engine ACURA TL 1995 Service Workshop Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 130 of 1771

Oil Pressur e Engin

e Oi l Temperatur e Switc h

Testin gTestin g

If th e oi l pressur e warnin g ligh t stay s o n wit h th e engin e

running , chec k th e engin e oi l level . I f th e oi l leve l i s cor -

rect :

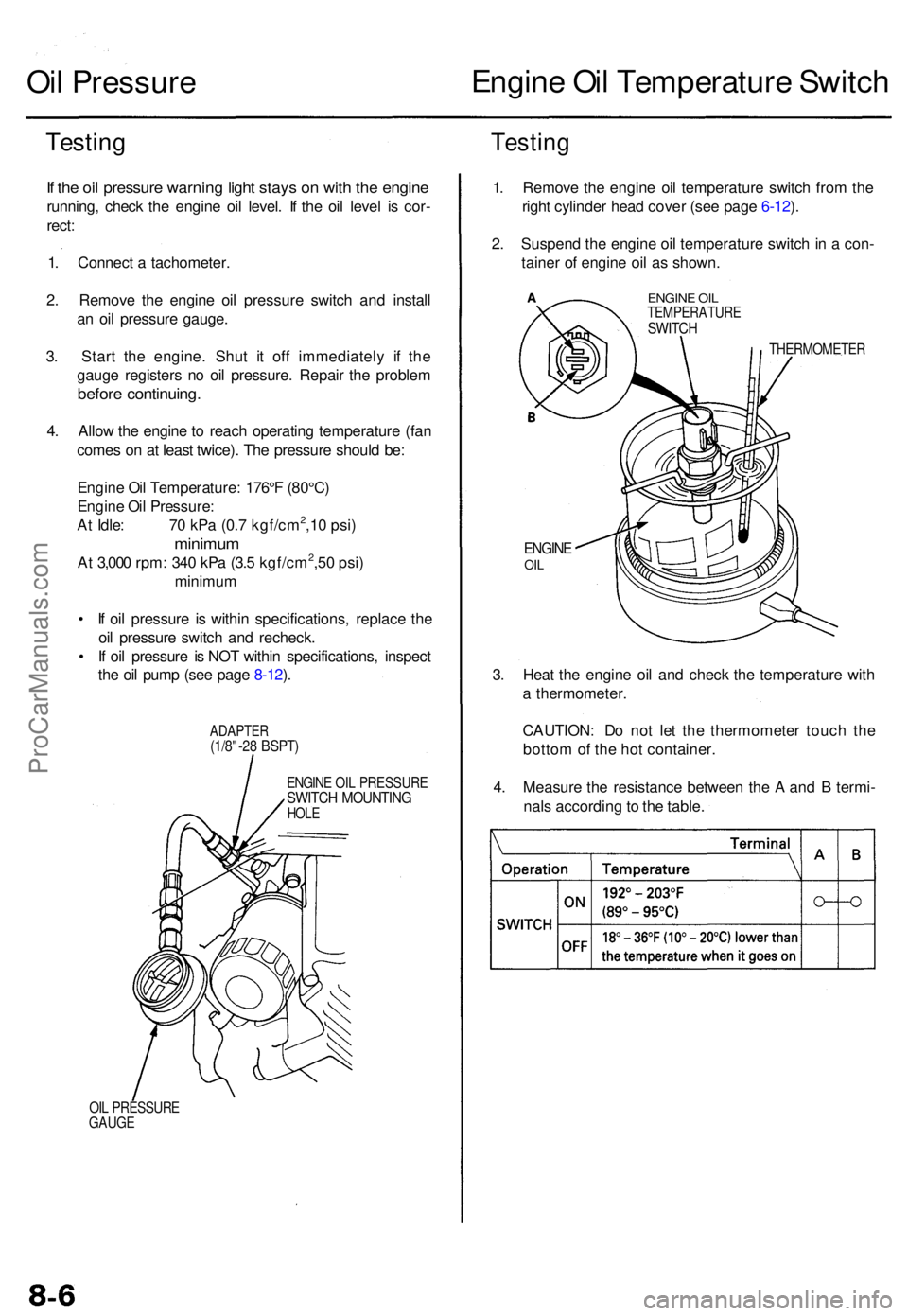

1 . Connec t a tachometer .

2 . Remov e th e engin e oi l pressur e switc h an d instal l

a n oi l pressur e gauge .

3 . Star t th e engine . Shu t i t of f immediatel y i f th e

gaug e register s n o oi l pressure . Repai r th e proble m

before continuing .

4. Allo w th e engin e to reac h operatin g temperatur e (fa n

come s o n a t leas t twice) . Th e pressur e shoul d be :

Engin e Oi l Temperature : 176° F (80°C )

Engin e Oi l Pressure :

A t Idle : 7 0 kP a (0. 7 kgf/cm

2,1 0 psi )

minimu m

At 3,00 0 rpm : 34 0 kP a (3. 5 kgf/cm2,5 0 psi )

minimu m

• I f oi l pressur e i s withi n specifications , replac e th e

oi l pressur e switc h an d recheck .

• I f oi l pressur e i s NO T withi n specifications , inspec t

th e oi l pum p (se e pag e 8-12 ).

ADAPTE R(1/8"-28 BSPT )

ENGIN E OI L PRESSUR ESWITCH MOUNTIN GHOLE

OIL PRESSUR E

GAUG E

1. Remov e th e engin e oi l temperatur e switc h fro m th e

righ t cylinde r hea d cove r (se e pag e 6-12 ).

2 . Suspen d th e engin e oi l temperatur e switc h in a con -

taine r o f engin e oi l a s shown .

ENGINE OI LTEMPERATUR ESWITCH

THERMOMETE R

ENGINEOIL

3. Hea t th e engin e oi l an d chec k th e temperatur e wit h

a thermometer .

CAUTION : D o no t le t th e thermomete r touc h th e

botto m of th e ho t container .

4 . Measur e th e resistanc e betwee n th e A an d B termi -

nal s accordin g to th e table .

ProCarManuals.com

Page 141 of 1771

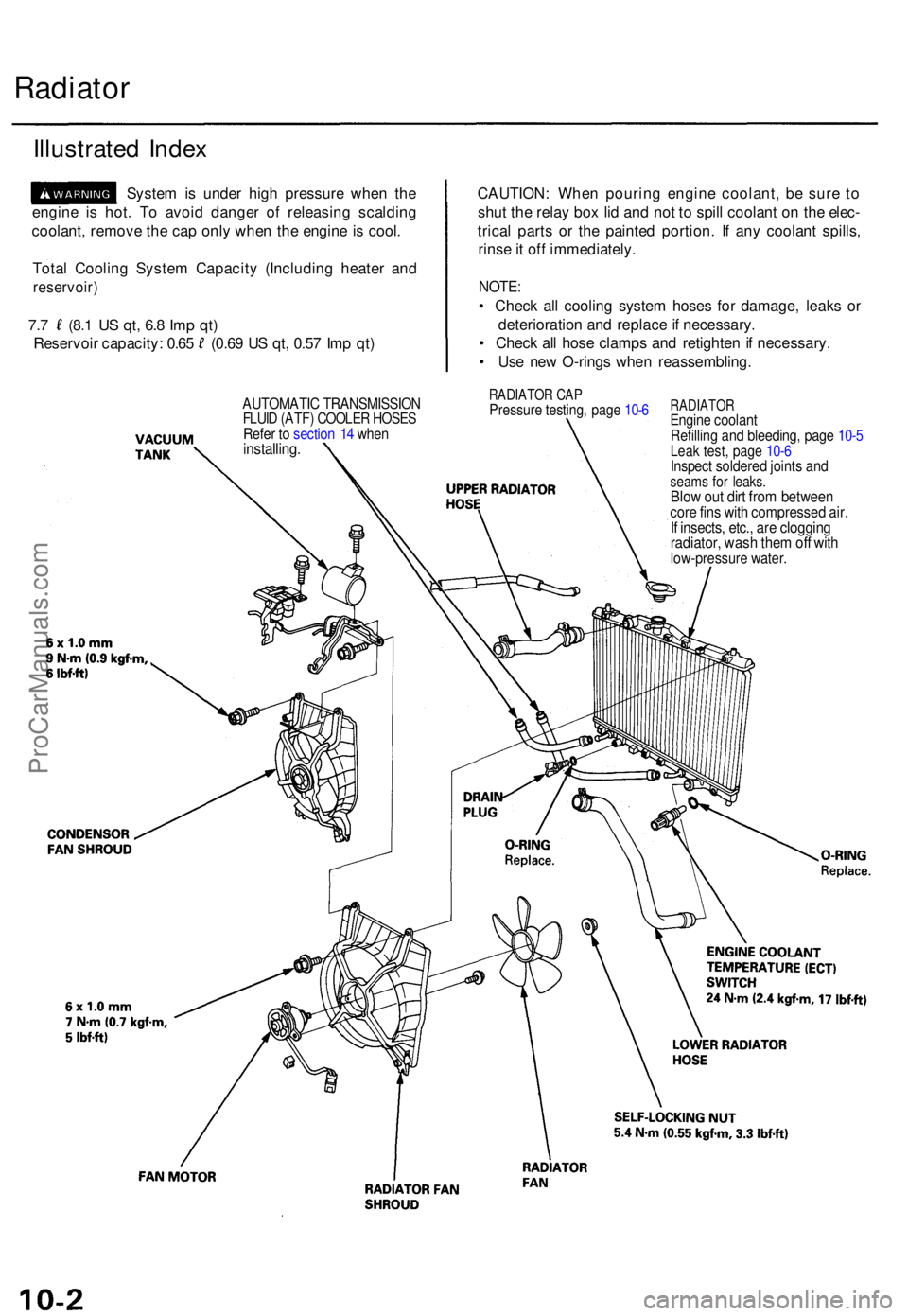

Radiator

Illustrate d Inde x

Syste m is unde r hig h pressur e whe n th e

engin e i s hot . T o avoi d dange r o f releasin g scaldin g

coolant , remov e th e ca p onl y whe n th e engin e is cool .

Tota l Coolin g Syste m Capacit y (Includin g heate r an d

reservoir )

7.7 (8. 1 US qt , 6. 8 Im p qt )

Reservoi r capacity : 0.6 5 (0.6 9 U S qt , 0.5 7 Im p qt ) CAUTION

: Whe n pourin g engin e coolant , b e sur e t o

shu t th e rela y bo x li d an d no t t o spil l coolan t o n th e elec -

trica l part s o r th e painte d portion . I f an y coolan t spills ,

rins e it of f immediately .

NOTE:

• Chec k al l coolin g syste m hose s fo r damage , leak s o r

deterioratio n an d replac e if necessary .

• Chec k al l hos e clamp s an d retighte n if necessary .

• Us e ne w O-ring s whe n reassembling .

RADIATOR CA PPressur e testing , pag e 10- 6RADIATO REngine coolan t

Refillin g an d bleeding , pag e 10- 5

Leak test , pag e 10- 6Inspec t soldere d joint s an dseam s fo r leaks .Blow ou t dir t fro m betwee ncore fin s wit h compresse d air .If insects , etc. , ar e cloggin gradiator , was h the m of f wit hlow-pressur e water .

AUTOMATI C TRANSMISSIO NFLUID (ATF ) COOLE R HOSE SRefer t o sectio n 1 4 whe ninstalling .

ProCarManuals.com

Page 142 of 1771

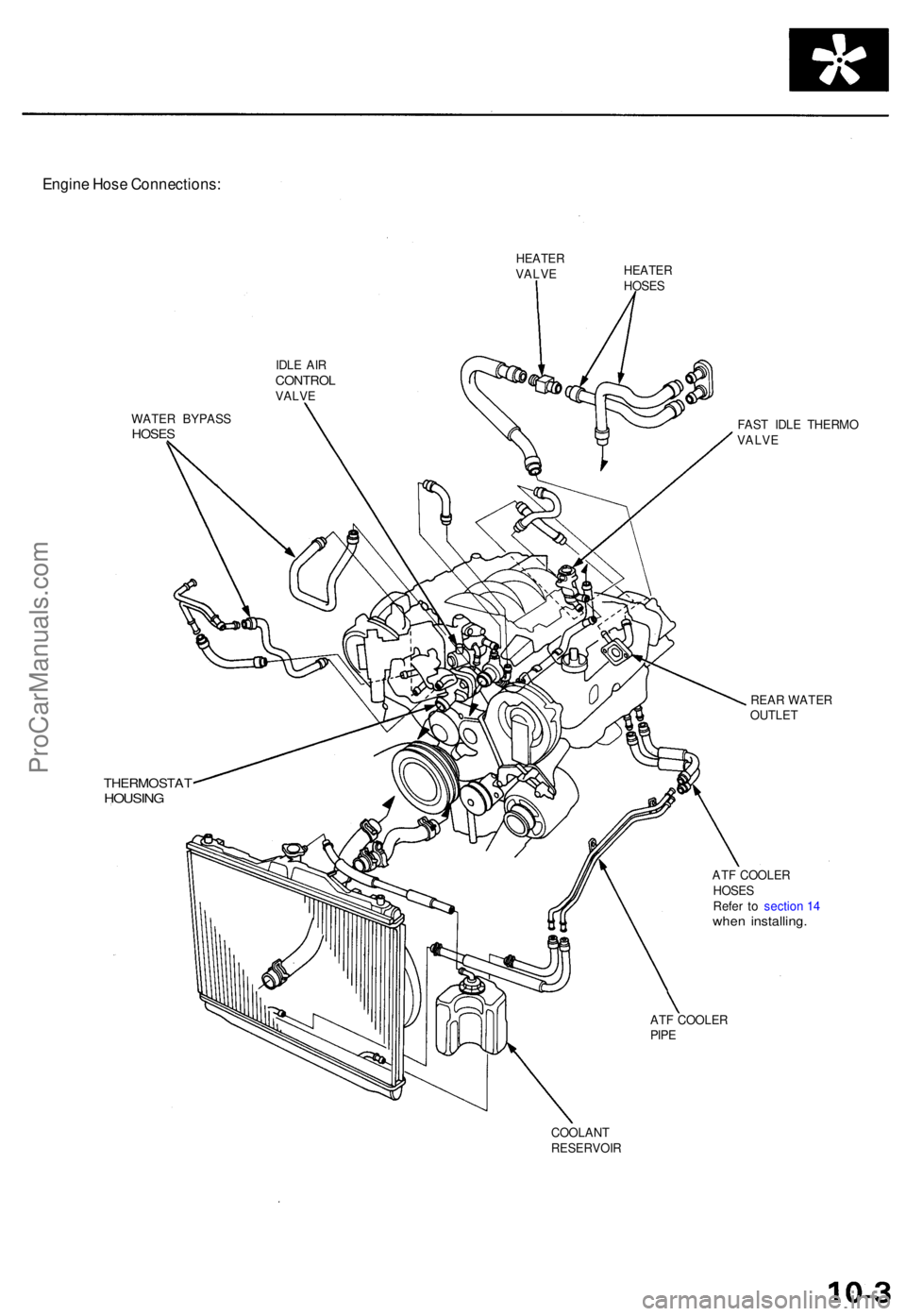

Engine Hos e Connections :

HEATERVALVEHEATE RHOSES

IDL E AI R

CONTRO LVALVE

WATE R BYPAS S

HOSES

THERMOSTA THOUSING

FAST IDL E THERM O

VALV E

REA R WATE R

OUTLE T

AT F COOLE R

HOSE S

Refe r t o sectio n 1 4

whe n installing .

ATF COOLE R

PIP E

COOLAN T

RESERVOI R

ProCarManuals.com

Page 144 of 1771

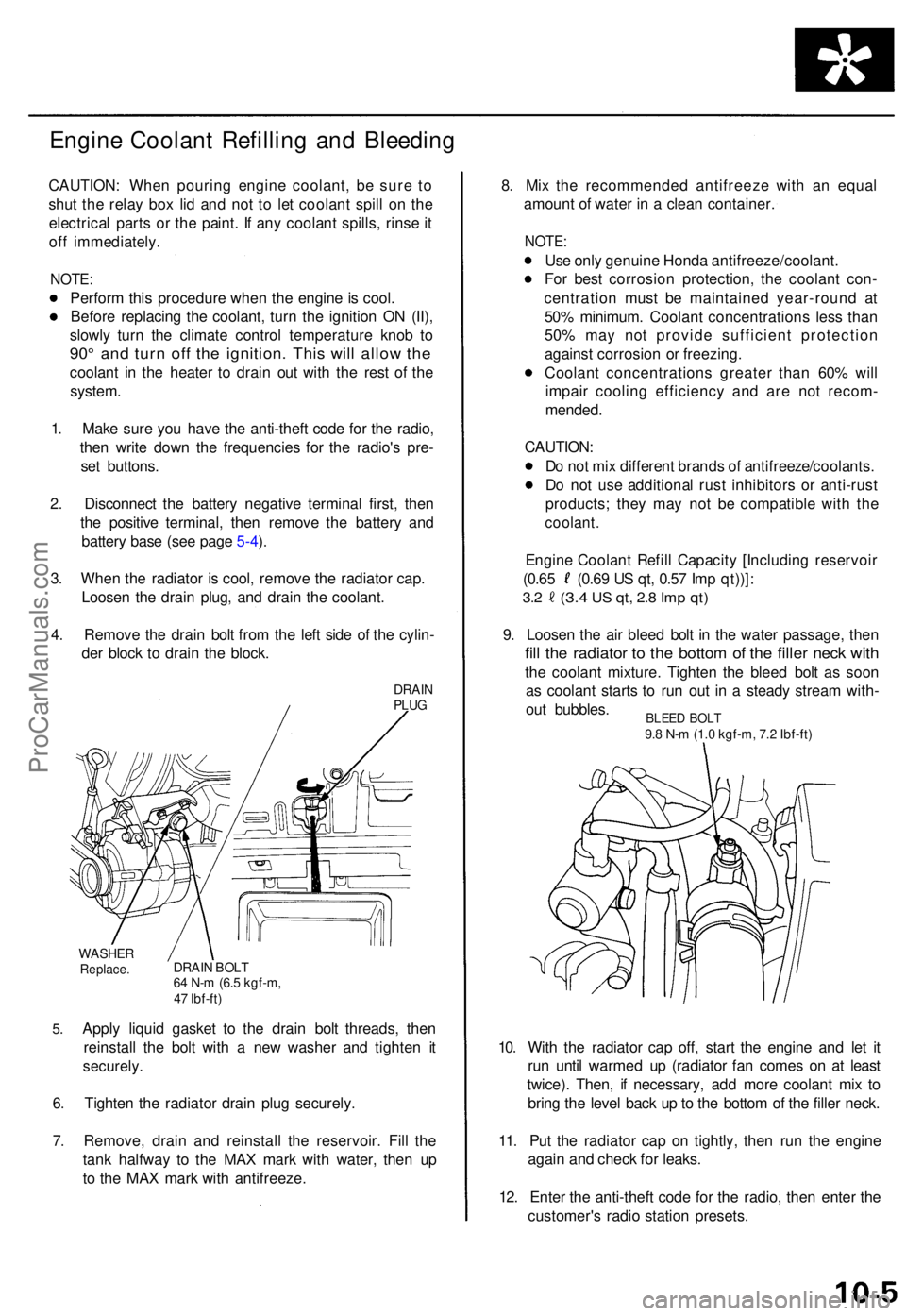

Engine Coolan t Refillin g an d Bleedin g

CAUTION : Whe n pourin g engin e coolant , b e sur e t o

shu t th e rela y bo x li d an d no t t o le t coolan t spil l o n th e

electrica l part s o r th e paint . I f an y coolan t spills , rins e it

of f immediately .

NOTE:

Perfor m thi s procedur e whe n th e engin e is cool .

Befor e replacin g th e coolant , tur n th e ignitio n O N (II) ,

slowl y tur n th e climat e contro l temperatur e kno b t o

90 ° an d tur n of f th e ignition . Thi s wil l allo w th e

coolan t i n th e heate r t o drai n ou t wit h th e res t o f th e

system .

1 . Mak e sur e yo u hav e th e anti-thef t cod e fo r th e radio ,

the n writ e dow n th e frequencie s fo r th e radio' s pre -

se t buttons .

2 . Disconnec t th e batter y negativ e termina l first , the n

th e positiv e terminal , the n remov e th e batter y an d

batter y bas e (se e pag e 5-4 ).

3 . Whe n th e radiato r i s cool , remov e th e radiato r cap .

Loose n th e drai n plug , an d drai n th e coolant .

4 . Remov e th e drai n bol t fro m th e lef t sid e o f th e cylin -

de r bloc k t o drai n th e block .

DRAINPLUG

5.

WASHE RReplace .DRAIN BOL T64 N- m (6. 5 kgf-m ,

4 7 Ibf-ft )

Apply liqui d gaske t t o th e drai n bol t threads , the n

reinstal l th e bol t wit h a ne w washe r an d tighte n i t

securely .

6. Tighte n th e radiato r drai n plu g securely .

7 . Remove , drai n an d reinstal l th e reservoir . Fil l th e

tan k halfwa y t o th e MA X mar k wit h water , the n u p

t o th e MA X mar k wit h antifreeze . 8

. Mi x th e recommende d antifreez e wit h a n equa l

amoun t o f wate r i n a clea n container .

NOTE:

Use onl y genuin e Hond a antifreeze/coolant .

Fo r bes t corrosio n protection , th e coolan t con -

centratio n mus t b e maintaine d year-roun d a t

50 % minimum . Coolan t concentration s les s tha n

50 % ma y no t provid e sufficien t protectio n

agains t corrosio n o r freezing .

Coolan t concentration s greate r tha n 60 % wil l

impai r coolin g efficienc y an d ar e no t recom -

mended .

CAUTION :

D o no t mi x differen t brand s o f antifreeze/coolants .

D o no t us e additiona l rus t inhibitor s o r anti-rus t

products ; the y ma y no t b e compatibl e wit h th e

coolant .

Engine Coolan t Refil l Capacit y [Includin g reservoi r

(0.65 (0.6 9 U S qt , 0.5 7 Im p qt))] :

3.2 (3. 4 US qt , 2. 8 Im p qt )

9. Loose n th e ai r blee d bol t i n th e wate r passage , the n

fill th e radiato r t o th e botto m o f th e fille r nec k wit h

the coolan t mixture . Tighte n th e blee d bol t a s soo n

a s coolan t start s t o ru n ou t i n a stead y strea m with -

ou t bubbles .

10 . Wit h th e radiato r ca p off , star t th e engin e an d le t i t

ru n unti l warme d u p (radiato r fa n come s o n a t leas t

twice) . Then , i f necessary , ad d mor e coolan t mi x t o

brin g th e leve l bac k u p to th e botto m o f th e fille r neck .

11 . Pu t th e radiato r cap on tightly , the n ru n th e engin e

agai n an d chec k fo r leaks .

12 . Ente r th e anti-thef t cod e fo r th e radio , the n ente r th e

customer' s radi o statio n presets .

BLEED BOL T9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

ProCarManuals.com

Page 145 of 1771

Radiator

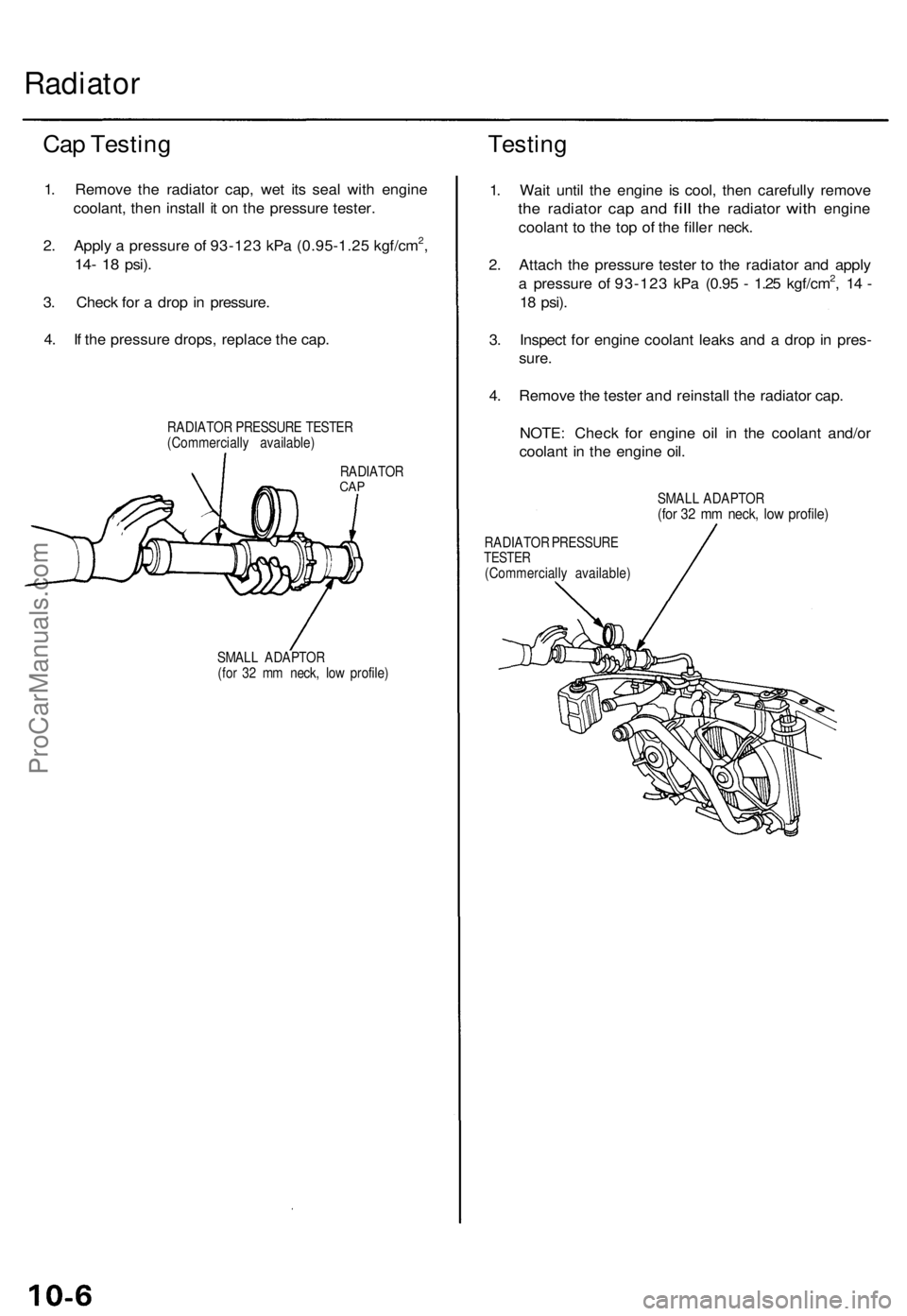

Cap Testing

1. Remove the radiator cap, wet its seal with engine

coolant, then install it on the pressure tester.

2. Apply a pressure of 93-123 kPa (0.95-1.25 kgf/cm2,

14- 18

psi).

3. Check for a drop in pressure.

4. If the pressure drops, replace the cap.

RADIATOR PRESSURE TESTER

(Commercially available)

Testing

RADIATOR

CAP

SMALL ADAPTOR

(for 32 mm neck, low profile)

1. Wait until the engine is cool, then carefully remove

the

radiator

cap and

fill

the

radiator

with

engine

coolant to the top of the filler neck.

2. Attach the pressure tester to the radiator and apply

a pressure of 93-123 kPa (0.95 - 1.25 kgf/cm2, 14 -

18

psi).

3. Inspect for engine coolant leaks and a drop in pres-

sure.

4. Remove the tester and reinstall the radiator cap.

NOTE: Check for engine oil in the coolant and/or

coolant in the engine oil.

SMALL ADAPTOR

(for 32 mm neck, low profile)

RADIATOR PRESSURE

TESTER

(Commercially available)ProCarManuals.com

Page 146 of 1771

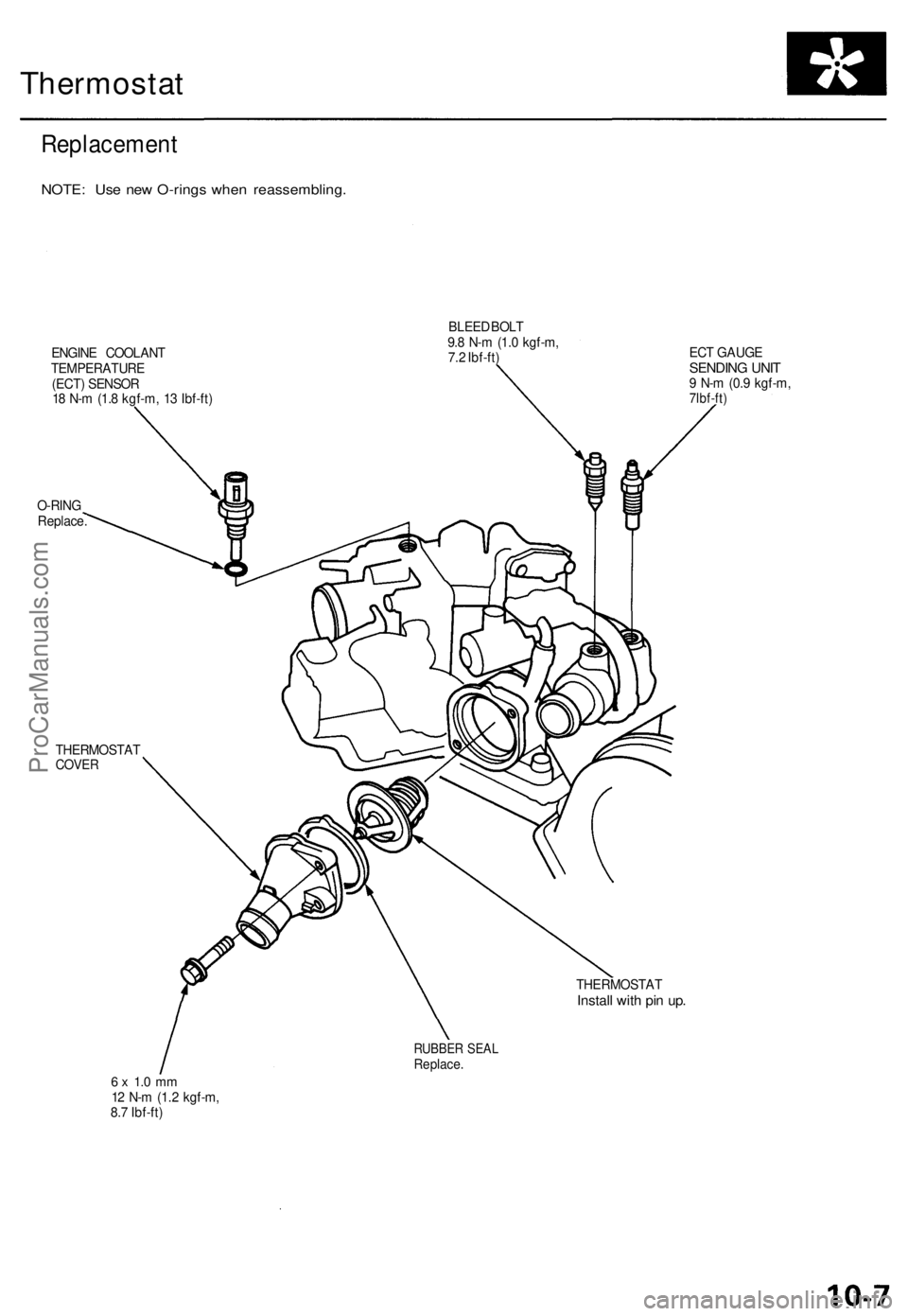

Thermostat

Replacement

NOTE: Use new O-rings when reassembling.

ENGINE COOLANT

TEMPERATURE

(ECT) SENSOR

18 N-m (1.8 kgf-m, 13 Ibf-ft)

BLEED BOLT

9.8 N-m (1.0 kgf-m,

7.2 Ibf-ft)

O-RING

Replace.

ECT GAUGE

SENDING UNIT

9 N-m (0.9 kgf-m,

7lbf-ft)

THERMOSTAT

COVER

THERMOSTAT

Install with pin up.

RUBBER SEAL

Replace.

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)ProCarManuals.com

Page 170 of 1771

![ACURA TL 1995 Service Workshop Manual System Descriptio n

System Connector s [Engin e Compartment ]

ENGINEWIREHARNES S

C106 C13

8

MAIN WIR EHARNES S

C127

C132

C131

C113 C130

C137

C136

C110

C107

C108

C11 1

C114

C109

ProCarManuals.co ACURA TL 1995 Service Workshop Manual System Descriptio n

System Connector s [Engin e Compartment ]

ENGINEWIREHARNES S

C106 C13

8

MAIN WIR EHARNES S

C127

C132

C131

C113 C130

C137

C136

C110

C107

C108

C11 1

C114

C109

ProCarManuals.co](/img/32/56993/w960_56993-169.png)

System Descriptio n

System Connector s [Engin e Compartment ]

ENGINEWIREHARNES S

C106 C13

8

MAIN WIR EHARNES S

C127

C132

C131

C113 C130

C137

C136

C110

C107

C108

C11 1

C114

C109

ProCarManuals.com

Page 174 of 1771

![ACURA TL 1995 Service Workshop Manual

System Description

System Connectors [Engine Compartment] (cont'd)

C173

C139

C120/

C171

C141

C119

C118

C116

ENGINE

WIRE

HARNESS

G101

C308

C311

MAIN WIRE

HARNESS

C172

C152/

C33 ACURA TL 1995 Service Workshop Manual

System Description

System Connectors [Engine Compartment] (cont'd)

C173

C139

C120/

C171

C141

C119

C118

C116

ENGINE

WIRE

HARNESS

G101

C308

C311

MAIN WIRE

HARNESS

C172

C152/

C33](/img/32/56993/w960_56993-173.png)

System Description

System Connectors [Engine Compartment] (cont'd)

C173

C139

C120/

C171

C141

C119

C118

C116

ENGINE

WIRE

HARNESS

G101

C308

C311

MAIN WIRE

HARNESS

C172

C152/

C332

C157

C338'2

C337'2

C333'1

C329

C320*1

C328

C324

C339*2

C123 C129

*1:'96 model

*2: '97 - 98 models

C126/

C322

C125

C135

C174*2

C140ProCarManuals.com

Page 183 of 1771

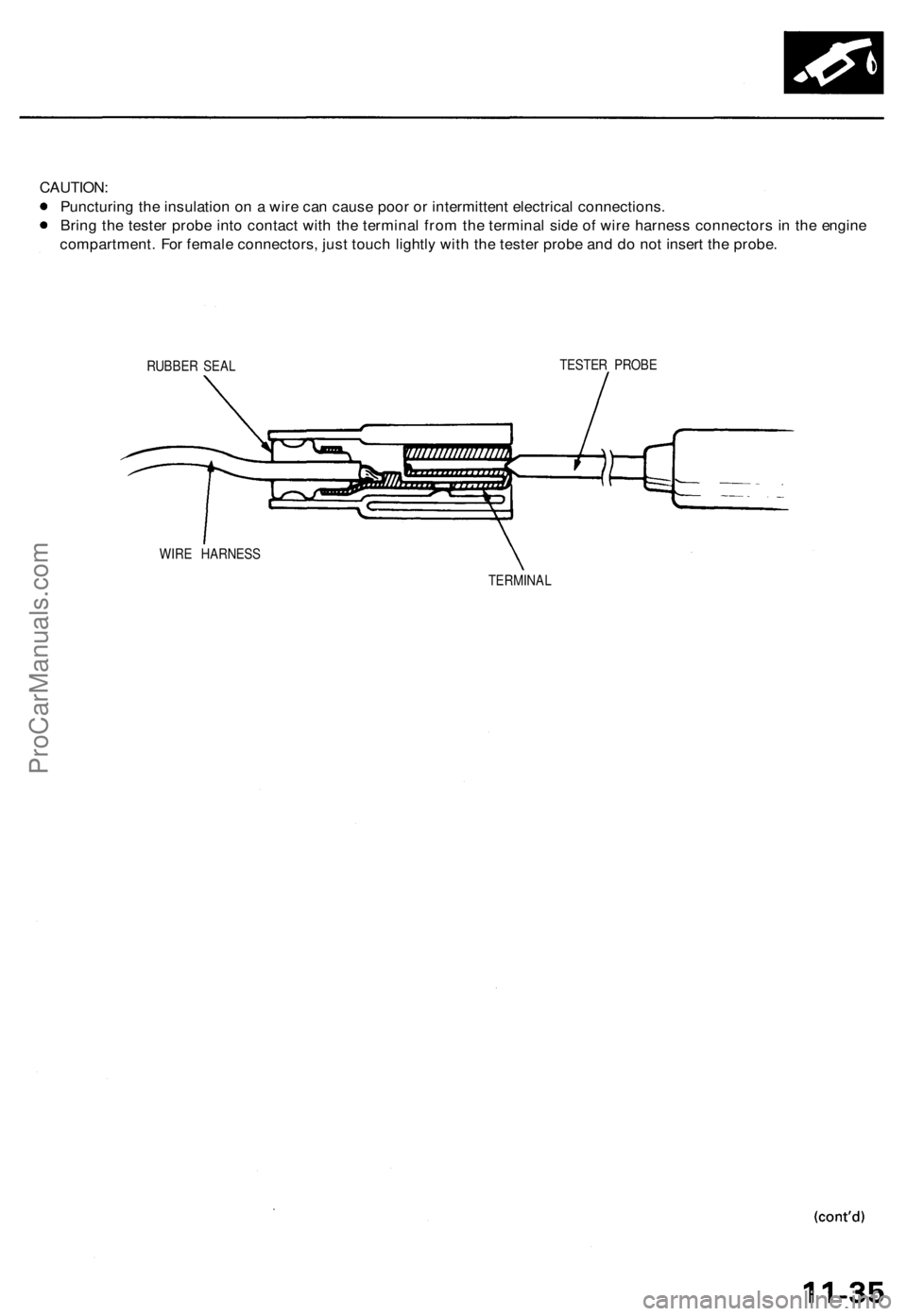

CAUTION:

Puncturing the insulation on a wire can cause poor or intermittent electrical connections.

Bring the tester probe into contact with the terminal from the terminal side of wire harness connectors in the engine

compartment. For female connectors, just touch lightly with the tester probe and do not insert the probe.

RUBBER SEAL

TESTER PROBE

WIRE HARNESS

TERMINALProCarManuals.com

Page 185 of 1771

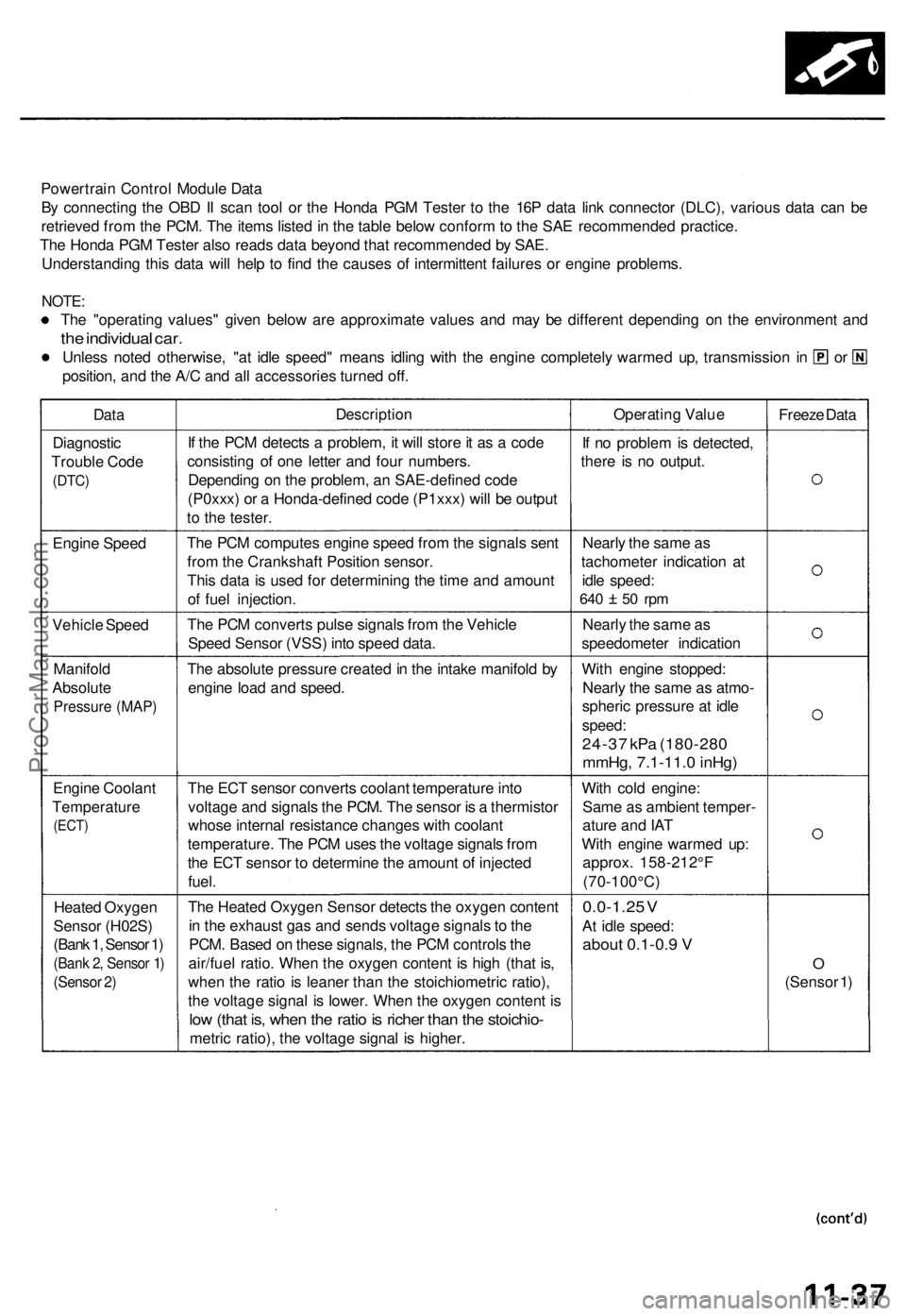

Powertrain Contro l Modul e Dat a

B y connectin g th e OB D II sca n too l o r th e Hond a PG M Teste r t o th e 16 P dat a lin k connecto r (DLC) , variou s dat a ca n b e

retrieve d fro m th e PCM . Th e item s liste d in th e tabl e belo w confor m to th e SA E recommende d practice .

Th e Hond a PG M Teste r als o read s dat a beyon d tha t recommende d b y SAE .

Understandin g thi s dat a wil l hel p t o fin d th e cause s o f intermitten t failure s o r engin e problems .

NOTE:

The "operatin g values " give n belo w ar e approximat e value s an d ma y b e differen t dependin g o n th e environmen t an d

the individua l car .

Unles s note d otherwise , "a t idl e speed " mean s idlin g wit h th e engine completel y warme d up , transmissio n i n o r

position , an d th e A/ C an d al l accessorie s turne d off .

Dat aDescriptio nOperating Valu e

Freeze Dat a

Diagnosti c

Troubl e Cod e

(DTC )

If th e PC M detect s a problem , i t wil l stor e it a s a cod e

consistin g o f on e lette r an d fou r numbers .

Dependin g o n th e problem , a n SAE-define d cod e

(P0xxx ) o r a Honda-define d cod e (P1xxx ) wil l b e outpu t

t o th e tester . I

f n o proble m is detected ,

ther e i s n o output .

Engin e Spee d Th

e PC M compute s engin e spee d fro m th e signal s sen t

fro m th e Crankshaf t Positio n sensor .

Thi s dat a is use d fo r determinin g th e tim e an d amoun t

o f fue l injection . Nearl

y th e sam e a s

tachomete r indicatio n a t

idl e speed :

640 5 0 rp m

Vehicl e Spee d Th

e PC M convert s puls e signal s fro m th e Vehicl e

Spee d Senso r (VSS ) int o spee d data . Nearl

y th e sam e a s

speedomete r indicatio n

Manifol d

Absolut e

Pressur e (MAP )

The absolut e pressur e create d in th e intak e manifol d b y

engin e loa d an d speed . Wit

h engin e stopped :

Nearl y th e sam e a s atmo -

spheri c pressur e a t idl e

speed :

24-37 kP a (180-28 0

mmHg, 7.1-11. 0 inHg )

Engin e Coolan t

Temperatur e

(ECT)

The EC T senso r convert s coolan t temperatur e int o

voltag e an d signal s th e PCM . Th e senso r i s a thermisto r

whos e interna l resistanc e change s wit h coolan t

temperature . Th e PC M use s th e voltag e signal s fro m

th e EC T senso r t o determin e th e amoun t o f injecte d

fuel . Wit

h col d engine :

Sam e a s ambien t temper -

atur e an d IA T

Wit h engin e warme d up :

approx . 158-212° F

(70-100°C )

Heate d Oxyge n

Senso r (H02S )

(Bank 1, Sensor 1)

(Ban k 2 , Senso r 1 )

(Senso r 2 )

Th e Heate d Oxyge n Senso r detect s th e oxyge n conten t

i n th e exhaus t ga s an d send s voltag e signal s to th e

PCM . Base d o n thes e signals , th e PC M control s th e

air/fue l ratio . Whe n th e oxyge n conten t i s hig h (tha t is ,

whe n th e rati o is leane r tha n th e stoichiometri c ratio) ,

th e voltag e signa l i s lower . Whe n th e oxyge n conten t i s

lo w (tha t is , whe n th e rati o is riche r tha n th e stoichio -

metric ratio) , th e voltag e signa l i s higher .

0.0-1.2 5 V

A t idl e speed :

about 0.1-0. 9 V

O

(Senso r 1 )

ProCarManuals.com