clock ACURA TL 1995 Service Owner's Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1268 of 1771

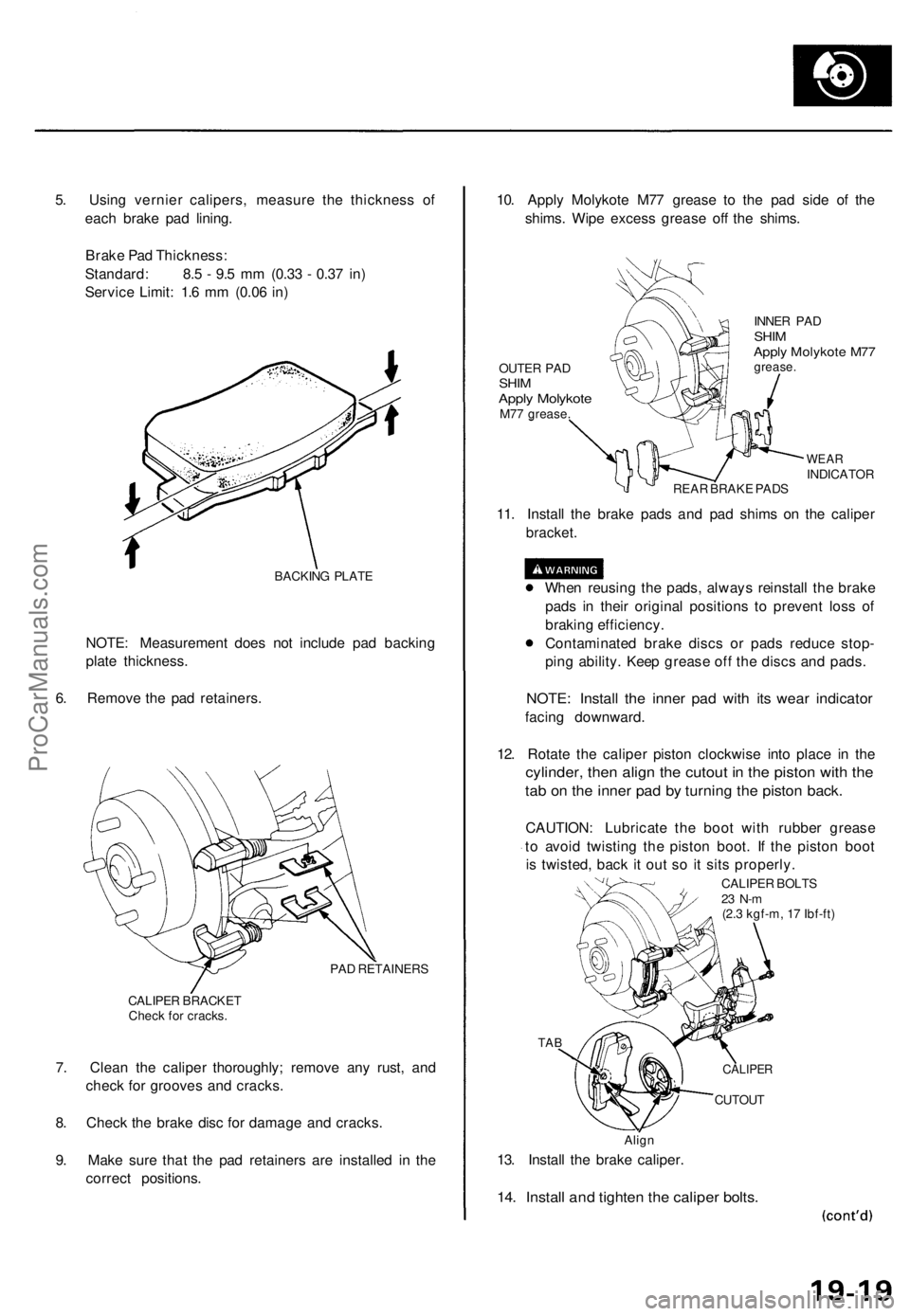

5. Using vernier calipers, measure the thickness of

each brake pad lining.

Brake Pad Thickness:

Standard: 8.5 - 9.5 mm (0.33 - 0.37 in)

Service Limit: 1.6 mm (0.06 in)

BACKING PLATE

NOTE: Measurement does not include pad backing

plate thickness.

6. Remove the pad retainers.

PAD RETAINERS

CALIPER BRACKET

Check for cracks.

7. Clean the caliper thoroughly; remove any rust, and

check for grooves and cracks.

8. Check the brake disc for damage and cracks.

9. Make sure that the pad retainers are installed in the

correct positions.

10. Apply Molykote M77 grease to the pad side of the

shims. Wipe excess grease off the shims.

OUTER PAD

SHIM

Apply Molykote

M77 grease.

INNER PAD

SHIM

Apply Molykote M77

grease.

WEAR

INDICATOR

REAR BRAKE PADS

11. Install the brake pads and pad shims on the caliper

bracket.

When reusing the pads, always reinstall the brake

pads in their original positions to prevent loss of

braking efficiency.

Contaminated brake discs or pads reduce stop-

ping ability. Keep grease off the discs and pads.

NOTE: Install the inner pad with its wear indicator

facing downward.

12. Rotate the caliper piston clockwise into place in the

cylinder, then align the cutout in the piston with the

tab on the inner pad by turning the piston back.

CAUTION: Lubricate the boot with rubber grease

to avoid twisting the piston boot. If the piston boot

is twisted, back it out so it sits properly.

CALIPER BOLTS

23 N-m

(2.3 kgf-m, 17 Ibf-ft)

TAB

CUTOUT

Align

13. Install the brake caliper.

14. Install and tighten the caliper bolts.

CALIPERProCarManuals.com

Page 1273 of 1771

Rear Brake Caliper

Disassembly (cont'd)

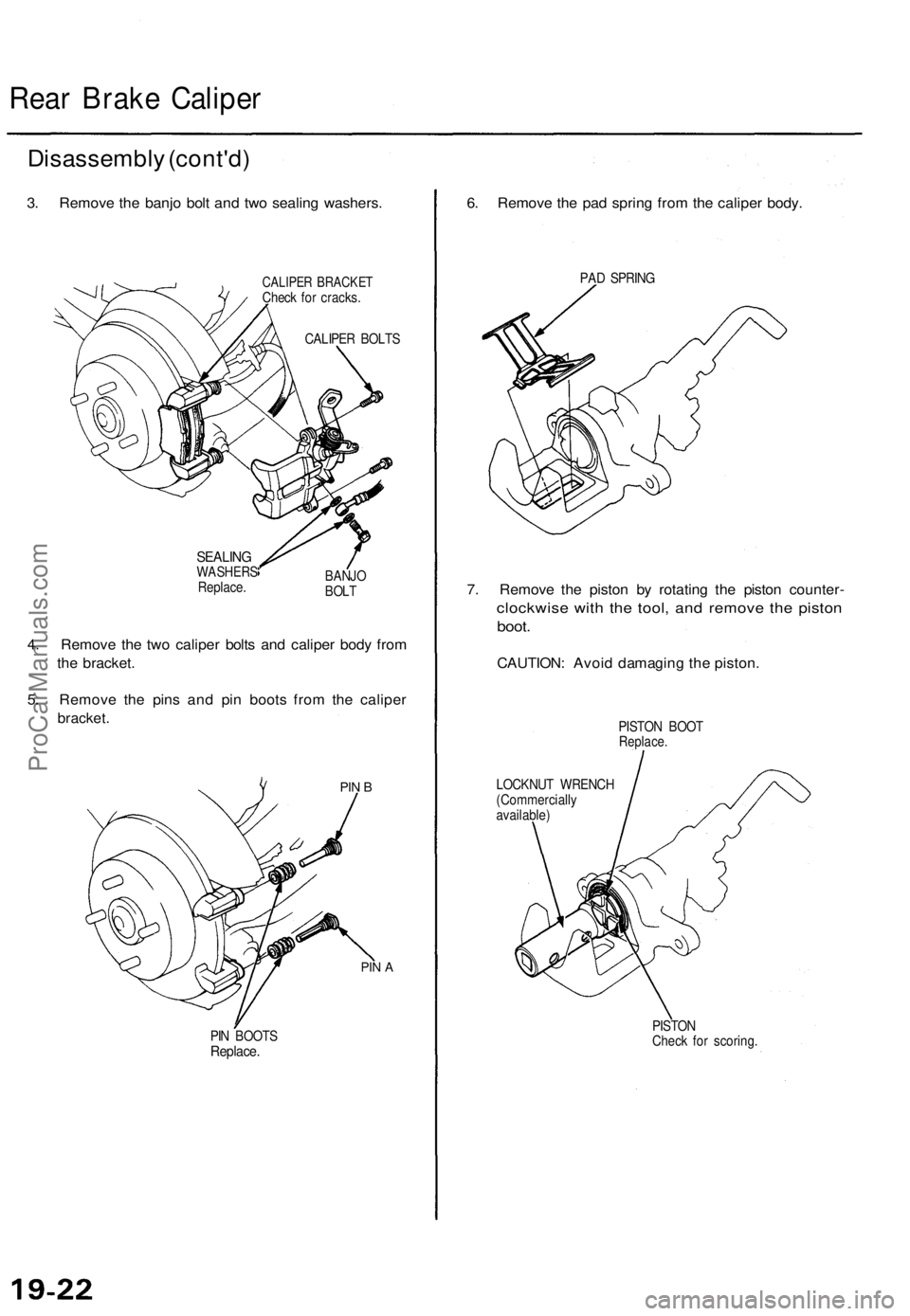

3. Remove the banjo bolt and two sealing washers.

CALIPER BRACKET

Check for cracks.

CALIPER BOLTS

SEALING

WASHERS

Replace.

BANJO

BOLT

4. Remove the two caliper bolts and caliper body from

the bracket.

5. Remove the pins and pin boots from the caliper

bracket.

PIN B

PIN A

PIN BOOTS

Replace.

6. Remove the pad spring from the caliper body.

PAD SPRING

7. Remove the piston by rotating the piston counter-

clockwise with the tool, and remove the piston

boot.

CAUTION: Avoid damaging the piston.

PISTON BOOT

Replace.

LOCKNUT WRENCH

(Commercially

available)

PISTON

Check for scoring.ProCarManuals.com

Page 1274 of 1771

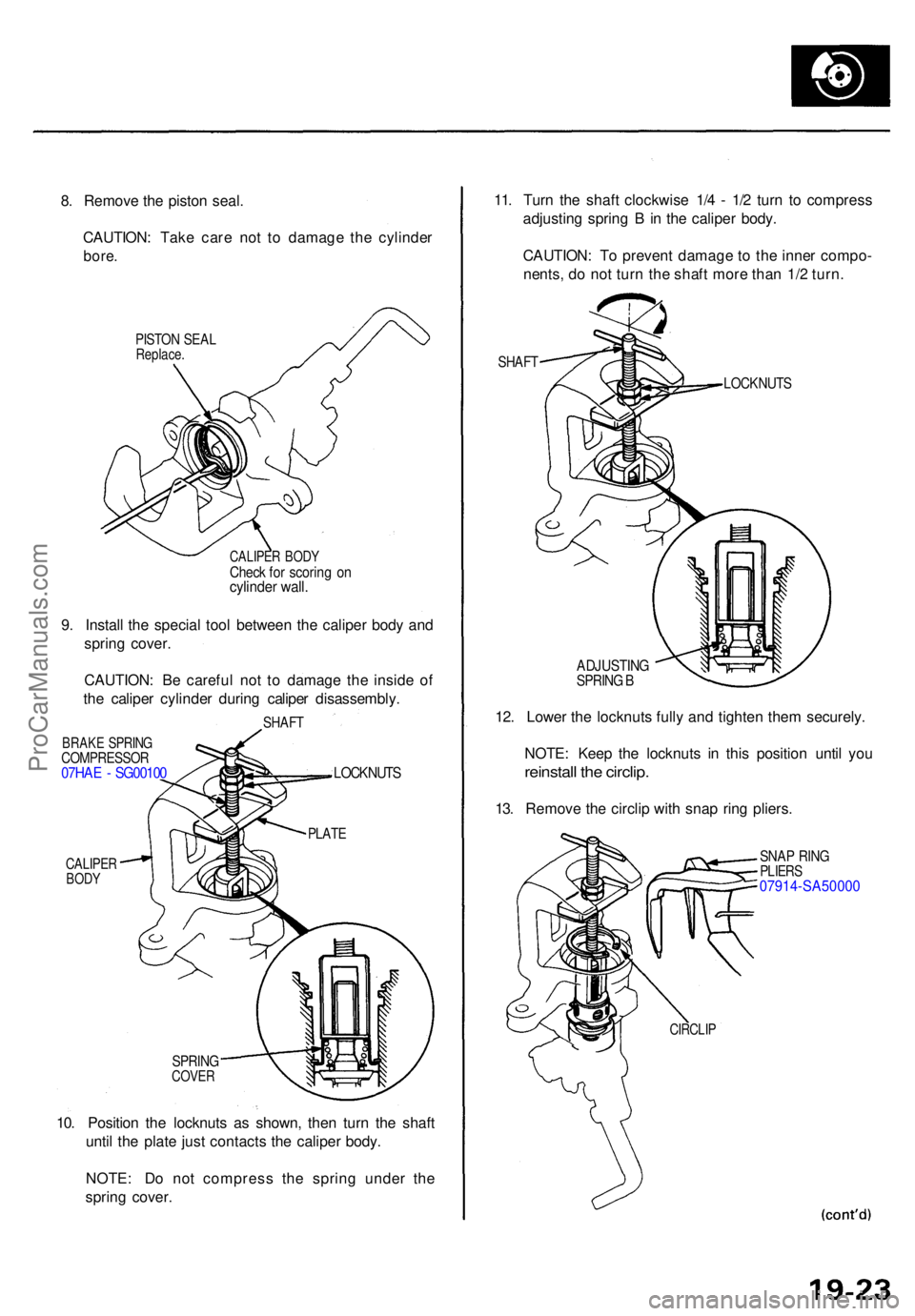

8. Remov e th e pisto n seal .

CAUTION : Tak e car e no t t o damag e th e cylinde r

bore.

PISTO N SEA LReplace .

CALIPER BOD YCheck fo r scorin g o ncylinde r wall .

9. Instal l th e specia l too l betwee n th e calipe r bod y an d

sprin g cover .

CAUTION : B e carefu l no t t o damag e th e insid e o f

th e calipe r cylinde r durin g calipe r disassembly .

SHAFT

BRAK E SPRIN GCOMPRESSO R07HAE - SG0010 0

CALIPERBODY

LOCKNUT S

SPRINGCOVER

10. Positio n th e locknut s a s shown , the n tur n th e shaf t

unti l th e plat e jus t contact s th e calipe r body .

NOTE : D o no t compres s th e sprin g unde r th e

sprin g cover . 11

. Tur n th e shaf t clockwis e 1/ 4 - 1/ 2 tur n t o compres s

adjustin g sprin g B in th e calipe r body .

CAUTION : T o preven t damag e t o th e inne r compo -

nents , d o no t tur n th e shaf t mor e tha n 1/ 2 turn .

SHAF T

LOCKNUT S

ADJUSTIN GSPRING B

12 . Lowe r th e locknut s full y an d tighte n the m securely .

NOTE : Kee p th e locknut s i n thi s positio n unti l yo u

reinstal l th e circlip .

13. Remov e th e circli p wit h sna p rin g pliers .

SNAP RIN GPLIER S07914-SA5000 0

CIRCLIP

PLATE

ProCarManuals.com

Page 1275 of 1771

Rear Brake Caliper

Disassembly (cont'd)

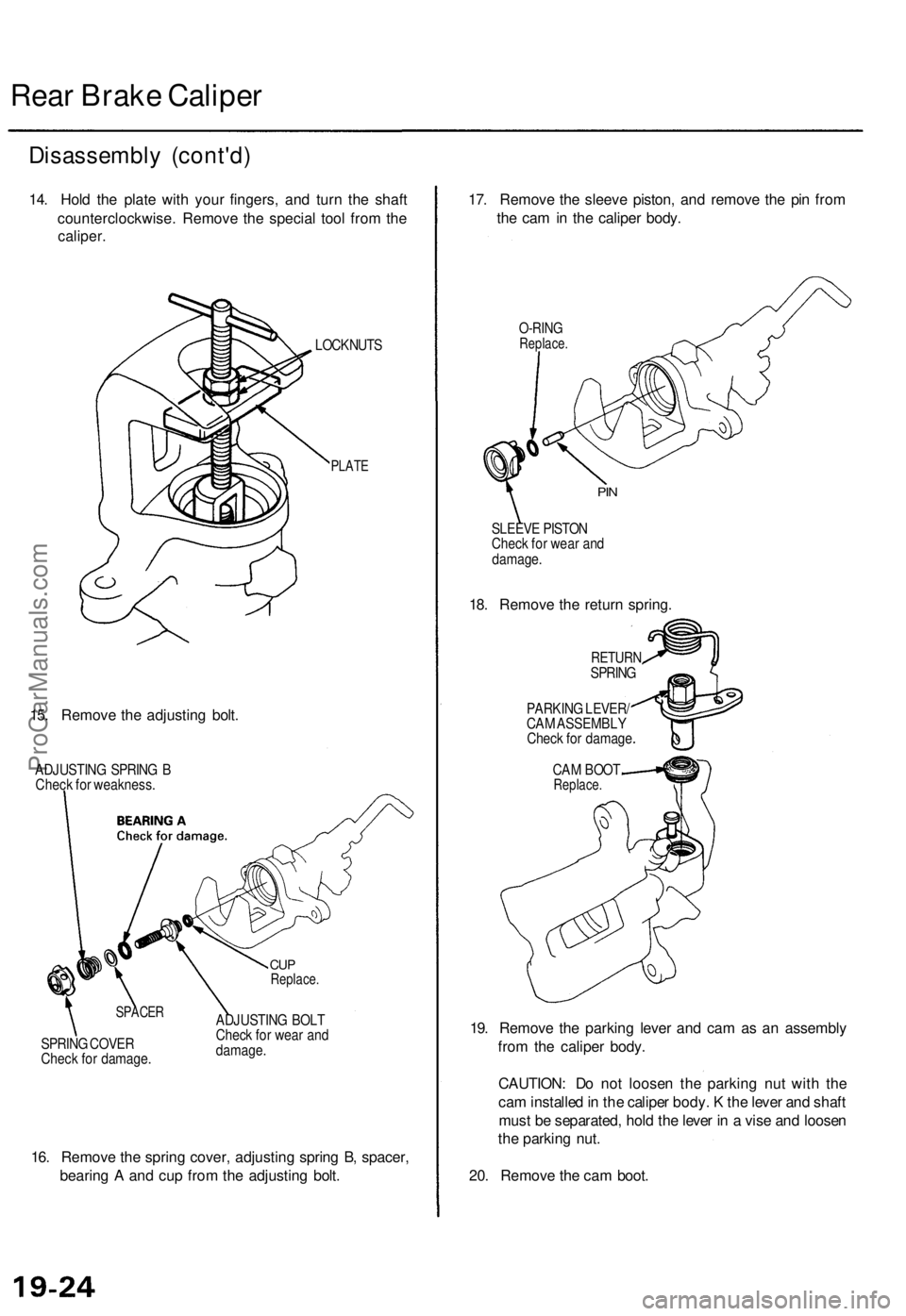

14. Hold the plate with your fingers, and turn the shaft

counterclockwise. Remove the special tool from the

caliper.

LOCKNUTS

PLATE

15. Remove the adjusting bolt.

ADJUSTING SPRING B

Check for weakness.

SPACER

SPRING COVER

Check for damage.

CUP

Replace.

ADJUSTING BOLT

Check for wear and

damage.

16. Remove the spring cover, adjusting spring B, spacer,

bearing A and cup from the adjusting bolt.

17. Remove the sleeve piston, and remove the pin from

the cam in the caliper body.

O-RING

Replace.

PIN

SLEEVE PISTON

Check for wear and

damage.

18. Remove the return spring.

RETURN

SPRING

PARKING LEVER/

CAM ASSEMBLY

Check for damage

CAM BOOT

Replace.

19. Remove the parking lever and cam as an assembly

from the caliper body.

CAUTION: Do not loosen the parking nut with the

cam installed in the caliper body. K the lever and shaft

must be separated, hold the lever in a vise and loosen

the parking nut.

20. Remove the cam boot.ProCarManuals.com

Page 1278 of 1771

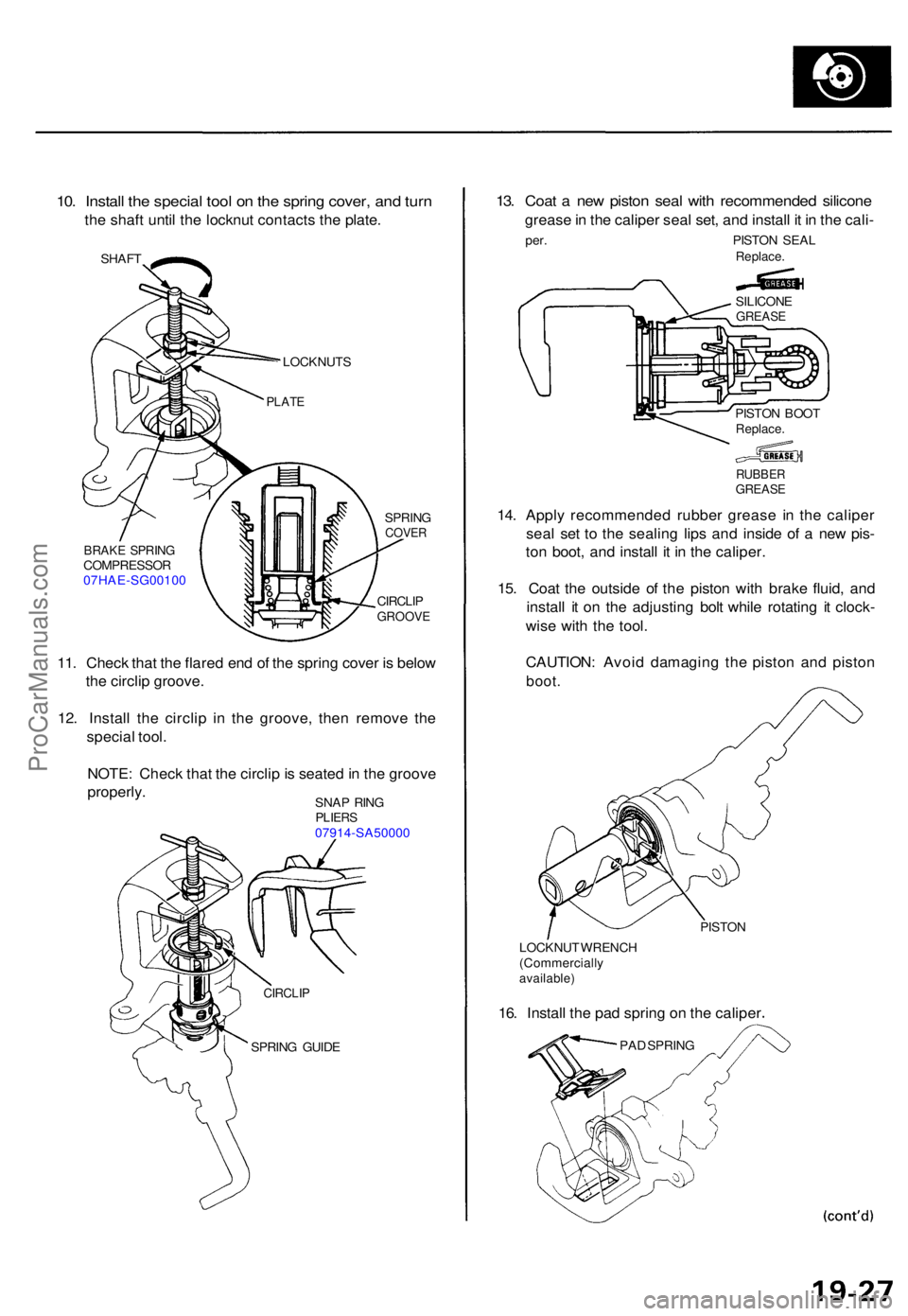

10. Instal l th e specia l too l o n th e sprin g cover , an d tur n

the shaf t unti l th e locknu t contact s th e plate .

SHAF T

LOCKNUT S

BRAKE SPRIN GCOMPRESSO R07HAE-SG0010 0 SPRIN

G

COVER

CIRCLI PGROOV E

11. Chec k tha t th e flare d en d o f th e sprin g cove r i s belo w

th e circli p groove .

12 . Instal l th e circli p i n th e groove , the n remov e th e

specia l tool .

NOTE : Chec k tha t th e circli p is seated in th e groov e

properly .

13. Coa t a ne w pisto n sea l wit h recommende d silicon e

grease in th e calipe r sea l set , an d instal l i t i n th e cali -

per. PISTO N SEA LReplace .

RUBBERGREAS E

14. Appl y recommende d rubbe r greas e i n th e calipe r

sea l se t t o th e sealin g lip s an d insid e o f a ne w pis -

to n boot , an d instal l i t i n th e caliper .

15 . Coa t th e outsid e o f th e pisto n wit h brak e fluid , an d

instal l i t o n th e adjustin g bol t whil e rotatin g i t clock -

wis e wit h th e tool .

CAUTION : Avoi d damagin g th e pisto n an d pisto n

boot.

PISTO N

LOCKNU T WRENC H

(Commerciall y

available)

16. Instal l th e pa d sprin g o n th e calipe r

PAD SPRIN G

PLATE

SILICON EGREASE

PISTON BOO TReplace .

CIRCLIP

SPRING GUID E

SNA

P RIN G

PLIER S07914-SA5000 0

ProCarManuals.com

Page 1404 of 1771

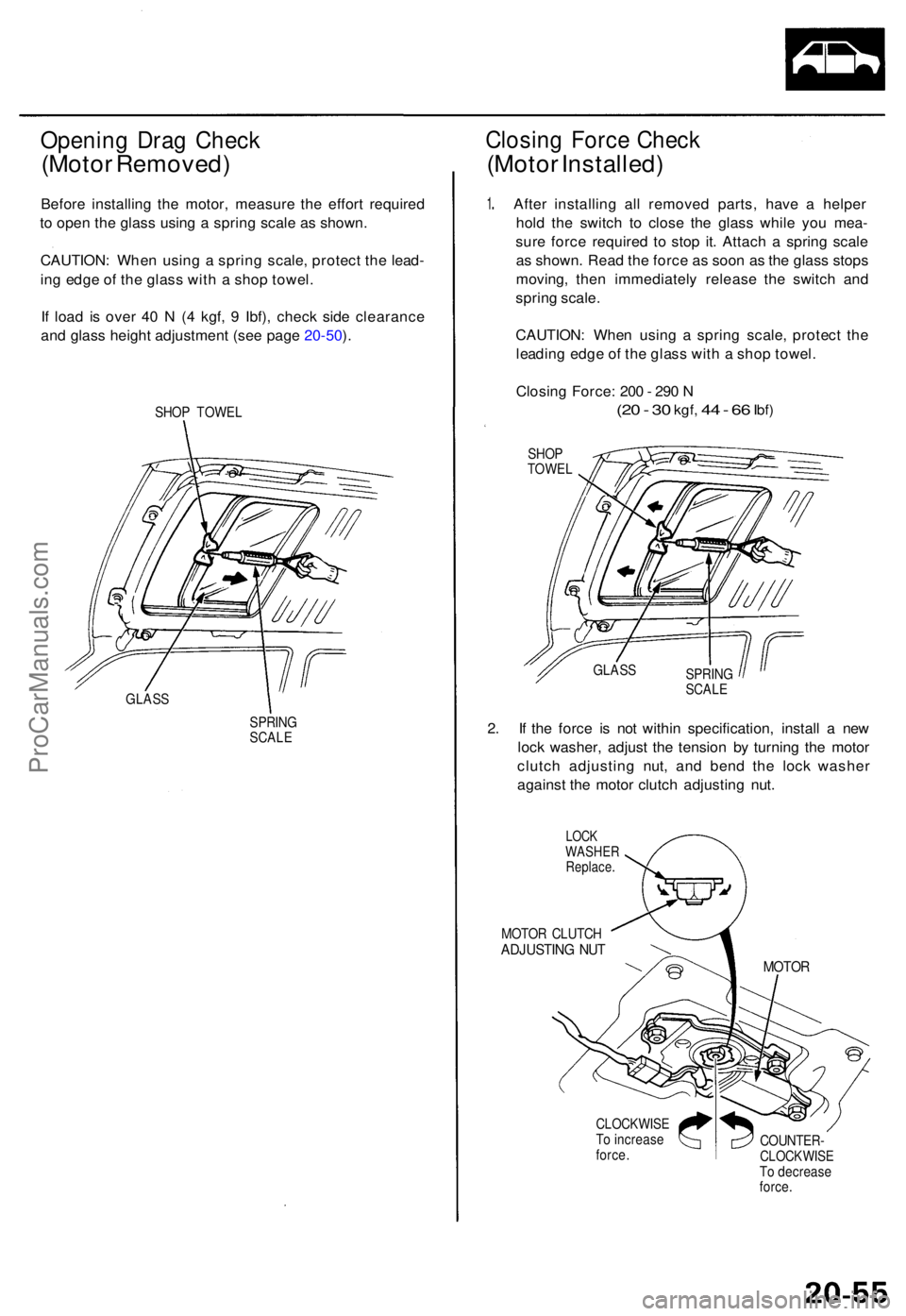

Opening Dra g Chec k

(Motor Removed )

Before installin g th e motor , measur e th e effor t require d

t o ope n th e glas s usin g a sprin g scal e a s shown .

CAUTION : Whe n usin g a sprin g scale , protec t th e lead -

in g edg e o f th e glas s wit h a sho p towel .

I f loa d i s ove r 4 0 N (4 kgf , 9 Ibf) , chec k sid e clearanc e

an d glas s heigh t adjustmen t (se e pag e 20-50 ).

SHO P TOWE L

GLAS S

SPRING

SCAL E

Closin g Forc e Chec k

(Moto r Installed )

1. Afte r installin g al l remove d parts , hav e a helpe r

hol d th e switc h t o clos e th e glas s whil e yo u mea -

sur e forc e require d t o sto p it . Attac h a sprin g scal e

a s shown . Rea d th e forc e a s soo n a s th e glas s stop s

moving , the n immediatel y releas e th e switc h an d

sprin g scale .

CAUTION : Whe n usin g a sprin g scale , protec t th e

leadin g edg e o f th e glas s wit h a sho p towel .

Closin g Force : 20 0 - 29 0 N

(2 0 - 3 0 kgf , 44 - 6 6 Ibf )

SHO P

TOWE L

SPRING

SCALE

2. I f th e forc e i s no t withi n specification , instal l a ne w

loc k washer , adjus t th e tensio n b y turnin g th e moto r

clutc h adjustin g nut , an d ben d th e loc k washe r

agains t th e moto r clutc h adjustin g nut .

LOC KWASHE RReplace .

MOTOR CLUTC HADJUSTIN G NU T

CLOCKWIS ETo increas eforce.COUNTER -CLOCKWIS ETo decreas e

force .

MOTO R

GLASS

ProCarManuals.com

Page 1413 of 1771

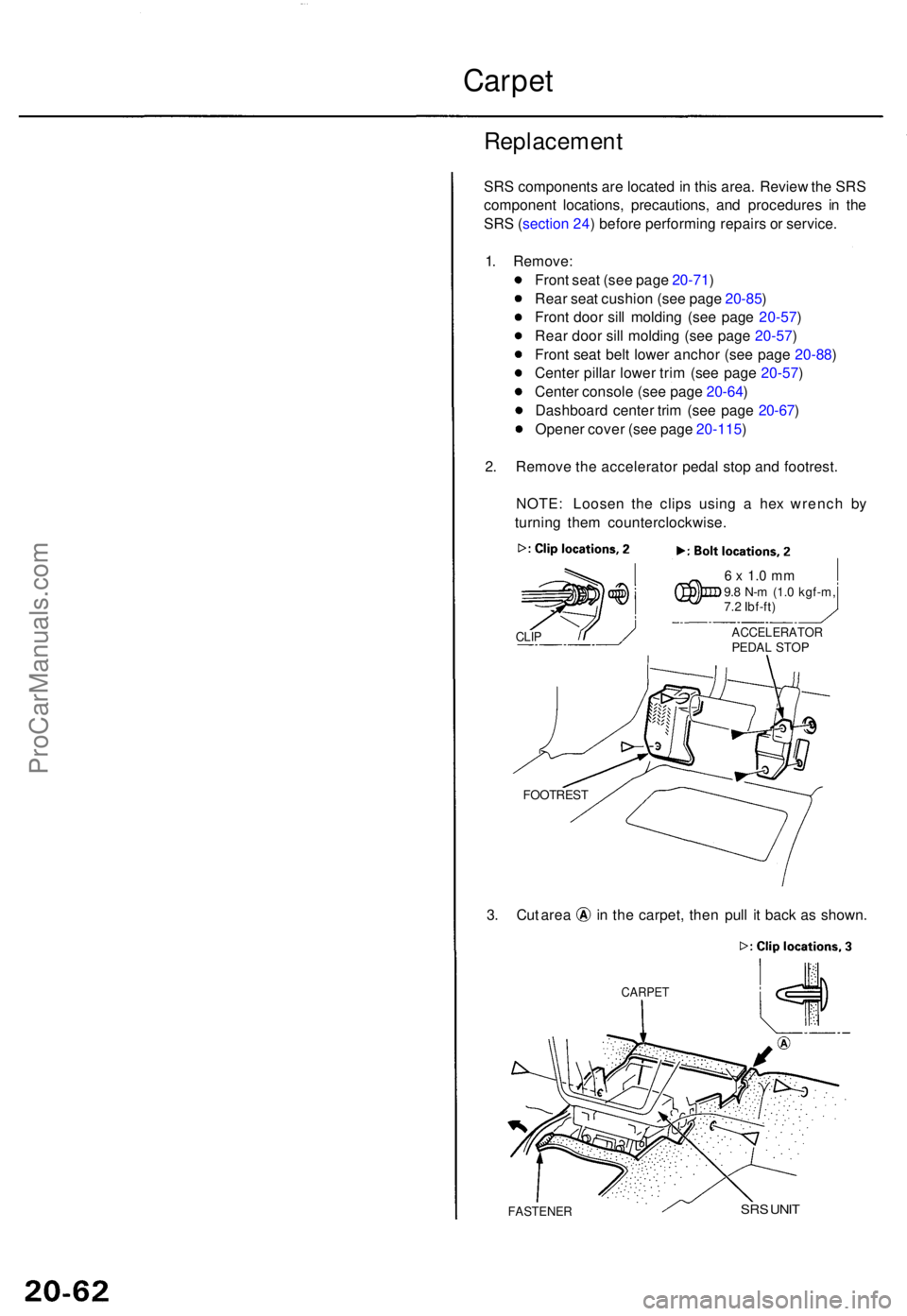

Carpet

Replacemen t

SRS component s ar e locate d in thi s area . Revie w th e SR S

componen t locations , precautions , an d procedure s i n th e

SR S (sectio n 24 ) befor e performin g repair s o r service .

1 . Remove :

Fron t sea t (se e pag e 20-71 )

Rea r sea t cushio n (se e pag e 20-85 )

Fron t doo r sil l moldin g (se e pag e 20-57 )

Rea r doo r sil l moldin g (se e pag e 20-57 )

Fron t sea t bel t lowe r ancho r (se e pag e 20-88 )

Cente r pilla r lowe r tri m (se e pag e 20-57 )

Cente r consol e (se e pag e 20-64 )

Dashboar d cente r tri m (se e pag e 20-67 )

Opene r cove r (se e pag e 20-115 )

2 . Remov e th e accelerato r peda l sto p an d footrest .

NOTE : Loose n th e clip s usin g a he x wrenc h b y

turnin g the m counterclockwise .

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

3. Cu t are a i n th e carpet , the n pul l i t bac k a s shown .

CARPE T

FASTENE RSRS UNI T

FOOTRES T

ACCELERATO RPEDAL STO PCLIP

ProCarManuals.com

Page 1416 of 1771

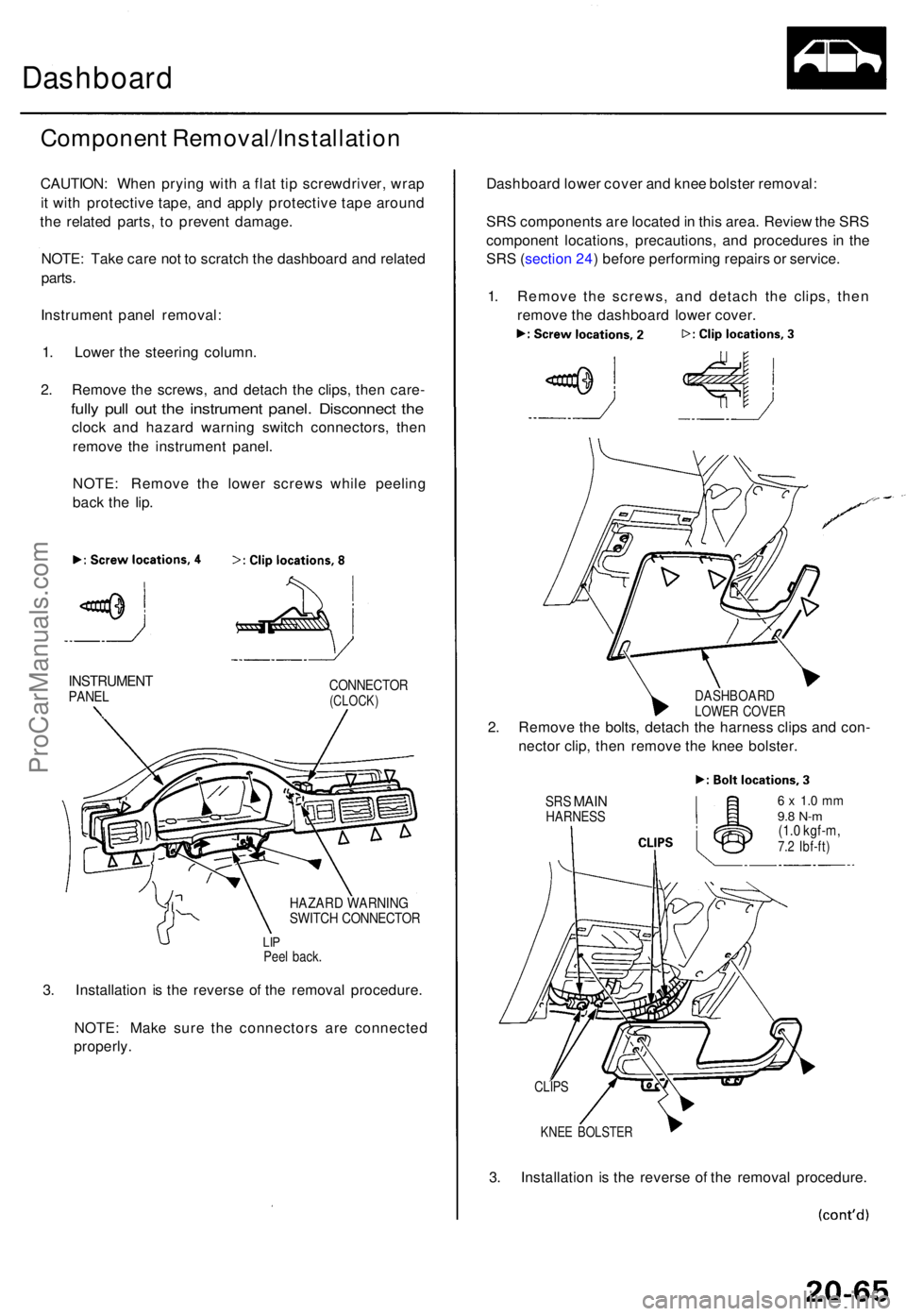

Dashboard

Componen t Removal/Installatio n

CAUTION: Whe n pryin g wit h a fla t ti p screwdriver , wra p

i t wit h protectiv e tape , an d appl y protectiv e tap e aroun d

th e relate d parts , t o preven t damage .

NOTE : Tak e car e no t t o scratc h th e dashboar d an d relate d

parts .

Instrumen t pane l removal :

1 . Lowe r th e steerin g column .

2 . Remov e th e screws , an d detac h th e clips , the n care -

fully pul l ou t th e instrumen t panel . Disconnec t th e

cloc k an d hazar d warnin g switc h connectors , the n

remov e th e instrumen t panel .

NOTE : Remov e th e lowe r screw s whil e peelin g

bac k th e lip .

INSTRUMEN TPANELCONNECTO R(CLOCK)

HAZARD WARNIN GSWITCH CONNECTO R

LIPPee l back .

3. Installatio n i s th e revers e o f th e remova l procedure .

NOTE : Mak e sur e th e connector s ar e connecte d

properly . Dashboar

d lowe r cove r an d kne e bolste r removal :

SR S component s ar e locate d in thi s area . Revie w th e SR S

componen t locations , precautions , an d procedure s i n th e

SR S (sectio n 24 ) befor e performin g repair s o r service .

1 . Remov e th e screws , an d detac h th e clips , the n

remov e th e dashboar d lowe r cover .

DASHBOAR DLOWER COVE R2. Remov e th e bolts , detac h th e harnes s clip s an d con -

necto r clip , the n remov e th e kne e bolster .

SRS MAI NHARNES S6 x 1. 0 m m9.8 N- m(1.0 kgf-m ,7.2 Ibf-ft )

KNEE BOLSTE R

3. Installatio n i s th e revers e o f th e remova l procedure .

CLIPS

ProCarManuals.com

Page 1636 of 1771

Lighting Syste m

Front Parkin g Ligh t

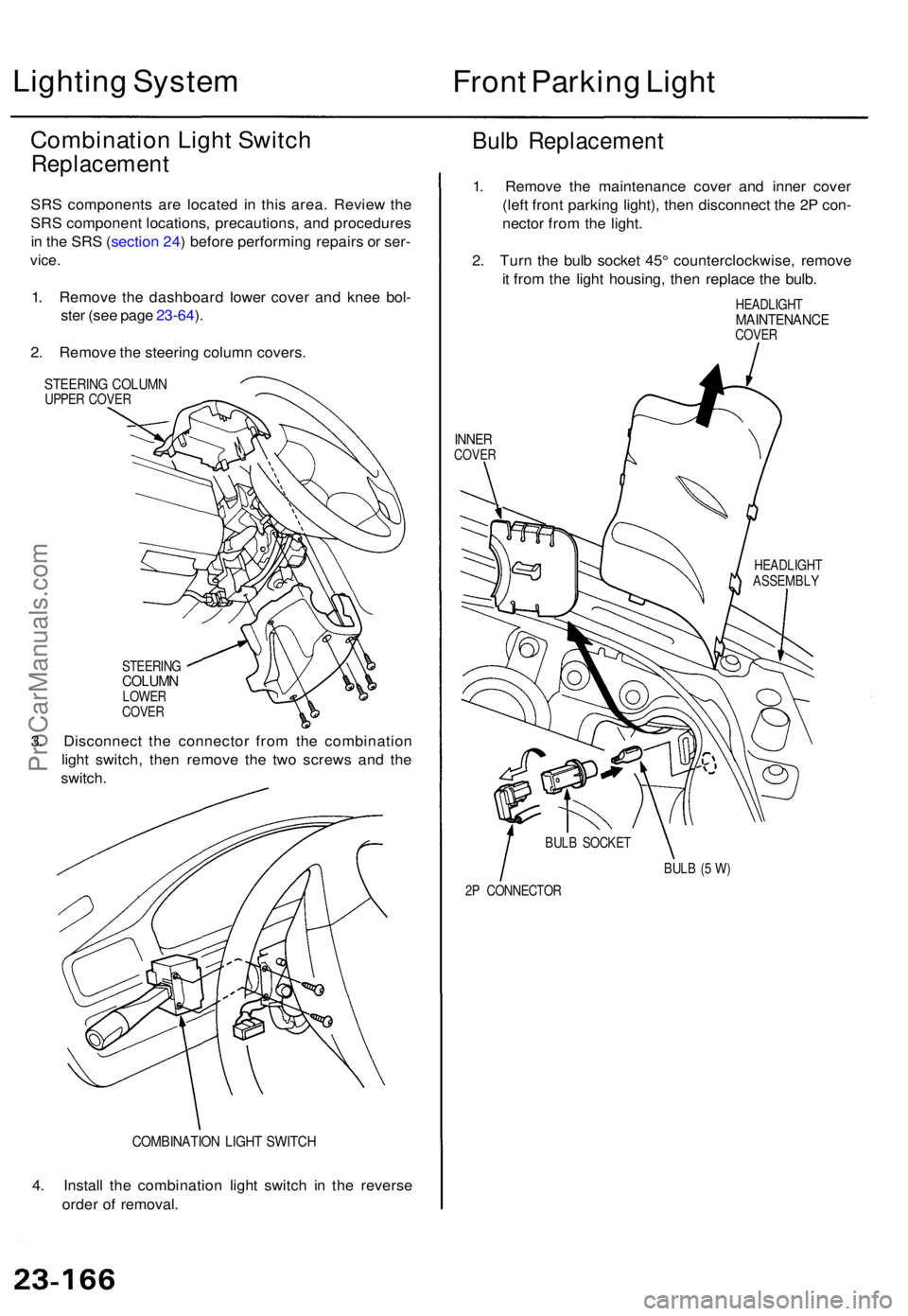

Combinatio n Ligh t Switc h

Replacemen t

SRS component s ar e locate d i n thi s area . Revie w th e

SR S componen t locations , precautions , an d procedure s

i n th e SR S (sectio n 24 ) befor e performin g repair s o r ser -

vice .

1. Remov e th e dashboar d lowe r cove r an d kne e bol -

ste r (se e pag e 23-64 ).

2 . Remov e th e steerin g colum n covers .

STEERIN G COLUM NUPPER COVE R

Bulb Replacemen t

STEERINGCOLUMNLOWER

COVE R

3. Disconnec t th e connecto r fro m th e combinatio n

ligh t switch , the n remov e th e tw o screw s an d th e

switch .

COMBINATIO N LIGH T SWITC H

4. Instal l th e combinatio n ligh t switc h i n th e revers e

orde r o f removal . 1

. Remov e th e maintenanc e cove r an d inne r cove r

(lef t fron t parkin g light) , the n disconnec t th e 2 P con -

necto r fro m th e light .

2 . Tur n th e bul b socke t 45 ° counterclockwise , remov e

i t fro m th e ligh t housing , the n replac e th e bulb .

HEADLIGH TMAINTENANC ECOVER

INNERCOVE R

HEADLIGH T

ASSEMBL Y

BUL B (5 W )

2 P CONNECTO R

BUL

B SOCKE T

ProCarManuals.com

Page 1641 of 1771

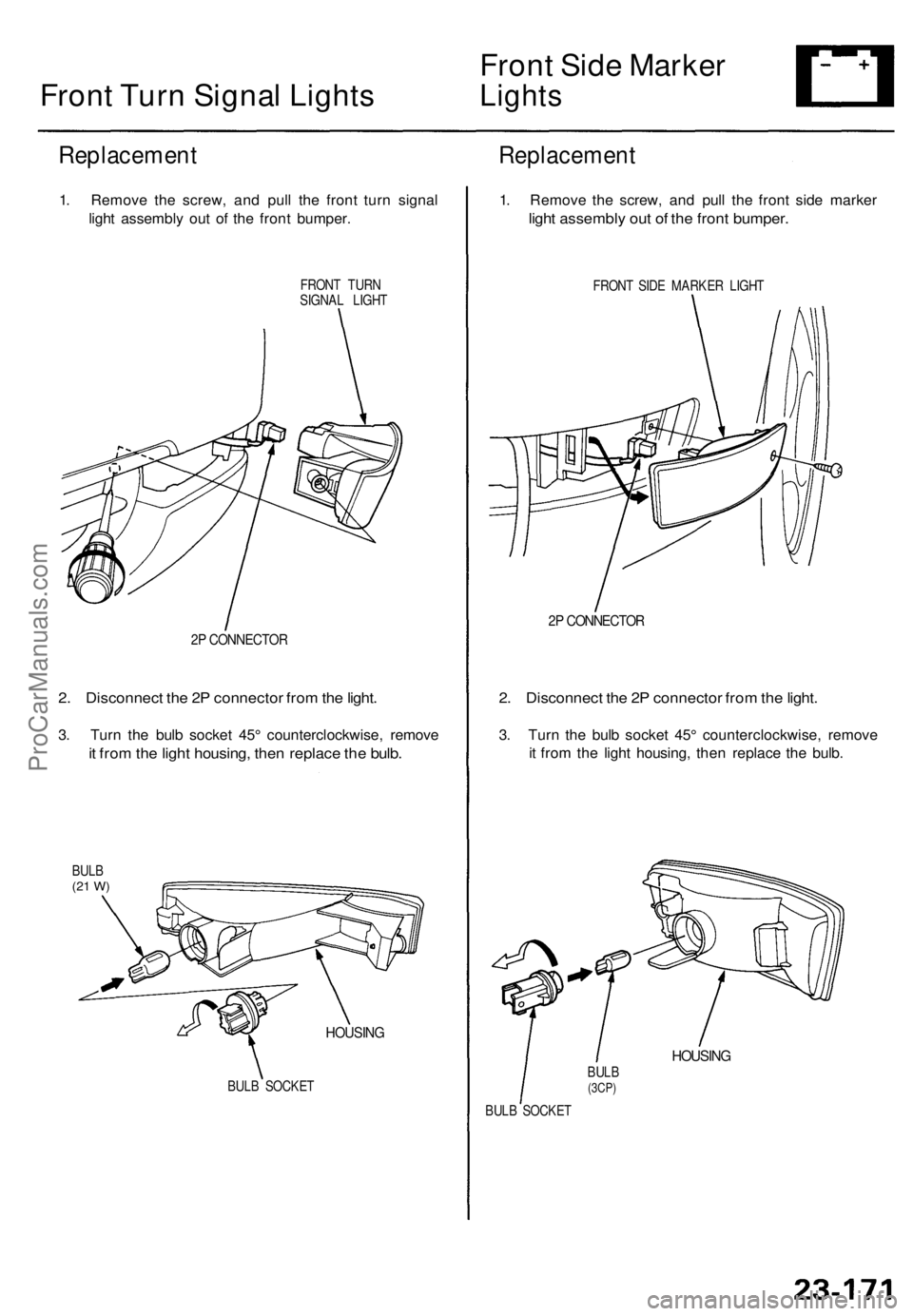

Front Tur n Signa l Light s Fron

t Sid e Marke rLights

Replacemen t

1. Remov e th e screw , an d pul l th e fron t tur n signa l

ligh t assembl y ou t o f th e fron t bumper .

FRONT TUR N

SIGNA L LIGH T

2P CONNECTO R

2. Disconnec t th e 2 P connecto r fro m th e light .

3. Tur n th e bul b socke t 45 ° counterclockwise , remov e

it fro m th e ligh t housing , the n replac e th e bulb .

BULB(21 W )

HOUSIN G

BULB SOCKE T

Replacemen t

1. Remov e th e screw , an d pul l th e fron t sid e marke r

light assembl y ou t o f th e fron t bumper .

FRONT SID E MARKE R LIGH T

2P CONNECTO R

2. Disconnec t th e 2 P connecto r fro m th e light .

3. Tur n th e bul b socke t 45 ° counterclockwise , remov e

i t fro m th e ligh t housing , the n replac e th e bulb .

HOUSIN GBULB(3CP)

BULB SOCKE T

ProCarManuals.com