ACURA TL 1995 Service Repair Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1061 of 1771

Secondary Drive n Gea r Shaf t

Tapere d Rolle r Bearin g Preloa d Adjustmen t

NOTE: I f th e transmissio n housing , torqu e converte r

housing, secondar y drive n gea r shaft , tapere d rolle r

bearing , oute r rac e o r thrus t shi m wer e replaced , th e

bearin g preloa d mus t b e adjusted .

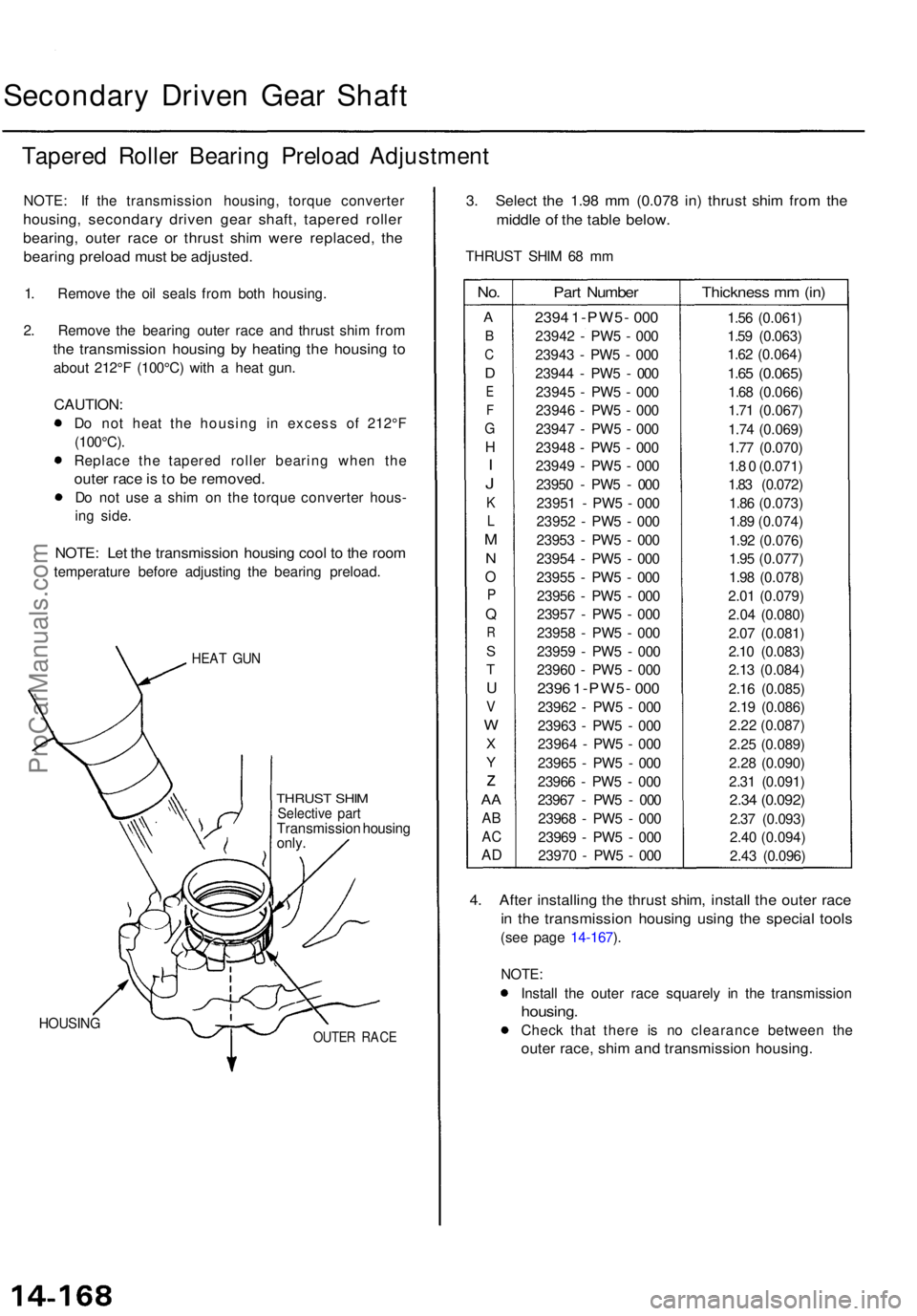

1. Remov e th e oi l seal s fro m bot h housing .

2 . Remov e th e bearin g oute r rac e an d thrus t shi m fro m

the transmissio n housin g b y heatin g th e housin g t o

abou t 212° F (100°C ) wit h a hea t gun .

CAUTION :

Do no t hea t th e housin g i n exces s o f 212° F

(100°C) .

Replac e th e tapere d rolle r bearin g whe n th e

oute r rac e is to b e removed .

Do no t us e a shi m o n th e torqu e converte r hous -

in g side .

NOTE : Le t th e transmissio n housin g coo l t o th e roo m

temperatur e befor e adjustin g th e bearin g preload .

HEAT GU N

THRUS T SHI MSelectiv e par tTransmissio n housin g

only .

HOUSIN GOUTER RAC E

3. Selec t th e 1.9 8 m m (0.07 8 in ) thrus t shi m fro m th e

middl e o f th e tabl e below .

THRUS T SHI M 6 8 m m

No.

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

z

AA

A B

AC

AD

Par t Numbe r

2394 1-PW5 - 00 0

2394 2 - PW 5 - 00 0

2394 3 - PW 5 - 00 0

2394 4 - PW 5 - 00 0

2394 5 - PW 5 - 00 0

2394 6 - PW 5 - 00 0

2394 7 - PW 5 - 00 0

2394 8 - PW 5 - 00 0

2394 9 - PW 5 - 00 0

2395 0 - PW 5 - 00 0

2395 1 - PW 5 - 00 0

2395 2 - PW 5 - 00 0

2395 3 - PW 5 - 00 0

2395 4 - PW 5 - 00 0

2395 5 - PW 5 - 00 0

2395 6 - PW 5 - 00 0

2395 7 - PW 5 - 00 0

2395 8 - PW 5 - 00 0

2395 9 - PW 5 - 00 0

2396 0 - PW 5 - 00 0

239 6 1-PW5 - 00 0

2396 2 - PW 5 - 00 0

2396 3 - PW 5 - 00 0

2396 4 - PW 5 - 00 0

2396 5 - PW 5 - 00 0

2396 6 - PW 5 - 00 0

2396 7 - PW 5 - 00 0

2396 8 - PW 5 - 00 0

2396 9 - PW 5 - 00 0

2397 0 - PW 5 - 00 0

Thicknes s m m (in )

1.56 (0.061 )

1.5 9 (0.063 )

1.6 2 (0.064 )

1.65 (0.065 )

1.68 (0.066 )

1.7 1 (0.067 )

1.7 4 (0.069 )

1.7 7 (0.070 )

1. 8 0 (0.071 )

1.8 3 (0.072 )

1.8 6 (0.073 )

1.8 9 (0.074 )

1.9 2 (0.076 )

1.9 5 (0.077 )

1.9 8 (0.078 )

2.0 1 (0.079 )

2.0 4 (0.080 )

2.0 7 (0.081 )

2.1 0 (0.083 )

2.1 3 (0.084 )

2.1 6 (0.085 )

2.1 9 (0.086 )

2.2 2 (0.087 )

2.2 5 (0.089 )

2.2 8 (0.090 )

2.3 1 (0.091 )

2.34 (0.092 )

2.37 (0.093 )

2.4 0 (0.094 )

2.4 3 (0.096 )

4. Afte r installin g th e thrus t shim , instal l th e oute r rac e

in th e transmissio n housin g usin g th e specia l tool s

(see pag e 14-167 ).

NOTE :

Instal l th e oute r rac e squarel y i n th e transmissio n

housing.

Check tha t ther e i s n o clearanc e betwee n th e

oute r race , shi m an d transmissio n housing .

ProCarManuals.com

Page 1062 of 1771

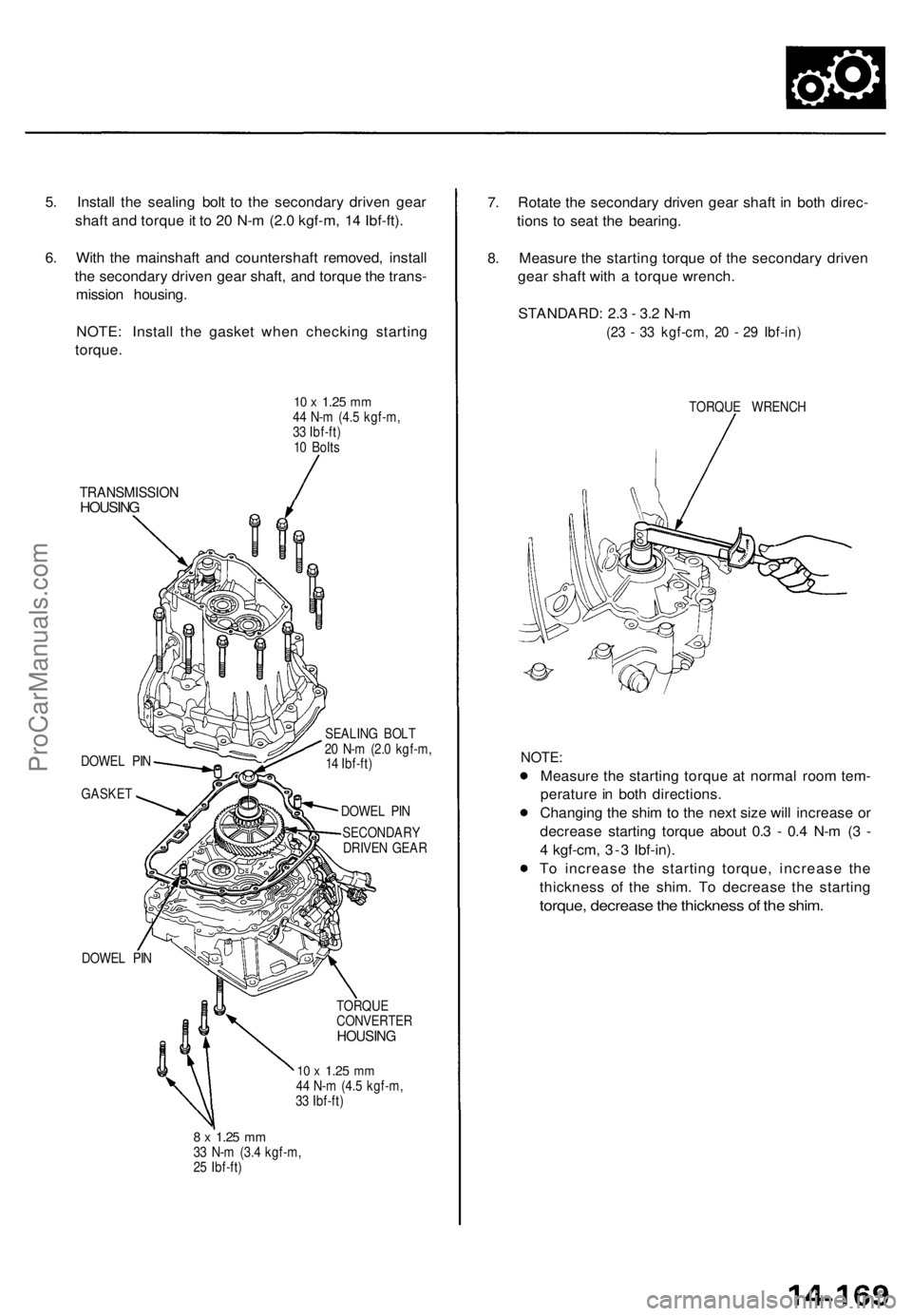

5. Install the sealing bolt to the secondary driven gear

shaft and torque it to 20 N-m (2.0 kgf-m, 14 Ibf-ft).

6. With the mainshaft and countershaft removed, install

the secondary driven gear shaft, and torque the trans-

mission housing.

NOTE: Install the gasket when checking starting

torque.

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

10 Bolts

TRANSMISSION

HOUSING

DOWEL PIN

GASKET

DOWEL PIN

SEALING BOLT

20 N-m (2.0 kgf-m,

14 Ibf-ft)

DOWEL PIN

SECONDARY

DRIVEN GEAR

TORQUE

CONVERTER

HOUSING

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

8 x

1.25

mm

33 N-m (3.4 kgf-m,

25 Ibf-ft)

7. Rotate the secondary driven gear shaft in both direc-

tions to seat the bearing.

8. Measure the starting torque of the secondary driven

gear shaft with a torque wrench.

STANDARD: 2.3 - 3.2 N-m

(23 - 33 kgf-cm, 20 - 29 Ibf-in)

TORQUE WRENCH

NOTE:

Measure the starting torque at normal room tem-

perature in both directions.

Changing the shim to the next size will increase or

decrease starting torque about 0.3 - 0.4 N-m (3 -

4 kgf-cm, 3-3 Ibf-in).

To increase the starting torque, increase the

thickness of the shim. To decrease the starting

torque, decrease the thickness of the shim.ProCarManuals.com

Page 1063 of 1771

Oil Seal s

Remova lInstallatio n

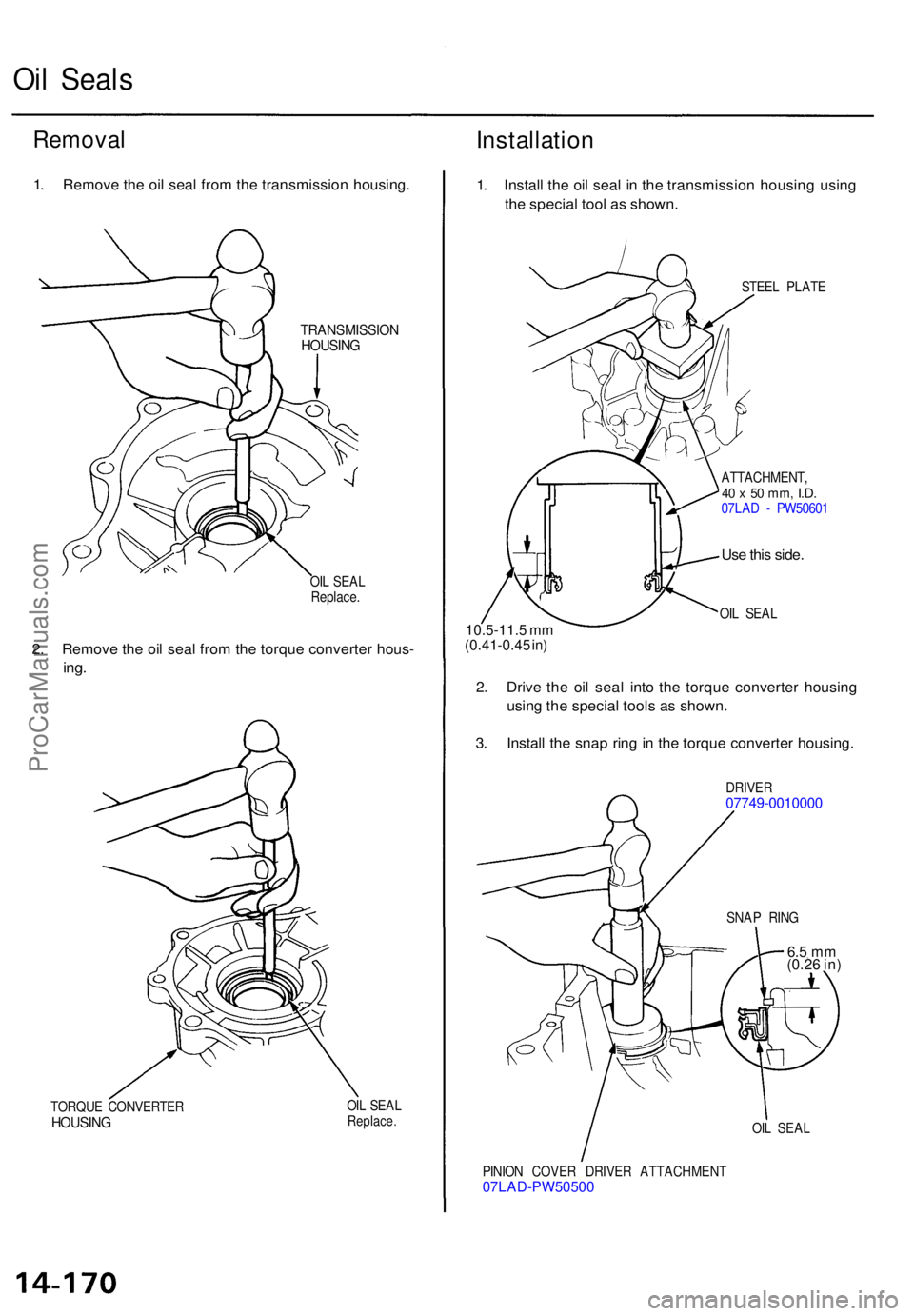

1. Remov e th e oi l sea l fro m th e transmissio n housing .

TRANSMISSIO NHOUSING

OIL SEA L

Replace .

2. Remov e th e oi l sea l fro m th e torqu e converte r hous -

ing.

TORQU E CONVERTE RHOUSING

OIL SEA LReplace .

1. Instal l th e oi l sea l i n th e transmissio n housin g usin g

th e specia l too l a s shown .

STEEL PLAT E

ATTACHMENT ,

40 x 50 mm , I.D.07LA D - PW5060 1

Use thi s side .

OIL SEA L10.5-11. 5 m m

(0.41-0.4 5 in )

2. Driv e th e oi l sea l int o th e torqu e converte r housin g

usin g th e specia l tool s a s shown .

3 . Instal l th e sna p rin g in th e torqu e converte r housing .

DRIVER07749-001000 0

OIL SEA L

PINIO N COVE R DRIVE R ATTACHMEN T

07LAD-PW5050 0

SNAP RIN G

6.5 m m

(0.2 6 in )

ProCarManuals.com

Page 1064 of 1771

Torque Converte r Housin g Bearing s

Mainshaf t Bearing/Oi l Sea l Replacemen t

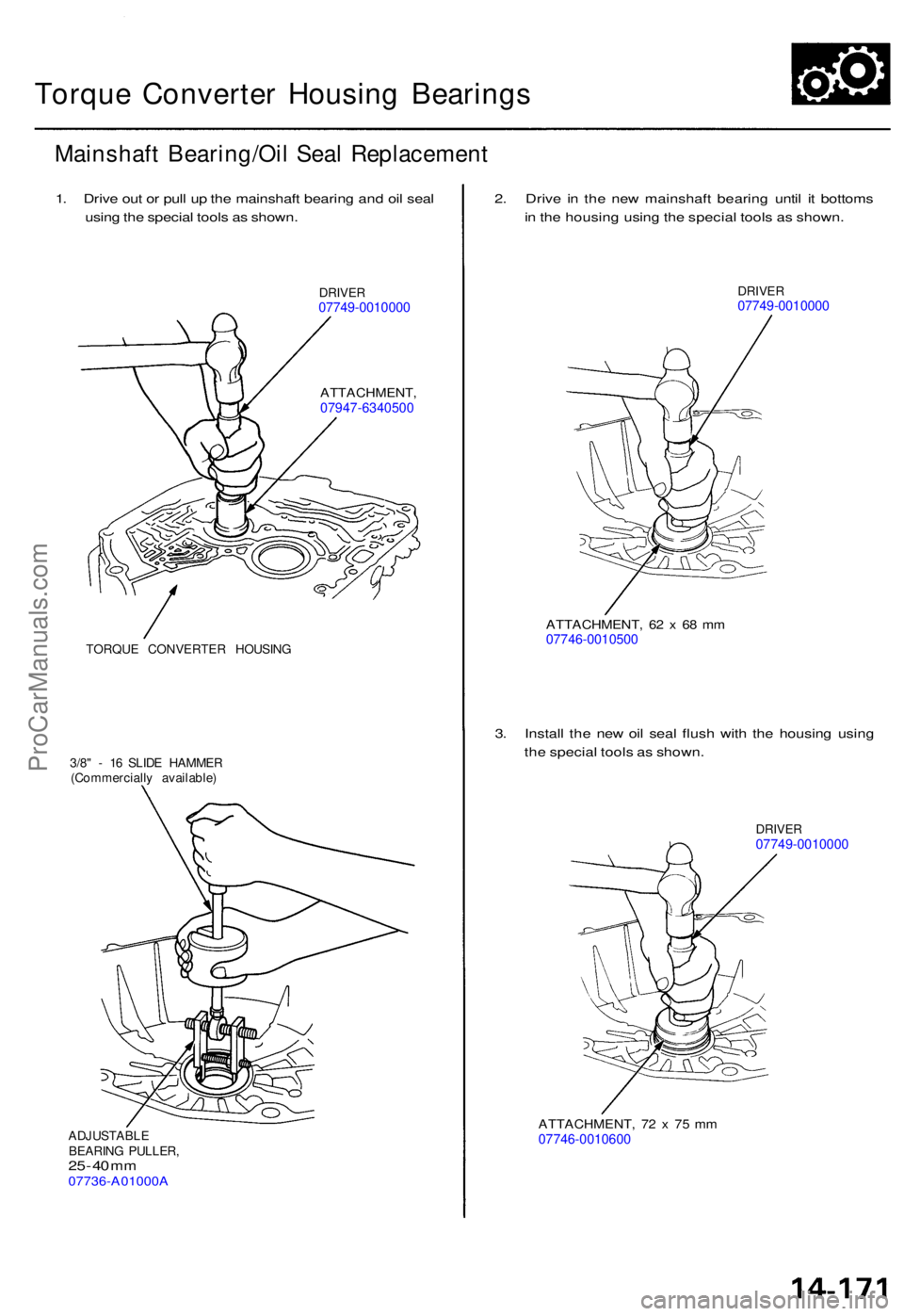

1. Driv e ou t o r pul l u p th e mainshaf t bearin g an d oi l sea l

usin g th e specia l tool s a s shown .

DRIVER07749-001000 0

ATTACHMENT ,07947-6340500

TORQUE CONVERTE R HOUSIN G

3/8 " - 1 6 SLID E HAMME R

(Commerciall y available )

ADJUSTABL E

BEARIN G PULLER ,

25 - 4 0 m m07736-A01000 A

2. Driv e i n th e ne w mainshaf t bearin g unti l i t bottom s

i n th e housin g usin g th e specia l tool s a s shown .

DRIVER07749-001000 0

ATTACHMENT , 6 2 x 68 m m07746-001050 0

3. Instal l th e ne w oi l sea l flus h wit h th e housin g usin g

th e specia l tool s a s shown .

DRIVER07749-001000 0

ATTACHMENT , 7 2 x 7 5 m m07746-001060 0

ProCarManuals.com

Page 1065 of 1771

Torque Converte r Housin g

Bearing

Transmissio n Housin g

Bearing

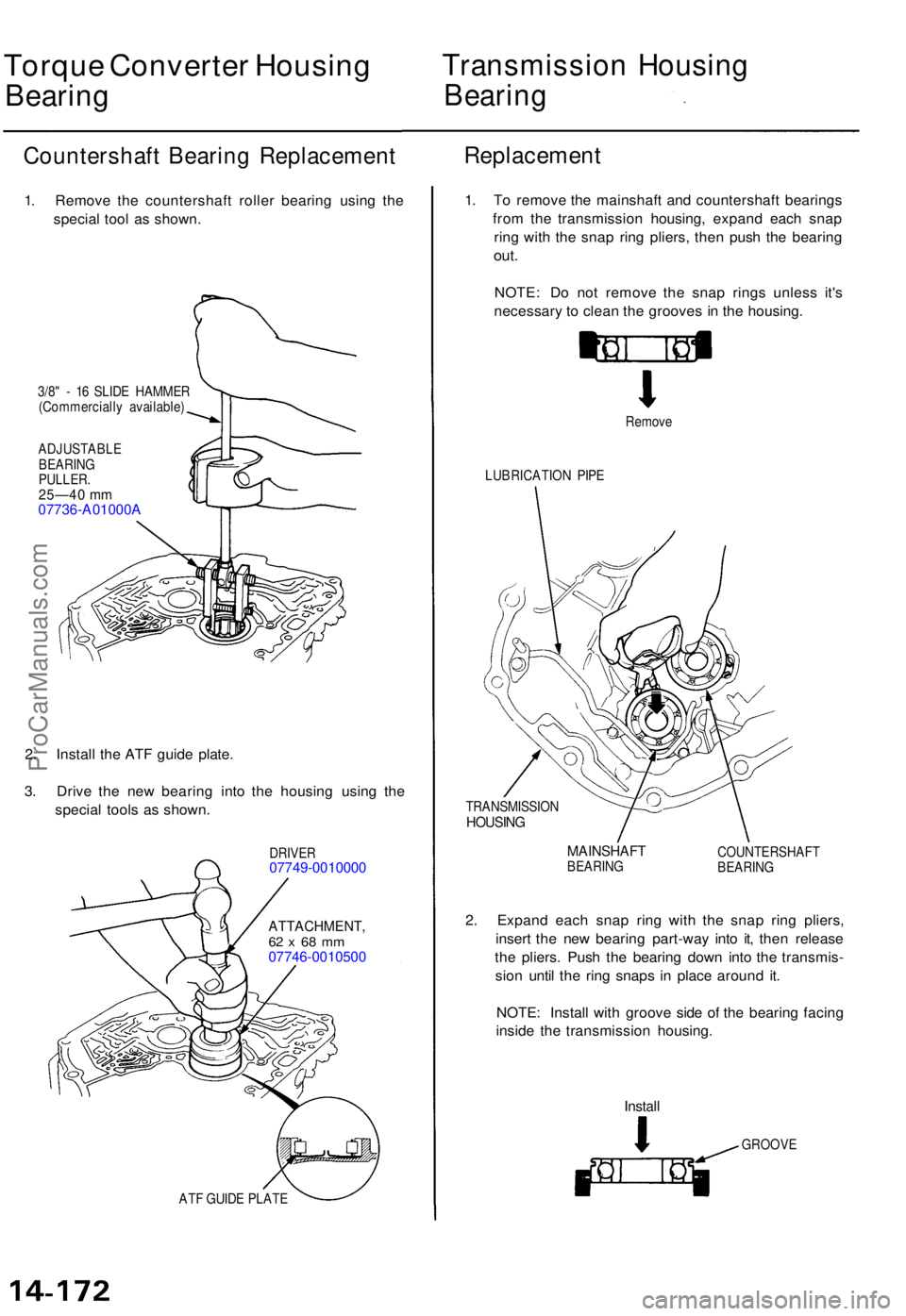

Countershaf t Bearin g Replacemen t

1. Remov e th e countershaf t rolle r bearin g usin g th e

specia l too l a s shown .

3/8" - 1 6 SLID E HAMME R

(Commerciall y available )

ADJUSTABL E

BEARIN G

PULLER .25—40 m m07736-A01000 A

2. Instal l th e AT F guid e plate .

3 . Driv e th e ne w bearin g int o th e housin g usin g th e

specia l tool s a s shown .

DRIVER07749-001000 0

ATTACHMENT ,62 x 68 m m07746-001050 0

Replacement

ATF GUID E PLAT E

1. T o remov e th e mainshaf t an d countershaf t bearing s

fro m th e transmissio n housing , expan d eac h sna p

rin g wit h th e sna p rin g pliers , the n pus h th e bearin g

out.

NOTE : D o no t remov e th e sna p ring s unles s it' s

necessar y t o clea n th e groove s i n th e housing .

Remove

LUBRICATIO N PIP E

TRANSMISSIO N

HOUSING

MAINSHAF TBEARING COUNTERSHAF

T

BEARIN G

2. Expan d eac h sna p rin g wit h th e sna p rin g pliers ,

inser t th e ne w bearin g part-wa y int o it , the n releas e

th e pliers . Pus h th e bearin g dow n int o th e transmis -

sio n unti l th e rin g snap s i n plac e aroun d it .

NOTE : Instal l wit h groov e sid e o f th e bearin g facin g

insid e th e transmissio n housing .

Install

GROOV E

ProCarManuals.com

Page 1066 of 1771

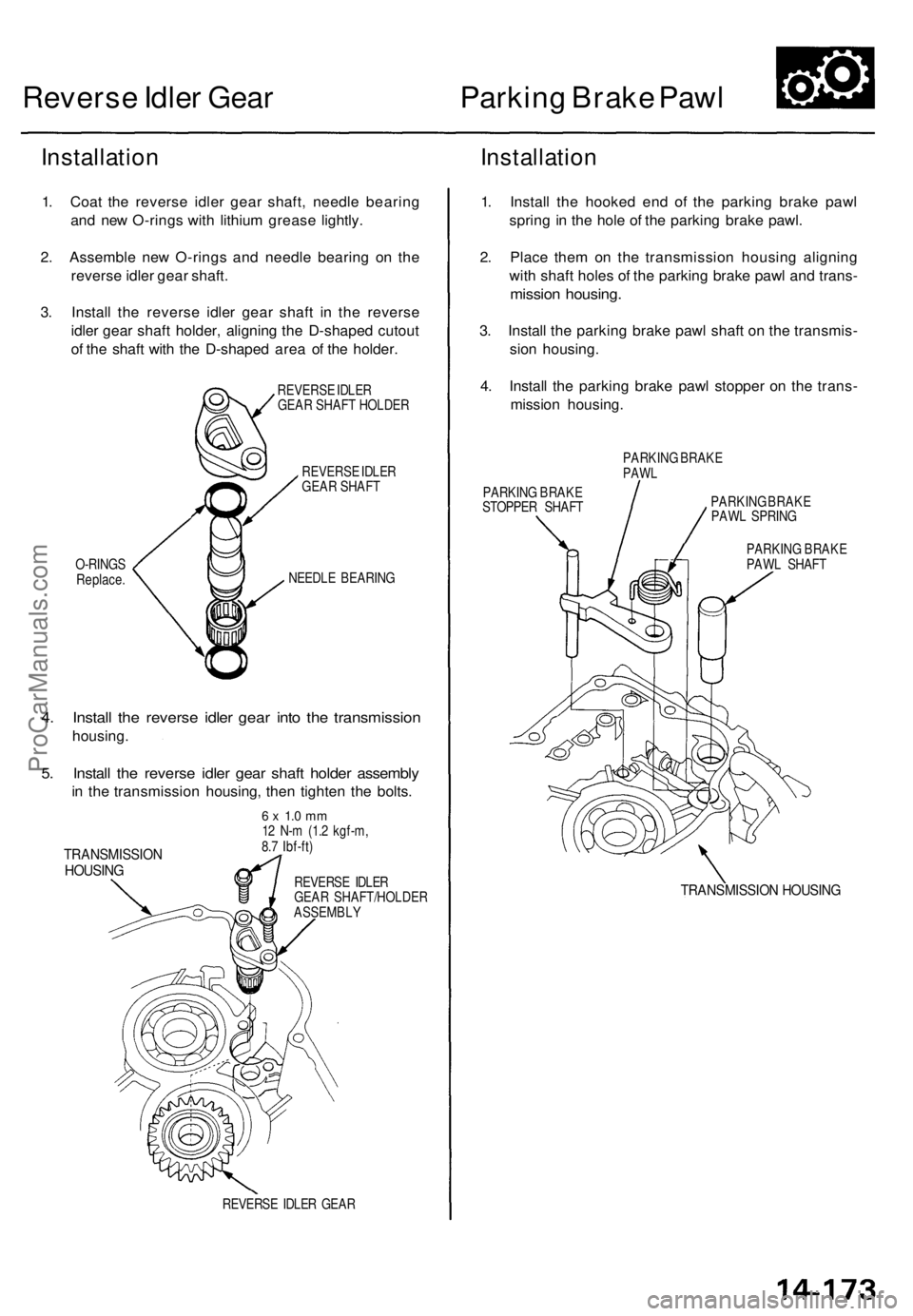

Reverse Idler Gear

Parking Brake Pawl

Installation

1. Coat the reverse idler gear shaft, needle bearing

and new O-rings with lithium grease lightly.

2. Assemble new O-rings and needle bearing on the

reverse idler gear shaft.

3. Install the reverse idler gear shaft in the reverse

idler gear shaft holder, aligning the D-shaped cutout

of the shaft with the D-shaped area of the holder.

REVERSE IDLER

GEAR SHAFT HOLDER

REVERSE IDLER

GEAR SHAFT

O-RINGS

Replace.

NEEDLE BEARING

4. Install the reverse idler gear into the transmission

housing.

5. Install the reverse idler gear shaft holder assembly

in the transmission housing, then tighten the bolts.

TRANSMISSION

HOUSING

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

REVERSE IDLER

GEAR SHAFT/HOLDER

ASSEMBLY

REVERSE IDLER GEAR

Installation

1. Install the hooked end of the parking brake pawl

spring in the hole of the parking brake pawl.

2. Place them on the transmission housing aligning

with shaft holes of the parking brake pawl and trans-

mission housing.

3. Install the parking brake pawl shaft on the transmis-

sion housing.

4. Install the parking brake pawl stopper on the trans-

mission housing.

PARKING BRAKE

PAWL

PARKING BRAKE

STOPPER SHAFT

PARKING BRAKE

PAWL SPRING

PARKING BRAKE

PAWL SHAFT

TRANSMISSION HOUSINGProCarManuals.com

Page 1067 of 1771

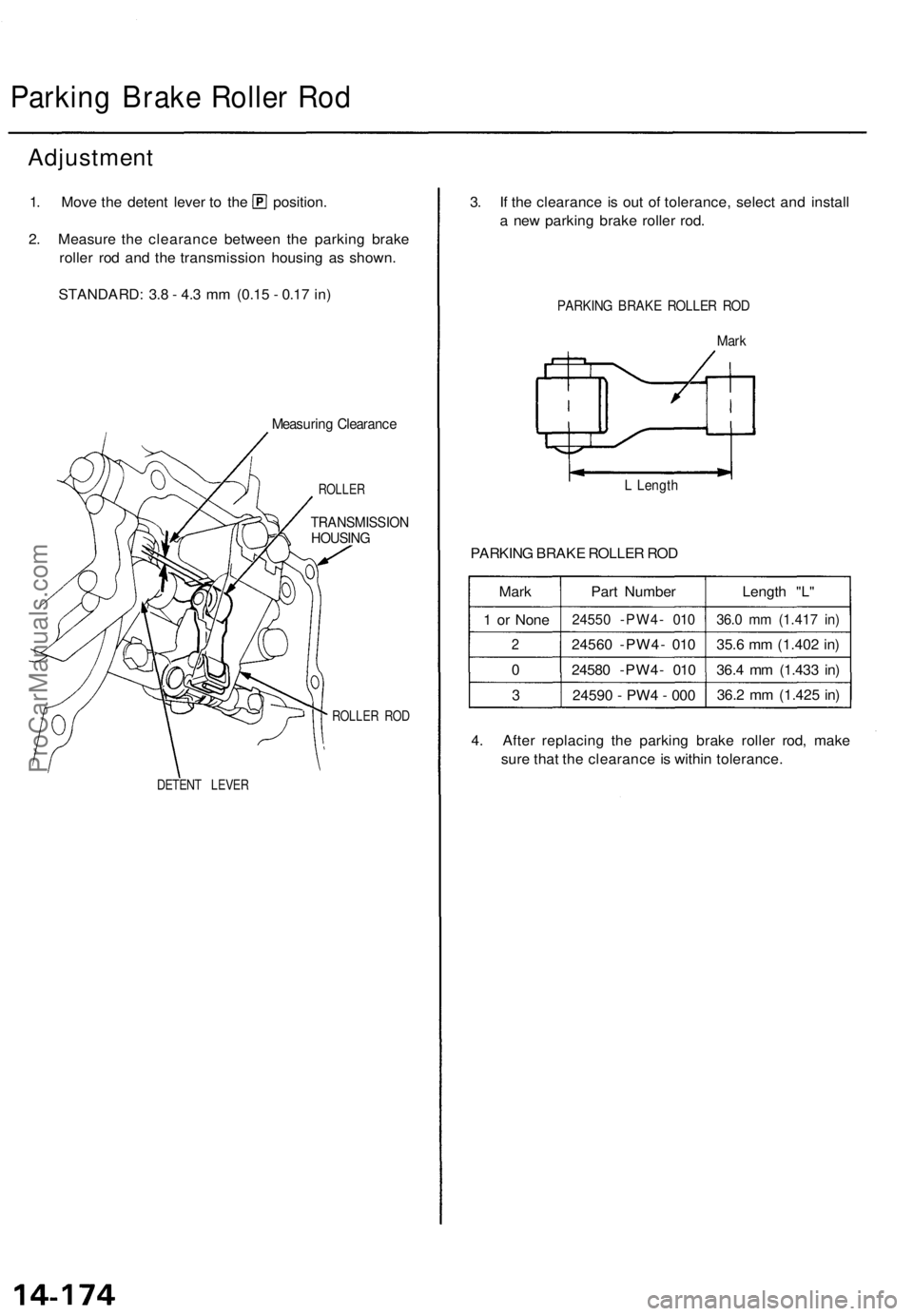

Parking Brake Roller Rod

Adjustment

1. Move the detent lever to the position.

2. Measure the clearance between the parking brake

roller rod and the transmission housing as shown.

STANDARD: 3.8 - 4.3 mm (0.15 - 0.17 in)

Measuring Clearance

ROLLER

TRANSMISSION

HOUSING

DETENT LEVER

ROLLER ROD

3. If the clearance is out of tolerance, select and install

a new parking brake roller rod.

PARKING BRAKE ROLLER ROD

Mark

L Length

PARKING BRAKE ROLLER ROD

Mark

1 or None

2

0

3

Part Number

24550 -PW4- 010

24560 -PW4- 010

24580 -PW4- 010

24590 - PW4 - 000

Length "L"

36.0 mm (1.417 in)

35.6 mm (1.402 in)

36.4 mm (1.433 in)

36.2 mm (1.425 in)

4. After replacing the parking brake roller rod, make

sure that the clearance is within tolerance.ProCarManuals.com

Page 1068 of 1771

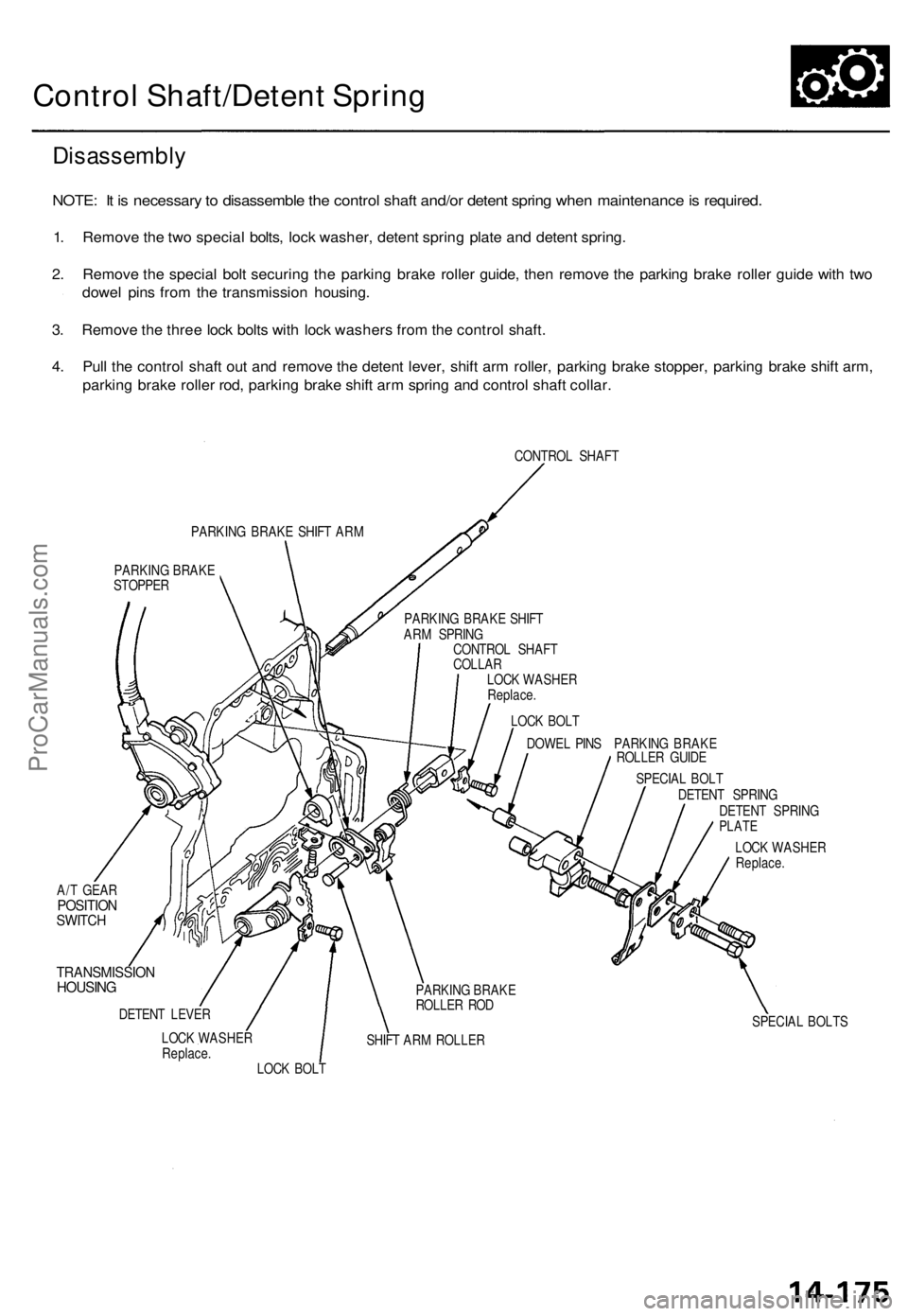

Control Shaft/Detent Spring

Disassembly

NOTE: It is necessary to disassemble the control shaft and/or detent spring when maintenance is required.

1. Remove the two special bolts, lock washer, detent spring plate and detent spring.

2. Remove the special bolt securing the parking brake roller guide, then remove the parking brake roller guide with two

dowel pins from the transmission housing.

3. Remove the three lock bolts with lock washers from the control shaft.

4. Pull the control shaft out and remove the detent lever, shift arm roller, parking brake stopper, parking brake shift arm,

parking brake roller rod, parking brake shift arm spring and control shaft collar.

CONTROL SHAFT

PARKING BRAKE SHIFT ARM

PARKING BRAKE

STOPPER

DOWEL PINS PARKING BRAKE

ROLLER GUIDE

A/T GEAR

POSITION

SWITCH

TRANSMISSION

HOUSING

DETENT LEVER

LOCK WASHER

Replace.

SHIFT ARM ROLLER

SPECIAL BOLT

DETENT SPRING

DETENT SPRING

PLATE

LOCK WASHER

Replace.

SPECIAL BOLTS

LOCK BOLT

PARKING BRAKE

ROLLER ROD

LOCK BOLT

LOCK WASHER

Replace.

CONTROL SHAFT

COLLAR

PARKING BRAKE SHIFT

ARM SPRINGProCarManuals.com

Page 1069 of 1771

Control Shaft/Deten t Sprin g

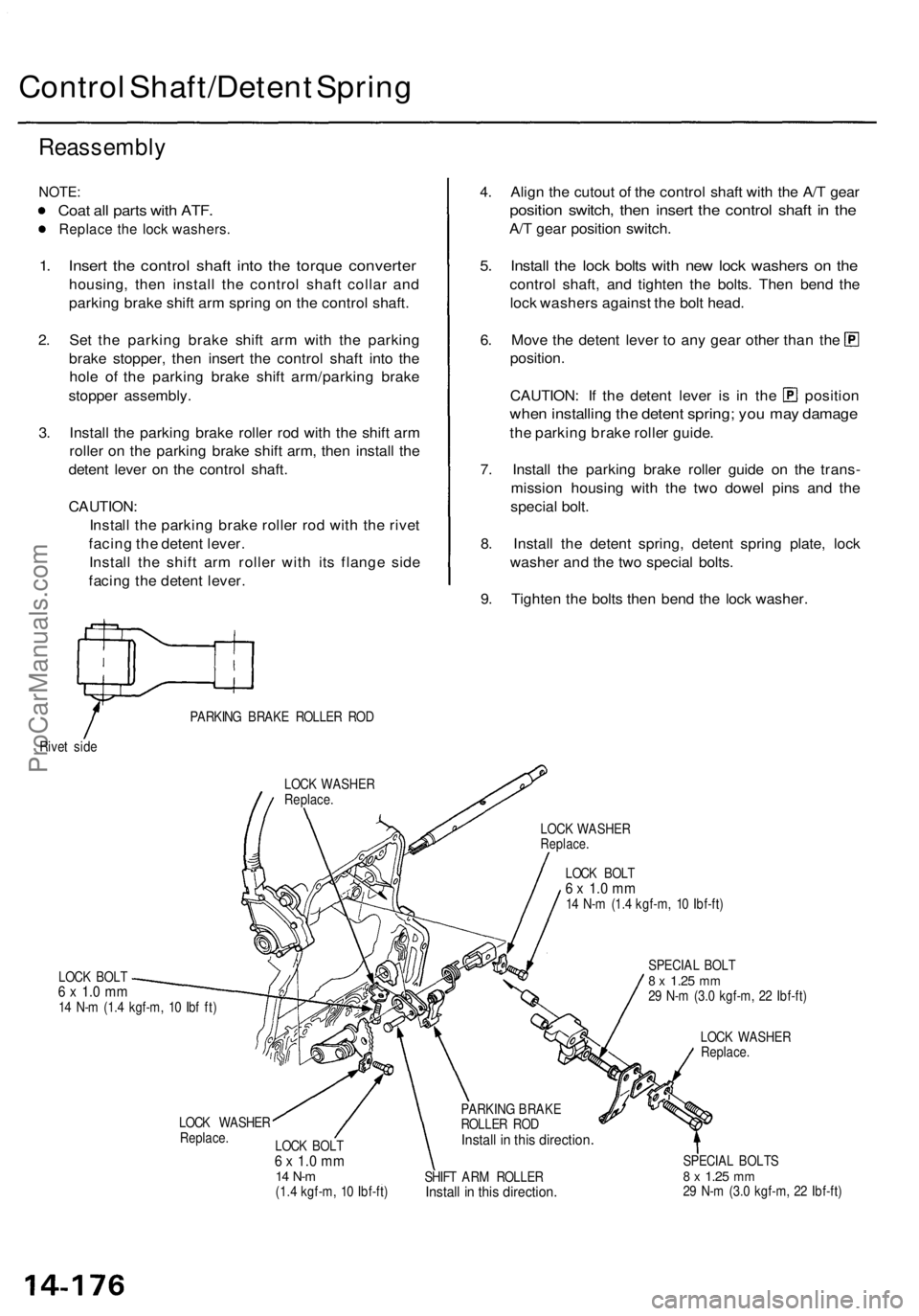

Reassembl y

NOTE:

Coat al l part s wit h ATF .

Replac e th e loc k washers .

1. Inser t th e contro l shaf t int o th e torqu e converte r

housing, the n instal l th e contro l shaf t colla r an d

parkin g brak e shif t ar m sprin g o n th e contro l shaft .

2 . Se t th e parkin g brak e shif t ar m wit h th e parkin g

brak e stopper , the n inser t th e contro l shaf t int o th e

hol e o f th e parkin g brak e shif t arm/parkin g brak e

stoppe r assembly .

3 . Instal l th e parkin g brak e rolle r ro d wit h th e shif t ar m

rolle r o n th e parkin g brak e shif t arm , the n instal l th e

deten t leve r o n th e contro l shaft .

CAUTION :

Instal l th e parkin g brak e rolle r ro d wit h th e rive t

facin g th e deten t lever .

Instal l th e shif t ar m rolle r wit h it s flang e sid e

facin g th e deten t lever .

Rivet sid e PARKIN

G BRAK E ROLLE R RO D

LOC K WASHE R

Replace.

LOCK BOL T6 x 1. 0 m m14 N- m (1. 4 kgf-m , 1 0 Ib f ft )

4. Alig n th e cutou t o f th e contro l shaf t wit h th e A/ T gea r

positio n switch , the n inser t th e contro l shaf t i n th e

A/T gea r positio n switch .

5. Instal l th e loc k bolt s wit h ne w loc k washer s o n th e

contro l shaft , an d tighte n th e bolts . The n ben d th e

loc k washer s agains t th e bol t head .

6. Mov e th e deten t leve r t o an y gea r othe r tha n th e

position .

CAUTION : I f th e deten t leve r i s i n th e positio n

when installin g th e deten t spring ; yo u ma y damag e

the parkin g brak e rolle r guide .

7 . Instal l th e parkin g brak e rolle r guid e o n th e trans -

missio n housin g wit h th e tw o dowe l pin s an d th e

specia l bolt .

8 . Instal l th e deten t spring , deten t sprin g plate , loc k

washe r an d th e tw o specia l bolts .

9 . Tighte n th e bolt s the n ben d th e loc k washer .

LOCK WASHE RReplace.

LOCK BOL T6 x 1. 0 m m14 N- m (1. 4 kgf-m , 1 0 Ibf-ft )

LOC K WASHE R

Replace.LOCK BOL T6 x 1. 0 m m14 N- m(1.4 kgf-m , 1 0 Ibf-ft ) SPECIA

L BOL T

8 x 1.2 5 mm29 N- m (3. 0 kgf-m , 2 2 Ibf-ft )

LOC K WASHE R

Replace.

PARKING BRAK E

ROLLE R RO D

Instal l i n thi s directio n

SHIFT AR M ROLLE RInstall i n thi s direction .

SPECIAL BOLT S8 x 1.2 5 mm29 N- m (3. 0 kgf-m , 2 2 Ibf-ft )

ProCarManuals.com

Page 1070 of 1771

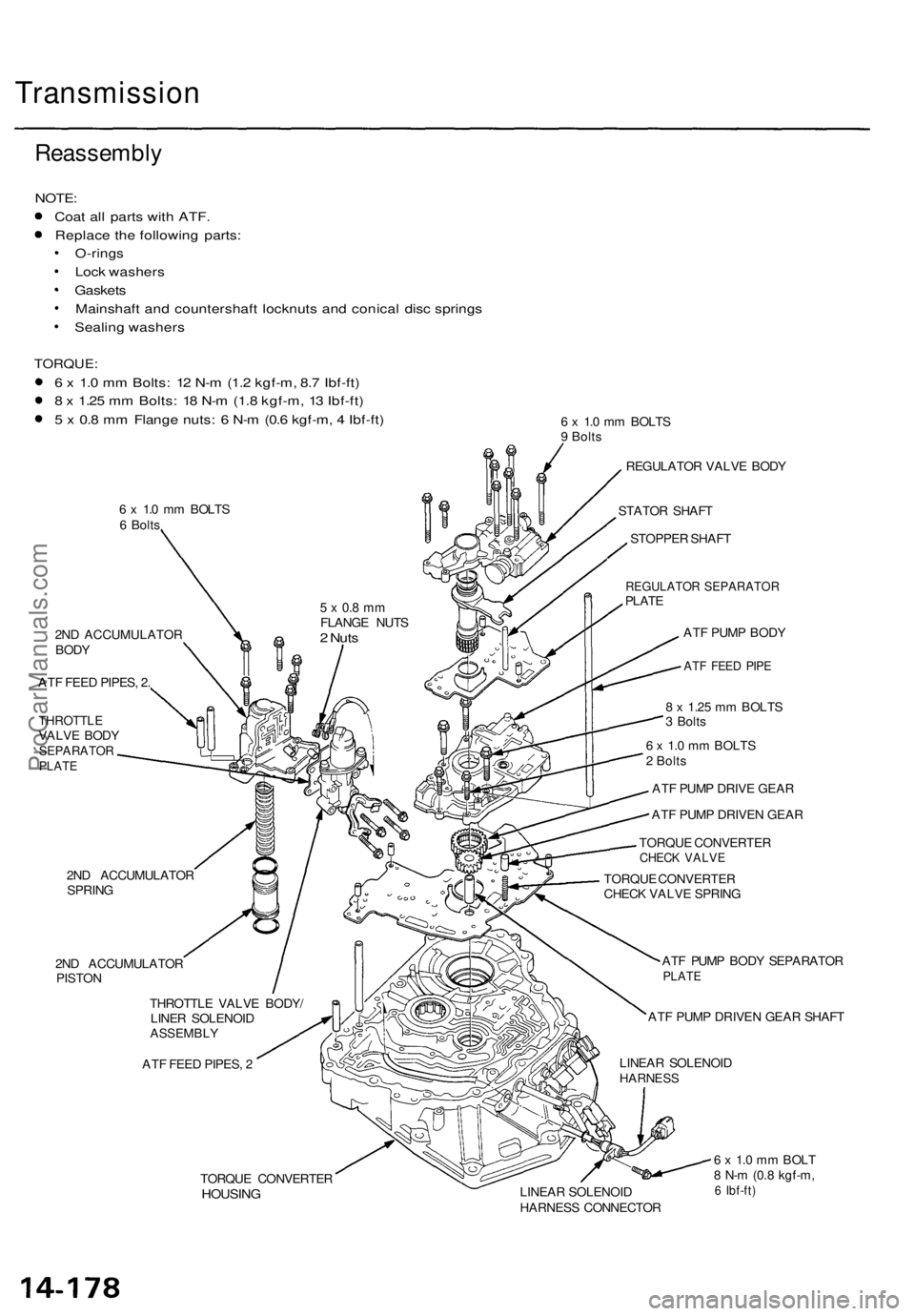

Transmission

Reassembly

NOTE:

Coat all parts with ATF.

Replace the following parts:

O-rings

Lock washers

Gaskets

Mainshaft and countershaft locknuts and conical disc springs

Sealing washers

TORQUE:

6 x 1.0 mm Bolts: 12 N-m (1.2 kgf-m, 8.7 Ibf-ft)

8 x 1.25 mm Bolts: 18 N-m (1.8 kgf-m, 13 Ibf-ft)

5 x 0.8 mm Flange nuts: 6 N-m (0.6 kgf-m, 4 Ibf-ft)

6 x 1.0 mm BOLTS

6 Bolts

6 x 1.0 mm BOLTS

9 Bolts

2ND ACCUMULATOR

BODY

ATF FEED PIPES, 2.

THROTTLE

VALVE BODY

SEPARATOR

PLATE

2ND ACCUMULATOR

SPRING

2ND ACCUMULATOR

PISTON

THROTTLE VALVE BODY/

LINER SOLENOID

ASSEMBLY

ATF FEED PIPES, 2

REGULATOR VALVE BODY

STATOR SHAFT

STOPPER SHAFT

REGULATOR SEPARATOR

PLATE

ATF PUMP BODY

ATF FEED PIPE

8 x 1.25 mm BOLTS

3 Bolts

6 x 1.0 mm BOLTS

2 Bolts

ATF PUMP DRIVE GEAR

ATF PUMP DRIVEN GEAR

TORQUE CONVERTER

CHECK VALVE

TORQUE CONVERTER

CHECK VALVE SPRING

ATF PUMP BODY SEPARATOR

PLATE

ATF PUMP DRIVEN GEAR SHAFT

LINEAR SOLENOID

HARNESS

TORQUE CONVERTER

HOUSING

LINEAR SOLENOID

HARNESS CONNECTOR

6 x 1.0 mm BOLT

8 N-m (0.8 kgf-m,

6 Ibf-ft)

5 x 0.8 mm

FLANGE NUTS

2 NutsProCarManuals.com