drain bolt ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 193 of 1503

Radiator

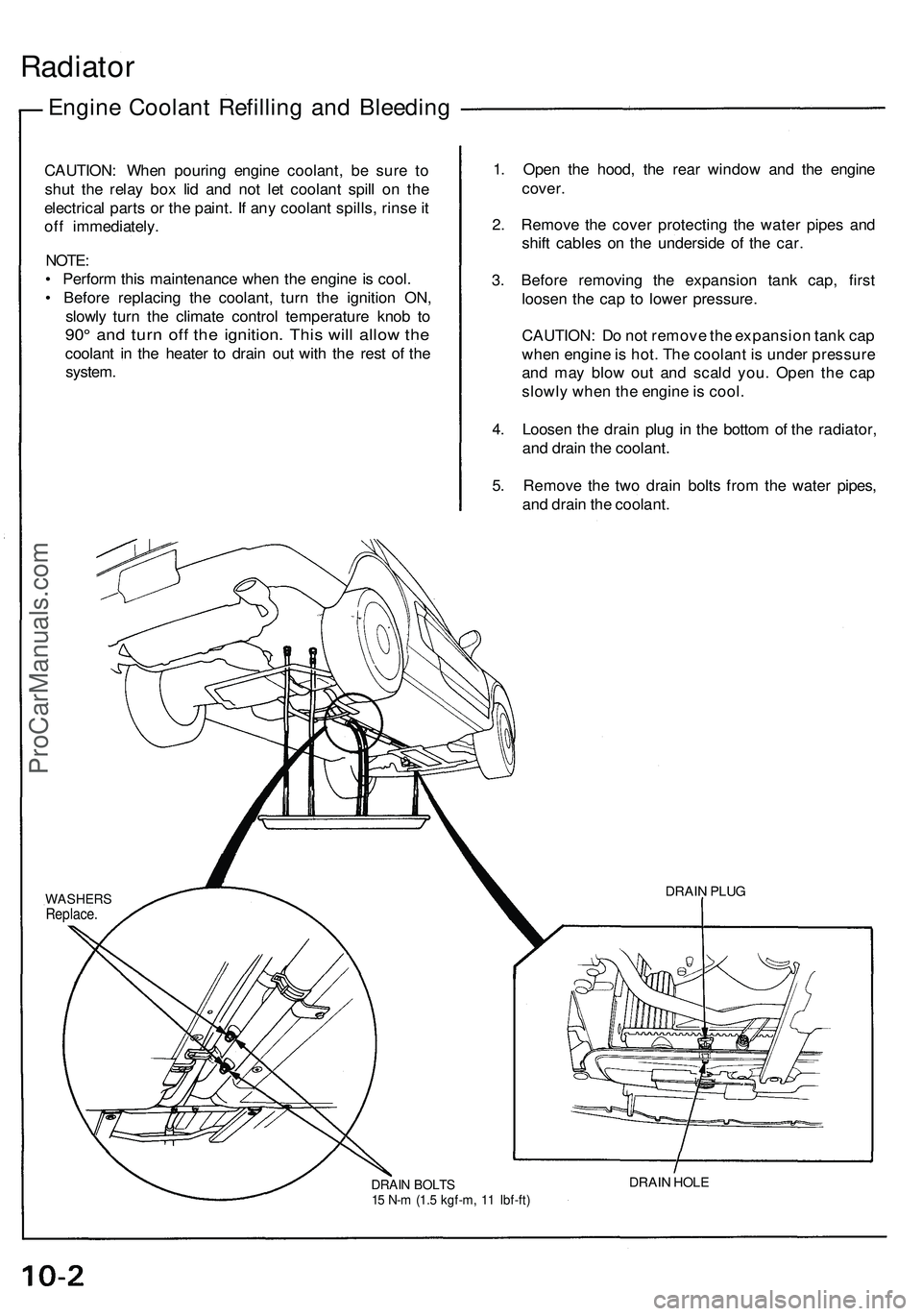

Engine Coolant Refilling and Bleeding

CAUTION: When pouring engine coolant, be sure to

shut the relay box lid and not let coolant spill on the

electrical parts or the paint. If any coolant spills, rinse it

off immediately.

NOTE:

• Perform this maintenance when the engine is cool.

• Before replacing the coolant, turn the ignition ON,

slowly turn the climate control temperature knob to

90° and turn off the ignition. This will allow the

coolant in the heater to drain out with the rest of the

system.

1. Open the hood, the rear window and the engine

cover.

2. Remove the cover protecting the water pipes and

shift cables on the underside of the car.

3. Before removing the expansion tank cap, first

loosen the cap to lower pressure.

CAUTION: Do not remove the expansion tank cap

when engine is hot. The coolant is under pressure

and may blow out and scald you. Open the cap

slowly when the engine is cool.

4. Loosen the drain plug in the bottom of the radiator,

and drain the coolant.

5. Remove the two drain bolts from the water pipes,

and drain the coolant.

DRAIN BOLTS

15 N-m (1.5 kgf-m, 11 Ibf-ft)

DRAIN HOLE

DRAIN PLUG

WASHERS

Replace.ProCarManuals.com

Page 194 of 1503

Engine Coolan t Refillin g an d Bleedin g (cont'd )

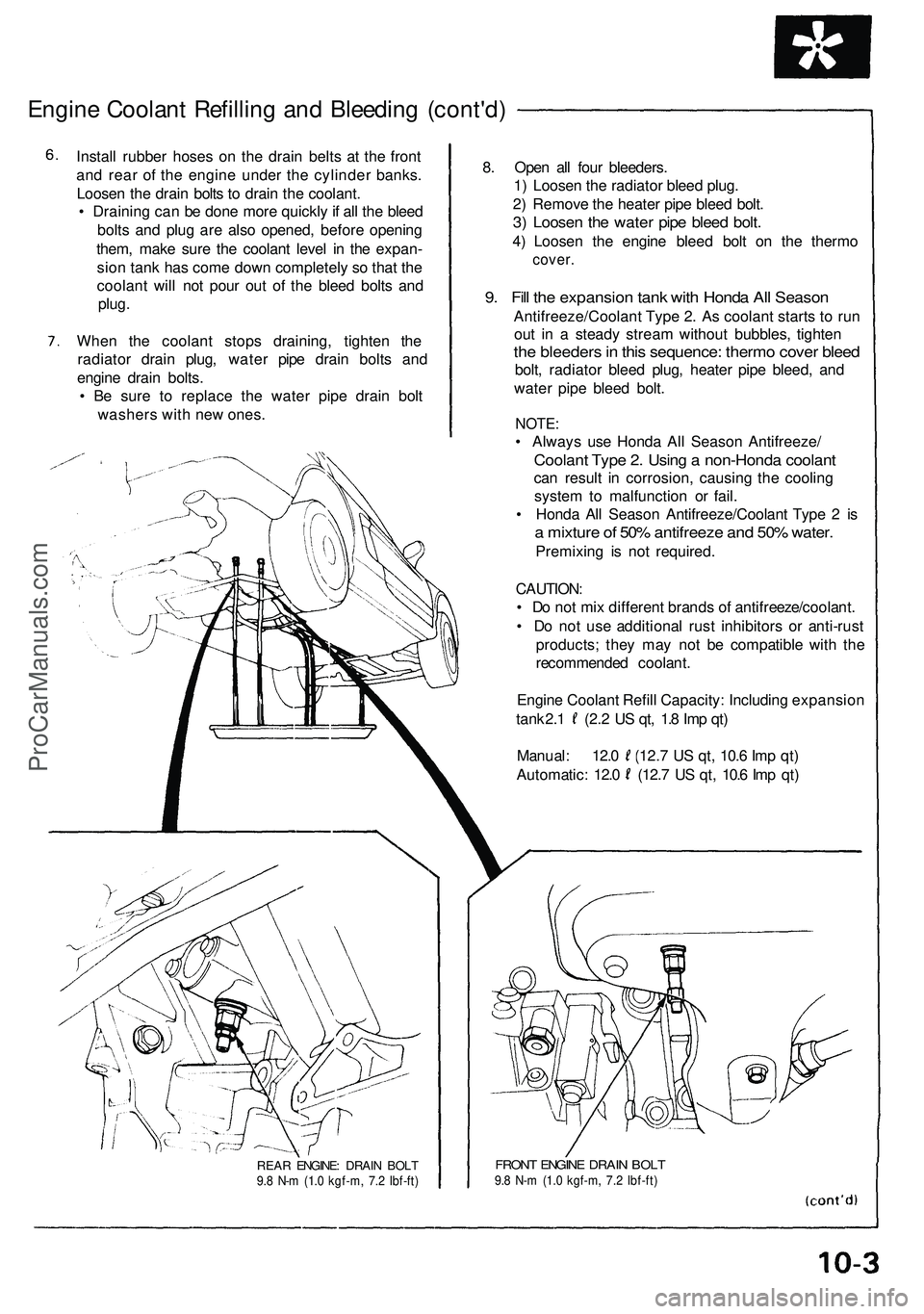

Install rubbe r hose s o n th e drai n belt s a t th e fron t

an d rea r o f th e engin e unde r th e cylinde r banks .

Loose n th e drai n bolt s t o drai n th e coolant .

• Drainin g ca n b e don e mor e quickl y if al l th e blee d

bolt s an d plu g ar e als o opened , befor e openin g

them , mak e sur e th e coolan t leve l i n th e expan -

sio n tan k ha s com e dow n completel y s o tha t th e

coolan t wil l no t pou r ou t o f th e blee d bolt s an d

plug .

Whe n th e coolan t stop s draining , tighte n th e

radiato r drai n plug , wate r pip e drain bolt s an d

engin e drai n bolts .

• B e sur e t o replac e th e wate r pip e drai n bol t

washer s wit h ne w ones . 8

. Ope n al l fou r bleeders .

1 ) Loose n th e radiato r blee d plug .

2 ) Remov e th e heate r pip e blee d bolt .

3) Loose n th e wate r pip e blee d bolt .

4) Loose n th e engin e blee d bol t o n th e therm o

cover.

9. Fil l th e expansio n tan k wit h Hond a Al l Seaso n

Antifreeze/Coolan t Typ e 2 . A s coolan t start s t o ru n

ou t i n a stead y strea m withou t bubbles , tighte n

the bleeder s in thi s sequence : therm o cove r blee d

bolt, radiato r blee d plug , heate r pip e bleed , an d

wate r pip e blee d bolt .

NOTE :

• Alway s us e Hond a Al l Seaso n Antifreeze /

Coolant Typ e 2 . Usin g a non-Hond a coolan t

can resul t i n corrosion , causin g th e coolin g

syste m to malfunctio n o r fail .

• Hond a Al l Seaso n Antifreeze/Coolan t Typ e 2 is

a mixtur e o f 50 % antifreez e an d 50 % water .

Premixin g i s no t required .

CAUTION :

• D o no t mi x differen t brand s o f antifreeze/coolant .

• D o no t us e additiona l rus t inhibitor s o r anti-rus t

products ; the y ma y no t b e compatibl e wit h th e

recommende d coolant .

Engin e Coolan t Refil l Capacity : Includin g expansio n

tank 2. 1 (2. 2 U S qt , 1. 8 Im p qt )

Manual : 12. 0 (12. 7 U S qt , 10. 6 Im p qt )

Automatic : 12. 0 (12. 7 U S qt , 10. 6 Im p qt )

REA R ENGINE : DRAI N BOL T9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )FRON T ENGIN E DRAI N BOL T9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

ProCarManuals.com

Page 521 of 1503

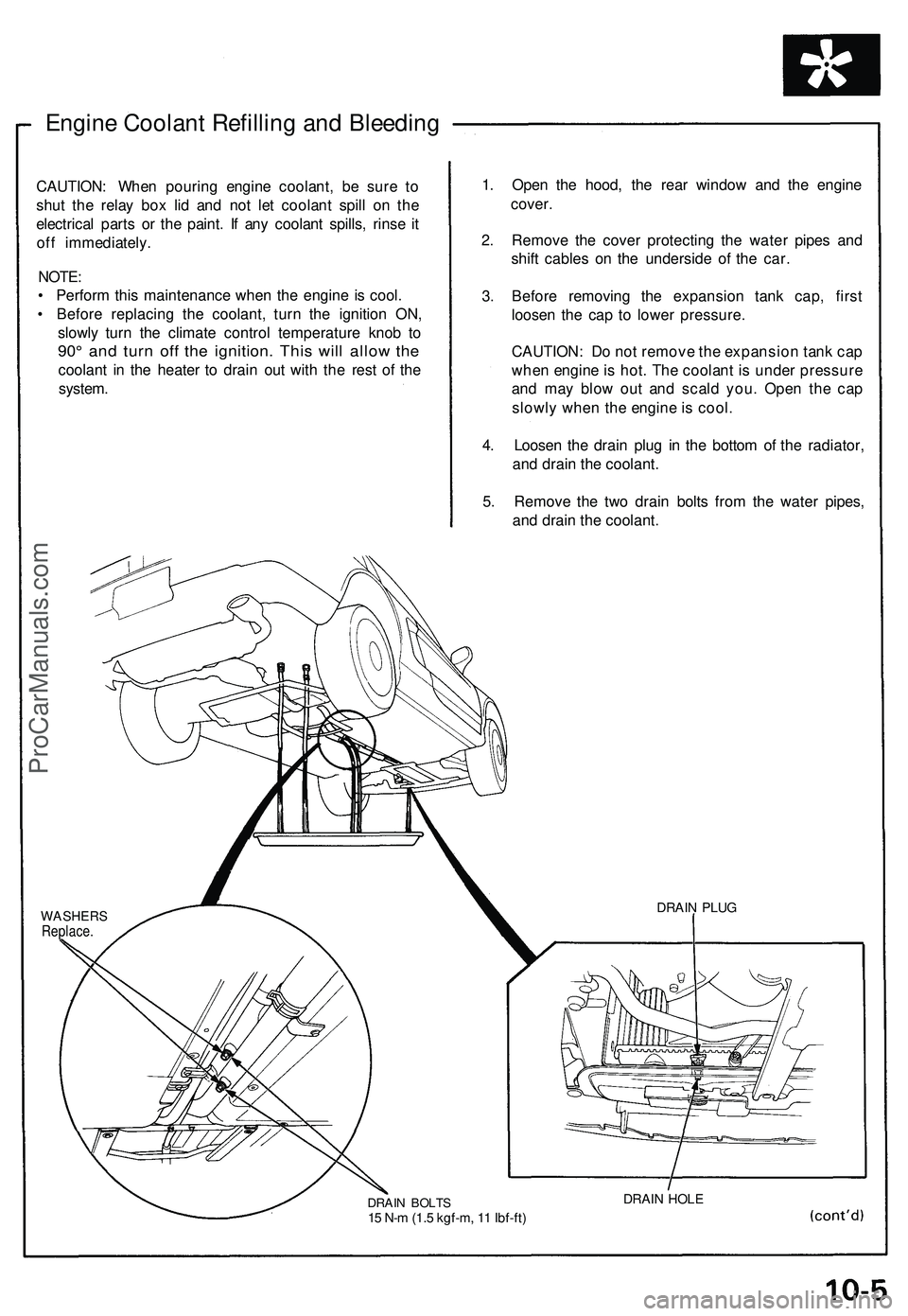

Engine Coolant Refilling and Bleeding

CAUTION: When pouring engine coolant, be sure to

shut the relay box lid and not let coolant spill on the

electrical parts or the paint. If any coolant spills, rinse it

off immediately.

NOTE:

• Perform this maintenance when the engine is cool.

• Before replacing the coolant, turn the ignition ON,

slowly turn the climate control temperature knob to

90° and turn off the ignition. This will allow the

coolant in the heater to drain out with the rest of the

system.

1. Open the hood, the rear window and the engine

cover.

2. Remove the cover protecting the water pipes and

shift cables on the underside of the car.

3. Before removing the expansion tank cap, first

loosen the cap to lower pressure.

CAUTION: Do not remove the expansion tank cap

when engine is hot. The coolant is under pressure

and may blow out and scald you. Open the cap

slowly when the engine is cool.

4. Loosen the drain plug in the bottom of the radiator,

and drain the coolant.

5. Remove the two drain bolts from the water pipes,

and drain the coolant.

WASHERS

Replace.

DRAIN BOLTS

15 N-m (1.5 kgf-m, 11 Ibf-ft)

DRAIN HOLE

DRAIN PLUGProCarManuals.com

Page 522 of 1503

Radiator

Engine Coolan t Refillin g an d Bleedin g (cont'd)

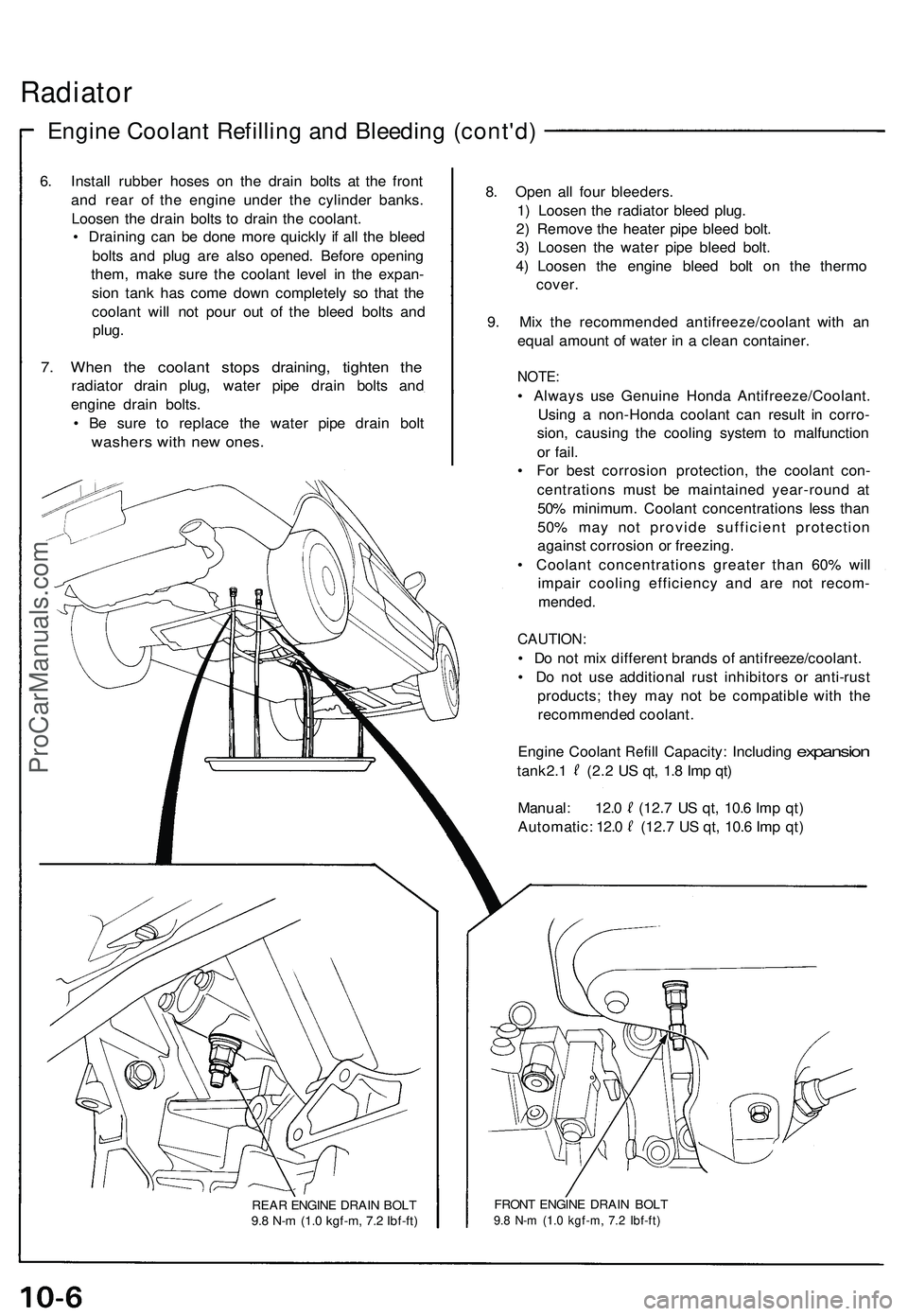

6. Instal l rubbe r hose s o n th e drai n bolt s a t th e fron t

an d rea r o f th e engin e unde r th e cylinde r banks .

Loose n th e drai n bolt s t o drai n th e coolant .

• Drainin g ca n b e don e mor e quickl y i f al l th e blee d

bolt s an d plu g ar e als o opened . Befor e openin g

them , mak e sur e th e coolan t leve l i n th e expan -

sio n tan k ha s com e dow n completel y s o tha t th e

coolan t wil l no t pou r ou t o f th e blee d bolt s an d

plug .

7. Whe n th e coolan t stop s draining , tighte n th e

radiato r drai n plug , wate r pip e drai n bolt s an d

engin e drai n bolts .

• B e sur e t o replac e th e wate r pip e drai n bol t

washer s wit h ne w ones .

REAR ENGIN E DRAI N BOL T

9. 8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

8. Ope n al l fou r bleeders .

1 ) Loose n th e radiato r blee d plug .

2 ) Remov e th e heate r pip e blee d bolt .

3 ) Loose n th e wate r pip e blee d bolt .

4 ) Loose n th e engin e blee d bol t o n th e therm o

cover .

9 . Mi x th e recommende d antifreeze/coolan t wit h a n

equa l amoun t o f wate r i n a clea n container .

NOTE:

• Alway s us e Genuin e Hond a Antifreeze/Coolant .

Usin g a non-Hond a coolan t ca n resul t i n corro -

sion , causin g th e coolin g syste m to malfunctio n

o r fail .

• Fo r bes t corrosio n protection , th e coolan t con -

centration s mus t b e maintaine d year-roun d a t

50 % minimum . Coolan t concentration s les s tha n

50 % ma y no t provid e sufficien t protectio n

agains t corrosio n o r freezing .

• Coolan t concentration s greate r tha n 60 % wil l

impai r coolin g efficienc y an d ar e no t recom -

mended .

CAUTION :

• D o no t mi x differen t brand s o f antifreeze/coolant .

• D o no t us e additiona l rus t inhibitor s o r anti-rus t

products ; the y ma y no t b e compatibl e wit h th e

recommende d coolant .

Engin e Coolan t

Refill Capacity : Includin g expansion

tank 2. 1 (2. 2 U S qt , 1. 8 Im p qt )

Manual : 12. 0 (12. 7 U S qt , 10. 6 Im p qt )

Automatic : 12. 0 (12. 7 U S qt , 10. 6 Im p qt )

FRON T ENGIN E DRAI N BOL T9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

ProCarManuals.com

Page 526 of 1503

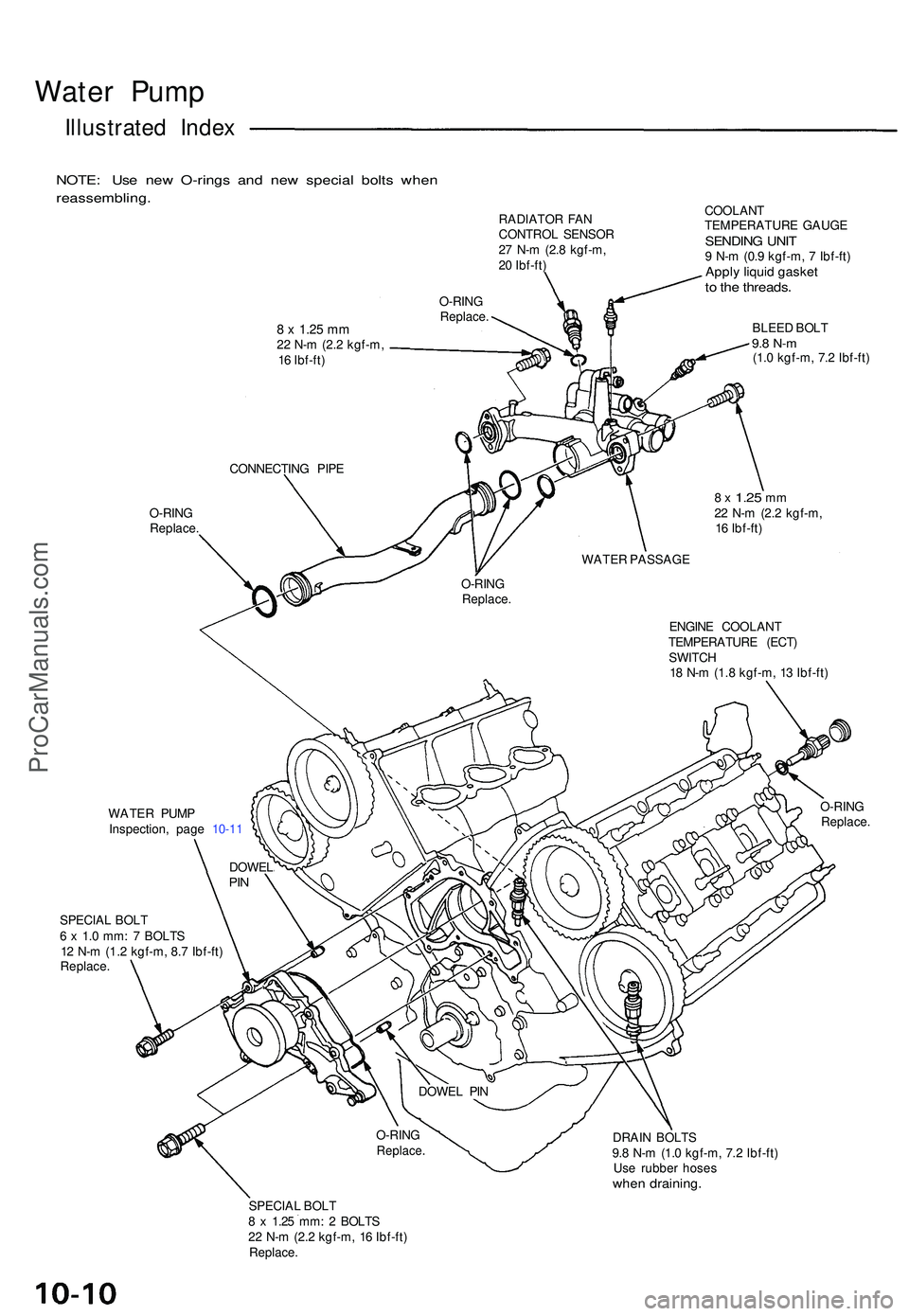

Water Pum p

Illustrate d Inde x

NOTE : Us e ne w O-ring s an d ne w specia l bolt s whe n

reassembling .

RADIATOR FA N

CONTRO L SENSO R

2 7 N- m (2. 8 kgf-m ,

2 0 Ibf-ft )

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft ) O-RIN

G

Replace .

O-RING

Replace . COOLAN

T

TEMPERATUR E GAUG E

SENDIN G UNI T9 N- m (0. 9 kgf-m , 7 Ibf-ft )Apply liqui d gaske tto th e threads .

BLEED BOL T9.8 N- m(1.0 kgf-m , 7. 2 Ibf-ft )

CONNECTIN G PIP E

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

WATE R PASSAG E

O-RIN G

Replace .

ENGINE COOLAN T

TEMPERATUR E (ECT )

SWITC H

1 8 N- m (1. 8 kgf-m , 1 3 Ibf-ft )

WATE R PUM P

Inspection , pag e 10-1 1 O-RIN

G

Replace .

SPECIAL BOL T

6 x 1. 0 mm : 7 BOLT S

1 2 N- m (1.2 kgf-m , 8. 7 Ibf-ft )

Replace .

DRAIN BOLT S

9. 8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

Us e rubbe r hose s

when draining .

SPECIAL BOL T

8 x 1.2 5 mm : 2 BOLT S

2 2 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

Replace .

DOWELPIN

DOWE L PI N

O-RIN G

Replace .

ProCarManuals.com

Page 621 of 1503

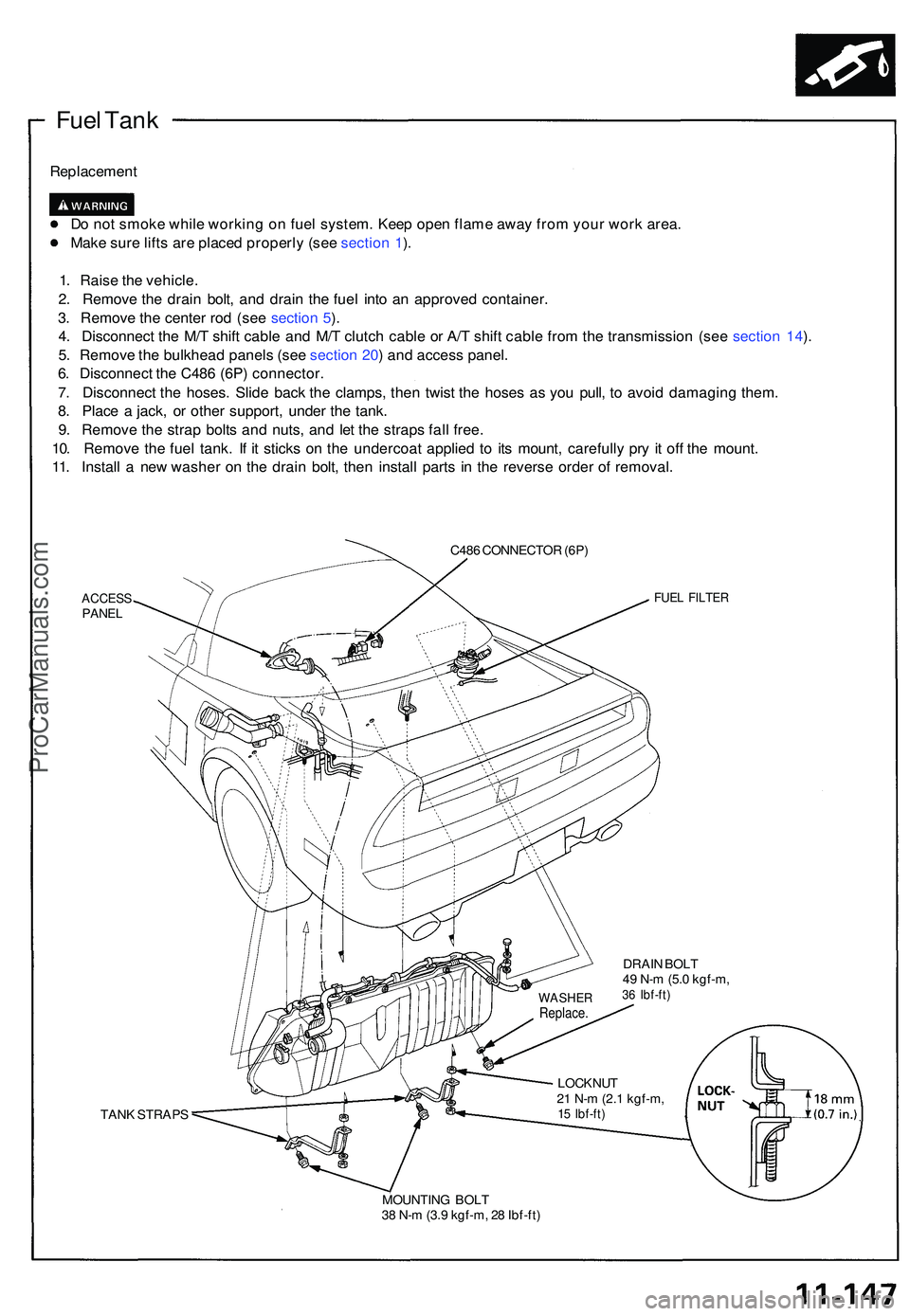

Fuel Tan k

Replacemen t

D o no t smok e whil e workin g o n fue l system . Kee p ope n flam e awa y fro m you r wor k area .

Mak e sur e lift s ar e place d properl y (se e sectio n 1 ).

1 . Rais e th e vehicle .

2 . Remov e th e drai n bolt , an d drai n th e fue l int o a n approve d container .

3 . Remov e th e cente r ro d (se e sectio n 5 ).

4 . Disconnec t th e M/ T shif t cabl e an d M/ T clutc h cabl e o r A/ T shif t cabl e fro m th e transmissio n (se e sectio n 14 ).

5 . Remov e th e bulkhea d panel s (se e sectio n 20 ) an d acces s panel .

6 . Disconnec t th e C48 6 (6P ) connector .

7 . Disconnec t th e hoses . Slid e bac k th e clamps , the n twis t th e hose s a s yo u pull , t o avoi d damagin g them .

8 . Plac e a jack , o r othe r support , unde r th e tank .

9 . Remov e th e stra p bolt s an d nuts , an d le t th e strap s fal l free .

10 . Remov e th e fue l tank . I f i t stick s o n th e undercoa t applie d t o it s mount , carefull y pr y i t of f th e mount .

11 . Instal l a ne w washe r o n th e drai n bolt , the n instal l part s i n th e revers e orde r o f removal .

C486 CONNECTO R (6P )

ACCES SPANELFUEL FILTE R

DRAIN BOL T

4 9 N- m (5. 0 kgf-m ,

36 Ibf-ft )

TANK STRAP S LOCKNU

T

2 1 N- m (2. 1 kgf-m ,15 Ibf-ft )

MOUNTIN G BOL T

3 8 N- m (3. 9 kgf-m , 2 8 Ibf-ft )

WASHE RReplace.

ProCarManuals.com

Page 665 of 1503

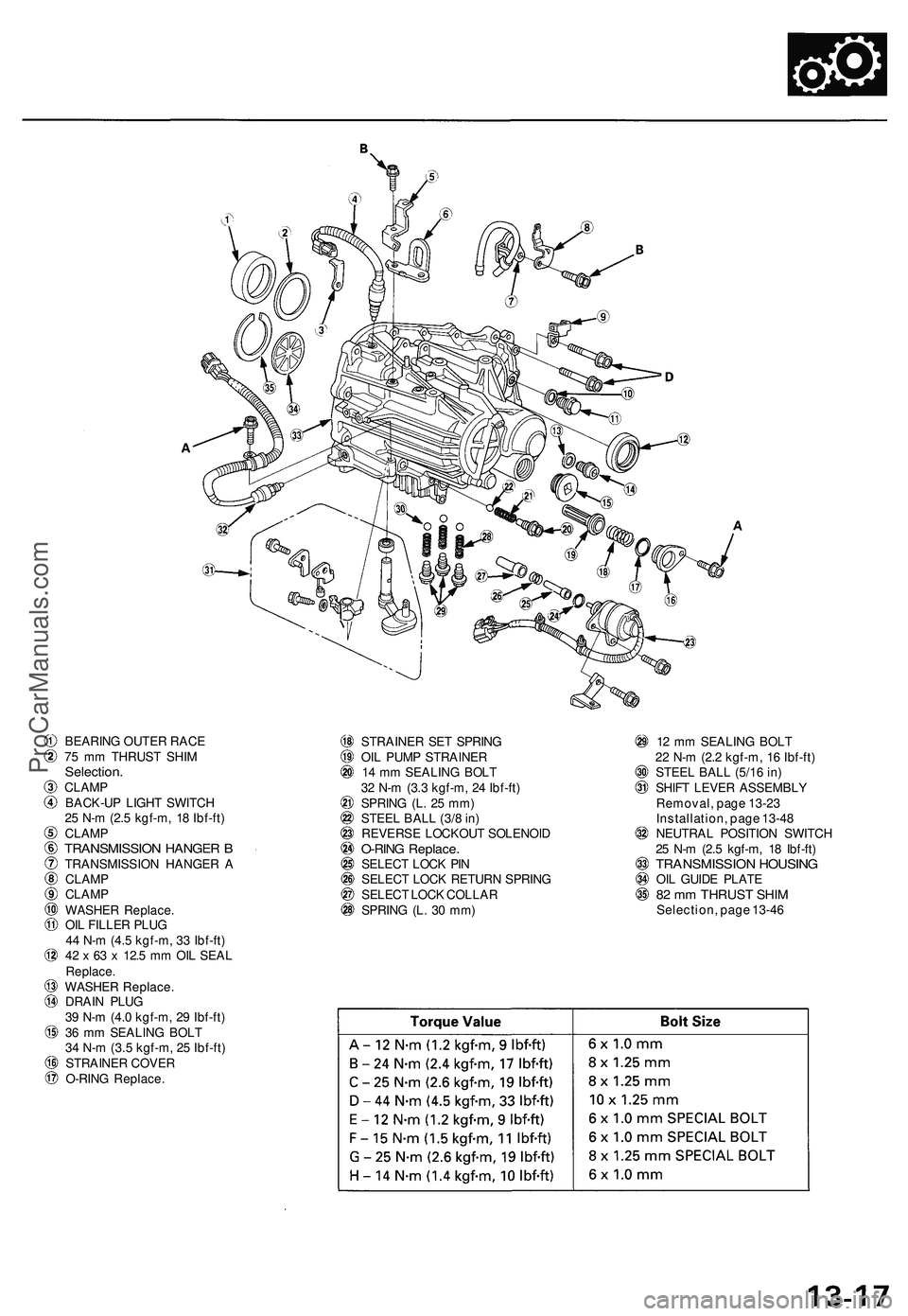

BEARING OUTER RACE

75 mm THRUST SHIM

Selection.

CLAMP

BACK-UP LIGHT SWITCH

25 N-m (2.5 kgf-m, 18 Ibf-ft)

CLAMP

TRANSMISSION HANGER B

TRANSMISSION HANGER A

CLAMP

CLAMP

WASHER Replace.

OIL FILLER PLUG

44 N-m (4.5 kgf-m, 33 Ibf-ft)

42 x 63 x 12.5 mm OIL SEAL

Replace.

WASHER Replace.

DRAIN PLUG

39 N-m (4.0 kgf-m, 29 Ibf-ft)

36 mm SEALING BOLT

34 N-m (3.5 kgf-m, 25 Ibf-ft)

STRAINER COVER

O-RING Replace.

STRAINER SET SPRING

OIL PUMP STRAINER

14 mm SEALING BOLT

32 N-m (3.3 kgf-m, 24 Ibf-ft)

SPRING (L. 25 mm)

STEEL BALL (3/8 in)

REVERSE LOCKOUT SOLENOID

O-RING Replace.

SELECT LOCK PIN

SELECT LOCK RETURN SPRING

SELECT LOCK COLLAR

SPRING (L. 30 mm)

12 mm SEALING BOLT

22 N-m (2.2 kgf-m, 16 Ibf-ft)

STEEL BALL (5/16 in)

SHIFT LEVER ASSEMBLY

Removal, page 13-23

Installation, page 13-48

NEUTRAL POSITION SWITCH

25 N-m (2.5 kgf-m, 18 Ibf-ft)

TRANSMISSION HOUSING

OIL GUIDE PLATE

82 mm THRUST SHIM

Selection, page 13-46ProCarManuals.com

Page 713 of 1503

Description

The automatic transmission is a combination of a 3-element torque converter and a triple-shaft electronically controlled

automatic transmission which provides 4 speeds forward and 1 speed reverse. The entire unit is positioned in line with the

engine.

Torque Converter, Gears, and Clutches

The torque converter consists of a pump, turbine, and stator, assembled in a single unit.

They are connected to the engine crankshaft so they turn together as a unit as the engine turns.

Around the outside of the torque converter is a ring gear which meshes with the starter pinion when the engine is being

started. The entire torque converter assembly serves as a flywheel while transmitting power to the transmission main-

shaft. The transmission has three parallel shafts: the mainshaft, the countershaft, and the secondary shaft. The mainshaft

is in line with the engine crankshaft.

The mainshaft includes the 1st and 4th clutches, and gears for 3rd, 4th, reverse, and 1st (3rd gear is integral with the main-

shaft, while reverse gear is integral with 4th gear).

The countershaft includes the 1st-hold and 3rd clutches, and gears for 2nd, 3rd, 4th, reverse, 1st, and parking.

The secondary shaft includes the 2nd clutch and gears for 2nd and 3rd.

The 4th and reverse gears can be locked to the countershaft at its center, providing 4th gear or reverse, depending on

which way the selector is moved.

The gears on the mainshaft and secondary shaft are in constant mesh with those on the countershaft.

When certain combinations of gears in the transmission are engaged by clutches, power is transmitted from the mainshaft

to the countershaft to provide positions.

Electronic Control

The electronic control system consists of the Transmission Control Module (TCM), sensors, a linear solenoid, a shift switch,

and 4 solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located on the insulator center bulkhead, behind the driver's seat.

Hydraulic Control

The valve bodies include the main valve body, secondary valve body, servo body, regulator valve body, throttle valve

body, lock-up valve body, and the 2nd accumulator body.

They are bolted to the torque converter housing as an assembly.

The main valve body contains the manual valve, 1-2 shift valve, 2-3 shift valve, 3-4 shift valve, relief valve, one-way relief

valve, and oil pump gears.

The secondary valve body contains the 3-2 kick-down valve, clutch pressure control (CPC) valve, 2nd orifice control valve, 3rd

orifice control valve, modulator valve, 4th exhaust valve, servo control valve, 2nd exhaust valve, and 4-3 kick-down valve.

The servo body contains the accumulator pistons and servo valve. The throttle valve body includes the throttle valve B

which is bolted to the servo body.

The regulator valve body contains the pressure regulator valve, lock-up control valve, and cooler relief valve. Fluid from

the regulator passes through the manual valve to the various control valves.

The lock-up valve body contains the lock-up timing B valve and lock-up shift valve. The 2nd accumulator body contains

the accumulator pistons and limited slip differential relief valve.

The torque converter check valve is located in the torque converter housing, under the main valve body.

The 1st, 1st-hold, 3rd, and 4th clutches receive fluid from their respective feed pipes and the 2nd clutch receives fluid from

the internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the vehicle determines which shift control solenoid valve the TCM will acti-

vate. Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes

a line to one of the clutches, engaging that clutch and its corresponding gear.

Lock-up Mechanism

In position and position in 2nd, 3rd, and 4th, pressurized fluid is drained from the back of the torque converter

through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes place, the

mainshaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the TCM optimizes the tim-

ing of the lock-up mechanism.

The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and B, and throttle valve B.

When lock-up control solenoid valves A and B activate, modulator pressure changes. The lock-up control solenoid valves

A and B are mounted on the torque converter housing, and are controlled by the TCM.

(cont'd)ProCarManuals.com

Page 1204 of 1503

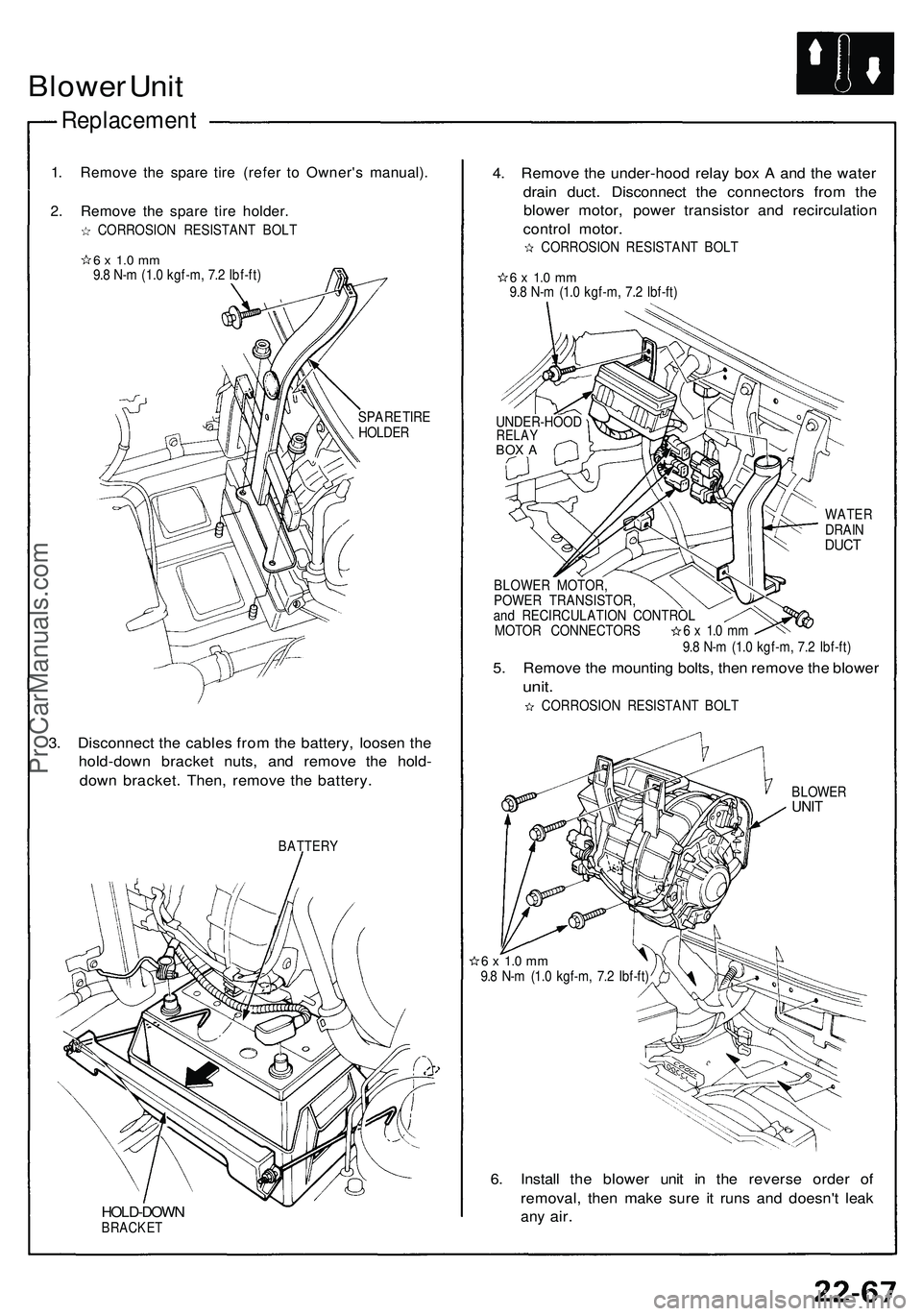

Blower Uni t

Replacemen t

1. Remov e th e spar e tir e (refe r t o Owner' s manual) .

2. Remov e th e spar e tir e holder .

CORROSIO N RESISTAN T BOL T

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

SPARE TIR E

HOLDE R

3. Disconnec t th e cable s fro m th e battery , loose n th e

hold-dow n bracke t nuts , an d remov e th e hold -

dow n bracket . Then , remov e th e battery .

BATTER Y

HOLD-DOW NBRACKET

4. Remov e th e under-hoo d rela y bo x A an d th e wate r

drai n duct . Disconnec t th e connector s fro m th e

blowe r motor , powe r transisto r an d recirculatio n

contro l motor .

CORROSIO N RESISTAN T BOL T

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

WATE RDRAINDUCT

BLOWE R MOTOR ,

POWE R TRANSISTOR ,

an d RECIRCULATIO N CONTRO L

MOTOR CONNECTOR S 6 x 1. 0 m m

9. 8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

5. Remov e th e mountin g bolts , the n remov e th e blowe r

unit.

CORROSIO N RESISTAN T BOL T

BLOWE RUNIT

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

6. Instal l th e blowe r uni t i n th e revers e orde r o f

removal , the n mak e sur e i t run s an d doesn' t lea k

any air .

UNDER-HOO DRELAYBOX A

ProCarManuals.com

Page 1206 of 1503

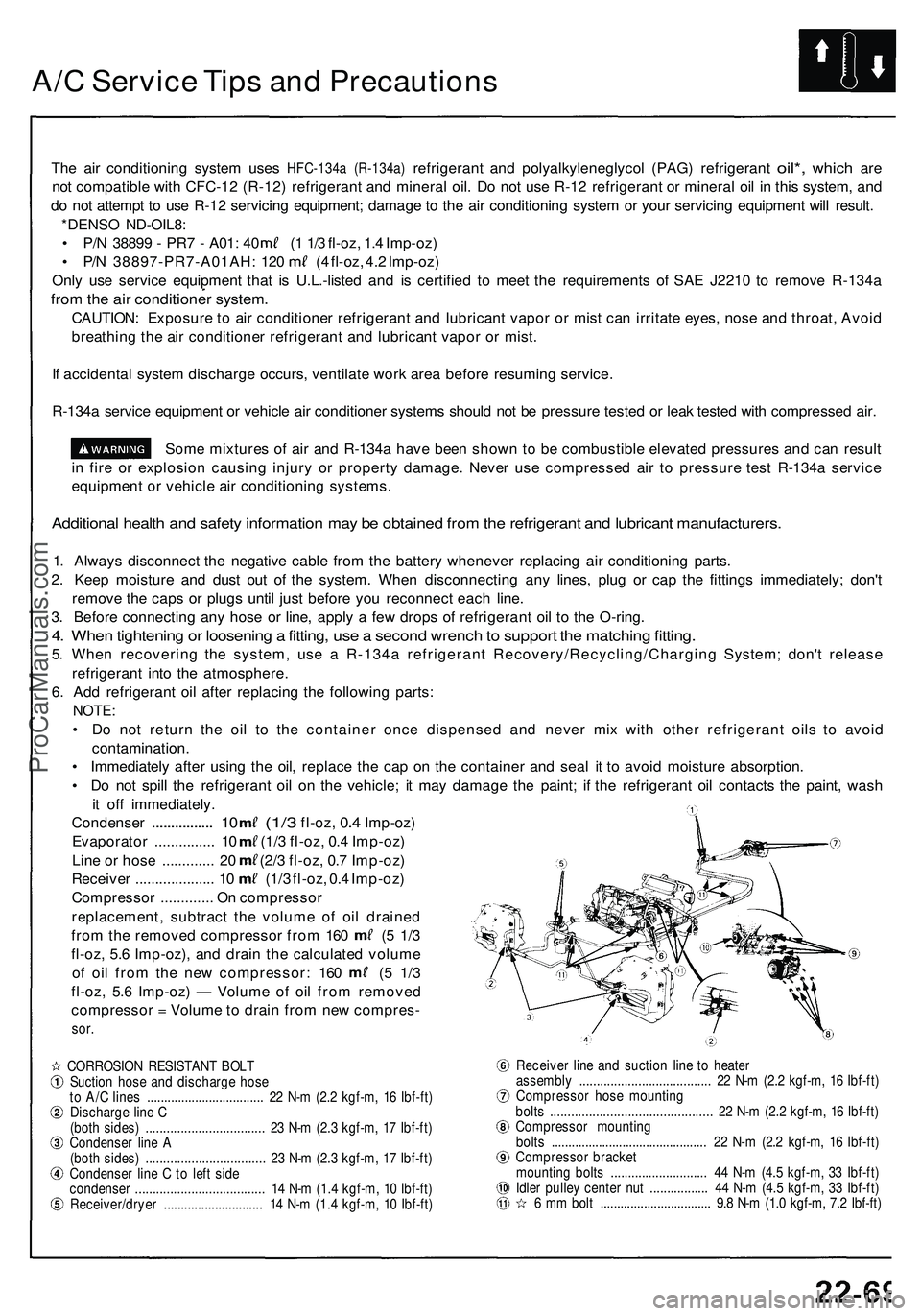

A/C Servic e Tip s an d Precaution s

The ai r conditionin g syste m use s HFC-134 a (R-134a ) refrigeran t and polyalkyleneglyco l (PAG ) refrigeran t oil*, whic h are

not compatibl e wit h CFC-1 2 (R-12 ) refrigeran t an d minera l oil . D o no t us e R-1 2 refrigeran t o r minera l oi l i n thi s system , an d

d o no t attemp t t o us e R-1 2 servicin g equipment ; damag e t o th e ai r conditionin g syste m o r you r servicin g equipmen t wil l result .

*DENS O ND-OIL8 :

• P/N 3889 9 - PR 7 - A01 : 4 0 ( 1 1/ 3 fl-oz , 1. 4 Imp-oz )

• P/ N 38897-PR7-A01AH : 12 0 ( 4 fl-oz , 4. 2 Imp-oz )

Onl y us e servic e equipmen t tha t i s U.L.-liste d an d i s certifie d t o mee t th e requirement s o f SA E J221 0 t o remov e R-134 a

from th e ai r conditione r system .

CAUTION : Exposur e t o ai r conditione r refrigeran t an d lubrican t vapo r o r mis t ca n irritat e eyes , nos e an d throat , Avoi d

breathin g th e ai r conditione r refrigeran t an d lubrican t vapo r o r mist .

I f accidenta l syste m discharg e occurs , ventilat e wor k are a befor e resumin g service .

R-134 a servic e equipmen t o r vehicl e ai r conditione r system s shoul d no t b e pressur e teste d o r lea k teste d wit h compresse d air .

Som e mixture s o f ai r an d R-134 a hav e bee n show n t o b e combustibl e elevate d pressure s an d ca n resul t

i n fir e o r explosio n causin g injur y o r propert y damage . Neve r us e compresse d ai r t o pressur e tes t R-134 a servic e

equipmen t o r vehicl e ai r conditionin g systems .

Additional healt h an d safet y informatio n ma y b e obtaine d fro m th e refrigeran t an d lubrican t manufacturers .

1. Alway s disconnec t th e negativ e cabl e fro m th e batter y wheneve r replacin g ai r conditionin g parts .

2 . Kee p moistur e an d dus t ou t o f th e system . Whe n disconnectin g an y lines , plu g o r ca p th e fitting s immediately ; don' t

remov e th e cap s o r plug s unti l jus t befor e yo u reconnec t eac h line .

3 . Befor e connectin g an y hos e o r line , appl y a fe w drop s o f refrigeran t oi l t o th e O-ring .

4. Whe n tightenin g o r loosenin g a fitting , us e a secon d wrenc h to suppor t th e matchin g fitting .

5. Whe n recoverin g th e system , us e a R-134 a refrigeran t Recovery/Recycling/Chargin g System ; don' t releas e

refrigeran t int o th e atmosphere .

6 . Ad d refrigeran t oi l afte r replacin g th e followin g parts :

NOTE :

• D o no t retur n th e oi l t o th e containe r onc e dispense d an d neve r mi x wit h othe r refrigeran t oil s t o avoi d

contamination .

• Immediatel y afte r usin g th e oil , replac e th e ca p o n th e containe r an d sea l i t t o avoi d moistur e absorption .

• D o no t spil l th e refrigeran t oi l o n th e vehicle ; i t ma y damag e th e paint ; i f th e refrigeran t oi l contact s th e paint , was h

i t of f immediately .

Condense r

............... . 1 0 (1/ 3 fl-oz, 0.4 Imp-oz )

Evaporato r .............. . 1 0 (1/ 3 fl-oz , 0. 4 Imp-oz )

Lin e o r hos e ............ . 2 0 (2/ 3 fl-oz , 0. 7 Imp-oz )

Receive r ................... . 1 0 (1/ 3 fl-oz , 0. 4 Imp-oz )

Compresso r ............ . O n compresso r

replacement , subtrac t th e volum e o f oi l draine d

from th e remove d compresso r fro m 16 0 ( 5 1/ 3

fl-oz , 5. 6 Imp-oz) , an d drai n th e calculate d volum e

of oi l fro m th e ne w compressor : 16 0 ( 5 1/ 3

fl-oz , 5. 6 Imp-oz ) — Volum e o f oi l fro m remove d

compresso r = Volum e t o drai n fro m ne w compres -

sor.

CORROSIO N RESISTAN T BOL T

Suctio n hos e an d discharg e hos e

t o A/ C line s ................................. . 2 2 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

Discharg e lin e C

(bot h sides ) .................................. 23 N- m (2. 3 kgf-m , 1 7 Ibf-ft )

Condense r lin e A

(bot h sides ) ................................. . 2 3 N- m (2. 3 kgf-m , 1 7 Ibf-ft )

Condense r lin e C to lef t sid e

condense r .................................... . 1 4 N- m (1. 4 kgf-m , 1 0 Ibf-ft )

Receiver/drye r ............................ . 1 4 N- m (1. 4 kgf-m , 1 0 Ibf-ft ) Receive

r lin e an d suctio n lin e t o heate r

assembl y ..................................... . 2 2 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

Compresso r hos e mountin g

bolt s ............................................. . 2 2 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

Compresso r mountin g

bolt s ............................................. . 2 2 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

Compresso r bracke t

mountin g bolt s ........................... . 4 4 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

Idle r pulle y cente r nu t ................ . 4 4 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

6 m m bol t ................................ . 9. 8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

ProCarManuals.com