seats ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 291 of 1503

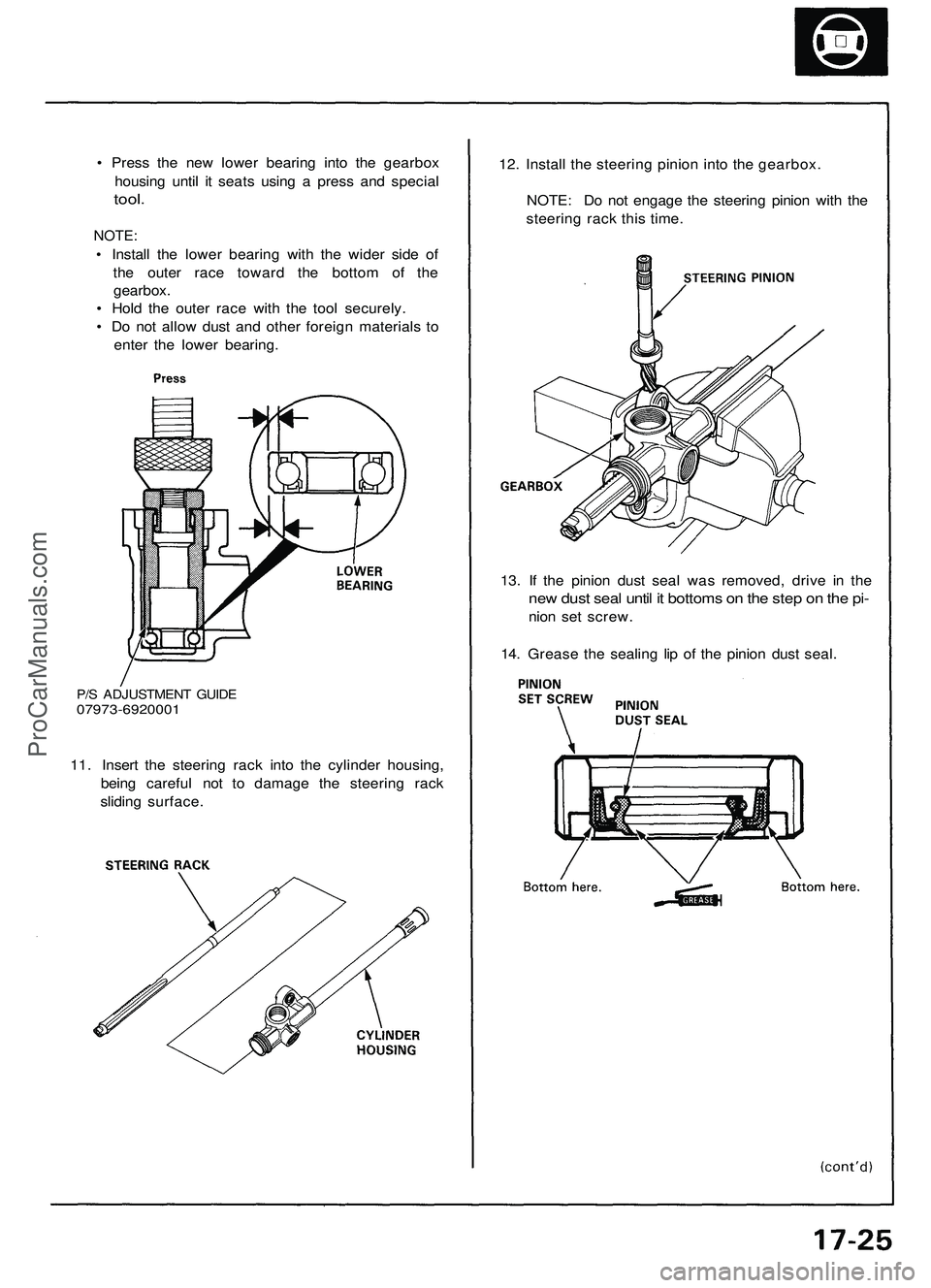

P/S ADJUSTMENT GUIDE

07973-6920001

11. Insert the steering rack into the cylinder housing,

being careful not to damage the steering rack

sliding surface.

13. If the pinion dust seal was removed, drive in the

new dust seal until it bottoms on the step on the pi-

nion set screw.

14. Grease the sealing lip of the pinion dust seal.

• Press the new lower bearing into the gearbox

housing until it seats using a press and special

tool.

NOTE:

• Install the lower bearing with the wider side of

the outer race toward the bottom of the

gearbox.

• Hold the outer race with the tool securely.

• Do not allow dust and other foreign materials to

enter the lower bearing.

12. Install the steering pinion into the gearbox.

NOTE: Do not engage the steering pinion with the

steering rack this time.ProCarManuals.com

Page 459 of 1503

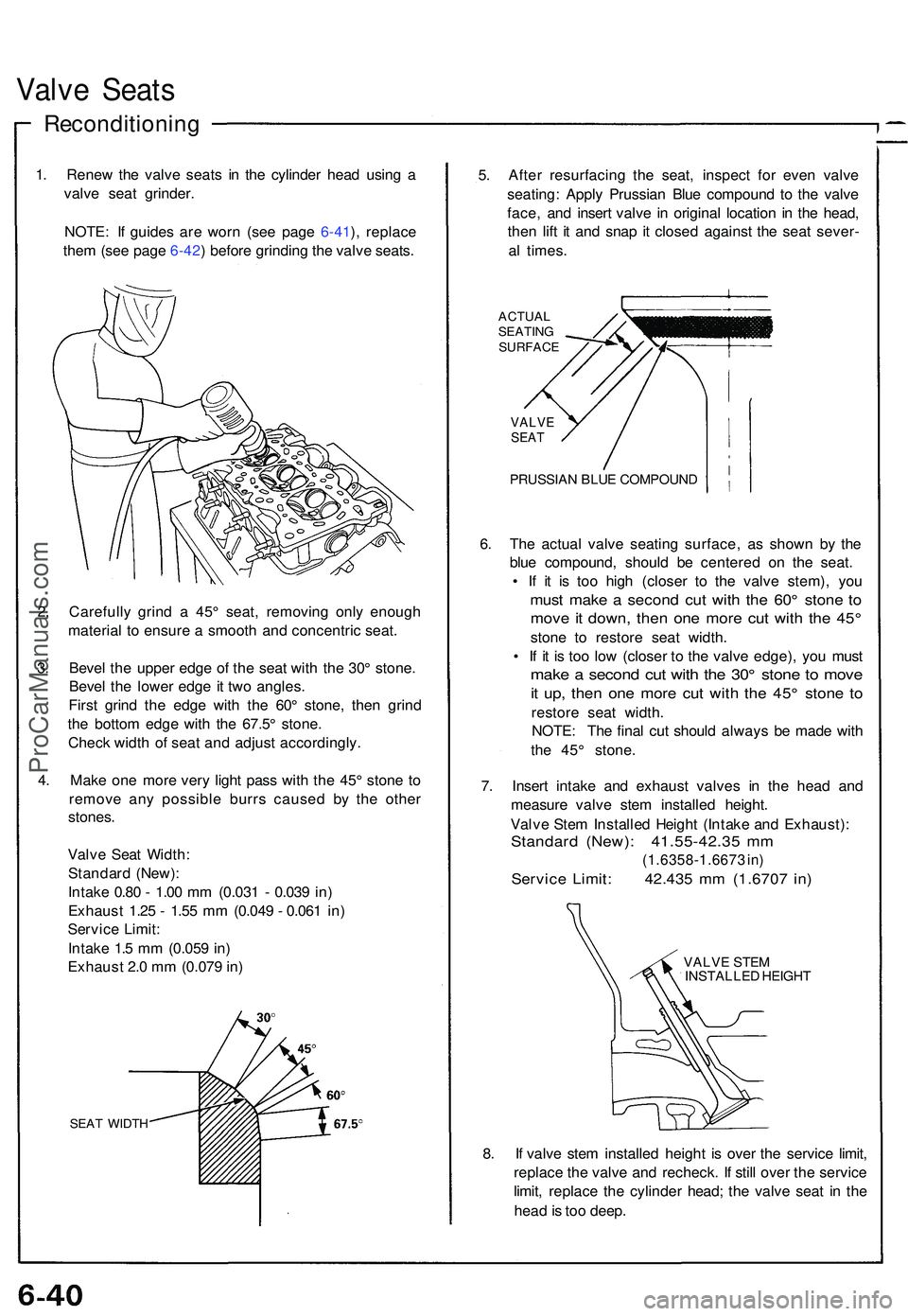

Valve Seat s

Reconditionin g

1. Rene w th e valv e seat s i n th e cylinde r hea d usin g a

valv e sea t grinder .

NOTE : I f guide s ar e wor n (se e pag e 6-41 ), replac e

the m (se e pag e 6-42 ) befor e grindin g th e valv e seats .

2 . Carefull y grin d a 45 ° seat , removin g onl y enoug h

materia l t o ensur e a smoot h an d concentri c seat .

3 . Beve l th e uppe r edg e o f th e sea t wit h th e 30 ° stone .

Beve l th e lowe r edg e i t tw o angles .

Firs t grin d th e edg e wit h th e 60 ° stone , the n grin d

th e botto m edg e wit h th e 67.5 ° stone .

Chec k widt h o f sea t an d adjus t accordingly .

4 . Mak e on e mor e ver y ligh t pas s wit h th e 45 ° ston e t o

remov e an y possibl e burr s cause d b y th e othe r

stones .

Valv e Sea t Width :

Standar d (New) :

Intak e 0.8 0 - 1.0 0 m m (0.03 1 - 0.03 9 in )

Exhaus t 1.2 5 - 1.5 5 m m (0.04 9 - 0.06 1 in )

Servic e Limit :

Intak e 1. 5 m m (0.05 9 in )

Exhaus t 2. 0 m m (0.07 9 in )

SEA T WIDT H

5. Afte r resurfacin g th e seat , inspec t fo r eve n valv e

seating : Appl y Prussia n Blu e compoun d t o th e valv e

face , an d inser t valv e i n origina l locatio n i n th e head ,

the n lif t i t an d sna p i t close d agains t th e sea t sever -

a l times .

ACTUA L

SEATIN G

SURFAC E

VALVESEAT

PRUSSIA N BLU E COMPOUN D

6. Th e actua l valv e seatin g surface , a s show n b y th e

blu e compound , shoul d b e centere d o n th e seat .

• I f i t i s to o hig h (close r t o th e valv e stem) , yo u

mus t mak e a secon d cu t wit h th e 60 ° ston e t o

mov e it down , the n on e mor e cu t wit h th e 45 °

ston e t o restor e sea t width .

• I f i t i s to o lo w (close r t o th e valv e edge) , yo u mus t

make a secon d cu t wit h th e 30 ° ston e t o mov e

it up , the n on e mor e cu t wit h th e 45 ° ston e t o

restor e sea t width .

NOTE : Th e fina l cu t shoul d alway s b e mad e wit h

th e 45 ° stone .

7 . Inser t intak e an d exhaus t valve s i n th e hea d an d

measur e valv e ste m installe d height .

Valv e Ste m Installe d Heigh t (Intak e an d Exhaust) :

Standard (New) : 41.55-42.3 5 m m

(1.6358-1.667 3 in )

Servic e Limit : 42.43 5 m m (1.670 7 in )

VALV E STE M

INSTALLE D HEIGH T

8. I f valv e ste m installe d heigh t i s ove r th e servic e limit ,

replac e th e valv e an d recheck . I f stil l ove r th e servic e

limit , replac e th e cylinde r head ; th e valv e sea t i n th e

hea d is to o deep .

ProCarManuals.com

Page 461 of 1503

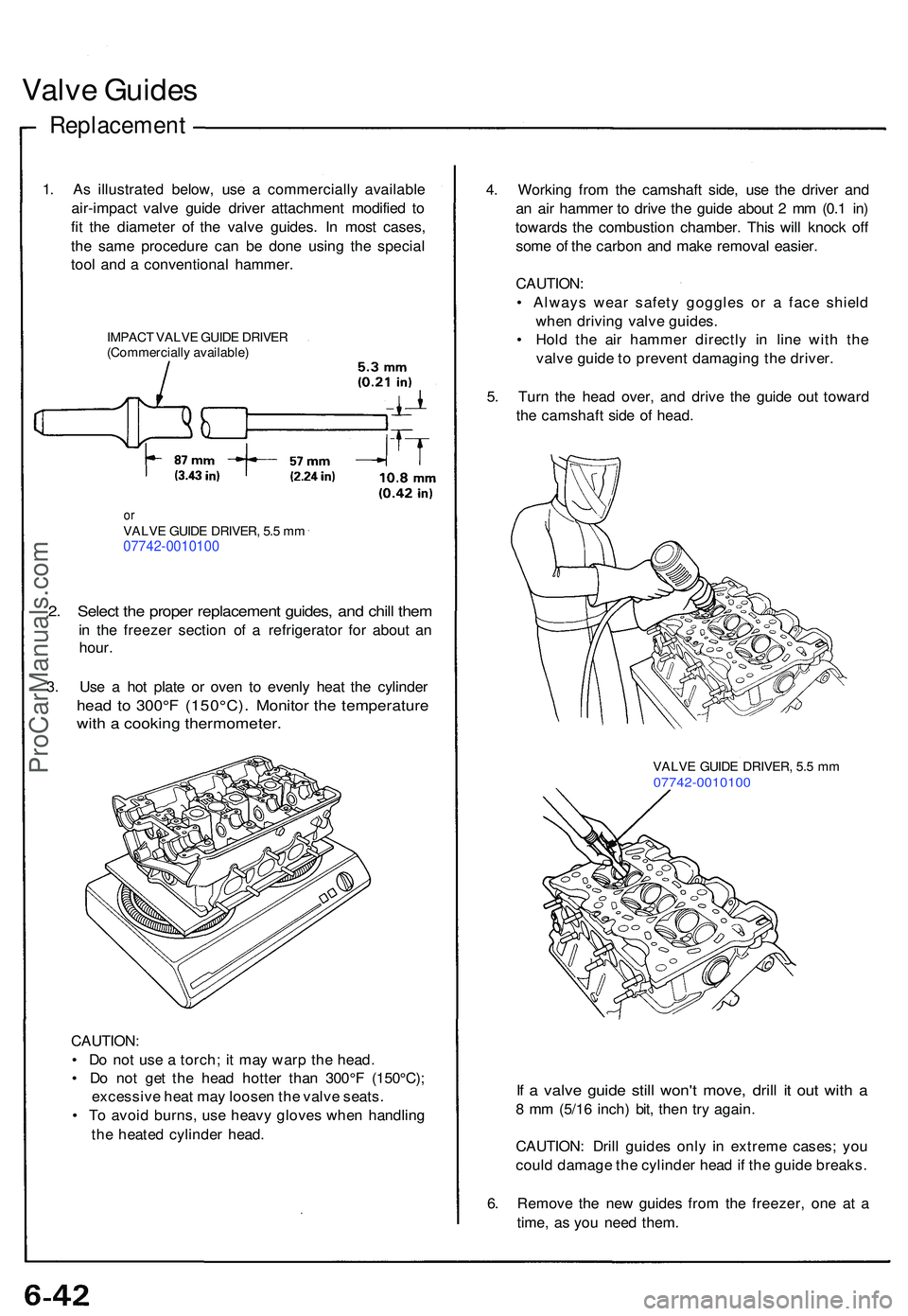

Valve Guide s

Replacemen t

1. A s illustrate d below , us e a commerciall y availabl e

air-impac t valv e guid e drive r attachmen t modifie d t o

fi t th e diamete r o f th e valv e guides . I n mos t cases ,

th e sam e procedur e ca n b e don e usin g th e specia l

too l an d a conventiona l hammer .

IMPACT VALV E GUID E DRIVE R

(Commerciall y available )

orVALV E GUID E DRIVER , 5. 5 m m07742-0010100

2. Selec t th e prope r replacemen t guides , an d chil l the m

in th e freeze r sectio n o f a refrigerato r fo r abou t a n

hour .

3 . Us e a ho t plat e o r ove n t o evenl y hea t th e cylinde r

head t o 300° F (150°C) . Monito r th e temperatur e

with a cookin g thermometer .

CAUTION:

• D o no t us e a torch ; i t ma y war p th e head .

• D o no t ge t th e hea d hotte r tha n 30 0°F (150°C) ;

excessiv e hea t ma y loose n th e valv e seats .

• T o avoi d burns , us e heav y glove s whe n handlin g

th e heate d cylinde r head . 4

. Workin g fro m th e camshaf t side , us e th e drive r an d

a n ai r hamme r t o driv e th e guid e abou t 2 m m (0. 1 in )

toward s th e combustion chamber. Thi s wil l knoc k of f

som e o f th e carbo n an d mak e remova l easier .

CAUTION :

• Alway s wea r safet y goggle s o r a fac e shiel d

whe n drivin g valv e guides .

• Hol d th e ai r hamme r directl y i n lin e wit h th e

valv e guid e t o preven t damagin g th e driver .

5 . Tur n th e hea d over , an d driv e th e guid e ou t towar d

th e camshaf t sid e o f head .

VALV E GUID E DRIVER , 5. 5 m m07742-001010 0

If a valv e guid e stil l won' t move , dril l i t ou t wit h a

8 m m (5/1 6 inch ) bit , the n tr y again .

CAUTION : Dril l guide s onl y i n extrem e cases ; yo u

coul d damag e th e cylinde r hea d if th e guid e breaks .

6 . Remov e th e ne w guide s fro m th e freezer , on e a t a

time , a s yo u nee d them .

ProCarManuals.com

Page 464 of 1503

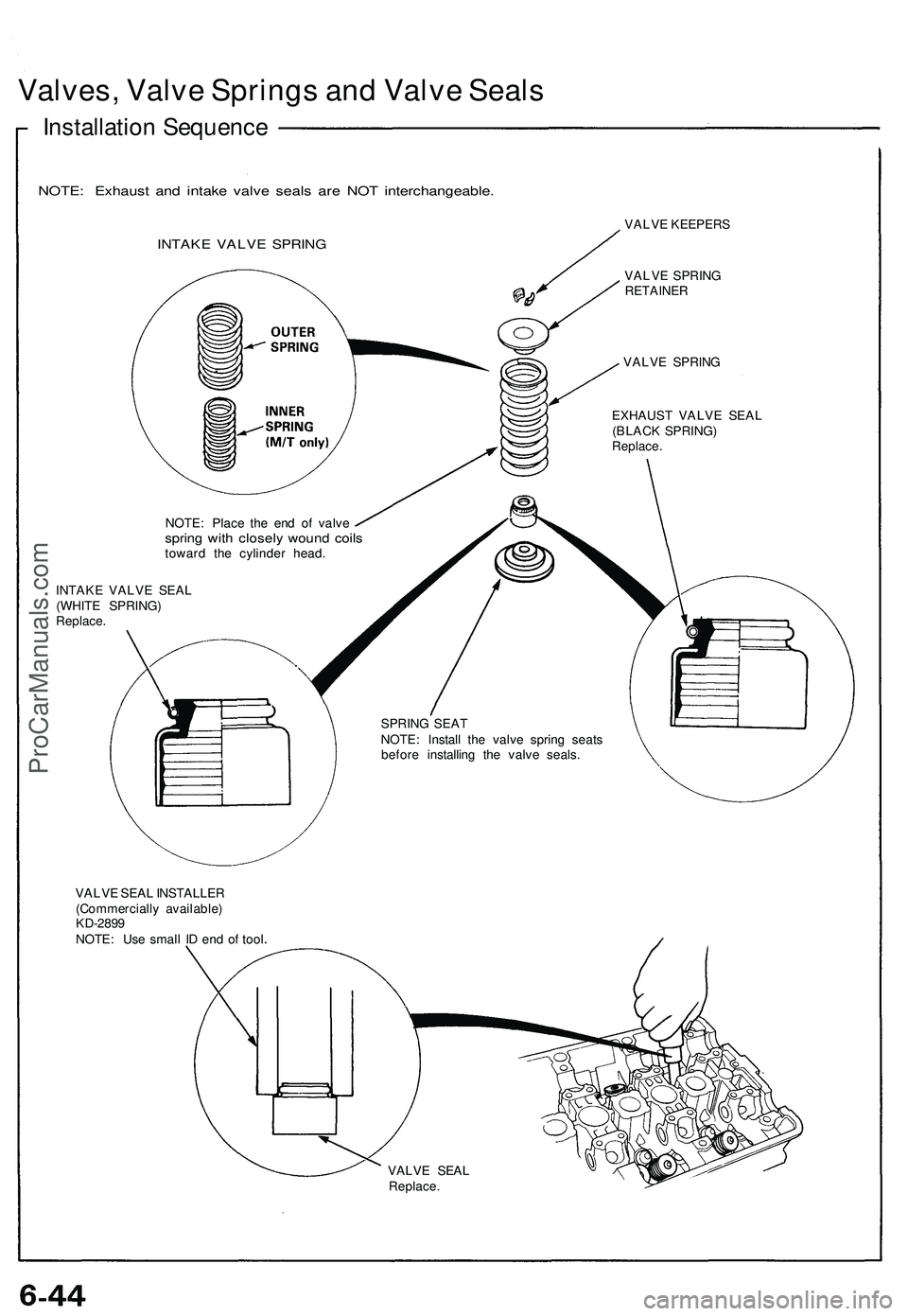

Valves, Valve Springs and Valve Seals

Installation Sequence

NOTE: Exhaust and intake valve seals are NOT interchangeable.

INTAKE VALVE SPRING

VALVE KEEPERS

VALVE SPRING

RETAINER

VALVE SPRING

EXHAUST VALVE SEAL

(BLACK SPRING)

Replace.

NOTE: Place the end of valve

spring with closely wound coils

toward the cylinder head.

INTAKE VALVE SEAL

(WHITE SPRING)

Replace.

SPRING SEAT

NOTE: Install the valve spring seats

before installing the valve seals.

VALVE SEAL INSTALLER

(Commercially available)

KD-2899

NOTE: Use small ID end of tool

VALVE SEAL

Replace.ProCarManuals.com

Page 1098 of 1503

Seats

Replacemen t

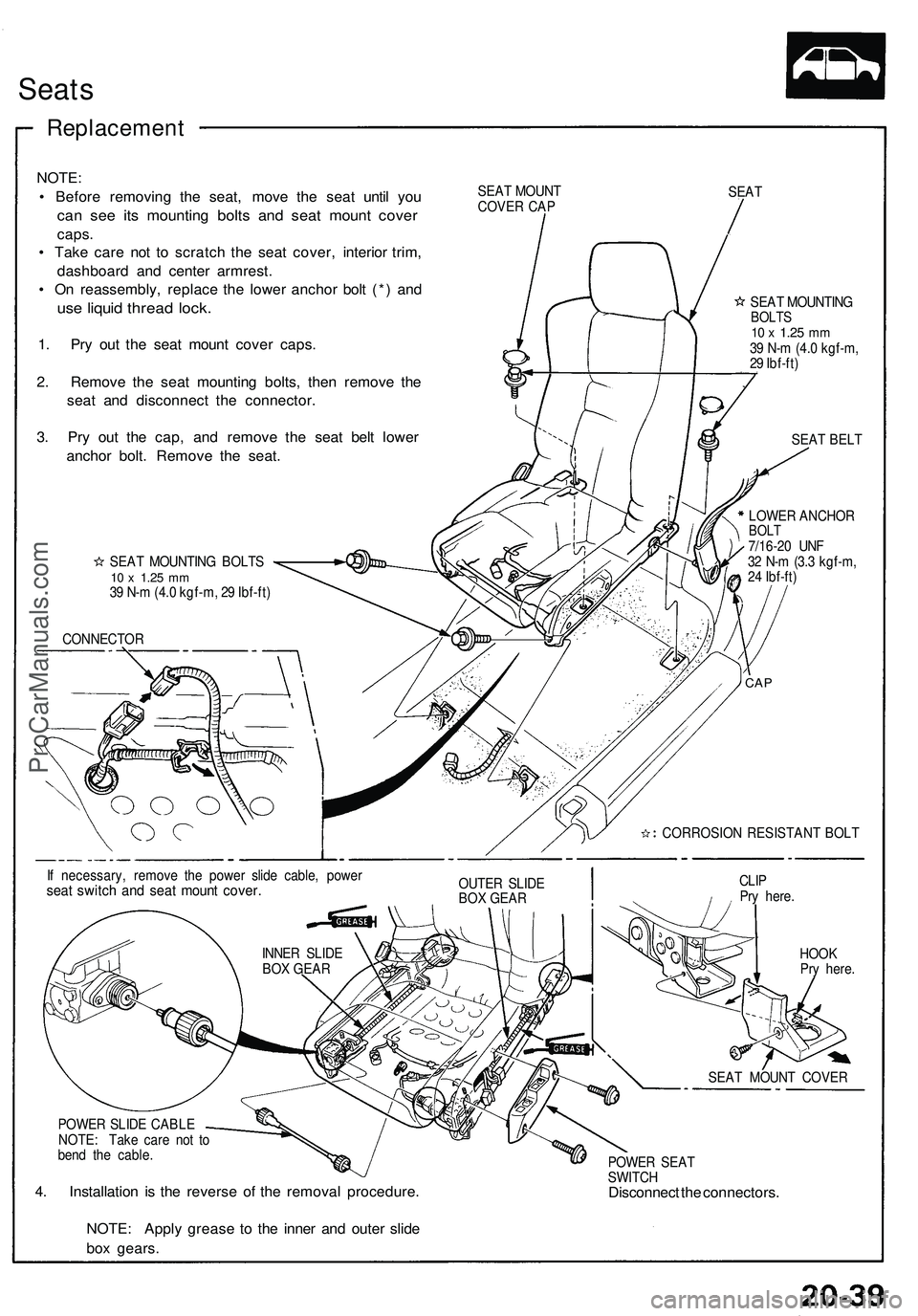

NOTE:

• Befor e removin g th e seat , mov e th e sea t unti l yo u

can se e it s mountin g bolt s an d sea t moun t cove r

caps.

• Tak e car e no t t o scratc h th e sea t cover , interio r trim ,

dashboar d an d cente r armrest .

• O n reassembly , replac e th e lowe r ancho r bol t (* ) an d

use liqui d threa d lock .

1. Pr y ou t th e seat moun t cove r caps .

2 . Remov e th e sea t mountin g bolts , the n remov e th e

sea t an d disconnec t th e connector .

3 . Pr y ou t th e cap , an d remov e th e sea t bel t lowe r

ancho r bolt . Remov e th e seat .

SEAT MOUN T

COVE R CA P SEA

T

SEA T MOUNTIN G BOLT S

10 x 1.2 5 mm39 N- m (4. 0 kgf-m , 2 9 Ibf-ft )

CONNECTO R SEA

T MOUNTIN G

BOLTS10 x 1.2 5 mm39 N- m (4. 0 kgf-m ,

2 9 Ibf-ft )

SEA T BEL T

LOWE R ANCHO R

BOLT7/16-2 0 UN F

3 2 N- m (3. 3 kgf-m ,

2 4 Ibf-ft )

I f necessary , remov e th e powe r slid e cable , powe r

seat switc h an d sea t moun t cover .OUTER SLID E

BO X GEA R CLI

P

Pr y here .

HOO K

Pr y here .

POWE R SLID E CABL E

NOTE : Tak e car e no t t o

ben d th e cable .

4. Installatio n i s th e revers e o f th e remova l procedure .

POWER SEA T

SWITC H

Disconnec t th e connectors .

NOTE : Appl y greas e t o th e inne r an d oute r slid e

bo x gears .

SEAT MOUN T COVE R

CORROSIO

N RESISTAN T BOL T

CAP

INNE R SLID E

BO X GEA R

ProCarManuals.com

Page 1099 of 1503

Seats

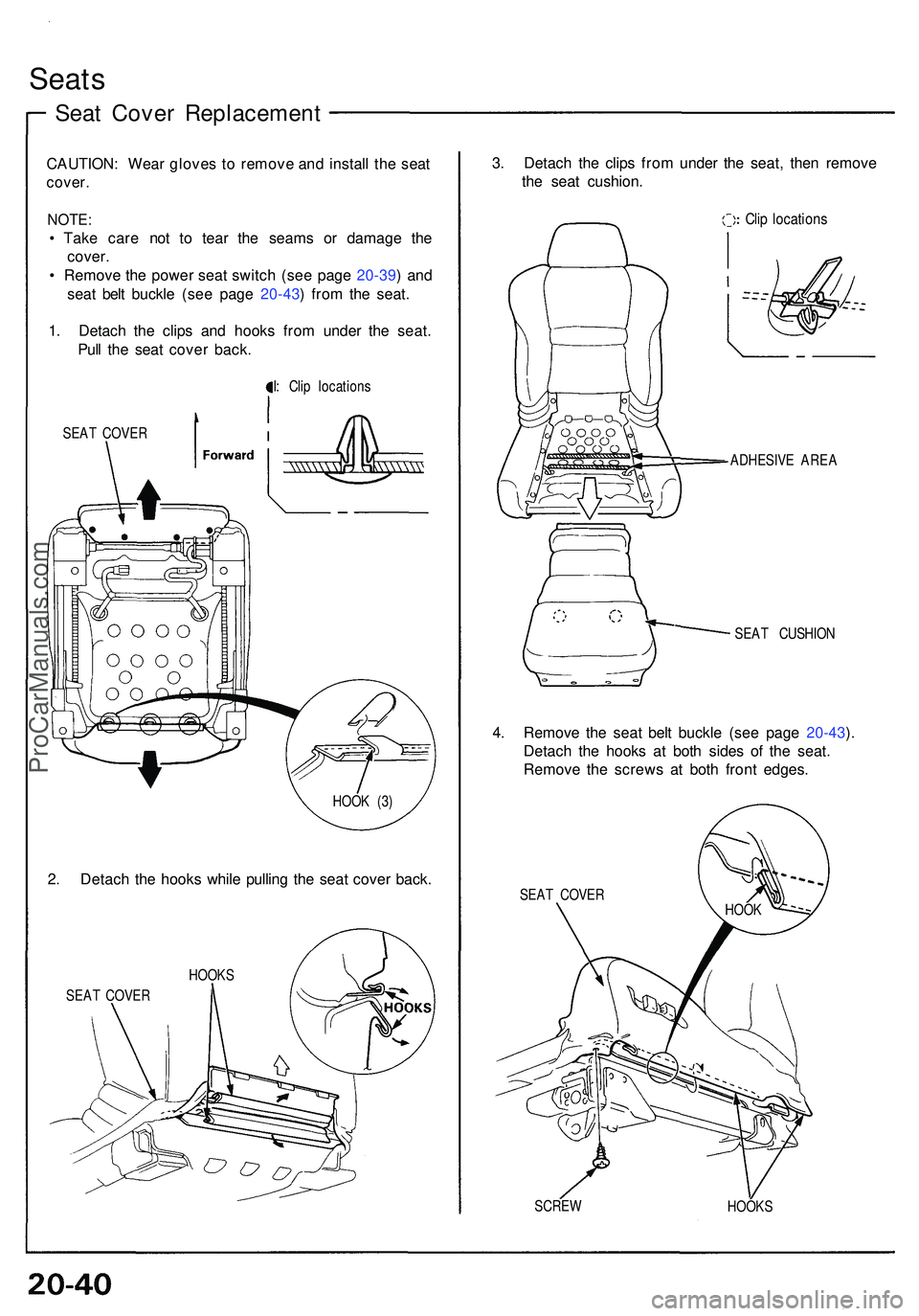

Seat Cove r Replacemen t

CAUTION: Wea r glove s t o remov e an d instal l th e sea t

cover .

NOTE :

• Tak e car e no t t o tea r th e seam s o r damag e th e

cover .

• Remov e th e powe r sea t switc h (se e pag e 20-39 ) an d

sea t bel t buckl e (se e pag e 20-43 ) fro m th e seat .

1 . Detac h th e clip s an d hook s fro m unde r th e seat .

Pul l th e sea t cove r back .

I: Cli p location s

SEA T COVE R

2. Detac h th e hook s whil e pullin g th e sea t cove r back .

SEAT COVE R

3. Detac h th e clip s fro m unde r th e seat , the n remov e

th e sea t cushion .

Clip location s

SEAT CUSHIO N

4. Remov e th e sea t bel t buckl e (se e pag e 20-43 ).

Detac h th e hook s a t bot h side s o f th e seat .

Remov e th e screw s a t bot h fron t edges .

SEAT COVE R

SCRE W

HOOKS

ADHESIV

E ARE A

HOOK S HOO

K (3 )

HOOK

ProCarManuals.com

Page 1101 of 1503

Seats

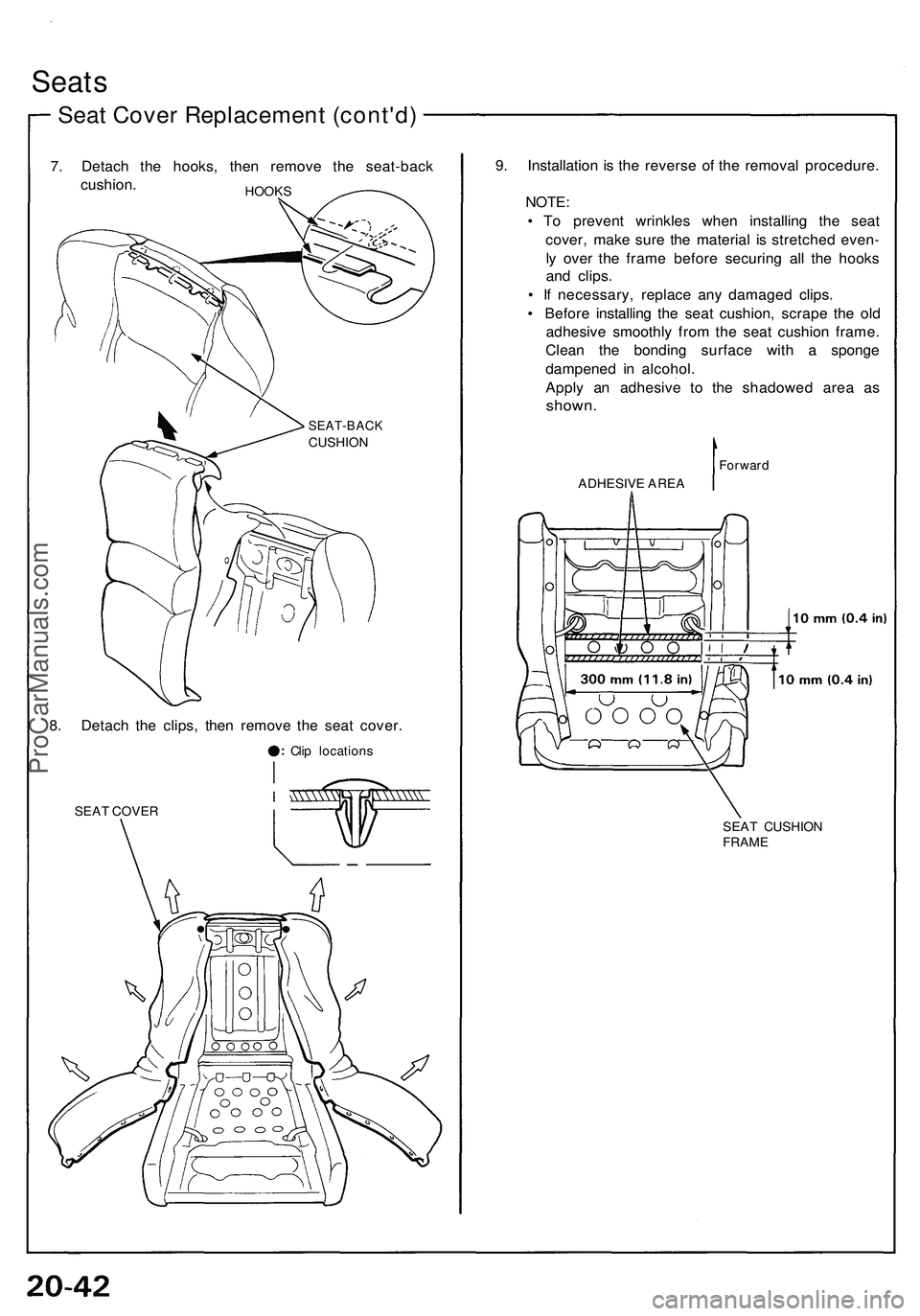

Seat Cover Replacement (cont'd)

7. Detach the hooks, then remove the seat-back

cushion.

HOOKS

8. Detach the clips, then remove the seat cover.

Clip locations

SEAT COVER

9. Installation is the reverse of the removal procedure.

NOTE:

• To prevent wrinkles when installing the seat

cover, make sure the material is stretched even-

ly over the frame before securing all the hooks

and clips.

• If necessary, replace any damaged clips.

• Before installing the seat cushion, scrape the old

adhesive smoothly from the seat cushion frame.

Clean the bonding surface with a sponge

dampened in alcohol.

Apply an adhesive to the shadowed area as

shown.

Forward

SEAT CUSHION

FRAME

SEAT-BACK

CUSHION

ADHESIVE AREAProCarManuals.com

Page 1185 of 1503

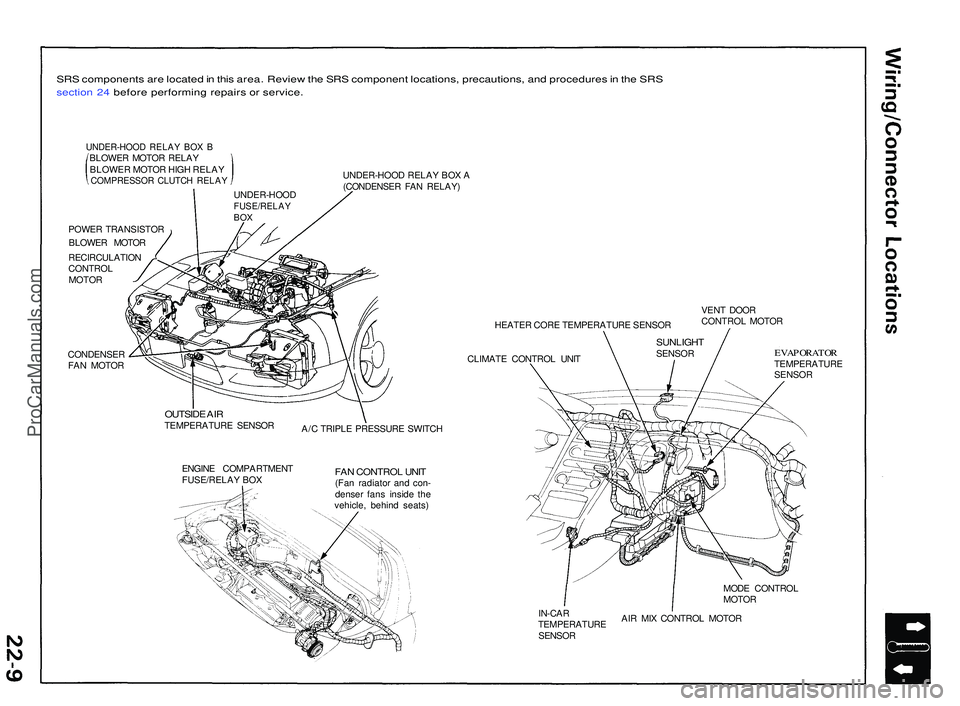

SRS component s ar e locate d in thi s area . Revie w th e SR S componen t locations , precautions , an d procedure s in th e SR S

sectio n 24 befor e performin g repair s o r service .

UNDER-HOO D RELA Y BO X BBLOWE R MOTO R RELA Y

BLOWE R MOTO R HIG H RELA Y

COMPRESSO R CLUTC H RELA Y

POWER TRANSISTO R

BLOWE R MOTO R

RECIRCULATIO N

CONTRO L

MOTO R

CONDENSE R

FA N MOTO R UNDER-HOO

D RELA Y BO X A

(CONDENSE R FA N RELAY )

HEATER COR E TEMPERATUR E SENSO R

CLIMAT E CONTRO L UNI T VEN

T DOO R

CONTRO L MOTO R

OUTSID E AI RTEMPERATUR E SENSO R

A/C TRIPL E PRESSUR E SWITC H

ENGIN E COMPARTMEN T

FUSE/RELA Y BO X

FAN CONTRO L UNI T(Fan radiato r an d con -

dense r fan s insid e th e

vehicle , behin d seats )

EVAPORATO RTEMPERATUR E

SENSO R

MOD E CONTRO L

MOTO R

IN-CA R

TEMPERATUR E

SENSO R AI

R MI X CONTRO L MOTO R

UNDER-HOO

D

FUSE/RELAYBOX

SUNLIGH TSENSOR

ProCarManuals.com

Page 1259 of 1503

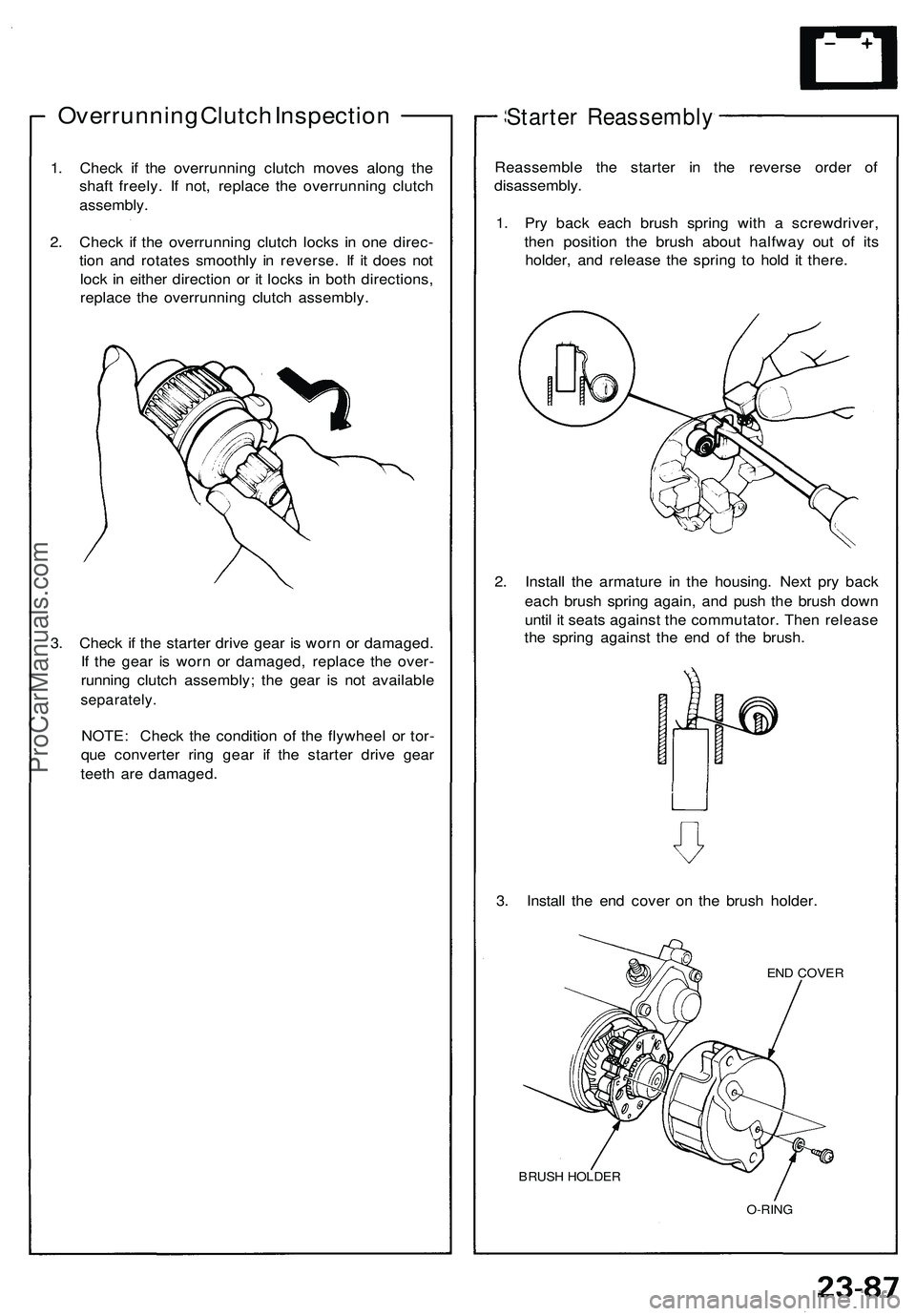

Overrunning Clutch Inspection

1. Check if the overrunning clutch moves along the

shaft freely. If not, replace the overrunning clutch

assembly.

2. Check if the overrunning clutch locks in one direc-

tion and rotates smoothly in reverse. If it does not

lock in either direction or it locks in both directions,

replace the overrunning clutch assembly.

3. Check if the starter drive gear is worn or damaged.

If the gear is worn or damaged, replace the over-

running clutch assembly; the gear is not available

separately.

NOTE: Check the condition of the flywheel or tor-

que converter ring gear if the starter drive gear

teeth are damaged.

Starter Reassembly

Reassemble the starter in the reverse order of

disassembly.

1. Pry back each brush spring with a screwdriver,

then position the brush about halfway out of its

holder, and release the spring to hold it there.

2. Install the armature in the housing. Next pry back

each brush spring again, and push the brush down

until it seats against the commutator. Then release

the spring against the end of the brush.

3. Install the end cover on the brush holder.

END COVER

BRUSH HOLDER

O-RINGProCarManuals.com

Page 1422 of 1503

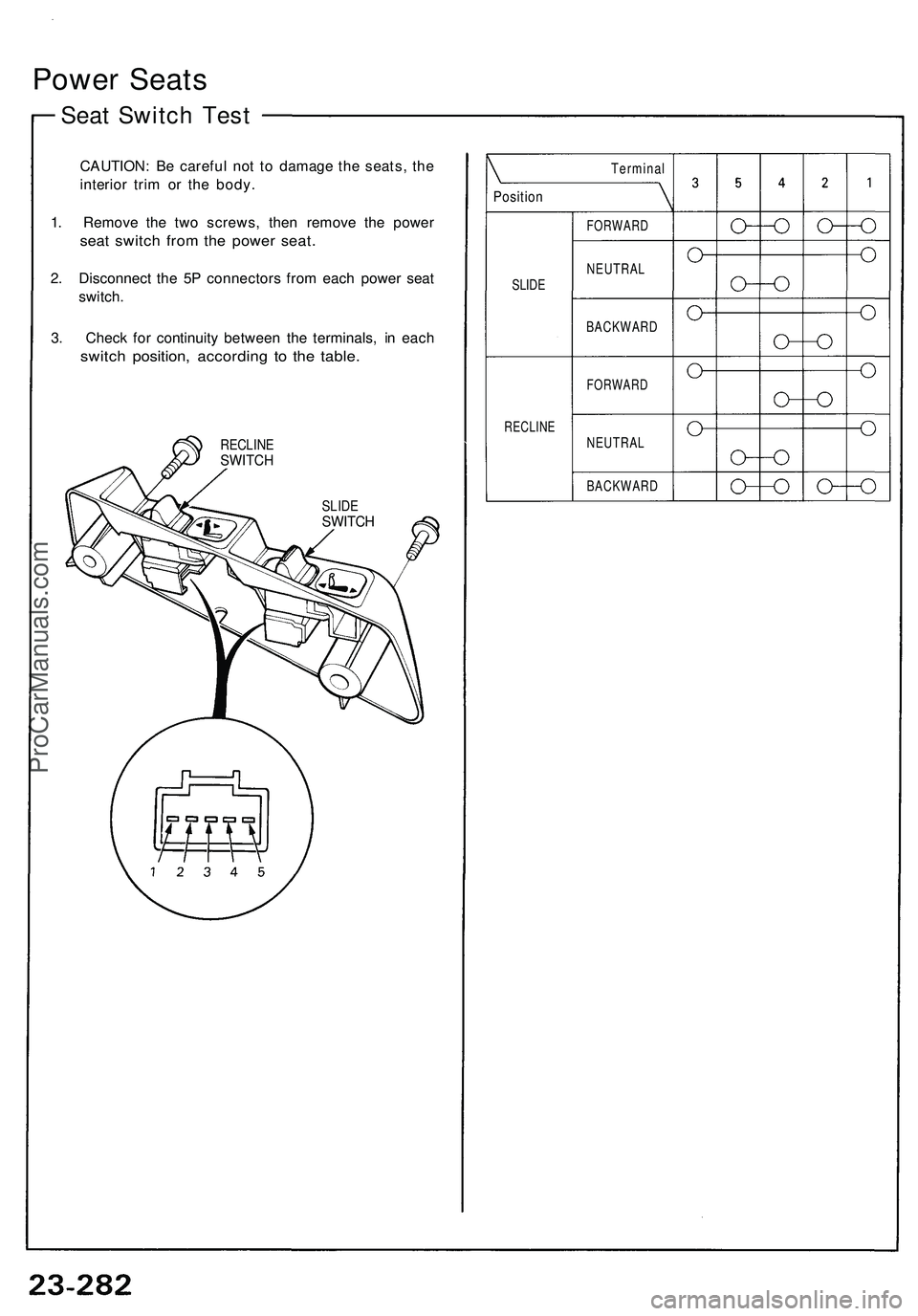

Power Seats

Seat Switch Test

CAUTION: Be careful not to damage the seats, the

interior trim or the body.

1. Remove the two screws, then remove the power

seat switch from the power seat.

2. Disconnect the 5P connectors from each power seat

switch.

3. Check for continuity between the terminals, in each

switch position, according to the table.

RECLINE

SWITCH

SLIDE

SWITCH

SLIDE

RECLINE

Position

Terminal

FORWARD

NEUTRAL

BACKWARD

FORWARD

NEUTRAL

BACKWARDProCarManuals.com