reset ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 33 of 1503

Troubleshooting Procedure s

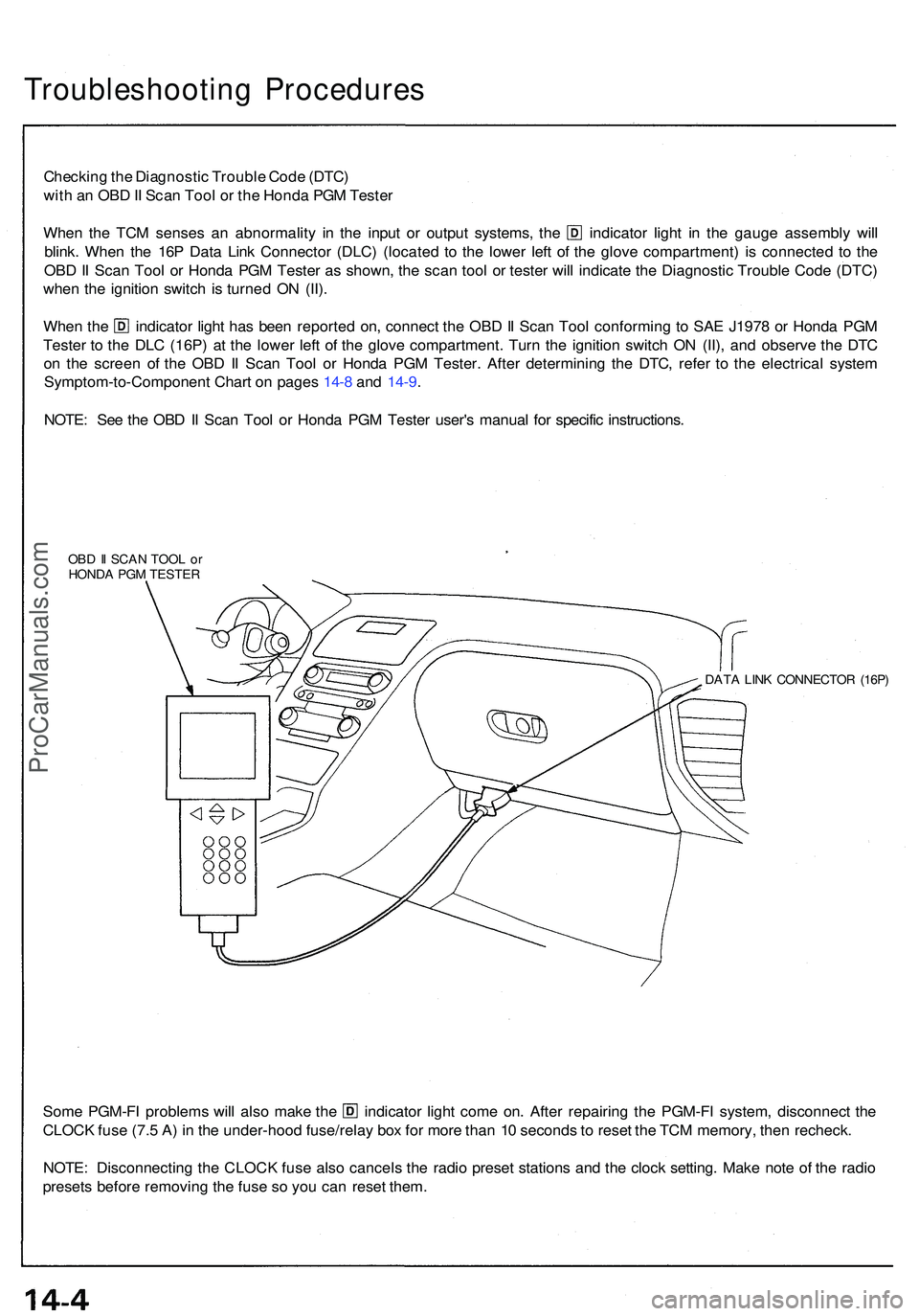

Checking th e Diagnosti c Troubl e Cod e (DTC )

wit h a n OB D II Sca n Too l o r th e Hond a PG M Teste r

When th e TC M sense s a n abnormalit y i n th e inpu t o r outpu t systems , th e indicato r ligh t i n th e gaug e assembl y wil l

blink . Whe n th e 16 P Dat a Lin k Connecto r (DLC ) (locate d t o th e lowe r lef t o f th e glov e compartment ) i s connecte d t o th e

OB D II Sca n Too l o r Hond a PG M Teste r a s shown , th e sca n too l o r teste r wil l indicat e th e Diagnosti c Troubl e Cod e (DTC )

whe n th e ignitio n switc h i s turne d O N (II) .

Whe n th e indicato r ligh t ha s bee n reporte d on , connec t th e OB D II Sca n Too l conformin g t o SA E J197 8 o r Hond a PG M

Teste r t o th e DL C (16P ) a t th e lowe r lef t o f th e glov e compartment . Tur n th e ignitio n switc h O N (II) , an d observ e th e DT C

o n th e scree n o f th e OB D II Sca n Too l o r Hond a PG M Tester . Afte r determinin g th e DTC , refe r t o th e electrica l syste m

Symptom-to-Componen t Char t o n page s 14- 8 an d 14-9 .

NOTE : Se e th e OB D II Sca n Too l o r Hond a PG M Teste r user' s manua l fo r specifi c instructions .

OBD II SCA N TOO L o r

HOND A PG M TESTE R

DATA LIN K CONNECTO R (16P )

Some PGM-F I problem s wil l als o mak e th e indicato r ligh t com e on . Afte r repairin g th e PGM-F I system , disconnec t th e

CLOC K fus e (7. 5 A ) i n th e under-hoo d fuse/rela y bo x fo r mor e tha n 1 0 second s t o rese t th e TC M memory , the n recheck .

NOTE : Disconnectin g th e CLOC K fus e als o cancel s th e radi o prese t station s an d th e cloc k setting . Mak e not e o f th e radi o

preset s befor e removin g th e fus e s o yo u ca n rese t them .

ProCarManuals.com

Page 34 of 1503

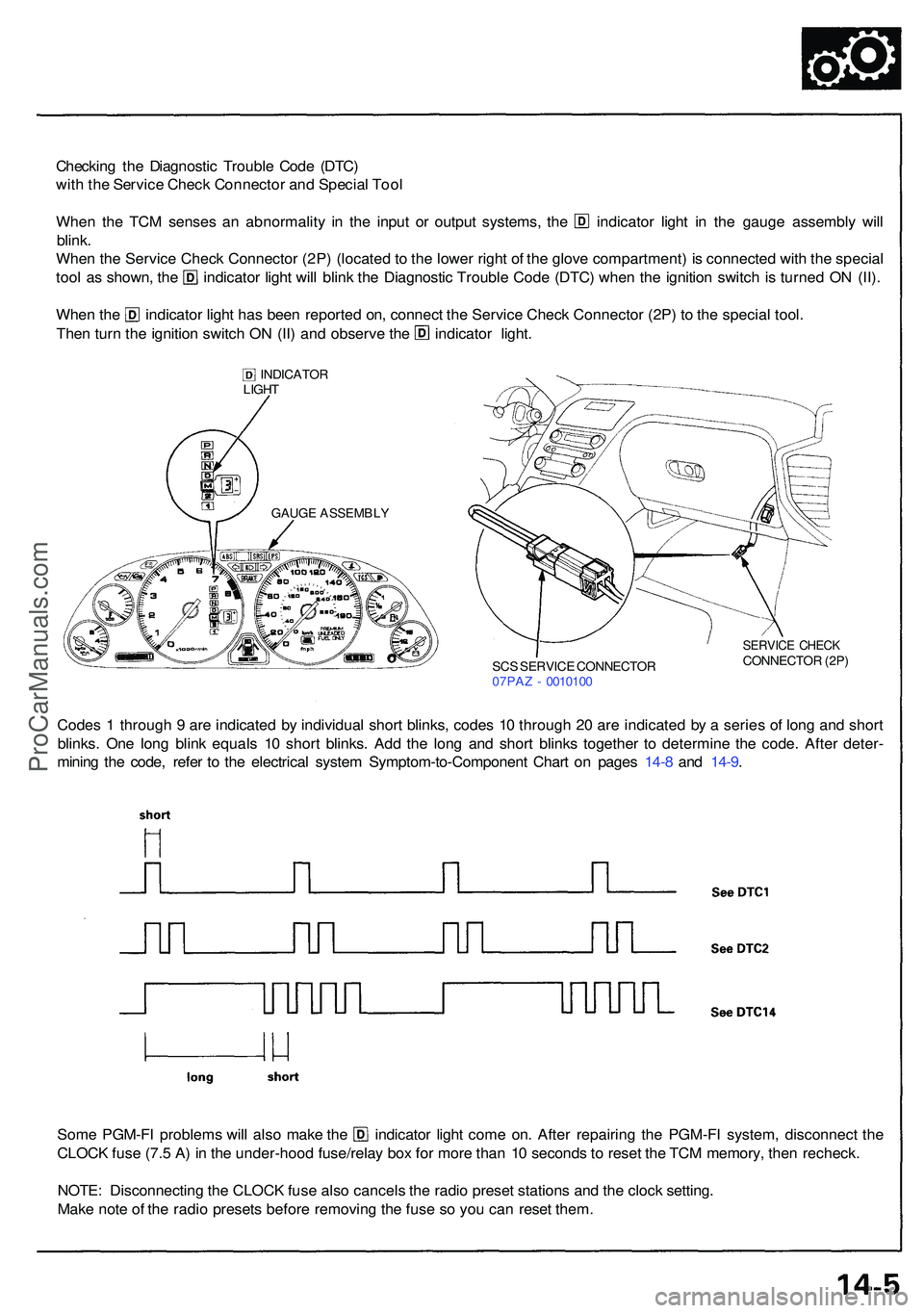

Checking th e Diagnosti c Troubl e Cod e (DTC )

wit h th e Servic e Chec k Connecto r an d Specia l Too l

Whe n th e TC M sense s a n abnormalit y i n th e inpu t o r outpu t systems , th e indicato r ligh t i n th e gaug e assembl y wil l

blink .

Whe n th e Servic e Chec k Connecto r (2P ) (locate d to th e lowe r righ t o f th e glov e compartment ) i s connecte d wit h th e specia l

tool a s shown , th e indicato r ligh t wil l blin k th e Diagnosti c Troubl e Cod e (DTC ) whe n th e ignitio n switc h i s turne d O N (II) .

Whe n th e indicato r ligh t ha s bee n reporte d on , connec t th e Servic e Chec k Connecto r (2P ) t o th e specia l tool .

Then tur n th e ignitio n switc h O N (II ) an d observ e th e indicato r light .

INDICATO R

LIGH T

SCS SERVIC E CONNECTO R

07PA Z - 001010 0

SERVIC E CHEC KCONNECTO R (2P )

Code s 1 throug h 9 ar e indicate d b y individua l shor t blinks , code s 1 0 throug h 2 0 ar e indicate d b y a serie s o f lon g an d shor t

blinks . On e lon g blin k equal s 1 0 shor t blinks . Ad d th e lon g an d shor t blink s togethe r t o determin e th e code . Afte r deter -

minin g th e code , refe r t o th e electrica l syste m Symptom-to-Componen t Char t o n page s 14-8 an d 14-9 .

Som e PGM-F I problem s wil l als o mak e th e indicato r ligh t com e on . Afte r repairin g th e PGM-F I system , disconnec t th e

CLOC K fus e (7. 5 A ) i n th e under-hoo d fuse/rela y bo x fo r mor e tha n 1 0 second s t o rese t th e TC M memory , the n recheck .

NOTE : Disconnectin g th e CLOC K fus e als o cancel s th e radi o prese t station s an d th e cloc k setting .

Mak e not e o f th e radi o preset s befor e removin g th e fus e s o yo u ca n rese t them .

GAUG E ASSEMBL Y

ProCarManuals.com

Page 36 of 1503

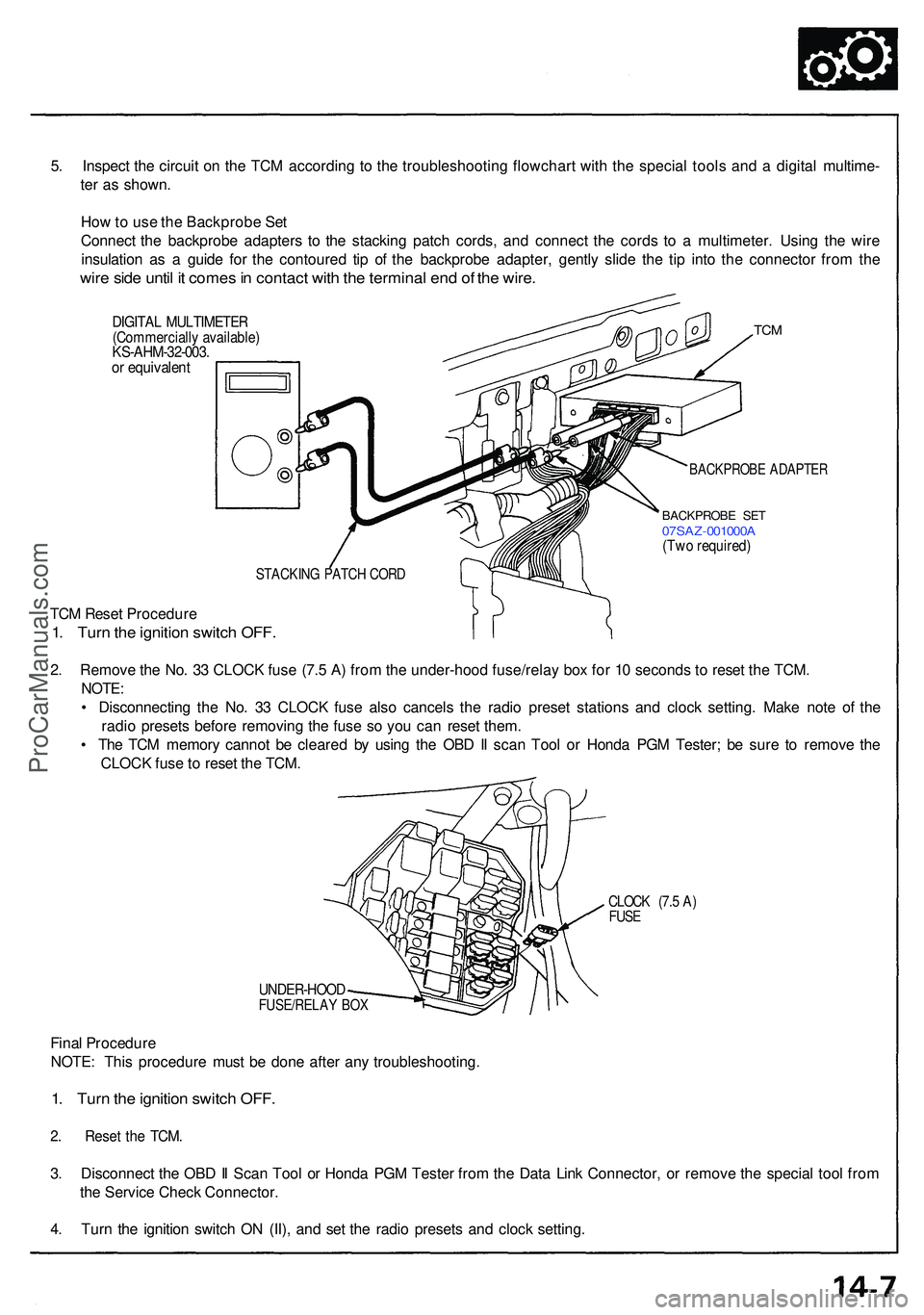

5. Inspec t th e circui t o n th e TC M accordin g t o th e troubleshootin g flowchar t wit h th e specia l tool s an d a digita l multime -

te r a s shown .

Ho w to us e th e Backprob e Se t

Connec t th e backprob e adapter s t o th e stackin g patc h cords , an d connec t th e cord s t o a multimeter . Usin g th e wir e

insulatio n a s a guid e fo r th e contoure d ti p o f th e backprob e adapter , gentl y slid e th e ti p int o th e connecto r fro m th e

wire sid e unti l i t come s in contac t wit h th e termina l en d o f th e wire .

DIGITA L MULTIMETE R(Commerciall y available )KS-AHM-32-003 .or equivalen t

TCM

BACKPROB E ADAPTE R

BACKPROB E SE T07SA Z-001000 A(Two required )

STACKIN G PATC H COR D

TCM Rese t Procedur e

1. Tur n th e ignitio n switc h OFF .

2. Remov e th e No . 3 3 CLOC K fus e (7. 5 A ) fro m th e under-hoo d fuse/rela y bo x fo r 1 0 second s t o rese t th e TCM .

NOTE :

• Disconnectin g th e No . 3 3 CLOC K fus e als o cancel s th e radi o prese t station s an d cloc k setting . Mak e not e o f th e

radi o preset s befor e removin g th e fus e s o yo u ca n rese t them .

• Th e TC M memor y canno t b e cleare d b y usin g th e OB D II sca n Too l o r Hond a PG M Tester ; b e sur e t o remov e th e

CLOC K fus e to rese t th e TCM .

CLOC K (7. 5 A )FUS E

UNDER-HOO DFUSE/RELAY BO X

Fina l Procedur e

NOTE : Thi s procedur e mus t b e don e afte r an y troubleshooting .

1. Tur n th e ignitio n switc h OFF .

2. Rese t th e TCM .

3. Disconnec t th e OB D II Sca n Too l o r Hond a PG M Teste r fro m th e Dat a Lin k Connector , o r remov e th e specia l too l fro m

th e Servic e Chec k Connector .

4 . Tur n th e ignitio n switc h O N (II) , an d se t th e radi o preset s an d cloc k setting .

ProCarManuals.com

Page 130 of 1503

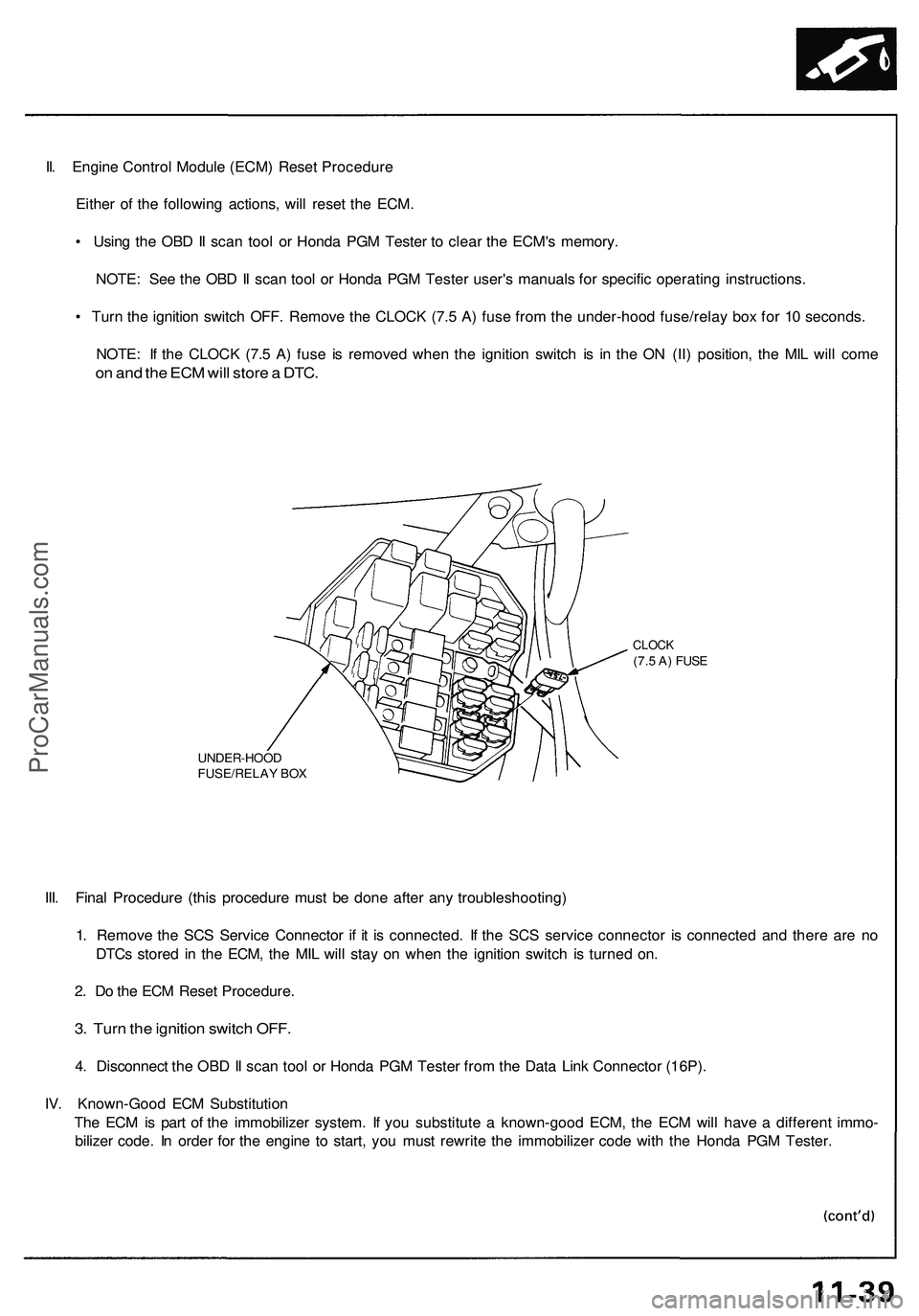

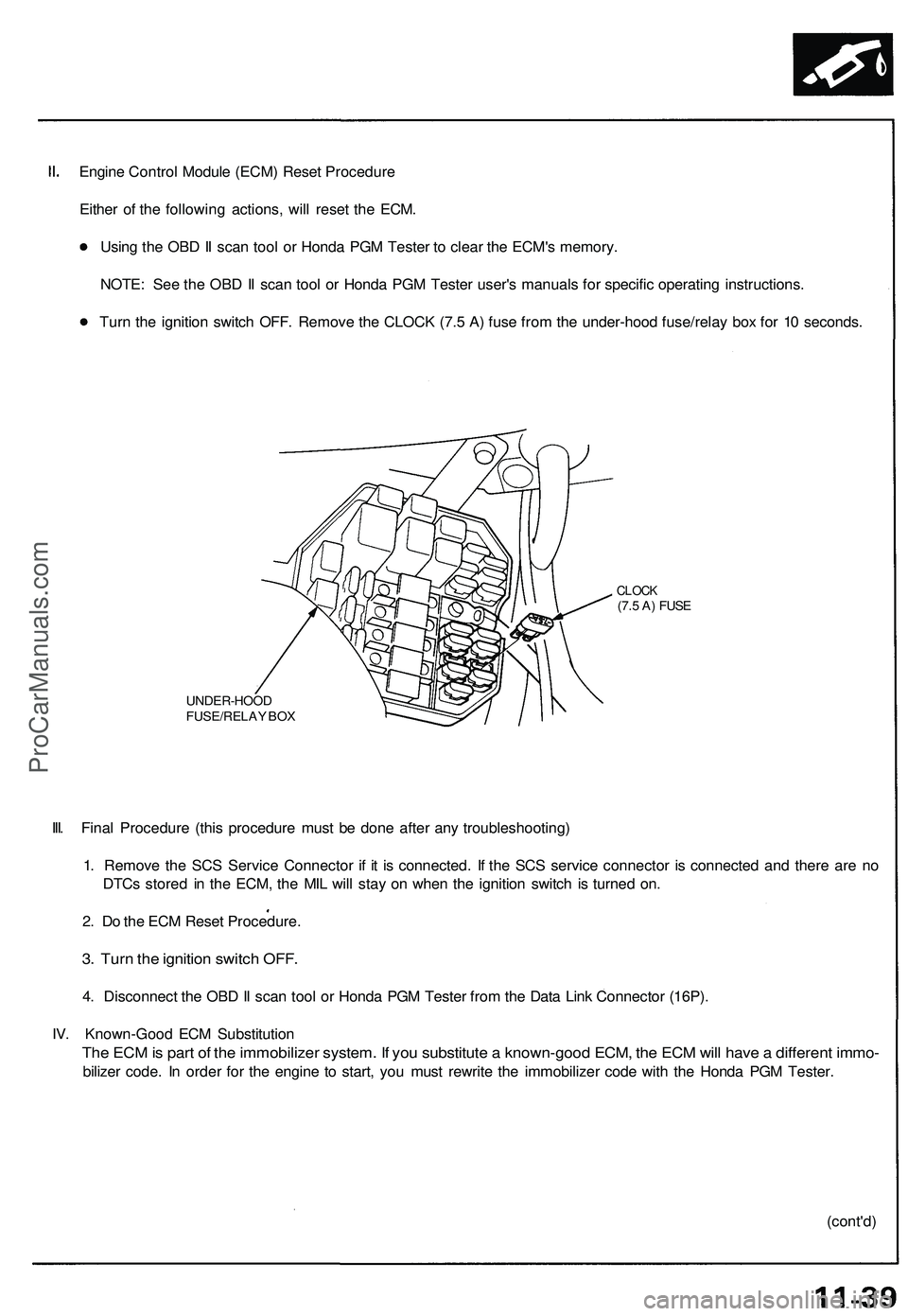

II. Engine Control Module (ECM) Reset Procedure

Either of the following actions, will reset the ECM.

• Using the OBD II scan tool or Honda PGM Tester to clear the ECM's memory.

NOTE: See the OBD II scan tool or Honda PGM Tester user's manuals for specific operating instructions.

• Turn the ignition switch OFF. Remove the CLOCK (7.5 A) fuse from the under-hood fuse/relay box for 10 seconds.

NOTE: If the CLOCK (7.5 A) fuse is removed when the ignition switch is in the ON (II) position, the MIL will come

on and the ECM will store a DTC.

UNDER-HOOD

FUSE/RELAY BOX

CLOCK

(7.5 A) FUSE

III. Final Procedure (this procedure must be done after any troubleshooting)

1. Remove the SCS Service Connector if it is connected. If the SCS service connector is connected and there are no

DTCs stored in the ECM, the MIL will stay on when the ignition switch is turned on.

2. Do the ECM Reset Procedure.

3. Turn the ignition switch OFF.

4. Disconnect the OBD II scan tool or Honda PGM Tester from the Data Link Connector (16P).

IV. Known-Good ECM Substitution

The ECM is part of the immobilizer system. If you substitute a known-good ECM, the ECM will have a different immo-

bilizer code. In order for the engine to start, you must rewrite the immobilizer code with the Honda PGM Tester.ProCarManuals.com

Page 270 of 1503

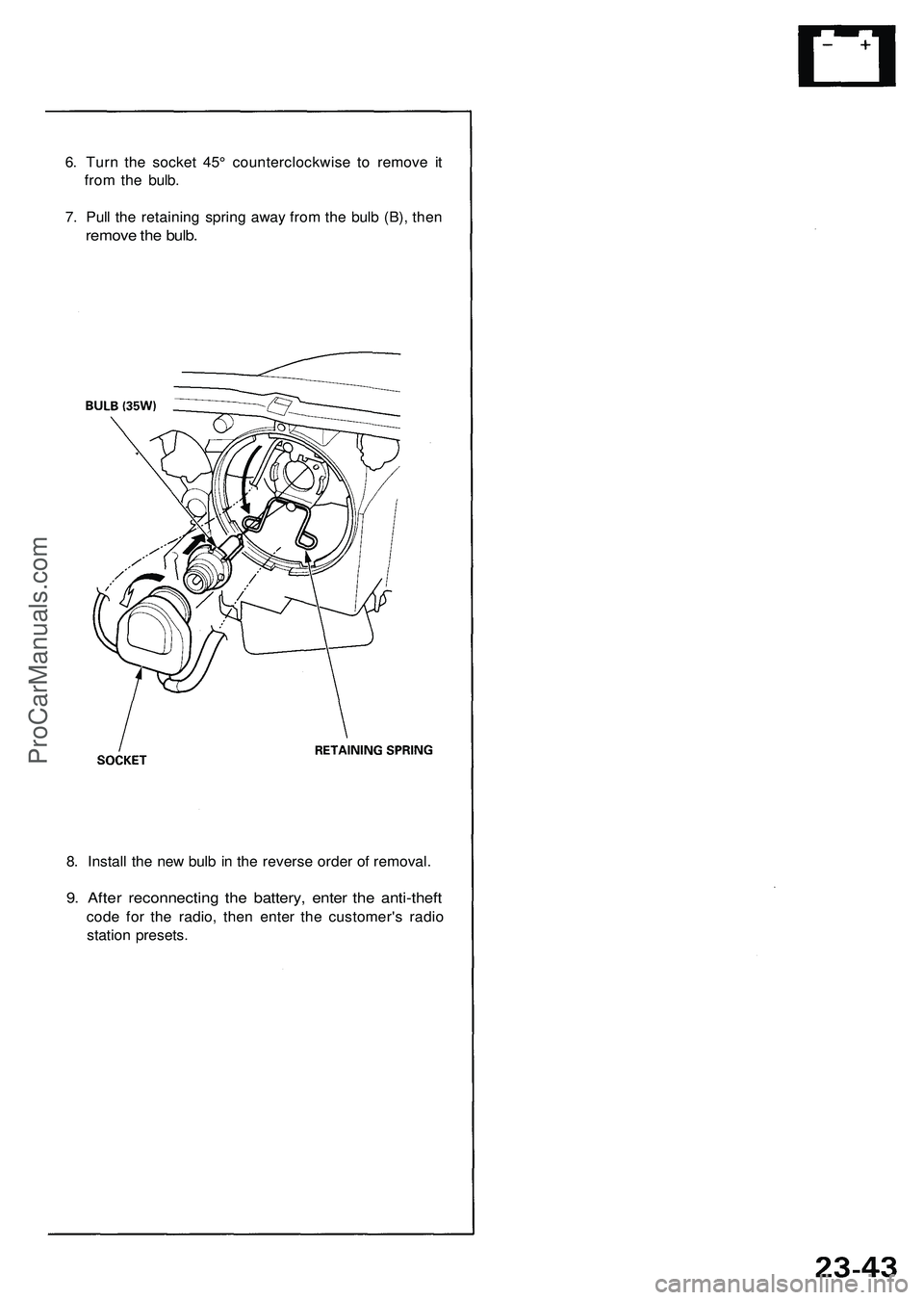

6. Turn the socket 45° counterclockwise to remove it

from the bulb.

7. Pull the retaining spring away from the bulb (B), then

remove the bulb.

8. Install the new bulb in the reverse order of removal.

9. After reconnecting the battery, enter the anti-theft

code for the radio, then enter the customer's radio

station presets.ProCarManuals.com

Page 359 of 1503

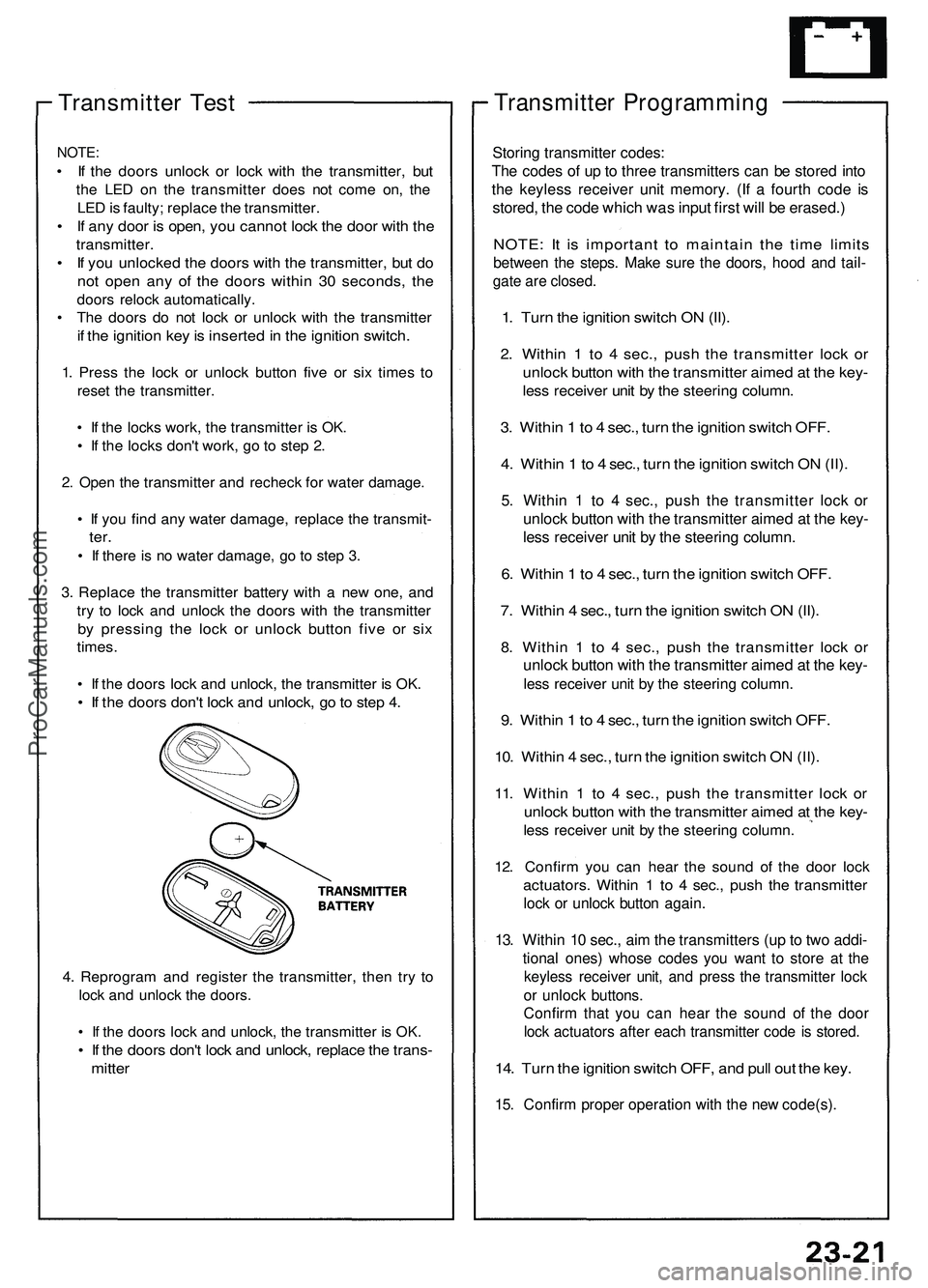

Transmitter Test

NOTE:

• If the doors unlock or lock with the transmitter, but

the LED on the transmitter does not come on, the

LED is faulty; replace the transmitter.

• If any door is open, you cannot lock the door with the

transmitter.

• If you unlocked the doors with the transmitter, but do

not open any of the doors within 30 seconds, the

doors relock automatically.

• The doors do not lock or unlock with the transmitter

if the ignition key is inserted in the ignition switch.

1. Press the lock or unlock button five or six times to

reset the transmitter.

• If the locks work, the transmitter is OK.

• If the locks don't work, go to step 2.

2. Open the transmitter and recheck for water damage.

• If you find any water damage, replace the transmit-

ter.

• If there is no water damage, go to step 3.

3. Replace the transmitter battery with a new one, and

try to lock and unlock the doors with the transmitter

by pressing the lock or unlock button five or six

times.

• If the doors lock and unlock, the transmitter is OK.

• If the doors don't lock and unlock, go to step 4.

4. Reprogram and register the transmitter, then try to

lock and unlock the doors.

• If the doors lock and unlock, the transmitter is OK.

• If the doors don't lock and unlock, replace the trans-

mitter

Transmitter Programming

Storing transmitter codes:

The codes of up to three transmitters can be stored into

the keyless receiver unit memory. (If a fourth code is

stored, the code which was input first will be erased.)

NOTE: It is important to maintain the time limits

between the steps. Make sure the doors, hood and tail-

gate are closed.

1. Turn the ignition switch ON (II).

2. Within 1 to 4 sec., push the transmitter lock or

unlock button with the transmitter aimed at the key-

less receiver unit by the steering column.

3. Within 1 to 4 sec., turn the ignition switch OFF.

4. Within 1 to 4 sec., turn the ignition switch ON (II).

5. Within 1 to 4 sec., push the transmitter lock or

unlock button with the transmitter aimed at the key-

less receiver unit by the steering column.

6. Within 1 to 4 sec., turn the ignition switch OFF.

7. Within 4 sec., turn the ignition switch ON (II).

8. Within 1 to 4 sec., push the transmitter lock or

unlock button with the transmitter aimed at the key-

less receiver unit by the steering column.

9. Within 1 to 4 sec., turn the ignition switch OFF.

10. Within 4 sec., turn the ignition switch ON (II).

11. Within 1 to 4 sec., push the transmitter lock or

unlock button with the transmitter aimed at the key-

less receiver unit by the steering column.

12. Confirm you can hear the sound of the door lock

actuators. Within 1 to 4 sec., push the transmitter

lock or unlock button again.

13. Within 10 sec., aim the transmitters (up to two addi-

tional ones) whose codes you want to store at the

keyless receiver unit, and press the transmitter lock

or unlock buttons.

Confirm that you can hear the sound of the door

lock actuators after each transmitter code is stored.

14. Turn the ignition switch OFF, and pull out the key.

15. Confirm proper operation with the new code(s).ProCarManuals.com

Page 467 of 1503

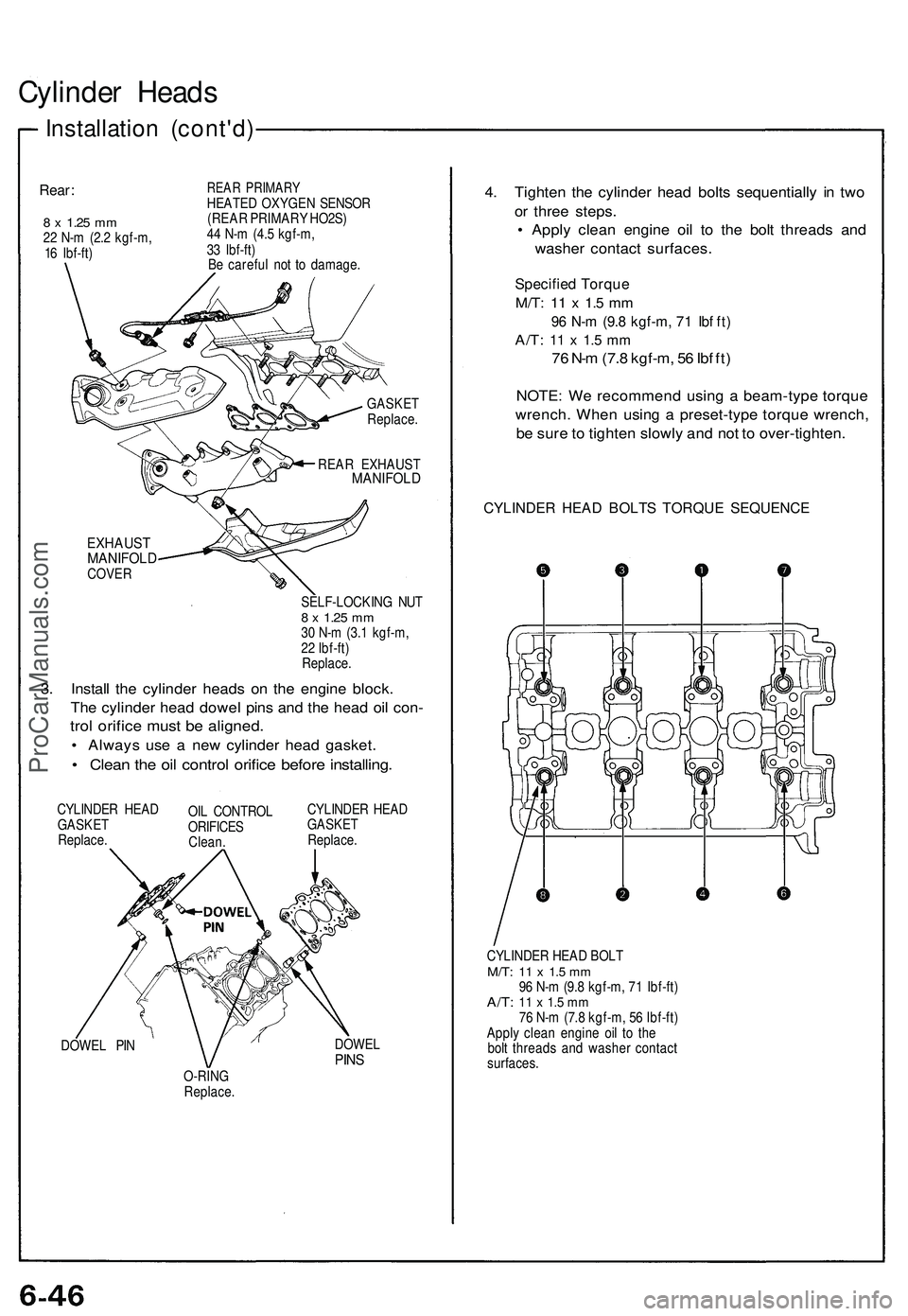

Cylinder Heads

Installation (cont'd)

Rear:

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

REAR PRIMARY

HEATED OXYGEN SENSOR

(REAR PRIMARY HO2S)

44 N-m (4.5 kgf-m,

33 Ibf-ft)

Be careful not to damage.

GASKET

Replace.

REAR EXHAUST

MANIFOLD

EXHAUST

MANIFOLD

COVER

SELF-LOCKING NUT

8 x

1.25

mm

30 N-m (3.1 kgf-m,

22 Ibf-ft)

Replace.

3. Install the cylinder heads on the engine block.

The cylinder head dowel pins and the head oil con-

trol orifice must be aligned.

• Always use a new cylinder head gasket.

• Clean the oil control orifice before installing.

CYLINDER HEAD

GASKET

Replace.

OIL CONTROL

ORIFICES

Clean.

CYLINDER HEAD

GASKET

Replace.

DOWEL PIN

DOWEL

PINS

O-RING

Replace.

4. Tighten the cylinder head bolts sequentially in two

or three steps.

• Apply clean engine oil to the bolt threads and

washer contact surfaces.

Specified Torque

M/T:

11 x 1.5 mm

96 N-m (9.8 kgf-m, 71 Ibf ft)

A/T:

11 x 1.5 mm

76 N-m (7.8 kgf-m, 56 Ibf ft)

NOTE: We recommend using a beam-type torque

wrench. When using a preset-type torque wrench,

be sure to tighten slowly and not to over-tighten.

CYLINDER HEAD BOLTS TORQUE SEQUENCE

CYLINDER HEAD BOLT

M/T:

11 x 1.5 mm

96 N-m (9.8 kgf-m, 71 Ibf-ft)

A/T:

11 x 1.5 mm

76 N-m (7.8 kgf-m, 56 Ibf-ft)

Apply clean engine oil to the

bolt threads and washer contact

surfaces.ProCarManuals.com

Page 565 of 1503

Engine Control Module (ECM) Reset Procedure

Either of the following actions, will reset the ECM.

Using the OBD II scan tool or Honda PGM Tester to clear the ECM's memory.

NOTE: See the OBD II scan tool or Honda PGM Tester user's manuals for specific operating instructions.

Turn the ignition switch OFF. Remove the CLOCK (7.5 A) fuse from the under-hood fuse/relay box for 10 seconds.

UNDER-HOOD

FUSE/RELAY BOX

CLOCK

(7.5 A) FUSE

III. Final Procedure (this procedure must be done after any troubleshooting)

1. Remove the SCS Service Connector if it is connected. If the SCS service connector is connected and there are no

DTCs stored in the ECM, the MIL will stay on when the ignition switch is turned on.

2. Do the ECM Reset Procedure.

3. Turn the ignition switch OFF.

4. Disconnect the OBD II scan tool or Honda PGM Tester from the Data Link Connector (16P).

IV. Known-Good ECM Substitution

The ECM is part of the immobilizer system. If you substitute a known-good ECM, the ECM will have a different immo-

bilizer code. In order for the engine to start, you must rewrite the immobilizer code with the Honda PGM Tester.

(cont'd)ProCarManuals.com

Page 574 of 1503

Troubleshooting

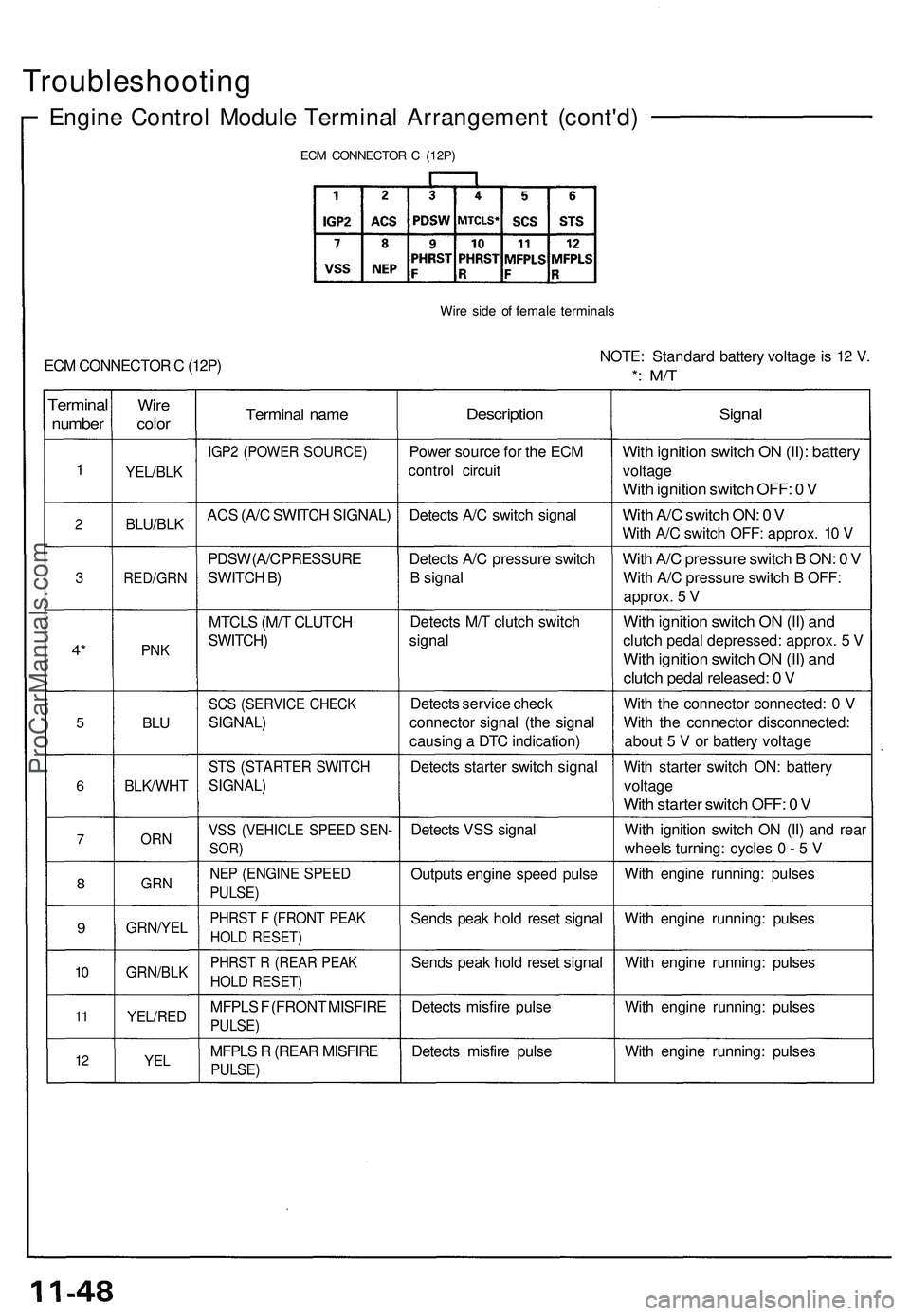

Engine Contro l Modul e Termina l Arrangemen t (cont'd )

ECM CONNECTO R C (12P )

Wire sid e o f femal e terminal s

ECM CONNECTO R C (12P ) NOTE

: Standar d batter y voltag e is 1 2 V .*: M/ T

Termina l

number

1

2

3

4*

5

6

7

8

9

10

1 1

1 2

Wir e

colo r

YEL/BL K

BLU/BLK

RED/GR N

PNK

BLU

BLK/WH T

ORN

GR N

GRN/YE L

GRN/BLK

YEL/RED

YEL

Termina l nam e

IGP2 (POWE R SOURCE )

ACS (A/ C SWITC H SIGNAL )

PDS W (A/ C PRESSUR E

SWITC H B )

MTCL S (M/ T CLUTC H

SWITCH )

SCS (SERVIC E CHEC K

SIGNAL )

STS (STARTE R SWITC H

SIGNAL )

VSS (VEHICL E SPEE D SEN -

SOR)

NEP (ENGIN E SPEE D

PULSE )

PHRST F (FRON T PEA K

HOLD RESET )

PHRST R (REA R PEA K

HOLD RESET )

MFPLS F (FRON T MISFIR E

PULSE)

MFPLS R (REA R MISFIR E

PULSE)

Descriptio n

Power sourc e fo r th e EC M

contro l circui t

Detect s A/ C switc h signa l

Detect s A/ C pressur e switc h

B signa l

Detect s M/ T clutc h switc h

signa l

Detect s servic e chec k

connecto r signa l (th e signa l

causin g a DT C indication )

Detect s starte r switc h signa l

Detect s VS S signa l

Output s engin e spee d puls e

Send s pea k hol d rese t signa l

Send s pea k hol d rese t signa l

Detect s misfir e puls e

Detect s misfir e puls e

Signa l

With ignitio n switc h O N (II) : batter y

voltage

With ignitio n switc h OFF : 0 V

Wit h A/ C switc h ON : 0 V

Wit h A/ C switc h OFF : approx . 1 0 V

Wit h A/ C pressur e switc h B ON : 0 V

Wit h A/ C pressur e switc h B OFF :

approx . 5 V

Wit h ignitio n switc h O N (II ) an d

clutc h peda l depressed : approx . 5 V

Wit h ignitio n switc h O N (II ) an d

clutc h peda l released : 0 V

Wit h th e connecto r connected : 0 V

Wit h th e connecto r disconnected :

abou t 5 V or batter y voltag e

Wit h starte r switc h ON : batter y

voltag e

With starte r switc h OFF : 0 V

Wit h ignitio n switc h O N (II ) an d rea r

wheel s turning : cycle s 0 - 5 V

Wit h engin e running : pulse s

Wit h engin e running : pulse s

Wit h engin e running : pulse s

Wit h engin e running : pulse s

Wit h engin e running : pulse s

ProCarManuals.com

Page 584 of 1503

Troubleshooting

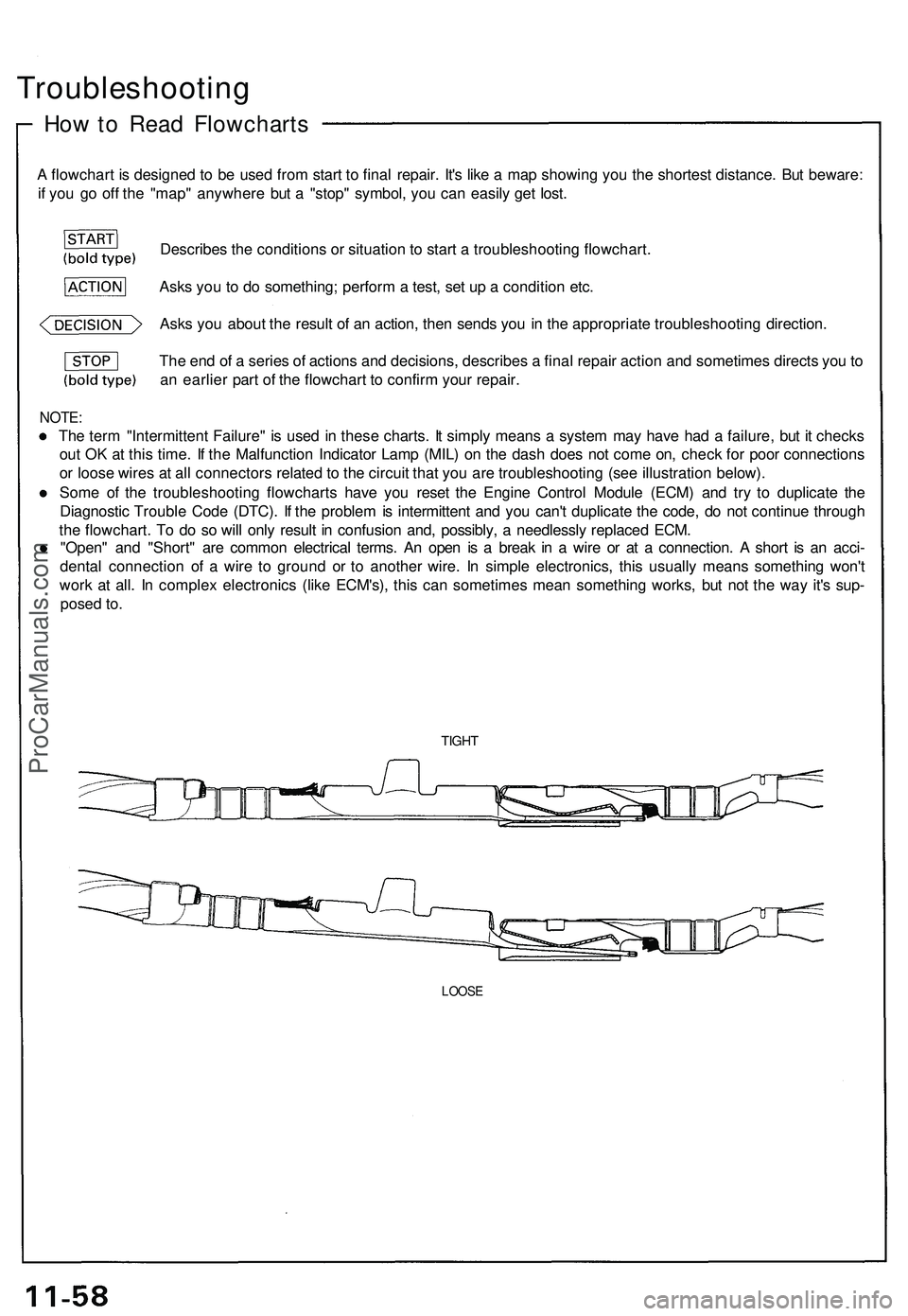

How to Read Flowcharts

A flowchart is designed to be used from start to final repair. It's like a map showing you the shortest distance. But beware:

if you go off the "map" anywhere but a "stop" symbol, you can easily get lost.

Describes the conditions or situation to start a troubleshooting flowchart.

Asks you to do something; perform a test, set up a condition etc.

Asks you about the result of an action, then sends you in the appropriate troubleshooting direction.

NOTE:

The term "Intermittent Failure" is used in these charts. It simply means a system may have had a failure, but it checks

out OK at this time. If the Malfunction Indicator Lamp (MIL) on the dash does not come on, check for poor connections

or loose wires at all connectors related to the circuit that you are troubleshooting (see illustration below).

Some of the troubleshooting flowcharts have you reset the Engine Control Module (ECM) and try to duplicate the

Diagnostic Trouble Code (DTC). If the problem is intermittent and you can't duplicate the code, do not continue through

the flowchart. To do so will only result in confusion and, possibly, a needlessly replaced ECM.

"Open" and "Short" are common electrical terms. An open is a break in a wire or at a connection. A short is an acci-

dental connection of a wire to ground or to another wire. In simple electronics, this usually means something won't

work at all. In complex electronics (like ECM's), this can sometimes mean something works, but not the way it's sup-

posed to.

TIGHT

LOOSE

The end of a series of actions and decisions, describes a final repair action and sometimes directs you to

an earlier part of the flowchart to confirm your repair.ProCarManuals.com