check engine light ACURA TL 1995 Service User Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 508 of 1771

Troubleshooting Precautions

ABS Indicator Light:

The ABS indicator light comes on for three seconds and then goes off when the control unit detects no problem during the

initial diagnosis right after the engine starts. However, the ABS indicator light can stay on for up to 40 seconds when the

control unit starts to check for pump overrun, etc. during the initial diagnosis. The ABS indicator light comes on, and the

ABS control unit memorizes the diagnostic trouble code (DTC) under certain conditions.

• The parking brake is applied for more than 30 seconds while the vehicle is being driven. (DTC 2-1)

• The transmission downshifted excessively. (DTC 4-1, 4-2)

• The vehicle loses traction, and the front wheels spin for more than one minute when starting from a stuck condition on

a muddy, snowy, or sandy road. (DTC 4-8)

• Tire adhesion is lost due to excessive cornering speed. (DTC 5, 5-4, 5-8)

• The vehicle is driven on an extremely rough road. (DTC 8-1)

• The vehicle is interfered by strong radio waves (noise), for example, illegal radio, etc. (DTC 8-2)

NOTE: If there is any trouble in the system, the ABS indicator light comes on during driving.

Diagnostic Trouble Code (DTC):

• When the control unit detects a problem and the ABS indicator light comes on, the control unit memorizes the DTC.

• The control unit has three memory registers. When a problem occurs, the control unit stores the DTC in the first memory

register. If another problem occurs, or the same problem occurs again, the control unit moves the first DTC to the next

memory register, and stores the second DTC in the first register. If there's a third problem occurrence, the two existing

DTCs are moved up one register, and the third DTC is stored in the first register. If problems continue to occur, the oldest

problem is moved out of the last register and lost, and the most recent problem is stored in the first register. When the

same problem occurs three times, the same DTC is stored in all memory registers. (Refer to the Symptom-to-System

Chart for diagnostic period.)

• The most recent DTC is indicated first, and the oldest DTC is indicated last.

• The DTCs are erased from the control unit when the ABS control unit +B2 power supply or connector is disconnected.

• The control unit's memory can be erased by disconnecting the ABS B2 fuse for more than three seconds.

Self-diagnosis:

• There are three self-diagnosises described below.

Initial diagnosis: Performed right after the engine starts until the ABS indicator light goes off.

Regular diagnosis: Continuously performed (under some conditions) after the ABS indicator light goes off until the

engine stops.

Individual part/system diagnosis: Diagnosis about a specific part/system under its operating conditions.

• The CPU (central processing unit) controls the following when it detects a problem during self-diagnosis:

Turns the ABS indicator light ON.

Turns the front and rear fail-safe relays off.

Stops the ABS control.

Stops the ABS pump. (The pump may work under some conditions.)

After the DTC is stored in the control unit, the CPU stops self-diagnosis.ProCarManuals.com

Page 509 of 1771

Kickback and Pump Operation:

• When the engine is started, the ABS control unit begins the initial diagnosis and operates the solenoid valve one time.

The kickback may be felt when the brake pedal is depressed.

• When the ABS control unit detects the pressure switch OFF signal during the initial diagnosis, it operates the pump

motor, and performs the pump motor over-run diagnosis and pump motor diagnosis. Therefore, there are two cases

where the pump motor operates or does not operate after the engine is started.

• Normally, after the initial diagnosis, the pump motor operates based on the pressure switch signal, regardless of the

vehicle speed.

Troubleshooting:

• When two or three DTCs are stored in the control unit, perform troubleshooting for the DTC that appears first.

• When a customer's reported problem cannot be verified on the car, ask the customer about the conditions when the

ABS indicator light came ON, and test-drive the car under those conditions, if possible. When the ABS indicator light

does not come ON during the test, check for loose terminals and check by shaking the harnesses and connectors while

following the flowchart.

• The connector terminal numbers are viewed from the wire side for the female terminals, and from the terminal side for

the male terminals.

• After the repair is completed, test-drive the car and check that the ABS indicator light does not come ON again during

the test. (Refer to the Symptom-to-System Chart for diagnostic period.)ProCarManuals.com

Page 511 of 1771

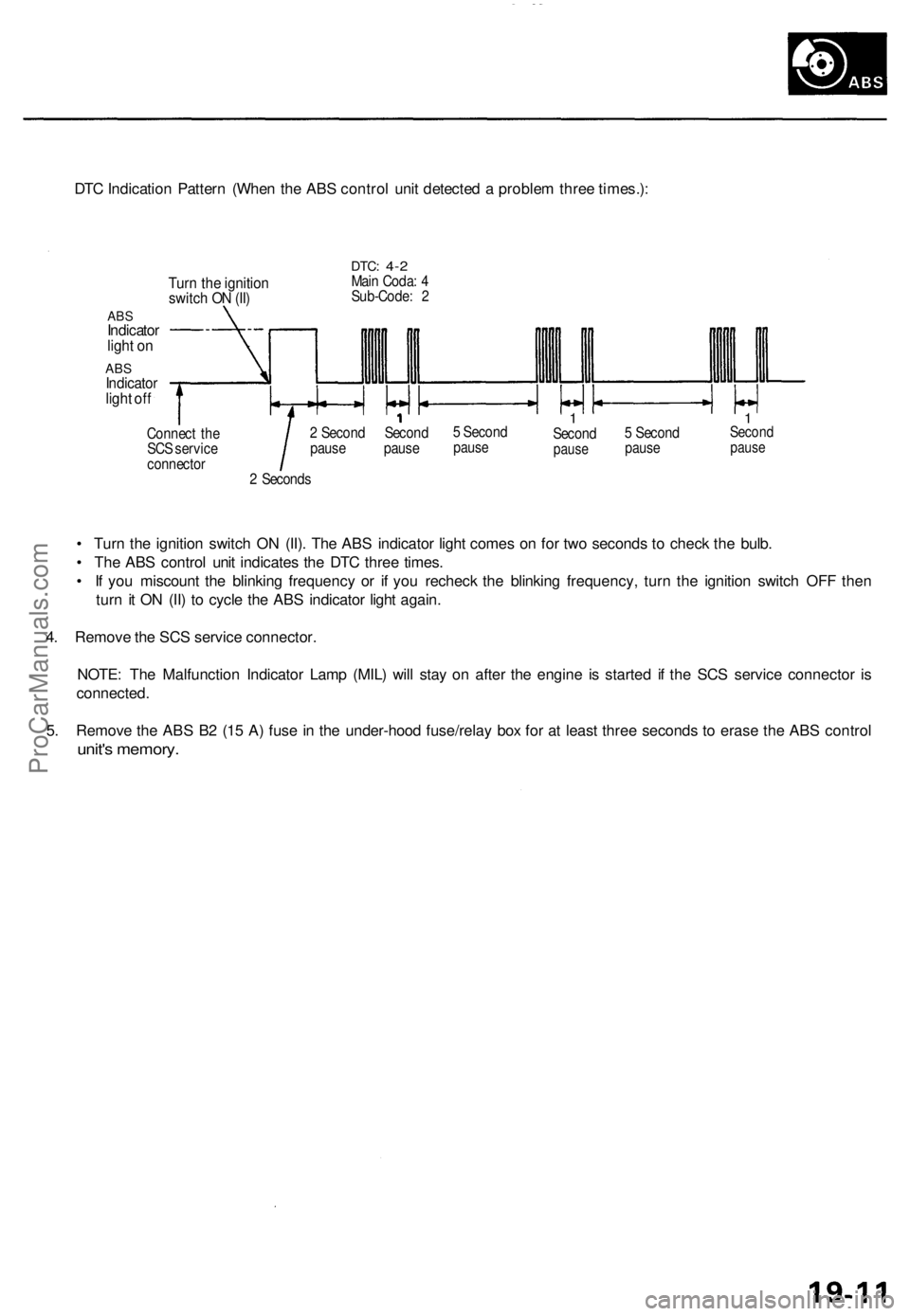

DTC Indication Pattern (When the ABS control unit detected a problem three times.):

Turn the ignition

switch ON (II)

ABS

Indicator

light on

ABS

Indicator

light off

DTC:

4-2

Main Coda: 4

Sub-Code: 2

Connect the

SCS service

connector

2 Second Second

pause pause

5 Second

pause

1

Second

pause

5 Second

pause

1

Second

pause

2 Seconds

• Turn the ignition switch ON (II). The ABS indicator light comes on for two seconds to check the bulb.

• The ABS control unit indicates the DTC three times.

• If you miscount the blinking frequency or if you recheck the blinking frequency, turn the ignition switch OFF then

turn it ON (II) to cycle the ABS indicator light again.

4. Remove the SCS service connector.

NOTE: The Malfunction Indicator Lamp (MIL) will stay on after the engine is started if the SCS service connector is

connected.

5. Remove the ABS B2 (15 A) fuse in the under-hood fuse/relay box for at least three seconds to erase the ABS control

unit's memory.ProCarManuals.com

Page 775 of 1771

Cylinder Head

Installation (cont'd)

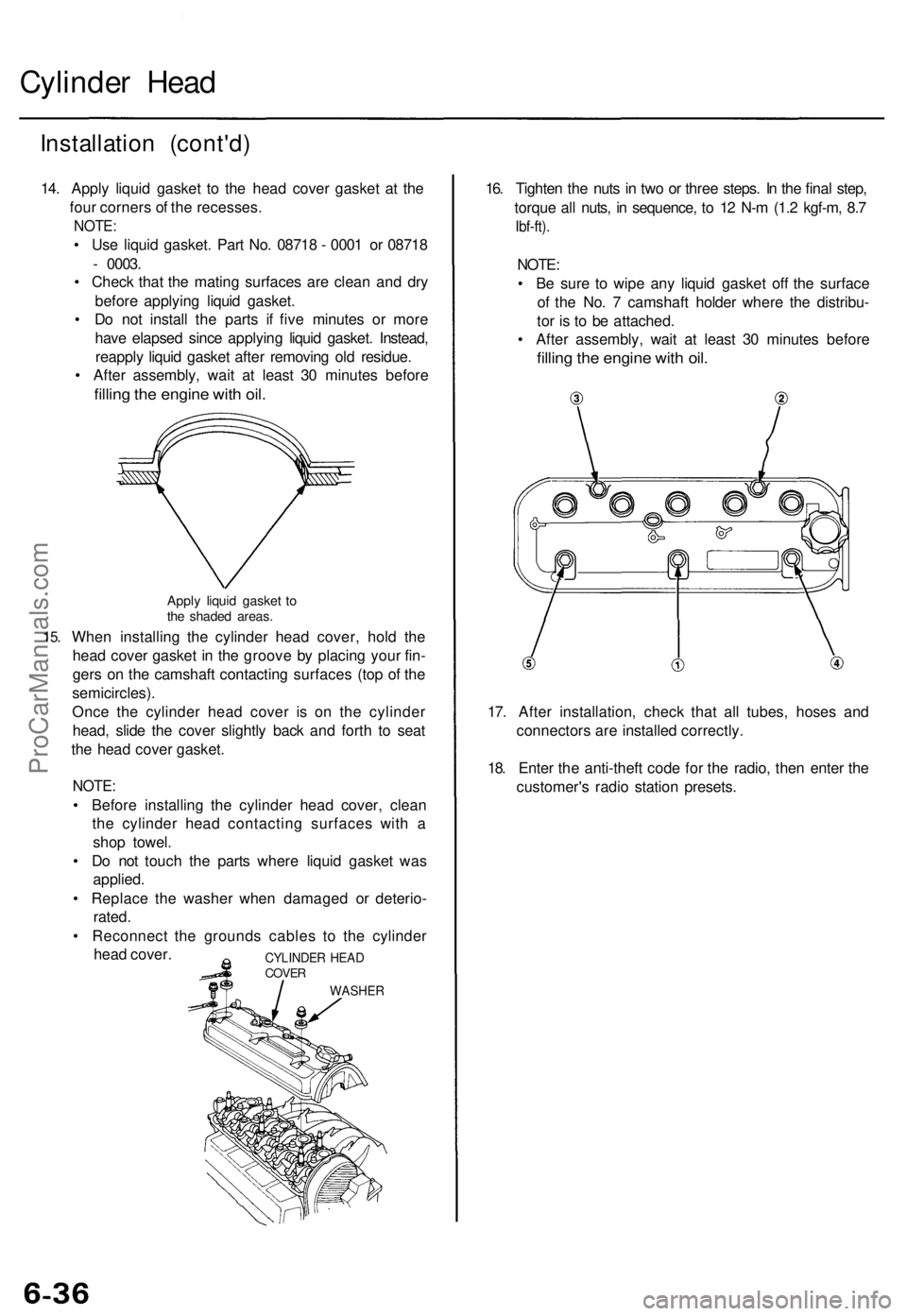

14. Apply liquid gasket to the head cover gasket at the

four corners of the recesses.

NOTE:

• Use liquid gasket. Part No. 08718 - 0001 or 08718

- 0003.

• Check that the mating surfaces are clean and dry

before applying liquid gasket.

• Do not install the parts if five minutes or more

have elapsed since applying liquid gasket. Instead,

reapply liquid gasket after removing old residue.

• After assembly, wait at least 30 minutes before

filling the engine with oil.

15.

Apply liquid gasket to

the shaded areas.

When installing the cylinder head cover, hold the

head cover gasket in the groove by placing your fin-

gers on the camshaft contacting surfaces (top of the

semicircles).

Once the cylinder head cover is on the cylinder

head, slide the cover slightly back and forth to seat

the head cover gasket.

NOTE:

• Before installing the cylinder head cover, clean

the cylinder head contacting surfaces with a

shop towel.

• Do not touch the parts where liquid gasket was

applied.

• Replace the washer when damaged or deterio-

rated.

• Reconnect the grounds cables to the cylinder

head cover.

16. Tighten the nuts in two or three steps. In the final step,

torque all nuts, in sequence, to 12 N-m (1.2 kgf-m, 8.7

Ibf-ft).

NOTE:

• Be sure to wipe any liquid gasket off the surface

of the No. 7 camshaft holder where the distribu-

tor is to be attached.

• After assembly, wait at least 30 minutes before

filling the engine with oil.

17. After installation, check that all tubes, hoses and

connectors are installed correctly.

18. Enter the anti-theft code for the radio, then enter the

customer's radio station presets.

CYLINDER HEAD

COVER

WASHERProCarManuals.com

Page 878 of 1771

4. A/ C Compresso r Clutc h Rela y

When th e EC M receive s a deman d fo r coolin g fro m th e ai r conditionin g system , i t delay s th e compresso r fro m bein g

energized , an d enriche s th e mixtur e to assur e smoot h transitio n to th e A/ C mode .

5 . Evaporativ e Emissio n (EVAP ) Purg e Contro l Solenoi d Valv e

Whe n th e engin e coolan t temperatur e i s belo w 167° F (75°C ) ('9 7 - 9 8 models : 158° F (70°C) , th e EC M control s th e

EVA P purg e contro l solenoi d valv e whic h cut s vacuu m to th e EVA P purg e contro l caniste r diaphragm .

6 . Intak e Ai r Bypas s (IAB ) Contro l Solenoi d Valv e

Whe n th e engin e spee d i s belo w 4,80 0 rpm , th e IA B contro l solenoi d valv e i s activate d b y a signa l fro m th e ECM ,

intak e ai r flow s throug h th e smalle r chamber , the n hig h torqu e i s delivered. At speed s highe r tha n 4,80 0 rpm , th e

solenoi d valv e i s deactivate d b y th e ECM , an d intak e ai r flow s throug h th e large r chambe r i n orde r t o reduc e th e

resistanc e in airflow .

7 . Exhaus t Ga s Recirculatio n (EGR ) Contro l Solenoi d Valv e

Whe n th e EG R is require d fo r contro l o f oxide s o f nitroge n (NOx ) emissions , th e EC M control s th e EG R contro l

solenoi d valv e whic h supplie s regulate d vacuu m to th e EG R valve .

8 . Alternato r Contro l

Th e syste m control s th e voltag e generate d a t th e alternato r i n accordanc e wit h th e electrica l loa d an d drivin g mode ,

whic h reduce s th e engin e loa d to improv e th e fue l economy .

ECM Fail-safe/Back-u p Function s

1. Fail-saf e Functio n

Whe n a n abnormalit y occur s in a signa l fro m a sensor , th e EC M ignore s tha t signa l an d assume s a pre-programme d

valu e fo r tha t senso r tha t allow s th e engin e to continu e to run .

2 . Back-u p Functio n

Whe n a n abnormalit y occur s in th e EC M itself , th e fue l injector s ar e controlle d b y a back-u p circui t independen t o f th e

syste m in orde r t o permi t minima l driving .

3 . Self-diagnosi s Functio n [Malfunctio n Indicato r Lam p (MIL) ]

Whe n a n abnormalit y occur s i n a signa l fro m a sensor , th e EC M supplie s groun d fo r th e MI L an d store s th e DT C in

erasable memory . Whe n th e ignitio n i s initiall y turne d on , th e EC M supplie s ground for th e MI L fo r tw o second s t o

chec k th e MI L bul b condition .

4 . Tw o Tri p Detectio n Metho d ('9 5 - 9 6 models )

T o preven t fals e indications , th e Tw o Tri p Detectio n Metho d is use d fo r th e MA F sensor , H02S , fue l metering-related ,

idl e contro l system , EC T sensor , an d EG R syste m self-diagnosti c functions . Whe n a n abnormalit y occurs , th e EC M

store s i t i n it s memory . Whe n th e sam e abnormalit y recur s afte r th e ignitio n switc h i s turne d OF F an d O N (II ) again ,

th e EC M inform s th e drive r b y lightin g th e MIL .

However ,

to eas e troubleshooting , thi s functio n is cancelle d when you shor t the servic e check connector . The MI L will

the n blin k immediatel y whe n a n abnormalit y occurs .

5 . Tw o (o r Three ) Drivin g Cycl e Detectio n Metho d ('9 5 - 9 6 models )

A "Drivin g Cycle " consist s o f startin g th e engine , beginnin g close d loo p operation , an d stoppin g th e engine . I f misfir -

in g tha t increase s emission s o r EVA P contro l syste m malfunctio n i s detecte d i n tw o consecutiv e drivin g cycles , o r

TW C deterioratio n is detecte d in thre e consecutiv e drivin g cycles , th e EC M turn s th e MI L on .

However , t o eas e troubleshooting , thi s functio n is cancelle d whe n yo u shor t th e servic e chec k connector . Th e MI L wil l

the n blin k immediatel y whe n a n abnormalit y occurs .

6 . Tw o Drivin g Cycl e Detectio n Metho d ('9 7 - 9 8 models )

T o preven t fals e indications , th e "tw o drivin g cycl e detectio n method " i s use d fo r th e H02S , fue l metering-related ,

idl e contro l system , EC T sensor , EG R system , TW C an d EVA P contro l syste m an d othe r self-diagnosti c functions .

Whe n a n abnormalit y occurs , th e EC M store s i t i n it s memory . Whe n th e sam e abnormalit y recur s afte r switc h i s

turne d OF F an d O N (II ) again , th e EC M inform s th e drive r b y turnin g o n th e MIL .

ProCarManuals.com

Page 879 of 1771

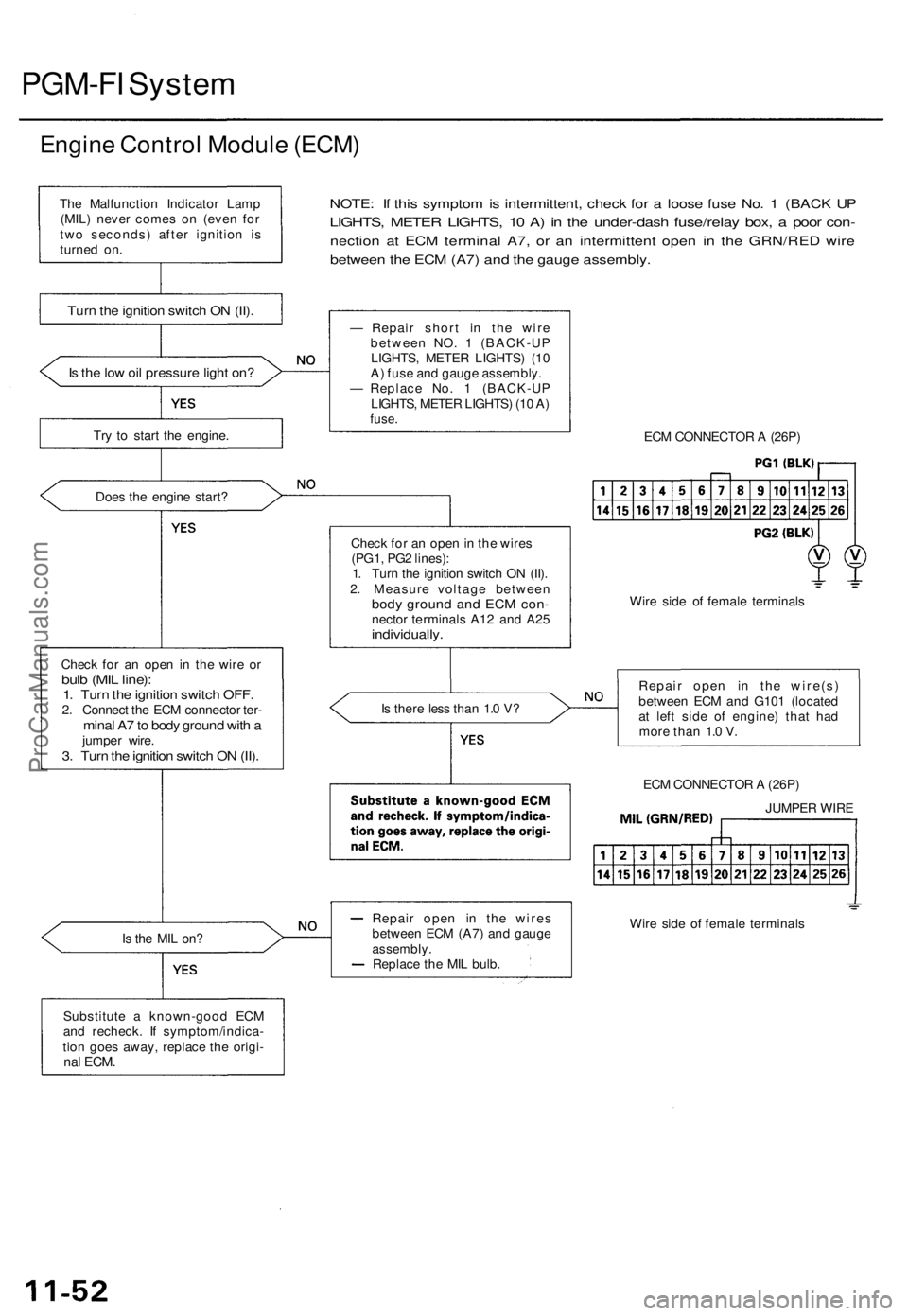

PGM-FI System

Engine Control Module (ECM)

Is the low oil pressure light on?

Try to start the engine.

Does the engine start?

Check for an open in the wire or

bulb (MIL line):

1. Turn the ignition switch OFF.

2. Connect the ECM connector ter-

minal A7 to body ground with a

jumper wire.

3. Turn the ignition switch ON (II).

NOTE: If this symptom is intermittent, check for a loose fuse No. 1 (BACK UP

LIGHTS, METER LIGHTS, 10 A) in the under-dash fuse/relay box, a poor con-

nection at ECM terminal A7, or an intermittent open in the GRN/RED wire

between the ECM (A7) and the gauge assembly.

Is the MIL on?

Substitute a known-good ECM

and recheck. If symptom/indica-

tion goes away, replace the origi-

nal

ECM.

— Repair short in the wire

between NO. 1 (BACK-UP

LIGHTS, METER LIGHTS) (10

A) fuse and gauge assembly.

— Replace No. 1 (BACK-UP

LIGHTS, METER LIGHTS) (10 A)

fuse.

Check for an open in the wires

(PG1, PG2 lines):

1. Turn the ignition switch ON (II).

2. Measure voltage between

body ground and ECM con-

nector terminals A12 and A25

individually.

Is there less than 1.0 V?

Repair open in the wires

between ECM (A7) and gauge

assembly.

Replace the MIL bulb.

ECM CONNECTOR A (26P)

Wire side of female terminals

Repair open in the wire(s)

between ECM and G101 (located

at left side of engine) that had

more than 1.0 V.

ECM CONNECTOR A (26P)

Wire side of female terminals

The Malfunction Indicator Lamp

(MIL) never comes on (even for

two seconds) after ignition is

turned on.

Turn the ignition switch ON (II).

JUMPER WIREProCarManuals.com

Page 888 of 1771

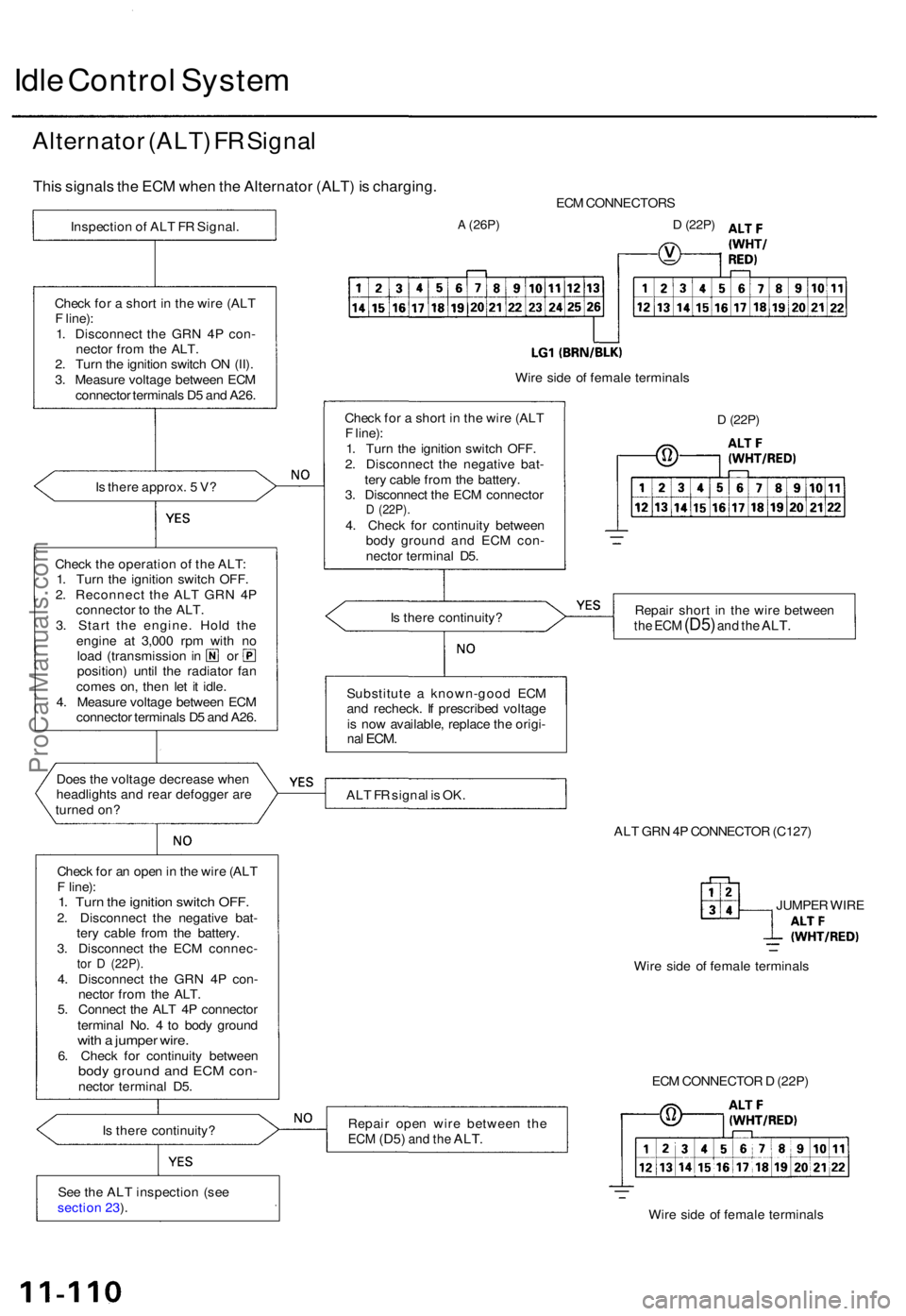

Idle Contro l Syste m

Alternato r (ALT ) F R Signa l

This signal s th e EC M whe n th e Alternato r (ALT ) i s charging .

Is ther e approx . 5 V ?

Chec k th e operatio n o f th e ALT :

1 . Tur n th e ignitio n switc h OFF .

2 . Reconnec t th e AL T GR N 4 P

connecto r t o th e ALT .

3 . Star t th e engine . Hol d th e

engin e a t 3,00 0 rp m wit h n o

loa d (transmissio n in o r

position ) unti l th e radiato r fa n

come s on , the n le t i t idle .

4 . Measur e voltag e betwee n EC M

connecto r terminal s D 5 an d A26 .

Doe s th e voltag e decreas e whe n

headlight s an d rea r defogge r ar e

turne d on ?

Chec k fo r a n ope n in th e wir e (AL T

F line) :

1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e negativ e bat -

ter y cabl e fro m th e battery .

3 . Disconnec t th e EC M connec -

tor D (22P) .4. Disconnec t th e GR N 4 P con -

necto r fro m th e ALT .

5 . Connec t th e AL T 4 P connecto r

termina l No . 4 to bod y groun d

with a jumpe r wire .6. Chec k fo r continuit y betwee nbody groun d an d EC M con -necto r termina l D5 .

I s ther e continuity ?

Se e th e AL T inspectio n (se e

sectio n 23 ). EC

M CONNECTOR S

A (26P)D (22P)

Wire sid e o f femal e terminal s

D (22P)

Repai r shor t i n th e wir e betwee nthe EC M (D5 ) and th e ALT .

ALT F R signa l i s OK .

ALT GR N 4P CONNECTO R (C127 )

JUMPE R WIR E

Wir e sid e o f femal e terminal s

Repai r ope n wir e betwee n th e

ECM (D5 ) and th e ALT .

ECM CONNECTO R D (22P )

Wir e sid e o f femal e terminal s

Substitut

e a known-goo d EC M

an d recheck . I f prescribe d voltag e

i s no w available , replac e th e origi -

nal ECM .

Is ther e continuity ?

Chec

k fo r a shor t i n th e wir e (AL T

F line) :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e negativ e bat -

ter y cabl e fro m th e battery .

3 . Disconnec t th e EC M connecto r

D (22P) .4. Chec k fo r continuit y betwee n

bod y groun d an d EC M con -

necto r termina l D5 .

Chec

k fo r a shor t i n th e wir e (AL T

F line) :

1 . Disconnec t th e GR N 4 P con -

necto r fro m th e ALT .

2 . Tur n th e ignitio n switc h O N (II) .

3 . Measur e voltag e betwee n EC M

connecto r terminal s D 5 an d A26 .

Inspectio

n o f AL T F R Signal .

ProCarManuals.com

Page 895 of 1771

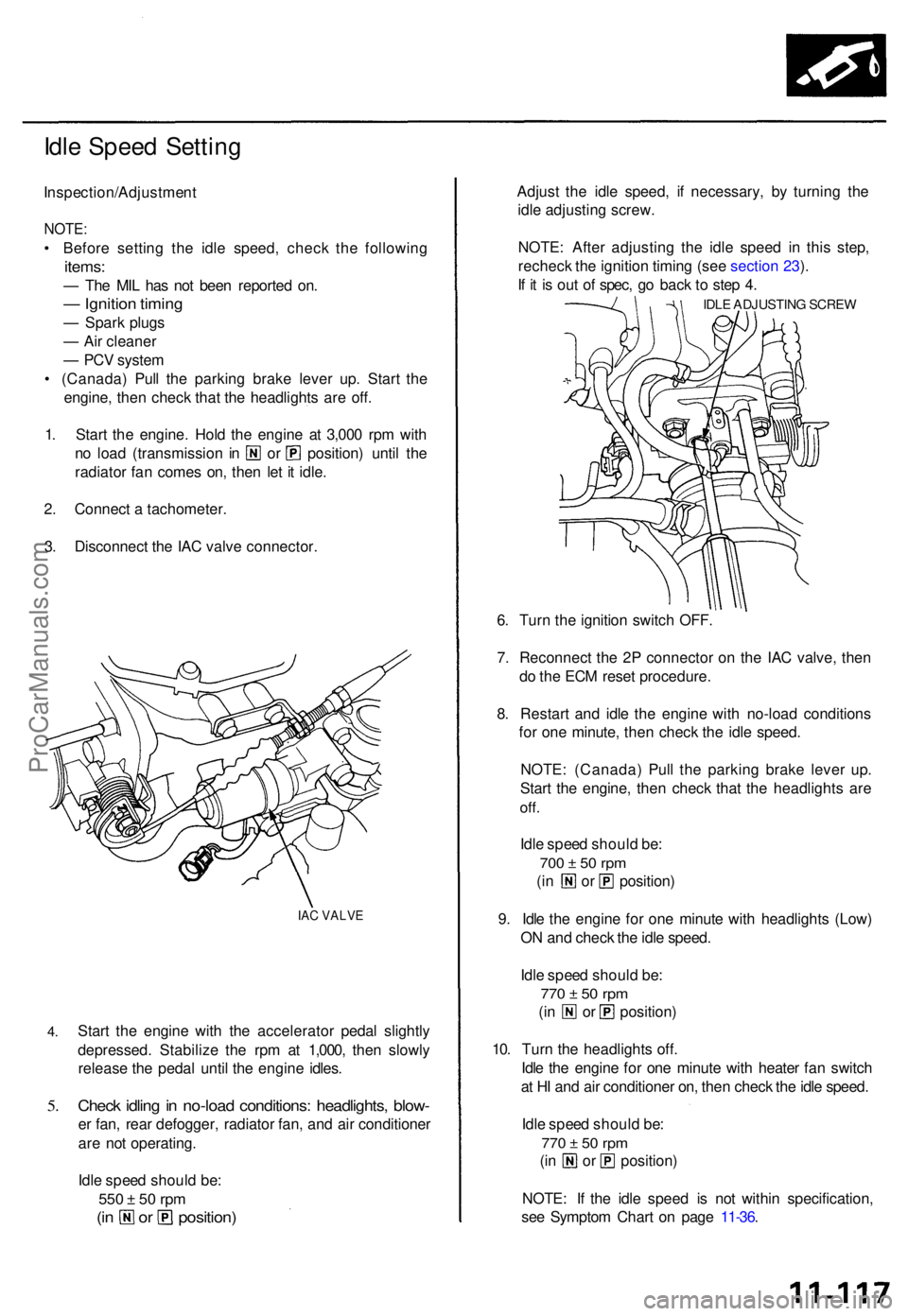

Idle Spee d Settin g

Inspection/Adjustmen t

NOTE:

• Befor e settin g th e idl e speed , chec k th e followin g

items:

— Th e MI L ha s no t bee n reporte d on .

— Ignitio n timin g

— Spar k plug s

— Ai r cleane r

— PC V syste m

• (Canada ) Pul l th e parkin g brak e leve r up . Star t th e

engine , the n chec k tha t th e headlight s ar e off .

1 . Star t th e engine . Hol d th e engine at 3,00 0 rp m wit h

no loa d (transmissio n i n o r position ) unti l th e

radiato r fa n come s on , the n le t i t idle .

2 . Connec t a tachometer .

3 . Disconnec t th e IA C valv e connector .

IAC VALV E

4.

5.

Star t th e engin e wit h th e accelerato r peda l slightl y

depressed . Stabiliz e th e rp m a t 1,000 , the n slowl y

releas e th e peda l unti l th e engin e idles .

Check idlin g in no-loa d conditions : headlights , blow -

er fan , rea r defogger , radiato r fan , an d ai r conditione r

ar e no t operating .

Idl e spee d shoul d be :

550 ± 5 0 rp m

(in o r position )

Adjust th e idl e speed , i f necessary, by turnin g th e

idl e adjustin g screw .

NOTE : Afte r adjustin g th e idl e spee d i n thi s step ,

rechec k th e ignitio n timin g (se e sectio n 23 ).

I f i t i s ou t o f spec , g o bac k t o ste p 4 .

IDL E ADJUSTIN G SCRE W

6. Tur n th e ignitio n switc h OFF .

7 . Reconnec t th e 2 P connecto r o n th e IA C valve , the n

d o th e EC M rese t procedure .

8 . Restar t an d idl e th e engine with no-loa d condition s

fo r on e minute , the n chec k th e idl e speed .

NOTE : (Canada ) Pul l th e parkin g brak e leve r up .

Star t th e engine , the n chec k tha t th e headlight s ar e

off.

Idle spee d shoul d be :

700 ± 5 0 rp m

(in o r position )

9 . Idl e th e engin e fo r on e minut e wit h headlight s (Low )

O N an d chec k th e idl e speed .

Idl e spee d shoul d be :

770 ± 5 0 rp m

(in o r position )

10 . Tur n th e headlight s off .

Idl e th e engin e fo r on e minut e wit h heate r fa n switc h

a t H I an d ai r conditione r on , the n chec k th e idl e speed .

Idl e spee d shoul d be :

770 ± 5 0 rp m

(in o r position )

NOTE : I f th e idl e spee d i s no t withi n specification ,

se e Sympto m Char t o n pag e 11-36 .

ProCarManuals.com

Page 929 of 1771

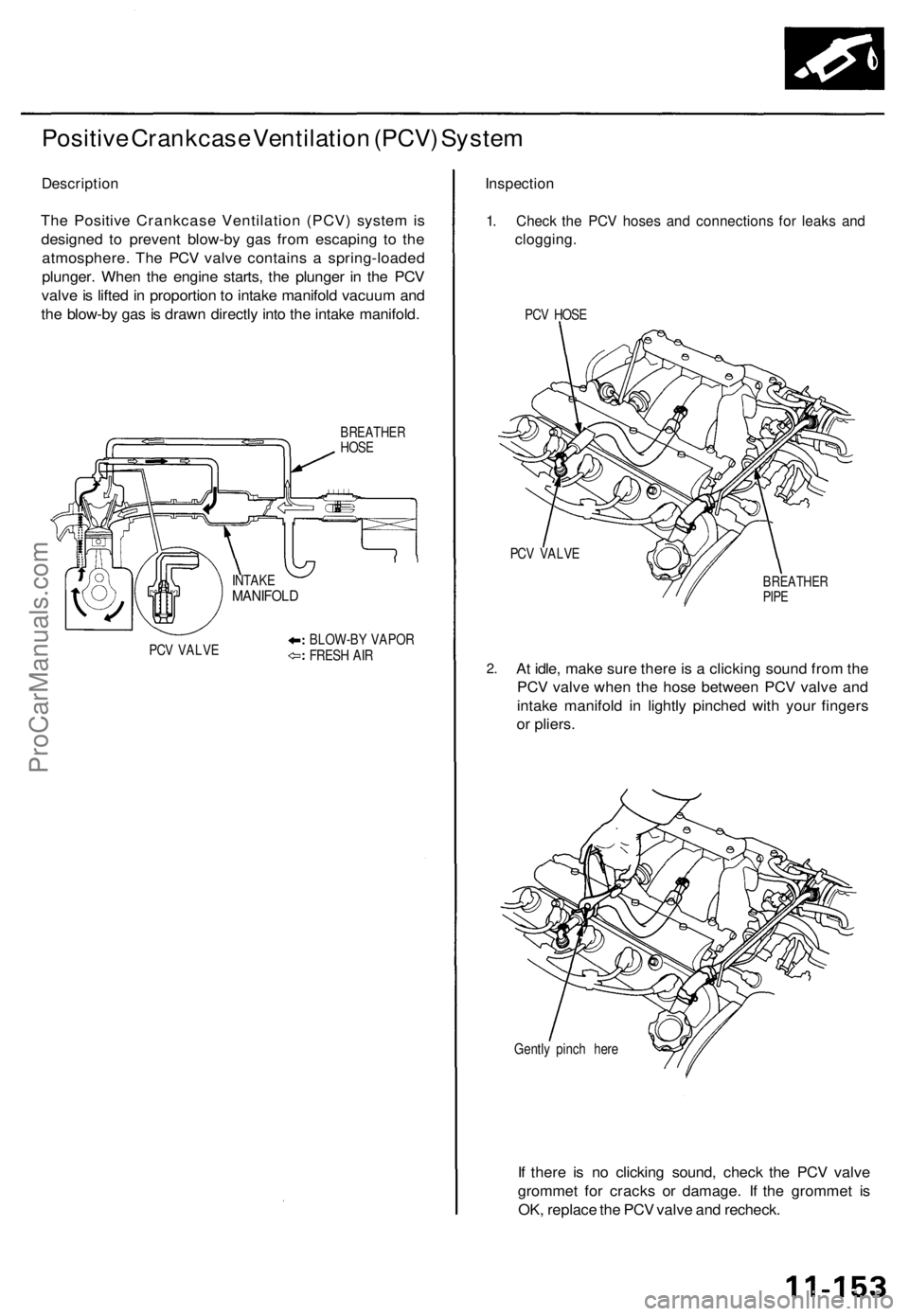

Positive Crankcase Ventilation (PCV) System

Description

The Positive Crankcase Ventilation (PCV) system is

designed to prevent blow-by gas from escaping to the

atmosphere. The PCV valve contains a spring-loaded

plunger. When the engine starts, the plunger in the PCV

valve is lifted in proportion to intake manifold vacuum and

the blow-by gas is drawn directly into the intake manifold.

BREATHER

HOSE

PCV VALVE

BLOW-BY VAPOR

FRESH AIR

Inspection

1. Check the PCV hoses and connections for leaks and

clogging.

PCV HOSE

PCV VALVE

2.

BREATHER

PIPE

At idle, make sure there is a clicking sound from the

PCV valve when the hose between PCV valve and

intake manifold in lightly pinched with your fingers

or pliers.

Gently pinch here

If there is no clicking sound, check the PCV valve

grommet for cracks or damage. If the grommet is

OK, replace the PCV valve and recheck.

INTAKE

MANIFOLDProCarManuals.com

Page 951 of 1771

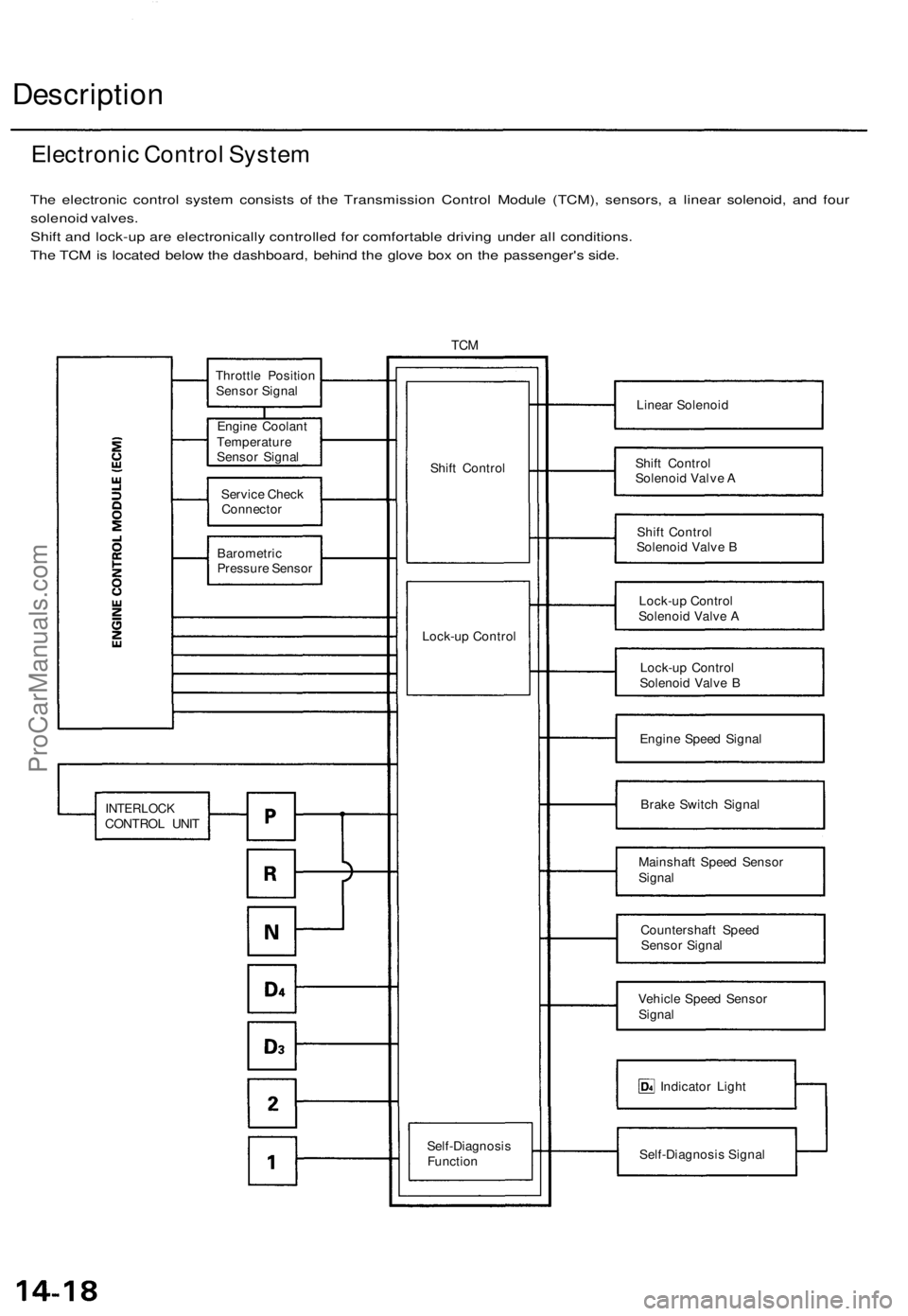

Description

The electronic control system consists of the Transmission Control Module (TCM), sensors, a linear solenoid, and four

solenoid valves.

Shift and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located below the dashboard, behind the glove box on the passenger's side.

TCM

Linear Solenoid

Shift Control

Solenoid Valve A

Shift Control

Solenoid Valve B

Lock-up Control

Solenoid Valve A

Lock-up Control

Solenoid Valve B

Engine Speed Signal

Brake Switch Signal

Mainshaft Speed Sensor

Signal

Countershaft Speed

Sensor Signal

Vehicle Speed Sensor

Signal

Indicator Light

Self-Diagnosis Signal

Electronic Control System

Shift Control

Lock-up Control

Throttle Position

Sensor Signal

Engine Coolant

Temperature

Sensor Signal

Service Check

Connector

Barometric

Pressure Sensor

INTERLOCK

CONTROL UNIT

Self-Diagnosis

FunctionProCarManuals.com