ignition ACURA RL KA9 1996 Service Owner's Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 560 of 1954

How to Set Readiness Codes

Catalytic Converter

NOTE:

• Do not turn the ignition switch OFF.

• When the battery negative cable is disconnected, all

readiness codes are cleared.

Required condition ('96 - 97 models):

• Ambient temperature between 32 - 95°F (0 - 35°C).

• Altitude below 2,400 m (7,874 ft.).

Required condition ('98 - 01 models):

Ambient temperature between 20 - 95°F (-7 - 35°C).

1. Connect the scan tool to the Data Link Connector

(DLC).

2. Start the engine. Hold it at 3,000 rpm with no load

(in Park or neutral) until the radiator fan comes on.

3. Drive for about 10 minutes without stopping on a

highway or freeway. Your speed can vary.

4. '96 - 97 models:

With the transmission in D4 position, drive at a

steady speed between 33 - 37 mph (53 - 59 km/h)

for 30 seconds.

'98 - 01 models:

With the A/T in D4 position, drive at a steady speed

between 50 - 62 mph (80 - 100 km/h) for 30 sec-

onds.

5. Do step 4 three times. Between each repetition,

close the throttle completely for 1 - 2 seconds. If the

engine is stopped during this part of the procedure,

go to step 3 and do the procedure again.

6. Check for the readiness code with the scan tool.

EGR Monitor

NOTE:

• Do not turn the ignition switch OFF.

• When the battery negative cable is disconnected, all

readiness codes are cleared.

Required condition ('96 - 97 models):

Altitude below 2,400 m (7,874 ft.).

1. Connect the scan tool to the Data Link Connector

(DLC).

2. Start the engine, and hold it at 3,000 rpm with no

load (in Park or neutral) until the radiator fan comes

on.

3. Drive at a steady speed with the transmission in D4

position, between 50 - 62 mph (80 - 100 km/h) for

more than 10 seconds.

4. With the A/T in D4 position, decelerate from 62 mph

(100 km/h) by completely releasing the throttle for

at least 5 seconds. If the engine is stopped during

this procedure, go to step 3 and do the procedure

again.

5. Check for the readiness code with the scan tool.

EVAP Leak Monitor

NOTE:

• When the battery negative cable is disconnected, all

readiness codes are cleared.

• If the engine is stopped while doing the procedure

between stops 6 and 16, do this procedure from step

1 again.

1. Make sure the gasoline level is 60 - 90% of fuel tank

capacity (not full).

2. Turn the ignition switch OFF.

3. Let the vehicle sit more than 8 hours.

4. '96 - 97 models:

Make sure the outside temperature is 32 - 95°F (0 -

35°C).

'98 - 01 models:

Make sure the outside temperature is 20 - 95°F (-7 -

35°C).

5. Connect the scan tool to the Data Link Connector

(DLC).

6. Start the engine and drive for about 15 minutes.

7. '96 - 97 models:

Keep the vehicle at a steady speed between 50 - 62

mph (80 - 100 km/h), without moving the accelera-

tor pedal, for about 1 minute.

'98 - 01 models:

Keep the vehicle at a steady speed between 50 - 70

mph (80 - 114 km/h), without moving the accelera-

tor pedal, for about 1 minute.

8. Stop the vehicle (do not stop engine).

9. Repeat steps 7 and 8 two more times.

10. Check for the readiness code with the scan tool. If

the readiness code does not set, go to step 11.

11. When ambient temperature is less than 32°F (0°C),

hold the engine at 3,000 rpm with no load (in Park

or neutral) until the radiator fan comes on.

12. When ambient temperature is more than 86°F

(30°C), remove the fuel fill cap, then install the fuel

fill cap.

13. After step 12, drive for about 20 minutes on a free-

way.

14. '96 - 97 models:

Keep the vehicle at a steady speed between 50 - 62

mph (80 - 100 km/h), without moving the accelera-

tor pedal, for about 1 minute.

'98 - 01 models:

Keep the vehicle at a steady speed between 50 - 70

mph (80 - 114 km/h), without moving the accelera-

tor pedal, for about 1 minute.

15. Stop the vehicle (do not stop the engine).

16. Repeat steps 14 and 15 two more times.

17. Check for the readiness code with the scan tool.ProCarManuals.com

Page 561 of 1954

PGM-FI System

How to Set Readiness Codes (cont'd)

HO2S Monitor

NOTE:

• Do not turn the ignition switch OFF.

• When the battery negative cable is disconnected, all

readiness codes are cleared.

Required condition ('96 - 97 models):

• Ambient temperature between 32 - 95°F (0 - 35°C).

• Altitude below 2,400 m (7,874 ft.).

Required condition ('98 - 01 models):

Ambient temperature between 20 - 95°F (-7 - 35°C).

1. Connect the scan tool to the Data Link Connector

(DLC).

2. Start the engine, and hold it at 3,000 rpm with no

load (in Park or neutral) until the radiator fan comes

on.

3. Let the engine idle for 5 seconds.

4. Drive at a steady speed between 50 - 62 mph (80 -

100 km/h) for about 2 minutes.

5. With the A/T in D4 position, decelerate from 62 mph

(100 km/h) by completely releasing the throttle for

at least 5 seconds. If the engine is stopped during

this procedure, go to step 4 and do the procedure

again.

6. Check for the readiness code with the scan tool.

HO2S Heater Monitor

NOTE: When the battery negative cable is disconnected,

all readiness codes are cleared.

1. Connect the scan tool to the Data Link Connector

(DLC).

2. Start the engine, and let the engine idle for 10 min-

utes.

3. Check for the readiness code with the scan tool.ProCarManuals.com

Page 572 of 1954

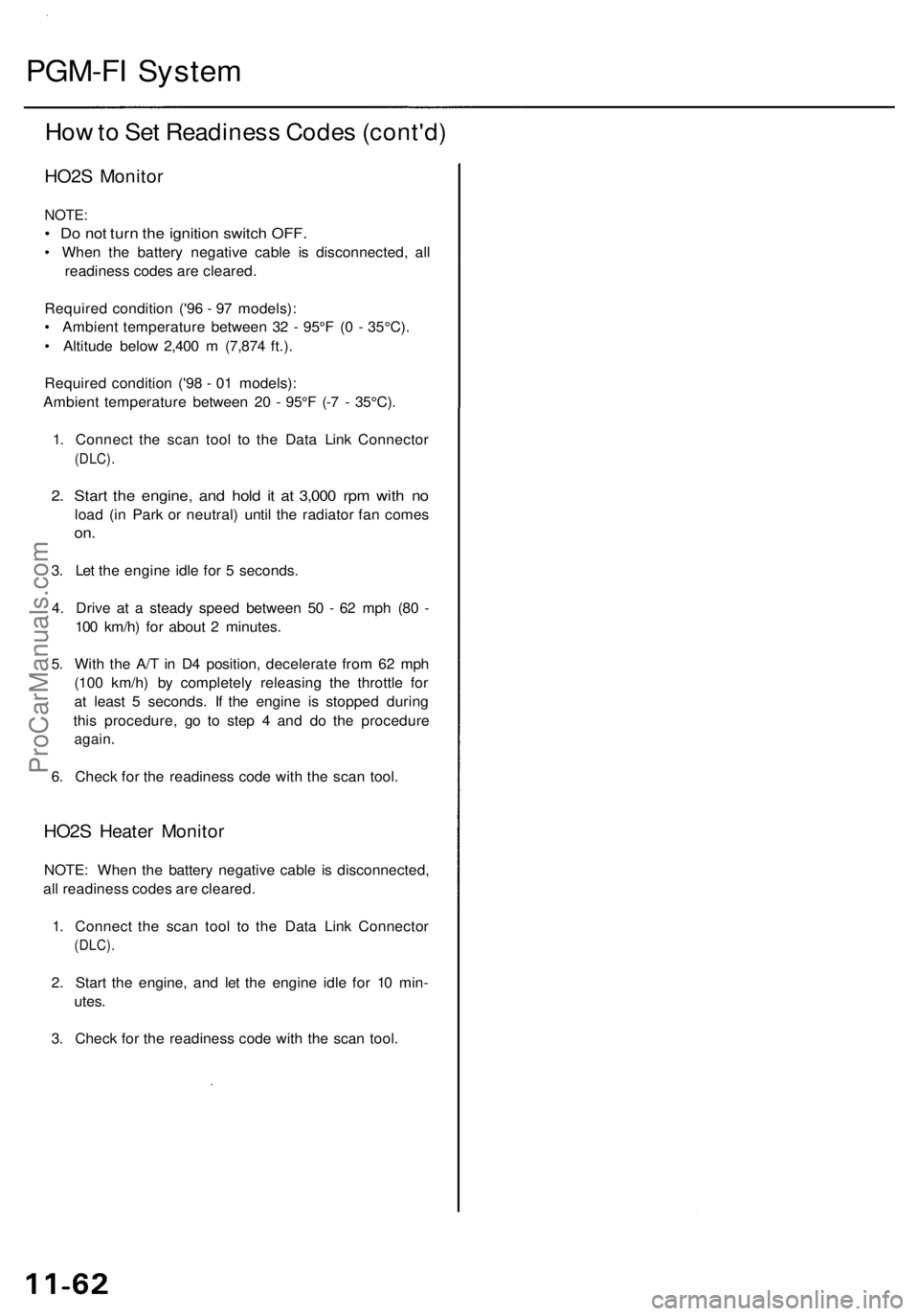

The scan tool indicates Diagnostic Trouble Code (DTC) P1128: Manifold Absolute Pressure (MAP) lower than

expected.

— The MIL has been reported on.

— DTC P1128 is stored.

Problem verification:

1. Turn the ignition switch ON (II).

2. Check the MAP with the scan

tool.

Is 54.1 kPa (406 mmHg, 16.0

in.Hg) or higher indicated?

Intermittent failure, system is OK

at this time.

The scan tool indicates Diagnostic Trouble Code (DTC) P1129: Manifold Absolute Pressure (MAP) higher than

expected.

Is 43.3 kPa (325 mmHg, 12.8

in.Hg) or less indicated?

Intermittent failure, system is OK

at this time.

Replace the MAP sensor.

NO

YES

Problem verification:

1. Start the engine. Hold the

engine at 3,000 rpm with no

load (in Park or neutral) until

the radiator fan comes on, then

let it idle.

2. Check the MAP with the scan

tool.

— The MIL has been reported on.

— DTC P1129 is stored.

Replace the MAP sensor.

NO

YESProCarManuals.com

Page 579 of 1954

PGM-FI Syste m

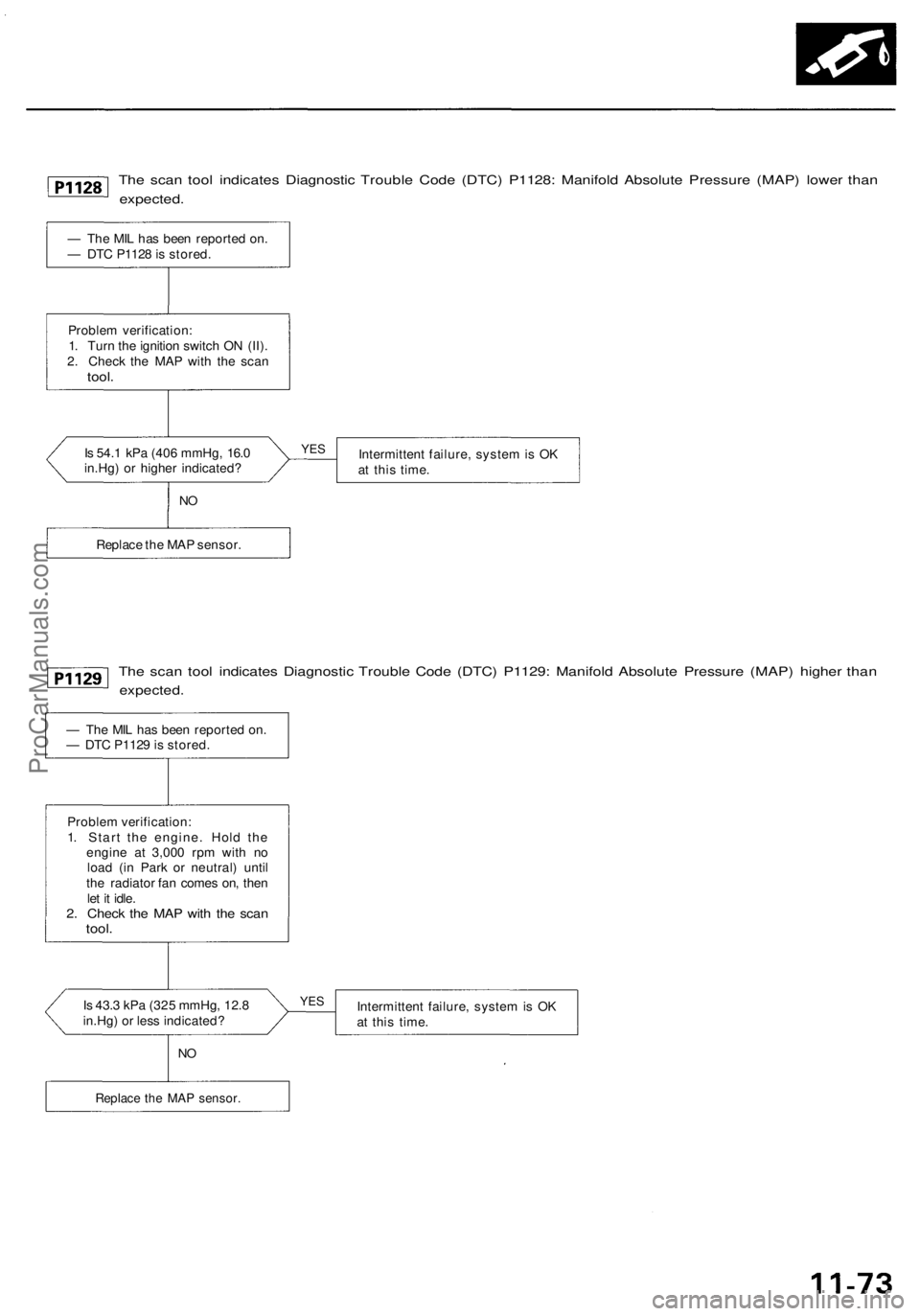

Throttl e Positio n (TP ) Senso r

The sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P0122 : A lo w voltag e proble m in th e Throttl e Positio n

(TP) senso r circuit .

The T P Senso r i s a potentiometer . I t i s connecte d t o th e throttl e valv e shaft . A s th e throttl e positio n changes , th e throttl e

position senso r varie s th e voltag e signa l t o th e PCM .

— Th e MI L ha s bee n reporte d on .

— DT C P012 2 is stored .

Proble m verification :

1 . Star t th e engine . Hol d th e

engin e a t 3,00 0 rp m wit h n o

loa d (i n Par k o r neutral ) unti l

th e radiato r fa n come s on ,

the n tur n th e ignitio n switc h

OFF.2. Turn the ignition switch ON (II).3. Chec k th e throttl e positio n

wit h th e sca n tool .

I s ther e approx . 10 % whe n

the throttl e is full y close dand approx . 90 % whe n th e

throttl e is full y opened ?

NO

Chec k fo r a n ope n i n the wire

(VCC 2 line) :

1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e T P senso r con -

nector .

3 . Tur n th e ignitio n switc h O N (II) .

4 . Measur e voltag e betwee n

No. 1 termina l an d No . 3 termi -nal o n th e T P senso r connector . BRUS

H

HOLDE R

BRUS H

RESISTO R

YES

Is ther e abou t 5 V ?NO

YE S

Chec k fo r a n ope n o r shor t i n T Psensor :1. Tur n th e ignitio n switc h OFF .

2 . Measur e resistanc e betwee n

No . 1 termina l an d No . 2 ter -

mina l o n th e senso r sid e o f

T P senso r connecto r wit h th e

throttl e full y closed .

(T o pag e 11-81 )

*: wit h TC S*1: wit h VS A TERMINA

L

INNERBUSHIN GIDLEFUL LTHROTTL E

THROTTLEOPENING

Intermitten t failure , syste m is O K

a t thi s time . Chec k fo r poo r con -

nection s o r loos e wire s a t C11 3

(T P sensor ) C251 , C253 , C25 4

(locate d a t lef t shoc k tower) ,

C62 3 (TC S contro l unit) * C45 0

(VS A converte r unit)*

1 an d PCM . T

P SENSO R CONNECTO R (C113 )

Wir e sid e o f femal e terminal s

Chec k fo r a n ope n in wir e (VCC2 ,

line):Measur e voltag e betwee n D2 1

termina l an d D2 2 termina l o n th e

PC M connector . Wir

e sid e o f femal e terminal s

I s ther e abou t 5 V ? Repai

r ope n in th e wir e betwee n

PCM (D21 ) an d T P sensor .

NO

Substitut e a known-goo d PC M

an d rechec k (se e pag e 11-42 fo r

immobilize r information) . I f pre -

scribe d voltag e is no w available ,

replac e th e origina l PCM .Termina l sid e o fmal e terminal s

YES

PCM CONNECTO R D (22P )

OUTPU

T VOLTAG E (V )

ProCarManuals.com

Page 582 of 1954

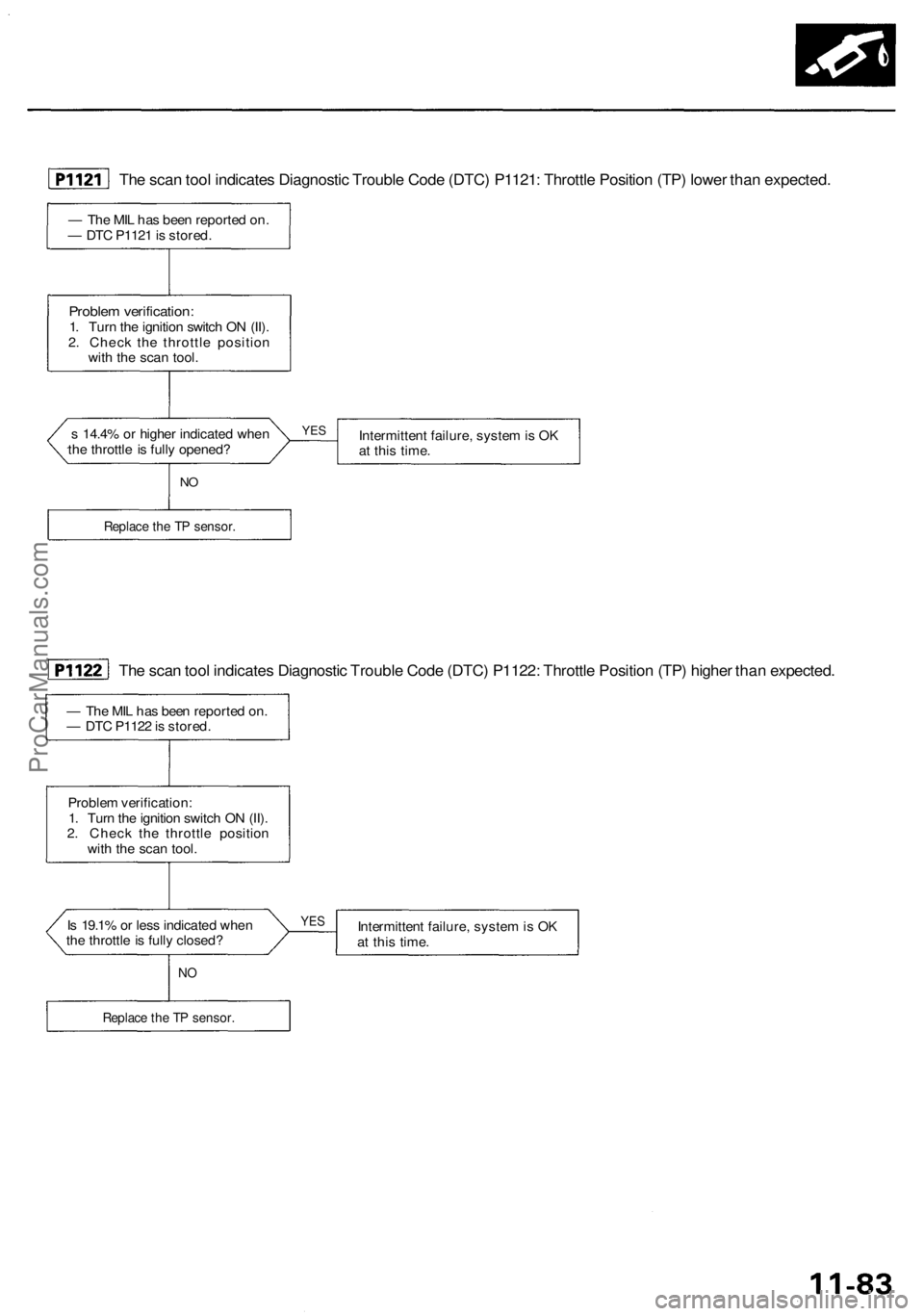

The scan tool indicates Diagnostic Trouble Code (DTC) P1121: Throttle Position (TP) lower than expected.

— The MIL has been reported on.

— DTC P1121 is stored.

Problem verification:

1. Turn the ignition switch ON (II).

2. Check the throttle position

with the scan tool.

I

s 14.4% or higher indicated when

the throttle is fully opened?

Intermittent failure, system is OK

at this time.

The scan tool indicates Diagnostic Trouble Code (DTC) P1122: Throttle Position (TP) higher than expected.

— The MIL has been reported on.

— DTC P1122 is stored.

Problem verification:

1. Turn the ignition switch ON (II).

2. Check the throttle position

with the scan tool.

Is 19.1% or less indicated when

the throttle is fully closed?

Intermittent failure, system is OK

at this time.

Replace the TP sensor.

NO

YES

Replace the TP sensor.

NO

YESProCarManuals.com

Page 593 of 1954

PGM-FI System

Fuel Supply System (cont'd)

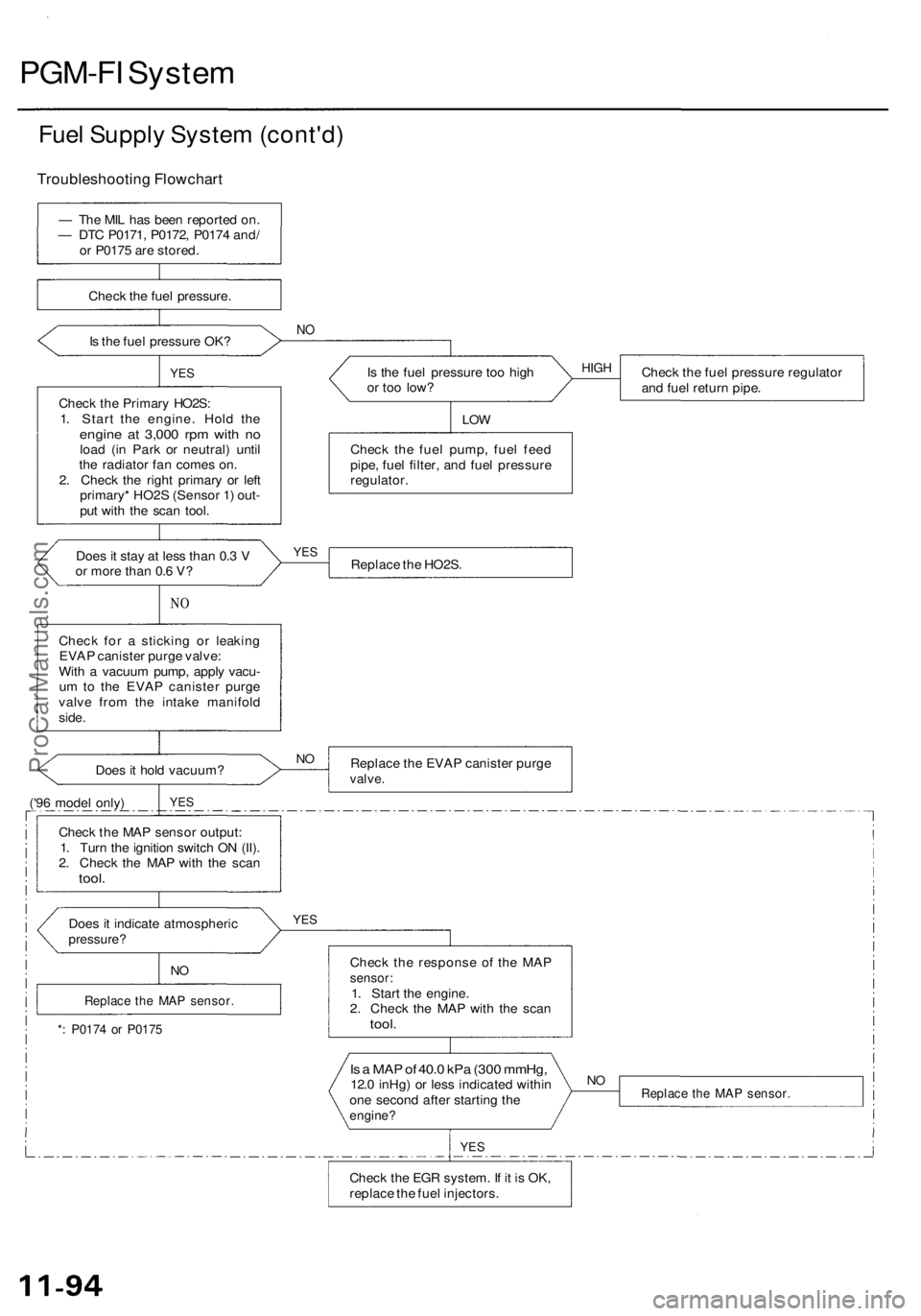

— The MIL has been reported on.

— DTC P0171, P0172, P0174 and/

or P0175 are stored.

Check the fuel pressure.

Is the fuel pressure OK?

NO

YES

Check the Primary HO2S:

1. Start the engine. Hold the

engine at 3,000 rpm with no

load (in Park or neutral) until

the radiator fan comes on.

2. Check the right primary or left

primary* HO2S (Sensor 1) out-

put with the scan tool.

Is the fuel pressure too high

or too low?

Check the fuel pressure regulator

and fuel return pipe.

LOW

Check the fuel pump, fuel feed

pipe, fuel filter, and fuel pressure

regulator.

Does it stay at less than 0.3 V

or more than 0.6 V?

Replace the HO2S.

NO

Check for a sticking or leaking

EVAP canister purge valve:

With a vacuum pump, apply vacu-

um to the EVAP canister purge

valve from the intake manifold

side.

Does it hold vacuum?

('96 model only)

Replace the EVAP canister purge

valve.

YES

Check the MAP sensor output:

1. Turn the ignition switch ON (II).

2. Check the MAP with the scan

tool.

Does it indicate atmospheric

pressure?

YES

*: P0174 or P0175

Check the response of the MAP

sensor:

1. Start the engine.

2. Check the MAP with the scan

tool.

Is a MAP of 40.0 kPa (300 mmHg,

12.0 inHg) or less indicated within

one second after starting the

engine?

Replace the MAP sensor.

YES

Check the EGR system. If it is OK,

replace the fuel injectors.

NO

NO

Replace the MAP sensor.

NO

YES

HIGH

Troubleshooting FlowchartProCarManuals.com

Page 595 of 1954

PGM-FI System

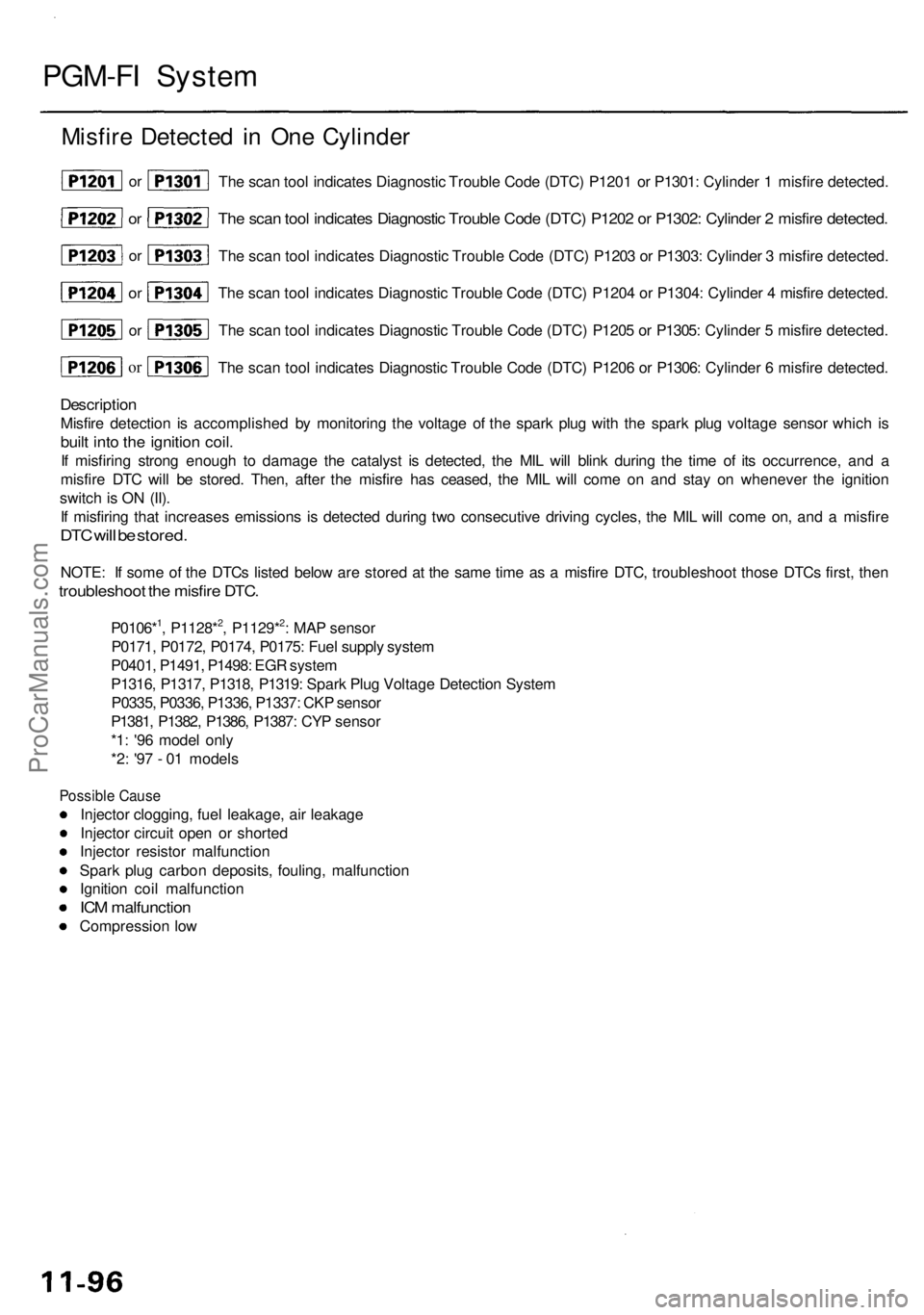

Misfire Detected in One Cylinder

The scan tool indicates Diagnostic Trouble Code (DTC) P1203 or P1303: Cylinder 3 misfire detected.

The scan tool indicates Diagnostic Trouble Code (DTC) P1204 or P1304: Cylinder 4 misfire detected.

The scan tool indicates Diagnostic Trouble Code (DTC) P1205 or P1305: Cylinder 5 misfire detected.

Description

Misfire detection is accomplished by monitoring the voltage of the spark plug with the spark plug voltage sensor which is

built into the ignition coil.

If misfiring strong enough to damage the catalyst is detected, the MIL will blink during the time of its occurrence, and a

misfire DTC will be stored. Then, after the misfire has ceased, the MIL will come on and stay on whenever the ignition

switch is ON (II).

If misfiring that increases emissions is detected during two consecutive driving cycles, the MIL will come on, and a misfire

DTC will be stored.

NOTE: If some of the DTCs listed below are stored at the same time as a misfire DTC, troubleshoot those DTCs first, then

troubleshoot the misfire DTC.

P0106*1, P1128*2, P1129*2: MAP sensor

P0171, P0172, P0174, P0175: Fuel supply system

P0401, P1491, P1498: EGR system

P1316, P1317, P1318, P1319: Spark Plug Voltage Detection System

P0335, P0336, P1336, P1337: CKP sensor

P1381, P1382, P1386, P1387: CYP sensor

*1: '96 model only

*2: '97 - 01 models

Possible Cause

Injector clogging, fuel leakage, air leakage

Injector circuit open or shorted

Injector resistor malfunction

Spark plug carbon deposits, fouling, malfunction

Ignition coil malfunction

ICM malfunction

Compression low

or

The scan tool indicates Diagnostic Trouble Code (DTC) P1206 or P1306: Cylinder 6 misfire detected.

or

or

or

The scan tool indicates Diagnostic Trouble Code (DTC) P1201 or P1301: Cylinder 1 misfire detected.

The scan tool indicates Diagnostic Trouble Code (DTC) P1202 or P1302: Cylinder 2 misfire detected.

or

orProCarManuals.com

Page 599 of 1954

PGM-FI Syste m

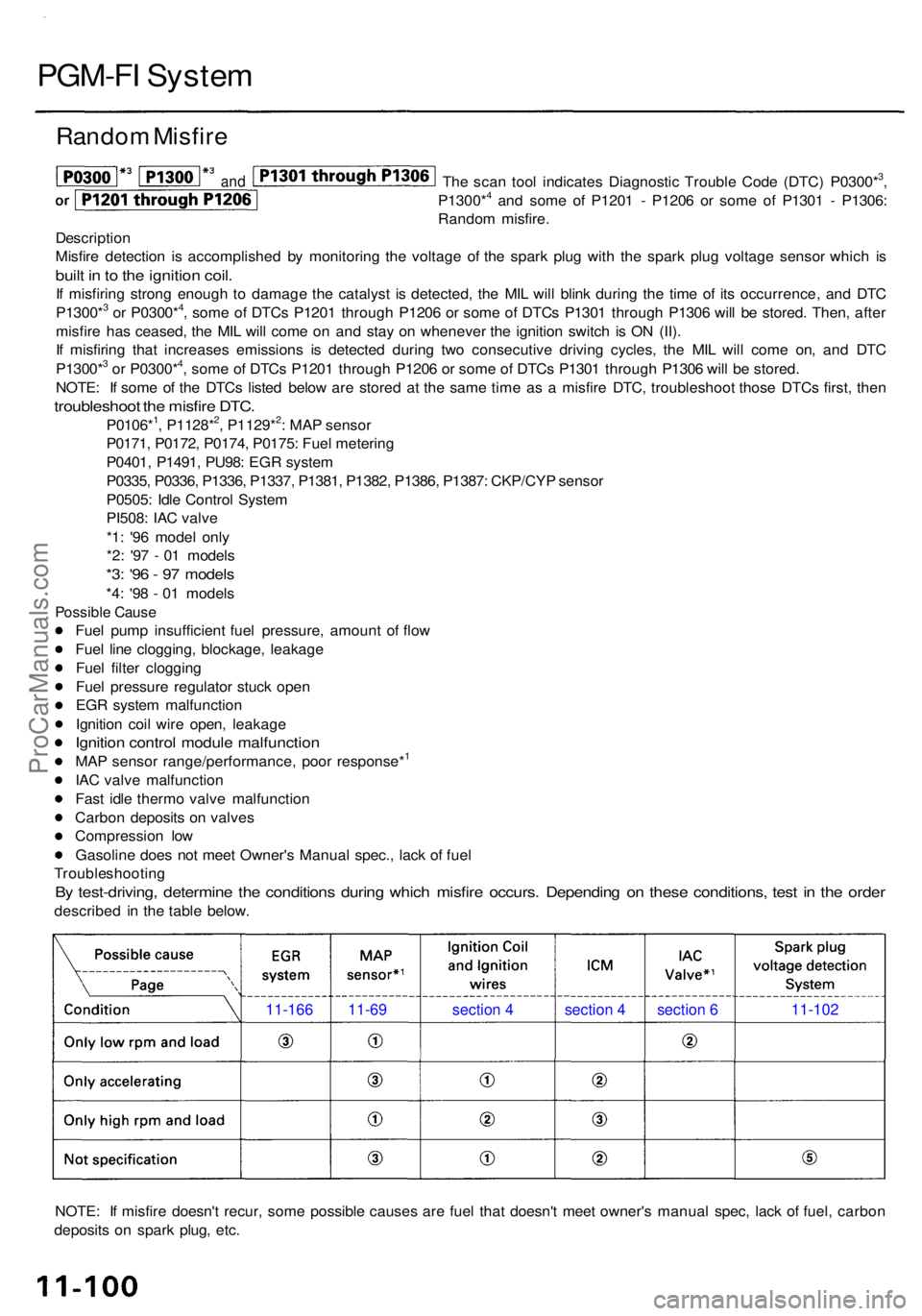

Rando m Misfir e

The sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P0300*3,

P1300*4 an d som e o f P120 1 - P120 6 o r som e o f P130 1 - P1306 :

Rando m misfire .

Descriptio n

Misfir e detectio n i s accomplishe d b y monitorin g th e voltag e o f th e spar k plu g wit h th e spar k plu g voltag e senso r whic h i s

buil t i n to th e ignitio n coil .

If misfirin g stron g enoug h t o damag e th e catalys t i s detected , th e MI L wil l blin k durin g th e tim e o f it s occurrence , an d DT C

P1300*3 o r P0300*4, som e o f DTC s P120 1 throug h P120 6 o r som e o f DTC s P130 1 throug h P130 6 wil l b e stored . Then , afte r

misfir e ha s ceased , th e MI L wil l com e o n an d sta y o n wheneve r th e ignitio n switc h i s O N (II) .

I f misfirin g tha t increase s emission s i s detecte d durin g tw o consecutiv e drivin g cycles , th e MI L wil l com e on , an d DT C

P1300*

3 o r P0300*4, som e o f DTC s P120 1 throug h P120 6 o r som e o f DTC s P130 1 throug h P130 6 wil l b e stored .

NOTE : I f som e o f th e DTC s liste d belo w ar e store d a t th e sam e tim e a s a misfir e DTC , troubleshoo t thos e DTC s first , the n

troubleshoo t th e misfir e DTC .

P0106*1, P1128*2, P1129*2: MA P senso r

P0171 , P0172 , P0174 , P0175 : Fue l meterin g

P0401 , P1491 , PU98 : EG R syste m

P0335 , P0336 , P1336 , P1337 , P1381 , P1382 , P1386 , P1387 : CKP/CY P senso r

P0505 : Idl e Contro l Syste m

PI508 : IA C valv e

*1 : '9 6 mode l onl y

*2 : '9 7 - 0 1 model s

*3: '9 6 - 9 7 model s

*4: '9 8 - 0 1 model s

Possibl e Caus e

Fuel pum p insufficien t fue l pressure , amoun t o f flo w

Fue l lin e clogging , blockage , leakag e

Fue l filte r cloggin g

Fue l pressur e regulato r stuc k ope n

EG R syste m malfunctio n

Ignitio n coi l wir e open , leakag e

Ignition contro l modul e malfunction

MA P senso r range/performance , poo r response*1

IA C valv e malfunctio n

Fas t idl e therm o valv e malfunctio n

Carbo n deposit s o n valve s

Compressio n lo w

Gasolin e doe s no t mee t Owner' s Manua l spec. , lac k o f fue l

Troubleshootin g

By test-driving , determin e th e condition s durin g whic h misfir e occurs . Dependin g o n thes e conditions , tes t i n th e orde r

describe d i n th e tabl e below .

NOTE : I f misfir e doesn' t recur , som e possibl e cause s ar e fue l tha t doesn' t mee t owner' s manua l spec , lac k o f fuel , carbo n

deposit s o n spar k plug , etc .

11-166 11-69 section 4 section 4 section 6 11-102

and

ProCarManuals.com

Page 634 of 1954

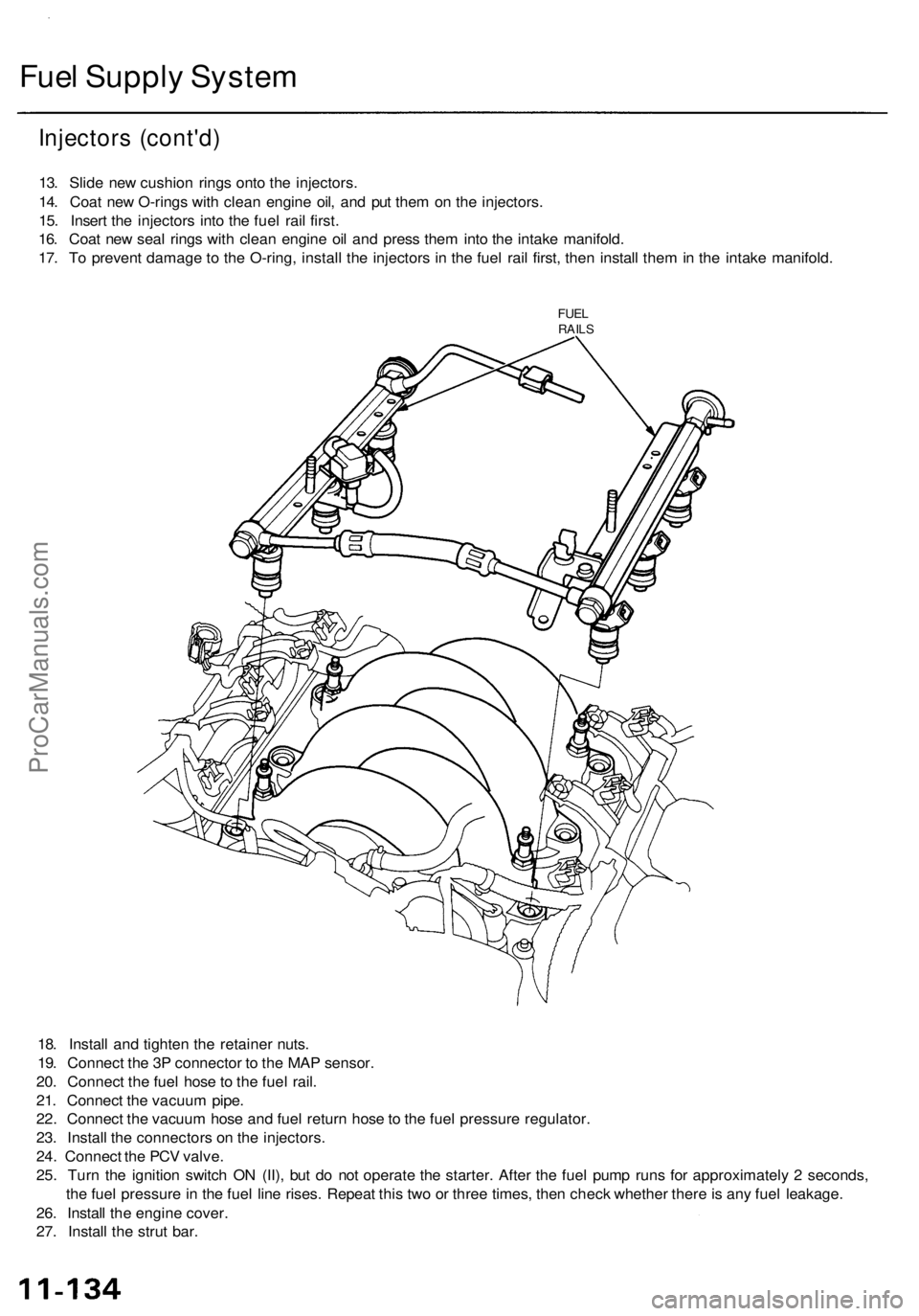

Fuel Supply System

Injectors (cont'd)

13. Slide new cushion rings onto the injectors.

14. Coat new O-rings with clean engine oil, and put them on the injectors.

15. Insert the injectors into the fuel rail first.

16. Coat new seal rings with clean engine oil and press them into the intake manifold.

17. To prevent damage to the O-ring, install the injectors in the fuel rail first, then install them in the intake manifold.

FUEL

RAILS

18. Install and tighten the retainer nuts.

19. Connect the 3P connector to the MAP sensor.

20. Connect the fuel hose to the fuel rail.

21. Connect the vacuum pipe.

22. Connect the vacuum hose and fuel return hose to the fuel pressure regulator.

23. Install the connectors on the injectors.

24. Connect the PCV valve.

25. Turn the ignition switch ON (II), but do not operate the starter. After the fuel pump runs for approximately 2 seconds,

the fuel pressure in the fuel line rises. Repeat this two or three times, then check whether there is any fuel leakage.

26. Install the engine cover.

27. Install the strut bar.ProCarManuals.com

Page 791 of 1954

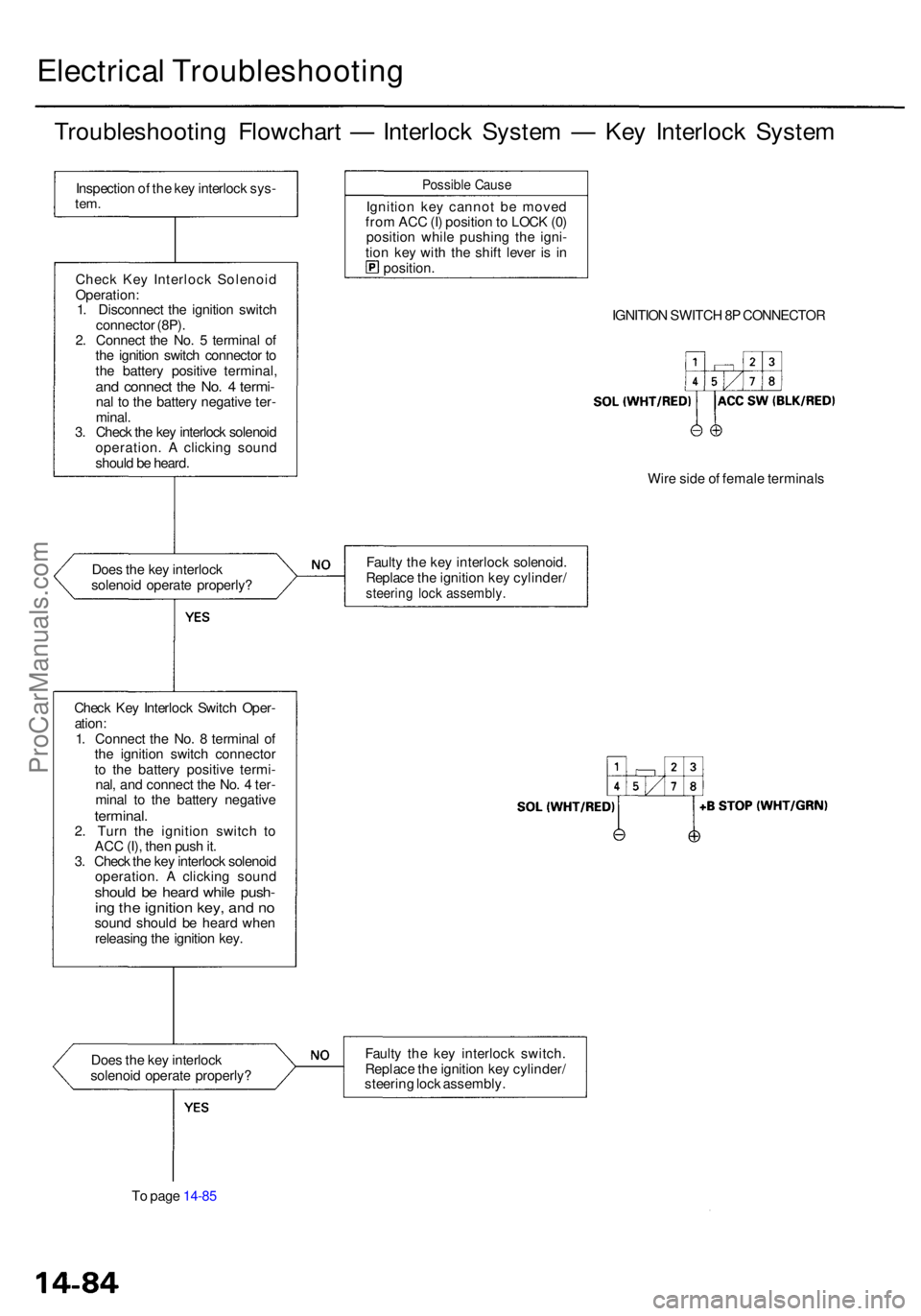

Electrical Troubleshootin g

Troubleshooting Flowchar t — Interloc k Syste m — Ke y Interloc k Syste m

Inspectio n o f th e ke y interloc k sys -tem.

Chec k Ke y Interloc k Solenoi d

Operation :

1 . Disconnec t th e ignitio n switc h

connecto r (8P) .

2 . Connec t th e No . 5 termina l o f

th e ignitio n switc h connecto r t o

th e batter y positiv e terminal ,

and connec t th e No . 4 termi -nal t o th e batter y negativ e ter -

minal .

3 . Chec k th e ke y interloc k solenoi d

operation . A clickin g soun d

shoul d b e heard .

Doe s th e ke y interloc k

solenoi d operat e properly ?

Chec k Ke y Interloc k Switc h Oper -

ation :

1 . Connec t th e No . 8 termina l o f

th e ignitio n switc h connecto r

t o th e batter y positiv e termi -

nal , an d connec t th e No . 4 ter -

mina l t o th e batter y negativ e

terminal.2. Tur n th e ignitio n switc h t o

AC C (I) , the n pus h it .

3 . Chec k th e ke y interloc k solenoi d

operation . A clickin g soun d

should b e hear d whil e push -ing th e ignitio n key , an d n osoun d shoul d b e hear d whe n

releasin g th e ignitio n key .

Doe s th e ke y interloc k

solenoi d operat e properly ?

T o pag e 14-8 5

Possibl e Caus e

Ignitio n ke y canno t b e move d

fro m AC C (I ) positio n to LOC K (0 )

positio n whil e pushin g th e igni -

tio n ke y wit h th e shif t leve r i s in

position .

IGNITION SWITC H 8P CONNECTO R

Wir e sid e o f femal e terminal s

Fault y th e ke y interloc k solenoid .

Replac e th e ignitio n ke y cylinder /

steering loc k assembly .

Faulty th e ke y interloc k switch .

Replac e th e ignitio n ke y cylinder /

steerin g loc k assembly .

ProCarManuals.com