engine ACURA TL 1995 Service Owners Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 275 of 1771

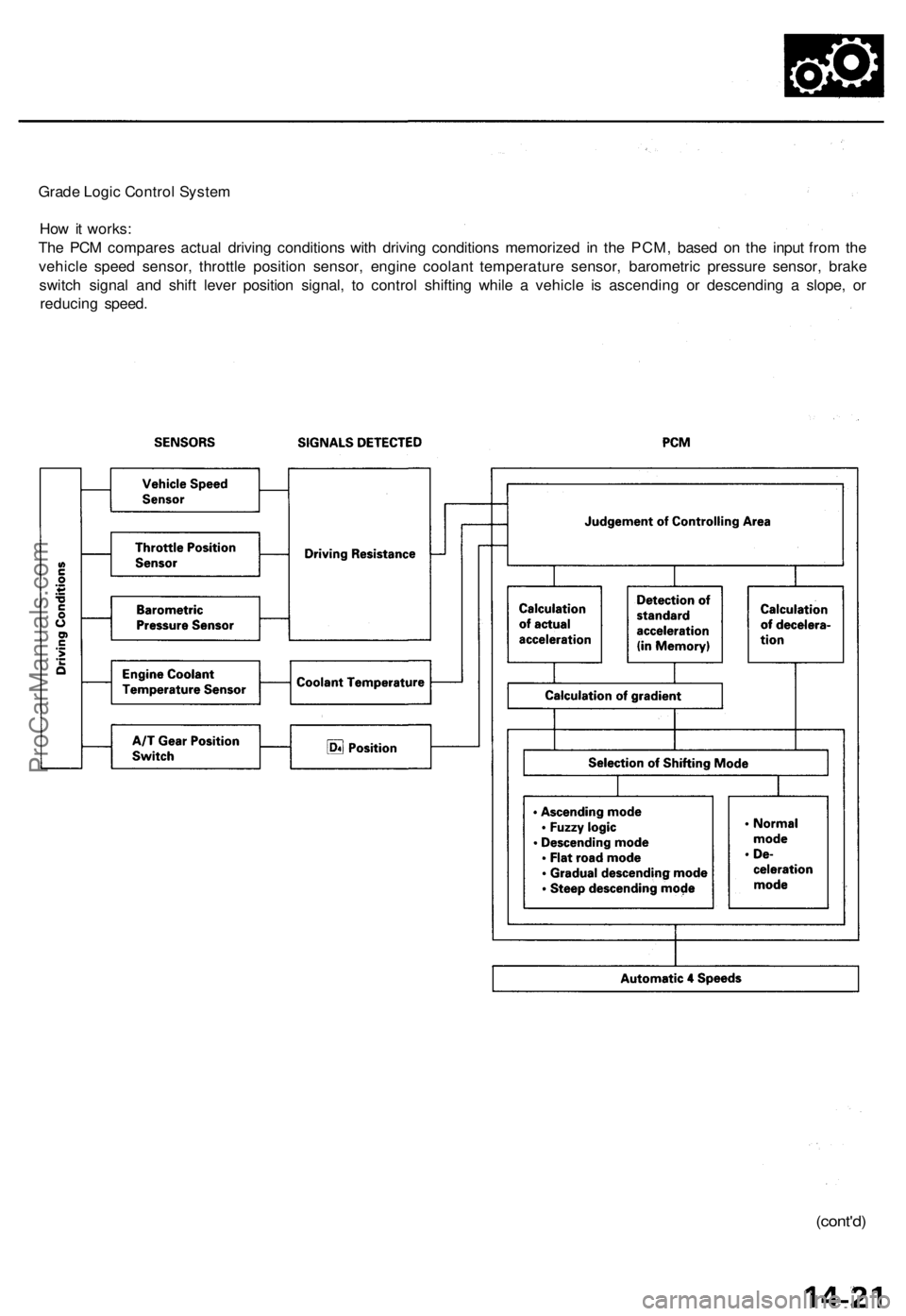

Grade Logic Control System

How it works:

The PCM compares actual driving conditions with driving conditions memorized in the PCM, based on the input from the

vehicle speed sensor, throttle position sensor, engine coolant temperature sensor, barometric pressure sensor, brake

switch signal and shift lever position signal, to control shifting while a vehicle is ascending or descending a slope, or

reducing speed.

(cont'd)ProCarManuals.com

Page 277 of 1771

Description

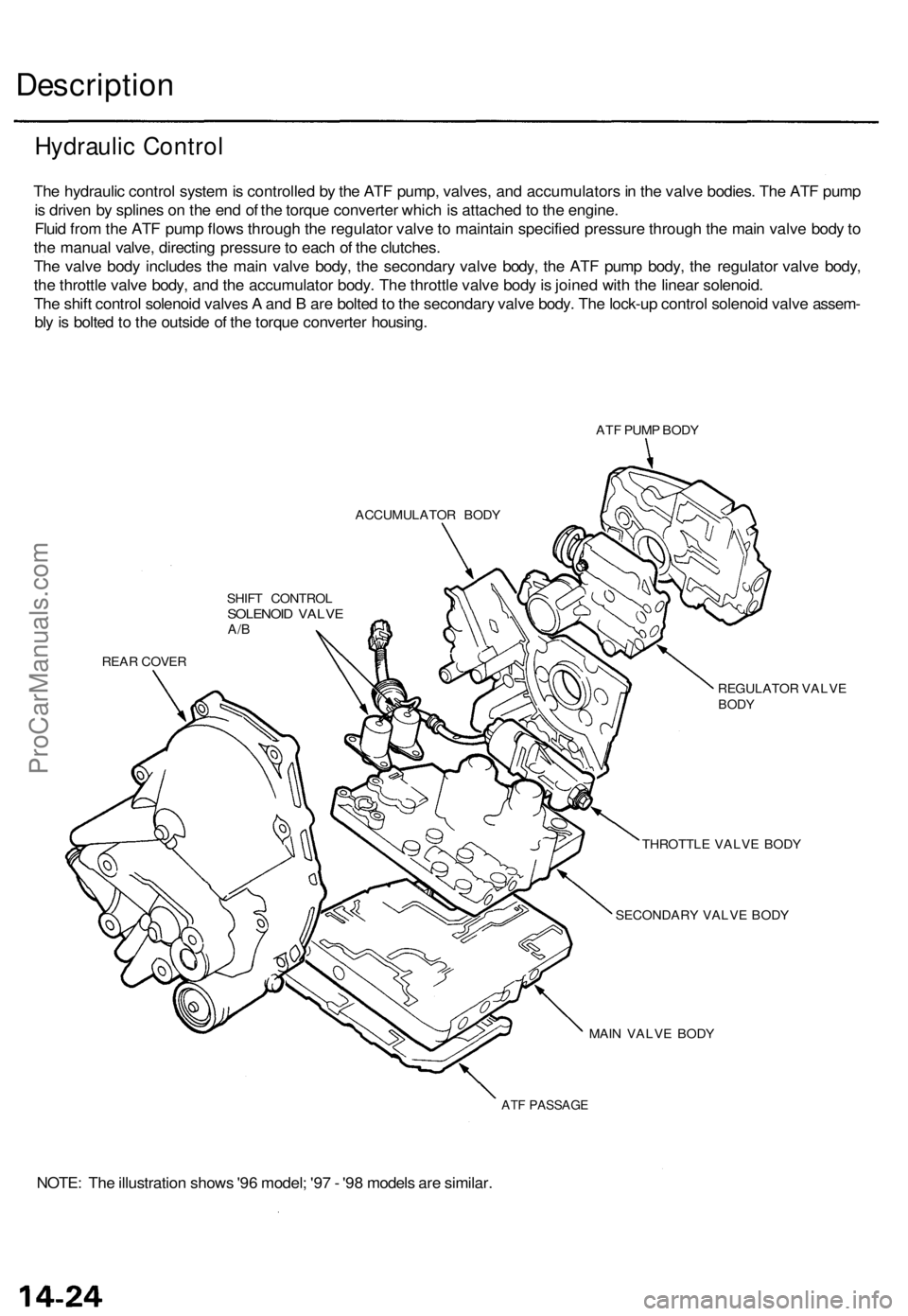

The hydraulic control system is controlled by the ATF pump, valves, and accumulators in the valve bodies. The ATF pump

is driven by splines on the end of the torque converter which is attached to the engine.

Fluid from the ATF pump flows through the regulator valve to maintain specified pressure through the main valve body to

the manual valve, directing pressure to each of the clutches.

The valve body includes the main valve body, the secondary valve body, the ATF pump body, the regulator valve body,

the throttle valve body, and the accumulator body. The throttle valve body is joined with the linear solenoid.

The shift control solenoid valves A and B are bolted to the secondary valve body. The lock-up control solenoid valve assem-

bly is bolted to the outside of the torque converter housing.

ATF PUMP BODY

ACCUMULATOR BODY

SHIFT CONTROL

SOLENOID VALVE

A/B

REAR COVER

REGULATOR VALVE

BODY

THROTTLE VALVE BODY

SECONDARY VALVE BODY

MAIN VALVE BODY

ATF PASSAGE

NOTE: The illustration shows '96 model; '97 - '98 models are similar.

Hydraulic ControlProCarManuals.com

Page 281 of 1771

Description

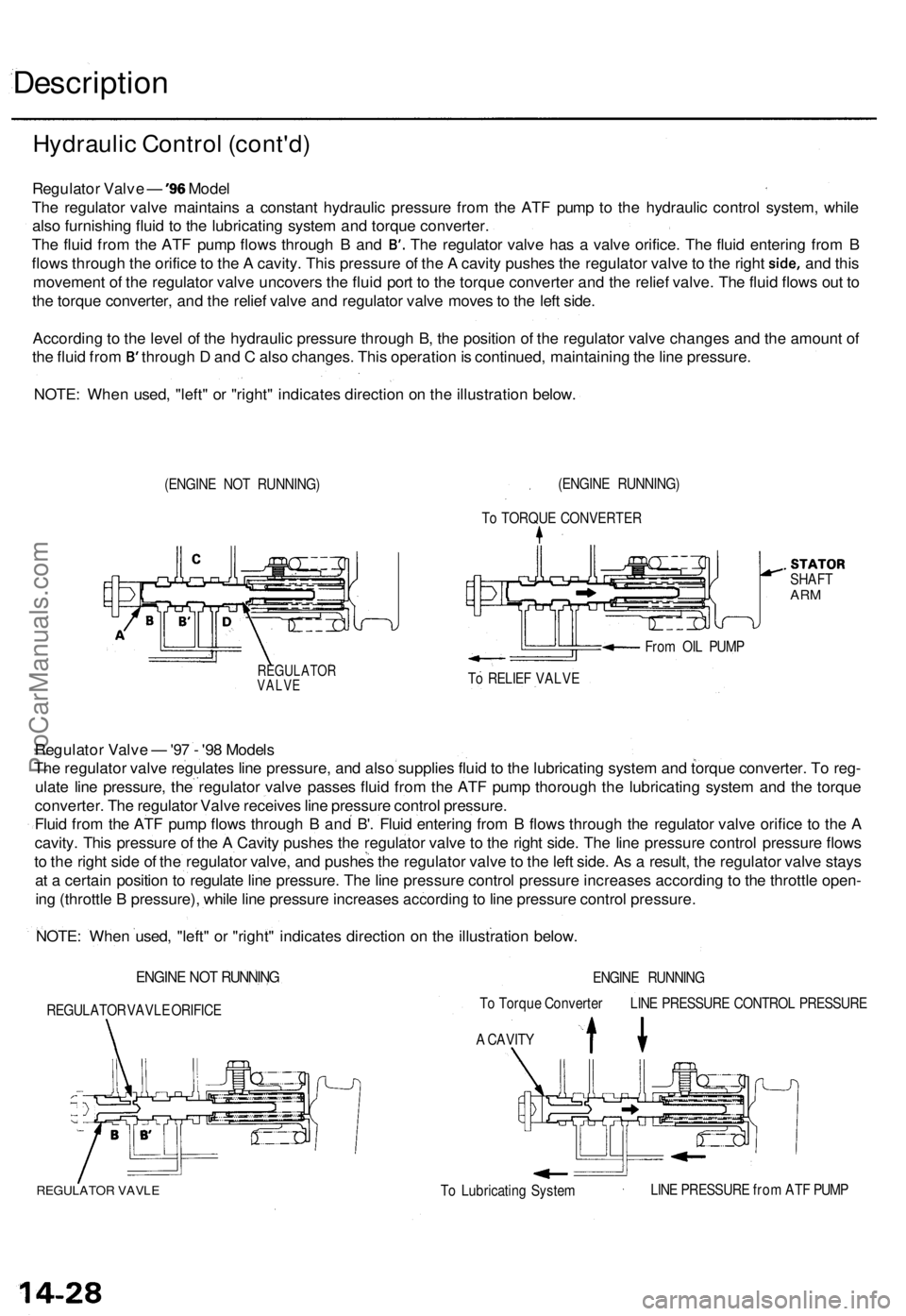

Regulator Valv e — '9 6 Mode l

Th e regulato r valv e maintain s a constan t hydrauli c pressur e fro m th e AT F pum p t o th e hydrauli c contro l system , whil e

als o furnishin g flui d t o th e lubricatin g syste m an d torqu e converter .

The flui d fro m th e AT F pum p flow s throug h B an d B'. Th e regulato r valv e ha s a valv e orifice . Th e flui d enterin g fro m B

flow s throug h th e orific e to th e A cavity . Thi s pressur e o f th e A cavit y pushe s th e regulato r valv e to th e righ t side , and thi s

movemen t o f th e regulato r valv e uncover s th e flui d por t t o th e torqu e converte r an d th e relie f valve . Th e flui d flow s ou t t o

th e torqu e converter , an d th e relie f valv e an d regulato r valv e move s to th e lef t side .

Accordin g to th e leve l o f th e hydrauli c pressur e throug h B , th e positio n o f th e regulato r valv e change s an d th e amoun t o f

th e flui d fro m B' throug h D an d C als o changes . Thi s operatio n is continued , maintainin g th e lin e pressure .

NOTE : Whe n used , "left " o r "right " indicate s directio n o n th e illustratio n below .

(ENGIN E NO T RUNNING )

.STATORSHAFTARM

Fro m OI L PUM P

REGULATO RVALVETo RELIE F VALV E

Regulato r Valv e — '9 7 - '98 Model s

Th e regulato r valv e regulate s lin e pressure , an d als o supplie s flui d to th e lubricatin g syste m an d torqu e converter . T o reg -

ulat e lin e pressure ,

the regulato r valv e passe s flui d fro m th e AT F pum p thoroug h th e lubricatin g syste m an d th e torqu e

converter . Th e regulato r Valv e receive s lin e pressur e contro l pressure .

Flui d fro m th e AT F pum p flow s throug h B an d

B'. Flui d enterin g fro m B flow s throug h th e regulato r valv e orific e t o th e A

cavity . Thi s pressur e o f th e A Cavit y pushe s th e regulato r valv e t o th e righ t side . Th e lin e pressur e contro l pressur e flow s

t o th e righ t sid e o f th e regulato r valve , an d pushe s th e regulato r valv e to th e lef t side . A s a result , th e regulato r valv e stay s

a t a certai n positio n to regulat e lin e pressure . Th e lin e pressur e contro l pressur e increase s accordin g t o th e throttl e open -

in g (throttl e B pressure) , whil e lin e pressur e increase s

accordin g to lin e pressur e contro l pressure .

NOTE : Whe n used , "left " o r "right " indicate s directio n o n th e illustratio n below .

ENGINE NO T RUNNIN G

REGULATO R VAVL E ORIFIC E ENGIN

E RUNNIN G

T o Torqu e Converte r LIN E PRESSUR E CONTRO L PRESSUR E

A CAVIT Y

REGULATO R VAVL ETo Lubricatin g Syste m LIN

E PRESSUR E fro m AT F PUM P

Hydrauli c Contro l (cont'd )

(ENGINE RUNNING )

T o TORQU E CONVERTE R

ProCarManuals.com

Page 284 of 1771

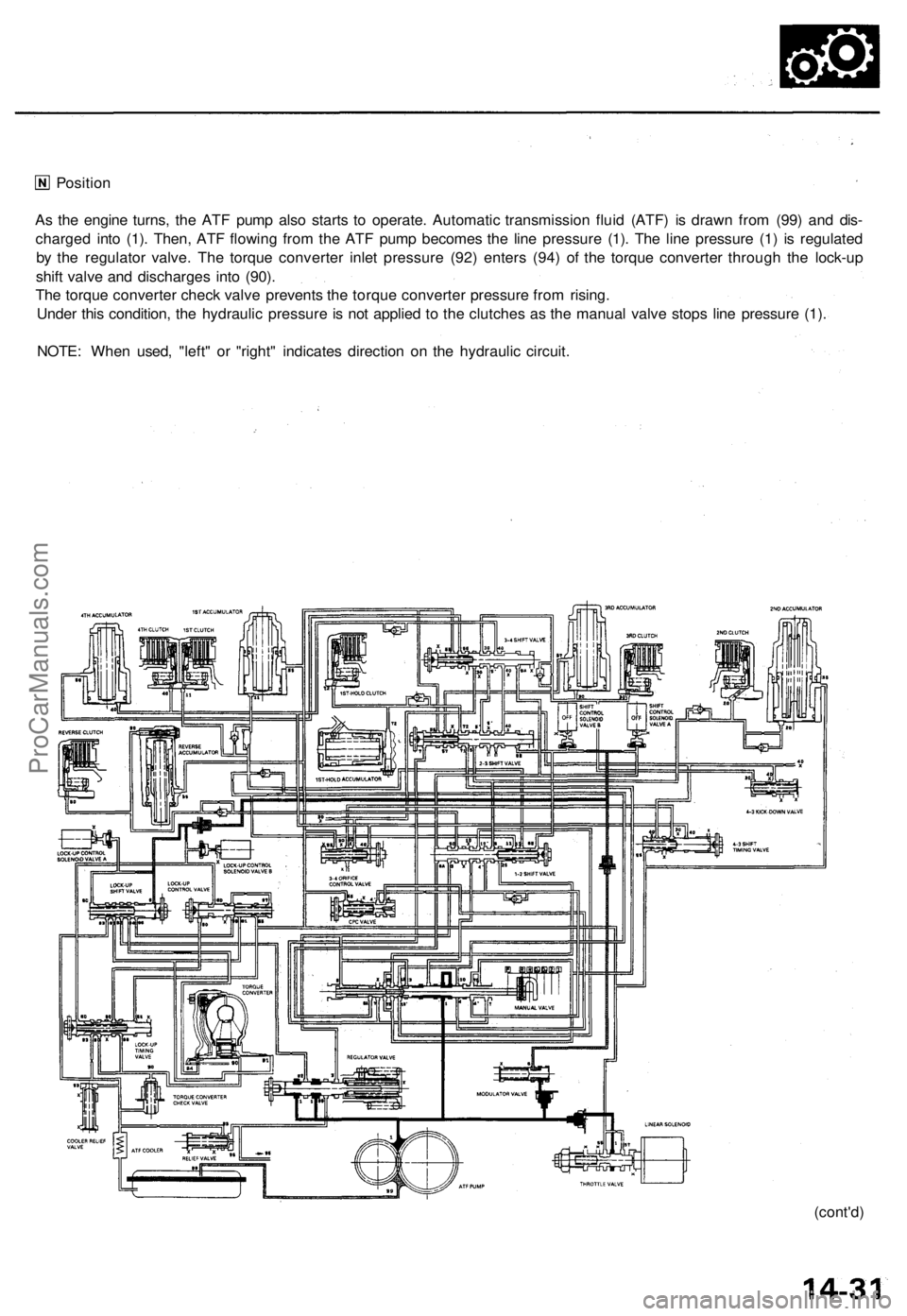

Position

(cont'd)

As the engine turns, the ATF pump also starts to operate. Automatic transmission fluid (ATF) is drawn from (99) and dis-

charged into (1). Then, ATF flowing from the ATF pump becomes the line pressure (1). The line pressure (1) is regulated

by the regulator valve. The torque converter inlet pressure (92) enters (94) of the torque converter through the lock-up

shift valve and discharges into (90).

The torque converter check valve prevents the torque converter pressure from rising.

Under this condition, the hydraulic pressure is not applied to the clutches as the manual valve stops line pressure (1).

NOTE: When used, "left" or "right" indicates direction on the hydraulic circuit.ProCarManuals.com

Page 287 of 1771

Description

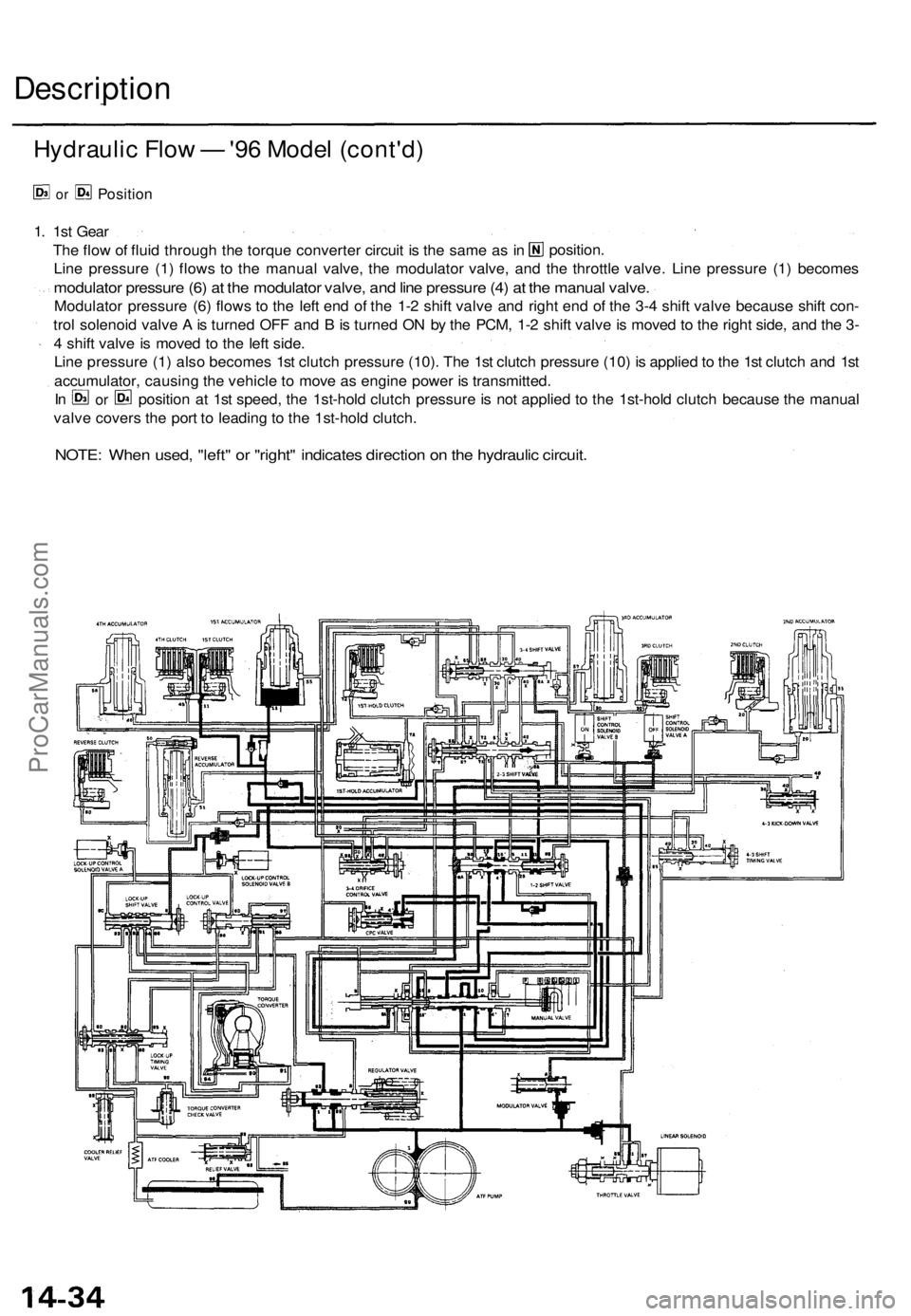

Hydraulic Flow — '96 Model (cont'd)

or

Position

NOTE: When used, "left" or "right" indicates direction on the hydraulic circuit.

1. 1st Gear

Line pressure (1) flows to the manual valve, the modulator valve, and the throttle valve. Line pressure (1) becomes

modulator pressure (6) at the modulator valve, and line pressure (4) at the manual valve.

Modulator pressure (6) flows to the left end of the 1-2 shift valve and right end of the 3-4 shift valve because shift con-

trol solenoid valve A is turned OFF and B is turned ON by the PCM, 1-2 shift valve is moved to the right side, and the 3-

4 shift valve is moved to the left side.

Line pressure (1) also becomes 1st clutch pressure (10). The 1st clutch pressure (10) is applied to the 1st clutch and 1st

accumulator, causing the vehicle to move as engine power is transmitted.

valve covers the port to leading to the 1st-hold clutch.

position.

The flow of fluid through the torque converter circuit is the same as in

In

or

position at 1st speed, the 1st-hold clutch pressure is not applied to the 1st-hold clutch because the manualProCarManuals.com

Page 293 of 1771

Description

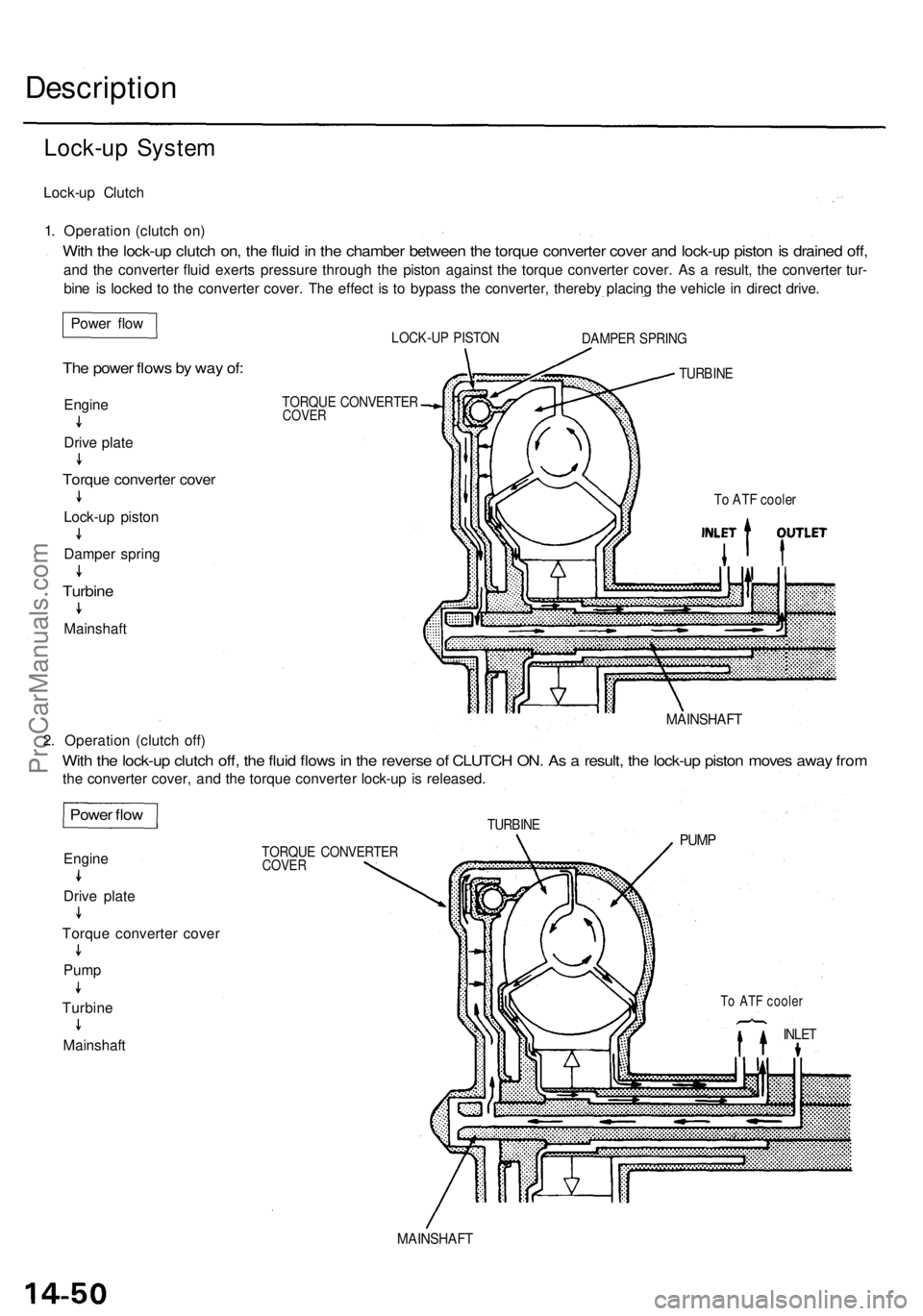

Lock-up System

Lock-up Clutch

1. Operation (clutch on)

With the lock-up clutch on, the fluid in the chamber between the torque converter cover and lock-up piston is drained off,

and the converter fluid exerts pressure through the piston against the torque converter cover. As a result, the converter tur-

bine is locked to the converter cover. The effect is to bypass the converter, thereby placing the vehicle in direct drive.

LOCK-UP PISTON

TORQUE CONVERTER

COVER

TURBINE

DAMPER SPRING

To ATF cooler

TURBINE

PUMP

To ATF cooler

INLET

TORQUE CONVERTER

COVER

2. Operation (clutch off)

With the lock-up clutch off, the fluid flows in the reverse of CLUTCH ON. As a result, the lock-up piston moves away from

the converter cover, and the torque converter lock-up is released.

MAINSHAFT

Power flow

The power flows by way of:

Engine

Drive plate

Torque converter cover

Lock-up piston

Damper spring

Turbine

Mainshaft

Power flow

Engine

Drive plate

Torque converter cover

Pump

Turbine

Mainshaft

MAINSHAFTProCarManuals.com

Page 319 of 1771

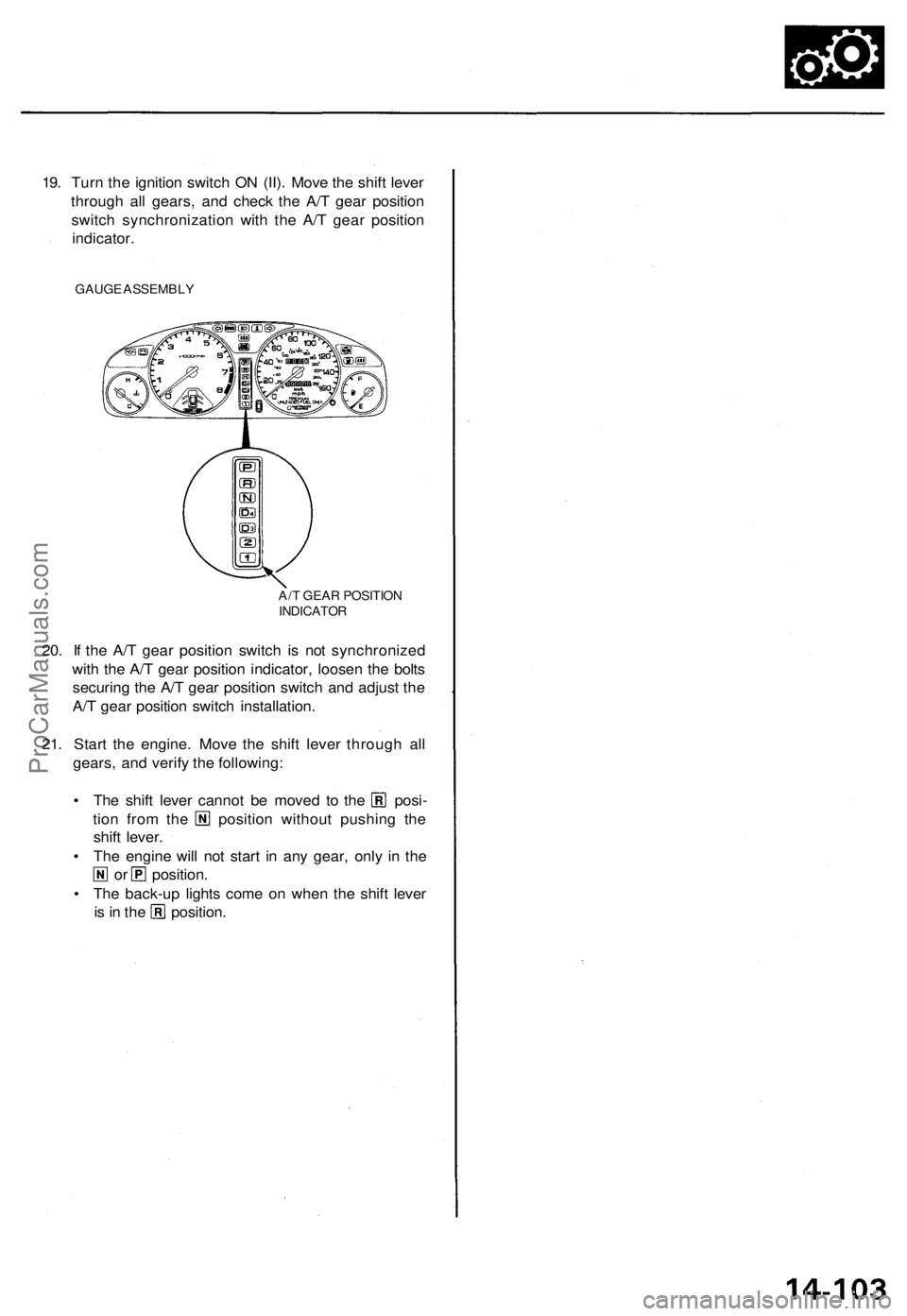

19. Turn the ignition switch ON (II). Move the shift lever

through all gears, and check the A/T gear position

switch synchronization with the A/T gear position

indicator.

GAUGE ASSEMBLY

20. If the A/T gear position switch is not synchronized

with the A/T gear position indicator, loosen the bolts

securing the A/T gear position switch and adjust the

A/T gear position switch installation.

21. Start the engine. Move the shift lever through all

gears, and verify the following:

• The shift lever cannot be moved to the posi-

tion from the position without pushing the

shift lever.

• The engine will not start in any gear, only in the

or position.

• The back-up lights come on when the shift lever

is in the position.

A/T GEAR POSITION

INDICATORProCarManuals.com

Page 320 of 1771

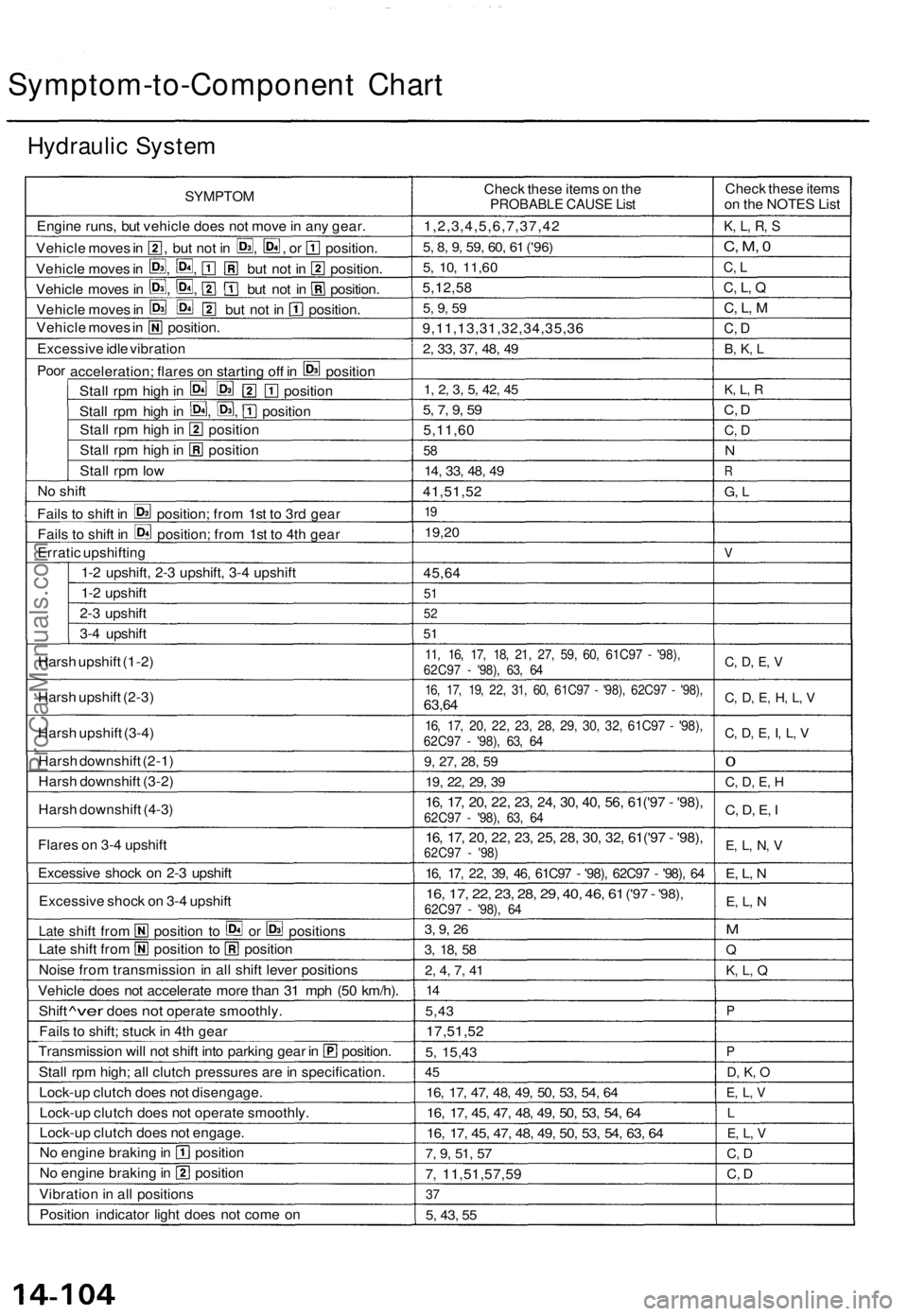

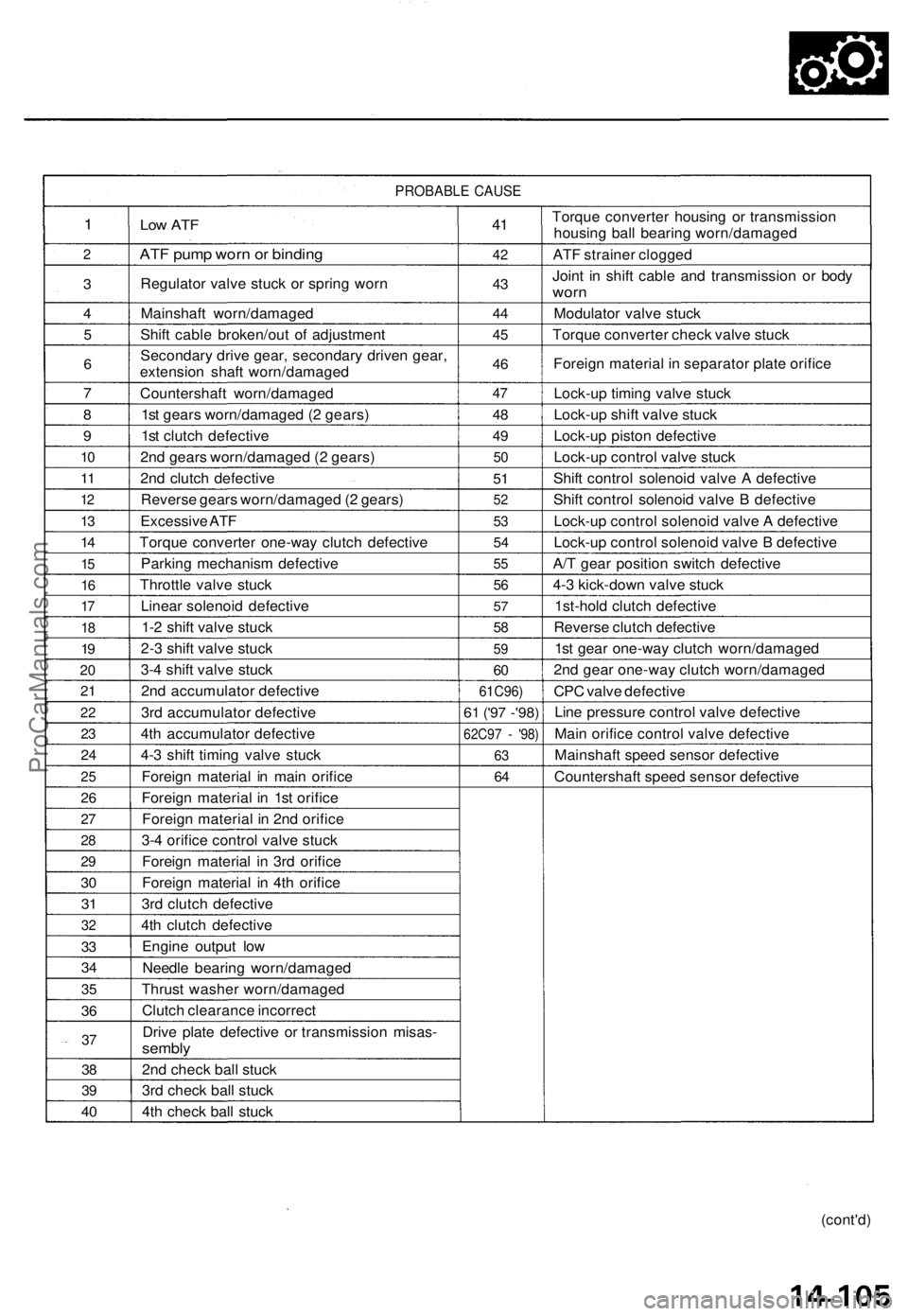

Symptom-to-Component Chart

Hydraulic System

SYMPTOM

Engine runs, but vehicle does not move in any gear.

Vehicle moves in , but not in , , or position.

Vehicle moves in , , but not in position.

Vehicle moves in , , but not in position.

Vehicle moves in but not in position.

Vehicle moves in position.

Excessive idle vibration

Poor

acceleration; flares on starting off in position

Stall rpm high in position

Stall rpm high in , , position

Stall rpm high in position

Stall rpm high in position

Stall rpm low

No shift

Fails to shift in position; from 1st to 3rd gear

Fails to shift in position; from 1st to 4th gear

Erratic upshifting

1-2 upshift, 2-3 upshift, 3-4 upshift

1-2 upshift

2-3 upshift

3-4 upshift

Harsh upshift (1-2)

Harsh upshift (2-3)

Harsh upshift (3-4)

Harsh downshift (2-1)

Harsh downshift (3-2)

Harsh downshift (4-3)

Flares on 3-4 upshift

Excessive shock on 2-3 upshift

Excessive shock on 3-4 upshift

Late

shift from position to or positions

Late shift from position to position

Noise from transmission in all shift lever positions

Vehicle does not accelerate more than 31 mph (50 km/h).

Shift

^ver

does

not

operate smoothly.

Fails to shift; stuck in 4th gear

Transmission will not shift into parking gear in position.

Stall

rpm high; all clutch pressures are in specification.

Lock-up clutch does not disengage.

Lock-up clutch does not operate smoothly.

Lock-up clutch does not engage.

No engine braking in position

No engine braking in position

Vibration in all positions

Position indicator light does not come on

Check these items on the

PROBABLE CAUSE List

1,2,3,4,5,6,7,37,42

5, 8, 9, 59, 60, 61

('96)

5, 10,

11,60

5,12,58

5, 9, 59

9,11,13,31,32,34,35,36

2, 33, 37, 48, 49

1, 2, 3, 5, 42, 45

5, 7, 9, 59

5,11,60

58

14, 33, 48, 49

41,51,52

19

19,20

45,64

51

52

51

11, 16, 17, 18, 21, 27, 59, 60, 61C97 - '98),

62C97 - '98), 63, 64

16, 17, 19, 22, 31, 60, 61C97 - '98), 62C97 - '98),

63,64

16, 17, 20, 22, 23, 28, 29, 30, 32, 61C97 - '98),

62C97 - '98), 63, 64

9, 27, 28, 59

19, 22, 29, 39

16, 17, 20, 22, 23, 24, 30, 40, 56, 61('97 - '98),

62C97 - '98), 63, 64

16, 17, 20, 22, 23, 25, 28, 30, 32, 61('97 - '98),

62C97 - '98)

16, 17, 22, 39, 46, 61C97 - '98), 62C97 - '98), 64

16, 17, 22, 23, 28, 29, 40, 46, 61

('97

-

'98),

62C97 - '98), 64

3, 9, 26

3, 18, 58

2, 4, 7, 41

14

5,43

17,51,52

5,

15,43

45

16, 17, 47, 48, 49, 50, 53, 54, 64

16, 17, 45, 47, 48, 49, 50, 53, 54, 64

16, 17, 45, 47, 48, 49, 50, 53, 54, 63, 64

7, 9, 51, 57

7, 11,51,57,59

37

5, 43, 55

Check these items

on the NOTES List

K, L, R, S

C, M, 0

C, L

C, L, Q

C, L, M

C, D

B, K, L

K, L, R

C, D

C, D

N

R

G, L

V

C, D, E, V

C, D, E, H, L, V

C, D, E, I, L, V

0

C, D, E, H

C, D, E, I

E, L, N, V

E, L, N

E, L, N

M

Q

K, L, Q

P

P

D, K, O

E, L, V

L

E, L, V

C, D

C, DProCarManuals.com

Page 321 of 1771

PROBABLE CAUSE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Low ATF

ATF pump worn or binding

Regulator valve stuck or spring worn

Mainshaft worn/damaged

Shift cable broken/out of adjustment

Secondary drive gear, secondary driven gear,

extension shaft worn/damaged

Countershaft worn/damaged

1st gears worn/damaged (2 gears)

1st clutch defective

2nd gears worn/damaged (2 gears)

2nd clutch defective

Reverse gears worn/damaged (2 gears)

Excessive ATF

Torque converter one-way clutch defective

Parking mechanism defective

Throttle valve stuck

Linear solenoid defective

1-2 shift valve stuck

2-3 shift valve stuck

3-4 shift valve stuck

2nd accumulator defective

3rd accumulator defective

4th accumulator defective

4-3 shift timing valve stuck

Foreign material in main orifice

Foreign material in 1st orifice

Foreign material in 2nd orifice

3-4 orifice control valve stuck

Foreign material in 3rd orifice

Foreign material in 4th orifice

3rd clutch defective

4th clutch defective

Engine output low

Needle bearing worn/damaged

Thrust washer worn/damaged

Clutch clearance incorrect

Drive plate defective or transmission misas-

sembly

2nd check ball stuck

3rd check ball stuck

4th check ball stuck

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61C96)

61

('97 -'98)

62C97 - '98)

63

64

Torque converter housing or transmission

housing ball bearing worn/damaged

ATF strainer clogged

Joint in shift cable and transmission or body

worn

Modulator valve stuck

Torque converter check valve stuck

Foreign material in separator plate orifice

Lock-up timing valve stuck

Lock-up shift valve stuck

Lock-up piston defective

Lock-up control valve stuck

Shift control solenoid valve A defective

Shift control solenoid valve B defective

Lock-up control solenoid valve A defective

Lock-up control solenoid valve B defective

A/T gear position switch defective

4-3 kick-down valve stuck

1st-hold clutch defective

Reverse clutch defective

1st gear one-way clutch worn/damaged

2nd gear one-way clutch worn/damaged

CPC valve defective

Line pressure control valve defective

Main orifice control valve defective

Mainshaft speed sensor defective

Countershaft speed sensor defective

(cont'd)ProCarManuals.com

Page 323 of 1771

Set idl e rp m in gea r t o specifie d idl e speed . I f stil l n o good , adjus t moto r mount s a s outline d in engine

sectio n o f servic e manual .

I f th e larg e clutc h pisto n 0-rin g i s broken , inspec t th e pisto n groov e fo r roug h machining .

I f th e clutc h pac k is seize d o r i s excessivel y worn , inspec t th e othe r clutche s fo r wea r an d chec k th e orific e

contro l valve s an d throttl e valv e fo r fre e movement .

I f throttl e valv e is stuck , inspec t th e clutche s fo r wear .

I f th e 1- 2 shif t valv e is stuc k closed , th e transmissio n wil l no t upshift . I f stuc k open , th e transmissio n ha s

n o 1s t gear .

I f th e 4- 3 shif t timin g valv e is stuck , inspec t th e 2n d an d 3r d clutc h pack s fo r wear .

I f th e 3- 4 orific e contro l valv e is stuck , inspec t th e 3r d an d 4t h clutc h pack s fo r wear .

If th e CP C valv e is stuc k closed , th e transmissio n wil l no t shif t ou t o f 1s t gear .

Imprope r alignmen t o f AT F pum p bod y an d torqu e converte r housin g ma y caus e AT F pum p seizure . Th e

symptom s ar e mostl y a n rpm-relate d ticking nois e o r a hig h pitche d squeak .

I f th e AT F straine r i s clogge d wit h particle s o f stee l o r aluminum , inspec t th e AT F pump . I f th e pum p is O K

an d n o caus e fo r th e contaminatio n is found , replac e th e torqu e converter .

If th e 1s t clutc h feedpip e guid e in th e rea r cove r i s score d b y th e mainshaft , inspect th e bal l bearin g fo r

excessiv e movemen t i n th e transmissio n housing . I f OK , replac e th e rea r cove r a s it i s dented . Th e O-rin g

unde r th e guid e is probabl y worn .

Replac e the mainshaf t if th e bushing s for the Islan d 2nd feedpip e are loos e or damaged . If th e 1s t feedpip e

i s damage d o r ou t o f round , replac e it . I f th e 2n d feedpip e is damage d o r ou t o f round , replac e th e rea r cover .

A wor n o r damage d one-wa y (sprag ) clutc h is mostl y a resul t o f shiftin g th e transmissio n in S o r S posi -

tion whil e the wheel s rotat e in reverse , suc h as rockin g the vehicl e in snow.__________________ _

Inspect th e fram e fo r collisio n damage .

Inspec t th e revers e clutc h fo r damag e o r wear .

Inspec t botto m o f 3r d clutc h fo r swir l marks .

Replac e revers e clutc h i f wor n o r damaged . I f transmissio n make s clicking , grindin g o r whirrin g noise , als o

replac e mainshaf t revers e gear , revers e idle r gear , an d countershaf t revers e gear .

I f botto m of 3r d clutc h ha s swir l marks , an d transmissio n make s gea r noise , replac e th e countershaft .

B e ver y carefu l no t t o damag e th e torqu e converte r housin g whe n replacin g th e mai n bal l bearing . Yo u

ma y als o damag e th e AT F pum p whe n yo u torqu e dow n th e AT F pum p body . Thi s wil l resul t i s AT F pum p

seizur e if no t detected . Us e th e prope r tools .

Instal l th e mai n sea l flus h wit h th e torqu e converte r housing . I f yo u pus h it int o th e torqu e converte r

housin g unti l i t bottom s out , i t wil l bloc k th e flui d retur n passag e an d resul t i n damage .

Hars h downshift s whe n coastin g to a sto p wit h zer o throttl e ma y b e cause d b y th e linea r solenoi d no t working .

Adjustin g th e throttl e valv e body , throttl e valve , an d linea r solenoi d is essentia l fo r prope r operatio n o f th e

transmission . No t onl y doe s it affec t th e shif t qualit y i f misadjusted , bu t als o th e lock-u p clutc h operation .

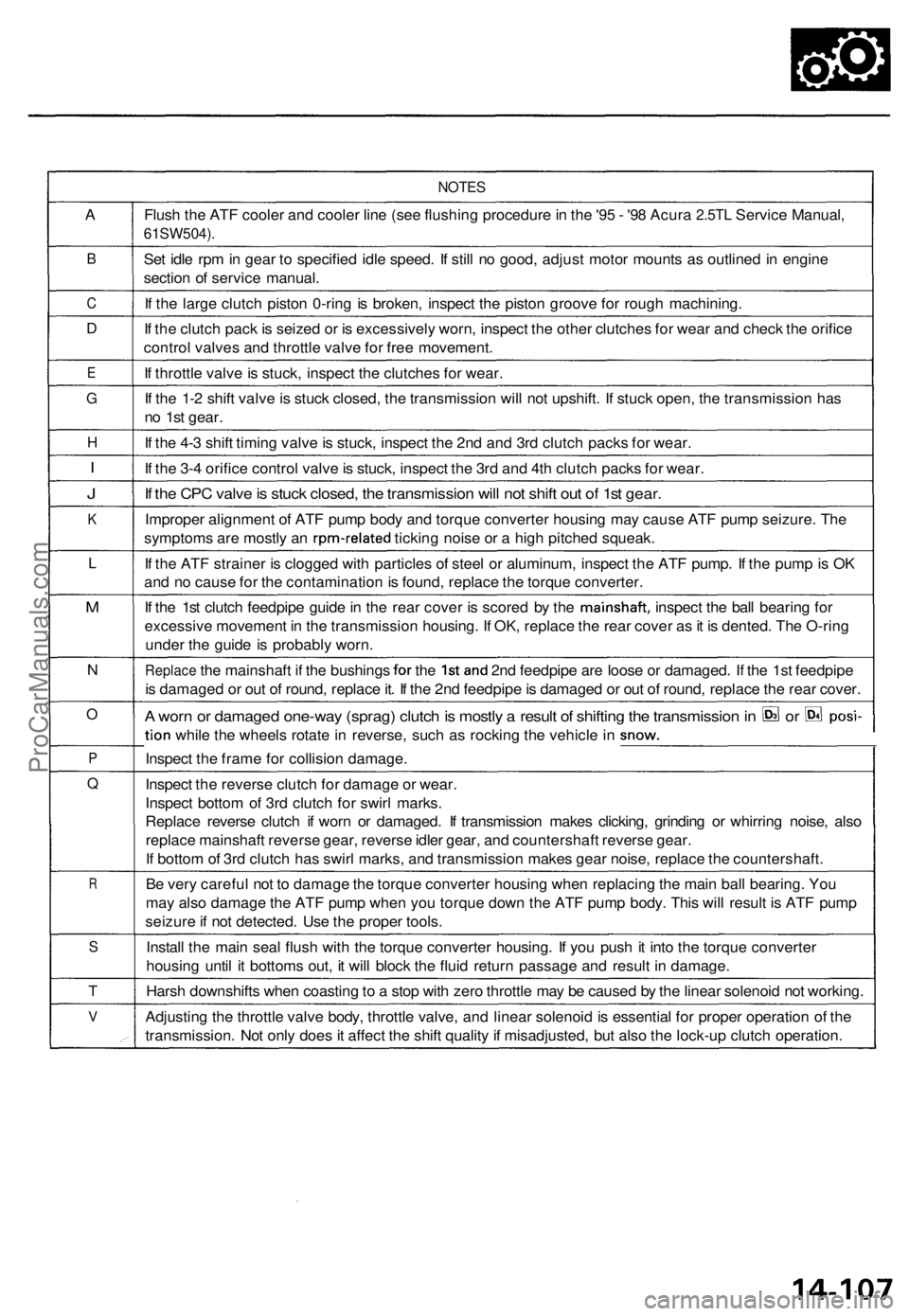

A

B

C

D

E

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

V

Flush th e AT F coole r an d coole r lin e (se e flushin g procedur e in th e '95 - '98 Acur a 2.5TL Servic e Manual ,

61SW504) .

NOTES

ProCarManuals.com