ignition ACURA RL KA9 1996 Service Owner's Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 340 of 1954

Ignition Syste m

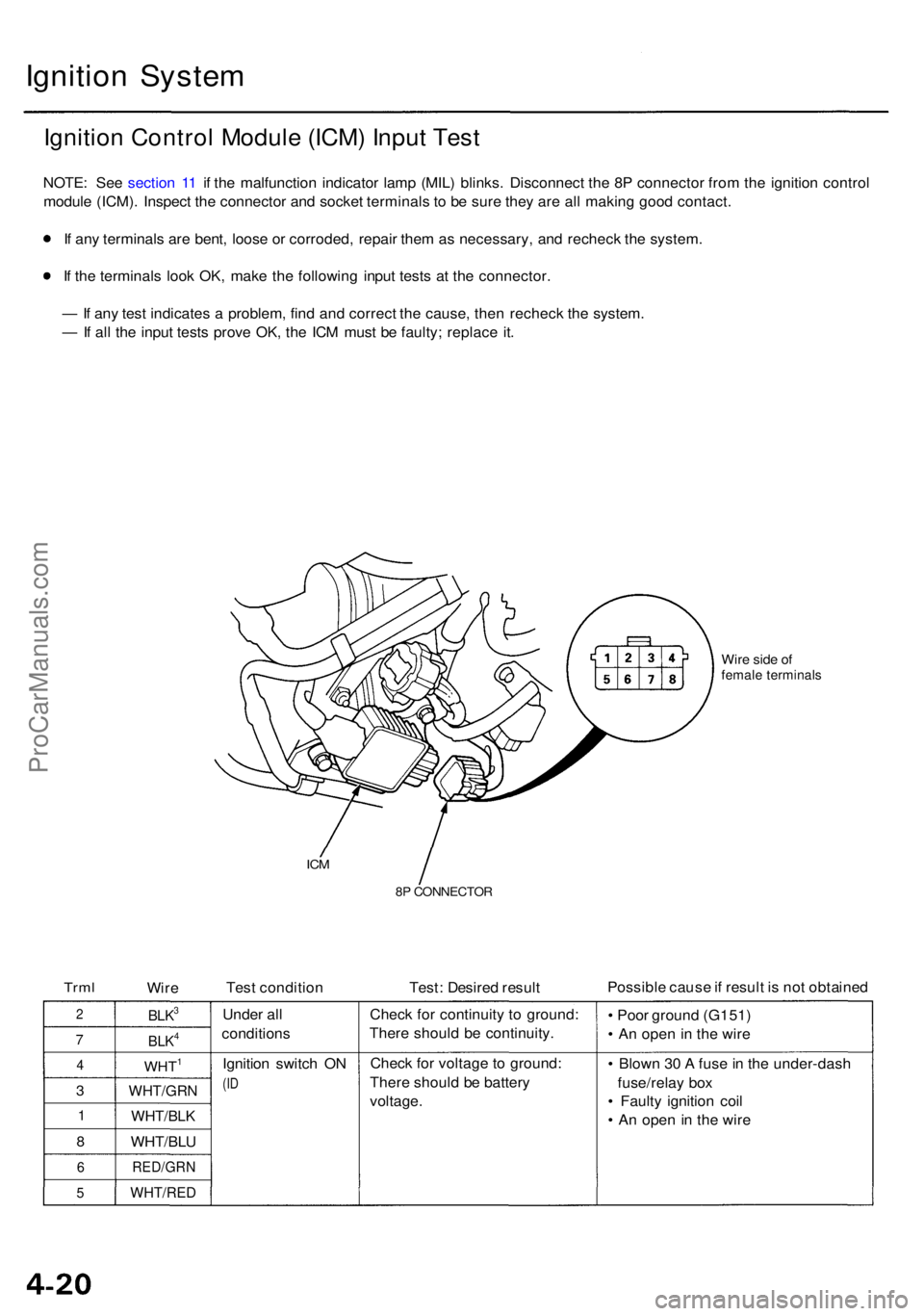

Ignition Contro l Modul e (ICM ) Inpu t Tes t

NOTE : Se e sectio n 1 1 i f th e malfunctio n indicator lamp (MIL ) blinks . Disconnec t th e 8 P connecto r fro m th e ignitio n contro l

modul e (ICM) . Inspec t th e connecto r an d socke t terminal s t o b e sur e the y ar e al l makin g goo d contact .

I f an y terminal s ar e bent , loos e o r corroded , repai r the m a s necessary , an d rechec k th e system .

I f th e terminal s loo k OK , mak e th e followin g inpu t test s a t th e connector .

— If an y tes t indicate s a problem , fin d an d correc t th e cause , the n rechec k th e system .

— If al l th e inpu t test s prov e OK , th e IC M mus t b e faulty ; replac e it .

Wir e sid e o ffemal e terminal s

ICM

8P CONNECTO R

TrmlWire Tes

t conditio n Test: Desire d resul t Possibl

e caus e if resul t i s no t obtaine d

2

7

4

3

1

8

6

5

BLK3

BLK4

WHT1

WHT/GR N

WHT/BLK

WHT/BLU

RED/GR N

WHT/RED

Under al l

condition s

Ignitio n switc h O N

(ID

Chec k fo r continuit y t o ground :

Ther e shoul d b e continuity .

Chec k fo r voltag e t o ground :

Ther e shoul d b e batter y

voltage . •

Poo r groun d (G151 )

• A n ope n in th e wir e

• Blow n 3 0 A fus e in th e under-das h

fuse/rela y bo x

• Fault y ignitio n coi l

• A n ope n i n th e wir e

ProCarManuals.com

Page 341 of 1954

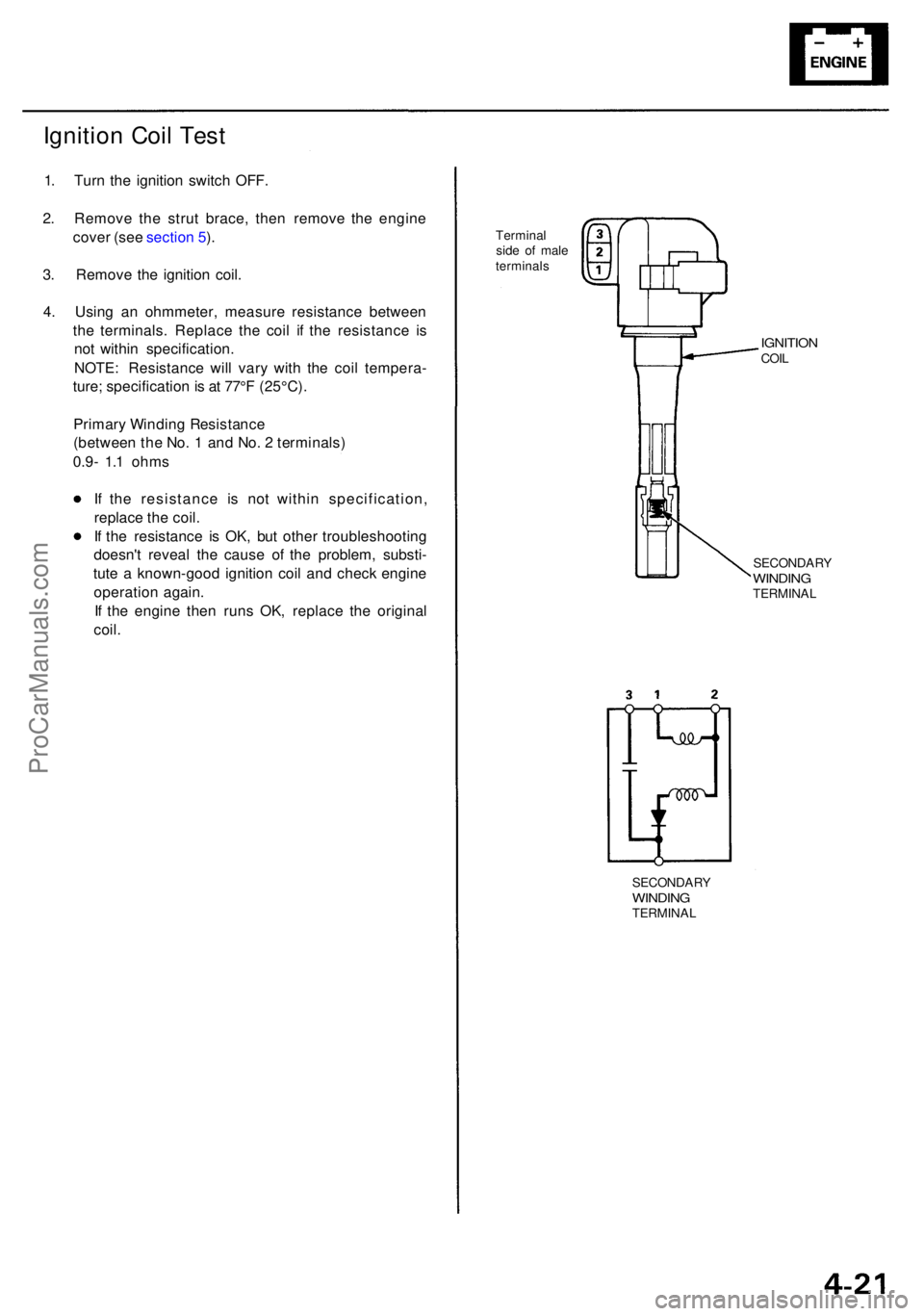

Ignition Coi l Tes t

1. Tur n th e ignitio n switc h OFF .

2 . Remov e th e stru t brace , the n remov e th e engin e

cove r (se e sectio n 5 ).

3 . Remov e th e ignitio n coil .

4 . Usin g a n ohmmeter , measur e resistanc e betwee n

th e terminals . Replac e th e coi l i f th e resistanc e i s

no t withi n specification .

NOTE : Resistanc e wil l var y wit h th e coi l tempera -

ture ; specificatio n is a t 77° F (25°C) .

Primar y Windin g Resistanc e

(betwee n th e No . 1 an d No . 2 terminals )

0.9- 1.1 ohm s

I f th e resistanc e i s no t withi n specification ,

replac e th e coil .

I f th e resistanc e i s OK , bu t othe r troubleshootin g

doesn' t revea l th e caus e o f th e problem , substi -

tut e a known-goo d ignitio n coi l an d chec k engin e

operatio n again .

I f th e engin e the n run s OK , replac e th e origina l

coil .

Termina l

sid e o f mal e

terminal s

IGNITIONCOIL

SECONDAR YWINDINGTERMINA L

SECONDAR YWINDINGTERMINA L

ProCarManuals.com

Page 342 of 1954

Ignition Syste m

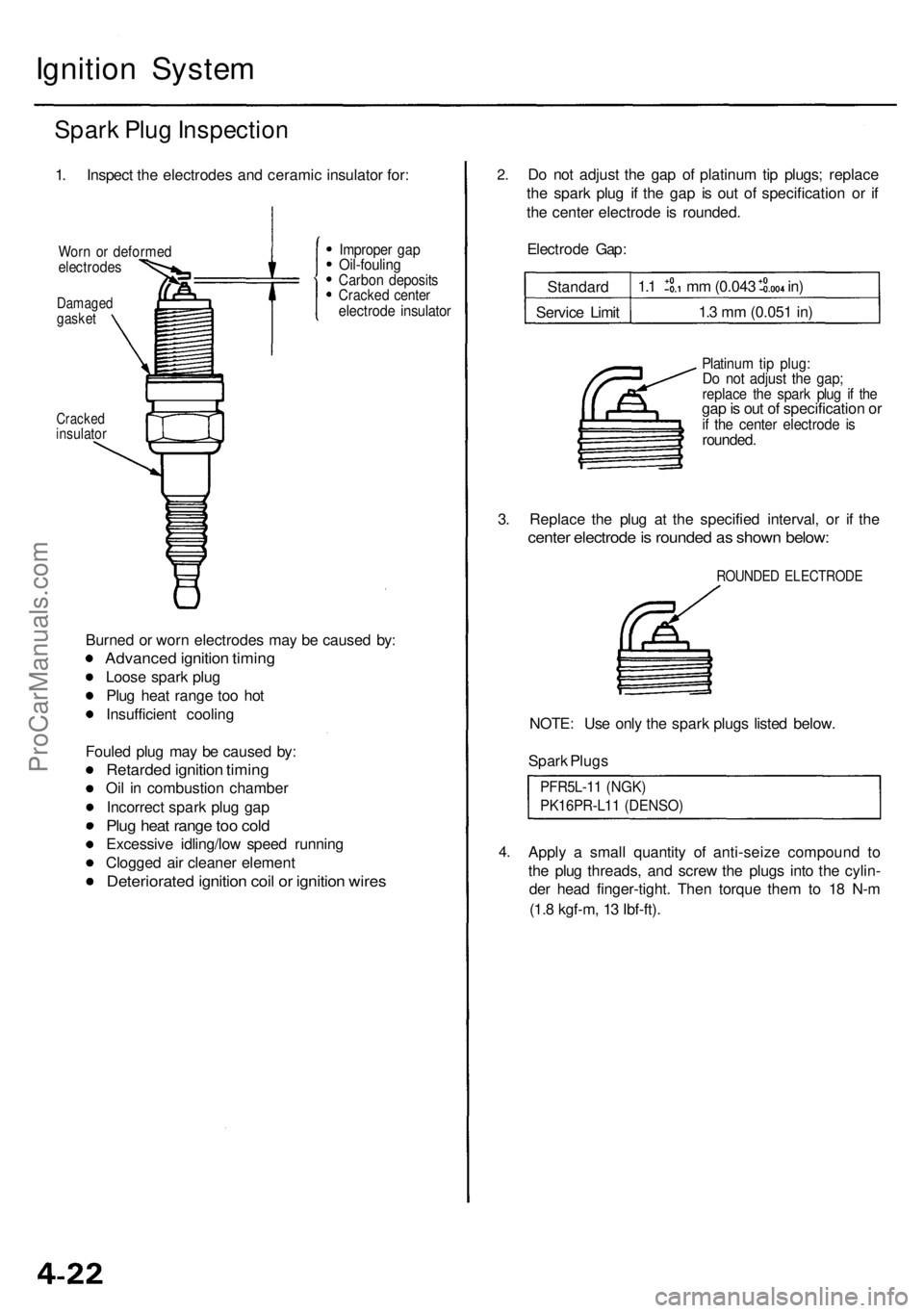

Spark Plu g Inspectio n

1. Inspec t th e electrode s an d cerami c insulato r for :

Wor n o r deforme delectrode s

Damagedgasket

Cracke dinsulato r

Improper ga pOil-foulin gCarbon deposit sCracked cente relectrod e insulato r

Burned o r wor n electrode s ma y b e cause d by :

Advance d ignitio n timin g

Loose spar k plu g

Plu g hea t rang e to o ho t

Insufficien t coolin g

Foule d plu g ma y b e cause d by :

Retarde d ignitio n timin g

Oil i n combustio n chambe r

Incorrec t spar k plu g ga p

Plug hea t rang e to o col d

Excessiv e idling/lo w spee d runnin g

Clogge d ai r cleane r elemen t

Deteriorate d ignitio n coi l o r ignitio n wire s

2.D o no t adjus t th e ga p o f platinu m ti p plugs ; replac e

th e spar k plu g i f th e ga p i s ou t o f specificatio n o r i f

th e cente r electrod e i s rounded .

Electrod e Gap :

Standar d

Servic e Limi t

1.1 m m (0.04 3 in )

1. 3 m m (0.05 1 in )

Platinu m tip plug :Do no t adjus t th e gap ;replac e th e spar k plu g i f th egap is ou t o f specificatio n o rif th e cente r electrod e i srounded .

3. Replac e th e plu g a t th e specifie d interval , o r i f th e

cente r electrod e is rounde d a s show n below :

ROUNDE D ELECTROD E

NOTE: Us e onl y th e spar k plug s liste d below .

Spar k Plug s

PFR5L-1 1 (NGK )

PK16PR-L1 1 (DENSO )

4.Appl y a smal l quantit y o f anti-seiz e compoun d t o

th e plu g threads , an d scre w th e plug s int o th e cylin -

de r hea d finger-tight . The n torqu e the m to 1 8 N- m

(1. 8 kgf-m , 1 3 Ibf-ft) .

ProCarManuals.com

Page 356 of 1954

Cruise Control

Control Unit Input Test (cont'd)

Cavity Wire

Test condition

Test: Desired result

Possible cause if result is not obtained

3

13

7

6

14

12

2

5

10

9

11

1

BLK

LT GRN

LT GRN/BLK

LT GRN/RED

PNK

BLU/WHT

GRY

GRN/WHT

BLU/YEL

BRN

BRN/BLK

BRN/WHT

Under all conditions

Ignition switch ON (II) and

main switch ON

Resume button pushed

Cancel button pushed

Set button pushed

Cancel button pushed

Shift lever in , or

Ignition switch ON (II), and

main switch ON; raise the

front of the vehicle, and rotate

one wheel slowly while

holding the other wheel.

Ignition switch ON (II), main

switch ON; brake pedal

pressed, then released

Brake pedal pressed then

released

Ignition switch ON (II)

Under all conditions

Under all conditions

Under all conditions

Check for continuity to ground:

There should be continuity.

Check for voltage to ground:

There should be battery voltage.

Check for voltage to ground:

There should be battery voltage.

When testing terminal No. 7, there

should be no voltage on terminal No. 6.

Check for voltage to ground:

There should be battery voltage.

When testing terminal No. 7, there

should be voltage on terminal No. 6.

Check for voltage to ground:

There should be battery voltage.

When testing terminal No. 6, there

should be no voltage on terminal No. 7.

Check for voltage to ground:

There should be battery voltage.

When testing terminal No. 6, there

should be voltage on terminal No. 7.

Check for continuity to ground:

There should be continuity.

NOTE: There should be no continuity

when the shift lever is in other positions.

Check for voltage between the

BLU/ WHT and BLK terminals:

There should be cycle 0 - 5 V or

battery voltage.

Check for voltage to ground:

There should be 0 V with the pedal

pressed, and battery voltage with

the pedal released.

Check for voltage to ground:

There should be battery voltage with

the pedal pressed, and 0 V with the

pedal released.

Attach to ground:

The cruise light in the gauge assembly

should come on.

Check for resistance to ground:

There should be 80 -120

Check for resistance to ground:

There should be 70 -110

Check for resistance to ground:

There should be 40 - 60

• Poor ground (G401, G402)

• An open in the wire

• Blown No. 20 (20 A) fuse in the

under-dash fuse/relay box

• Faulty main switch

• An open in the wire

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty horn relay

• Faulty set/resume/cancel switch

• Faulty cable reel

• An open in the wire

• Short between LT GRN/BLK and

LT GRN/RED wires

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty horn relay

• Faulty set/resume/cancel switch

• Faulty cable reel

• An open in the wire

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty horn relay

• Faulty set/resume/cancel switch

• Faulty cable reel

• An open in the wire

• Short between LT GRN/BLK and

LT GRN/RED wires

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty horn relay

• Faulty set/resume/cancel switch

• Faulty cable reel

• An open in the wire

• Faulty A/T gear position switch

• Poor ground (G401, G402)

• An open in the wire

• Faulty vehicle speed sensor (VSS)

• An open in the wire

• Short to ground

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty brake switch

• An open in the wire

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty brake switch

• An open in the wire

• Blown bulb

• Faulty gauge circuit

• An open in the wire

• Faulty actuator solenoid

• An open in the wireProCarManuals.com

Page 404 of 1954

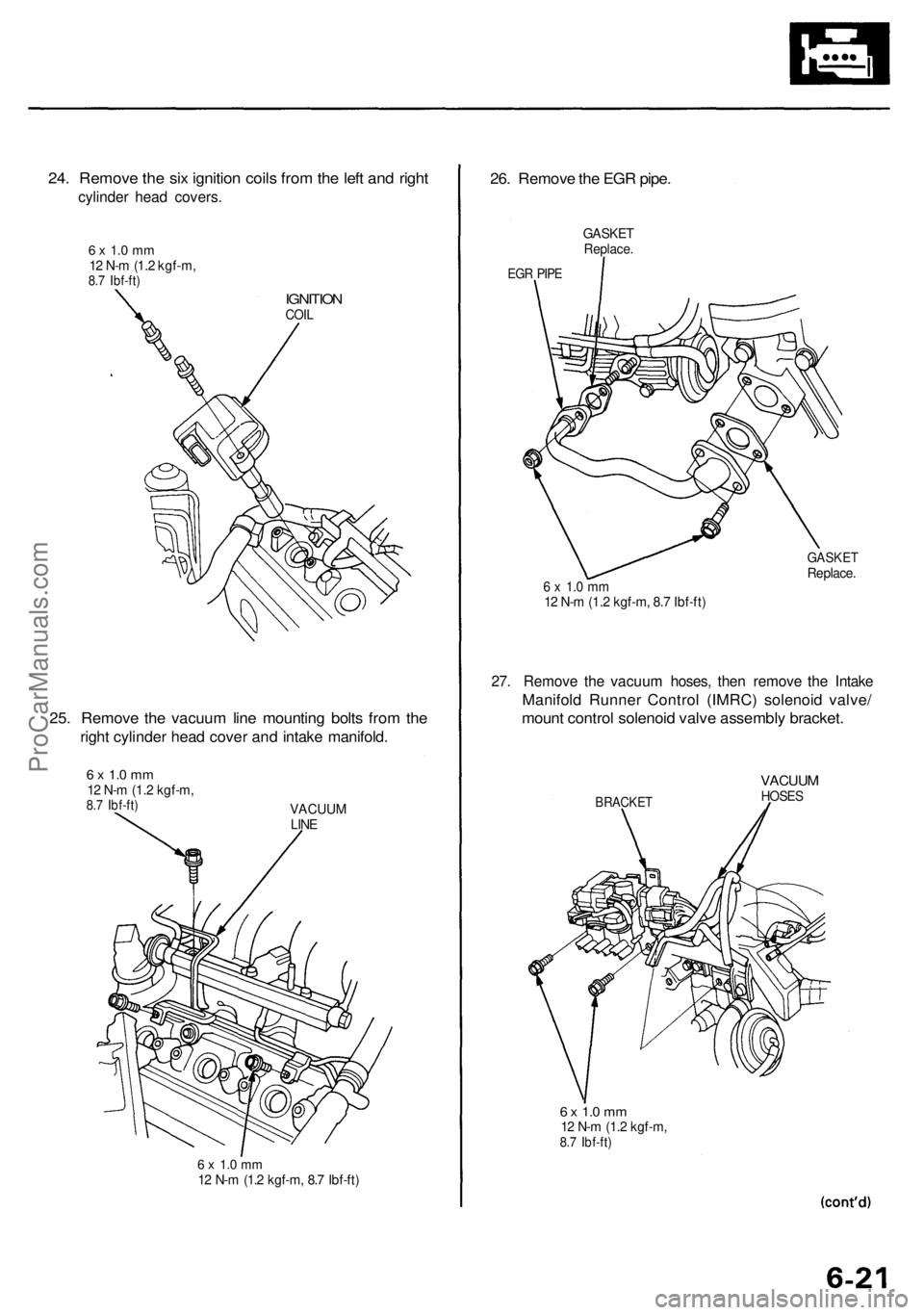

24. Remove the six ignition coils from the left and right

cylinder head covers.

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

IGNITION

COIL

25. Remove the vacuum line mounting bolts from the

right cylinder head cover and intake manifold.

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

VACUUM

LINE

6 x 1.0 mm

12 N-m (1.2 kgf-m, 8.7 Ibf-ft)

26. Remove the EGR pipe.

GASKET

Replace.

EGR PIPE

6 x 1.0 mm

12 N-m (1.2 kgf-m, 8.7 Ibf-ft)

GASKET

Replace.

27. Remove the vacuum hoses, then remove the Intake

Manifold Runner Control (IMRC) solenoid valve/

mount control solenoid valve assembly bracket.

BRACKET

VACUUM

HOSES

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)ProCarManuals.com

Page 490 of 1954

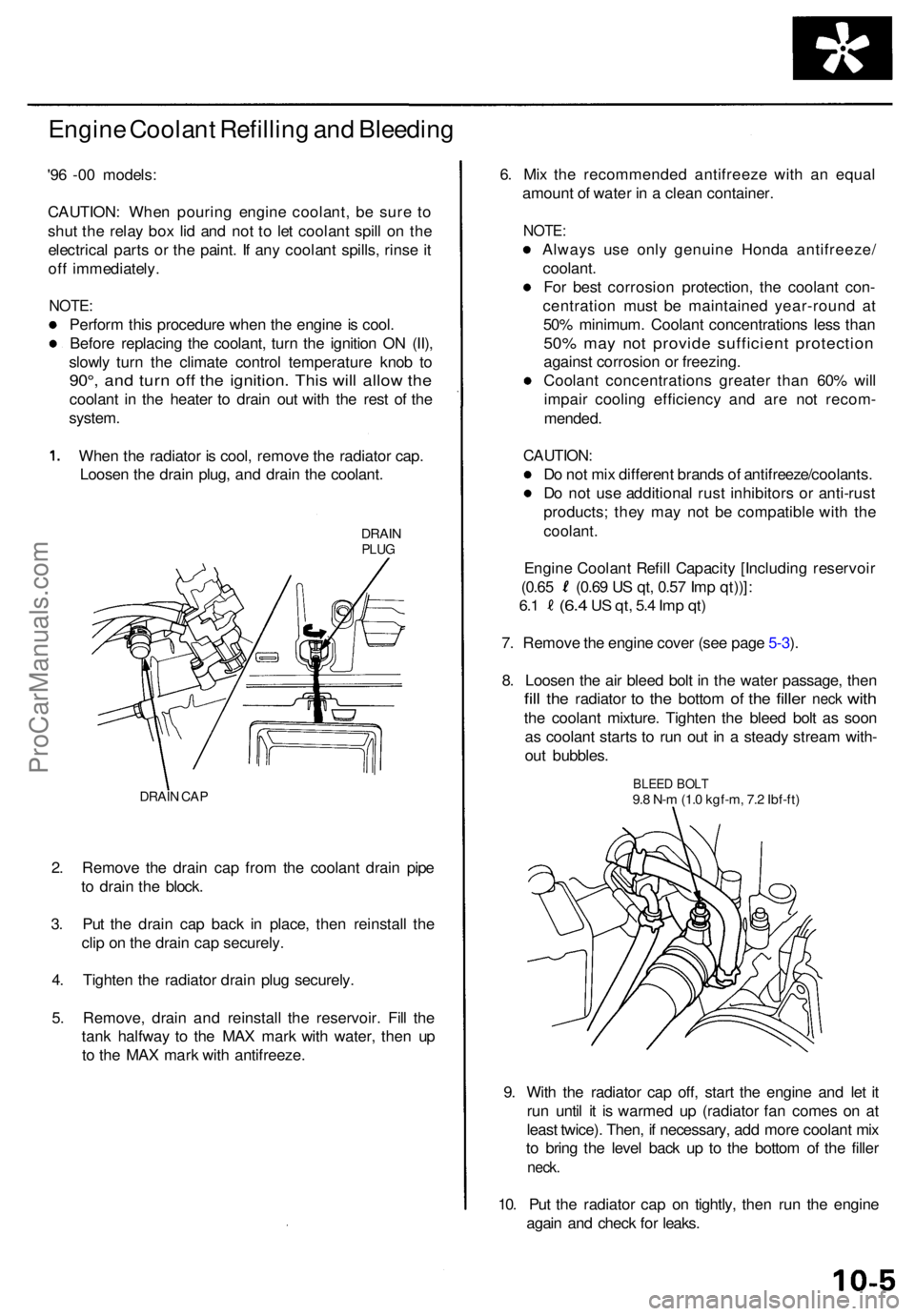

Engine Coolan t Refillin g an d Bleedin g

'96 -0 0 models :

CAUTION : Whe n pourin g engin e coolant , b e sur e t o

shu t th e rela y bo x li d an d no t t o le t coolan t spil l o n th e

electrica l part s o r th e paint . I f an y coolan t spills , rins e it

of f immediately .

NOTE:

Perfor m thi s procedur e whe n th e engin e is cool .

Befor e replacin g th e coolant , tur n th e ignitio n O N (II) ,

slowl y tur n th e climat e contro l temperatur e kno b t o

90° , an d tur n of f th e ignition . Thi s wil l allo w th e

coolan t i n th e heate r t o drai n ou t wit h th e res t o f th e

system .

Whe n th e radiato r i s cool , remov e th e radiato r cap .

Loose n th e drai n plug , an d drai n th e coolant .

DRAINPLUG

DRAI N CA P

2. Remov e th e drai n cap from th e coolan t drai n pip e

t o drai n th e block .

3 . Pu t th e drai n ca p bac k i n place , the n reinstal l th e

cli p o n th e drai n ca p securely .

4 . Tighte n th e radiato r drai n plu g securely .

5 . Remove , drai n an d reinstal l th e reservoir . Fil l th e

tan k halfwa y t o th e MA X mar k wit h water , the n u p

t o th e MA X mar k wit h antifreeze . 6

. Mi x th e recommende d antifreez e wit h a n equa l

amoun t o f wate r i n a clea n container .

NOTE:

Alway s us e onl y genuin e Hond a antifreeze /

coolant .

Fo r bes t corrosio n protection , th e coolan t con -

centratio n mus t b e maintaine d year-roun d a t

50 % minimum . Coolan t concentration s les s tha n

50% ma y no t provid e sufficien t protectio n

against corrosio n o r freezing .

Coolan t concentration s greate r tha n 60 % wil l

impai r coolin g efficienc y an d ar e no t recom -

mended .

CAUTION :

Do no t mi x differen t brand s o f antifreeze/coolants .

D o no t us e additiona l rus t inhibitor s o r anti-rus t

products ; the y ma y no t b e compatibl e wit h th e

coolant .

Engine Coolan t Refil l Capacit y [Includin g reservoi r

(0.65 (0.6 9 U S qt , 0.5 7 Im p qt))] :

6.1 (6. 4 US qt , 5. 4 Im p qt )

7. Remov e th e engin e cove r (se e pag e 5-3 ).

8 . Loose n th e ai r blee d bol t i n th e wate r passage , the n

fill th e radiato r to th e botto m of th e fille r nec k with

the coolan t mixture . Tighte n th e blee d bol t a s soo n

a s coolan t start s t o ru n ou t i n a stead y strea m with -

ou t bubbles .

9 . Wit h th e radiato r ca p off , star t th e engin e an d le t i t

ru n unti l i t i s warme d u p (radiato r fa n come s o n a t

leas t twice) . Then , i f necessary , ad d mor e coolan t mi x

t o brin g th e leve l bac k u p t o th e botto m o f th e fille r

neck .

10. Pu t th e radiato r ca p o n tightly , the n ru n th e engin e

agai n an d chec k fo r leaks .

BLEE D BOL T9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

ProCarManuals.com

Page 491 of 1954

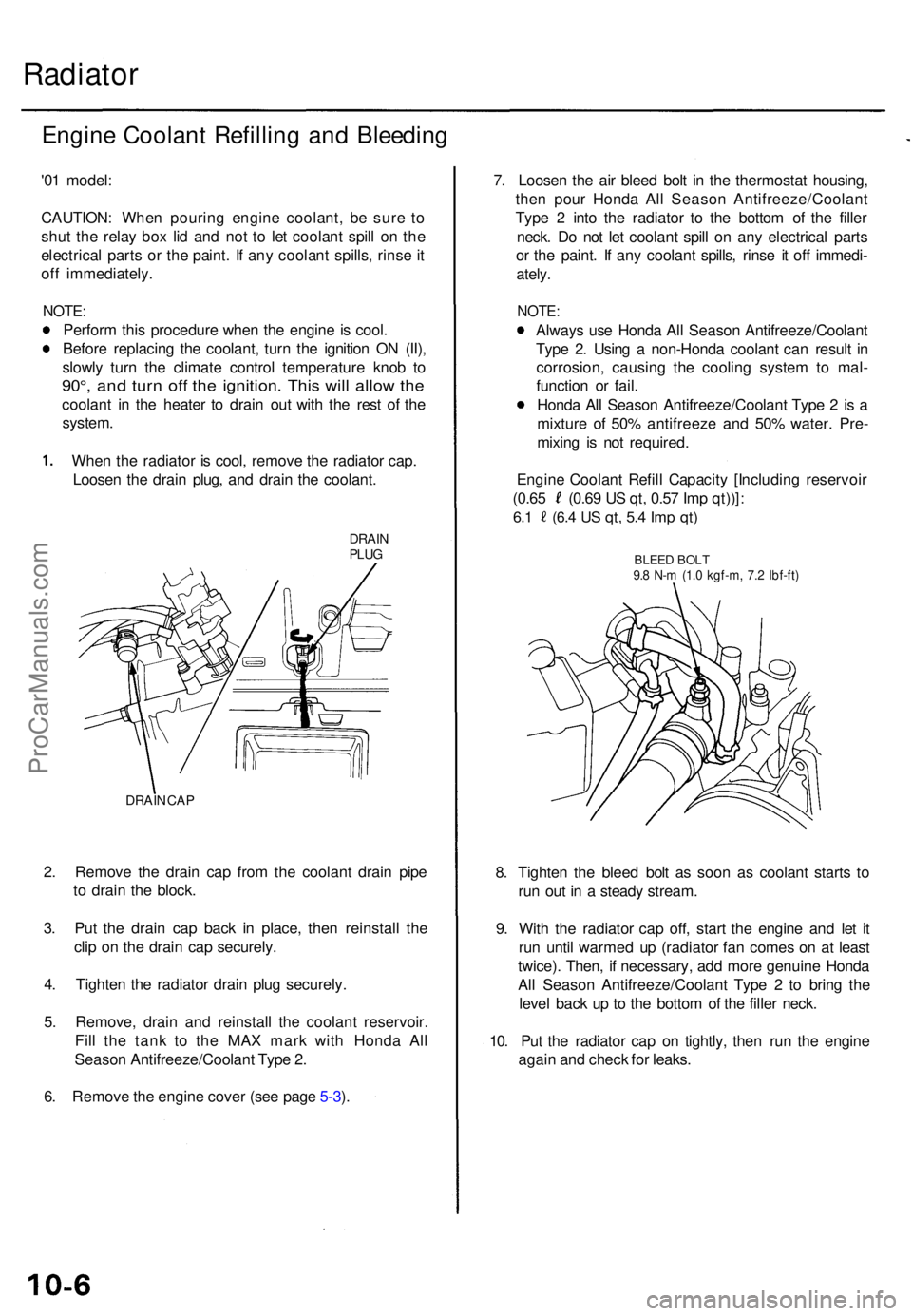

Radiator

Engine Coolan t Refillin g an d Bleedin g

'01 model :

CAUTION : Whe n pourin g engin e coolant , b e sur e t o

shu t th e rela y bo x li d an d no t t o le t coolan t spil l o n th e

electrica l part s o r th e paint . I f an y coolan t spills , rins e it

of f immediately .

NOTE:

Perfor m thi s procedur e whe n th e engin e is cool .

Befor e replacin g th e coolant , tur n th e ignitio n O N (II) ,

slowl y tur n th e climat e contro l temperatur e kno b t o

90° , an d tur n of f th e ignition . Thi s wil l allo w th e

coolan t i n th e heate r t o drai n ou t wit h th e res t o f th e

system .

Whe n th e radiato r i s cool , remov e th e radiato r cap .

Loose n th e drai n plug , an d drai n th e coolant .

DRAINPLUG

DRAI N CA P

2. Remov e th e drai n ca p fro m th e coolan t drai n pip e

t o drai n th e block .

3 . Pu t th e drai n ca p bac k i n place , the n reinstal l th e

cli p o n th e drai n ca p securely .

4 . Tighte n th e radiato r drai n plu g securely .

5 . Remove , drai n an d reinstal l th e coolan t reservoir .

Fil l th e tan k t o th e MA X mar k wit h Hond a Al l

Seaso n Antifreeze/Coolan t Typ e 2 .

6 . Remov e th e engine cover (se e pag e 5-3 ). 7

. Loose n th e ai r blee d bol t i n th e thermosta t housing ,

the n pou r Hond a Al l Seaso n Antifreeze/Coolan t

Typ e 2 int o th e radiato r t o th e botto m o f th e fille r

neck . D o no t le t coolan t spil l o n an y electrica l part s

o r th e paint . I f an y coolan t spills , rins e i t of f immedi -

ately .

NOTE :

Alway s us e Hond a Al l Seaso n Antifreeze/Coolan t

Typ e 2 . Usin g a non-Hond a coolan t ca n resul t i n

corrosion , causin g th e coolin g syste m to mal -

functio n o r fail .

Hond a Al l Seaso n Antifreeze/Coolan t Typ e 2 is a

mixtur e o f 50 % antifreez e an d 50 % water . Pre -

mixin g i s no t required .

8 . Tighte n th e blee d bol t a s soo n a s coolan t start s t o

ru n ou t i n a stead y stream .

9 . Wit h th e radiato r cap off, star t th e engin e an d le t i t

ru n unti l warme d u p (radiato r fa n come s o n a t leas t

twice) . Then , i f necessary , ad d mor e genuin e Hond a

Al l Seaso n Antifreeze/Coolan t Typ e 2 to brin g th e

leve l bac k u p t o th e botto m o f th e fille r neck .

10 . Pu t th e radiato r ca p o n tightly , the n ru n th e engin e

agai n an d chec k fo r leaks .

Engin

e Coolan t Refil l Capacit y [Includin g reservoi r

(0.65 (0.6 9 U S qt , 0.5 7 Im p qt))] :

6.1 (6. 4 US qt , 5. 4 Im p qt )

BLEE D BOL T9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

ProCarManuals.com

Page 541 of 1954

PCM

PCM

COVER

9.8 N-m

(1.0 kgf-m,

7.2 Ibf-ft)

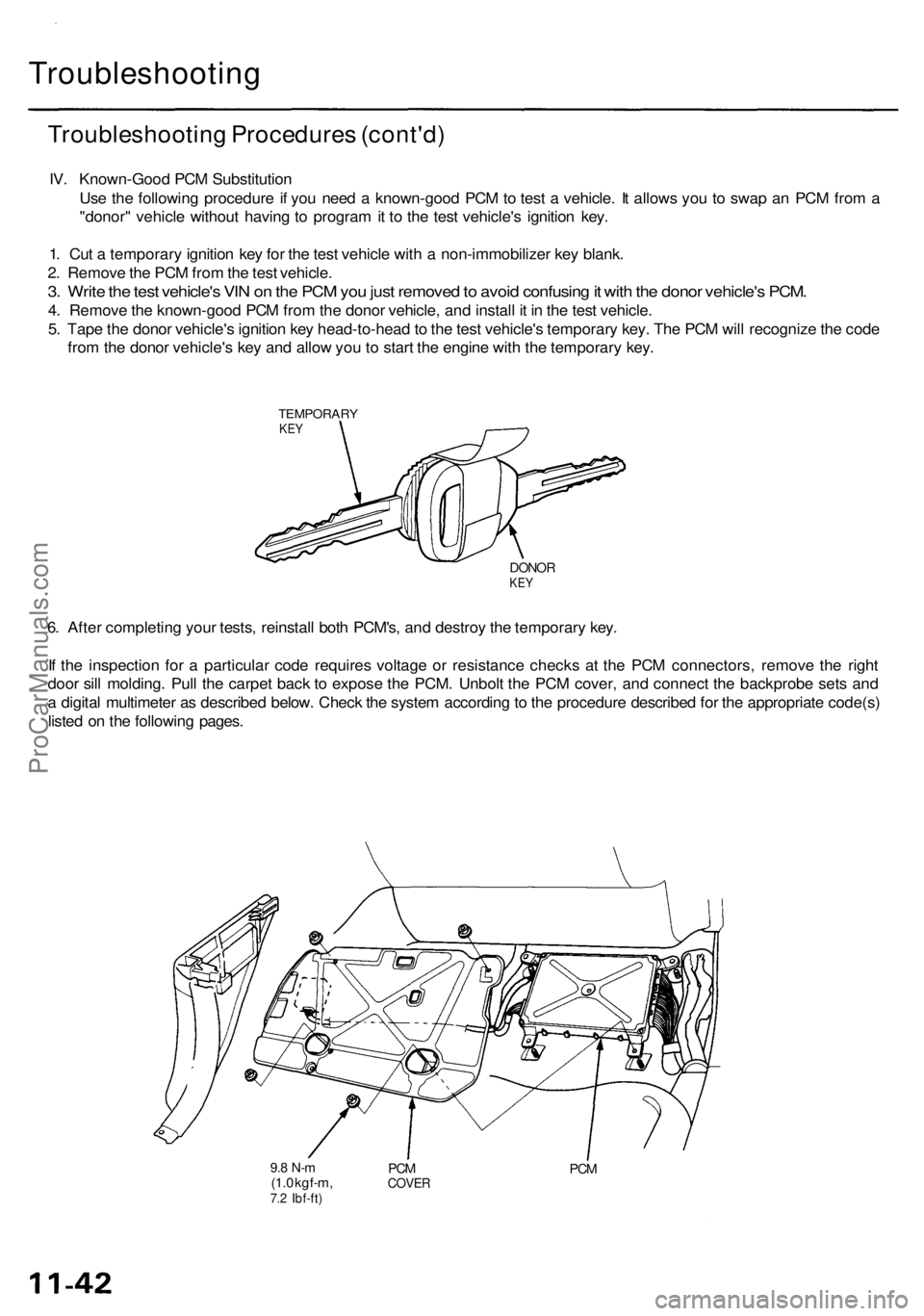

6. After completing your tests, reinstall both PCM's, and destroy the temporary key.

If the inspection for a particular code requires voltage or resistance checks at the PCM connectors, remove the right

door sill molding. Pull the carpet back to expose the PCM. Unbolt the PCM cover, and connect the backprobe sets and

a digital multimeter as described below. Check the system according to the procedure described for the appropriate code(s)

listed on the following pages.

DONOR

KEY

TEMPORARY

KEY

Troubleshooting

Troubleshooting Procedures (cont'd)

IV. Known-Good PCM Substitution

Use the following procedure if you need a known-good PCM to test a vehicle. It allows you to swap an PCM from a

"donor" vehicle without having to program it to the test vehicle's ignition key.

1. Cut a temporary ignition key for the test vehicle with a non-immobilizer key blank.

2. Remove the PCM from the test vehicle.

3. Write the test vehicle's VIN on the PCM you just removed to avoid confusing it with the donor vehicle's PCM.

4. Remove the known-good PCM from the donor vehicle, and install it in the test vehicle.

5. Tape the donor vehicle's ignition key head-to-head to the test vehicle's temporary key. The PCM will recognize the code

from the donor vehicle's key and allow you to start the engine with the temporary key.ProCarManuals.com

Page 545 of 1954

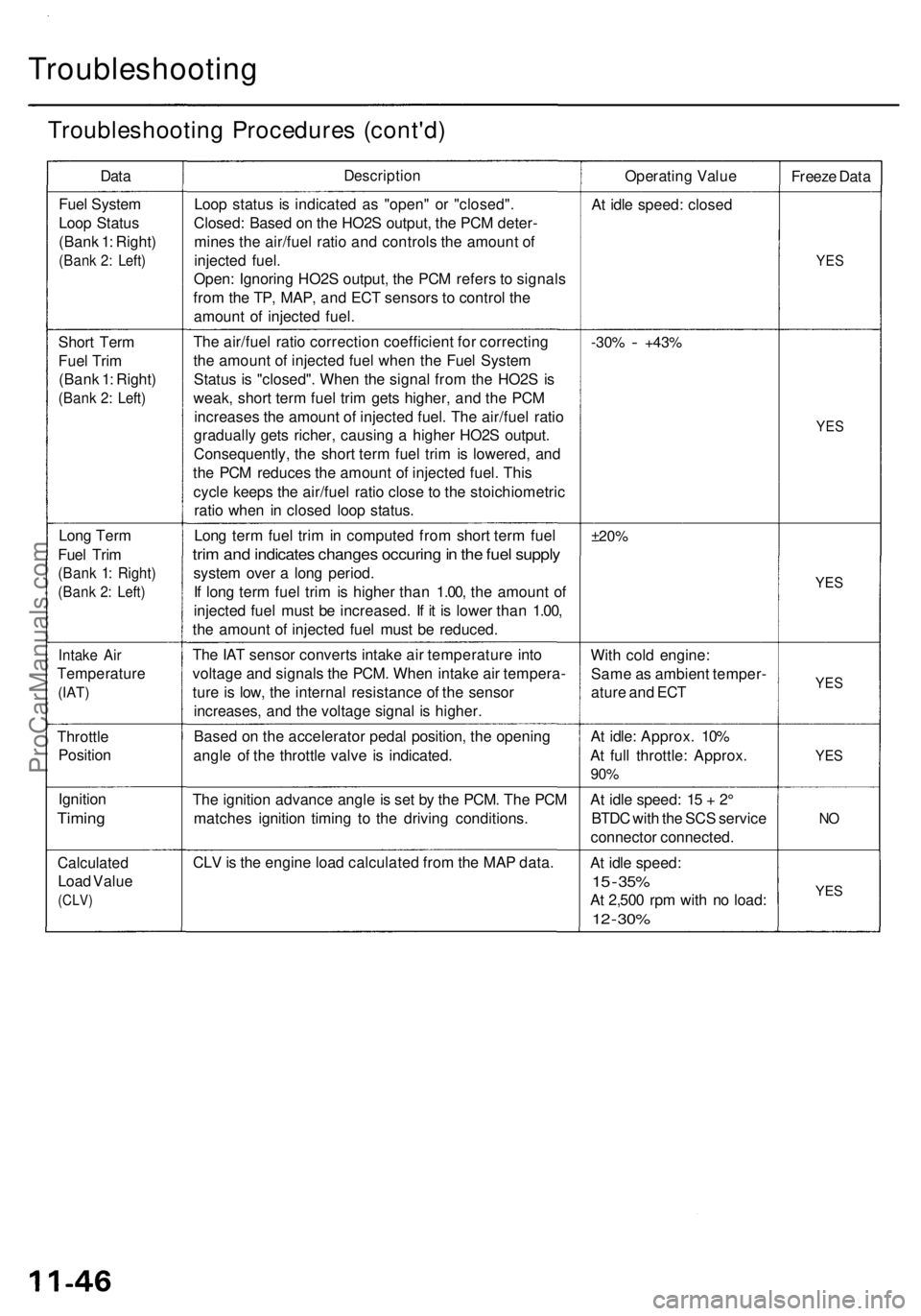

Troubleshooting

Troubleshooting Procedures (cont'd)

Data

Description

Operating Value

Freeze Data

Fuel System

Loop Status

(Bank 1: Right)

(Bank 2: Left)

Loop status is indicated as "open" or "closed".

Closed: Based on the HO2S output, the PCM deter-

mines the air/fuel ratio and controls the amount of

injected fuel.

Open: Ignoring HO2S output, the PCM refers to signals

from the TP, MAP, and ECT sensors to control the

amount of injected fuel.

At idle speed: closed

YES

Short Term

Fuel Trim

(Bank 1: Right)

(Bank 2: Left)

The air/fuel ratio correction coefficient for correcting

the amount of injected fuel when the Fuel System

Status is "closed". When the signal from the HO2S is

weak, short term fuel trim gets higher, and the PCM

increases the amount of injected fuel. The air/fuel ratio

gradually gets richer, causing a higher HO2S output.

Consequently, the short term fuel trim is lowered, and

the PCM reduces the amount of injected fuel. This

cycle keeps the air/fuel ratio close to the stoichiometric

ratio when in closed loop status.

-30%

-

+43%

YES

Long Term

Fuel Trim

(Bank 1: Right)

(Bank 2: Left)

Long term fuel trim in computed from short term fuel

trim and indicates changes occuring in the fuel supply

system over a long period.

If long term fuel trim is higher than 1.00, the amount of

injected fuel must be increased. If it is lower than 1.00,

the amount of injected fuel must be reduced.

±20%

YES

Intake Air

Temperature

(IAT)

The IAT sensor converts intake air temperature into

voltage and signals the PCM. When intake air tempera-

ture is low, the internal resistance of the sensor

increases, and the voltage signal is higher.

With cold engine:

Same as ambient temper-

ature and ECT

YES

Throttle

Position

Based on the accelerator pedal position, the opening

angle of the throttle valve is indicated.

At idle: Approx. 10%

At full throttle: Approx.

90%

YES

Ignition

Timing

The ignition advance angle is set by the PCM. The PCM

matches ignition timing to the driving conditions.

At idle speed: 15 + 2°

BTDC with the SCS service

connector connected.

NO

Calculated

Load Value

(CLV)

CLV is the engine load calculated from the MAP data.

At idle speed:

15

-

35%

At 2,500 rpm with no load:

12

-

30%

YESProCarManuals.com

Page 558 of 1954

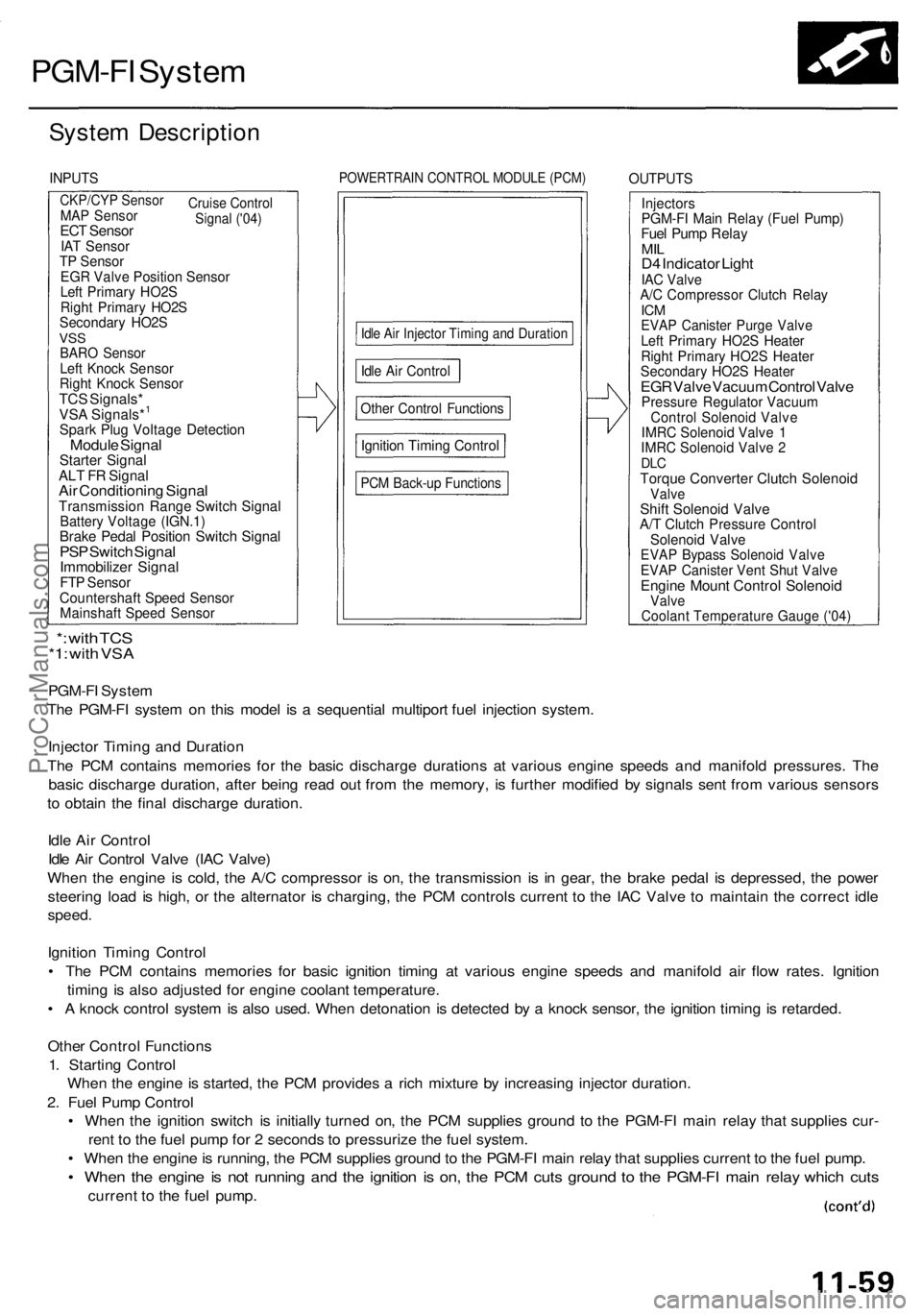

PGM-FI Syste m

System Descriptio n

INPUTSPOWERTRAI N CONTRO L MODUL E (PCM )OUTPUT S

CKP/CYP Senso r

Cruise

Control

Signal ('04)MA P Senso rECT Senso rIAT Senso rTP Senso rEGR Valv e Positio n Senso rLeft Primar y HO2 SRight Primar y HO2 SSecondar y HO2 SVSSBAR O Senso rLeft Knoc k Senso rRight Knoc k Senso rTCS Signals *VSA Signals*1

Spar k Plu g Voltag e Detectio nModule Signa lStarte r Signa lALT F R Signa lAir Conditionin g Signa lTransmissio n Rang e Switc h Signa lBattery Voltag e (IGN.1 )Brake Peda l Positio n Switc h Signa lPSP Switc h Signa lImmobilize r Signa lFTP Senso rCountershaf t Spee d Senso rMainshaf t Spee d Senso r

Idle Ai r Injecto r Timin g an d Duratio n

Other Contro l Function s

Ignition Timin g Contro l

PCM Back-u p Function s

InjectorsPGM-FI Mai n Rela y (Fue l Pump )Fuel Pum p Rela yMILD4 Indicato r Ligh tIAC Valv eA/C Compresso r Clutc h Rela yICMEVA P Caniste r Purg e Valv eLeft Primar y HO2 S Heate rRight Primar y HO2 S Heate rSecondar y HO2 S Heate rEGR Valv e Vacuu m Contro l Valv ePressur e Regulato r Vacuu mControl Solenoi d Valv eIMRC Solenoi d Valv e 1IMR C Solenoi d Valv e 2DL CTorqu e Converte r Clutc h Solenoi dValveShift Solenoi d Valv eA/T Clutc h Pressur e Contro lSolenoid Valv eEVAP Bypas s Solenoi d Valv eEVAP Caniste r Ven t Shu t Valv eEngin e Moun t Contro l Solenoi dValve

PGM-F I Syste m

Th e PGM-F I syste m o n thi s mode l i s a sequentia l multipor t fue l injectio n system .

Injecto r Timin g an d Duratio n

Th e PC M contain s memorie s fo r th e basi c discharg e duration s a t variou s engin e speed s an d manifol d pressures . Th e

basi c discharg e duration , afte r bein g rea d ou t fro m th e memory , i s furthe r modifie d b y signal s sen t fro m variou s sensor s

t o obtai n th e fina l discharg e duration .

Idl e Ai r Contro l

Idl e Ai r Contro l Valv e (IA C Valve )

Whe n th e engin e i s cold , th e A/ C compresso r i s on , th e transmissio n i s i n gear , th e brak e peda l i s depressed , th e powe r

steerin g loa d i s high , o r th e alternato r i s charging , th e PC M control s curren t t o th e IA C Valv e t o maintai n th e correc t idl e

speed .

Ignition Timin g Contro l

• Th e PC M contain s memorie s fo r basi c ignitio n timin g a t variou s engin e speed s an d manifol d ai r flo w rates . Ignitio n

timin g i s als o adjuste d fo r engin e coolan t temperature .

• A knoc k contro l syste m is als o used . Whe n detonatio n i s detecte d b y a knoc k sensor , th e ignitio n timin g is retarded .

Othe r Contro l Function s

1 . Startin g Contro l

Whe n th e engin e is started , th e PC M provide s a ric h mixtur e b y increasin g injecto r duration .

2 . Fue l Pum p Contro l

• Whe n th e ignitio n switc h i s initiall y turne d on , th e PC M supplie s groun d t o th e PGM-F I mai n rela y tha t supplie s cur -

ren t t o th e fue l pum p fo r 2 second s t o pressuriz e th e fue l system .

• Whe n th e engin e is running , th e PC M supplie s groun d to th e PGM-F I mai n rela y tha t supplie s current to th e fue l pump .

• Whe n th e engin e is no t runnin g an d th e ignitio n i s on , th e PC M cut s groun d t o th e PGM-F I mai n rela y whic h cut s

curren t t o th e fue l pump .

*: wit h TC S*1: wit h VS A

Idle Ai r Contro l

Coolant Temperature Gauge ('04)

ProCarManuals.com