fuel cap ACURA RL KA9 1996 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 178 of 1954

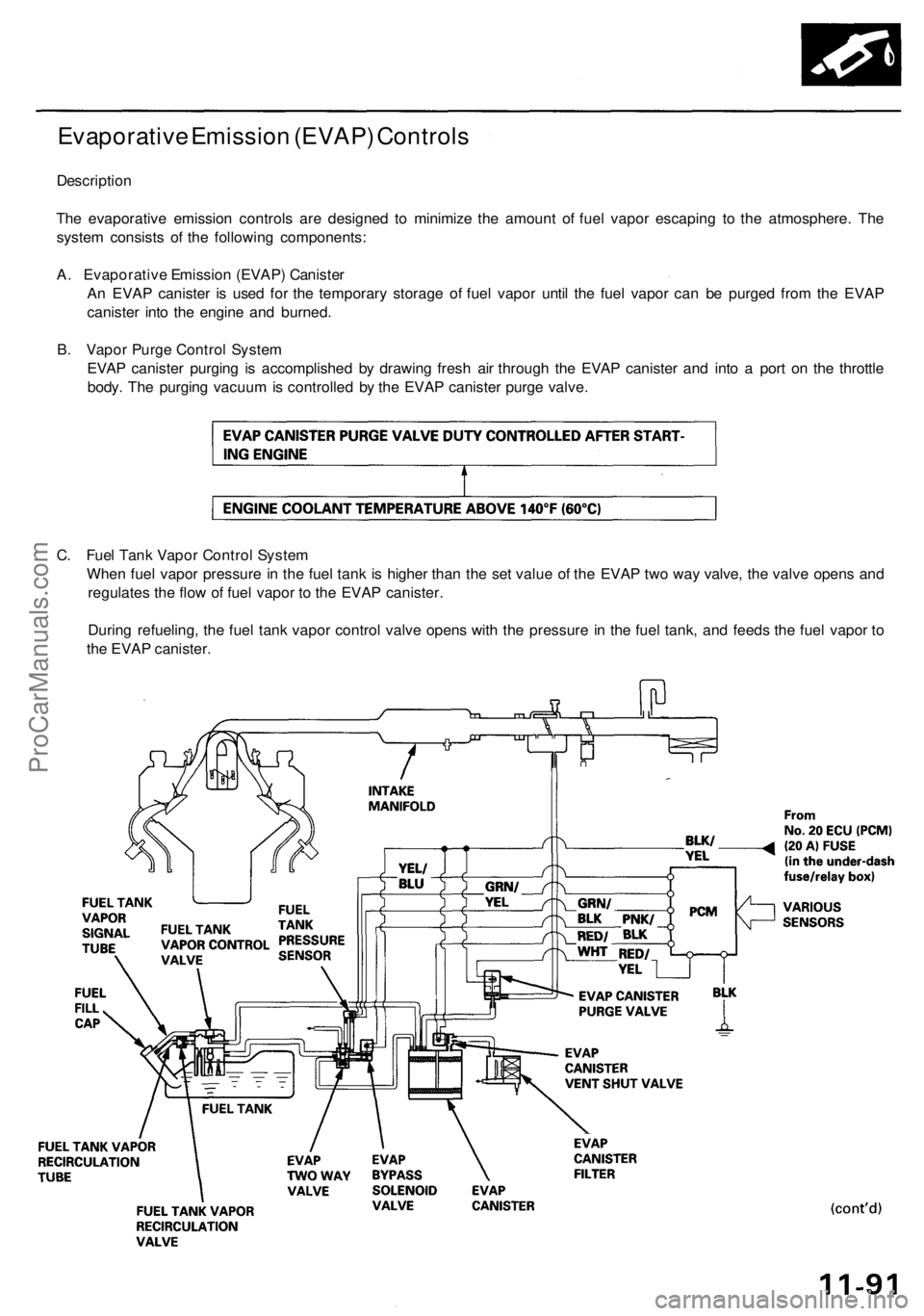

Evaporative Emission (EVAP) Controls

Description

The evaporative emission controls are designed to minimize the amount of fuel vapor escaping to the atmosphere. The

system consists of the following components:

A. Evaporative Emission (EVAP) Canister

An EVAP canister is used for the temporary storage of fuel vapor until the fuel vapor can be purged from the EVAP

canister into the engine and burned.

B. Vapor Purge Control System

EVAP canister purging is accomplished by drawing fresh air through the EVAP canister and into a port on the throttle

body. The purging vacuum is controlled by the EVAP canister purge valve.

C. Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the valve opens and

regulates the flow of fuel vapor to the EVAP canister.

During refueling, the fuel tank vapor control valve opens with the pressure in the fuel tank, and feeds the fuel vapor to

the EVAP canister.ProCarManuals.com

Page 187 of 1954

Emission Contro l Syste m

Evaporativ e Emissio n (EVAP ) Control s (cont'd )

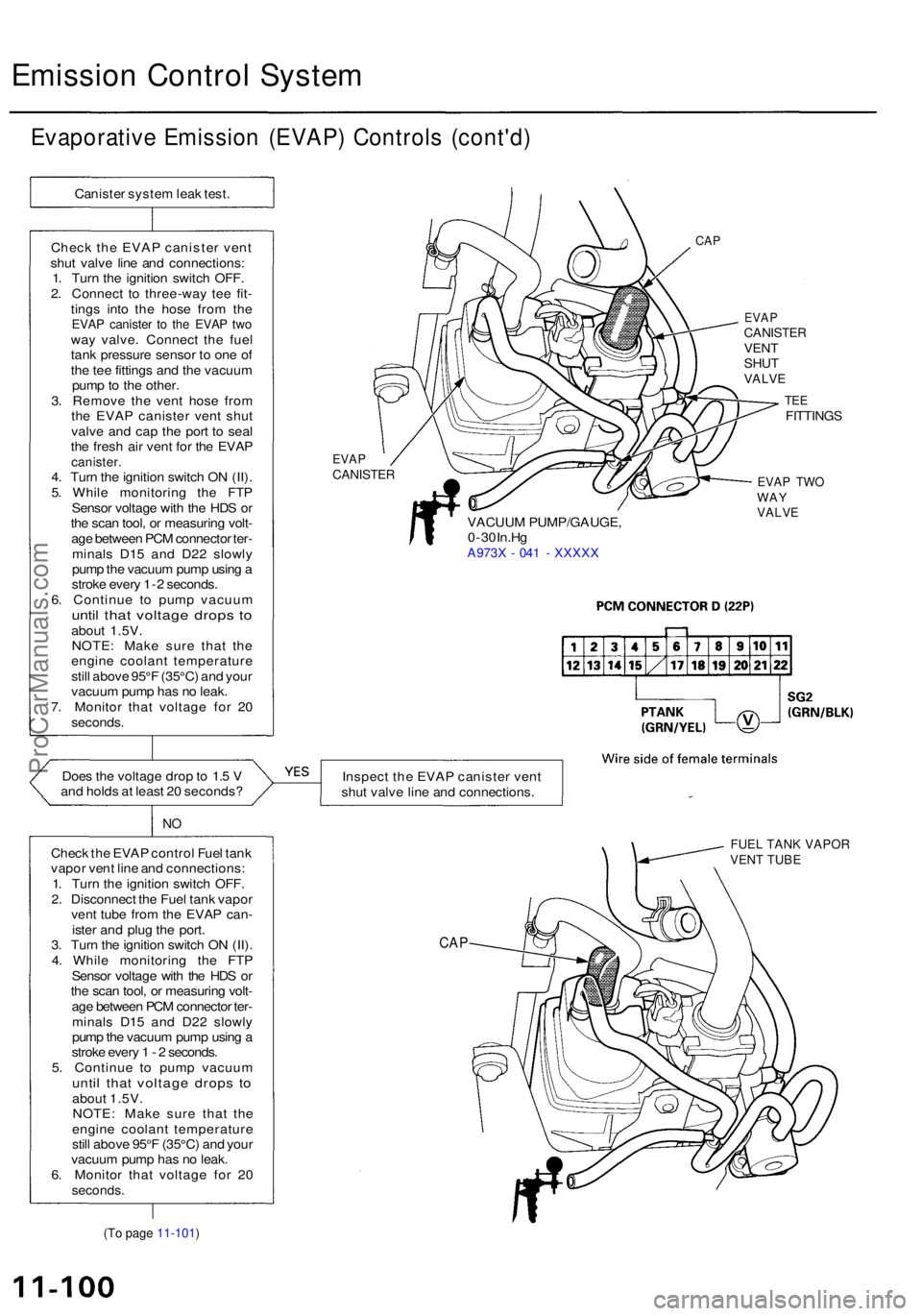

Canister syste m lea k test .

Chec k th e EVA P caniste r ven t

shu t valv e lin e an d connections :

1 . Tur n th e ignitio n switc h OFF .

2 . Connec t t o three-wa y te e fit -

ting s int o th e hos e fro m th e

EVA P caniste r t o th e EVA P tw oway valve . Connec t th e fue l

tan k pressur e senso r t o on e o f

th e te e fitting s an d th e vacuu m

pum p to th e other .

3 . Remov e th e ven t hos e fro m

th e EVA P caniste r ven t shu t

valv e an d ca p th e por t t o sea l

th e fres h ai r ven t fo r th e EVA P

canister .4. Tur n th e ignitio n switc h O N (II) .

5 . Whil e monitorin g th e FT P

Senso r voltag e wit h th e HD S o r

th e sca n tool , o r measurin g volt -

ag e betwee n PC M connecto r ter -

minal s D1 5 an d D2 2 slowl y

pum p th e vacuu m pum p usin g a

strok e ever y 1- 2 seconds .

6 . Continu e t o pum p vacuu m

until tha t voltag e drop s t oabou t 1.5V .

NOTE : Mak e sur e tha t th e

engin e coolan t temperatur e

stil l abov e 95° F (35°C ) an d you r

vacuu m pum p ha s n o leak .

7 . Monito r tha t voltag e fo r 2 0

seconds .

Doe s th e voltag e dro p to 1. 5 V

an d hold s a t leas t 2 0 seconds ?

NO

Chec k th e EVA P contro l Fue l tan k

vapo r ven t lin e an d connections :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e Fue l tan k vapo r

ven t tub e fro m th e EVA P can -

iste r an d plu g th e port .

3 . Tur n th e ignitio n switc h O N (II) .

4 . Whil e monitorin g th e FT P

Senso r voltag e wit h th e HD S o r

th e sca n tool , o r measurin g volt -

ag e betwee n PC M connecto r ter -

minal s D1 5 an d D2 2 slowl y

pum p th e vacuu m pum p usin g a

strok e ever y 1 - 2 seconds .

5 . Continu e t o pum p vacuu m

until tha t voltag e drop s t oabou t 1.5V .

NOTE : Mak e sur e tha t th e

engin e coolan t temperatur e

stil l abov e 95° F (35°C ) an d you r

vacuu m pum p ha s n o leak .

6 . Monito r tha t voltag e fo r 2 0

seconds .

CAP

EVA PCANISTE R

EVAPCANISTE RVENTSHU TVALV E

VACUU M PUMP/GAUGE ,

0 - 3 0 In.H g

A973 X - 04 1 - XXXX X

TEEFITTING S

EVAP TW OWAYVALV E

Inspec t th e EVA P caniste r ven t

shu t valv e lin e an d connections .

FUEL TANK VAPOR

VENT TUBE

CA P

(To page 11-101)

ProCarManuals.com

Page 506 of 1954

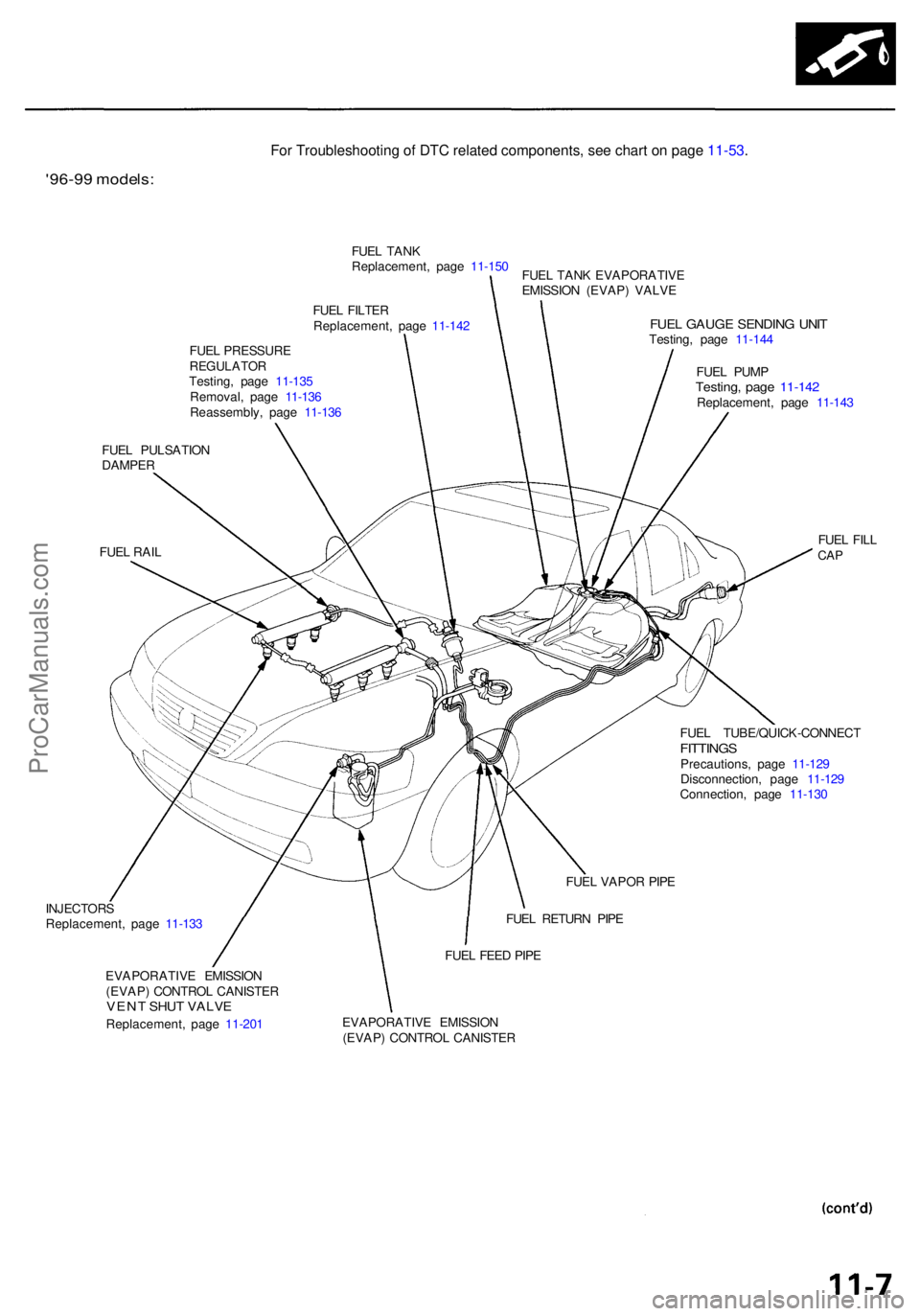

'96-99 models :

FUEL FILTE R

Replacement , pag e 11-14 2

FUE L PRESSUR E

REGULATO RTesting, pag e 11-13 5

Removal , pag e 11-13 6

Reassembly , pag e 11-13 6

FUEL GAUG E SENDIN G UNI TTesting , pag e 11-14 4

FUE L PUM P

Testing , pag e 11-14 2Replacement , pag e 11-14 3

FUE L PULSATIO N

DAMPE R

FUE L RAI L FUE

L FIL L

CAP

FUE L TUBE/QUICK-CONNEC TFITTINGSPrecautions , pag e 11-12 9

Disconnection , pag e 11-12 9

Connection , pag e 11-13 0

INJECTOR S

Replacement , pag e 11-133

EVAPORATIV E EMISSIO N

(EVAP ) CONTRO L CANISTE R

VENT SHU T VALV E

Replacement , pag e 11-20 1 EVAPORATIV

E EMISSIO N

(EVAP ) CONTRO L CANISTE R

FUE

L FEE D PIP E

FUE

L RETUR N PIP E

FUE

L VAPO R PIP E

FUE

L TAN K

Replacement , pag e 11-15 0

FUE L TAN K EVAPORATIV E

EMISSIO N (EVAP ) VALV E

For Troubleshooting of DTC related components, see chart on page 11-53.

ProCarManuals.com

Page 507 of 1954

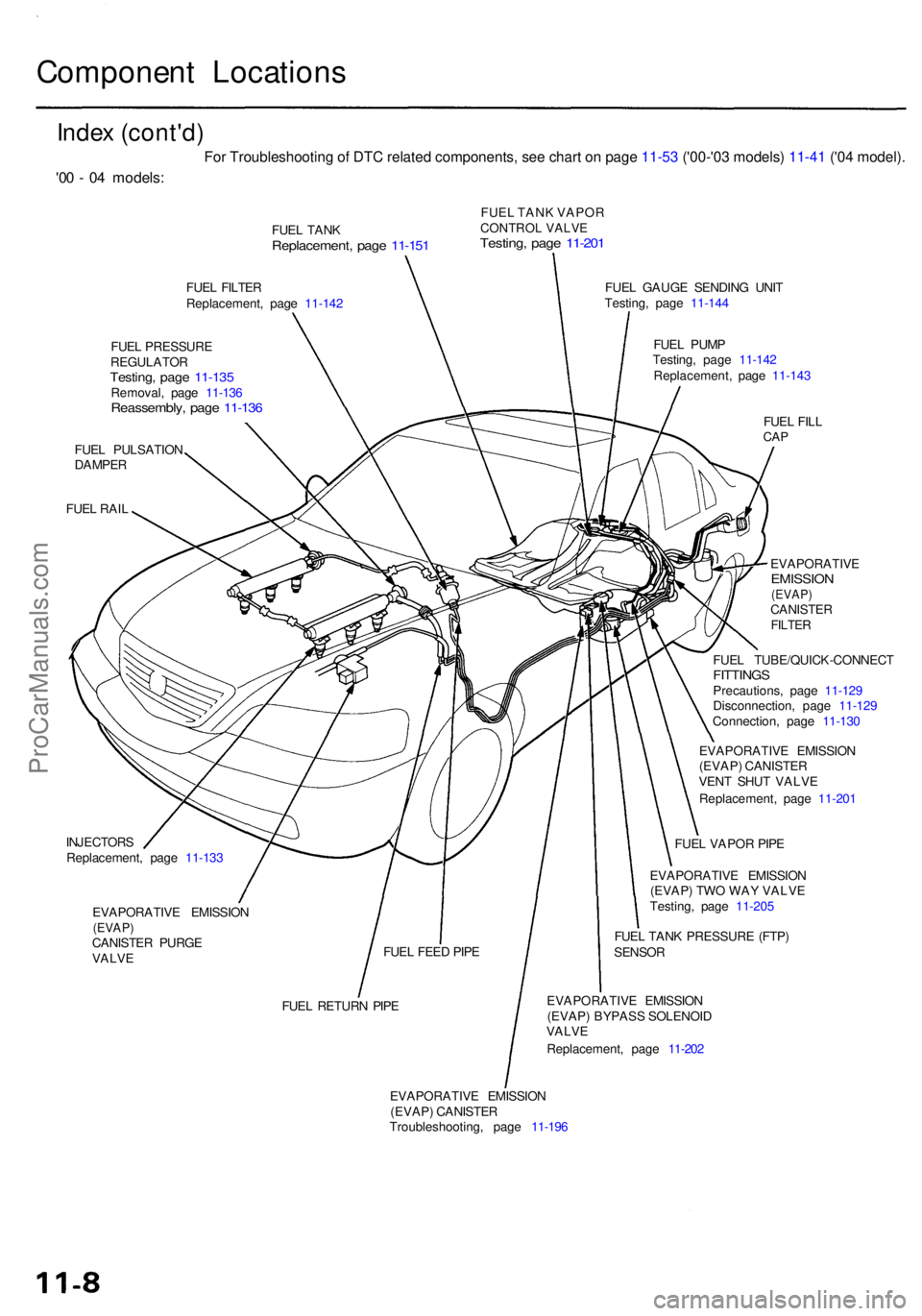

Component Location s

Index (cont'd )

FUEL TAN KReplacement , pag e 11-15 1

FUEL TAN K VAPO RCONTROL VALVETesting, pag e 11-20 1

FUEL FILTE R

Replacement , pag e 11-14 2

FUE L PRESSUR E

REGULATO R

Testing, pag e 11-13 5Removal , pag e 11-13 6Reassembly , pag e 11-13 6

FUEL PULSATIO N

DAMPE R

FUE L RAI L

INJECTOR S

Replacement , pag e 11-13 3

EVAPORATIV E EMISSIO N

(EVAP)CANISTE R PURG E

VALV E FUE

L GAUG E SENDIN G UNI T

Testing , pag e 11-14 4

FUE L PUM P

Testing , pag e 11-14 2

Replacement , pag e 11-14 3

FUE L FIL L

CAP

EVAPORATIV EEMISSION(EVAP)CANISTE RFILTER

FUEL TUBE/QUICK-CONNEC TFITTINGSPrecautions , pag e 11-12 9

Disconnection , pag e 11-12 9

Connection , pag e 11-13 0

EVAPORATIV E EMISSIO N

(EVAP ) CANISTE R

VEN T SHU T VALV E

Replacement , pag e 11-20 1

FUE L VAPO R PIP E

EVAPORATIV E EMISSIO N

(EVAP ) TW O WA Y VALV E

Testing , pag e 11-20 5

FUE L TAN K PRESSUR E (FTP )

SENSO R

FUE L RETUR N PIP E EVAPORATIV

E EMISSIO N

(EVAP ) BYPAS S SOLENOI D

VALV E

Replacement , pag e 11-20 2

EVAPORATIV E EMISSIO N

(EVAP ) CANISTE R

Troubleshooting , pag e 11-19 6

FUE

L FEE D PIP E

'00 - 0 4 models :

For Troubleshooting of DTC related components, see chart on page 11-53 ('00-'03 models) 11-41 ('04 model).

ProCarManuals.com

Page 560 of 1954

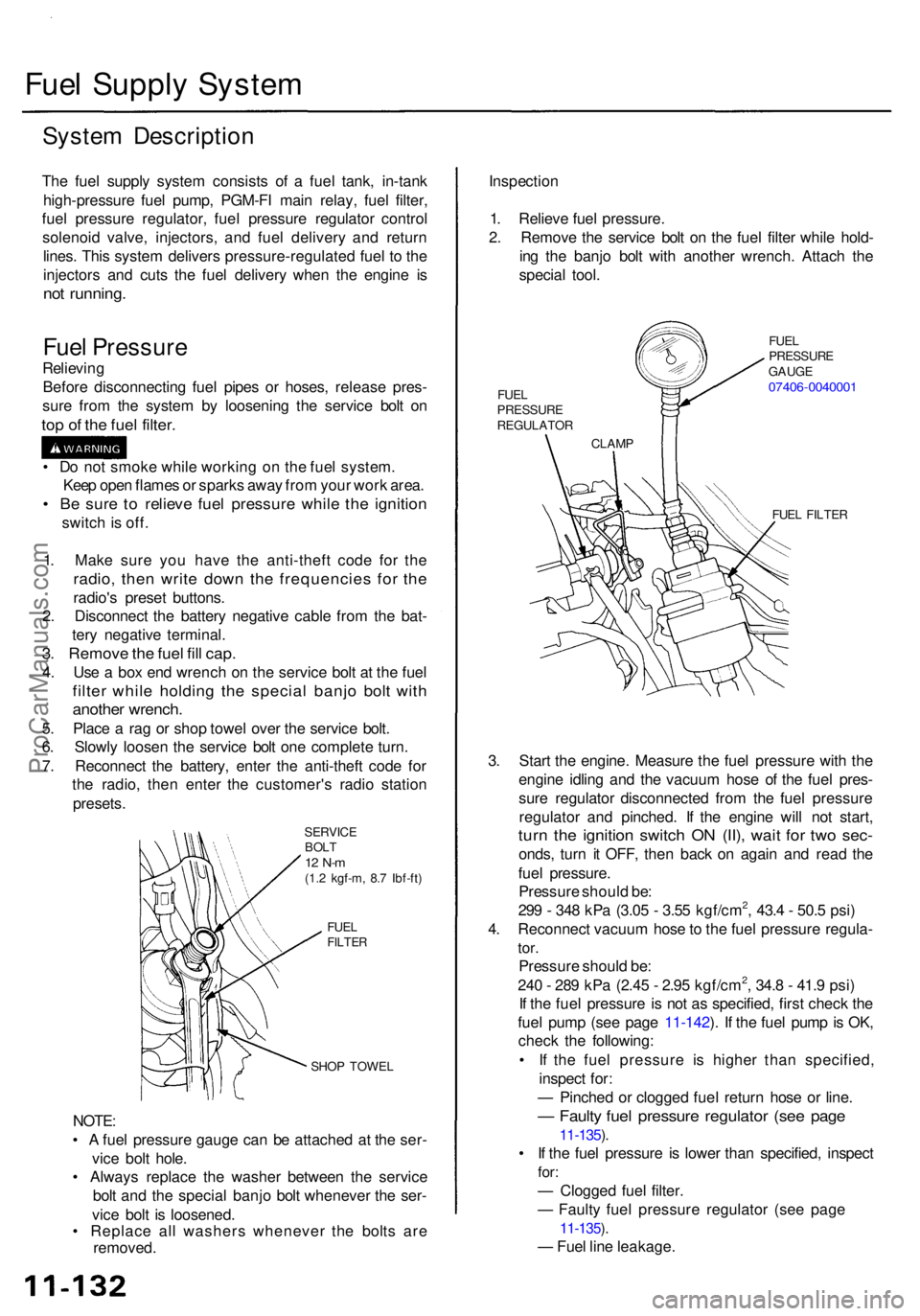

How to Set Readiness Codes

Catalytic Converter

NOTE:

• Do not turn the ignition switch OFF.

• When the battery negative cable is disconnected, all

readiness codes are cleared.

Required condition ('96 - 97 models):

• Ambient temperature between 32 - 95°F (0 - 35°C).

• Altitude below 2,400 m (7,874 ft.).

Required condition ('98 - 01 models):

Ambient temperature between 20 - 95°F (-7 - 35°C).

1. Connect the scan tool to the Data Link Connector

(DLC).

2. Start the engine. Hold it at 3,000 rpm with no load

(in Park or neutral) until the radiator fan comes on.

3. Drive for about 10 minutes without stopping on a

highway or freeway. Your speed can vary.

4. '96 - 97 models:

With the transmission in D4 position, drive at a

steady speed between 33 - 37 mph (53 - 59 km/h)

for 30 seconds.

'98 - 01 models:

With the A/T in D4 position, drive at a steady speed

between 50 - 62 mph (80 - 100 km/h) for 30 sec-

onds.

5. Do step 4 three times. Between each repetition,

close the throttle completely for 1 - 2 seconds. If the

engine is stopped during this part of the procedure,

go to step 3 and do the procedure again.

6. Check for the readiness code with the scan tool.

EGR Monitor

NOTE:

• Do not turn the ignition switch OFF.

• When the battery negative cable is disconnected, all

readiness codes are cleared.

Required condition ('96 - 97 models):

Altitude below 2,400 m (7,874 ft.).

1. Connect the scan tool to the Data Link Connector

(DLC).

2. Start the engine, and hold it at 3,000 rpm with no

load (in Park or neutral) until the radiator fan comes

on.

3. Drive at a steady speed with the transmission in D4

position, between 50 - 62 mph (80 - 100 km/h) for

more than 10 seconds.

4. With the A/T in D4 position, decelerate from 62 mph

(100 km/h) by completely releasing the throttle for

at least 5 seconds. If the engine is stopped during

this procedure, go to step 3 and do the procedure

again.

5. Check for the readiness code with the scan tool.

EVAP Leak Monitor

NOTE:

• When the battery negative cable is disconnected, all

readiness codes are cleared.

• If the engine is stopped while doing the procedure

between stops 6 and 16, do this procedure from step

1 again.

1. Make sure the gasoline level is 60 - 90% of fuel tank

capacity (not full).

2. Turn the ignition switch OFF.

3. Let the vehicle sit more than 8 hours.

4. '96 - 97 models:

Make sure the outside temperature is 32 - 95°F (0 -

35°C).

'98 - 01 models:

Make sure the outside temperature is 20 - 95°F (-7 -

35°C).

5. Connect the scan tool to the Data Link Connector

(DLC).

6. Start the engine and drive for about 15 minutes.

7. '96 - 97 models:

Keep the vehicle at a steady speed between 50 - 62

mph (80 - 100 km/h), without moving the accelera-

tor pedal, for about 1 minute.

'98 - 01 models:

Keep the vehicle at a steady speed between 50 - 70

mph (80 - 114 km/h), without moving the accelera-

tor pedal, for about 1 minute.

8. Stop the vehicle (do not stop engine).

9. Repeat steps 7 and 8 two more times.

10. Check for the readiness code with the scan tool. If

the readiness code does not set, go to step 11.

11. When ambient temperature is less than 32°F (0°C),

hold the engine at 3,000 rpm with no load (in Park

or neutral) until the radiator fan comes on.

12. When ambient temperature is more than 86°F

(30°C), remove the fuel fill cap, then install the fuel

fill cap.

13. After step 12, drive for about 20 minutes on a free-

way.

14. '96 - 97 models:

Keep the vehicle at a steady speed between 50 - 62

mph (80 - 100 km/h), without moving the accelera-

tor pedal, for about 1 minute.

'98 - 01 models:

Keep the vehicle at a steady speed between 50 - 70

mph (80 - 114 km/h), without moving the accelera-

tor pedal, for about 1 minute.

15. Stop the vehicle (do not stop the engine).

16. Repeat steps 14 and 15 two more times.

17. Check for the readiness code with the scan tool.ProCarManuals.com

Page 632 of 1954

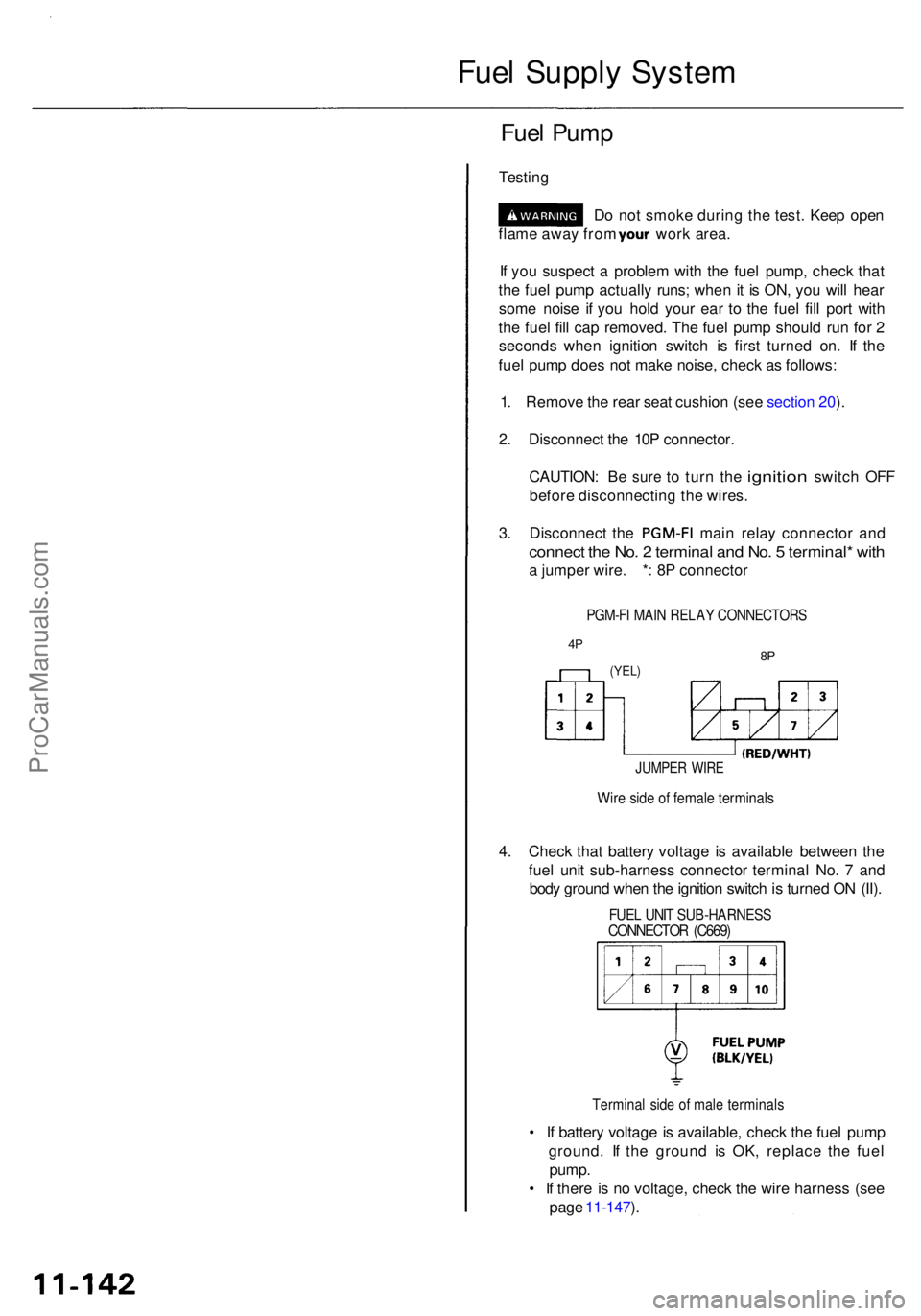

Fuel Suppl y Syste m

System Descriptio n

The fue l suppl y syste m consist s o f a fue l tank , in-tan k

high-pressur e fue l pump , PGM-F I mai n relay , fue l filter ,

fue l pressur e regulator , fue l pressur e regulato r contro l

solenoi d valve , injectors , an d fue l deliver y an d retur n

lines . Thi s syste m deliver s pressure-regulate d fue l t o th e

injector s an d cut s th e fue l deliver y whe n th e engin e i s

no t running .

Fuel Pressur e

Relieving

Befor e disconnectin g fue l pipe s o r hoses , releas e pres -

sur e fro m th e syste m b y loosenin g th e servic e bol t o n

top o f th e fue l filter .

SERVIC E

BOL T

12 N- m(1.2 kgf-m , 8. 7 Ibf-ft )

FUE L

FILTE R

SHOP TOWE L

NOTE:

• A fue l pressur e gaug e can be attache d a t th e ser -

vic e bol t hole .

• Alway s replac e th e washe r betwee n th e servic e

bol t an d th e specia l banj o bol t wheneve r th e ser -

vic e bol t i s loosened .

• Replac e al l washer s wheneve r th e bolt s ar e

removed . Inspectio

n

1 . Reliev e fue l pressure .

2 . Remov e th e servic e bol t o n th e fue l filte r whil e hold -

in g th e banj o bol t wit h anothe r wrench . Attac h th e

specia l tool .

FUEL FILTE R

3. Star t th e engine . Measur e th e fue l pressur e wit h th e

engin e idlin g an d th e vacuu m hos e o f th e fue l pres -

sur e regulato r disconnecte d fro m th e fue l pressur e

regulato r an d pinched . I f th e engin e wil l no t start ,

turn th e ignitio n switc h O N (II) , wai t fo r tw o sec -

onds , tur n i t OFF , the n bac k o n agai n an d rea d th e

fue l pressure .

Pressur e shoul d be :

29 9 - 34 8 kP a (3.0 5 - 3.5 5 kgf/cm

2, 43. 4 - 50. 5 psi )

4 . Reconnec t vacuu m hos e to th e fue l pressur e regula -

tor.

Pressur e shoul d be :

24 0 - 28 9 kP a (2.4 5 - 2.9 5 kgf/cm2, 34. 8 - 41. 9 psi )

I f th e fue l pressur e i s no t a s specified , firs t chec k th e

fue l pum p (se e pag e 11-142 ). I f th e fue l pum p is OK ,

chec k th e following :

• I f th e fue l pressur e i s highe r tha n specified ,

inspec t for :

— Pinche d o r clogge d fue l retur n hos e o r line .

— Fault y fue l pressur e regulato r (se e pag e

11-135 ).

• I f th e fue l pressur e i s lowe r tha n specified , inspec t

for:

— Clogge d fue l filter .

— Fault y fue l pressur e regulato r (se e pag e

11-135 ).

— Fue l lin e leakage .

1

. Mak e sur e yo u hav e th e anti-thef t cod e fo r th e

radio , the n writ e dow n th e frequencie s fo r th e

radio' s prese t buttons .

2 . Disconnec t th e batter y negativ e cabl e fro m th e bat -

ter y negativ e terminal .

3. Remov e th e fue l fil l cap .

4. Us e a bo x en d wrenc h o n th e servic e bol t a t th e fue l

filte r whil e holdin g th e specia l banj o bol t wit h

anothe r wrench .

5. Plac e a ra g o r sho p towe l ove r th e servic e bolt .

6 . Slowl y loose n th e servic e bol t on e complet e turn .

7 . Reconnec t th e battery , ente r th e anti-thef t cod e fo r

th e radio , the n ente r th e customer' s radi o statio n

presets .

•

D o no t smok e whil e workin g o n th e fue l system .

Kee p ope n flame s o r spark s awa y fro m you r wor k area .

• B e sur e t o reliev e fue l pressur e whil e th e ignitio n

switch is off .

CLAM P

FUE

L

PRESSUR E

REGULATO R FUE

L

PRESSUR E

GAUG E

07406-004000 1

ProCarManuals.com

Page 643 of 1954

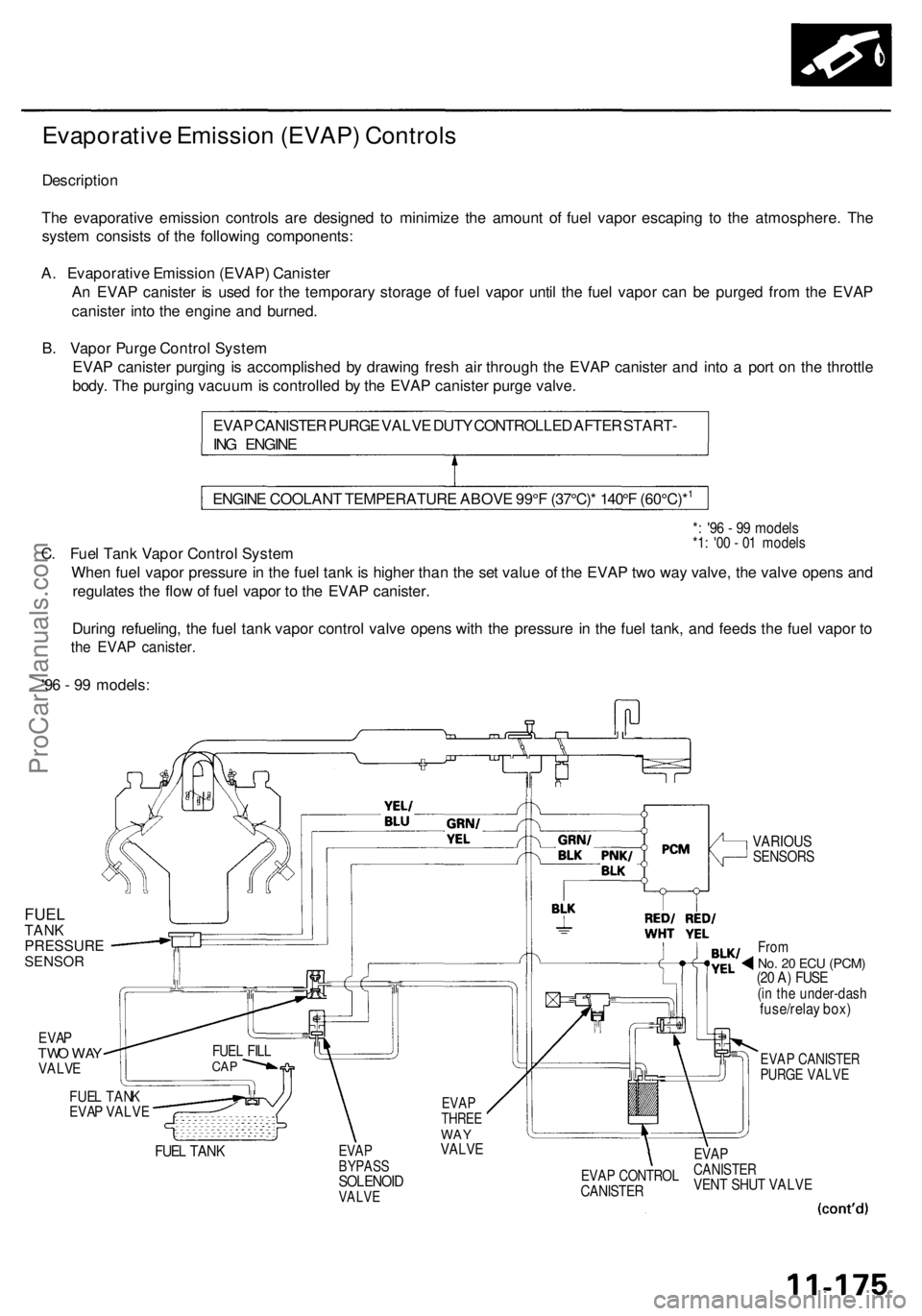

Fuel Suppl y Syste m

Fuel Pum p

Testin g

Do no t smok e durin g th e test . Kee p ope n

flam e awa y fro m you r wor k area .

I f yo u suspec t a proble m wit h th e fue l pump , chec k tha t

th e fue l pum p actuall y runs ; whe n it i s ON , yo u wil l hea r

som e nois e i f yo u hol d you r ea r t o th e fue l fil l por t wit h

th e fue l fil l cap removed . Th e fue l pum p shoul d ru n fo r 2

second s whe n ignitio n switc h i s firs t turne d on . I f th e

fue l pum p doe s no t mak e noise , chec k a s follows :

1 . Remov e th e rea r sea t cushio n (se e sectio n 20 ).

2 . Disconnec t th e 10 P connector .

CAUTION :

Be sur e to tur n the ignitio n switch OFF

befor e disconnectin g th e wires .

3. Disconnec t th e PGM-F I main rela y connecto r an d

connec t th e No . 2 termina l an d No . 5 terminal * wit h

a jumpe r wire . * : 8 P connecto r

PGM-FI MAI N RELA Y CONNECTOR S

4P8P(YEL )

JUMPE R WIR E

Wire sid e o f femal e terminal s

4. Chec k tha t batter y voltag e i s availabl e betwee n th e

fue l uni t sub-harnes s connecto r termina l No . 7 an d

bod y groun d whe n th e ignitio n switc h is turne d O N (II) .

FUE L UNI T SUB-HARNES SCONNECTOR (C669 )

Termina l sid e o f mal e terminal s

• I f batter y voltag e is available , chec k th e fue l pum p

ground . I f th e groun d i s OK , replac e th e fue l

pump .

• I f ther e is n o voltage , chec k th e wir e harnes s (se e

pag e 11-147 ).

ProCarManuals.com

Page 679 of 1954

Evaporative Emissio n (EVAP ) Control s

Descriptio n

Th e evaporativ e emissio n control s ar e designe d t o minimiz e th e amoun t o f fue l vapo r escapin g t o th e atmosphere . Th e

syste m consist s o f th e followin g components :

A . Evaporativ e Emissio n (EVAP ) Caniste r

A n EVA P caniste r i s use d fo r th e temporar y storag e o f fue l vapo r unti l th e fue l vapo r can be purge d fro m th e EVA P

caniste r int o th e engin e an d burned .

B . Vapo r Purg e Contro l Syste m

EVA P caniste r purgin g is accomplishe d b y drawin g fres h ai r throug h th e EVA P caniste r an d int o a por t o n th e throttl e

body . Th e purgin g vacuu m is controlle d b y th e EVA P caniste r purg e valve .

EVA P CANISTE R PURG E VALV E DUT Y CONTROLLE D AFTE R START -

IN G ENGIN E

*: '9 6 - 9 9 model s*1: '0 0 - 0 1 model sC. Fue l Tan k Vapo r Contro l Syste m

Whe n fue l vapo r pressur e in th e fue l tan k is highe r tha n th e se t valu e o f th e EVA P tw o wa y valve , th e valv e open s an d

regulate s th e flo w o f fue l vapo r t o th e EVA P canister .

Durin g refueling , th e fue l tan k vapo r contro l valv e open s wit h th e pressur e in th e fue l tank , an d feed s th e fue l vapo r t o

th e EVA P canister .

'96 - 9 9 models :

FUELTANKPRESSURESENSOR

EVAPTWO WAYVALVE

FUEL TANKEVAP VALVE

FUEL TAN K

EVAP CANISTE RPURGE VALV E

EVAPBYPAS SSOLENOI DVALVE

EVAPCANISTE RVENT SHU T VALV EEVAP CONTRO LCANISTER

EVAPTHRE EWAYVALV E

FUEL FIL LCAP

Fro mNo. 2 0 EC U (PCM )(20 A ) FUS E(in th e under-das hfuse/relay box )

VARIOU SSENSOR S

ENGINE COOLAN T TEMPERATUR E ABOV E 99° F (37°C) * 140° F (60°C)*1

ProCarManuals.com

Page 680 of 1954

Emission Control System

Evaporative Emission (EVAP) Controls (cont'd)

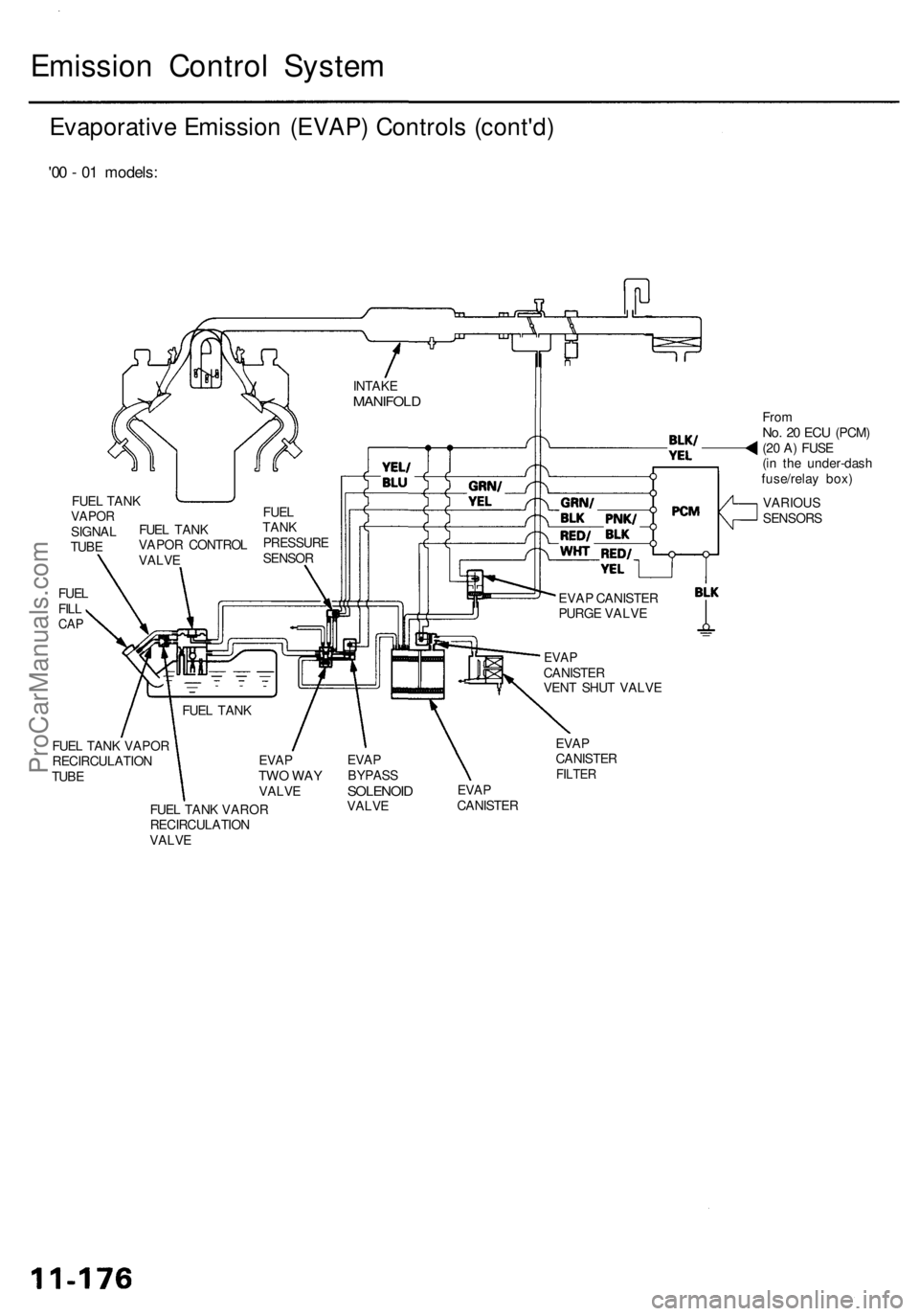

'00 - 01 models:

From

No. 20 ECU

(PCM)

(20 A) FUSE

(in the under-dash

fuse/relay box)

FUEL TANK VAPOR

RECIRCULATION

TUBE

EVAP

BYPASS

SOLENOID

VALVE

EVAP

CANISTER

FILTER

EVAP

CANISTER

FUEL TANK VAROR

RECIRCULATION

VALVE

EVAP

TWO WAY

VALVE

FUEL TANK

EVAP

CANISTER

VENT SHUT VALVE

EVAP CANISTER

PURGE VALVE

VARIOUS

SENSORS

INTAKE

MANIFOLD

FUEL

TANK

PRESSURE

SENSOR

FUEL TANK

VAPOR CONTROL

VALVE

FUEL

FILL

CAP

FUEL TANK

VAPOR

SIGNAL

TUBEProCarManuals.com

Page 682 of 1954

Emission Contro l Syste m

Evaporativ e Emissio n (EVAP ) Control s (cont'd )

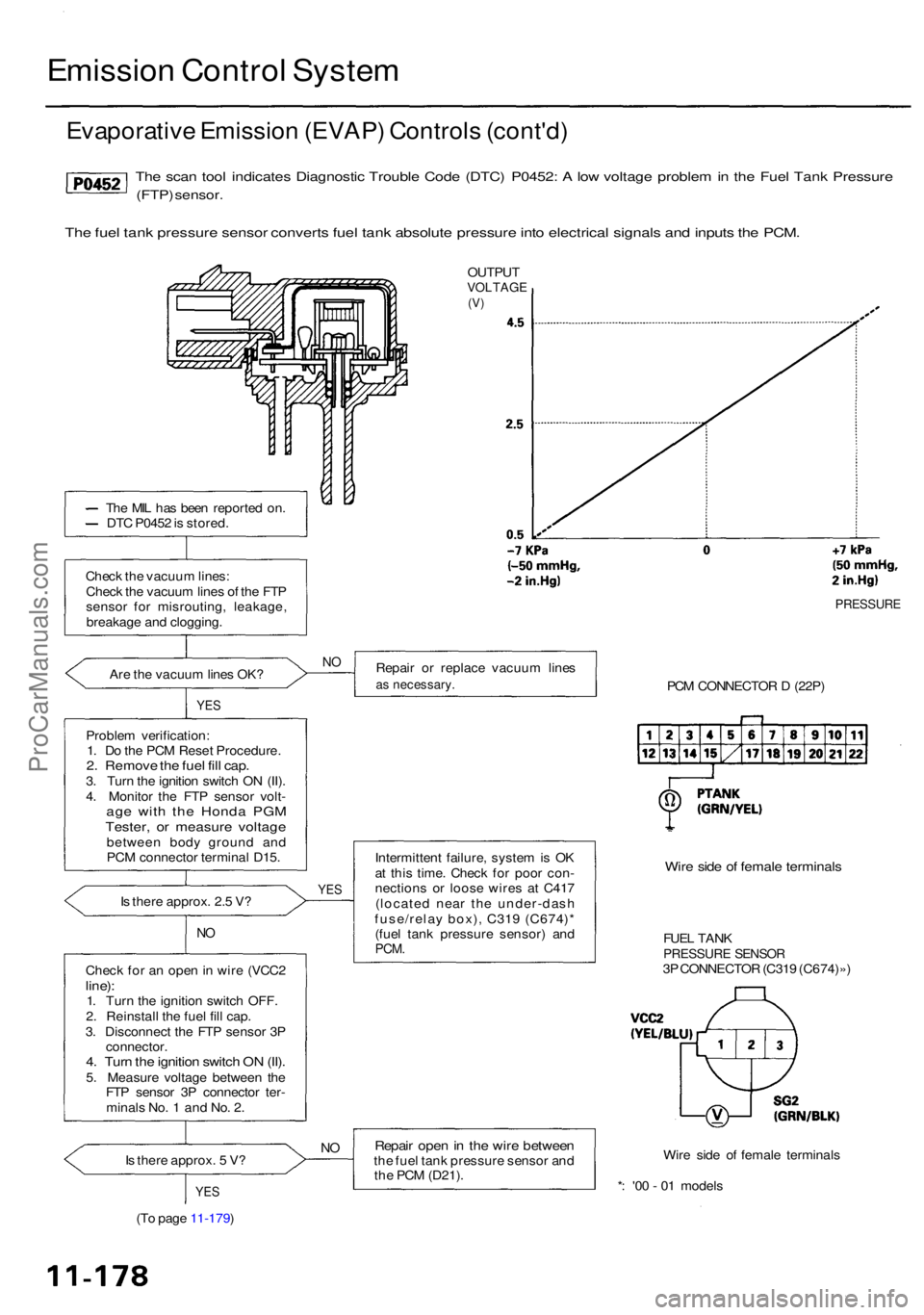

The sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P0452 : A lo w voltag e proble m in th e Fue l Tan k Pressur e

(FTP) sensor .

The fue l tan k pressur e senso r convert s fue l tan k absolut e pressur e int o electrica l signal s an d input s th e PCM .

OUTPU TVOLTAG E(V)

Th e MI L ha s bee n reporte d on .

DT C P045 2 is stored .

Chec k th e vacuu m lines :

Chec k th e vacuu m line s o f th e FT P

senso r fo r misrouting , leakage ,

breakag e an d clogging .

Ar e th e vacuu m line s OK ?

YES

Proble m verification :

1 . D o th e PC M Rese t Procedure .

2. Remov e th e fue l fil l cap .3. Tur n th e ignitio n switc h O N (II) .

4 . Monito r th e FT P sensor volt-

age wit h th e Hond a PG MTester , o r measur e voltag ebetwee n bod y groun d an d

PC M connecto r termina l D15 .

I s ther e approx . 2. 5 V ?

NO

Chec k fo r a n ope n in wir e (VCC 2line):1. Tur n th e ignitio n switc h OFF .

2 . Reinstal l th e fue l fil l cap .

3 . Disconnec t th e FT P senso r 3 P

connector .

4. Tur n th e ignitio n switc h O N (II) .5. Measur e voltag e betwee n th e

FT P senso r 3 P connecto r ter -

minal s No . 1 an d No . 2 .

I s ther e approx . 5 V ?

YE S

Repai r o r replac e vacuu m line sas necessary .

Intermittent failure , syste m is O K

a t thi s time . Chec k fo r poo r con -

nection s o r loos e wire s a t C41 7

(locate d nea r th e under-das h

fuse/rela y box) , C31 9 (C674) *

(fue l tan k pressur e sensor ) an d

PCM .

Repai r ope n in th e wir e betwee nthe fue l tan k pressur e senso r an d

th e PC M (D21) .

PRESSUR E

PCM CONNECTO R D (22P )

Wire sid e o f femal e terminal s

FUEL TAN KPRESSUR E SENSO R3P CONNECTO R (C31 9 (C674)» )

Wir e sid e o f femal e terminal s

* : '0 0 - 0 1 model s

(T o pag e 11-179 )

YES

NO

N O

ProCarManuals.com