check oil ACURA RL KA9 1996 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 151 of 1954

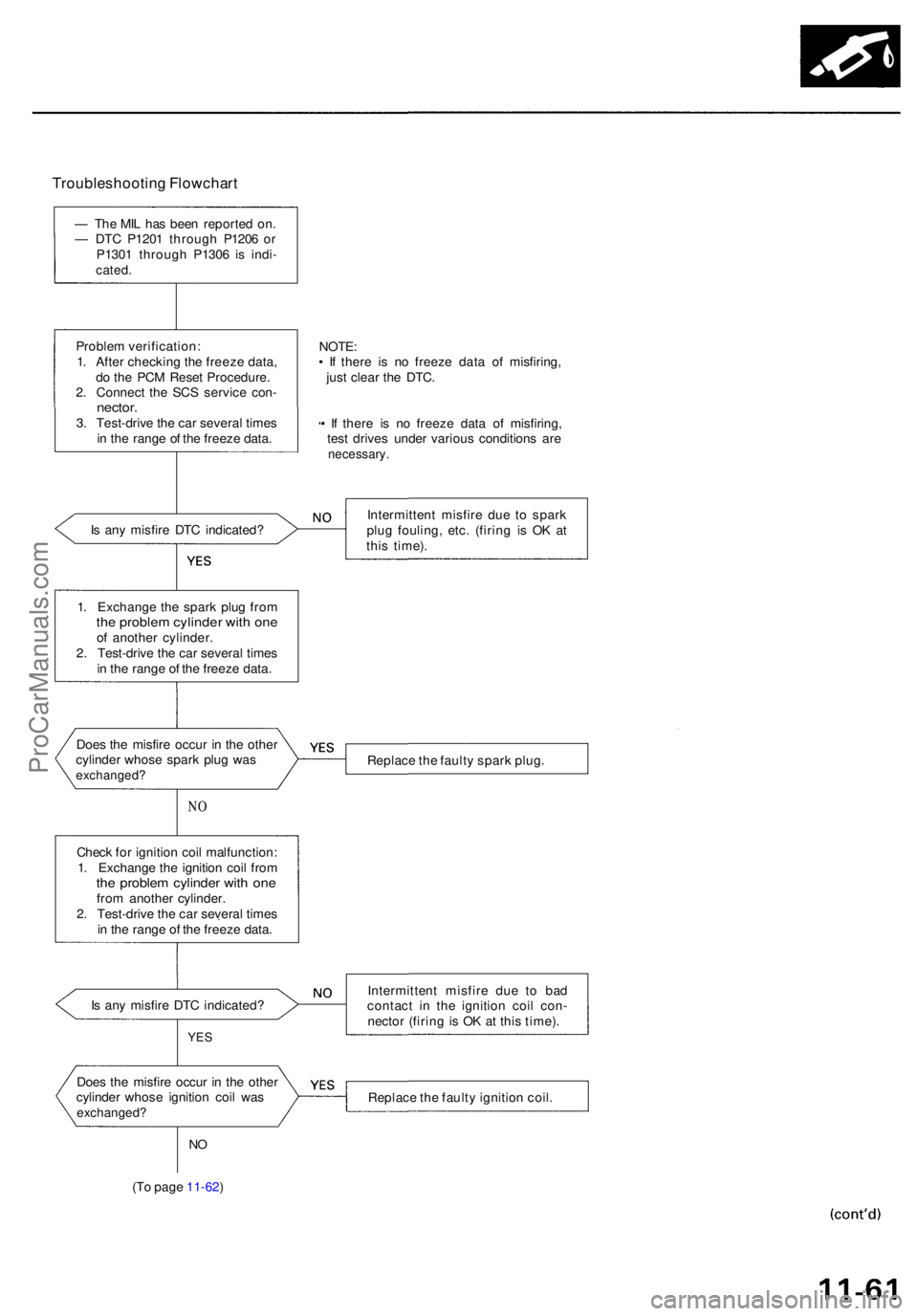

Troubleshooting Flowchar t

— Th e MI L ha s bee n reporte d on .

— DT C P120 1 throug h P120 6 o r

P130 1 throug h P130 6 i s indi -

cated .

Proble m verification :

1 . Afte r checkin g th e freez e data ,

d o th e PC M Rese t Procedure .

2 . Connec t th e SC S servic e con -

nector .3. Test-driv e th e ca r severa l time s

i n th e rang e o f th e freez e data .

I s an y misfir e DT C indicated ?

NO

Chec k fo r ignitio n coi l malfunction :

1 . Exchang e th e ignitio n coi l fro m

the proble m cylinde r wit h on efrom anothe r cylinder .

2 . Test-driv e th e ca r severa l time s

i n th e rang e o f th e freez e data .

I s an y misfir e DT C indicated ?

YES

NO

(T o pag e 11-62 )

NOTE:• I f ther e i s n o freez e dat a o f misfiring ,

jus t clea r th e DTC .

• I f ther e i s n o freez e dat a o f misfiring ,

tes t drive s unde r variou s condition s ar e

necessary .

Intermitten t misfir e du e t o spar k

plu g fouling , etc . (firin g i s O K a t

thi s time) .

Replac e th e fault y spar k plug .

Intermitten t misfir e du e t o ba d

contac t i n th e ignitio n coi l con -

necto r (firin g is O K a t thi s time) .

Replac e th e fault y ignitio n coil .

Doe

s th e misfir e occu r i n th e othe r

cylinde r whos e spar k plu g wa s

exchanged ?

Does th e misfir e occu r i n th e othe r

cylinde r whos e ignitio n coi l wa s

exchanged ?

1. Exchang e th e spar k plu g fro mthe proble m cylinde r wit h on eof anothe r cylinder .

2 . Test-driv e th e ca r severa l time s

i n th e rang e o f th e freez e data .

ProCarManuals.com

Page 154 of 1954

PGM-FI Syste m

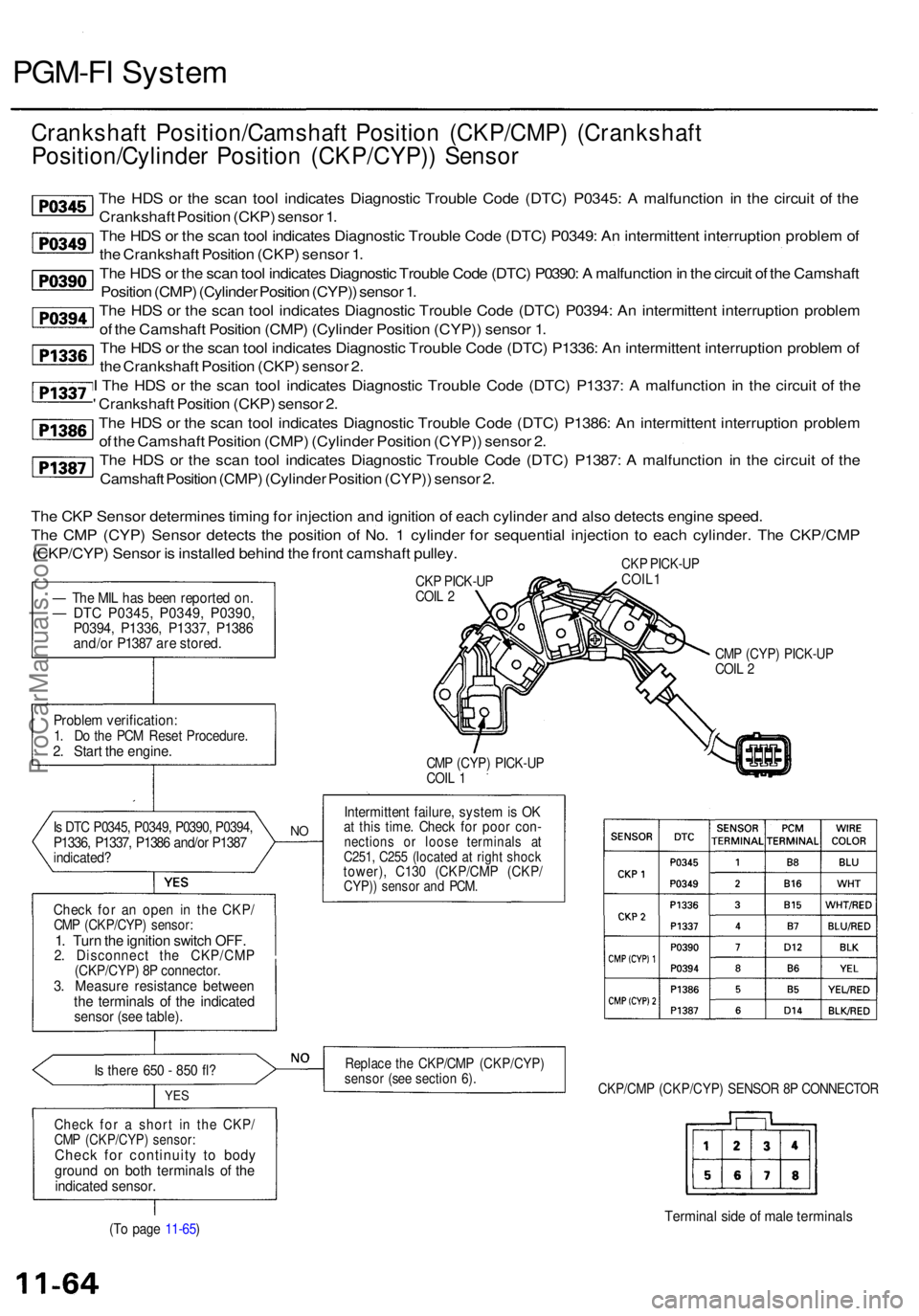

Crankshaf t Position/Camshaf t Positio n (CKP/CMP ) (Crankshaf t

Position/Cylinde r Positio n (CKP/CYP) ) Senso r

The HD S o r th e sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P0345 : A malfunctio n i n th e circui t o f th e

Crankshaf t Positio n (CKP ) senso r 1 .

Th e HD S o r th e sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P0349 : A n intermitten t interruptio n proble m of

th e Crankshaf t Positio n (CKP ) senso r 1 .

Th e HD S o r th e sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P0390 : A malfunctio n in th e circui t o f th e Camshaf t

Positio n (CMP ) (Cylinde r Positio n (CYP) ) senso r 1 .

Th e HD S o r th e sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P0394 : A n intermitten t interruptio n proble m

o f th e Camshaf t Positio n (CMP ) (Cylinde r Positio n (CYP) ) senso r 1 .

Th e HD S o r th e sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P1336 : A n intermitten t interruptio n proble m o f

th e Crankshaf t Positio n (CKP ) senso r 2 .

I Th e HD S o r th e sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P1337 : A malfunctio n i n th e circui t o f th e

' Crankshaf t Positio n (CKP ) senso r 2 .

Th e HD S o r th e sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P1386 : A n intermitten t interruptio n proble m

o f th e Camshaf t Positio n (CMP ) (Cylinde r Positio n (CYP) ) senso r 2 .

Th e HD S o r th e sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P1387 : A malfunctio n i n th e circui t o f th e

Camshaf t Positio n (CMP ) (Cylinde r Positio n (CYP) ) senso r 2 .

Th e CK P Senso r determine s timin g fo r injectio n an d ignitio n o f eac h cylinde r an d als o detect s engin e speed .

Th e CM P (CYP ) Senso r detect s th e positio n o f No . 1 cylinde r fo r sequentia l injectio n t o eac h cylinder . Th e CKP/CM P

(CKP/CYP ) Senso r i s installe d behin d th e fron t camshaf t pulley .

— Th e MI L ha s bee n reporte d on .— DT C P0345 , P0349 , P0390 ,P0394, P1336 , P1337 , P138 6

and/o r P138 7 ar e stored .

Proble m verification :

1. D o th e PC M Rese t Procedure .2. Star t th e engine .

Check fo r a n ope n i n th e CKP /CMP (CKP/CYP ) sensor :1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e CKP/CM P(CKP/CYP) 8 P connector .3. Measur e resistanc e betwee nthe terminal s o f th e indicate dsensor (se e table) .

Is ther e 65 0 - 85 0 fl ?

YE S

Chec k fo r a shor t i n th e CKP /CMP (CKP/CYP ) sensor :Check fo r continuit y t o bod ygroun d o n bot h terminal s o f th eindicate d sensor .

CKP PICK-U PCOIL 2

CM P (CYP ) PICK-U PCOIL 1

N O

Intermitten t failure , syste m is O Kat thi s time . Chec k fo r poo r con -nection s o r loos e terminal s a tC251 , C25 5 (locate d a t righ t shoc ktower) , C13 0 (CKP/CM P (CKP /CYP)) senso r an d PCM .

Replac e th e CKP/CM P (CKP/CYP )sensor (se e sectio n 6) .

CK P PICK-U PCOIL1

CMP (CYP ) PICK-U PCOIL 2

CKP/CM P (CKP/CYP ) SENSO R 8 P CONNECTO R

(To pag e 11-65 )Termina l sid e o f mal e terminal s

Is DT C P0345 , P0349 , P0390 , P0394 ,P1336, P1337 , P138 6 and/o r P138 7indicated ?

ProCarManuals.com

Page 330 of 1954

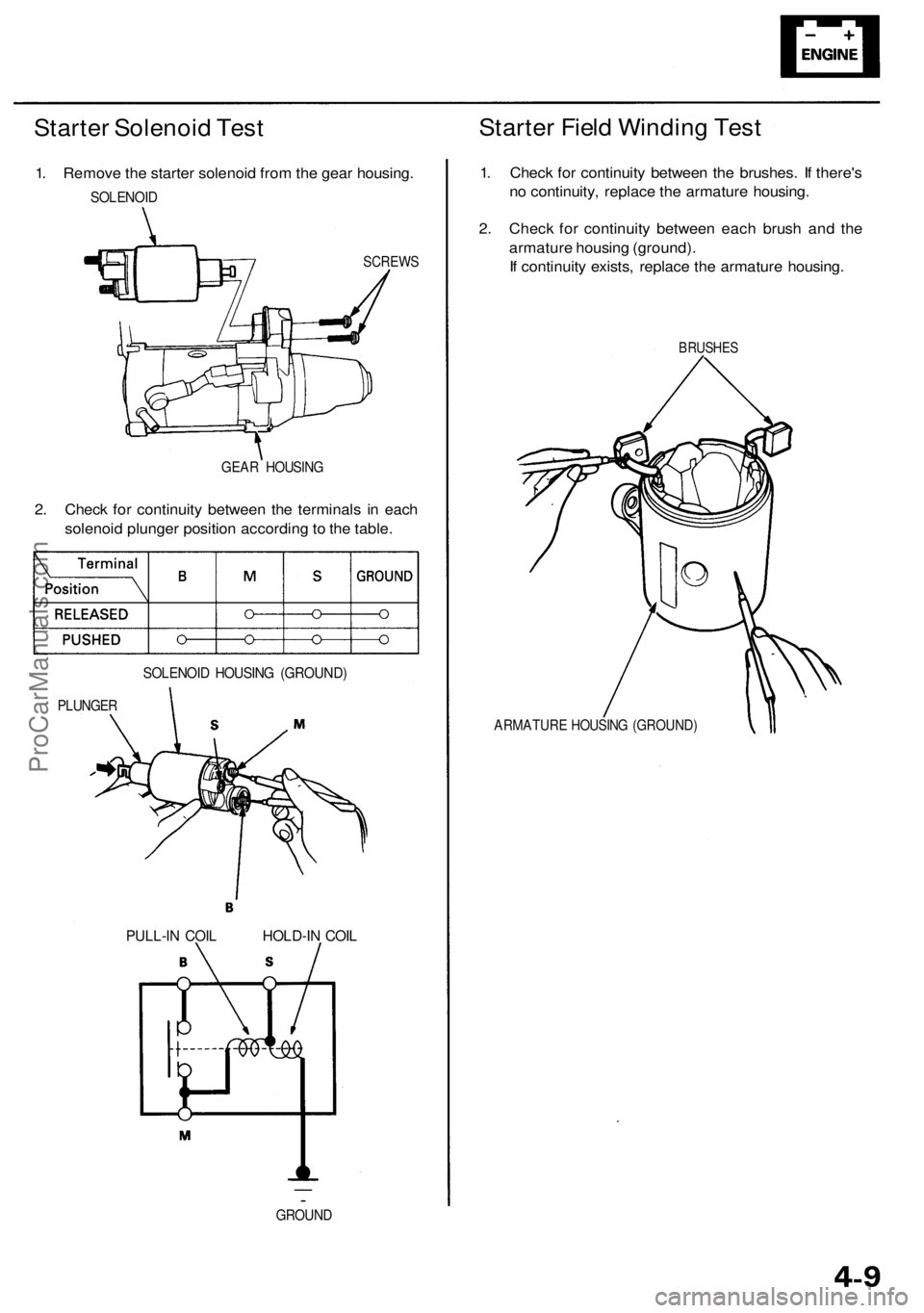

Starter Solenoid Test

1. Remove the starter solenoid from the gear housing.

SOLENOID

SCREWS

GEAR HOUSING

2. Check for continuity between the terminals in each

solenoid plunger position according to the table.

PLUNGER

SOLENOID HOUSING (GROUND)

Starter Field Winding Test

1. Check for continuity between the brushes. If there's

no continuity, replace the armature housing.

2. Check for continuity between each brush and the

armature housing (ground).

If continuity exists, replace the armature housing.

BRUSHES

ARMATURE HOUSING (GROUND)

GROUND

PULL-IN COIL

HOLD-IN COILProCarManuals.com

Page 332 of 1954

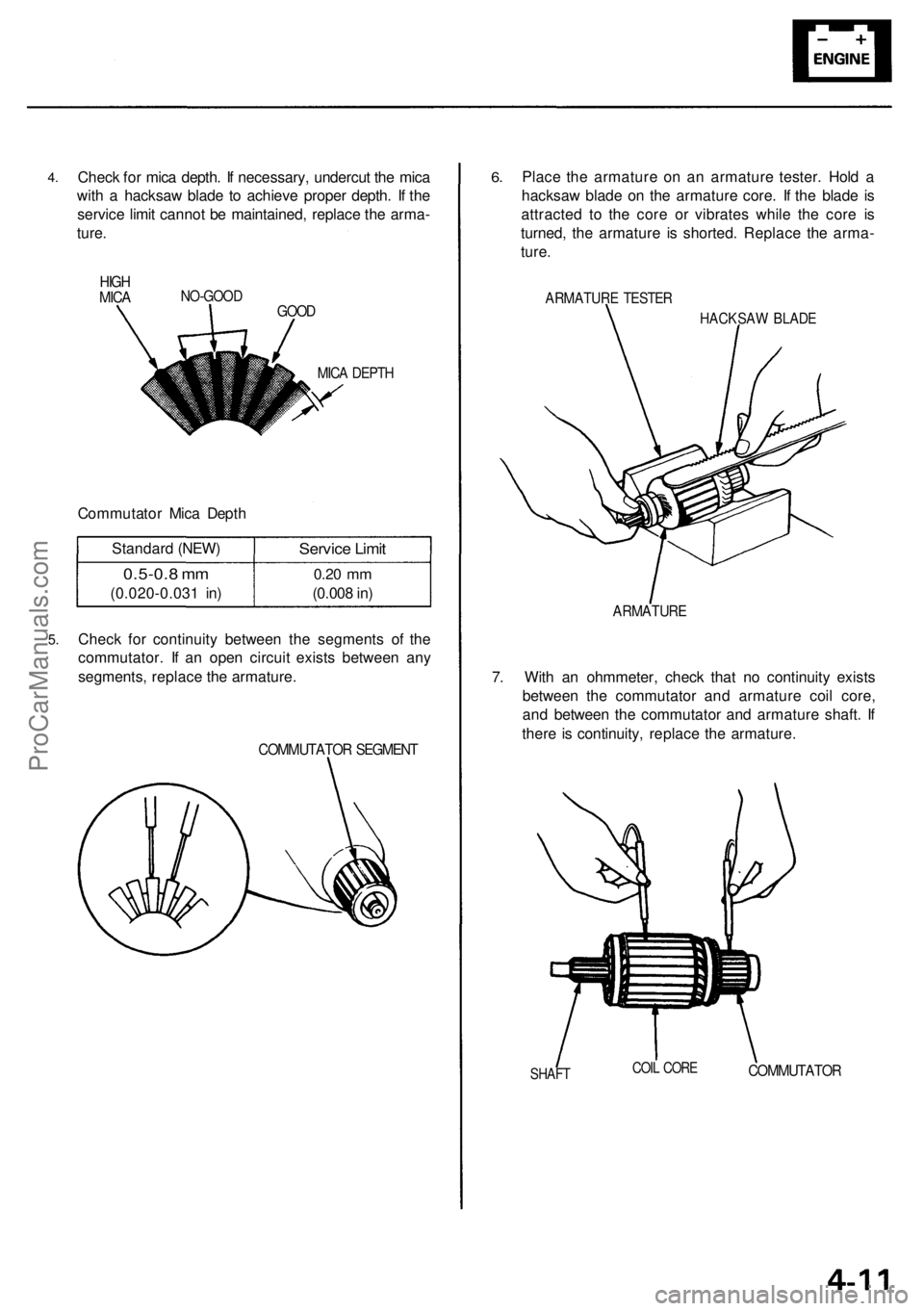

4.

Check for mica depth. If necessary, undercut the mica

with a hacksaw blade to achieve proper depth. If the

service limit cannot be maintained, replace the arma-

ture.

NO-GOOD

GOOD

MICA DEPTH

Commutator Mica Depth

Standard (NEW)

0.5-0.8 mm

(0.020-0.031 in)

Service Limit

0.20

mm

(0.008 in)

5.

Check for continuity between the segments of the

commutator. If an open circuit exists between any

segments, replace the armature.

COMMUTATOR SEGMENT

6.

Place the armature on an armature tester. Hold a

hacksaw blade on the armature core. If the blade is

attracted to the core or vibrates while the core is

turned, the armature is shorted. Replace the arma-

ture.

ARMATURE TESTER

HACKSAW BLADE

ARMATURE

7. With an ohmmeter, check that no continuity exists

between the commutator and armature coil core,

and between the commutator and armature shaft. If

there is continuity, replace the armature.

SHAFT

COIL CORE

COMMUTATOR

HIGH

MICAProCarManuals.com

Page 351 of 1954

Charging System

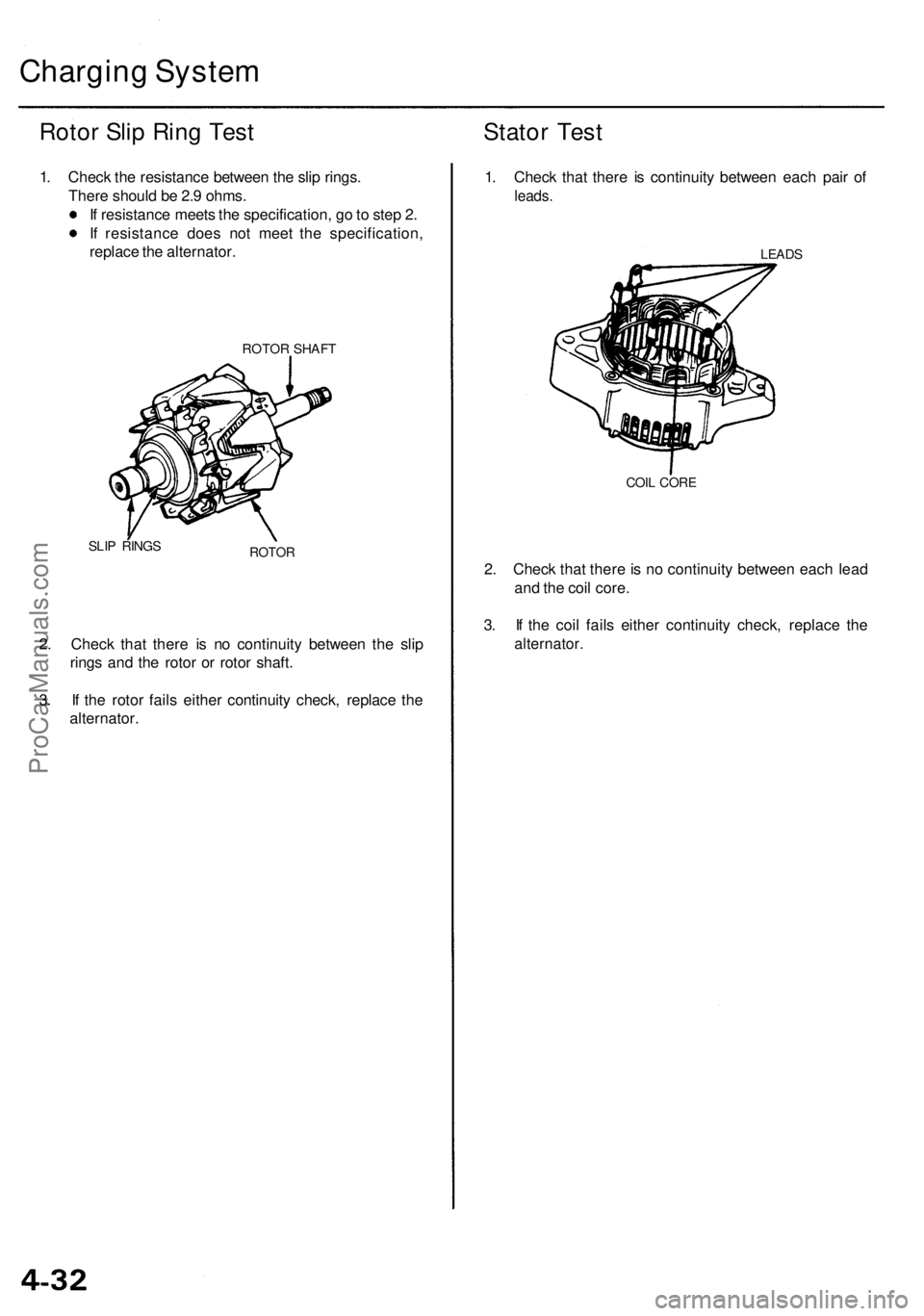

Rotor Slip Ring Test

1. Check the resistance between the slip rings.

There should be 2.9 ohms.

If resistance meets the specification, go to step 2.

If resistance does not meet the specification,

replace the alternator.

ROTOR SHAFT

SLIP RINGS

ROTOR

2. Check that there is no continuity between the slip

rings and the rotor or rotor shaft.

3. If the rotor fails either continuity check, replace the

alternator.

Stator Test

1. Check that there is continuity between each pair of

leads.

LEADS

COIL CORE

2. Check that there is no continuity between each lead

and the coil core.

3. If the coil fails either continuity check, replace the

alternator.ProCarManuals.com

Page 411 of 1954

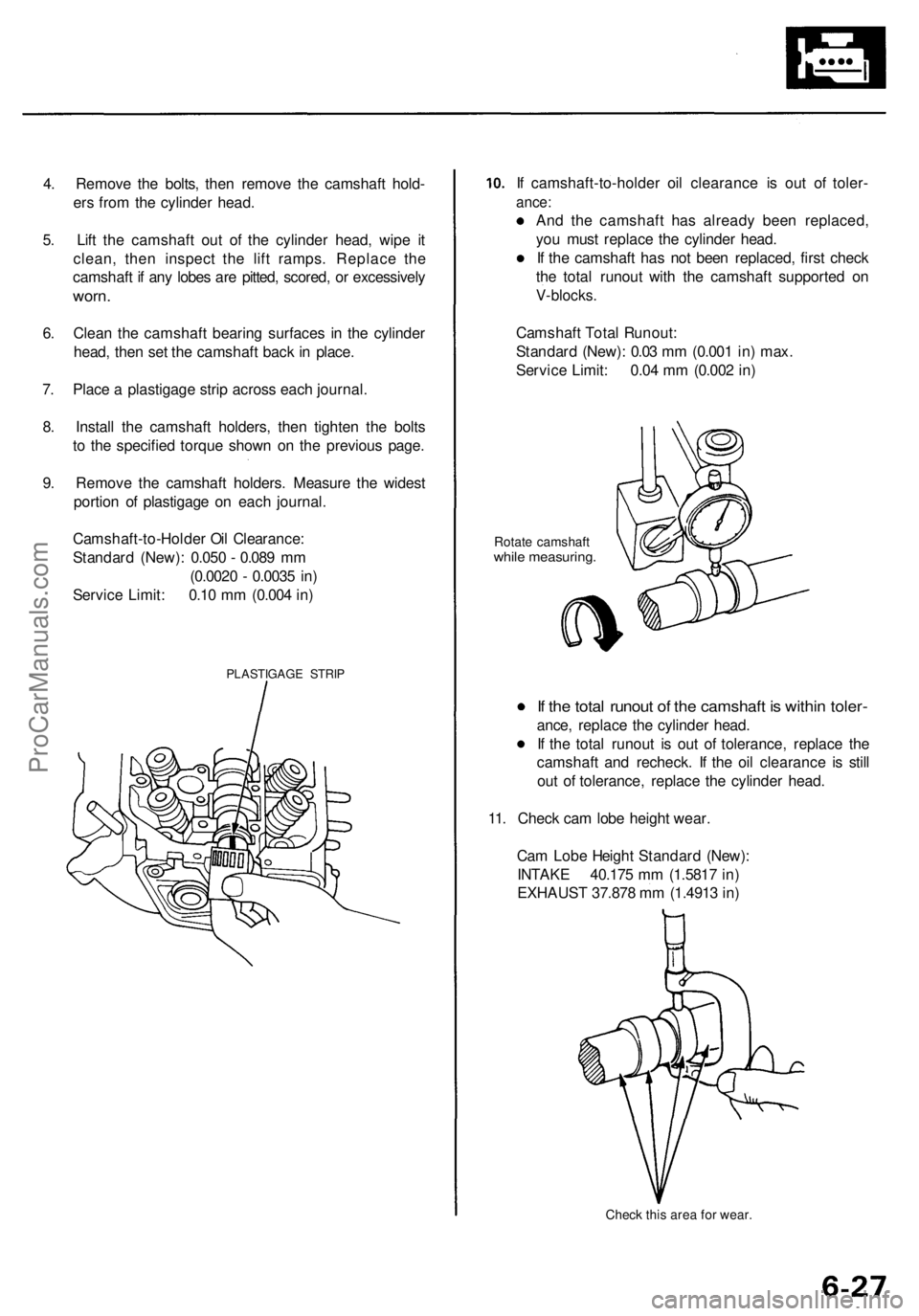

4. Remove the bolts, then remove the camshaft hold-

ers from the cylinder head.

5. Lift the camshaft out of the cylinder head, wipe it

clean, then inspect the lift ramps. Replace the

camshaft if any lobes are pitted, scored, or excessively

worn.

6. Clean the camshaft bearing surfaces in the cylinder

head, then set the camshaft back in place.

7. Place a plastigage strip across each journal.

8. Install the camshaft holders, then tighten the bolts

to the specified torque shown on the previous page.

9. Remove the camshaft holders. Measure the widest

portion of plastigage on each journal.

PLASTIGAGE STRIP

If camshaft-to-holder oil clearance is out of toler-

ance:

And the camshaft has already been replaced,

you must replace the cylinder head.

If the camshaft has not been replaced, first check

the total runout with the camshaft supported on

V-blocks.

Rotate camshaft

while measuring.

If the total runout of the camshaft is within toler-

ance, replace the cylinder head.

If the total runout is out of tolerance, replace the

camshaft and recheck. If the oil clearance is still

out of tolerance, replace the cylinder head.

11. Check cam lobe height wear.

Check this area for wear.

Cam Lobe Height Standard (New):

INTAKE 40.175 mm (1.5817 in)

EXHAUST 37.878 mm (1.4913 in)

Camshaft Total Runout:

Standard (New): 0.03 mm (0.001 in) max.

Service Limit: 0.04 mm (0.002 in)

Camshaft-to-Holder Oil Clearance:

Standard (New): 0.050 - 0.089 mm

(0.0020 - 0.0035 in)

Service Limit: 0.10 mm (0.004 in)ProCarManuals.com

Page 422 of 1954

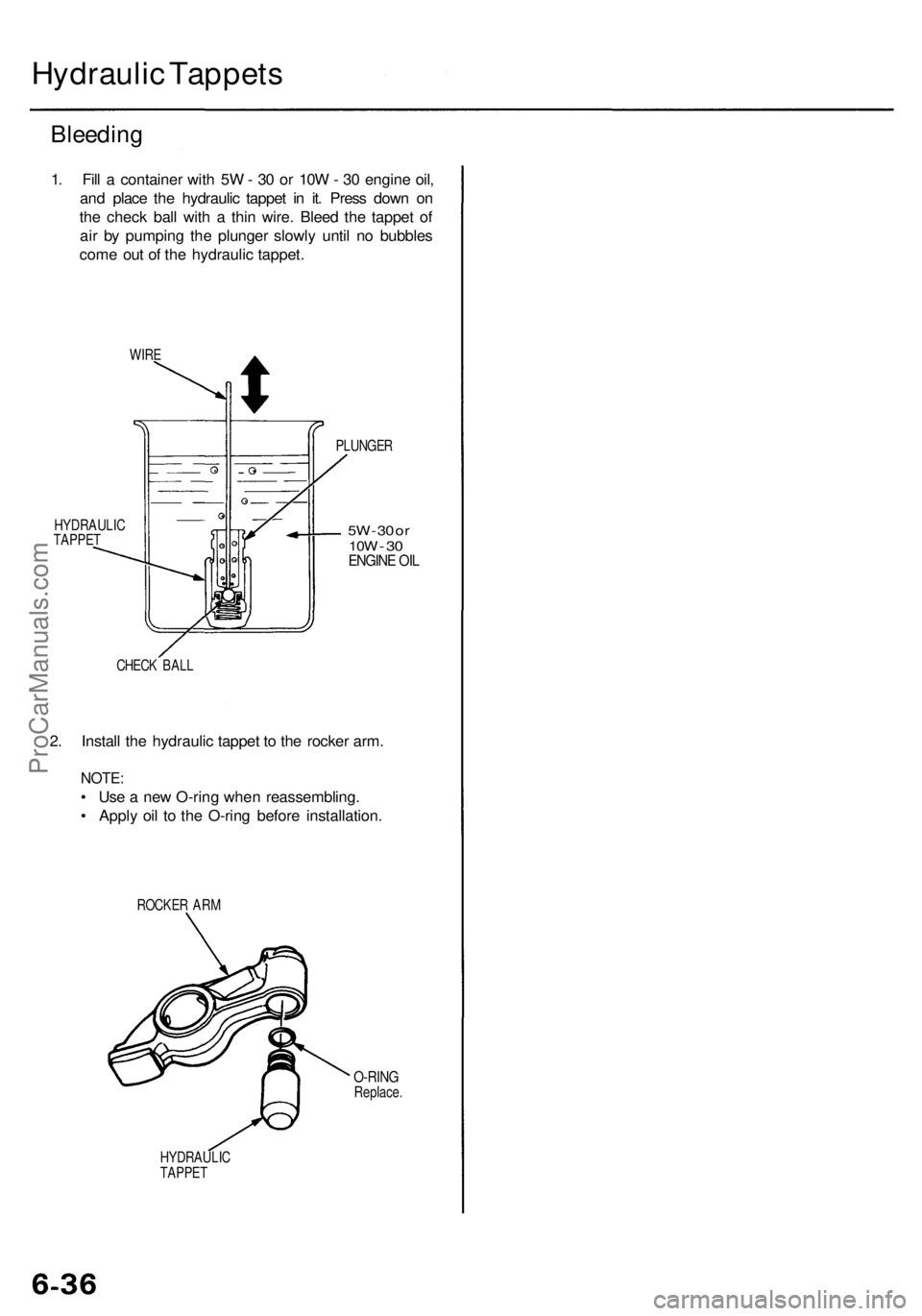

Hydraulic Tappets

Bleeding

1. Fill a container with 5W - 30 or 10W - 30 engine oil,

and place the hydraulic tappet in it. Press down on

the check ball with a thin wire. Bleed the tappet of

air by pumping the plunger slowly until no bubbles

come out of the hydraulic tappet.

WIRE

HYDRAULIC

TAPPET

PLUNGER

5W

- 30 or

10W

-

30

ENGINE OIL

CHECK BALL

2. Install the hydraulic tappet to the rocker arm.

NOTE:

• Use a new O-ring when reassembling.

• Apply oil to the O-ring before installation.

ROCKER ARM

O-RING

Replace.

HYDRAULIC

TAPPETProCarManuals.com

Page 426 of 1954

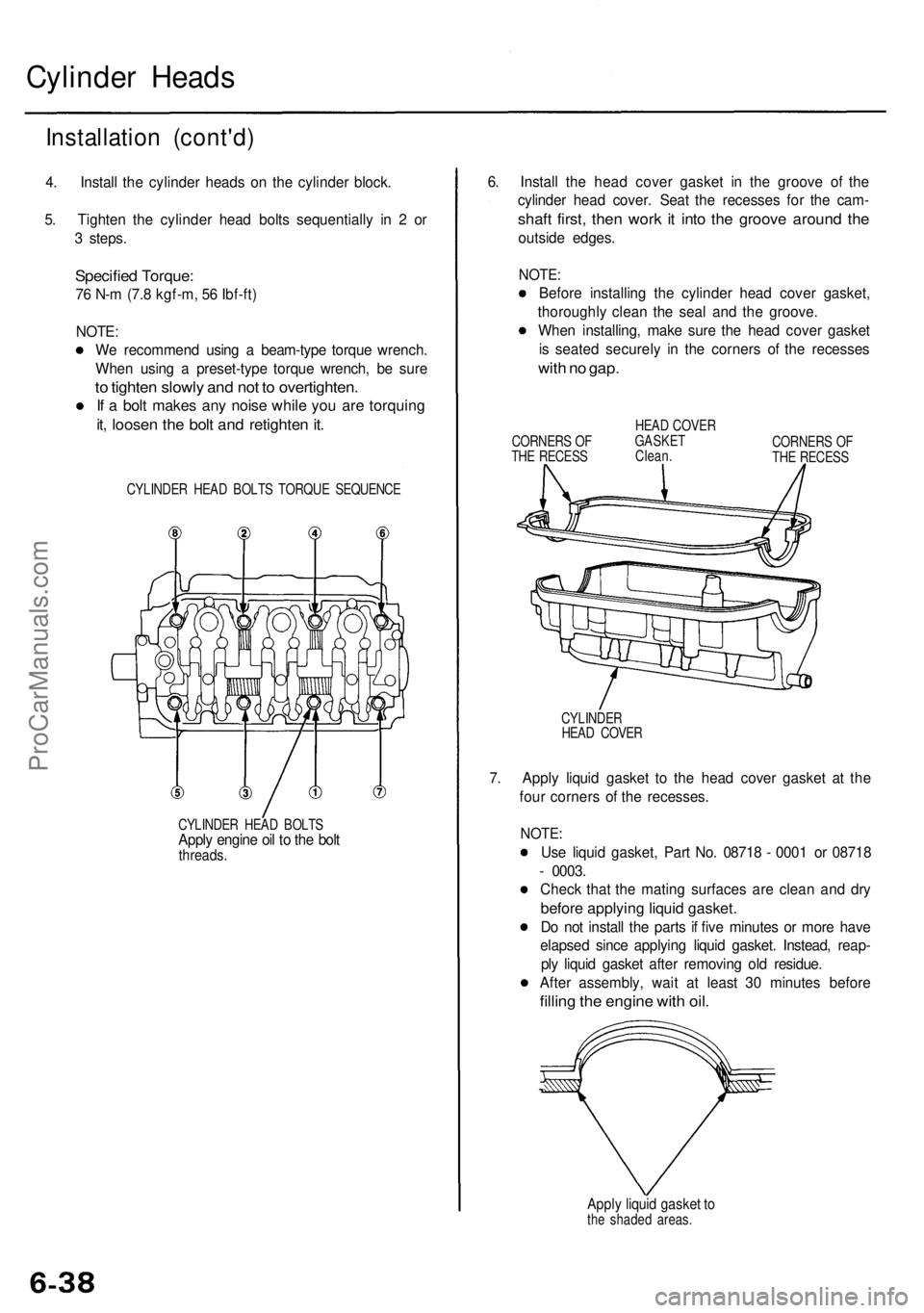

Cylinder Heads

Installation (cont'd)

4. Install the cylinder heads on the cylinder block.

5. Tighten the cylinder head bolts sequentially in 2 or

3 steps.

Specified Torque:

76 N-m (7.8 kgf-m, 56 Ibf-ft)

NOTE:

We recommend using a beam-type torque wrench.

When using a preset-type torque wrench, be sure

to tighten slowly and not to overtighten.

If a bolt makes any noise while you are torquing

it, loosen the bolt and retighten it.

CYLINDER HEAD BOLTS TORQUE SEQUENCE

CYLINDER HEAD BOLTS

Apply engine oil to the bolt

threads.

6. Install the head cover gasket in the groove of the

cylinder head cover. Seat the recesses for the cam-

shaft first, then work it into the groove around the

outside edges.

NOTE:

Before installing the cylinder head cover gasket,

thoroughly clean the seal and the groove.

When installing, make sure the head cover gasket

is seated securely in the corners of the recesses

with no gap.

CORNERS OF

THE RECESS

HEAD COVER

GASKET

Clean.

CORNERS OF

THE RECESS

CYLINDER

HEAD COVER

7. Apply liquid gasket to the head cover gasket at the

four corners of the recesses.

NOTE:

Use liquid gasket, Part No. 08718 - 0001 or 08718

- 0003.

Check that the mating surfaces are clean and dry

before applying liquid gasket.

Do not install the parts if five minutes or more have

elapsed since applying liquid gasket. Instead, reap-

ply liquid gasket after removing old residue.

After assembly, wait at least 30 minutes before

filling the engine with oil.

Apply liquid gasket to

the shaded areas.ProCarManuals.com

Page 440 of 1954

Crankshaft

Inspection

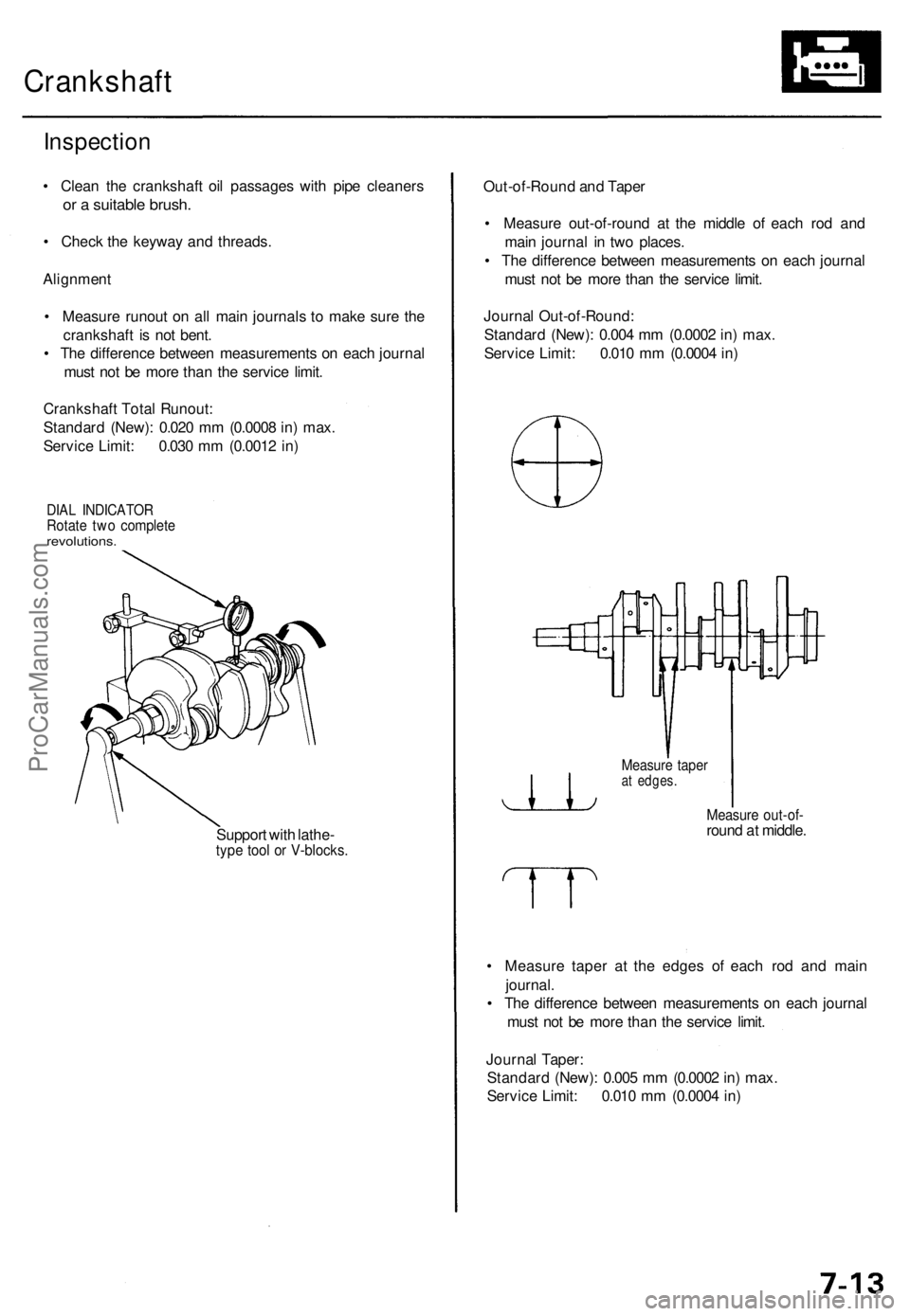

• Clean the crankshaft oil passages with pipe cleaners

or a suitable brush.

• Check the keyway and threads.

Alignment

• Measure runout on all main journals to make sure the

crankshaft is not bent.

• The difference between measurements on each journal

must not be more than the service limit.

Crankshaft Total Runout:

Standard (New): 0.020 mm (0.0008 in) max.

Service Limit: 0.030 mm (0.0012 in)

DIAL INDICATOR

Rotate two complete

revolutions.

Support with lathe-

type tool or V-blocks.

Out-of-Round and Taper

• Measure out-of-round at the middle of each rod and

main journal in two places.

• The difference between measurements on each journal

must not be more than the service limit.

Journal Out-of-Round:

Standard (New): 0.004 mm (0.0002 in) max.

Service Limit: 0.010 mm (0.0004 in)

Measure taper

at edges.

Measure out-of-

round at middle.

• Measure taper at the edges of each rod and main

journal.

• The difference between measurements on each journal

must not be more than the service limit.

Journal Taper:

Standard (New): 0.005 mm (0.0002 in) max.

Service Limit: 0.010 mm (0.0004 in)ProCarManuals.com

Page 454 of 1954

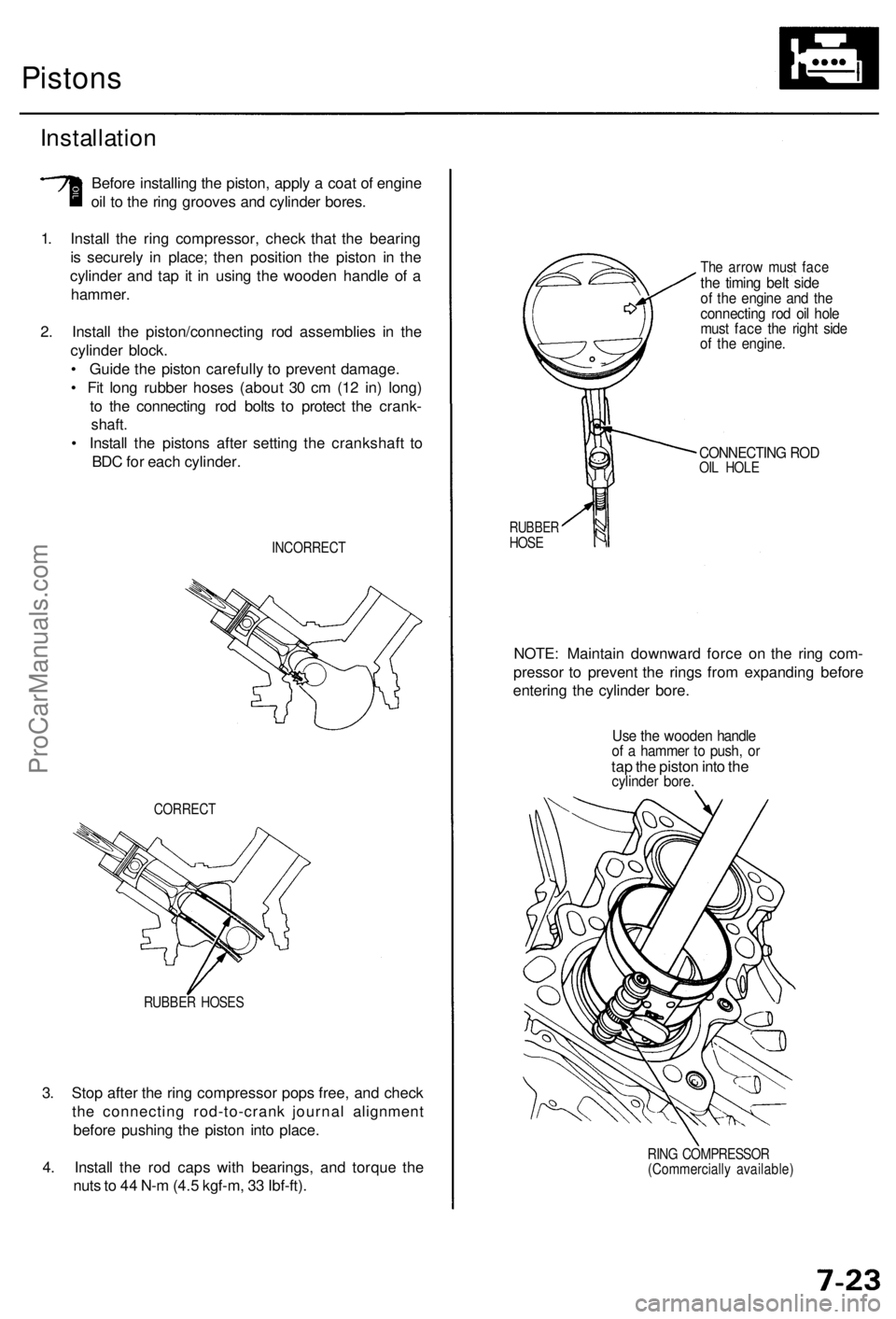

3. Stop after the ring compressor pops free, and check

the connecting rod-to-crank journal alignment

before pushing the piston into place.

4. Install the rod caps with bearings, and torque the

nuts to 44 N-m (4.5 kgf-m, 33 Ibf-ft).

RUBBER HOSES

CORRECT

Pistons

Installation

Before installing the piston, apply a coat of engine

oil to the ring grooves and cylinder bores.

1. Install the ring compressor, check that the bearing

is securely in place; then position the piston in the

cylinder and tap it in using the wooden handle of a

hammer.

2. Install the piston/connecting rod assemblies in the

cylinder block.

• Guide the piston carefully to prevent damage.

• Fit long rubber hoses (about 30 cm (12 in) long)

to the connecting rod bolts to protect the crank-

shaft.

• Install the pistons after setting the crankshaft to

BDC for each cylinder.

INCORRECT

The arrow must face

the timing belt side

of the engine and the

connecting rod oil hole

must face the right side

of the engine.

CONNECTING ROD

OIL HOLE

RUBBER

HOSE

NOTE: Maintain downward force on the ring com-

pressor to prevent the rings from expanding before

entering the cylinder bore.

Use the wooden handle

of a hammer to push, or

tap the piston into the

cylinder bore.

RING COMPRESSOR

(Commercially available)ProCarManuals.com