check engine light ACURA TL 1995 Service Owner's Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 988 of 1771

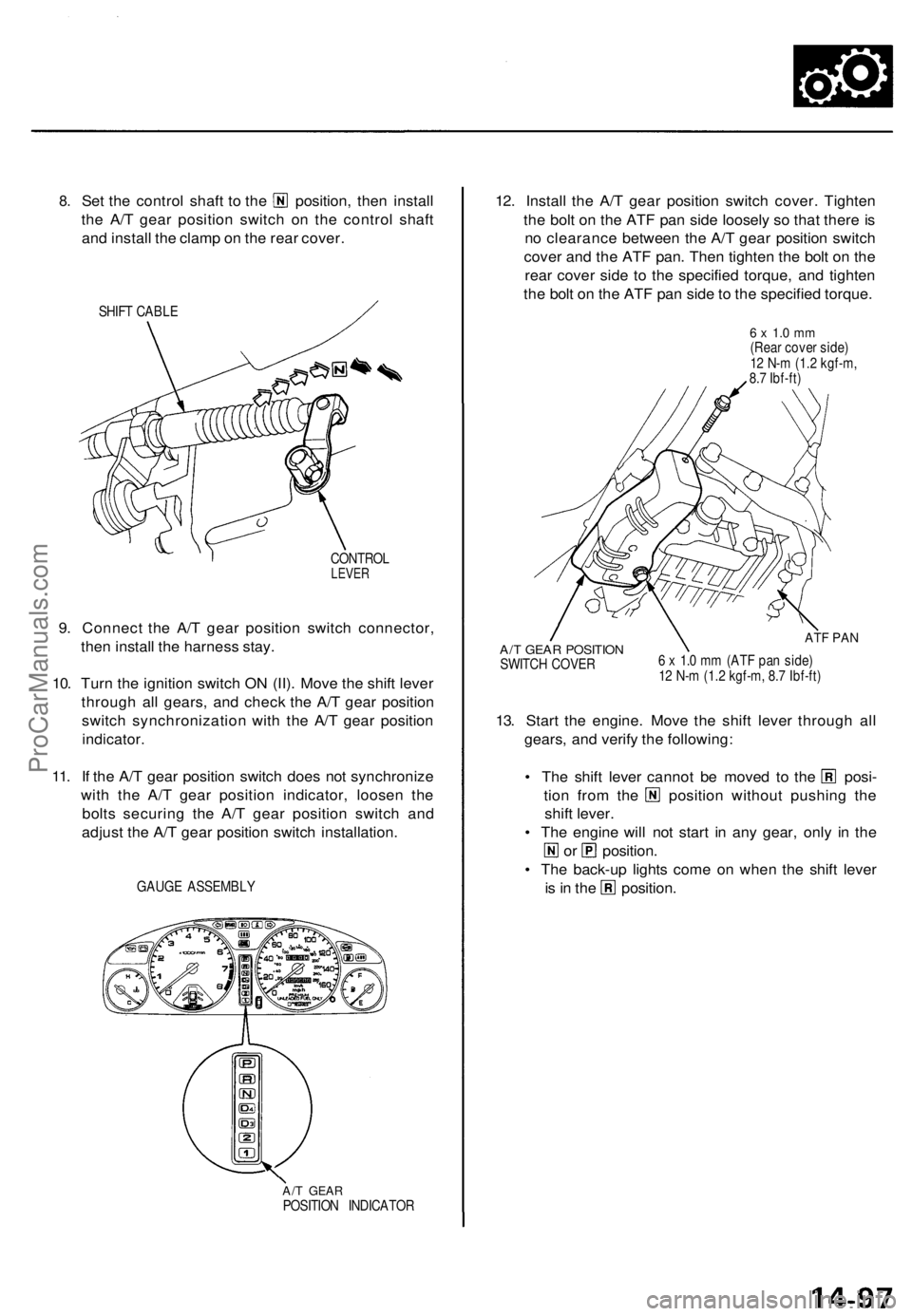

8.

Set the control shaft to the position, then install

the A/T gear position switch on the control shaft

and install the clamp on the rear cover.

SHIFT CABLE

CONTROL

LEVER

9. Connect the A/T gear position switch connector,

then install the harness stay.

10. Turn the ignition switch ON (II). Move the shift lever

through all gears, and check the A/T gear position

switch synchronization with the A/T gear position

indicator.

11. If the A/T gear position switch does not synchronize

with the A/T gear position indicator, loosen the

bolts securing the A/T gear position switch and

adjust the A/T gear position switch installation.

GAUGE ASSEMBLY

A/T GEAR

POSITION INDICATOR

12. Install the A/T gear position switch cover. Tighten

the bolt on the ATF pan side loosely so that there is

no clearance between the A/T gear position switch

cover and the ATF pan. Then tighten the bolt on the

rear cover side to the specified torque, and tighten

the bolt on the ATF pan side to the specified torque.

6 x 1.0 mm

(Rear cover side)

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

A/T GEAR POSITION

SWITCH COVER

ATF PAN

6 x 1.0 mm (ATF pan side)

12 N-m (1.2 kgf-m, 8.7 Ibf-ft)

13. Start the engine. Move the shift lever through all

gears, and verify the following:

• The shift lever cannot be moved to the posi-

tion from the position without pushing the

shift lever.

• The engine will not start in any gear, only in the

or position.

• The back-up lights come on when the shift lever

is in the position.ProCarManuals.com

Page 1263 of 1771

Brake Booster

Inspection

Functional Test

1. With the engine stopped, depress the brake pedal

several times to deplete the vacuum reservoir, then

depress the pedal hard and hold it for 15 seconds. If

the pedal sinks, either the master cylinder is

bypassing internally, or the brake system (master

cylinder, lines, modulator, proportioning valve, or

caliper) is leaking.

2. Start the engine with the pedal depressed. If the

pedal sinks slightly, the vacuum booster is operat-

ing normally. If the pedal height does not vary, the

booster or check valve is faulty.

3. With the engine running, depress the brake pedal

lightly. Apply just enough pressure to hold back

automatic transmission creep. If the brake pedal

sinks more than 25 mm (1.0 in.) in three minutes, the

master cylinder is faulty. A slight change in pedal

height when the A/C compressor cycles on and off if

normal. (The A/C compressor load changes the vac-

uum available to the booster.)

Leak Test

1. Depress the brake pedal with the engine running,

then stop the engine. If the pedal height does not

vary while depressed for 30 seconds, the vacuum

booster is OK. If the pedal rises, the booster is faulty.

2. With the engine stopped, depress the brake pedal

several times using normal pressure. When the

pedal is first depressed, it should be low. On consec-

utive applications, the pedal height should gradually

rise. If the pedal position does not vary, check the

booster check valve.ProCarManuals.com

Page 1291 of 1771

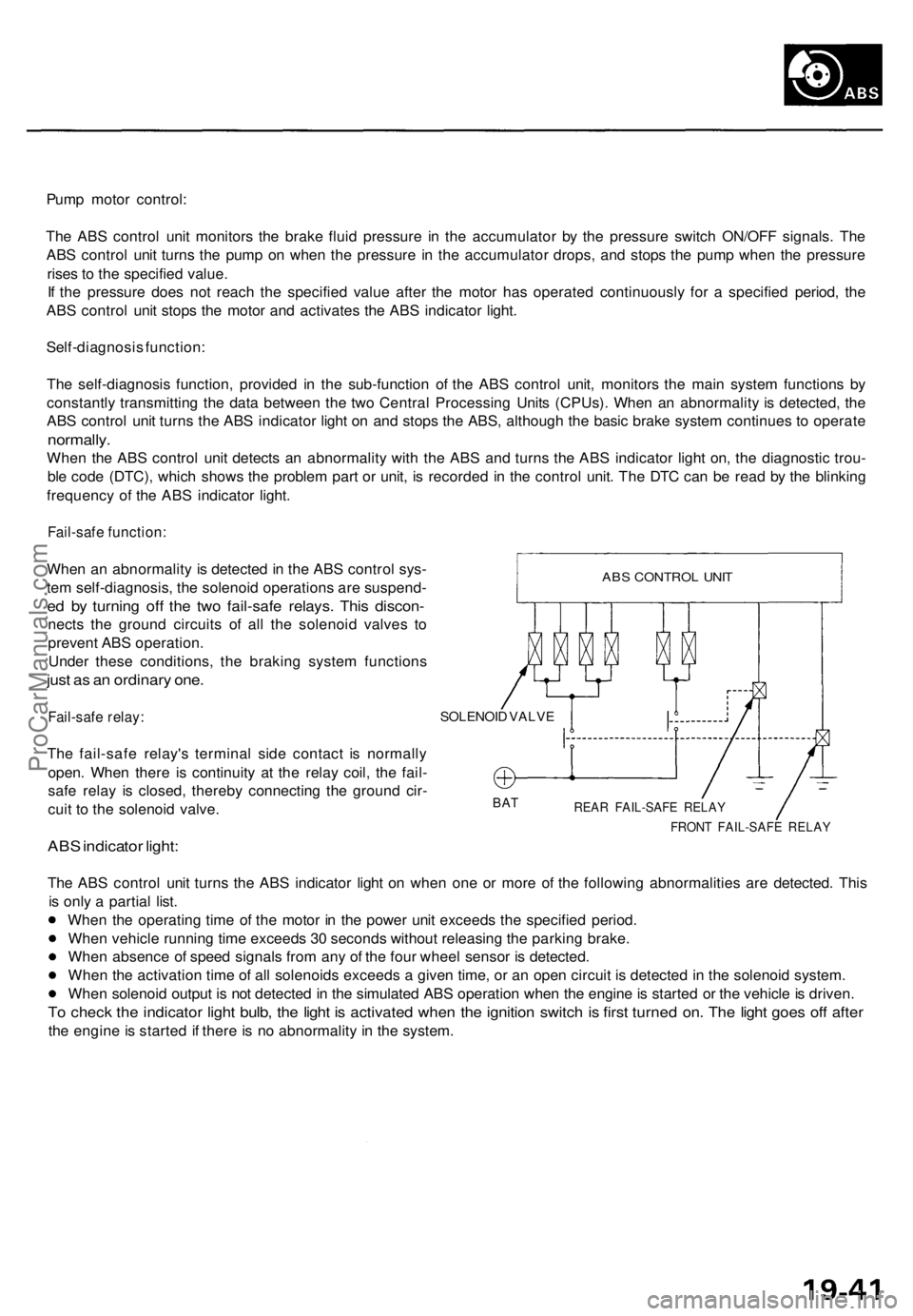

Pump motor control:

The ABS control unit monitors the brake fluid pressure in the accumulator by the pressure switch ON/OFF signals. The

ABS control unit turns the pump on when the pressure in the accumulator drops, and stops the pump when the pressure

rises to the specified value.

If the pressure does not reach the specified value after the motor has operated continuously for a specified period, the

ABS control unit stops the motor and activates the ABS indicator light.

Self-diagnosis function:

The self-diagnosis function, provided in the sub-function of the ABS control unit, monitors the main system functions by

constantly transmitting the data between the two Central Processing Units (CPUs). When an abnormality is detected, the

ABS control unit turns the ABS indicator light on and stops the ABS, although the basic brake system continues to operate

normally.

When the ABS control unit detects an abnormality with the ABS and turns the ABS indicator light on, the diagnostic trou-

ble code (DTC), which shows the problem part or unit, is recorded in the control unit. The DTC can be read by the blinking

frequency of the ABS indicator light.

Fail-safe function:

When an abnormality is detected in the ABS control sys-

tem self-diagnosis, the solenoid operations are suspend-

ed by turning off the two fail-safe relays. This discon-

nects the ground circuits of all the solenoid valves to

prevent ABS operation.

Under these conditions, the braking system functions

just as an ordinary one.

Fail-safe relay:

The fail-safe relay's terminal side contact is normally

open. When there is continuity at the relay coil, the fail-

safe relay is closed, thereby connecting the ground cir-

cuit to the solenoid valve.

ABS indicator light:

SOLENOID VALVE

BAT

REAR FAIL-SAFE RELAY

FRONT FAIL-SAFE RELAY

The ABS control unit turns the ABS indicator light on when one or more of the following abnormalities are detected. This

is only a partial list.

When the operating time of the motor in the power unit exceeds the specified period.

When vehicle running time exceeds 30 seconds without releasing the parking brake.

When absence of speed signals from any of the four wheel sensor is detected.

When the activation time of all solenoids exceeds a given time, or an open circuit is detected in the solenoid system.

When solenoid output is not detected in the simulated ABS operation when the engine is started or the vehicle is driven.

To check the indicator light bulb, the light is activated when the ignition switch is first turned on. The light goes off after

the engine is started if there is no abnormality in the system.

ABS CONTROL UNITProCarManuals.com

Page 1299 of 1771

Troubleshooting Precautions

ABS Indicator Light:

The ABS indicator light comes on for three seconds and then goes off when the control unit detects no problem during the

initial diagnosis right after the engine starts. However, the ABS indicator light can stay on for up to 40 seconds when the

control unit starts to check for pump overrun, etc. during the initial diagnosis. The ABS indicator light comes on, and the

ABS control unit memorizes the diagnostic trouble code (DTC) under certain conditions.

The parking brake is applied for more than 30 seconds while the vehicle is being driven. (DTC 2-1)

The transmission downshifted excessively. (DTC 4-1, 4-2)

The vehicle loses traction, and the front wheels spin for more than one minute when starting from a stuck condition on

a muddy, snowy, or sandy road. (DTC 4-8)

Tire adhesion is lost due to excessive cornering speed. (DTC 5, 5-4, 5-8)

The vehicle is driven on an extremely rough road. (DTC 8-1)

The vehicle is interfered by strong radio waves (noise), for example, illegal radio, etc. (DTC 8-2)

NOTE: If there is any trouble in the system, the ABS indicator light comes on during driving.

Diagnostic Trouble Code (DTC):

When the control unit detects a problem and the ABS indicator light comes on, the control unit memorizes the DTC.

The control unit has three memory registers. When a problem occurs, the control unit stores the DTC in the first memory

register. If another problem occurs, or the same problem occurs again, the control unit moves the first DTC to the next

memory register, and stores the second DTC in the first register. If there's a third problem occurrence, the two existing

DTCs are moved up one register, and the third DTC is stored in the first register. If problems continue to occur, the oldest

problem is moved out of the last register and lost, and the most recent problem is stored in the first register. When the

same problem occurs three times, the same DTC is stored in all memory registers. (Refer to the Symptom-to-System

Chart for diagnostic period.)

The most recent DTC is indicated first, and the oldest DTC is indicated last.

The DTCs are erased from the control unit when the ABS control unit +B2 power supply or connector is disconnected.

The control unit's memory can be erased by disconnecting the ABS B2 fuse for more than three seconds.

Self-diagnosis:

There are three self-diagnosises described below.

Initial diagnosis: Performed right after the engine starts until the ABS indicator light goes off.

Regular diagnosis: Continuously performed (under some conditions) after the ABS indicator light goes off until the

engine stops.

Individual part/system diagnosis: Diagnosis about a specific part/system under its operating conditions.

The CPU (central processing unit) controls the following when it detects a problem during self-diagnosis:

Turns the ABS indicator light ON.

Turns the front and rear fail-safe relays off.

Stops the ABS control.

Stops the ABS pump. (The pump may work under some conditions.)

After the DTC is stored in the control unit, the CPU stops self-diagnosis.ProCarManuals.com

Page 1300 of 1771

Kickback and Pump Operation:

When the engine is started, the ABS control unit begins the initial diagnosis and operates the solenoid valve one time.

The kickback may be felt when the brake pedal is depressed.

When the ABS control unit detects the pressure switch OFF signal during the initial diagnosis, it operates the pump

motor, and performs the pump motor over-run diagnosis and pump motor diagnosis. Therefore, there are two cases

where the pump motor operates or does not operate after the engine is started.

Normally, after the initial diagnosis, the pump motor operates based on the pressure switch signal, regardless of the

vehicle speed.

Troubleshooting:

When two or three DTCs are stored in the control unit, perform troubleshooting for the DTC that appears first.

When a customer's reported problem cannot be verified on the car, ask the customer about the conditions when the

ABS indicator light came ON, and test-drive the car under those conditions, if possible. When the ABS indicator light

does not come ON during the test, check for loose terminals and check by shaking the harnesses and connectors while

following the flowchart.

The connector terminal numbers are viewed from the wire side for the female terminals, and from the terminal side for

the male terminals.

After the repair is completed, test-drive the car and check that the ABS indicator light does not come ON again during

the test. (Refer to the Symptom-to-System Chart for diagnostic period.)ProCarManuals.com

Page 1302 of 1771

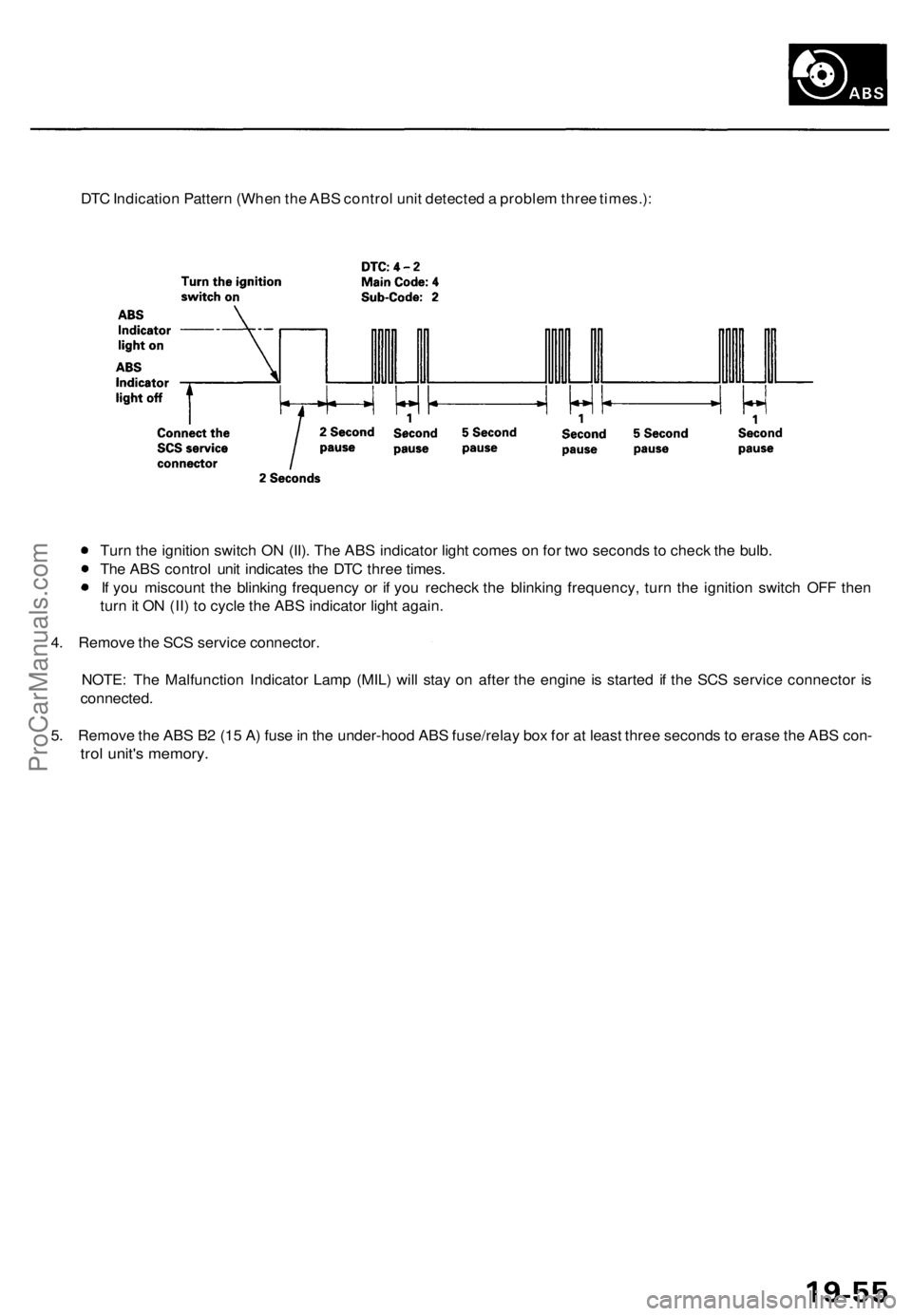

DTC Indication Pattern (When the ABS control unit detected a problem three times.):

Turn the ignition switch ON (II). The ABS indicator light comes on for two seconds to check the bulb.

The ABS control unit indicates the DTC three times.

If you miscount the blinking frequency or if you recheck the blinking frequency, turn the ignition switch OFF then

turn it ON (II) to cycle the ABS indicator light again.

4. Remove the SCS service connector.

NOTE: The Malfunction Indicator Lamp (MIL) will stay on after the engine is started if the SCS service connector is

connected.

5. Remove the ABS B2 (15 A) fuse in the under-hood ABS fuse/relay box for at least three seconds to erase the ABS con-

trol unit's memory.ProCarManuals.com

Page 1335 of 1771

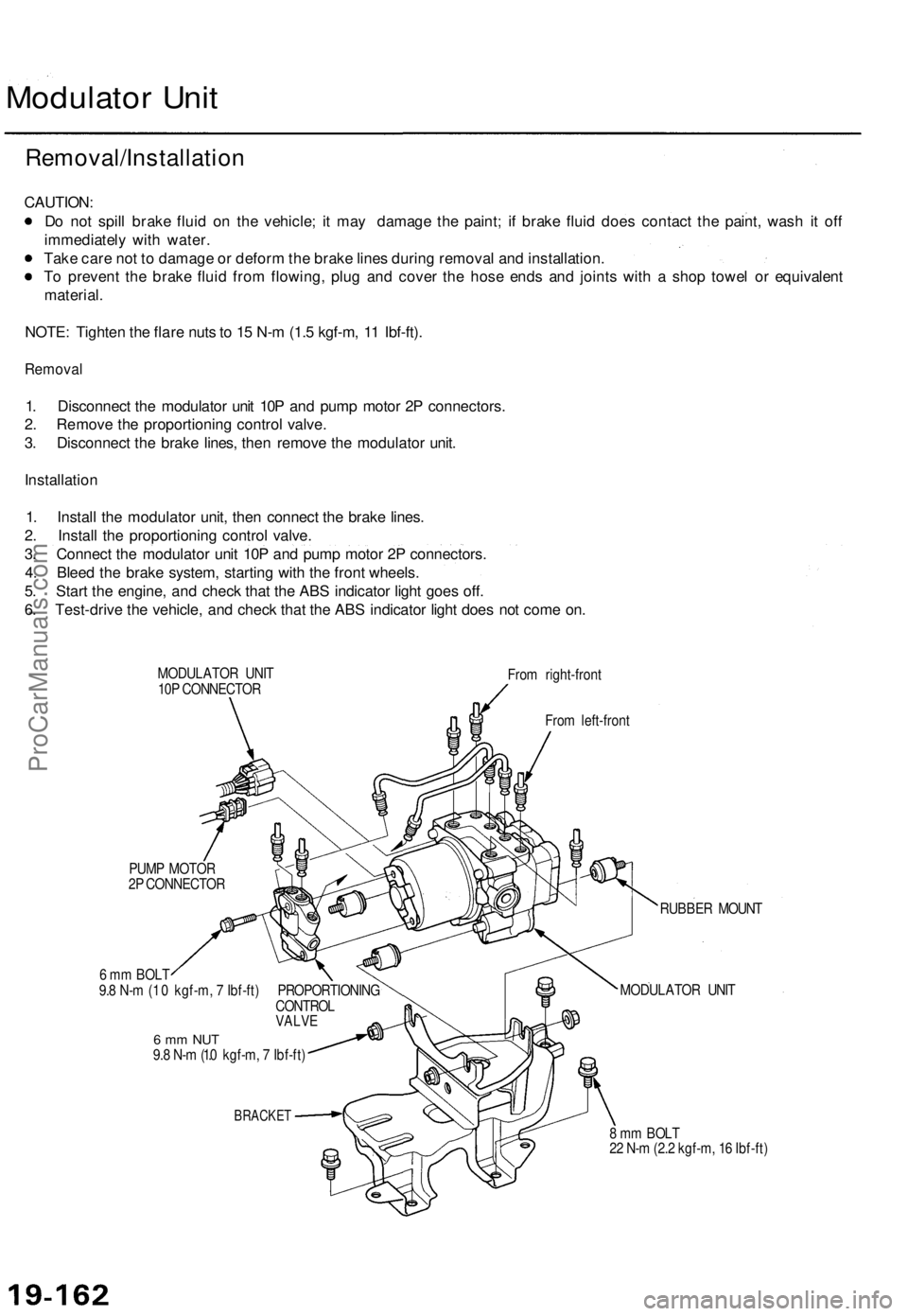

Modulator Unit

Removal/Installation

CAUTION:

Do not spill brake fluid on the vehicle; it may damage the paint; if brake fluid does contact the paint, wash it off

immediately with water.

Take care not to damage or deform the brake lines during removal and installation.

To prevent the brake fluid from flowing, plug and cover the hose ends and joints with a shop towel or equivalent

material.

NOTE: Tighten the flare nuts to 15 N-m (1.5 kgf-m, 11 Ibf-ft).

Removal

1. Disconnect the modulator unit 10P and pump motor 2P connectors.

2. Remove the proportioning control valve.

3. Disconnect the brake lines, then remove the modulator unit.

Installation

1. Install the modulator unit, then connect the brake lines.

2. Install the proportioning control valve.

3. Connect the modulator unit 10P and pump motor 2P connectors.

4. Bleed the brake system, starting with the front wheels.

5. Start the engine, and check that the ABS indicator light goes off.

6. Test-drive the vehicle, and check that the ABS indicator light does not come on.

MODULATOR UNIT

10P CONNECTOR

From right-front

From left-front

PUMP MOTOR

2P CONNECTOR

6 mm BOLT

9.8 N-m (1 .0 kgf-m, 7 Ibf-ft) PROPORTIONING

CONTROL

VALVE

6 mm NUT

9.8 N-m (1.0 kgf-m, 7 Ibf-ft)

BRACKET

RUBBER MOUNT

MODULATOR UNIT

8 mm BOLT

22 N-m (2.2 kgf-m, 16 Ibf-ft)ProCarManuals.com

Page 1580 of 1771

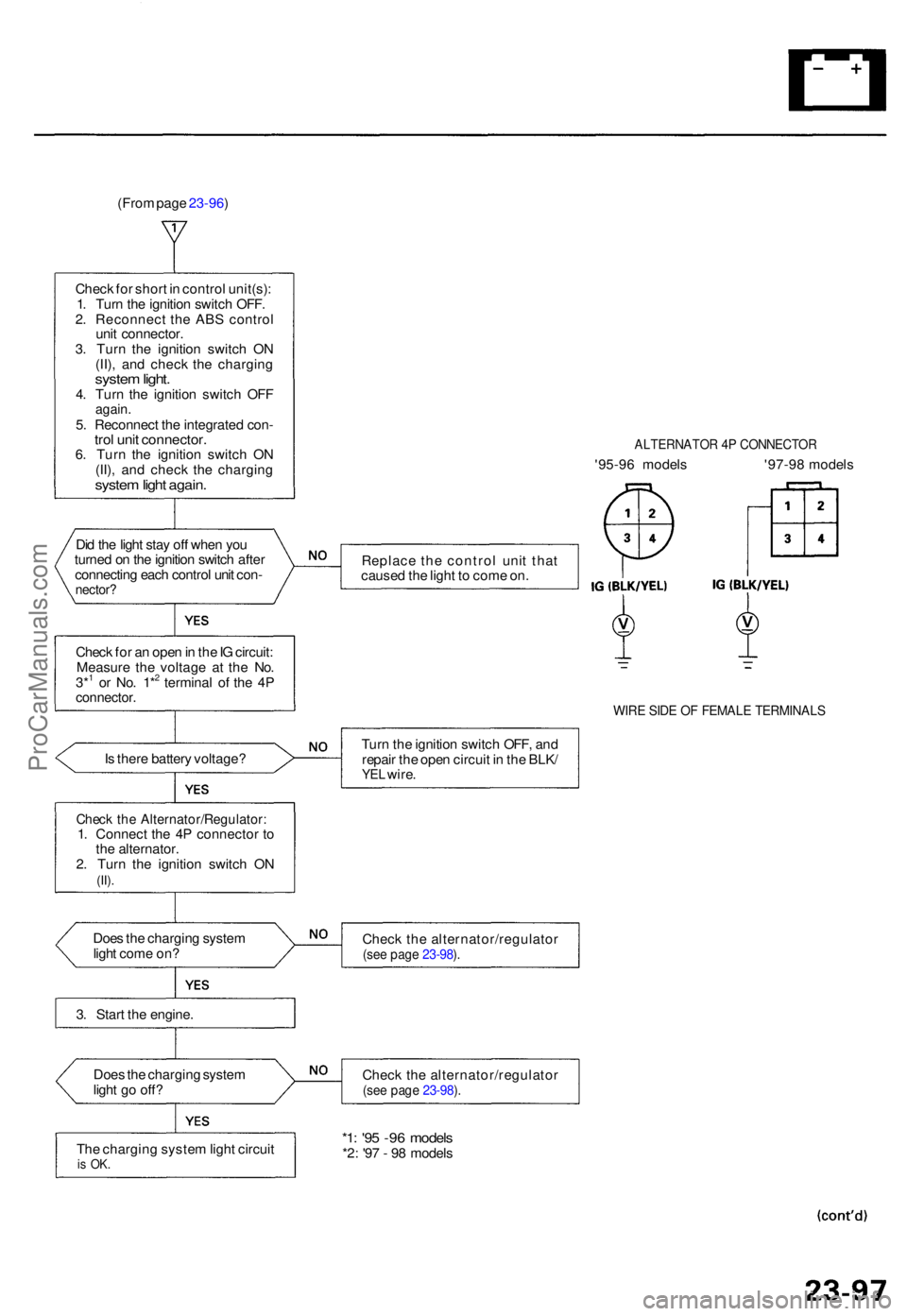

(From page 23-96 )

Chec k fo r shor t i n contro l unit(s) :

1 . Tur n th e ignitio n switc h OFF .

2 . Reconnec t th e AB S contro l

uni t connector .

3 . Tur n th e ignitio n switc h O N

(II) , an d chec k th e chargin g

system light .4. Tur n th e ignitio n switc h OF Fagain .5. Reconnec t th e integrate d con -trol uni t connector .6. Tur n th e ignitio n switc h O N

(II) , an d chec k th e chargin g

system ligh t again .

Did th e ligh t sta y of f whe n yo u

turne d o n th e ignitio n switc h afte r

connectin g eac h contro l uni t con -

nector ?

Check fo r a n ope n in th e IG circuit :

Measur e th e voltag e a t th e No .

3*

1 o r No . 1*2 termina l o f th e 4 Pconnector .

ALTERNATO R 4 P CONNECTO R

'95-96 model s '97-9 8 model s

Replac e th e contro l uni t tha t

cause d th e ligh t t o com e on .

WIR E SID E O F FEMAL E TERMINAL S

Is ther e batter y voltage ? Tur

n th e ignitio n switc h OFF , an d

repai r th e ope n circui t i n th e BLK /YEL wire .

Chec k th e Alternator/Regulator :1. Connec t th e 4 P connecto r t o

th e alternator .

2 . Tur n th e ignitio n switc h O N

(II).

Doe s th e chargin g syste m

ligh t com e on ? Chec

k th e alternator/regulato r(see pag e 23-98 ).

3 . Star t th e engine .

Doe s th e chargin g syste m

ligh t g o off ? Chec

k th e alternator/regulato r

(see pag e 23-98 ).

Th e chargin g syste m ligh t circui tis OK .

*1: '9 5 -9 6 model s*2: '9 7 - 9 8 model s

ProCarManuals.com