oil change ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 31 of 1503

Engine Oi l

Replacemen t

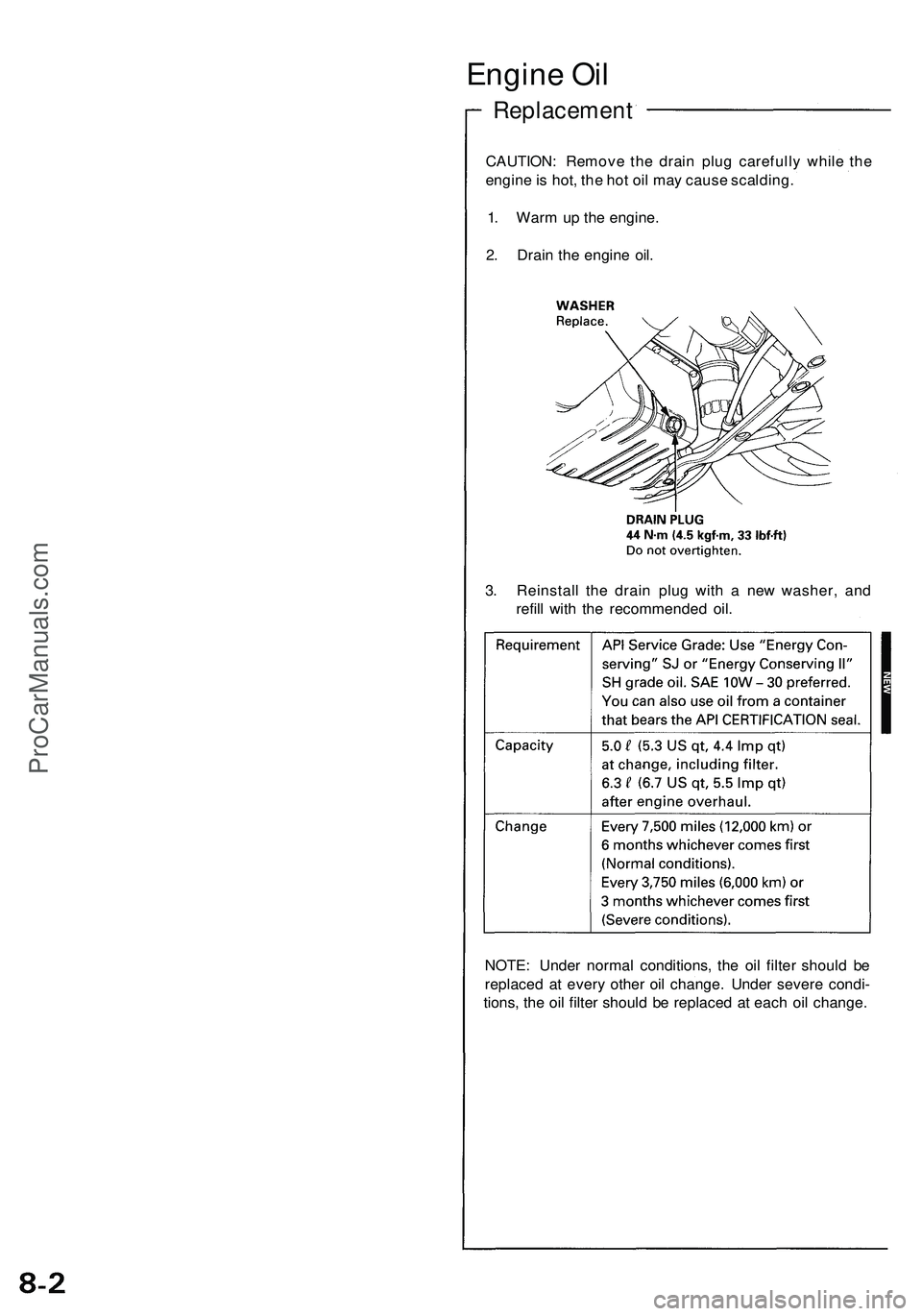

CAUTION: Remov e th e drai n plu g carefull y whil e th e

engin e is hot , th e ho t oi l ma y caus e scalding .

1 . War m u p th e engine .

2 . Drai n th e engin e oil .

3 . Reinstal l th e drai n plu g wit h a ne w washer , an d

refil l wit h th e recommende d oil .

NOTE : Unde r norma l conditions , th e oi l filte r shoul d b e

replace d a t ever y othe r oi l change . Unde r sever e condi -

tions , th e oi l filte r shoul d b e replace d a t eac h oi l change .

ProCarManuals.com

Page 371 of 1503

4-2

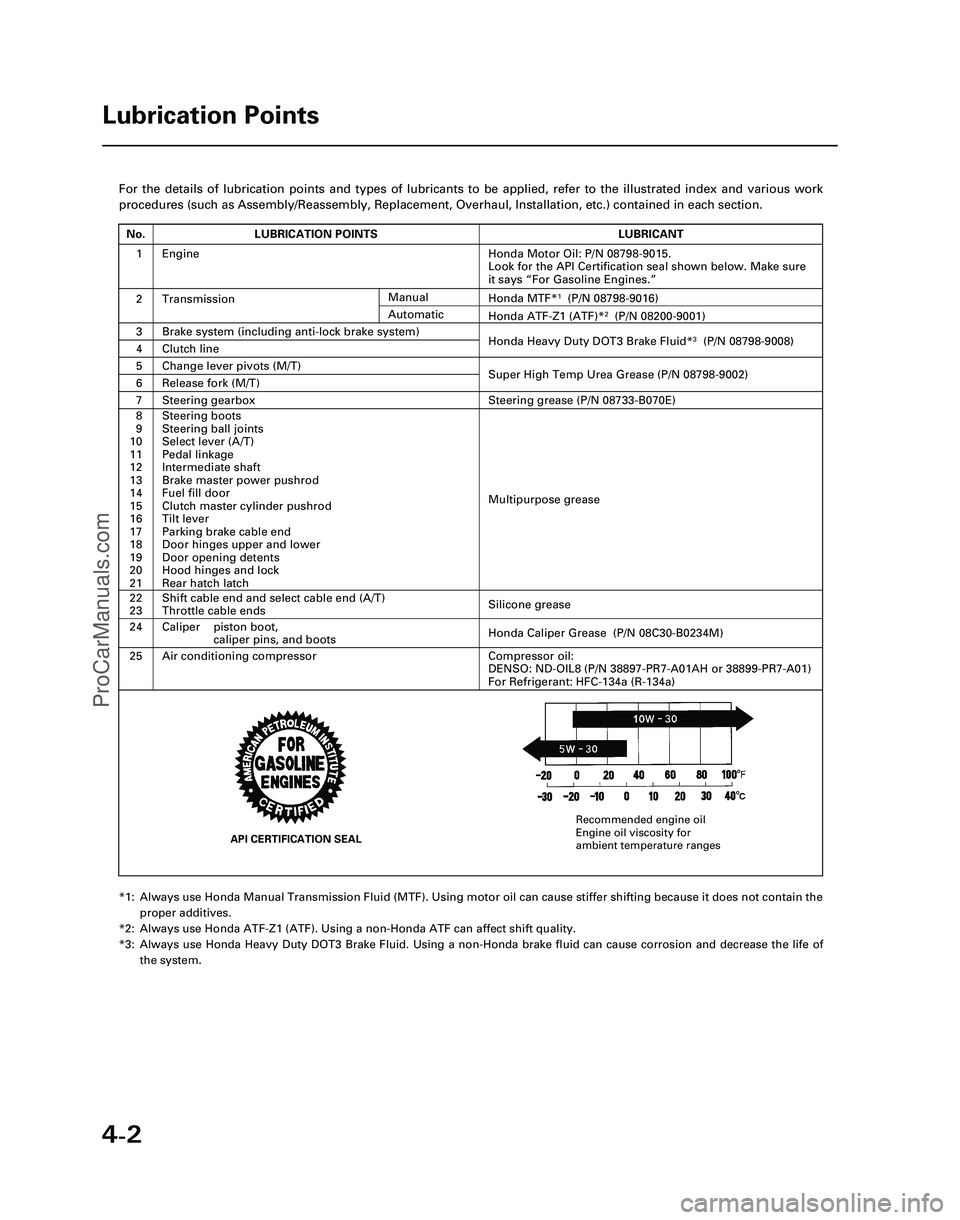

For the details of lubrication points and types of lubricants to be appl\

ied, refer to the illustrated index and various work

procedures (such as Assembly/Reassembly, Replacement, Overhaul, Install\

ation, etc.) contained in each section.

*1: Always use Honda Manual Transmission Fluid (MTF). Using motor oil can \

cause stiffer shifting because it does not contain theproper additives.

*2: Always use Honda ATF-Z1 (ATF). Using a non-Honda ATF can affect shift \

quality.

*3: Always use Honda Heavy Duty DOT3 Brake Fluid. Using a non-Honda brake fl\

uid can cause corrosion and decrease the life of the system.

Lubrication Points

No.LUBRICATION POINTSLUBRICANT

1Honda Motor Oil: P/N 08798-9015.

Look for the API Certification seal shown below. Make sure

it says “For Gasoline Engines.”

2TransmissionHonda MTF*1(P/N 08798-9016)

3Brake system (including anti-lock brake system)Honda Heavy Duty DOT3 Brake Fluid*3(P/N 08798-9008)4Clutch line

5Change lever pivots (M/T)Super High Temp Urea Grease (P/N 08798-9002)6Release fork (M/T)

8

9

10

11

12

13

14

15

16

17

18

19

20

21Steering boots

Steering ball joints

Select lever (A/T)

Pedal linkage

Intermediate shaft

Brake master power pushrod

Fuel fill door

Clutch master cylinder pushrod

Tilt lever

Parking brake cable end

Door hinges upper and lower

Door opening detents

Hood hinges and lock

Rear hatch latch

Multipurpose grease

24

22

23

Caliper piston boot, caliper pins, and boots

Shift cable end and select cable end (A/T)

Throttle cable ends

Honda Caliper Grease (P/N 08C30-B0234M)

Silicone grease

25Air conditioning compressorCompressor oil:

DENSO: ND-OIL8 (P/N 38897-PR7-A01AH or 38899-PR7-A01)

For Refrigerant: HFC-134a (R-134a)

Manual

Honda ATF-Z1 (ATF)*2(P/N 08200-9001)Automatic

7Steering gearboxSteering grease (P/N 08733-B070E)

Engine

API CERTIFICATION SEAL

Recommended engine oil

Engine oil viscosity for

ambient temperature ranges

*05-NSX (61SW004)SEC04(01-10) 9/22/04 1:49 PM Page 4-2

ProCarManuals.com

Page 464 of 1503

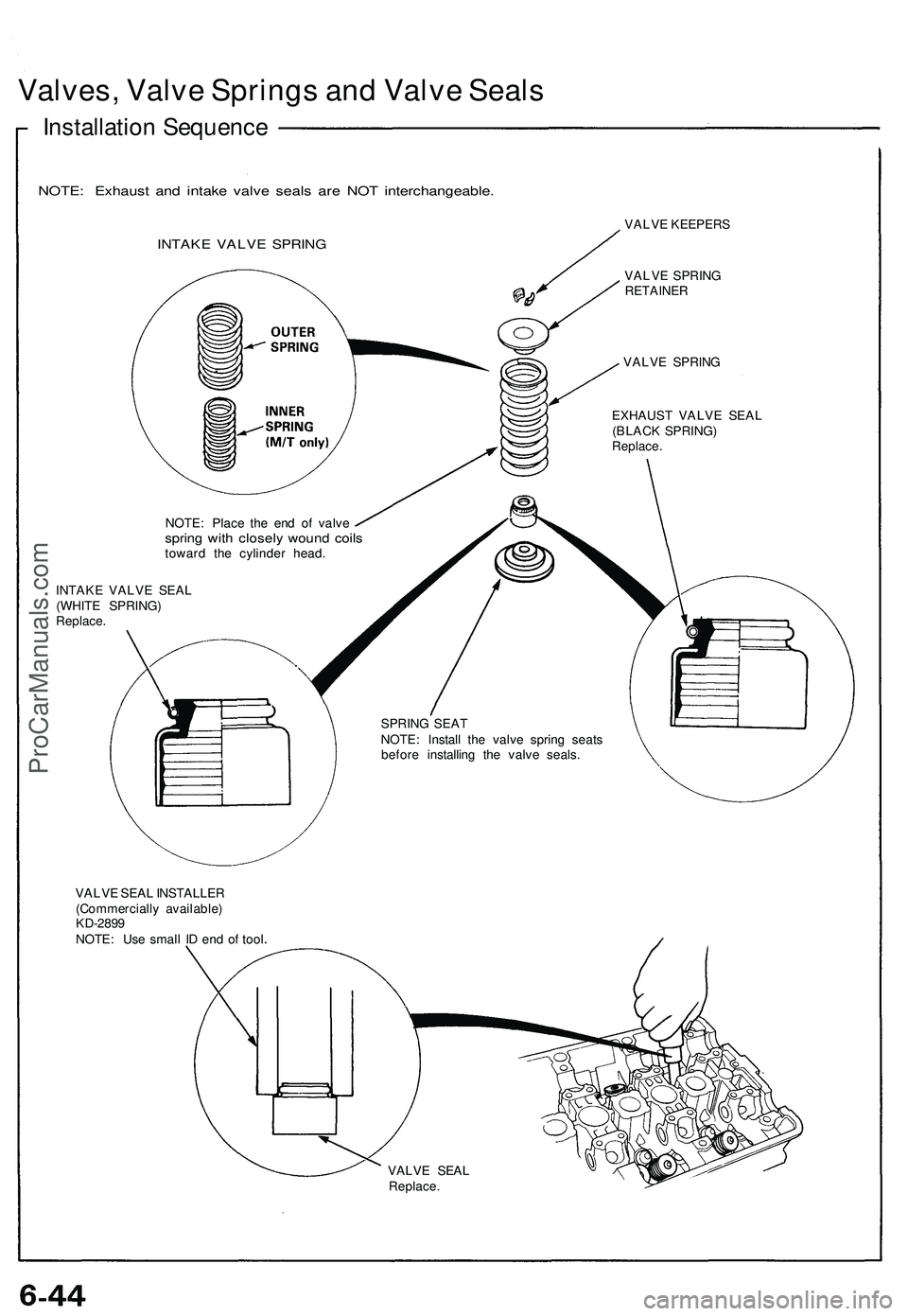

Valves, Valve Springs and Valve Seals

Installation Sequence

NOTE: Exhaust and intake valve seals are NOT interchangeable.

INTAKE VALVE SPRING

VALVE KEEPERS

VALVE SPRING

RETAINER

VALVE SPRING

EXHAUST VALVE SEAL

(BLACK SPRING)

Replace.

NOTE: Place the end of valve

spring with closely wound coils

toward the cylinder head.

INTAKE VALVE SEAL

(WHITE SPRING)

Replace.

SPRING SEAT

NOTE: Install the valve spring seats

before installing the valve seals.

VALVE SEAL INSTALLER

(Commercially available)

KD-2899

NOTE: Use small ID end of tool

VALVE SEAL

Replace.ProCarManuals.com

Page 502 of 1503

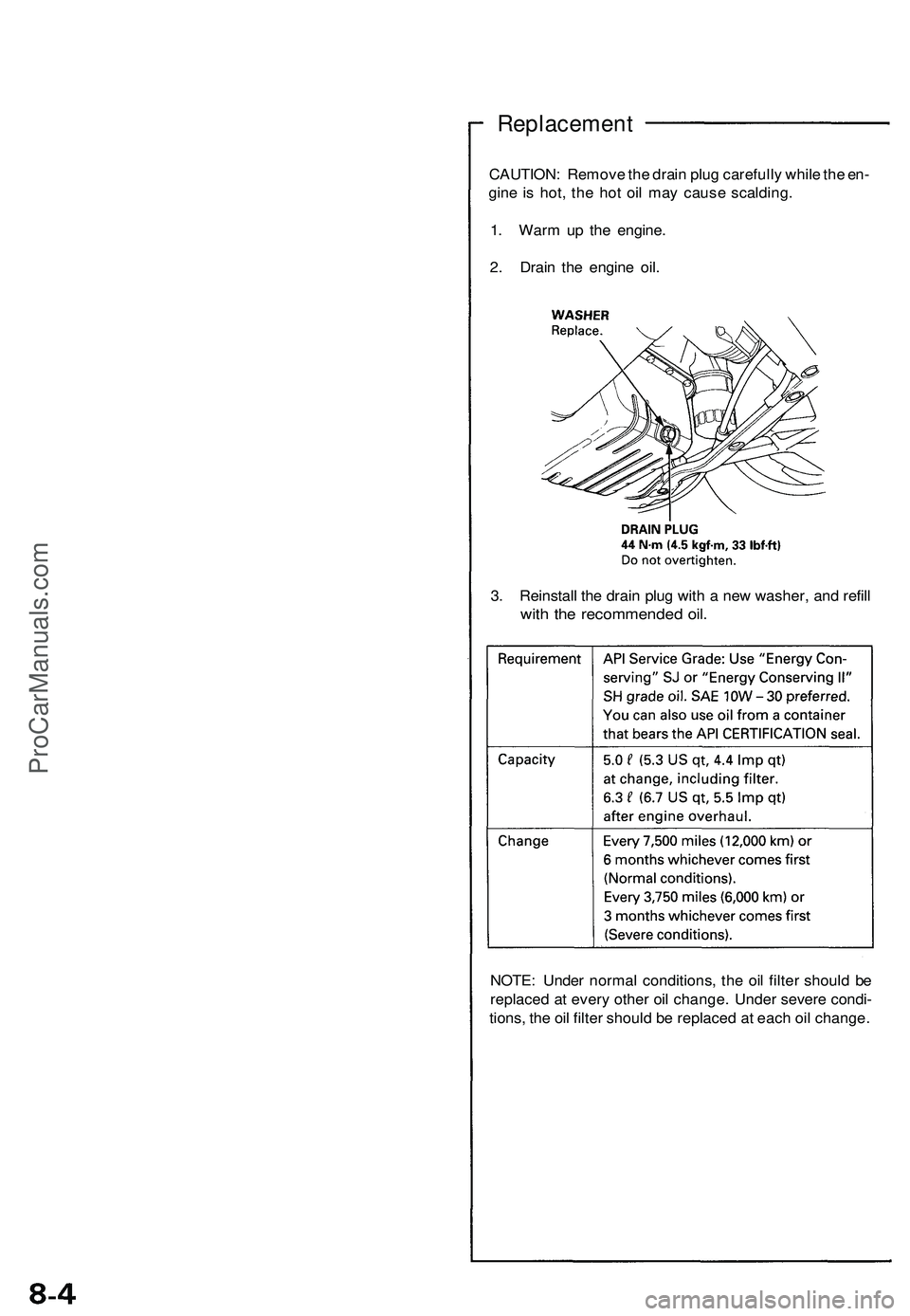

Replacement

CAUTION: Remove the drain plug carefully while the en-

gine is hot, the hot oil may cause scalding.

1. Warm up the engine.

2. Drain the engine oil.

3. Reinstall the drain plug with a new washer, and refill

with the recommended oil.

NOTE: Under normal conditions, the oil filter should be

replaced at every other oil change. Under severe condi-

tions, the oil filter should be replaced at each oil change.ProCarManuals.com

Page 652 of 1503

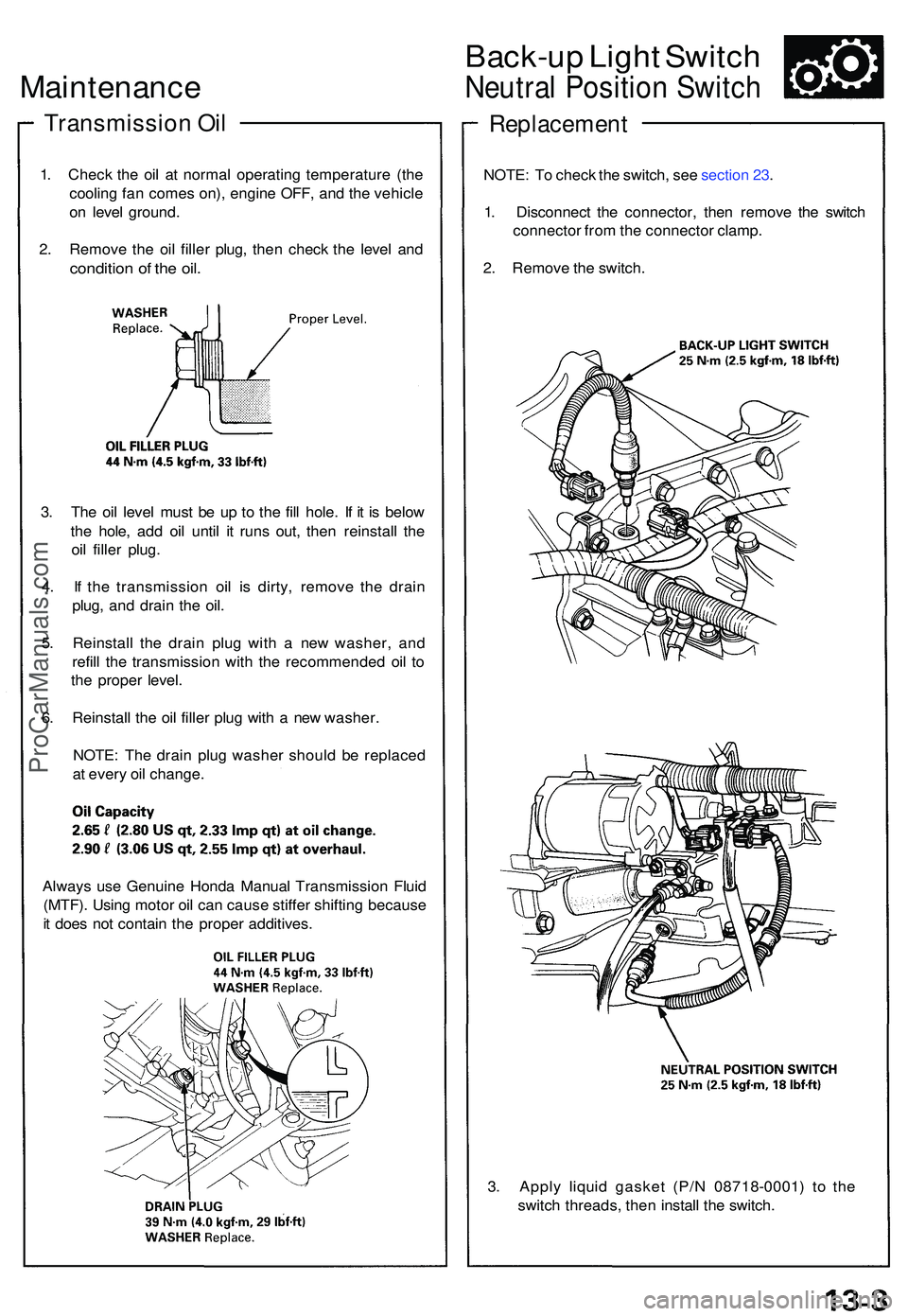

Maintenance

Transmissio n Oi l

1. Chec k th e oi l a t norma l operating temperatur e (th e

coolin g fa n come s on) , engin e OFF , an d th e vehicl e

o n leve l ground .

2 . Remov e th e oi l fille r plug , the n chec k th e leve l an d

conditio n o f th e oil .

3. Th e oi l leve l mus t b e u p t o th e fil l hole . I f i t i s belo w

th e hole , ad d oi l unti l i t run s out , the n reinstal l th e

oi l fille r plug .

4 . I f th e transmissio n oi l i s dirty , remov e th e drai n

plug , an d drai n th e oil .

5 . Reinstal l th e drai n plu g wit h a ne w washer , an d

refil l th e transmissio n wit h th e recommende d oi l t o

th e prope r level .

6 . Reinstal l th e oi l fille r plu g wit h a ne w washer .

NOTE : Th e drai n plu g washe r shoul d b e replace d

a t ever y oi l change .

Back-up Ligh t Switc h

Neutra l Positio n Switc h

Replacemen t

NOTE: T o chec k th e switch , se e sectio n 23 .

1 . Disconnec t th e connector , the n remov e th e switc h

connecto r fro m th e connecto r clamp .

2 . Remov e th e switch .

3 . Appl y liqui d gaske t (P/ N 0871 8-0001 ) t o th e

switc h threads , the n instal l th e switch .

Alway

s us e Genuin e Hond a Manua l Transmissio n Flui d

(MTF) . Usin g moto r oi l ca n caus e stiffe r shiftin g becaus e

i t doe s no t contai n th e prope r additives .

ProCarManuals.com

Page 713 of 1503

Description

The automatic transmission is a combination of a 3-element torque converter and a triple-shaft electronically controlled

automatic transmission which provides 4 speeds forward and 1 speed reverse. The entire unit is positioned in line with the

engine.

Torque Converter, Gears, and Clutches

The torque converter consists of a pump, turbine, and stator, assembled in a single unit.

They are connected to the engine crankshaft so they turn together as a unit as the engine turns.

Around the outside of the torque converter is a ring gear which meshes with the starter pinion when the engine is being

started. The entire torque converter assembly serves as a flywheel while transmitting power to the transmission main-

shaft. The transmission has three parallel shafts: the mainshaft, the countershaft, and the secondary shaft. The mainshaft

is in line with the engine crankshaft.

The mainshaft includes the 1st and 4th clutches, and gears for 3rd, 4th, reverse, and 1st (3rd gear is integral with the main-

shaft, while reverse gear is integral with 4th gear).

The countershaft includes the 1st-hold and 3rd clutches, and gears for 2nd, 3rd, 4th, reverse, 1st, and parking.

The secondary shaft includes the 2nd clutch and gears for 2nd and 3rd.

The 4th and reverse gears can be locked to the countershaft at its center, providing 4th gear or reverse, depending on

which way the selector is moved.

The gears on the mainshaft and secondary shaft are in constant mesh with those on the countershaft.

When certain combinations of gears in the transmission are engaged by clutches, power is transmitted from the mainshaft

to the countershaft to provide positions.

Electronic Control

The electronic control system consists of the Transmission Control Module (TCM), sensors, a linear solenoid, a shift switch,

and 4 solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located on the insulator center bulkhead, behind the driver's seat.

Hydraulic Control

The valve bodies include the main valve body, secondary valve body, servo body, regulator valve body, throttle valve

body, lock-up valve body, and the 2nd accumulator body.

They are bolted to the torque converter housing as an assembly.

The main valve body contains the manual valve, 1-2 shift valve, 2-3 shift valve, 3-4 shift valve, relief valve, one-way relief

valve, and oil pump gears.

The secondary valve body contains the 3-2 kick-down valve, clutch pressure control (CPC) valve, 2nd orifice control valve, 3rd

orifice control valve, modulator valve, 4th exhaust valve, servo control valve, 2nd exhaust valve, and 4-3 kick-down valve.

The servo body contains the accumulator pistons and servo valve. The throttle valve body includes the throttle valve B

which is bolted to the servo body.

The regulator valve body contains the pressure regulator valve, lock-up control valve, and cooler relief valve. Fluid from

the regulator passes through the manual valve to the various control valves.

The lock-up valve body contains the lock-up timing B valve and lock-up shift valve. The 2nd accumulator body contains

the accumulator pistons and limited slip differential relief valve.

The torque converter check valve is located in the torque converter housing, under the main valve body.

The 1st, 1st-hold, 3rd, and 4th clutches receive fluid from their respective feed pipes and the 2nd clutch receives fluid from

the internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the vehicle determines which shift control solenoid valve the TCM will acti-

vate. Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes

a line to one of the clutches, engaging that clutch and its corresponding gear.

Lock-up Mechanism

In position and position in 2nd, 3rd, and 4th, pressurized fluid is drained from the back of the torque converter

through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes place, the

mainshaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the TCM optimizes the tim-

ing of the lock-up mechanism.

The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and B, and throttle valve B.

When lock-up control solenoid valves A and B activate, modulator pressure changes. The lock-up control solenoid valves

A and B are mounted on the torque converter housing, and are controlled by the TCM.

(cont'd)ProCarManuals.com

Page 899 of 1503

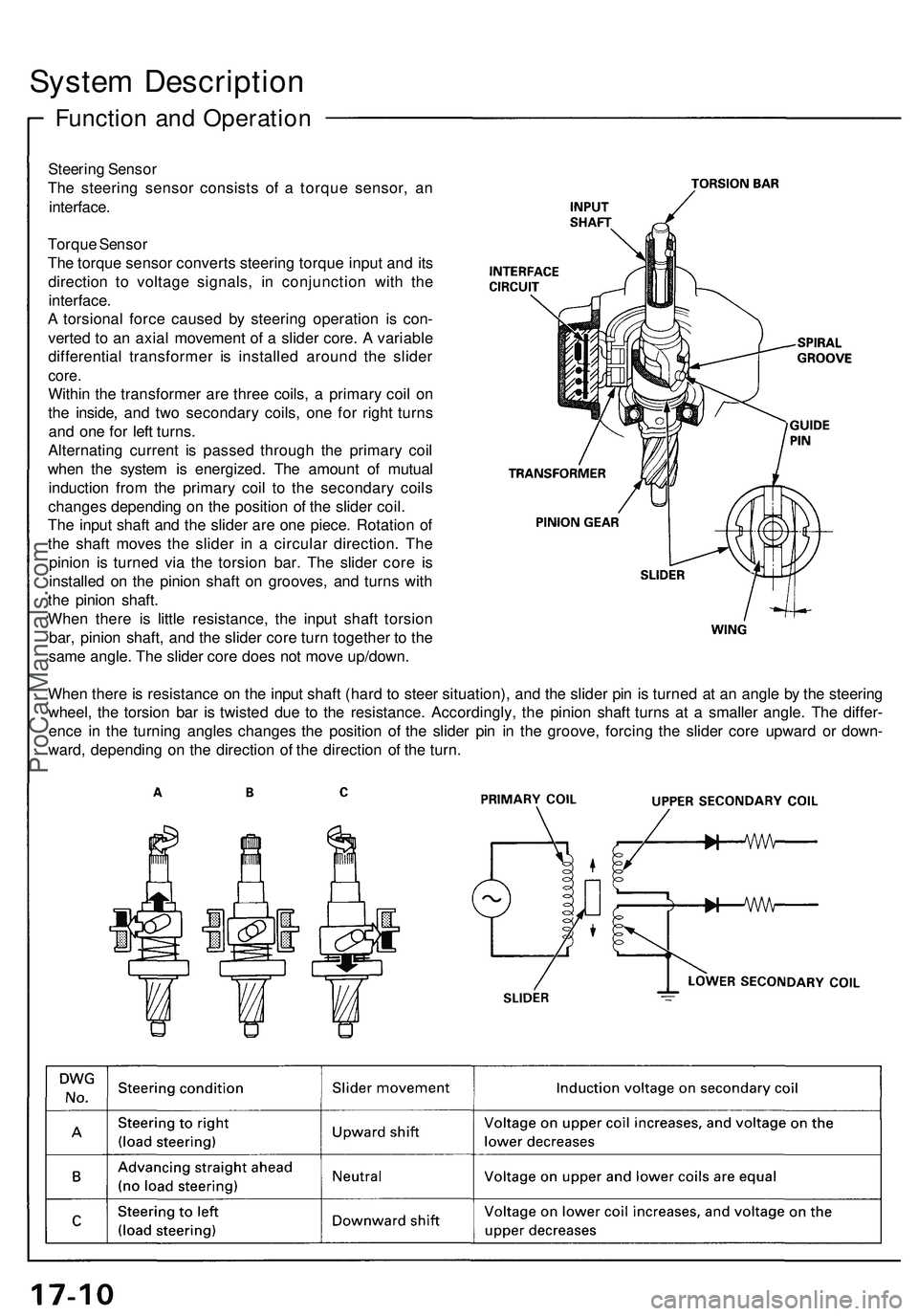

System Description

Function and Operation

Steering Sensor

The steering sensor consists of a torque sensor, an

interface.

Torque Sensor

The torque sensor converts steering torque input and its

direction to voltage signals, in conjunction with the

interface.

A torsional force caused by steering operation is con-

verted to an axial movement of a slider core. A variable

differential transformer is installed around the slider

core.

Within the transformer are three coils, a primary coil on

the inside, and two secondary coils, one for right turns

and one for left turns.

Alternating current is passed through the primary coil

when the system is energized. The amount of mutual

induction from the primary coil to the secondary coils

changes depending on the position of the slider coil.

The input shaft and the slider are one piece. Rotation of

the shaft moves the slider in a circular direction. The

pinion is turned via the torsion bar. The slider core is

installed on the pinion shaft on grooves, and turns with

the pinion shaft.

When there is little resistance, the input shaft torsion

bar, pinion shaft, and the slider core turn together to the

same angle. The slider core does not move up/down.

When there is resistance on the input shaft (hard to steer situation), and the slider pin is turned at an angle by the steering

wheel, the torsion bar is twisted due to the resistance. Accordingly, the pinion shaft turns at a smaller angle. The differ-

ence in the turning angles changes the position of the slider pin in the groove, forcing the slider core upward or down-

ward, depending on the direction of the direction of the turn.ProCarManuals.com

Page 1222 of 1503

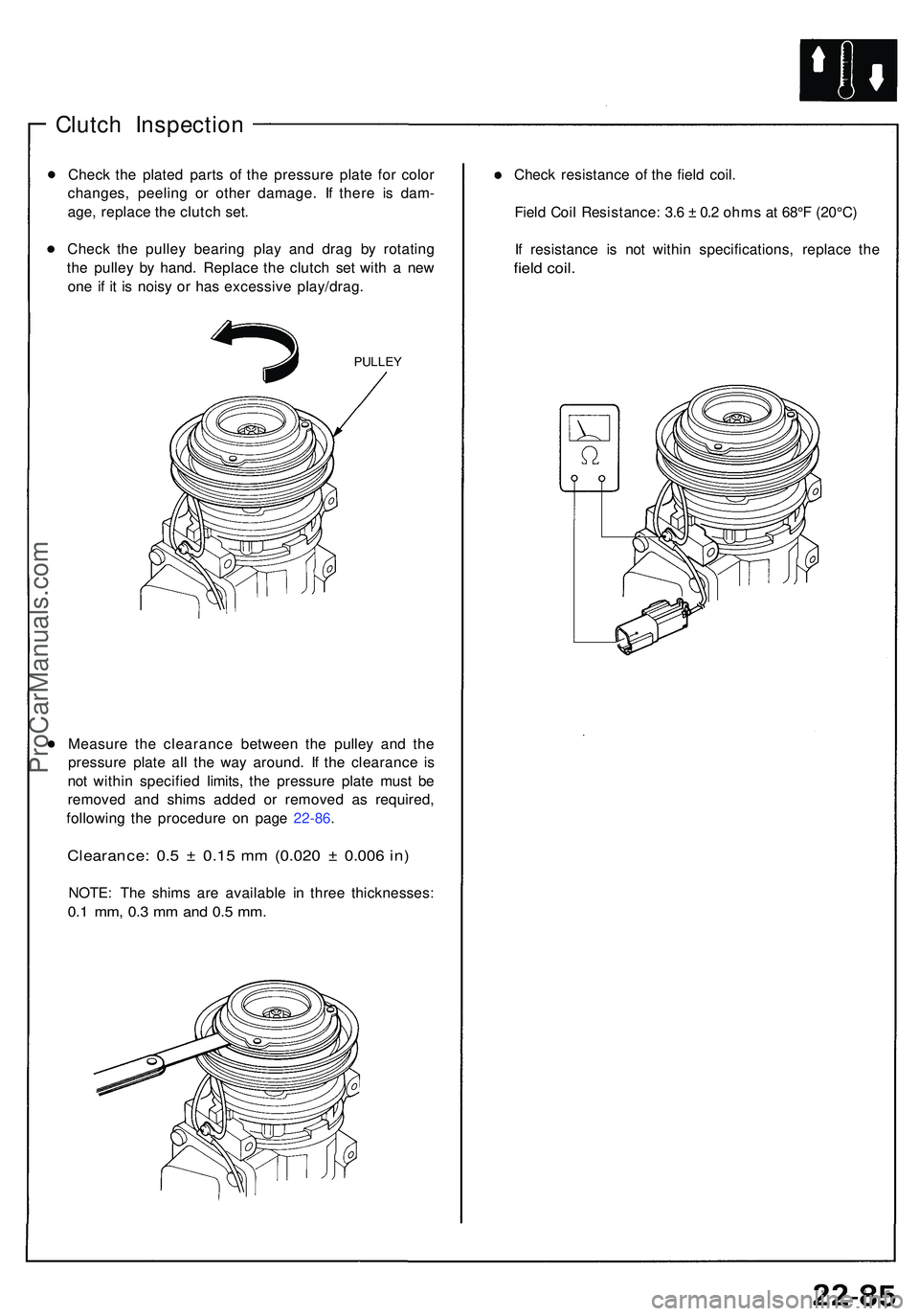

Clutch Inspectio n

Check th e plate d part s o f th e pressur e plat e fo r colo r

changes , peelin g o r othe r damage . I f ther e i s dam -

age , replac e th e clutc h set .

Chec k th e pulle y bearin g pla y an d dra g b y rotatin g

th e pulle y b y hand . Replac e th e clutc h se t wit h a ne w

on e i f i t i s nois y o r ha s excessiv e play/drag .

PULLEY

Measur e th e clearanc e betwee n th e pulle y an d th e

pressur e plat e al l th e wa y around . I f th e clearanc e i s

no t withi n specifie d limits , th e pressur e plat e mus t b e

remove d an d shim s adde d o r remove d a s required ,

followin g th e procedur e o n pag e 22-86 .

Clearance : 0. 5 ± 0.1 5 m m (0.02 0 ± 0.00 6 in )

NOTE : Th e shim s ar e availabl e i n thre e thicknesses :

0.1 mm , 0. 3 m m an d 0. 5 mm .

Chec k resistanc e o f th e fiel d coil .

Fiel d Coi l Resistance : 3. 6 ± 0. 2 ohm s a t 68° F (20°C )

I f resistanc e i s no t withi n specifications , replac e th e

field coil .

ProCarManuals.com