fog light ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 64 of 1503

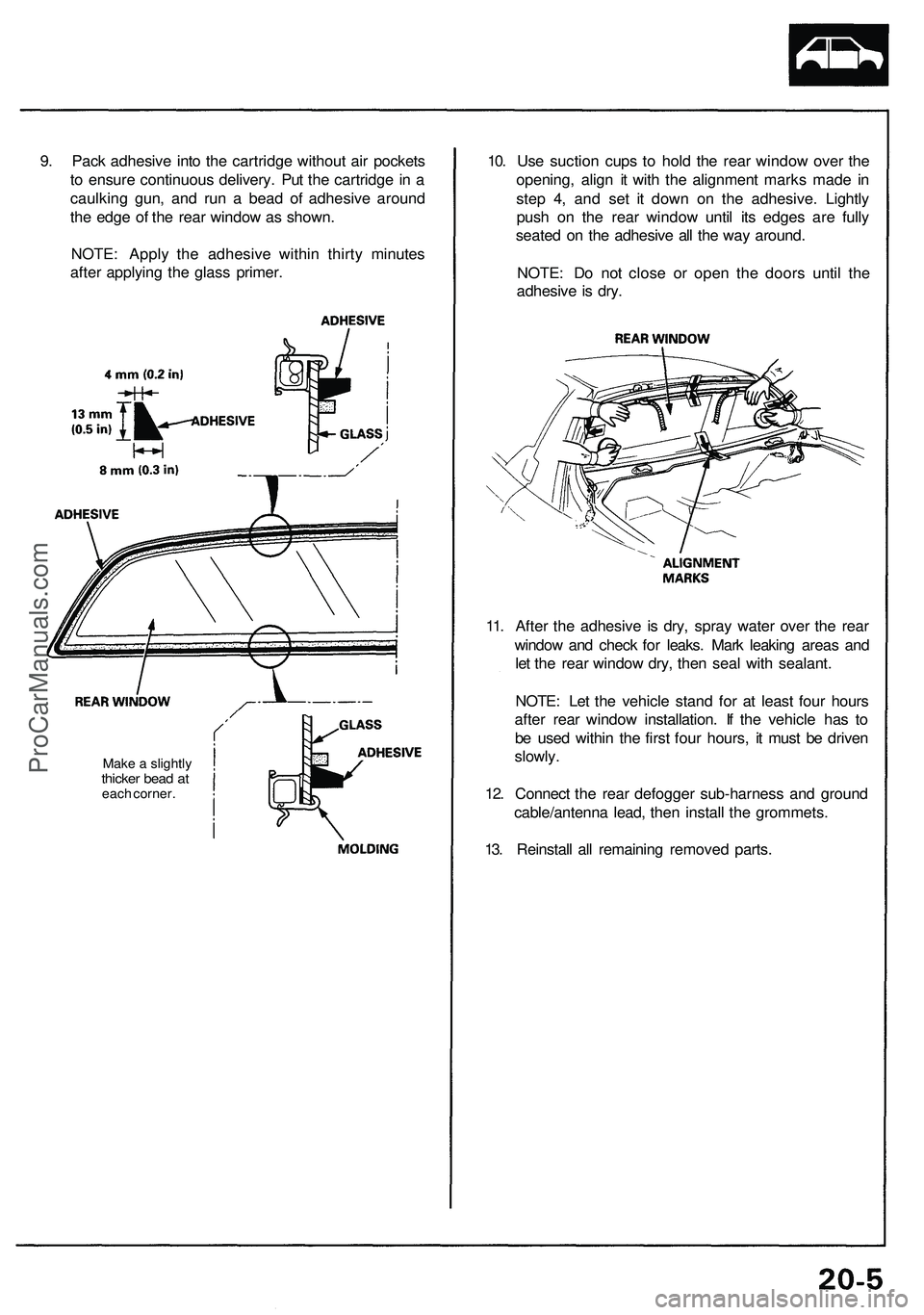

9. Pack adhesive into the cartridge without air pockets

to ensure continuous delivery. Put the cartridge in a

caulking gun, and run a bead of adhesive around

the edge of the rear window as shown.

NOTE: Apply the adhesive within thirty minutes

after applying the glass primer.

Make a slightly

thicker bead at

each corner.

10. Use suction cups to hold the rear window over the

opening, align it with the alignment marks made in

step 4, and set it down on the adhesive. Lightly

push on the rear window until its edges are fully

seated on the adhesive all the way around.

NOTE: Do not close or open the doors until the

adhesive is dry.

11. After the adhesive is dry, spray water over the rear

window and check for leaks. Mark leaking areas and

let the rear window dry, then seal with sealant.

NOTE: Let the vehicle stand for at least four hours

after rear window installation. If the vehicle has to

be used within the first four hours, it must be driven

slowly.

12. Connect the rear defogger sub-harness and ground

cable/antenna lead, then install the grommets.

13. Reinstall all remaining removed parts.ProCarManuals.com

Page 595 of 1503

Idle Contro l Syste m

Alternato r (ALT ) F R Signa l

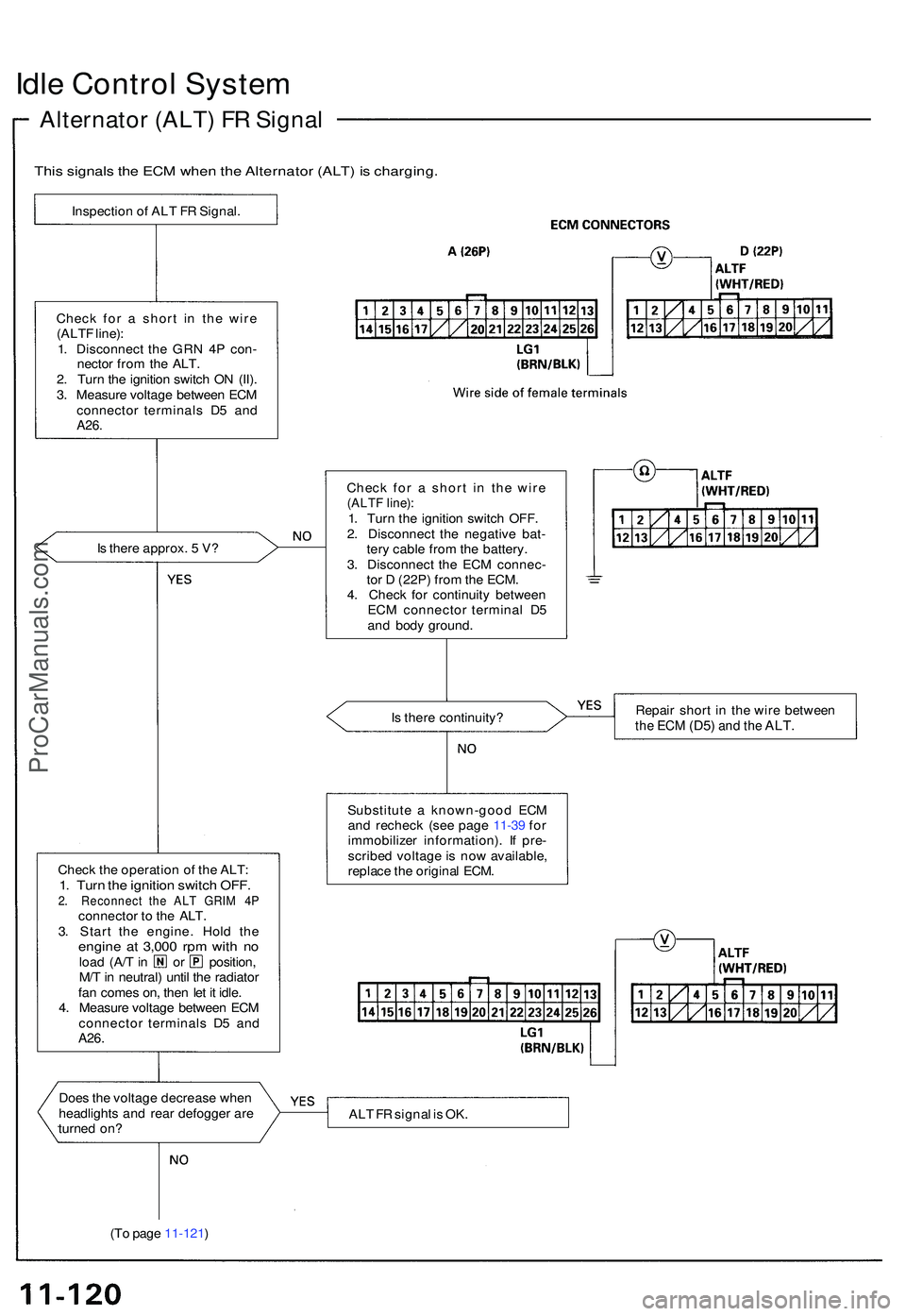

This signal s th e EC M whe n th e Alternato r (ALT ) i s charging .

Inspection o f AL T F R Signal .

Chec k fo r a shor t i n th e wir e

(ALT F line) :

1 . Disconnec t th e GR N 4 P con -

necto r fro m th e ALT .

2 . Tur n th e ignitio n switc h O N (II) .

3 . Measur e voltag e betwee n EC M

connecto r terminal s D 5 an d

A26.

Is ther e approx . 5 V ?

Chec k th e operatio n o f th e ALT :

1. Tur n th e ignitio n switc h OFF .2. Reconnec t th e AL T GRI M 4 Pconnecto r t o th e ALT .

3 . Star t th e engine . Hol d th e

engin e a t 3,00 0 rp m wit h n oloa d (A/ T in o r position ,

M/ T in neutral ) unti l th e radiato r

fa n come s on , the n le t i t idle .

4 . Measur e voltag e betwee n EC M

connecto r terminal s D 5 an d

A26 .

I

Doe s th e voltag e decreas e whe n

headlight s an d rea r defogge r ar e

turne d on ?

(T o pag e 11-121 ) Chec

k fo r a shor t i n th e wir e

(ALT F line) :1. Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e negativ e bat -

ter y cabl e fro m th e battery .

3 . Disconnec t th e EC M connec -

to r D (22P ) fro m th e ECM .

4 . Chec k fo r continuit y betwee n

EC M connecto r termina l D 5

an d bod y ground .

I s ther e continuity ? Repai

r shor t i n th e wir e betwee n

the EC M (D5 ) and th e ALT .

Substitut e a known-goo d EC M

an d rechec k (se e pag e 11-3 9 fo r

immobilize r information) . I f pre -

scribe d voltag e is no w available ,

replac e th e origina l ECM .

AL T F R signa l i s OK .

ProCarManuals.com

Page 604 of 1503

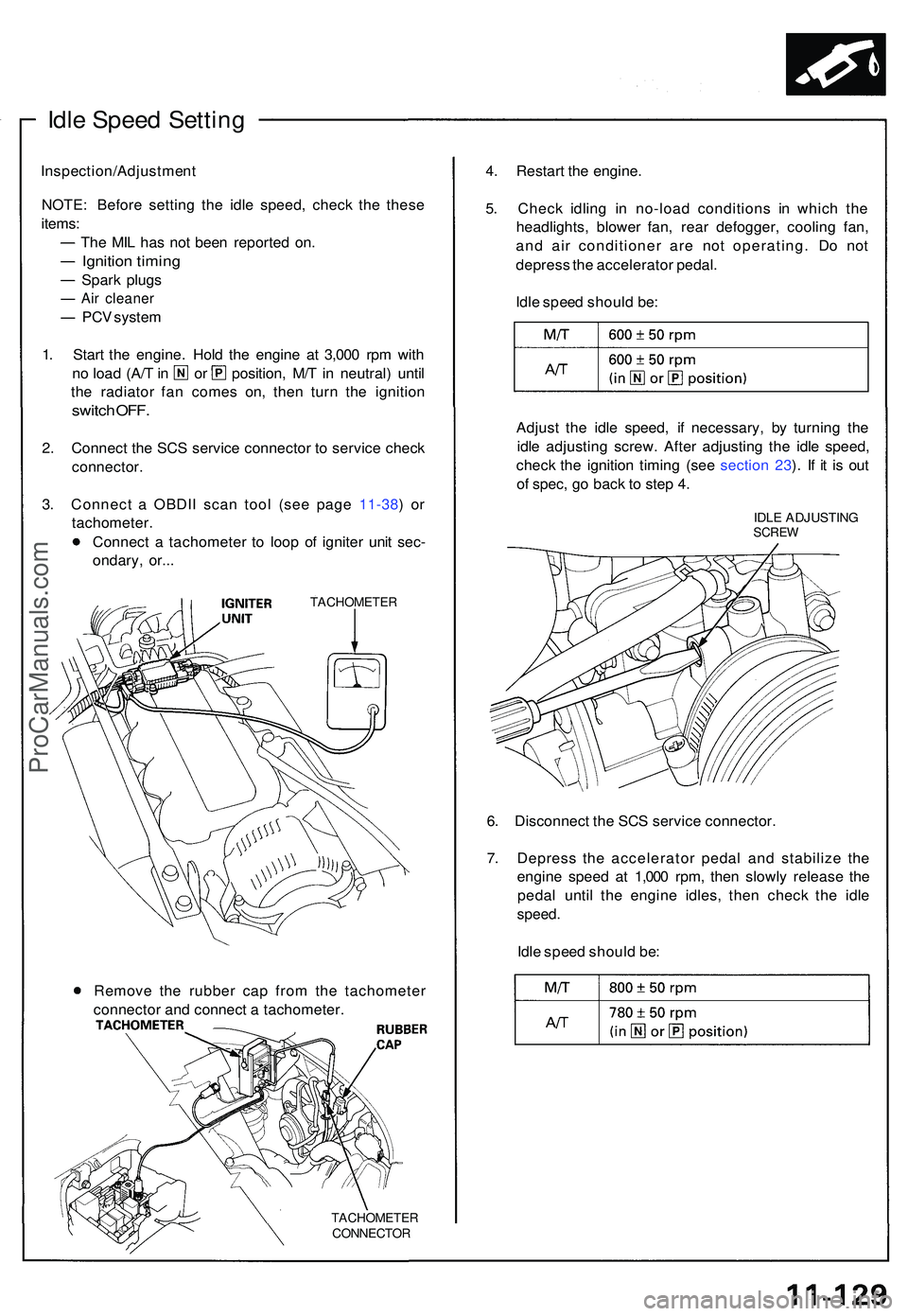

Idle Spee d Settin g

Inspection/Adjustmen t

NOTE : Befor e settin g th e idl e speed , chec k th e thes e

items :

Th e MI L ha s no t bee n reporte d on .

Ignitio n timin g

Spark plug s

Air cleane r

PCV syste m

1 . Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

no loa d (A/ T in o r position , M/ T in neutral ) unti l

th e radiato r fa n come s on , the n tur n th e ignitio n

switch OFF .

2. Connec t th e SC S servic e connecto r t o servic e chec k

connector .

3. Connec t a OBDI I sca n too l (se e pag e 11-38 ) o r

tachometer .

Connec t a tachomete r t o loo p o f ignite r uni t sec -

ondary , or.. .

TACHOMETE R

TACHOMETE R

CONNECTOR

4. Restar t th e engine .

5 . Chec k idlin g i n no-loa d condition s i n whic h th e

headlights , blowe r fan , rea r defogger , coolin g fan ,

an d ai r conditione r ar e no t operating . D o no t

depres s th e accelerato r pedal .

Idl e spee d shoul d be :

Adjus t th e idl e speed , i f necessary , b y turnin g th e

idl e adjustin g screw . Afte r adjustin g th e idl e speed ,

chec k th e ignitio n timin g (se e sectio n 23 ). I f i t i s ou t

o f spec , g o bac k t o ste p 4 .

IDL E ADJUSTIN GSCREW

6. Disconnec t th e SC S servic e connector .

7 . Depres s th e accelerato r peda l an d stabiliz e th e

engin e spee d a t 1,00 0 rpm , the n slowl y releas e th e

peda l unti l th e engin e idles , the n chec k th e idl e

speed .

Idle spee d shoul d be :

Remov e th e rubbe r ca p fro m th e tachomete r

connecto r an d connec t a tachometer .

ProCarManuals.com

Page 632 of 1503

Emission Contro l Syste m

System Descriptio n

The emissio n contro l syste m include s tw o Thre e Wa y

Catalyti c Converter s (TWCs) , Exhaus t Ga s Recirculatio n

(EGR ) system , Positiv e Crankcas e Ventilatio n (PCV ) sys -

te m an d Evaporativ e Emissio n (EVAP ) Contro l system .

Th e emissio n contro l syste m is designe d t o mee t federa l

an d stat e emissio n standards .

Tailpipe Emissio n

1. Star t th e engine . Hol d th e engine at 3,00 0 rp m wit h

no loa d (A/ T in o r position , M/ T in neutral ) unti l

th e radiato r fa n come s on , the n le t i t idle .

2 . Connec t a tachometer .

3 . Chec k an d adjus t th e idl e speed , i f necessar y (se e

pag e 11-129 ).

4 . War m u p an d calibrat e th e C O mete r accordin g t o

th e mete r manufacturer' s instructions .

5 . Chec k idl e C O wit h th e headlights , heate r blower ,

rea r windo w defogger , coolin g fan , an d ai r condi -

tione r off .

NOTE : (Canada ) Pul l th e parkin g brak e leve r up .

Star t th e engine , the n chec k tha t th e headlight s ar e

off.

CO mete r shoul d indicat e 0.1 % maximum .

Inspection

any ope n flam e awa y fro m you r wor k area .

D

o no t smok e durin g thi s procedure . Kee p

ProCarManuals.com

Page 1089 of 1503

Rear Window

Installation (cont'd)

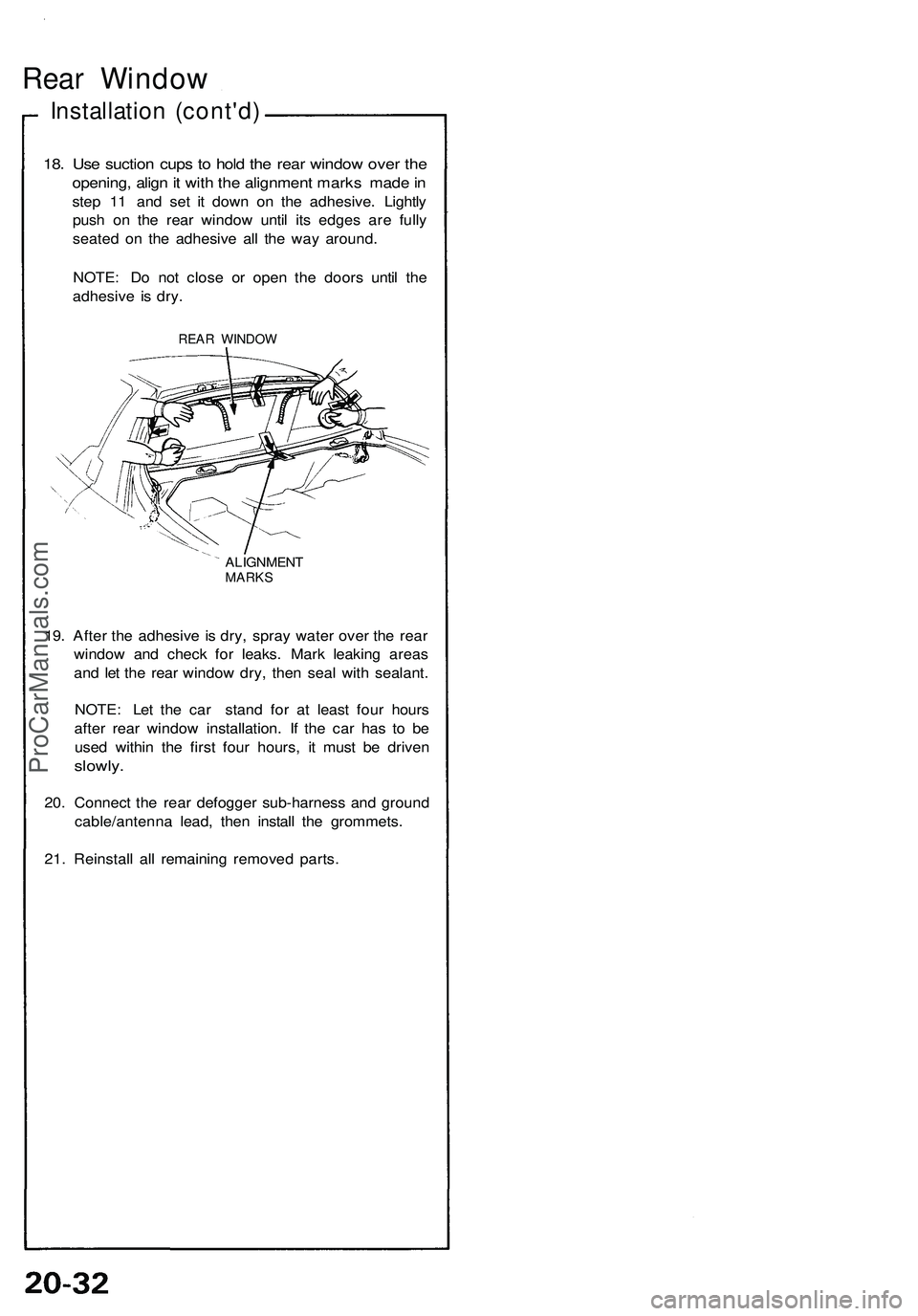

18. Use suction cups to hold the rear window over the

opening, align it with the alignment marks made in

step 11 and set it down on the adhesive. Lightly

push on the rear window until its edges are fully

seated on the adhesive all the way around.

NOTE: Do not close or open the doors until the

adhesive is dry.

REAR WINDOW

ALIGNMENT

MARKS

19. After the adhesive is dry, spray water over the rear

window and check for leaks. Mark leaking areas

and let the rear window dry, then seal with sealant.

NOTE: Let the car stand for at least four hours

after rear window installation. If the car has to be

used within the first four hours, it must be driven

slowly.

20. Connect the rear defogger sub-harness and ground

cable/antenna lead, then install the grommets.

21. Reinstall all remaining removed parts.ProCarManuals.com

Page 1323 of 1503

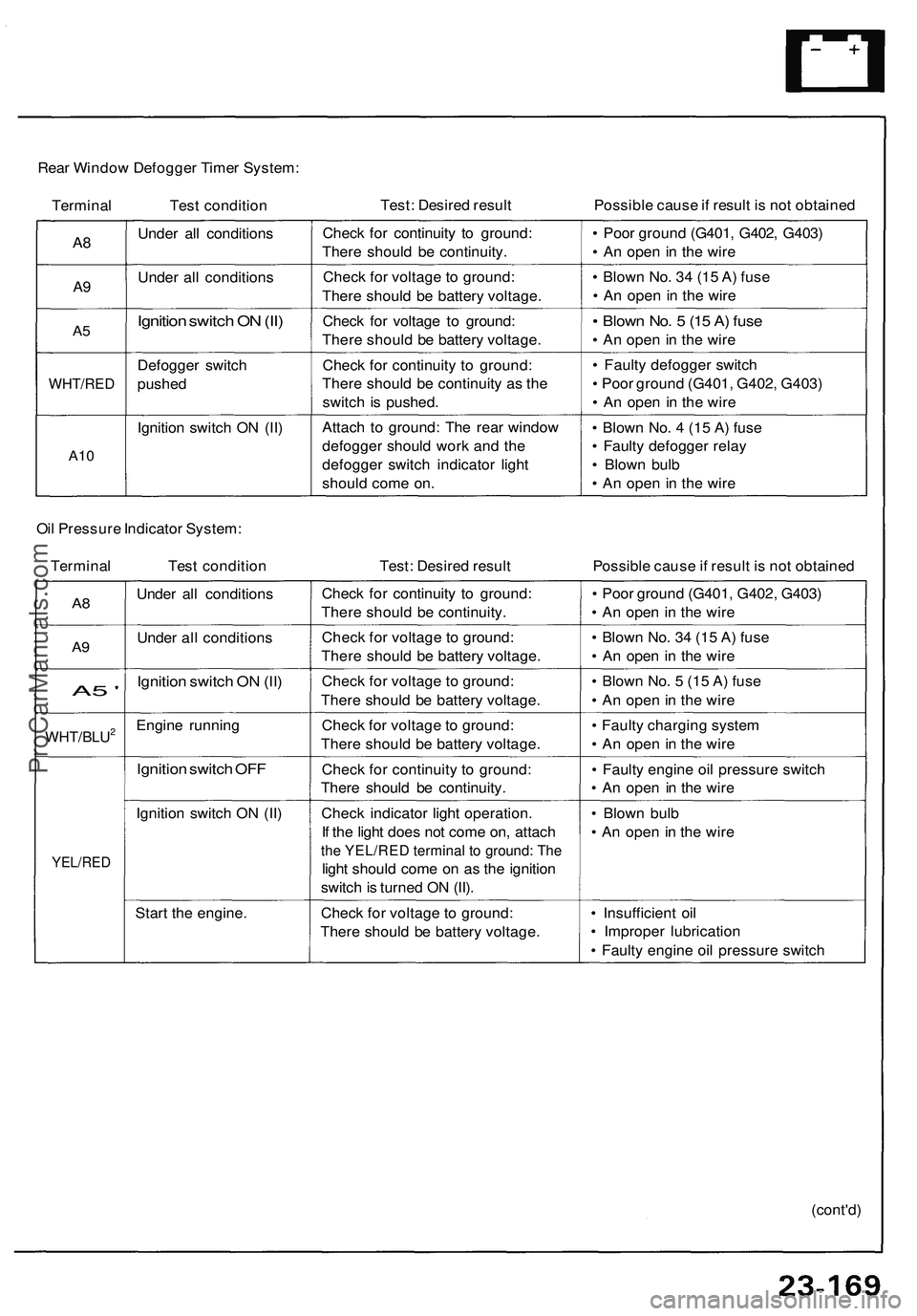

Rear Window Defogger Timer System:

Terminal Test condition

Test: Desired result

Possible cause if result is not obtained

A8

A9

A5

WHT/RED

A10

Under all conditions

Under all conditions

Ignition switch ON (II)

Defogger switch

pushed

Ignition switch ON (II)

Check for continuity to ground:

There should be continuity.

Check for voltage to ground:

There should be battery voltage.

Check for voltage to ground:

There should be battery voltage.

Check for continuity to ground:

There should be continuity as the

switch is pushed.

Attach to ground: The rear window

defogger should work and the

defogger switch indicator light

should come on.

• Poor ground (G401, G402, G403)

• An open in the wire

• Blown No. 34 (15 A) fuse

• An open in the wire

• Blown No. 5 (15 A) fuse

• An open in the wire

• Faulty defogger switch

• Poor ground (G401, G402, G403)

• An open in the wire

• Blown No. 4 (15 A) fuse

• Faulty defogger relay

• Blown bulb

• An open in the wire

Oil Pressure Indicator System:

Terminal Test condition

Test: Desired result

Possible cause if result is not obtained

A8

A9

A5 '

WHT/BLU2

YEL/RED

Under all conditions

Under all conditions

Ignition switch ON (II)

Engine running

Ignition switch OFF

Ignition switch ON (II)

Start the engine.

Check for continuity to ground:

There should be continuity.

Check for voltage to ground:

There should be battery voltage.

Check for voltage to ground:

There should be battery voltage.

Check for voltage to ground:

There should be battery voltage.

Check for continuity to ground:

There should be continuity.

Check indicator light operation.

If the light does not come on, attach

the YEL/RED terminal to ground: The

light should come on as the ignition

switch is turned ON (II).

Check for voltage to ground:

There should be battery voltage.

• Poor ground (G401, G402, G403)

• An open in the wire

• Blown No. 34 (15 A) fuse

• An open in the wire

• Blown No. 5 (15 A) fuse

• An open in the wire

• Faulty charging system

• An open in the wire

• Faulty engine oil pressure switch

• An open in the wire

• Blown bulb

• An open in the wire

• Insufficient oil

• Improper lubrication

• Faulty engine oil pressure switch

(cont'd)ProCarManuals.com

Page 1427 of 1503

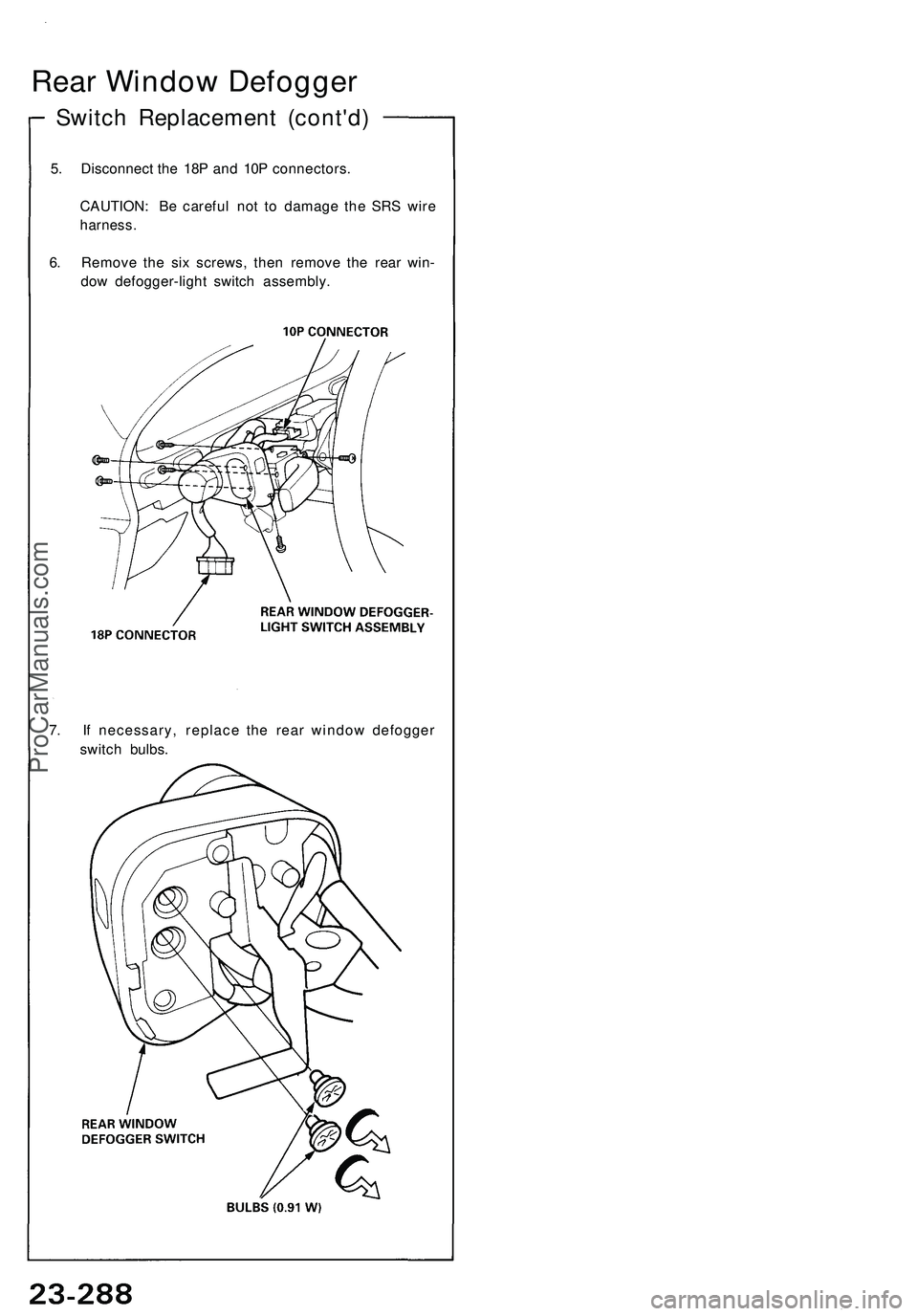

Switch Replacement (cont'd)

Rear Window Defogger

5. Disconnect the 18P and 10P connectors.

CAUTION: Be careful not to damage the SRS wire

harness.

6. Remove the six screws, then remove the rear win-

dow defogger-light switch assembly.

7. If necessary, replace the rear window defogger

switch bulbs.ProCarManuals.com

Page 1430 of 1503

Rear Window Defogger

Function Test

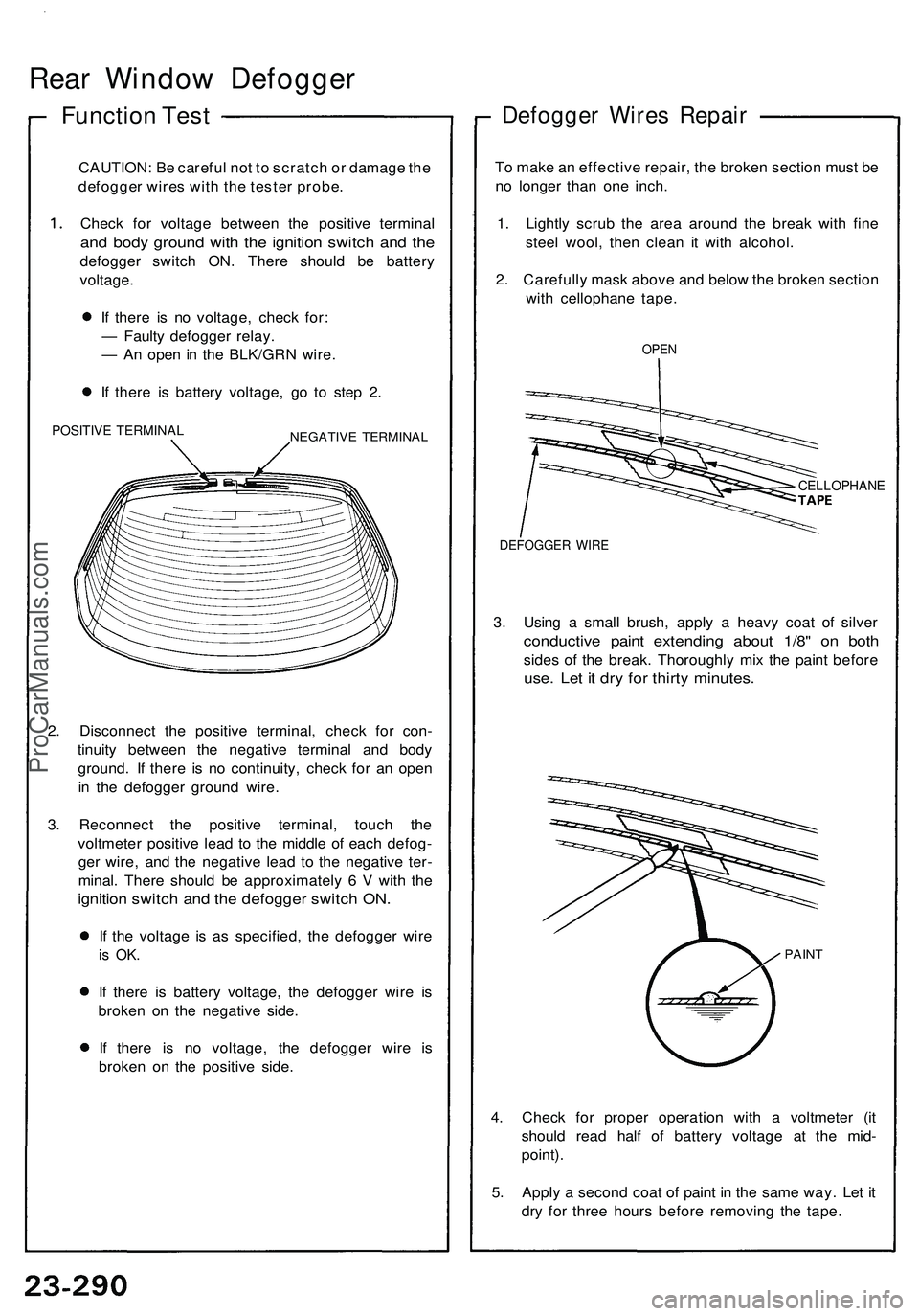

CAUTION: Be careful not to scratch or damage the

defogger wires with the tester probe.

Check for voltage between the positive terminal

and body ground with the ignition switch and the

defogger switch ON. There should be battery

voltage.

If there is no voltage, check for:

— Faulty defogger relay.

— An open in the BLK/GRN wire.

If there is battery voltage, go to step 2.

POSITIVE TERMINAL

NEGATIVE TERMINAL

2. Disconnect the positive terminal, check for con-

tinuity between the negative terminal and body

ground. If there is no continuity, check for an open

in the defogger ground wire.

3. Reconnect the positive terminal, touch the

voltmeter positive lead to the middle of each defog-

ger wire, and the negative lead to the negative ter-

minal. There should be approximately 6 V with the

ignition switch and the defogger switch ON.

If the voltage is as specified, the defogger wire

is OK.

If there is battery voltage, the defogger wire is

broken on the negative side.

If there is no voltage, the defogger wire is

broken on the positive side.

Defogger Wires Repair

To make an effective repair, the broken section must be

no longer than one inch.

1. Lightly scrub the area around the break with fine

steel wool, then clean it with alcohol.

2. Carefully mask above and below the broken section

with cellophane tape.

OPEN

CELLOPHANE

DEFOGGER WIRE

3. Using a small brush, apply a heavy coat of silver

conductive paint extending about 1/8" on both

sides of the break. Thoroughly mix the paint before

use. Let it dry for thirty minutes.

PAINT

4. Check for proper operation with a voltmeter (it

should read half of battery voltage at the mid-

point).

5. Apply a second coat of paint in the same way. Let it

dry for three hours before removing the tape.ProCarManuals.com