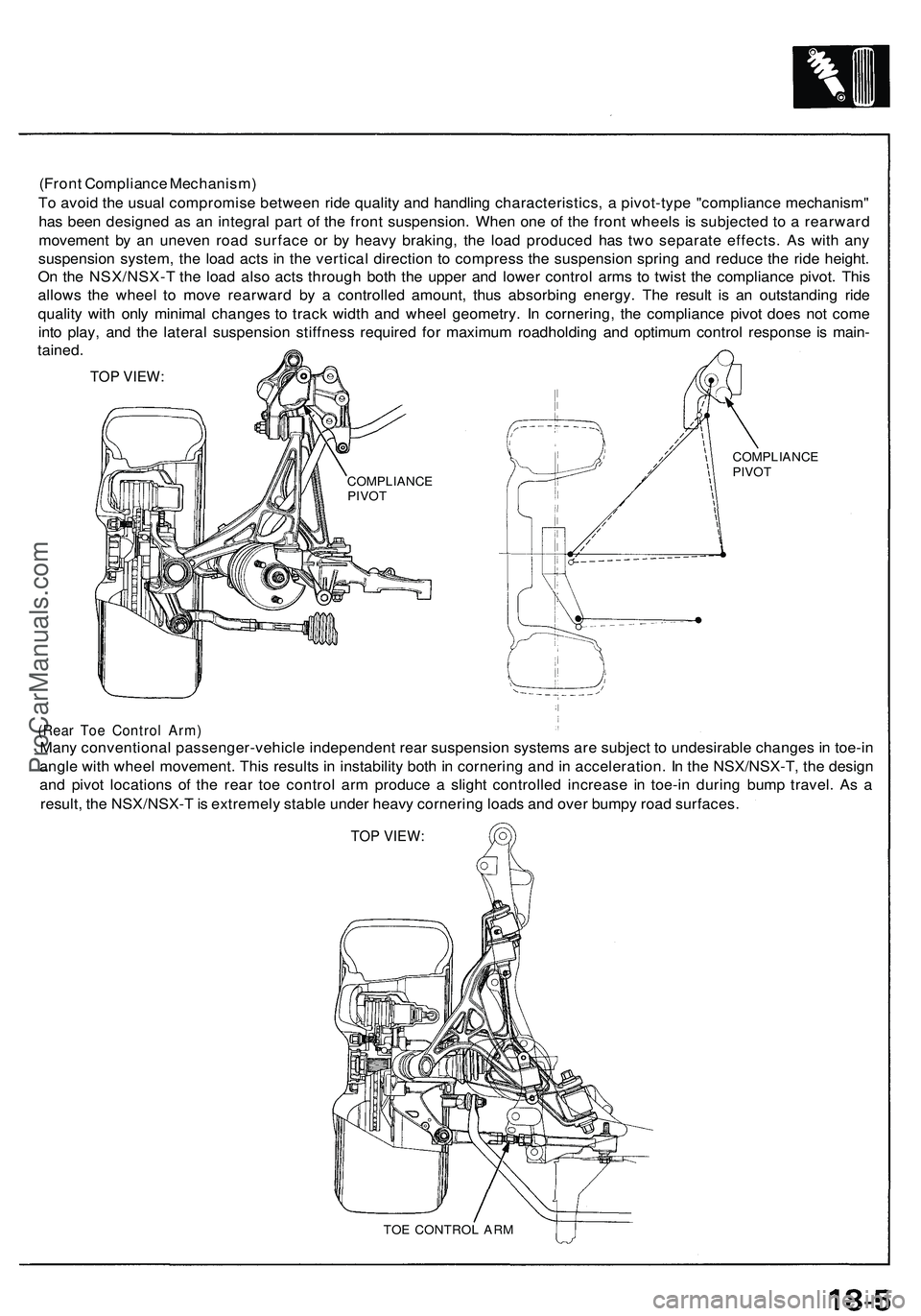

(Front Compliance Mechanism)

To avoid the usual compromise between ride quality and handling characteristics, a pivot-type "compliance mechanism"

has been designed as an integral part of the front suspension. When one of the front wheels is subjected to a rearward

movement by an uneven road surface or by heavy braking, the load produced has two separate effects. As with any

suspension system, the load acts in the vertical direction to compress the suspension spring and reduce the ride height.

On the NSX/NSX-T the load also acts through both the upper and lower control arms to twist the compliance pivot. This

allows the wheel to move rearward by a controlled amount, thus absorbing energy. The result is an outstanding ride

quality with only minimal changes to track width and wheel geometry. In cornering, the compliance pivot does not come

into play, and the lateral suspension stiffness required for maximum roadholding and optimum control response is main-

tained.

TOP VIEW:

(Rear Toe Control Arm)

Many conventional passenger-vehicle independent rear suspension systems are subject to undesirable changes in toe-in

angle with wheel movement. This results in instability both in cornering and in acceleration. In the NSX/NSX-T, the design

and pivot locations of the rear toe control arm produce a slight controlled increase in toe-in during bump travel. As a

result, the NSX/NSX-T is extremely stable under heavy cornering loads and over bumpy road surfaces.

TOP VIEW:

TOE CONTROL ARM

COMPLIANCE

PIVOT

COMPLIANCE

PIVOTProCarManuals.com

Page 940 of 1503

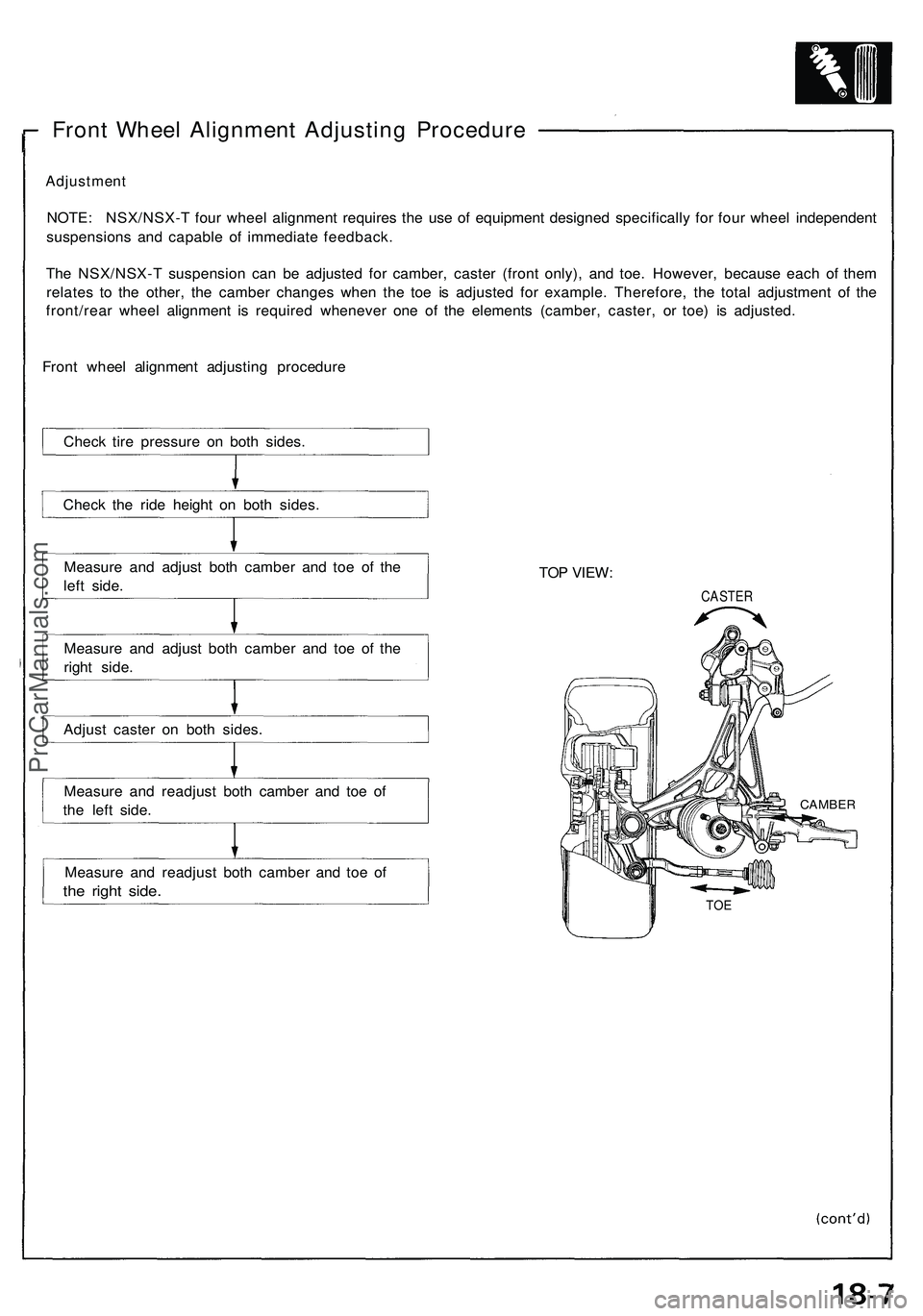

Front Wheel Alignment Adjusting Procedure

Adjustment

NOTE: NSX/NSX-T four wheel alignment requires the use of equipment designed specifically for four wheel independent

suspensions and capable of immediate feedback.

The NSX/NSX-T suspension can be adjusted for camber, caster (front only), and toe. However, because each of them

relates to the other, the camber changes when the toe is adjusted for example. Therefore, the total adjustment of the

front/rear wheel alignment is required whenever one of the elements (camber, caster, or toe) is adjusted.

Front wheel alignment adjusting procedure

Measure and adjust both camber and toe of the

left side.

Measure and adjust both camber and toe of the

right side.

Adjust caster on both sides.

Measure and readjust both camber and toe of

the left side.

Measure and readjust both camber and toe of

the right side.

TOP VIEW:

CASTER

TOE

CAMBER

Check tire pressure on both sides.

Check the ride height on both sides.ProCarManuals.com