boot ACURA RL KA9 1996 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 262 of 1954

Display day/nigh t mod e doe s no t wor k

Diagnosti c Test : Ca r Statu s

NOTE :

• Alway s chec k th e connector s fo r poo r connection s o r

loos e terminals .

• Befor e troubleshooting , ge t th e navigatio n syste m

anti-thef t codes .

• Afte r troubleshooting , ente r th e navigatio n syste m

anti-thef t codes .

1 . Chang e th e day/nigh t mod e t o "AUTO " unde r Set-up ,

an d recheck .

Doe s the display change to day and night modes?

YES—Th e syste m is O K a t thi s time .

NO—G o to ste p 2 .

2 . G o int o th e Diagnosti c Mod e an d us e diagnosti c th e

"Ca r Status " fo r a n IL L signa l (se e pag e 23-45 ) t o

check .

Is the "ILL" signal OK?

YES—Th e syste m is OK .

NO—Chec k th e IL L + circui t betwee n th e navigatio n

uni t an d tailligh t relay .

System lock s u p constantl y

Diagnostic Test : Uni t Chec k

1. Star t th e engin e an d tur n th e ignitio n switc h OFF ,

the n tur n th e ignitio n switc h O N (II) .

Doe s the system reboot?

YES—Th e syste m is O K a t thi s time .

NO—Chec k th e DV D fo r scratche s o r damag e an d th e

navigatio n uni t fo r wate r damage . I f OK , perfor m al l

o f th e "Uni t check " check s unde r Syste m Diagnosi s

Test (se e pag e 23-43 ).

ProCarManuals.com

Page 269 of 1954

Navigation Syste m

System Diagnosi s Mod e (cont'd )

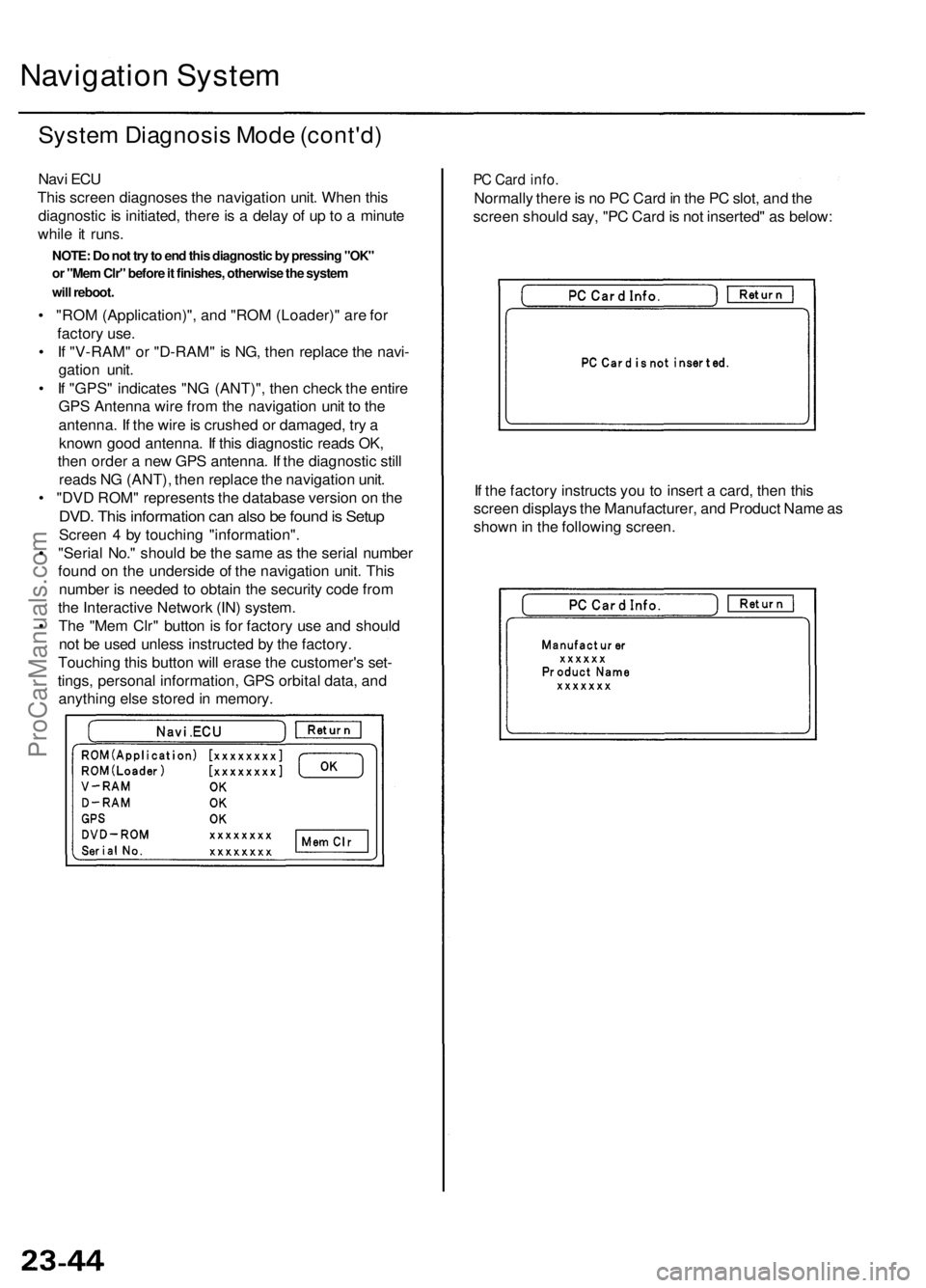

Navi EC U

Thi s scree n diagnose s th e navigatio n unit . Whe n thi s

diagnosti c i s initiated , ther e is a dela y o f u p to a minut e

whil e it runs .

• "RO M (Application)" , an d "RO M (Loader) " ar e fo r

factor y use .

• I f "V-RAM " o r "D-RAM " i s NG , the n replac e th e navi -

gatio n unit .

• I f "GPS " indicate s "N G (ANT)" , the n chec k th e entir e

GP S Antenn a wir e fro m th e navigatio n uni t t o th e

antenna . I f th e wir e is crushe d o r damaged , tr y a

know n goo d antenna . I f thi s diagnosti c read s OK ,

the n orde r a ne w GP S antenna . I f th e diagnosti c stil l

read s N G (ANT) , the n replac e th e navigatio n unit .

• "DV D ROM " represent s th e databas e versio n o n th e

DVD . Thi s informatio n ca n als o b e foun d is Setu p

Scree n 4 by touchin g "information" .

• "Seria l No. " shoul d b e th e sam e a s th e seria l numbe r

foun d o n th e undersid e o f th e navigatio n unit . Thi s

numbe r i s neede d t o obtai n th e securit y cod e fro m

th e Interactiv e Networ k (IN ) system .

• Th e "Me m Clr " butto n is fo r factor y us e an d shoul d

no t b e use d unles s instructe d b y th e factory .

Touchin g thi s butto n wil l eras e th e customer' s set -

tings , persona l information , GP S orbita l data , an d

anythin g els e store d in memory .

PC Car d info .

Normall y ther e is n o P C Car d in th e P C slot , an d th e

scree n shoul d say , "P C Car d is no t inserted " a s below :

I f th e factor y instruct s yo u t o inser t a card , the n thi s

scree n display s th e Manufacturer , an d Produc t Nam e a s

show n in th e followin g screen .

NOTE: Do not try to end this diagnostic by pressing "OK"

or "Mem Clr" before it finishes, otherwise the system

will reboot.

ProCarManuals.com

Page 309 of 1954

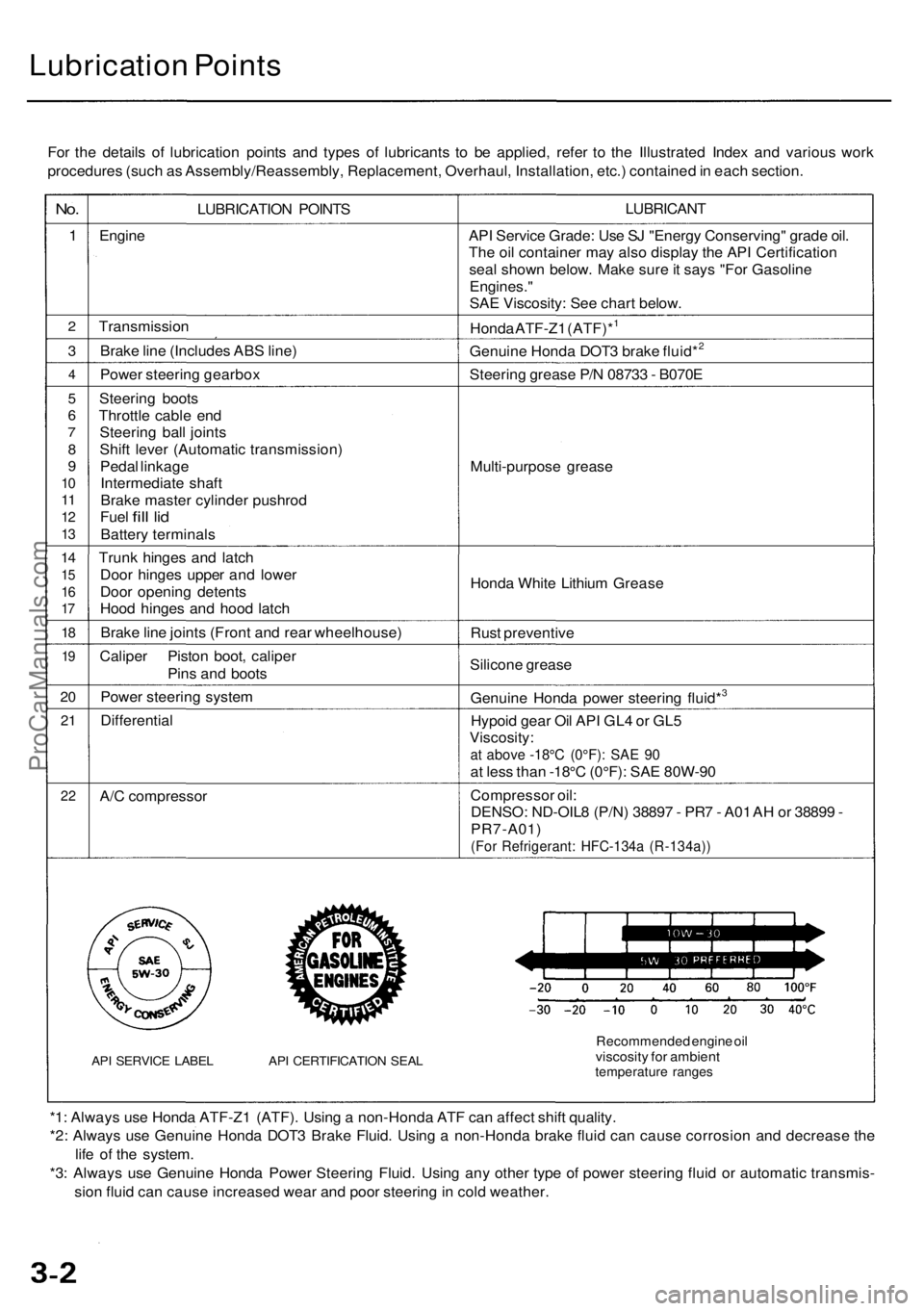

Lubrication Points

For the details of lubrication points and types of lubricants to be applied, refer to the Illustrated Index and various work

procedures (such as Assembly/Reassembly, Replacement, Overhaul, Installation, etc.) contained in each section.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

LUBRICATION POINTS

Engine

Transmission

Brake line (Includes ABS line)

Power steering gearbox

Steering boots

Throttle cable end

Steering ball joints

Shift lever (Automatic transmission)

Pedal linkage

Intermediate shaft

Brake master cylinder pushrod

Fuel

fill

lid

Battery terminals

Trunk hinges and latch

Door hinges upper and lower

Door opening detents

Hood hinges and hood latch

Brake line joints (Front and rear wheelhouse)

Caliper Piston boot, caliper

Pins and boots

Power steering system

Differential

A/C compressor

API SERVICE LABEL API CERTIFICATION SEAL

LUBRICANT

API Service Grade: Use SJ "Energy Conserving" grade oil.

The oil container may also display the API Certification

seal shown below. Make sure it says "For Gasoline

Engines."

SAE Viscosity: See chart below.

Honda ATF-Z1 (ATF)*1

Genuine Honda DOT3 brake fluid*2

Steering grease P/N 08733 - B070E

Multi-purpose grease

Honda White Lithium Grease

Rust preventive

Silicone grease

Genuine Honda power steering fluid*3

Hypoid gear Oil API GL4 or GL5

Viscosity:

at above -18°C (0°F): SAE 90

at less than -18°C (0°F): SAE 80W-90

Compressor oil:

DENSO: ND-OIL8 (P/N) 38897 - PR7 - A01 AH or 38899 -

PR7-A01)

(For Refrigerant: HFC-134a (R-134a))

Recommended engine oil

viscosity for ambient

temperature ranges

*1: Always use Honda ATF-Z1 (ATF). Using a non-Honda ATF can affect shift quality.

*2: Always use Genuine Honda DOT3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease the

life of the system.

*3: Always use Genuine Honda Power Steering Fluid. Using any other type of power steering fluid or automatic transmis-

sion fluid can cause increased wear and poor steering in cold weather.ProCarManuals.com

Page 944 of 1954

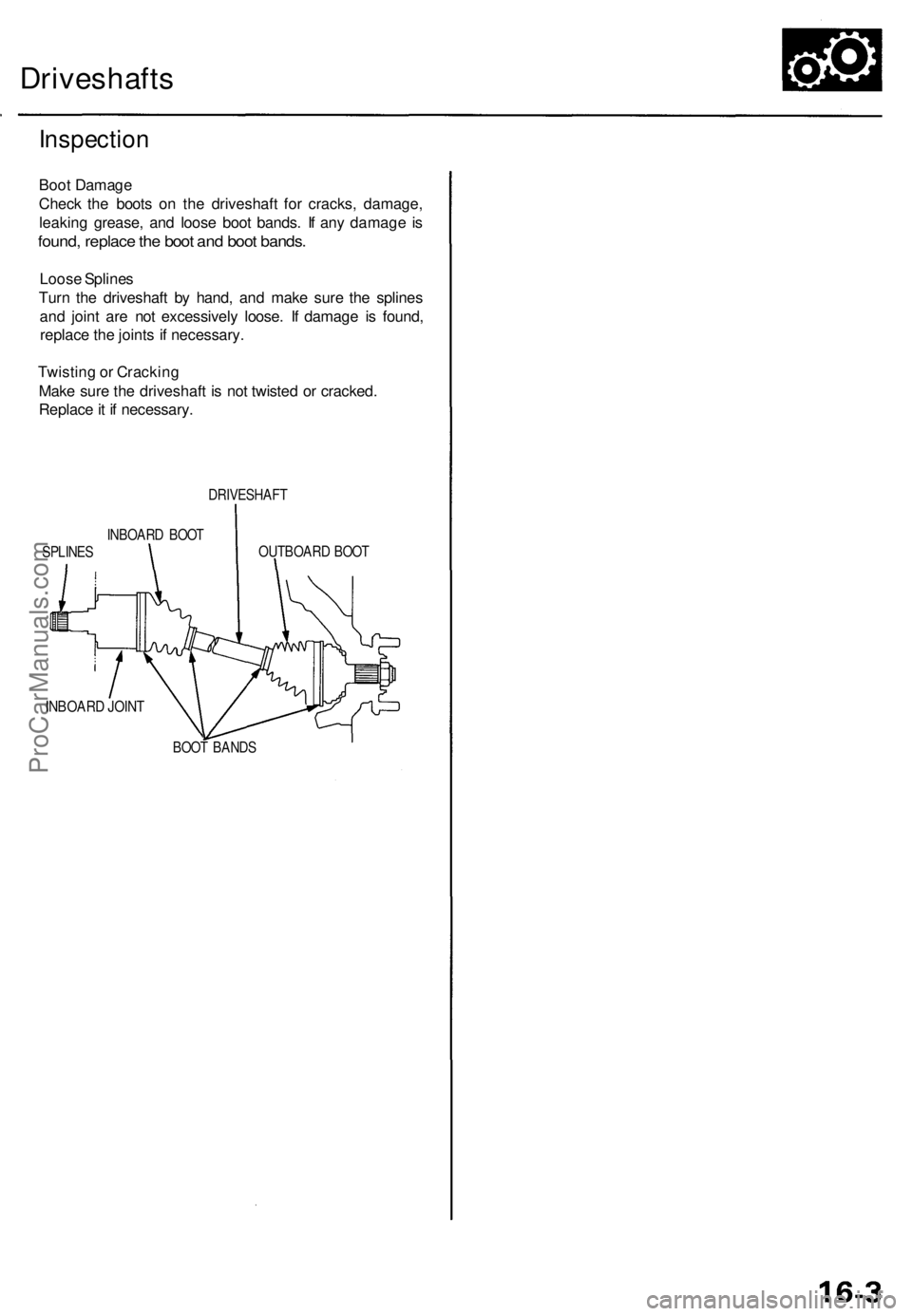

Driveshafts

Inspection

Boot Damage

Check the boots on the driveshaft for cracks, damage,

leaking grease, and loose boot bands. If any damage is

found, replace the boot and boot bands.

Loose Splines

Turn the driveshaft by hand, and make sure the splines

and joint are not excessively loose. If damage is found,

replace the joints if necessary.

Twisting or Cracking

Make sure the driveshaft is not twisted or cracked.

Replace it if necessary.

DRIVESHAFT

INBOARD BOOT

SPLINES

OUTBOARD BOOT

INBOARD JOINT

BOOT BANDSProCarManuals.com

Page 946 of 1954

DRIVESHAFT

KNUCKLE

13. Pul l th e knuckl e outward , an d remov e th e driveshaf t

outboar d join t fro m th e fron t whee l hu b usin g a plas -

ti c hammer .

12

. Pul l th e inboar d joint , an d remov e th e driveshaf t

fro m th e differentia l cas e a s a n assembly .

CAUTION:

• D o no t pul l o n th e driveshaft ; th e inboar d join t

may com e apart .

• Us e car e whe n pryin g ou t th e assembly , an d

dra w it straigh t ou t t o avoi d damagin g th e dif -

ferentia l oi l seal .

INBOAR D JOIN T

Remova l (cont'd )

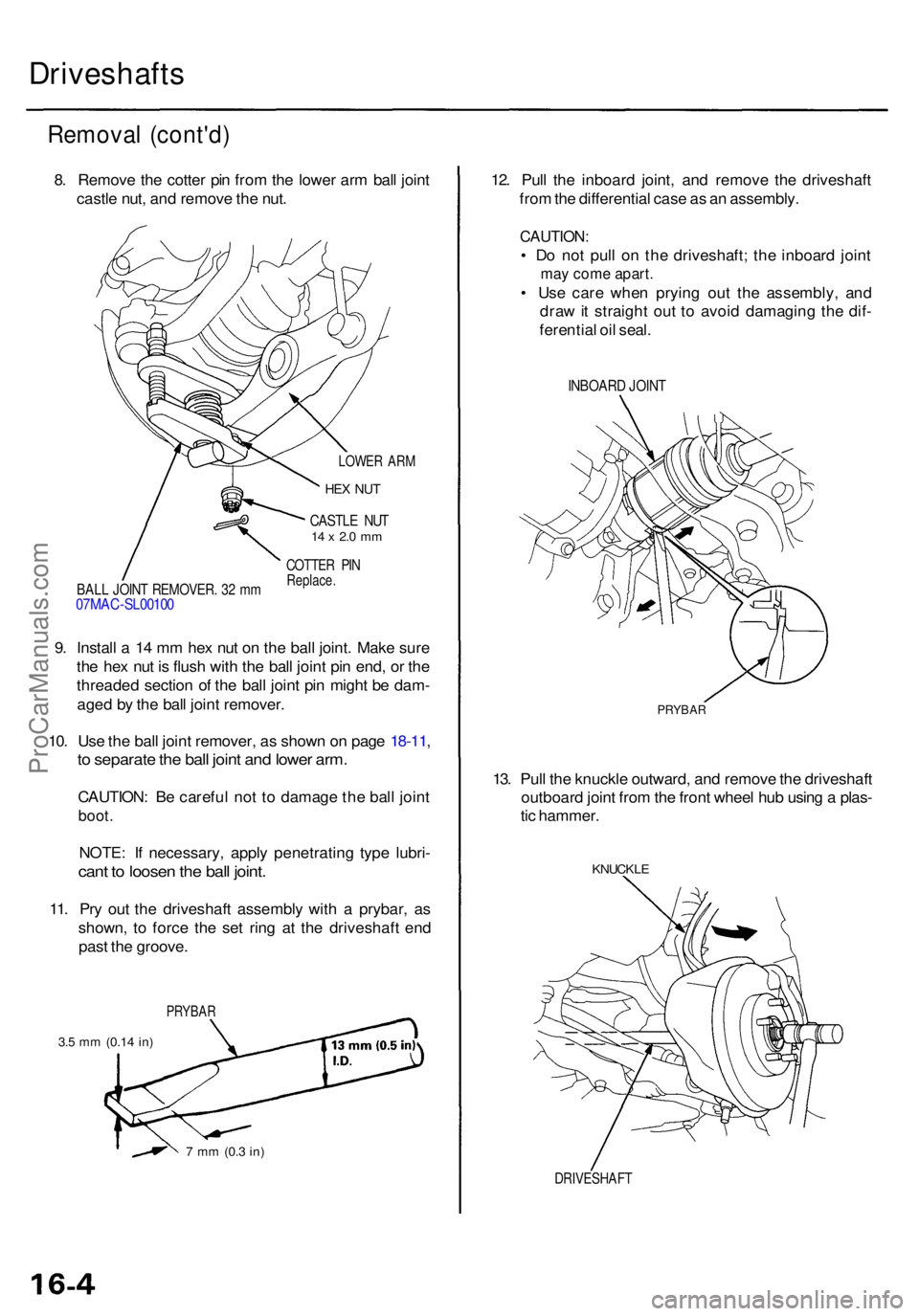

8. Remov e th e cotte r pi n fro m th e lowe r ar m bal l join t

castl e nut , an d remov e th e nut .

Driveshaft s

LOWER AR M

HEX NU T

CASTL E NU T14 x 2. 0 m m

COTTE R PI NReplace .BALL JOIN T REMOVER . 3 2 m m07MA C-SL0010 0

9. Instal l a 14 m m he x nu t o n th e bal l joint . Mak e sur e

th e he x nu t i s flus h wit h th e bal l join t pi n end , o r th e

threade d sectio n o f th e bal l join t pi n migh t b e dam -

age d b y th e bal l join t remover .

10 . Us e th e bal l join t remover , a s show n o n pag e 18-11 ,

to separat e th e bal l join t an d lowe r arm .

CAUTION : B e carefu l no t t o damag e th e bal l join t

boot .

NOTE : I f necessary , appl y penetratin g typ e lubri -

cant t o loose n th e bal l joint .

11. Pr y ou t th e driveshaf t assembl y wit h a prybar , a s

shown , t o forc e th e se t rin g a t th e driveshaf t en d

pas t th e groove .

PRYBA R

3.5 m m (0.1 4 in)

7 m m (0. 3 in)

PRYBA R

ProCarManuals.com

Page 947 of 1954

SET RIN GReplace .

Welded Typ e

BOO T BAN DReplace .

INBOARD JOIN T

SHOP TOWE L

Marks

Crimpin g Typ e

BOO T BAN DReplace .

Double Loo p Typ e

DOUBL E LOO P BAN DReplace .

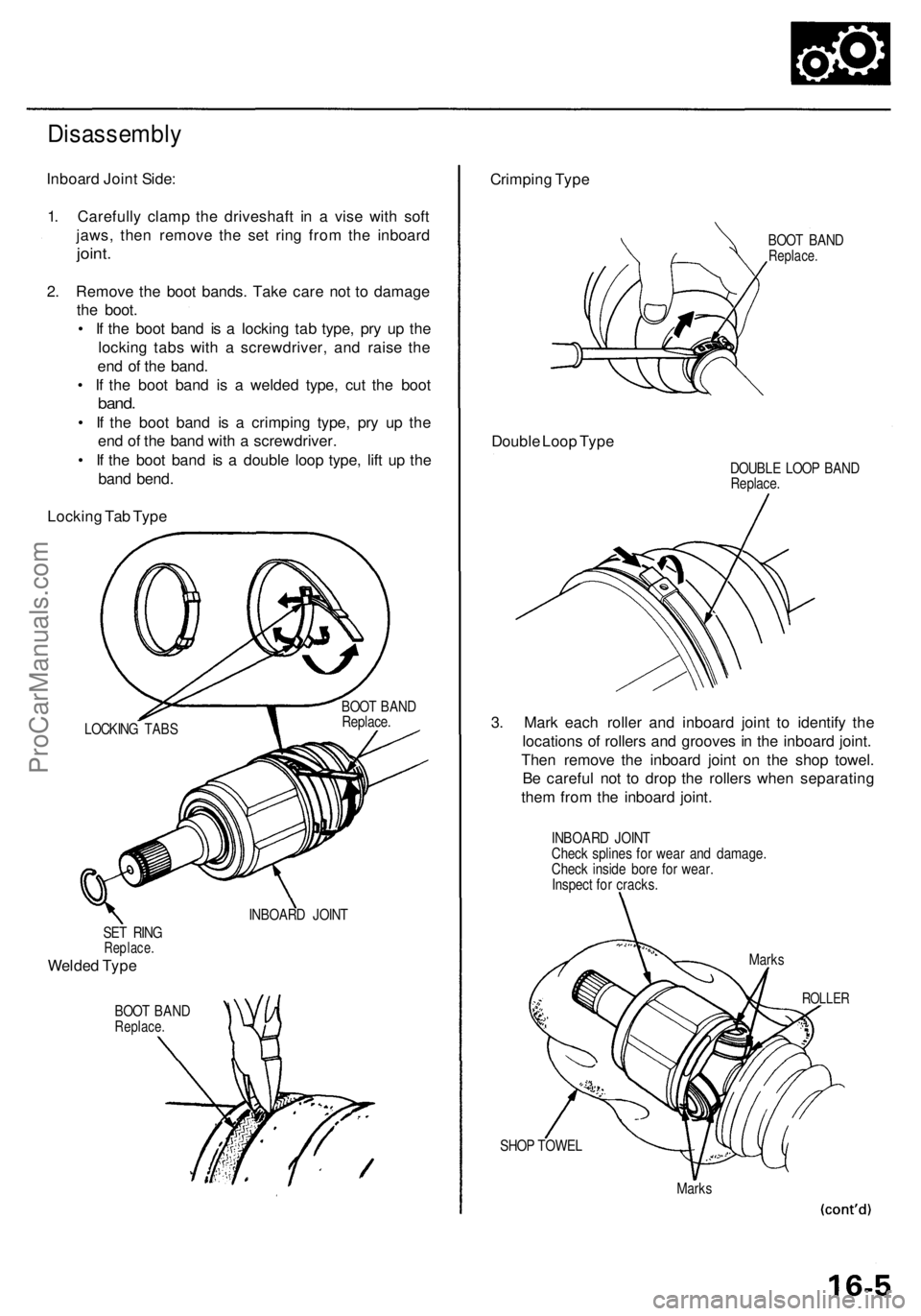

3. Mar k eac h rolle r an d inboar d join t t o identif y th e

location s o f roller s an d groove s in th e inboar d joint .

The n remov e th e inboar d join t o n th e sho p towel .

B e carefu l no t t o dro p th e roller s whe n separatin g

the m fro m th e inboar d joint .

INBOAR D JOIN T

Chec k spline s fo r wea r an d damage .

Chec k insid e bor e fo r wear .

Inspec t fo r cracks .

ROLLER

Marks

Disassembl y

Inboard Join t Side :

1 . Carefull y clam p th e driveshaf t i n a vis e wit h sof t

jaws , the n remov e th e se t rin g fro m th e inboar d

joint.

2. Remov e th e boo t bands . Tak e car e no t t o damag e

th e boot .

• I f th e boo t ban d i s a lockin g ta b type , pr y u p th e

lockin g tab s wit h a screwdriver , an d rais e th e

en d o f th e band .

• I f th e boo t ban d i s a welde d type , cu t th e boo t

band.

• I f th e boo t ban d i s a crimpin g type , pr y u p th e

en d o f th e ban d wit h a screwdriver .

• I f th e boo t ban d i s a doubl e loo p type , lif t u p th e

ban d bend .

Lockin g Ta b Typ e

LOCKIN G TAB S BOO

T BAN D

Replace .

ProCarManuals.com

Page 948 of 1954

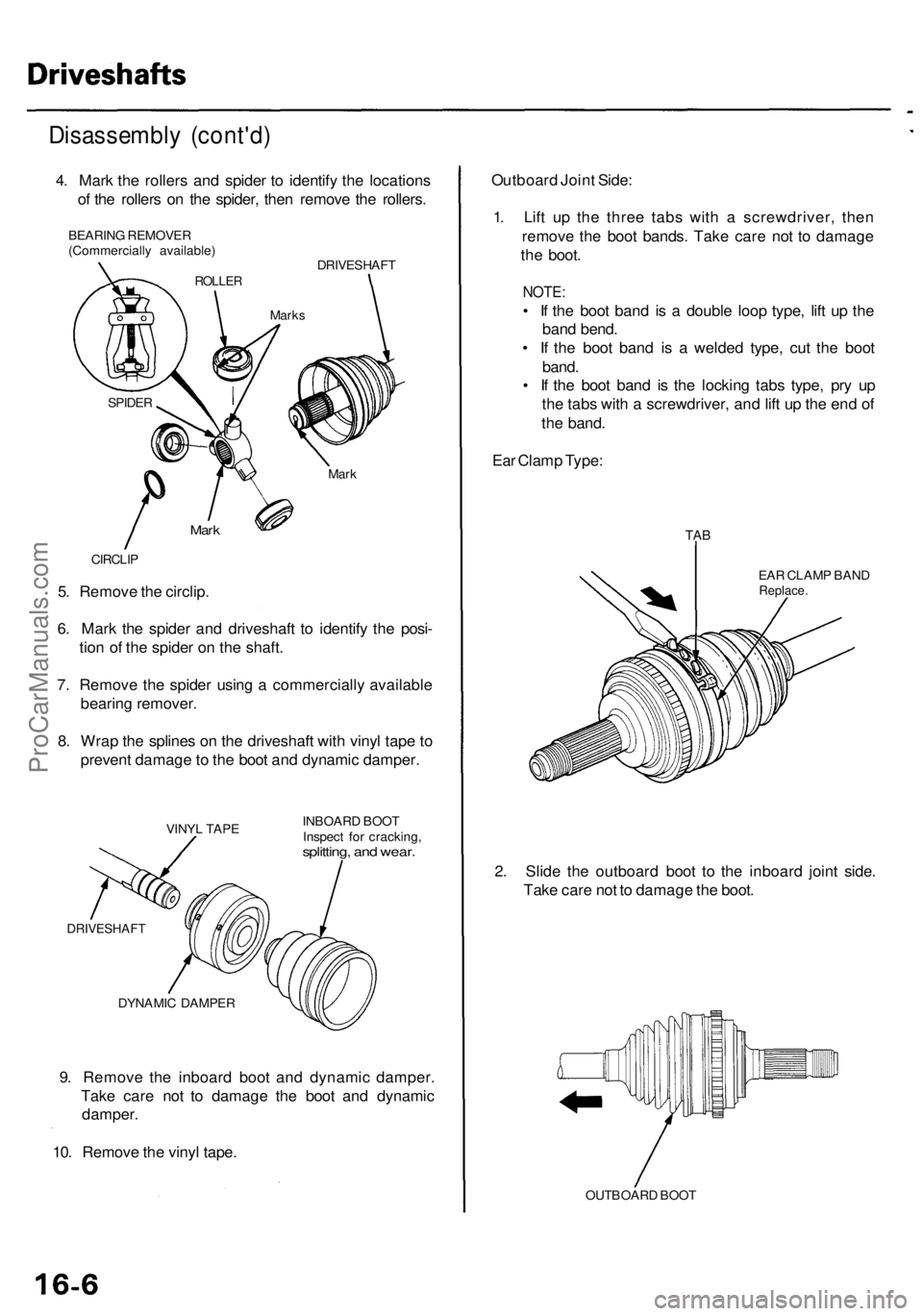

9. Remov e th e inboar d boo t an d dynami c damper .

Tak e car e no t t o damag e th e boo t an d dynami c

damper .

10 . Remov e th e viny l tape .

DYNAMI C DAMPE R INBOAR

D BOO T

Inspec t fo r cracking ,

splitting, an d wear .

VINY L TAP E

DRIVESHAF T

5. Remov e th e circlip .

6 . Mar k th e spide r an d driveshaf t t o identif y th e posi -

tio n o f th e spide r o n th e shaft .

7 . Remov e th e spide r usin g a commerciall y availabl e

bearin g remover .

8 . Wra p th e spline s o n th e driveshaf t wit h viny l tap e t o

preven t damag e to th e boo t an d dynami c damper .

CIRCLIP

Mark

Mar k

SPIDE R

Disassembl y (cont'd )

4. Mar k th e roller s an d spide r t o identif y th e location s

o f th e roller s o n th e spider , the n remov e th e rollers .

BEARIN G REMOVE R

(Commerciall y available )

ROLLER

Marks

DRIVESHAF T

Outboard Join t Side :

1 . Lif t u p th e thre e tab s wit h a screwdriver , the n

remov e th e boo t bands . Tak e car e no t t o damag e

th e boot .

NOTE :

• I f th e boo t ban d i s a doubl e loo p type , lif t u p th e

ban d bend .

• I f th e boo t ban d i s a welde d type , cu t th e boo t

band .

• I f th e boo t ban d i s th e lockin g tab s type , pr y u p

th e tab s wit h a screwdriver , an d lif t u p th e en d o f

th e band .

Ea r Clam p Type :

EAR CLAM P BAN DReplace .

TAB

2. Slid e th e outboar d boo t t o th e inboar d join t side .

Tak e car e no t t o damag e th e boot .

OUTBOAR D BOO T

ProCarManuals.com

Page 949 of 1954

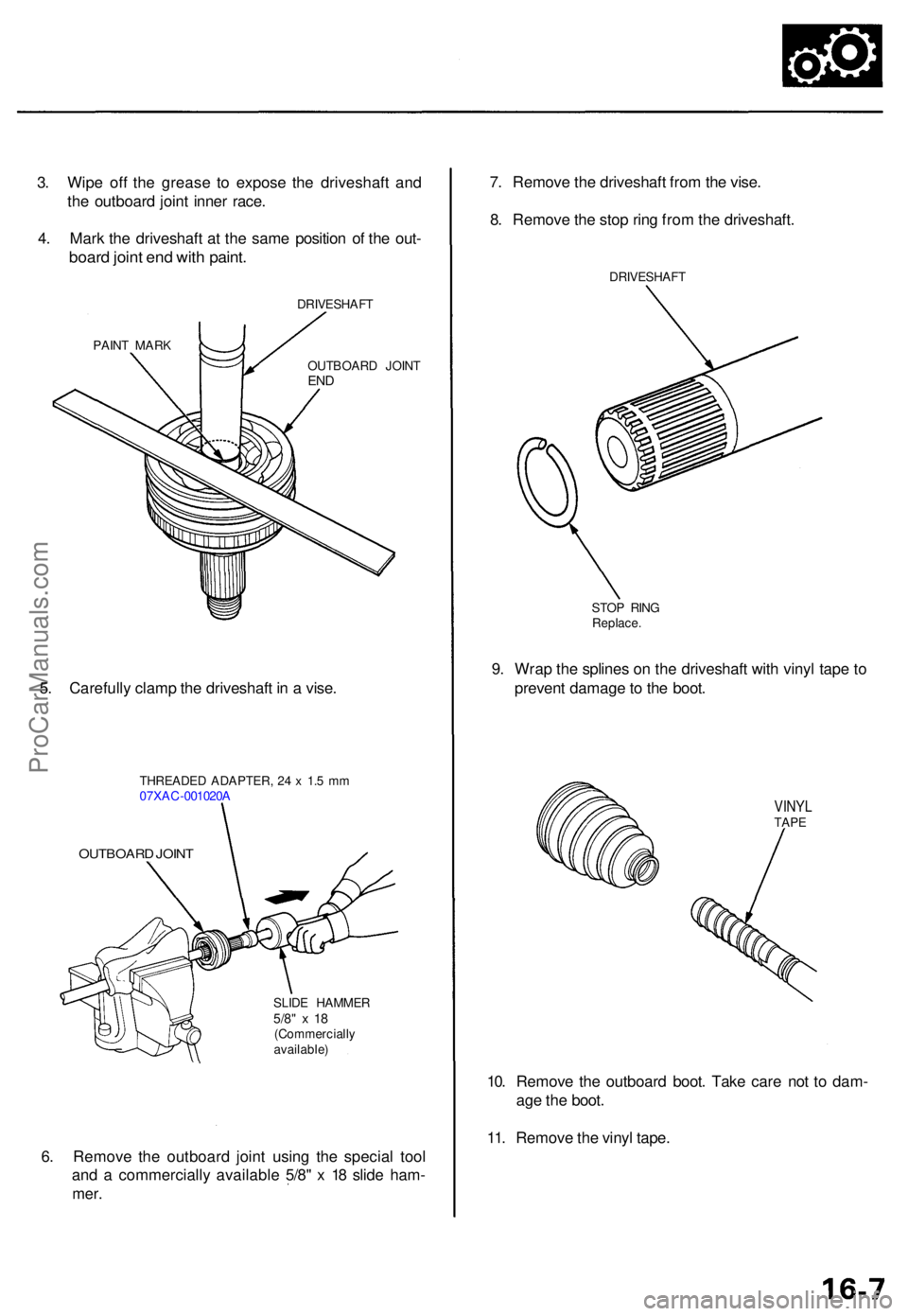

6. Remov e th e outboar d join t usin g th e specia l too l

an d a commerciall y availabl e 5/8 " x 1 8 slid e ham -

mer.

SLID E HAMME R5/8" x 1 8(Commerciall y

available )

OUTBOAR D JOIN T

THREADE D ADAPTER , 2 4 x 1. 5 m m

07XA C-001020 A

10. Remov e th e outboar d boot . Tak e car e no t t o dam -

ag e th e boot .

11 . Remov e th e viny l tape .

7

. Remov e th e driveshaf t fro m th e vise .

8 . Remov e th e sto p rin g fro m th e driveshaft .

DRIVESHAF T

STO P RIN G

Replace .

9. Wra p th e spline s o n th e driveshaf t wit h viny l tap e t o

preven t damag e to th e boot .

VINY LTAPE

5. Carefull y clam p th e driveshaf t i n a vise .

OUTBOAR D JOIN TEND

PAIN T MAR K DRIVESHAF

T

3. Wip e of f th e greas e t o expos e th e driveshaf t an d

th e outboar d join t inne r race .

4 . Mar k th e driveshaf t a t th e sam e positio n o f th e out -

boar d join t en d wit h paint .

ProCarManuals.com

Page 950 of 1954

Driveshafts

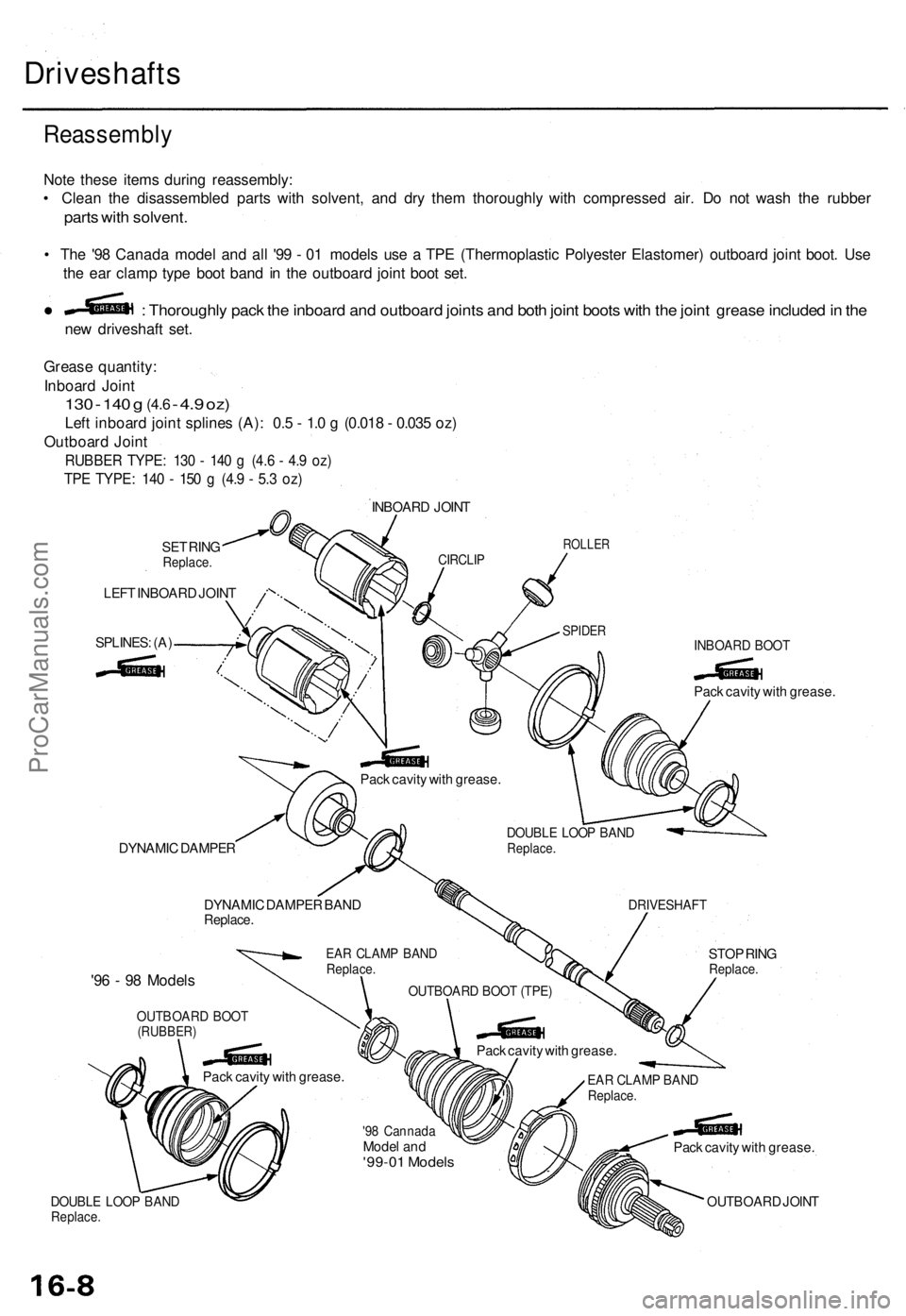

Reassembl y

Note thes e item s durin g reassembly :

• Clea n th e disassemble d part s wit h solvent , an d dr y the m thoroughl y wit h compresse d air . D o no t was h th e rubbe r

parts wit h solvent .

• Th e '9 8 Canad a mode l an d al l '9 9 - 0 1 model s us e a TP E (Thermoplasti c Polyeste r Elastomer ) outboar d join t boot . Us e

th e ea r clam p typ e boo t ban d i n th e outboar d join t boo t set .

ne w driveshaf t set .

: Thoroughl y pac k th e inboar d an d outboar d joint s an d bot h join t boot s wit h th e join t greas e include d in th e

Greas e quantity :

Inboar d Join t

130 - 14 0 g (4. 6 - 4. 9 oz )

Lef t inboar d join t spline s (A) : 0. 5 - 1. 0 g (0.01 8 - 0.03 5 oz )

Outboar d Join t

RUBBE R TYPE : 13 0 - 14 0 g (4. 6 - 4. 9 oz )

TPE TYPE : 14 0 - 15 0 g (4. 9 - 5. 3 oz )

SET RIN GReplace .

LEFT INBOAR D JOIN T

SPLINES : (A )

INBOAR D JOIN T

CIRCLI PROLLE R

SPIDERINBOAR D BOO T

Pack cavit y wit h grease .

STO P RIN G

Replace .

DRIVESHAF T

DOUBLE LOO P BAN DReplace .

Pack cavit y wit h grease .

Pack cavit y wit h grease .

OUTBOAR D JOIN T

EAR CLAM P BAN DReplace .

'98 Cannad aModel an d'99-0 1 Model s

DYNAMI C DAMPE R

DYNAMI C DAMPE R BAN D

Replace .

EAR CLAM P BAN DReplace .

OUTBOAR D BOO T (TPE )

Pack cavit y wit h grease .

Pac k cavit y wit h grease .

'96 - 9 8 Model s

OUTBOAR D BOO T(RUBBER )

DOUBLE LOO P BAN DReplace .

ProCarManuals.com

Page 952 of 1954

Driveshafts

Reassembl y (cont'd )

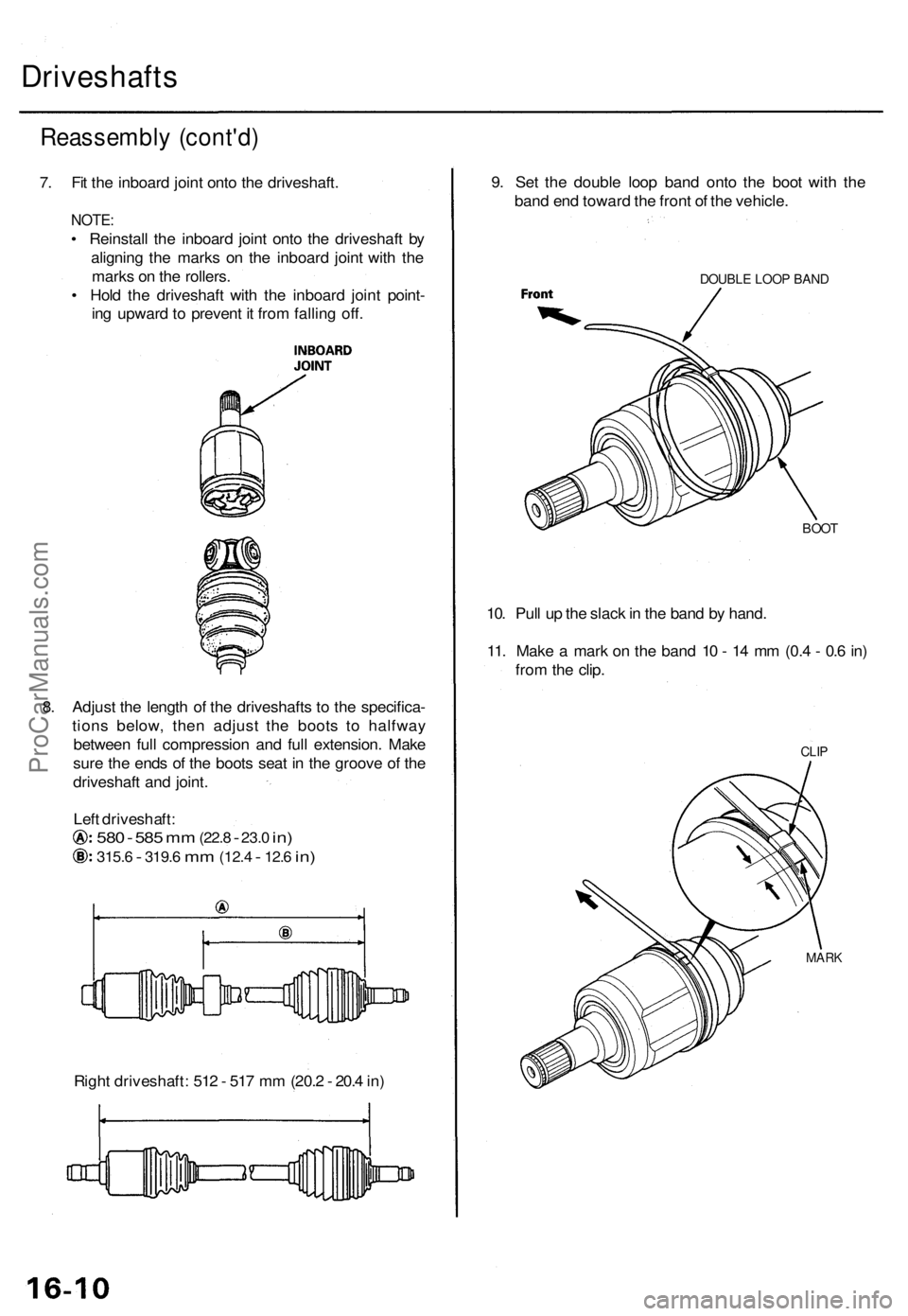

7. Fi t th e inboar d join t ont o th e driveshaft .

NOTE:

• Reinstal l th e inboar d join t ont o th e driveshaf t b y

alignin g th e mark s o n th e inboar d join t wit h th e

mark s o n th e rollers .

• Hol d th e driveshaf t wit h th e inboar d join t point -

in g upwar d to preven t i t fro m fallin g off .

8 . Adjus t th e lengt h o f th e driveshaft s t o th e specifica -

tion s below , the n adjus t th e boot s t o halfwa y

betwee n ful l compressio n an d ful l extension . Mak e

sur e th e end s o f th e boot s sea t i n th e groov e o f th e

driveshaf t an d joint .

Lef t driveshaft :

580 - 58 5 mm (22. 8 - 23.0 in)

315. 6 - 319. 6 mm (12. 4 - 12.6 in)

Righ t driveshaft : 51 2 - 51 7 m m (20. 2 - 20. 4 in ) 9

. Se t th e doubl e loo p ban d ont o th e boo t wit h th e

ban d en d towar d th e fron t o f th e vehicle .

10 . Pul l u p th e slac k in th e ban d b y hand .

11 . Mak e a mar k o n th e ban d 1 0 - 1 4 m m (0. 4 - 0. 6 in )

fro m th e clip .

DOUBL E LOO P BAN D

BOOT

MAR K

CLIP

ProCarManuals.com