fuel ACURA RL KA9 1996 Service Service Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 592 of 1954

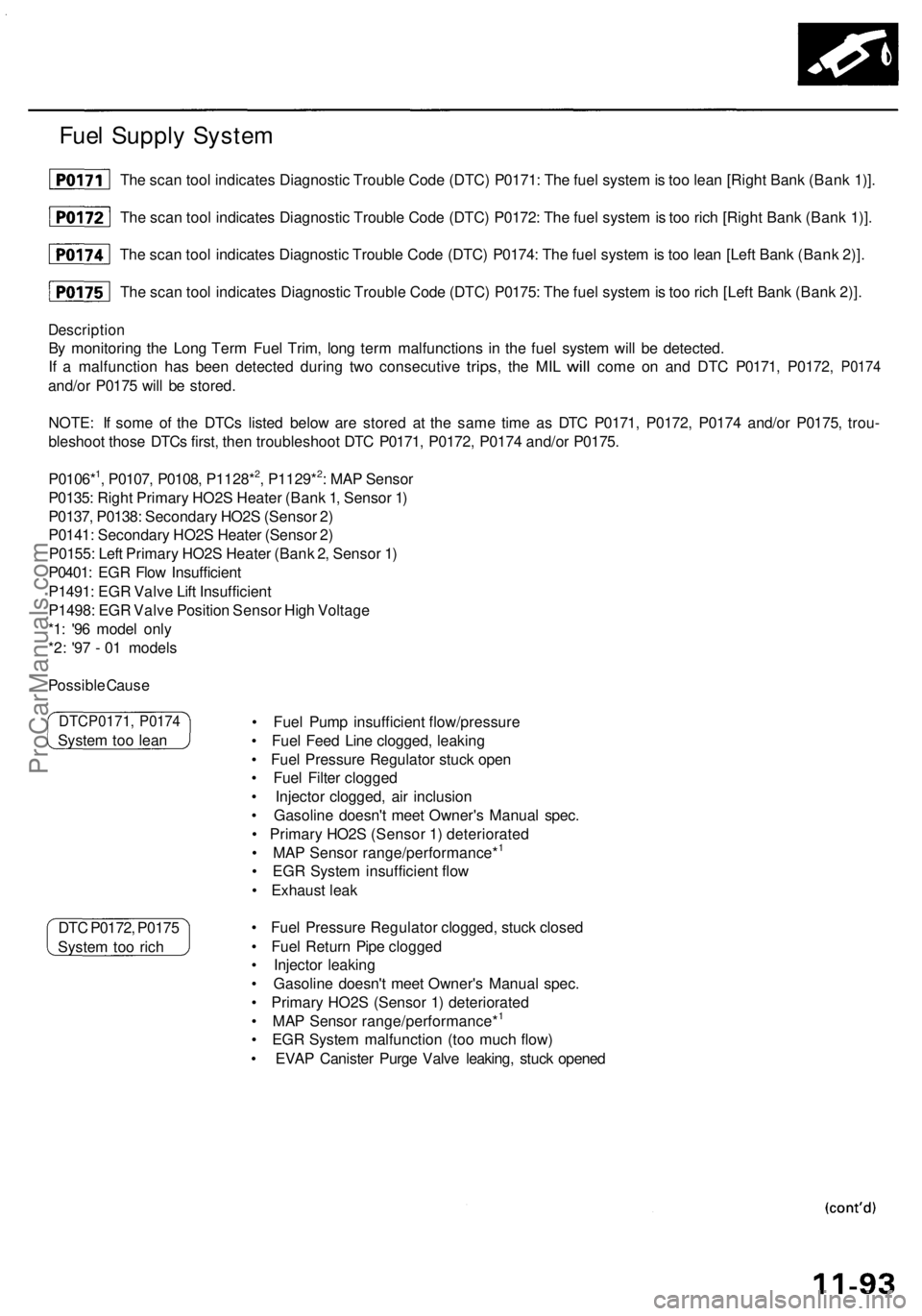

Fuel Supply System

Description

By monitoring the Long Term Fuel Trim, long term malfunctions in the fuel system will be detected.

If a

malfunction

has

been detected during

two

consecutive

trips,

the MIL

will

come

on and DTC

P0171, P0172,

P0174

and/or P0175 will be stored.

NOTE: If some of the DTCs listed below are stored at the same time as DTC P0171, P0172, P0174 and/or P0175, trou-

bleshoot those DTCs first, then troubleshoot DTC P0171, P0172, P0174 and/or P0175.

P0106*1, P0107, P0108, P1128*2, P1129*2: MAP Sensor

P0135: Right Primary HO2S Heater (Bank 1, Sensor 1)

P0137, P0138: Secondary HO2S (Sensor 2)

P0141: Secondary HO2S Heater (Sensor 2)

P0155: Left Primary HO2S Heater (Bank 2, Sensor 1)

P0401: EGR Flow Insufficient

P1491: EGR Valve Lift Insufficient

P1498: EGR Valve Position Sensor High Voltage

*1: '96 model only

*2: '97 - 01 models

DTC P0172, P0175

System too rich

• Fuel Pump insufficient flow/pressure

• Fuel Feed Line clogged, leaking

• Fuel Pressure Regulator stuck open

• Fuel Filter clogged

• Injector clogged, air inclusion

• Gasoline doesn't meet Owner's Manual spec.

• Primary HO2S (Sensor 1) deteriorated

• MAP Sensor range/performance*1

• EGR System insufficient flow

• Exhaust leak

• Fuel Pressure Regulator clogged, stuck closed

• Fuel Return Pipe clogged

• Injector leaking

• Gasoline doesn't meet Owner's Manual spec.

• Primary HO2S (Sensor 1) deteriorated

• MAP Sensor range/performance*1

• EGR System malfunction (too much flow)

• EVAP Canister Purge Valve leaking, stuck opened

DTCP0171, P0174

System too lean

The scan tool indicates Diagnostic Trouble Code (DTC) P0171: The fuel system is too lean [Right Bank (Bank 1)].

The scan tool indicates Diagnostic Trouble Code (DTC) P0172: The fuel system is too rich [Right Bank (Bank 1)].

The scan tool indicates Diagnostic Trouble Code (DTC) P0174: The fuel system is too lean [Left Bank (Bank 2)].

The scan tool indicates Diagnostic Trouble Code (DTC) P0175: The fuel system is too rich [Left Bank (Bank 2)].

Possible CauseProCarManuals.com

Page 593 of 1954

PGM-FI System

Fuel Supply System (cont'd)

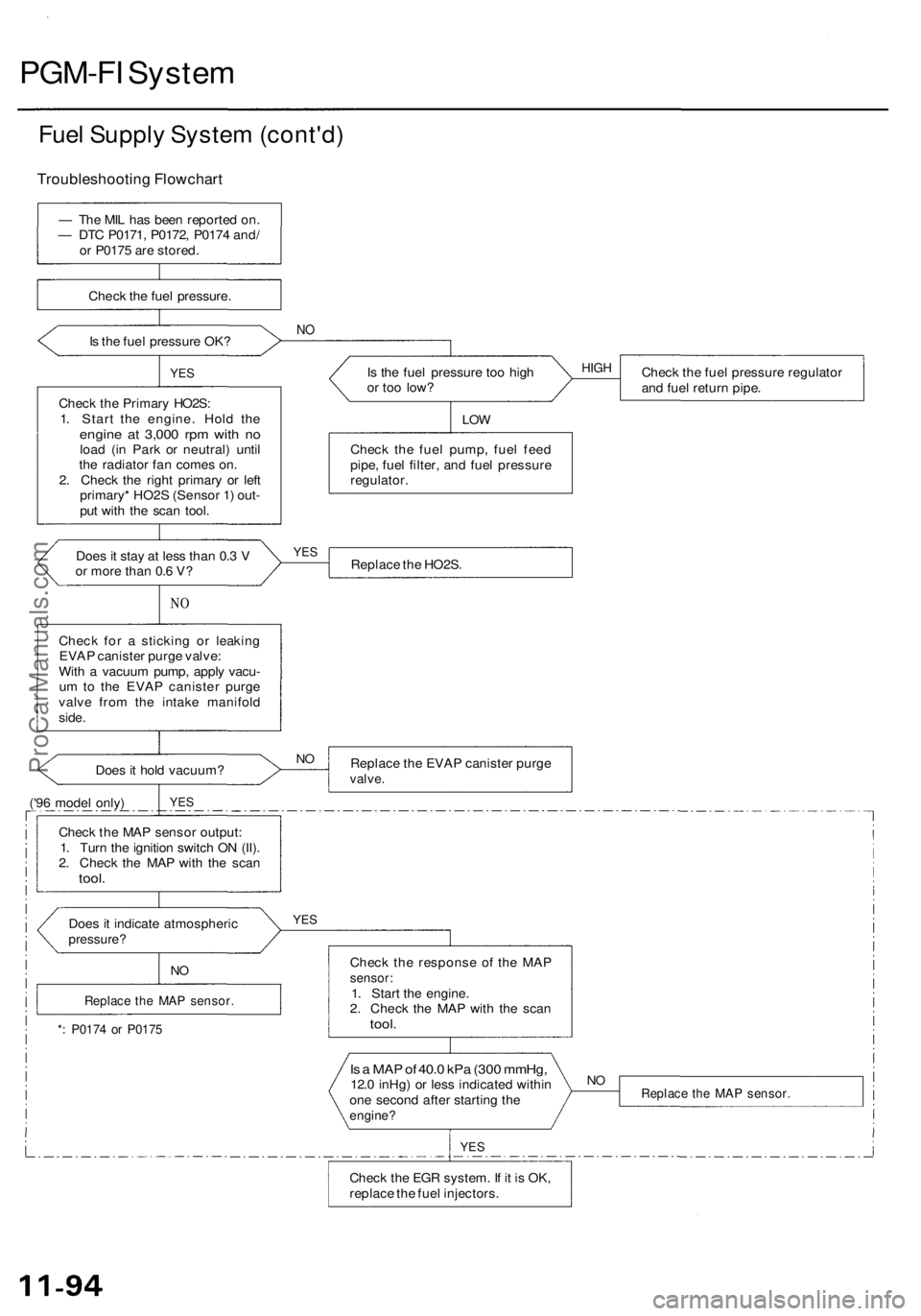

— The MIL has been reported on.

— DTC P0171, P0172, P0174 and/

or P0175 are stored.

Check the fuel pressure.

Is the fuel pressure OK?

NO

YES

Check the Primary HO2S:

1. Start the engine. Hold the

engine at 3,000 rpm with no

load (in Park or neutral) until

the radiator fan comes on.

2. Check the right primary or left

primary* HO2S (Sensor 1) out-

put with the scan tool.

Is the fuel pressure too high

or too low?

Check the fuel pressure regulator

and fuel return pipe.

LOW

Check the fuel pump, fuel feed

pipe, fuel filter, and fuel pressure

regulator.

Does it stay at less than 0.3 V

or more than 0.6 V?

Replace the HO2S.

NO

Check for a sticking or leaking

EVAP canister purge valve:

With a vacuum pump, apply vacu-

um to the EVAP canister purge

valve from the intake manifold

side.

Does it hold vacuum?

('96 model only)

Replace the EVAP canister purge

valve.

YES

Check the MAP sensor output:

1. Turn the ignition switch ON (II).

2. Check the MAP with the scan

tool.

Does it indicate atmospheric

pressure?

YES

*: P0174 or P0175

Check the response of the MAP

sensor:

1. Start the engine.

2. Check the MAP with the scan

tool.

Is a MAP of 40.0 kPa (300 mmHg,

12.0 inHg) or less indicated within

one second after starting the

engine?

Replace the MAP sensor.

YES

Check the EGR system. If it is OK,

replace the fuel injectors.

NO

NO

Replace the MAP sensor.

NO

YES

HIGH

Troubleshooting FlowchartProCarManuals.com

Page 595 of 1954

PGM-FI System

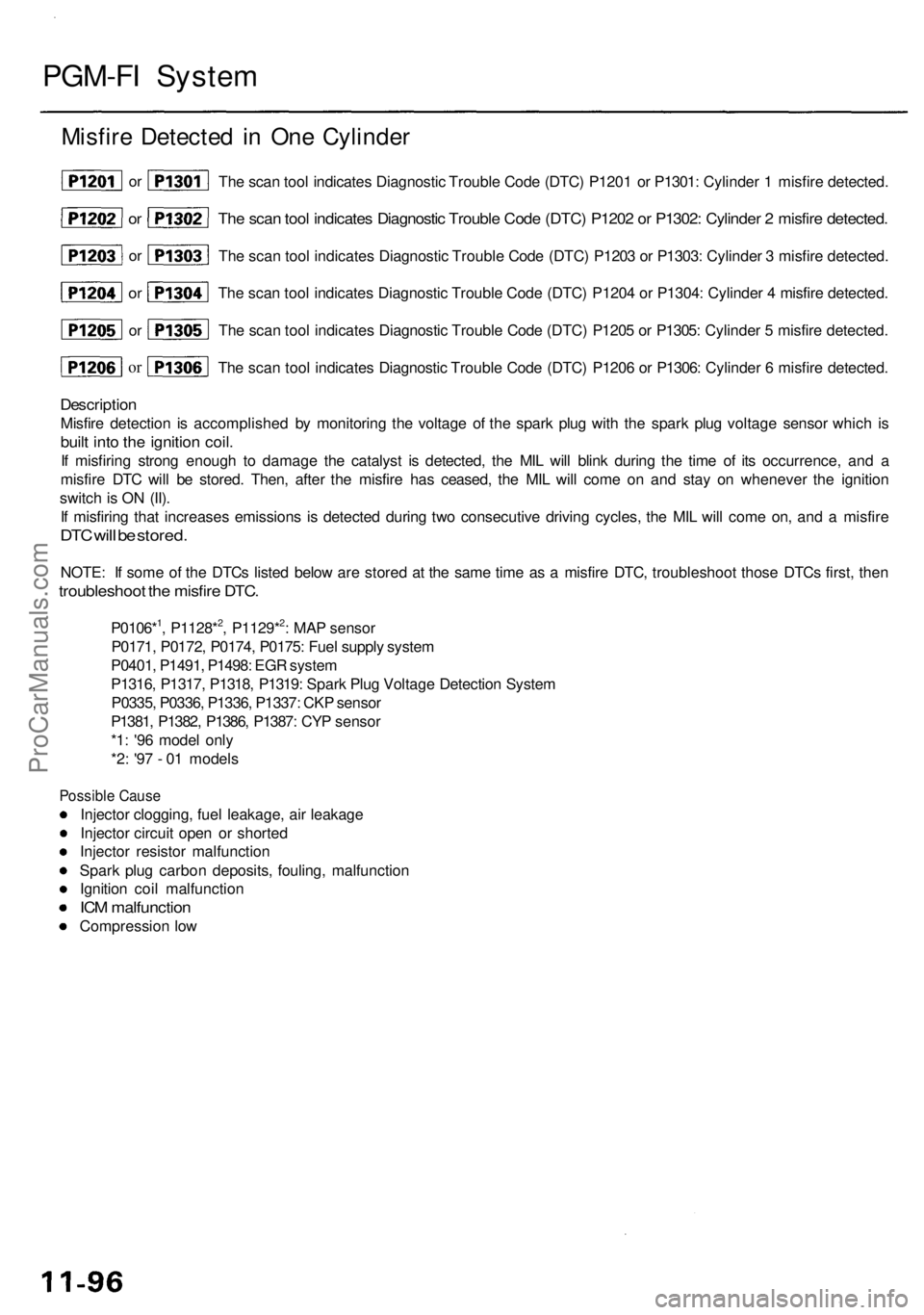

Misfire Detected in One Cylinder

The scan tool indicates Diagnostic Trouble Code (DTC) P1203 or P1303: Cylinder 3 misfire detected.

The scan tool indicates Diagnostic Trouble Code (DTC) P1204 or P1304: Cylinder 4 misfire detected.

The scan tool indicates Diagnostic Trouble Code (DTC) P1205 or P1305: Cylinder 5 misfire detected.

Description

Misfire detection is accomplished by monitoring the voltage of the spark plug with the spark plug voltage sensor which is

built into the ignition coil.

If misfiring strong enough to damage the catalyst is detected, the MIL will blink during the time of its occurrence, and a

misfire DTC will be stored. Then, after the misfire has ceased, the MIL will come on and stay on whenever the ignition

switch is ON (II).

If misfiring that increases emissions is detected during two consecutive driving cycles, the MIL will come on, and a misfire

DTC will be stored.

NOTE: If some of the DTCs listed below are stored at the same time as a misfire DTC, troubleshoot those DTCs first, then

troubleshoot the misfire DTC.

P0106*1, P1128*2, P1129*2: MAP sensor

P0171, P0172, P0174, P0175: Fuel supply system

P0401, P1491, P1498: EGR system

P1316, P1317, P1318, P1319: Spark Plug Voltage Detection System

P0335, P0336, P1336, P1337: CKP sensor

P1381, P1382, P1386, P1387: CYP sensor

*1: '96 model only

*2: '97 - 01 models

Possible Cause

Injector clogging, fuel leakage, air leakage

Injector circuit open or shorted

Injector resistor malfunction

Spark plug carbon deposits, fouling, malfunction

Ignition coil malfunction

ICM malfunction

Compression low

or

The scan tool indicates Diagnostic Trouble Code (DTC) P1206 or P1306: Cylinder 6 misfire detected.

or

or

or

The scan tool indicates Diagnostic Trouble Code (DTC) P1201 or P1301: Cylinder 1 misfire detected.

The scan tool indicates Diagnostic Trouble Code (DTC) P1202 or P1302: Cylinder 2 misfire detected.

or

orProCarManuals.com

Page 599 of 1954

PGM-FI Syste m

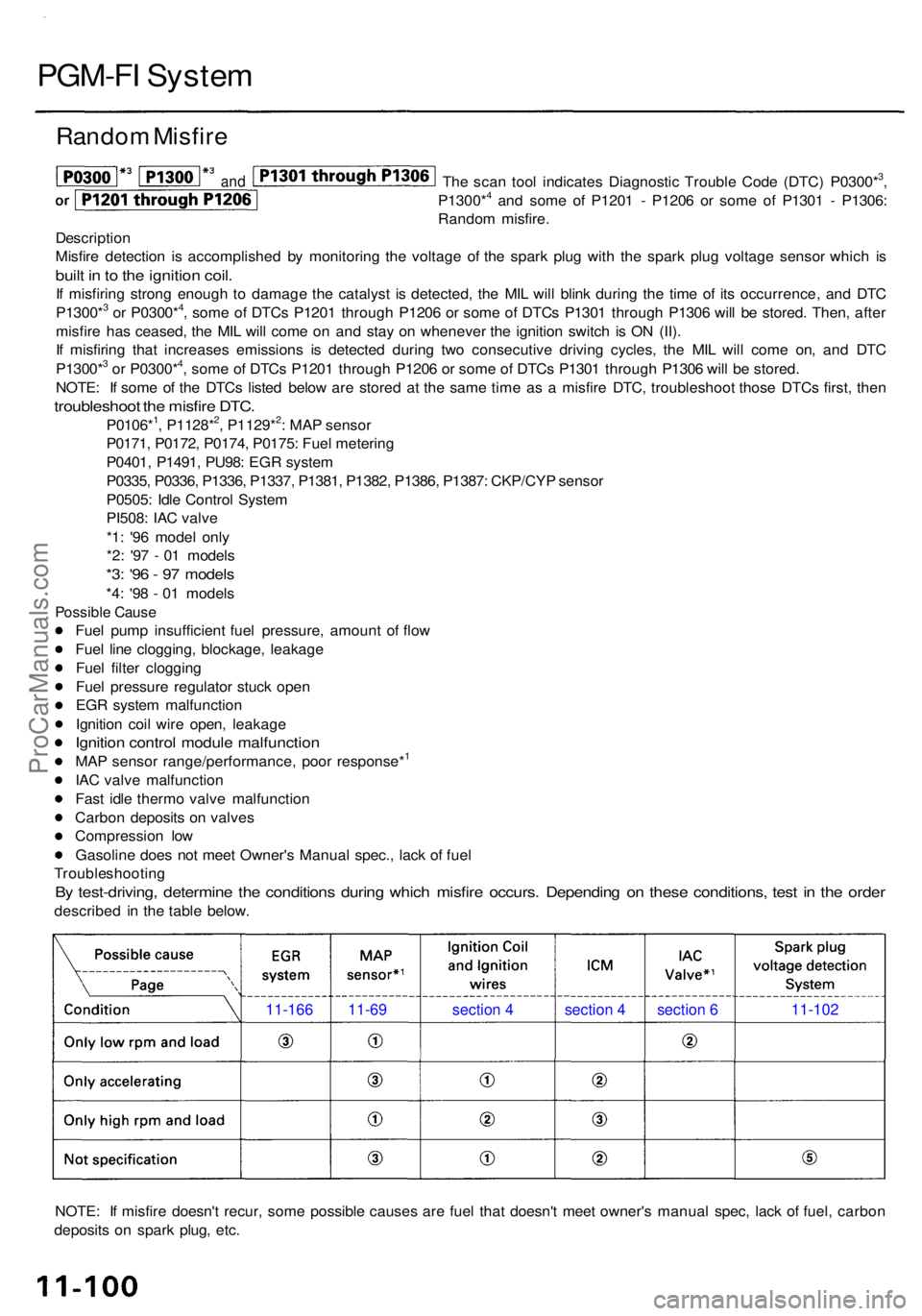

Rando m Misfir e

The sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P0300*3,

P1300*4 an d som e o f P120 1 - P120 6 o r som e o f P130 1 - P1306 :

Rando m misfire .

Descriptio n

Misfir e detectio n i s accomplishe d b y monitorin g th e voltag e o f th e spar k plu g wit h th e spar k plu g voltag e senso r whic h i s

buil t i n to th e ignitio n coil .

If misfirin g stron g enoug h t o damag e th e catalys t i s detected , th e MI L wil l blin k durin g th e tim e o f it s occurrence , an d DT C

P1300*3 o r P0300*4, som e o f DTC s P120 1 throug h P120 6 o r som e o f DTC s P130 1 throug h P130 6 wil l b e stored . Then , afte r

misfir e ha s ceased , th e MI L wil l com e o n an d sta y o n wheneve r th e ignitio n switc h i s O N (II) .

I f misfirin g tha t increase s emission s i s detecte d durin g tw o consecutiv e drivin g cycles , th e MI L wil l com e on , an d DT C

P1300*

3 o r P0300*4, som e o f DTC s P120 1 throug h P120 6 o r som e o f DTC s P130 1 throug h P130 6 wil l b e stored .

NOTE : I f som e o f th e DTC s liste d belo w ar e store d a t th e sam e tim e a s a misfir e DTC , troubleshoo t thos e DTC s first , the n

troubleshoo t th e misfir e DTC .

P0106*1, P1128*2, P1129*2: MA P senso r

P0171 , P0172 , P0174 , P0175 : Fue l meterin g

P0401 , P1491 , PU98 : EG R syste m

P0335 , P0336 , P1336 , P1337 , P1381 , P1382 , P1386 , P1387 : CKP/CY P senso r

P0505 : Idl e Contro l Syste m

PI508 : IA C valv e

*1 : '9 6 mode l onl y

*2 : '9 7 - 0 1 model s

*3: '9 6 - 9 7 model s

*4: '9 8 - 0 1 model s

Possibl e Caus e

Fuel pum p insufficien t fue l pressure , amoun t o f flo w

Fue l lin e clogging , blockage , leakag e

Fue l filte r cloggin g

Fue l pressur e regulato r stuc k ope n

EG R syste m malfunctio n

Ignitio n coi l wir e open , leakag e

Ignition contro l modul e malfunction

MA P senso r range/performance , poo r response*1

IA C valv e malfunctio n

Fas t idl e therm o valv e malfunctio n

Carbo n deposit s o n valve s

Compressio n lo w

Gasolin e doe s no t mee t Owner' s Manua l spec. , lac k o f fue l

Troubleshootin g

By test-driving , determin e th e condition s durin g whic h misfir e occurs . Dependin g o n thes e conditions , tes t i n th e orde r

describe d i n th e tabl e below .

NOTE : I f misfir e doesn' t recur , som e possibl e cause s ar e fue l tha t doesn' t mee t owner' s manua l spec , lac k o f fuel , carbo n

deposit s o n spar k plug , etc .

11-166 11-69 section 4 section 4 section 6 11-102

and

ProCarManuals.com

Page 626 of 1954

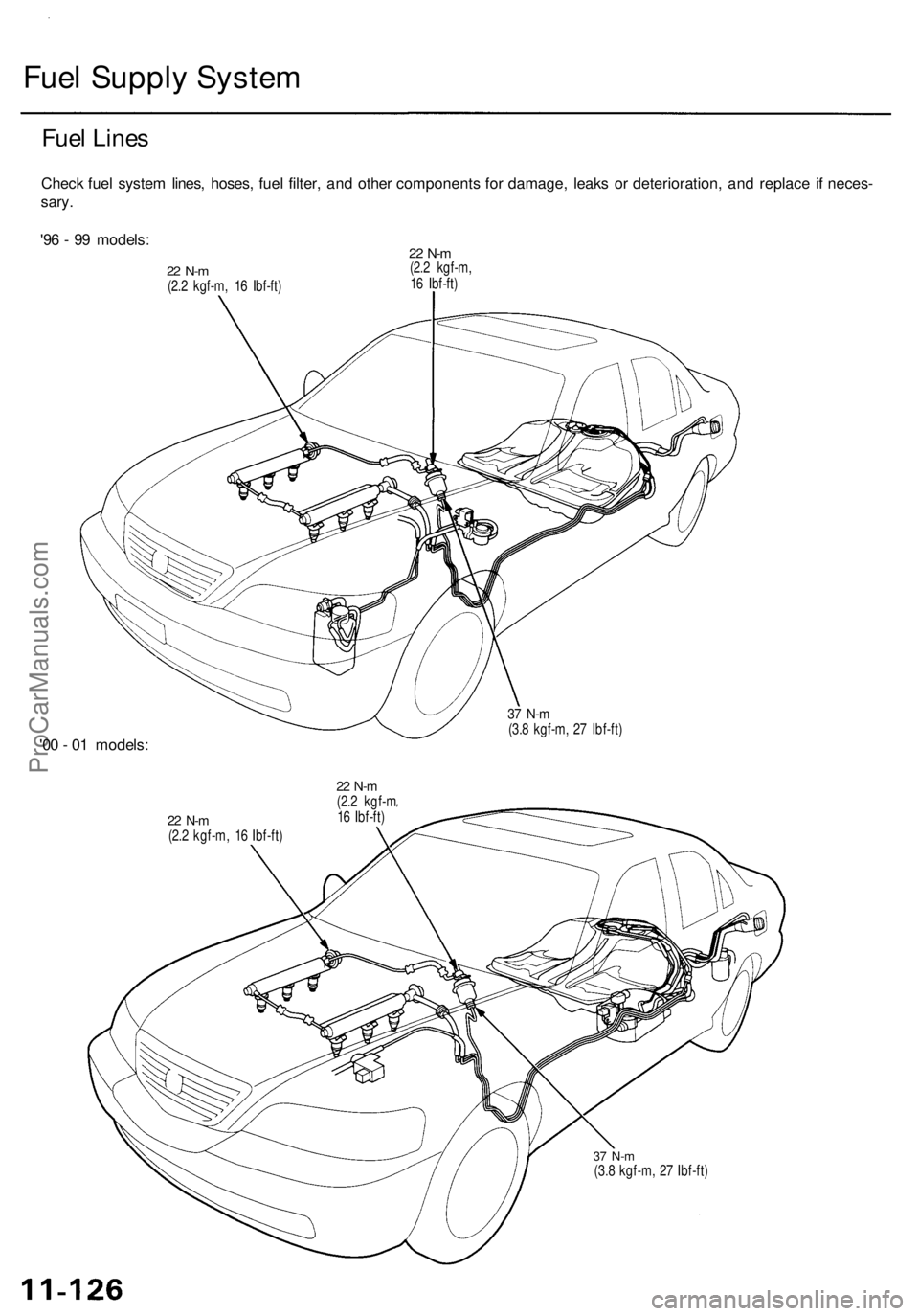

Fuel Supply System

Fuel Lines

Check fuel system lines, hoses, fuel filter, and other components for damage, leaks or deterioration, and replace if neces-

sary.

'96 - 99 models:

22 N-m

(2.2 kgf-m, 16 Ibf-ft)

22 N-m

(2.2 kgf-m,

16 Ibf-ft)

'00 - 01 models:

37 N-m

(3.8 kgf-m, 27 Ibf-ft)

22 N-m

(2.2 kgf-m, 16 Ibf-ft)

22 N-m

(2.2 kgf-m

16 Ibf-ft)

37 N-m

(3.8 kgf-m, 27 Ibf-ft)ProCarManuals.com

Page 627 of 1954

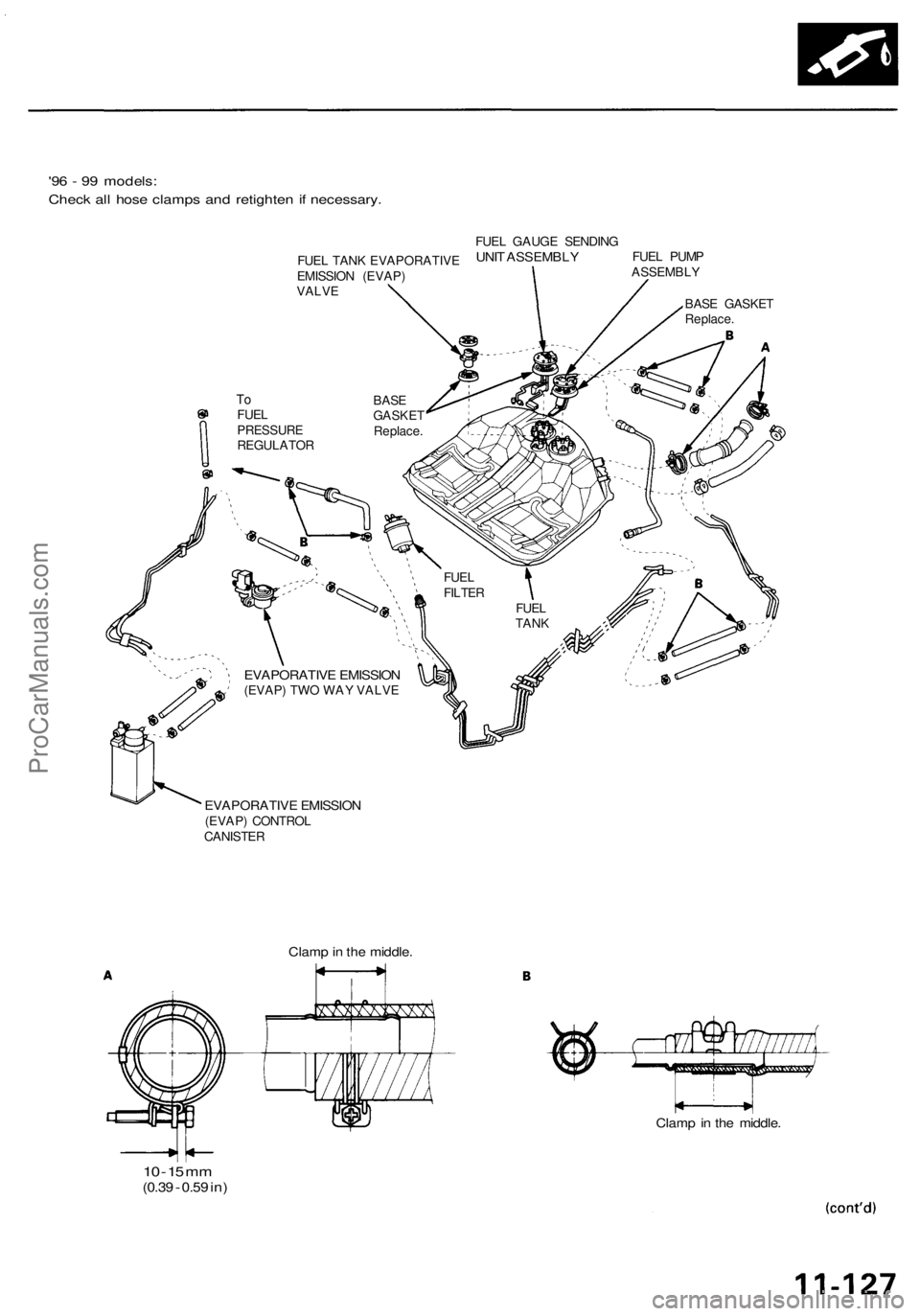

'96 - 99 models:

Check all hose clamps and retighten if necessary.

EVAPORATIVE EMISSION

(EVAP) TWO WAY VALVE

EVAPORATIVE EMISSION

(EVAP) CONTROL

CANISTER

10 -

15

mm

(0.39

-

0.59

in)

Clamp in the middle.

Clamp in the middle.

FUEL

TANK

FUEL

FILTER

To

FUEL

PRESSURE

REGULATOR

BASE

GASKET

Replace.

BASE GASKET

Replace.

FUEL PUMP

ASSEMBLY

FUEL GAUGE SENDING

UNIT ASSEMBLY

FUEL TANK EVAPORATIVE

EMISSION (EVAP)

VALVEProCarManuals.com

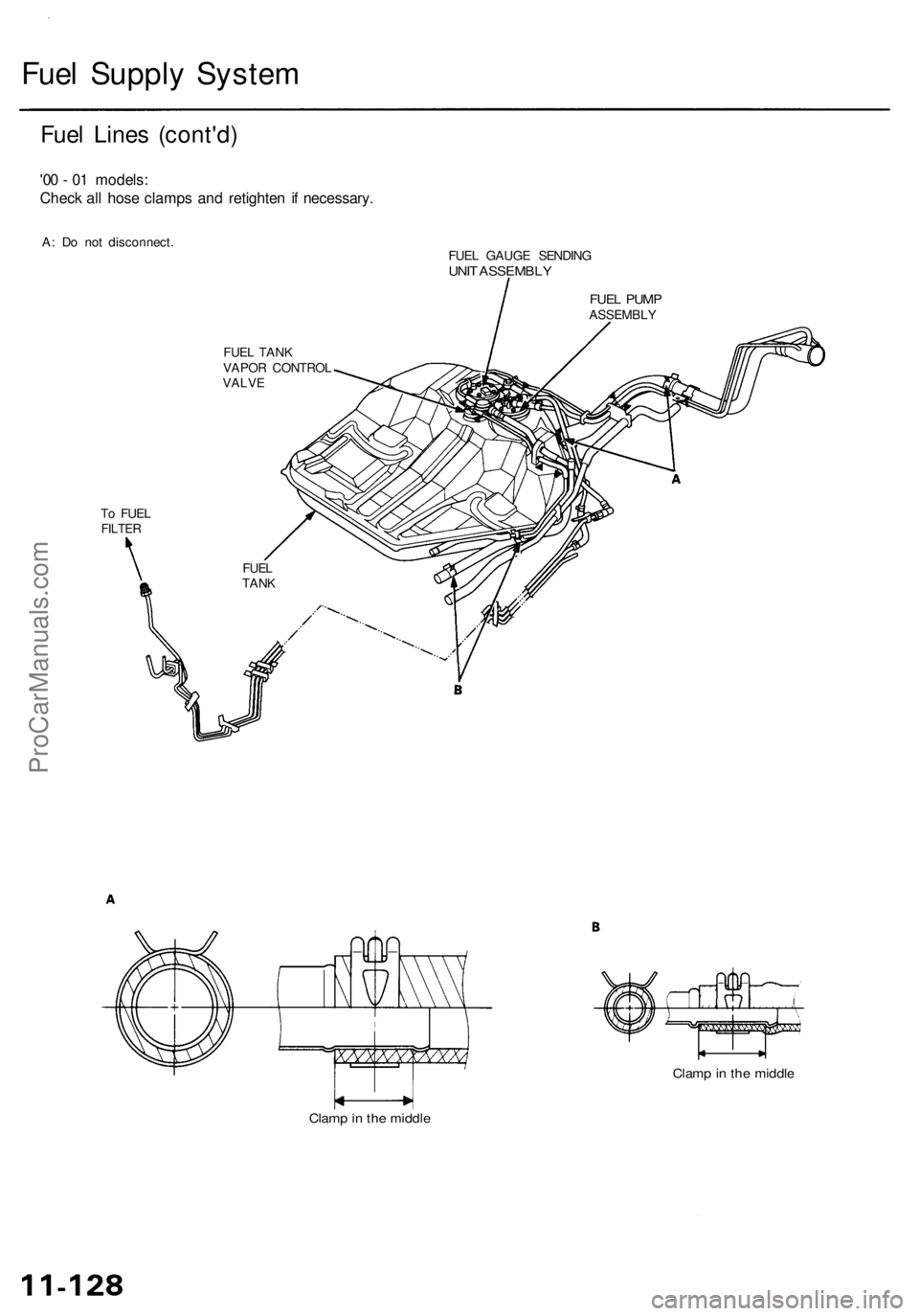

Page 628 of 1954

Fuel Supply System

Fuel Lines (cont'd)

'00 - 01 models:

Check all hose clamps and retighten if necessary.

A: Do not disconnect.

To FUEL

FILTER

FUEL TANK

VAPOR CONTROL

VALVE

FUEL GAUGE SENDING

UNIT ASSEMBLY

Clamp in the middle

Clamp in the middle

FUEL

TANK

FUEL PUMP

ASSEMBLYProCarManuals.com

Page 629 of 1954

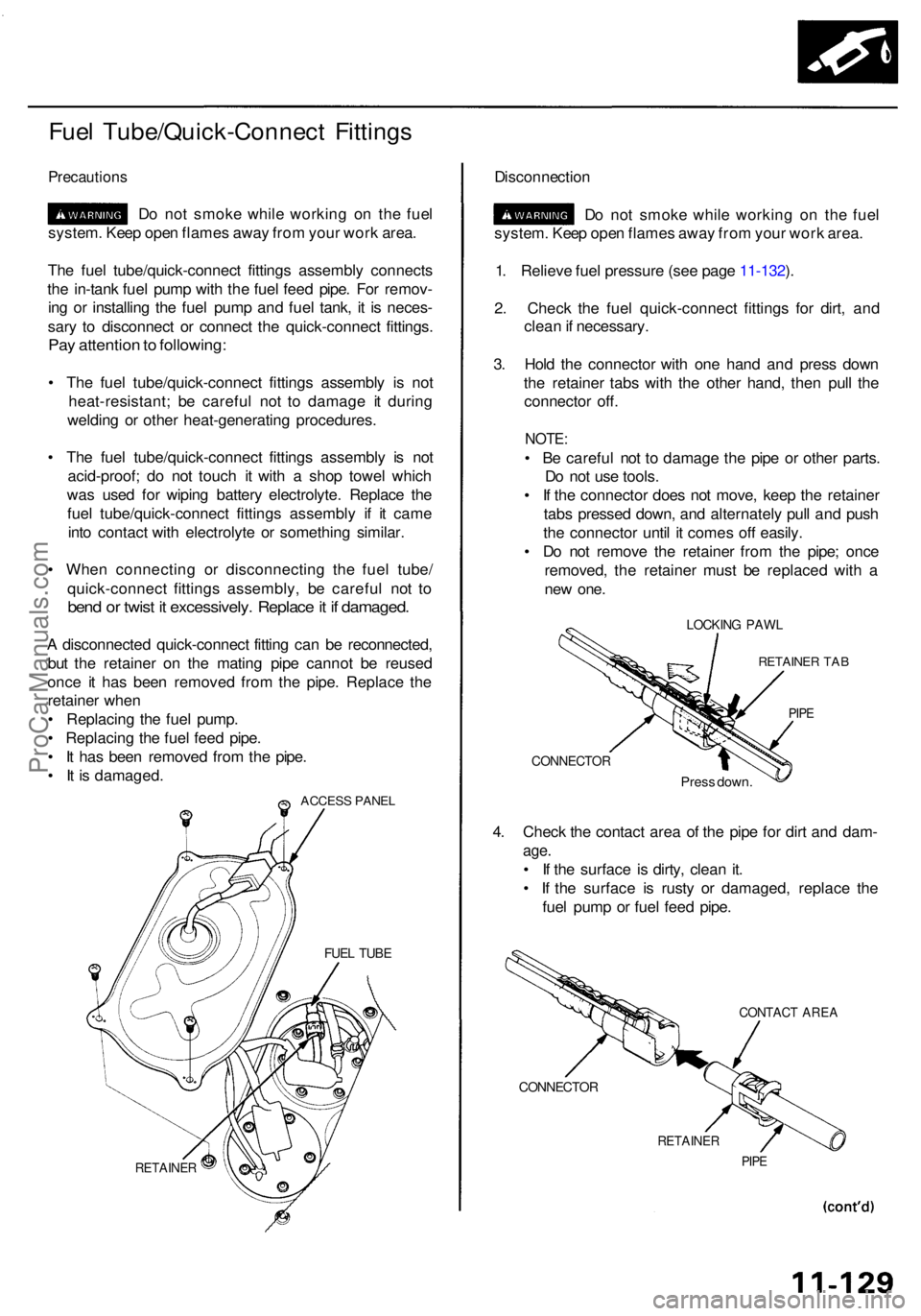

Fuel Tube/Quick-Connec t Fitting s

Precaution s

Do no t smok e whil e workin g o n th e fue l

system . Kee p ope n flame s awa y fro m you r wor k area .

Th e fue l tube/quick-connec t fitting s assembl y connect s

th e in-tan k fue l pum p wit h th e fue l fee d pipe . Fo r remov -

in g o r installin g th e fue l pum p an d fue l tank , i t i s neces -

sar y t o disconnec t o r connec t th e quick-connec t fittings .

Pay attentio n to following :

• Th e fue l tube/quick-connec t fitting s assembl y i s no t

heat-resistant ; b e carefu l no t t o damag e i t durin g

weldin g o r othe r heat-generatin g procedures .

• Th e fue l tube/quick-connec t fitting s assembl y i s no t

acid-proof ; d o no t touc h i t wit h a sho p towe l whic h

wa s use d fo r wipin g batter y electrolyte . Replac e th e

fue l tube/quick-connec t fitting s assembl y i f i t cam e

int o contac t wit h electrolyt e o r somethin g similar .

• Whe n connectin g o r disconnectin g th e fue l tube /

quick-connec t fitting s assembly , b e carefu l no t t o

ben d o r twis t i t excessively . Replac e it i f damaged .

A disconnecte d quick-connec t fittin g ca n b e reconnected ,

bu t th e retaine r o n th e matin g pip e canno t b e reuse d

onc e i t ha s bee n remove d fro m th e pipe . Replac e th e

retaine r whe n

• Replacin g th e fue l pump .

• Replacin g th e fue l fee d pipe .

• I t ha s bee n remove d fro m th e pipe .

• I t i s damaged .

ACCESS PANE L

RETAINE R

Disconnectio n

D o no t smok e whil e workin g o n th e fue l

system . Kee p ope n flame s awa y fro m you r wor k area .

1 . Reliev e fue l pressur e (se e pag e 11-132 ).

2 . Chec k th e fue l quick-connec t fitting s fo r dirt , an d

clea n if necessary .

3 . Hol d th e connecto r wit h on e han d an d pres s dow n

th e retaine r tab s wit h th e othe r hand , the n pul l th e

connecto r off .

NOTE :

• B e carefu l no t t o damag e th e pip e o r othe r parts .

D o no t us e tools .

• I f th e connecto r doe s no t move , kee p th e retaine r

tab s presse d down , an d alternatel y pul l an d pus h

th e connecto r unti l i t come s of f easily .

• D o no t remov e th e retaine r fro m th e pipe ; onc e

removed , th e retaine r mus t b e replace d wit h a

ne w one .

LOCKIN G PAW L

RETAINE R TA B

PIPE

CONNECTO R

Press down .

4. Chec k th e contac t are a o f th e pip e fo r dir t an d dam -

age.

• I f th e surfac e i s dirty , clea n it .

• I f th e surfac e i s rust y o r damaged , replac e th e

fue l pum p o r fue l fee d pipe .

CONTAC T ARE A

CONNECTO R

RETAINER

PIPE

FUE L TUB E

ProCarManuals.com

Page 630 of 1954

Fuel Supply System

Fuel Tube/Quick-Connect Fittings (cont'd)

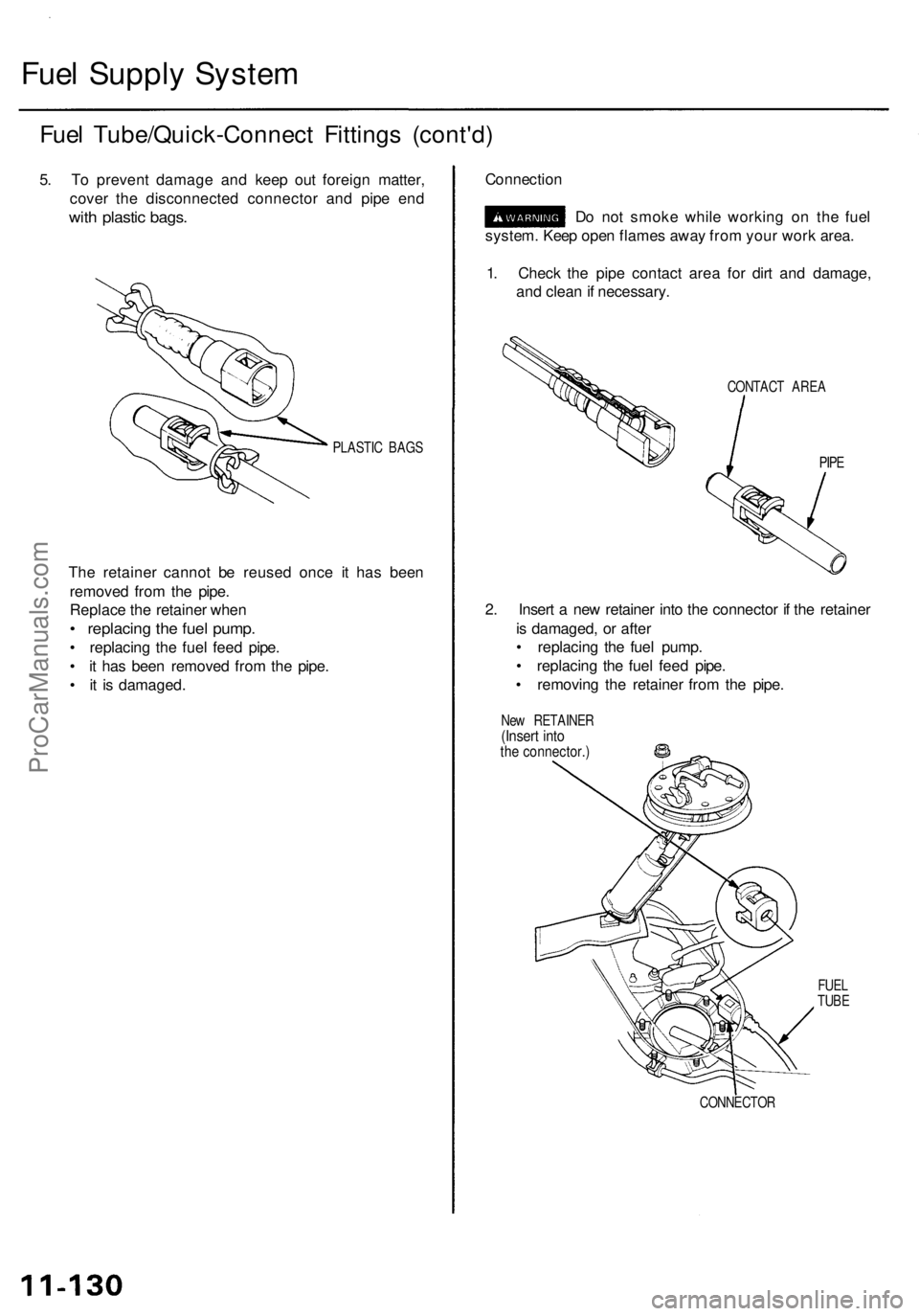

5. To prevent damage and keep out foreign matter,

cover the disconnected connector and pipe end

with plastic bags.

PLASTIC BAGS

The retainer cannot be reused once it has been

removed from the pipe.

Replace the retainer when

• replacing the fuel pump.

• replacing the fuel feed pipe.

• it has been removed from the pipe.

• it is damaged.

Connection

Do not smoke while working on the fuel

system. Keep open flames away from your work area.

1. Check the pipe contact area for dirt and damage,

and clean if necessary.

CONTACT AREA

PIPE

2. Insert a new retainer into the connector if the retainer

is damaged, or after

• replacing the fuel pump.

• replacing the fuel feed pipe.

• removing the retainer from the pipe.

New RETAINER

(Insert into

the connector.)

CONNECTOR

FUEL

TUBEProCarManuals.com

Page 632 of 1954

Fuel Suppl y Syste m

System Descriptio n

The fue l suppl y syste m consist s o f a fue l tank , in-tan k

high-pressur e fue l pump , PGM-F I mai n relay , fue l filter ,

fue l pressur e regulator , fue l pressur e regulato r contro l

solenoi d valve , injectors , an d fue l deliver y an d retur n

lines . Thi s syste m deliver s pressure-regulate d fue l t o th e

injector s an d cut s th e fue l deliver y whe n th e engin e i s

no t running .

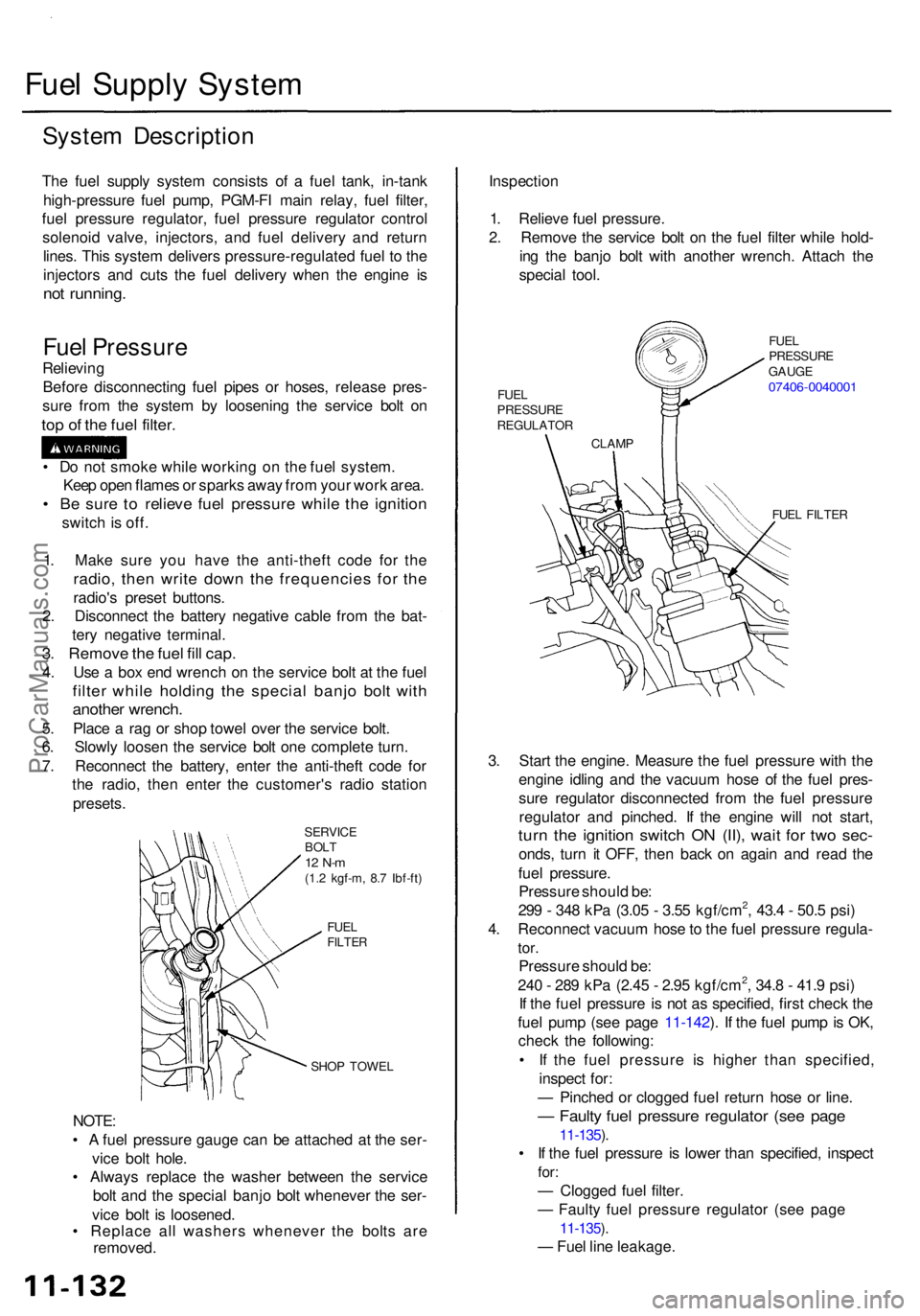

Fuel Pressur e

Relieving

Befor e disconnectin g fue l pipe s o r hoses , releas e pres -

sur e fro m th e syste m b y loosenin g th e servic e bol t o n

top o f th e fue l filter .

SERVIC E

BOL T

12 N- m(1.2 kgf-m , 8. 7 Ibf-ft )

FUE L

FILTE R

SHOP TOWE L

NOTE:

• A fue l pressur e gaug e can be attache d a t th e ser -

vic e bol t hole .

• Alway s replac e th e washe r betwee n th e servic e

bol t an d th e specia l banj o bol t wheneve r th e ser -

vic e bol t i s loosened .

• Replac e al l washer s wheneve r th e bolt s ar e

removed . Inspectio

n

1 . Reliev e fue l pressure .

2 . Remov e th e servic e bol t o n th e fue l filte r whil e hold -

in g th e banj o bol t wit h anothe r wrench . Attac h th e

specia l tool .

FUEL FILTE R

3. Star t th e engine . Measur e th e fue l pressur e wit h th e

engin e idlin g an d th e vacuu m hos e o f th e fue l pres -

sur e regulato r disconnecte d fro m th e fue l pressur e

regulato r an d pinched . I f th e engin e wil l no t start ,

turn th e ignitio n switc h O N (II) , wai t fo r tw o sec -

onds , tur n i t OFF , the n bac k o n agai n an d rea d th e

fue l pressure .

Pressur e shoul d be :

29 9 - 34 8 kP a (3.0 5 - 3.5 5 kgf/cm

2, 43. 4 - 50. 5 psi )

4 . Reconnec t vacuu m hos e to th e fue l pressur e regula -

tor.

Pressur e shoul d be :

24 0 - 28 9 kP a (2.4 5 - 2.9 5 kgf/cm2, 34. 8 - 41. 9 psi )

I f th e fue l pressur e i s no t a s specified , firs t chec k th e

fue l pum p (se e pag e 11-142 ). I f th e fue l pum p is OK ,

chec k th e following :

• I f th e fue l pressur e i s highe r tha n specified ,

inspec t for :

— Pinche d o r clogge d fue l retur n hos e o r line .

— Fault y fue l pressur e regulato r (se e pag e

11-135 ).

• I f th e fue l pressur e i s lowe r tha n specified , inspec t

for:

— Clogge d fue l filter .

— Fault y fue l pressur e regulato r (se e pag e

11-135 ).

— Fue l lin e leakage .

1

. Mak e sur e yo u hav e th e anti-thef t cod e fo r th e

radio , the n writ e dow n th e frequencie s fo r th e

radio' s prese t buttons .

2 . Disconnec t th e batter y negativ e cabl e fro m th e bat -

ter y negativ e terminal .

3. Remov e th e fue l fil l cap .

4. Us e a bo x en d wrenc h o n th e servic e bol t a t th e fue l

filte r whil e holdin g th e specia l banj o bol t wit h

anothe r wrench .

5. Plac e a ra g o r sho p towe l ove r th e servic e bolt .

6 . Slowl y loose n th e servic e bol t on e complet e turn .

7 . Reconnec t th e battery , ente r th e anti-thef t cod e fo r

th e radio , the n ente r th e customer' s radi o statio n

presets .

•

D o no t smok e whil e workin g o n th e fue l system .

Kee p ope n flame s o r spark s awa y fro m you r wor k area .

• B e sur e t o reliev e fue l pressur e whil e th e ignitio n

switch is off .

CLAM P

FUE

L

PRESSUR E

REGULATO R FUE

L

PRESSUR E

GAUG E

07406-004000 1

ProCarManuals.com