clock ACURA TL 1995 Service User Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 738 of 1771

Valve Clearanc e

Adjustmen t (cont'd )

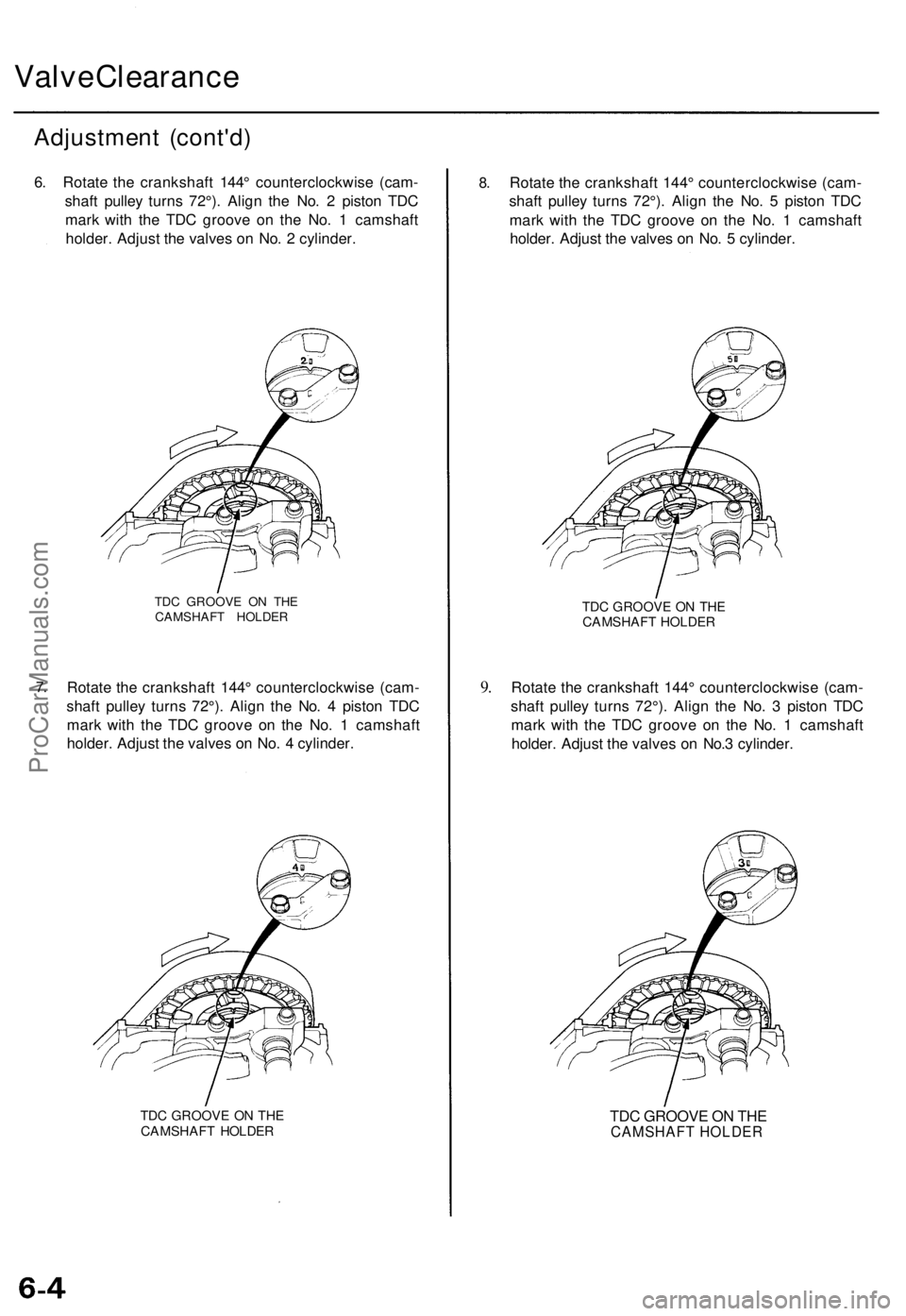

6. Rotat e th e crankshaf t 144 ° counterclockwis e (cam -

shaf t pulle y turn s 72°) . Alig n th e No . 2 pisto n TD C

mar k wit h th e TD C groov e o n th e No . 1 camshaf t

holder . Adjus t th e valve s o n No . 2 cylinder .

7.

TD C GROOV E O N TH ECAMSHAF T HOLDE R

Rotate th e crankshaf t 144 ° counterclockwis e (cam -

shaf t pulle y turn s 72°) . Alig n th e No . 4 pisto n TD C

mar k wit h th e TD C groov e o n th e No . 1 camshaf t

holder . Adjus t th e valve s o n No . 4 cylinder .

TDC GROOV E O N TH ECAMSHAF T HOLDE R

8.Rotat e th e crankshaf t 144 ° counterclockwis e (cam -

shaf t pulle y turn s 72°) . Alig n th e No . 5 pisto n TD C

mar k wit h th e TD C groov e o n th e No . 1 camshaf t

holder . Adjus t th e valve s o n No . 5 cylinder .

9.

TD C GROOV E O N TH ECAMSHAF T HOLDE R

Rotate th e crankshaf t 144 ° counterclockwis e (cam -

shaf t pulle y turn s 72°) . Alig n th e No . 3 pisto n TD C

mar k wit h th e TD C groov e o n th e No . 1 camshaf t

holder . Adjust the valve s o n No. 3 cylinder .

TDC GROOVE ON THE

CAMSHAFT HOLDER

ProCarManuals.com

Page 743 of 1771

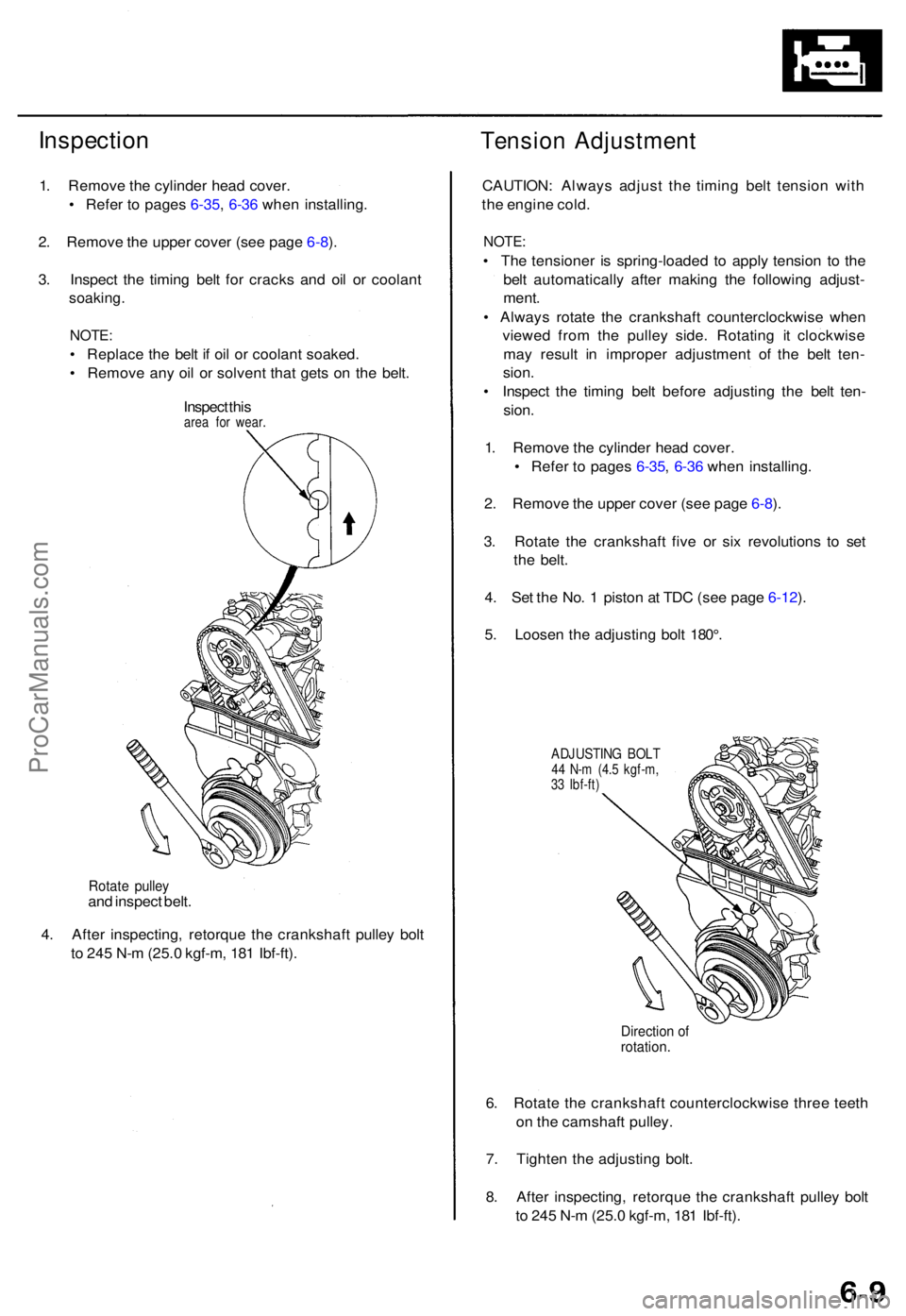

Inspection

1. Remov e th e cylinde r hea d cover .

• Refe r t o page s 6-35 , 6-3 6 whe n installing .

2 . Remov e th e uppe r cove r (se e pag e 6-8 ).

3 . Inspec t th e timin g bel t fo r crack s an d oi l o r coolan t

soaking .

NOTE:

• Replac e th e bel t i f oi l o r coolan t soaked .

• Remov e an y oi l o r solven t tha t get s o n th e belt .

Inspec t thi s

are a fo r wear .

Tensio n Adjustmen t

Rotate pulle yand inspec t belt .

4 . Afte r inspecting , retorqu e th e crankshaf t pulle y bol t

t o 24 5 N- m (25. 0 kgf-m , 18 1 Ibf-ft) . CAUTION

: Alway s adjus t th e timin g bel t tensio n wit h

th e engin e cold .

NOTE :

• Th e tensione r i s spring-loade d t o appl y tensio n t o th e

bel t automaticall y afte r makin g th e followin g adjust -

ment .

• Alway s rotat e th e crankshaf t counterclockwis e whe n

viewe d fro m th e pulle y side . Rotatin g i t clockwis e

ma y resul t i n imprope r adjustmen t of the bel t ten -

sion .

• Inspec t th e timin g bel t befor e adjustin g th e bel t ten -

sion .

1 . Remov e th e cylinde r hea d cover .

• Refe r t o page s 6-35 , 6-3 6 whe n installing .

2 . Remov e th e uppe r cove r (se e pag e 6-8 ).

3 . Rotat e th e crankshaf t fiv e o r si x revolution s t o se t

th e belt .

4 . Se t th e No . 1 pisto n a t TD C (se e pag e 6-12 ).

5 . Loose n th e adjustin g bol t 180° .

ADJUSTIN G BOL T44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

Directio n o frotation .

6. Rotat e th e crankshaf t counterclockwis e thre e teet h

o n th e camshaf t pulley .

7 . Tighte n th e adjustin g bolt .

8 . Afte r inspecting , retorqu e th e crankshaf t pulle y bol t

t o 24 5 N- m (25. 0 kgf-m , 18 1 Ibf-ft) .

ProCarManuals.com

Page 746 of 1771

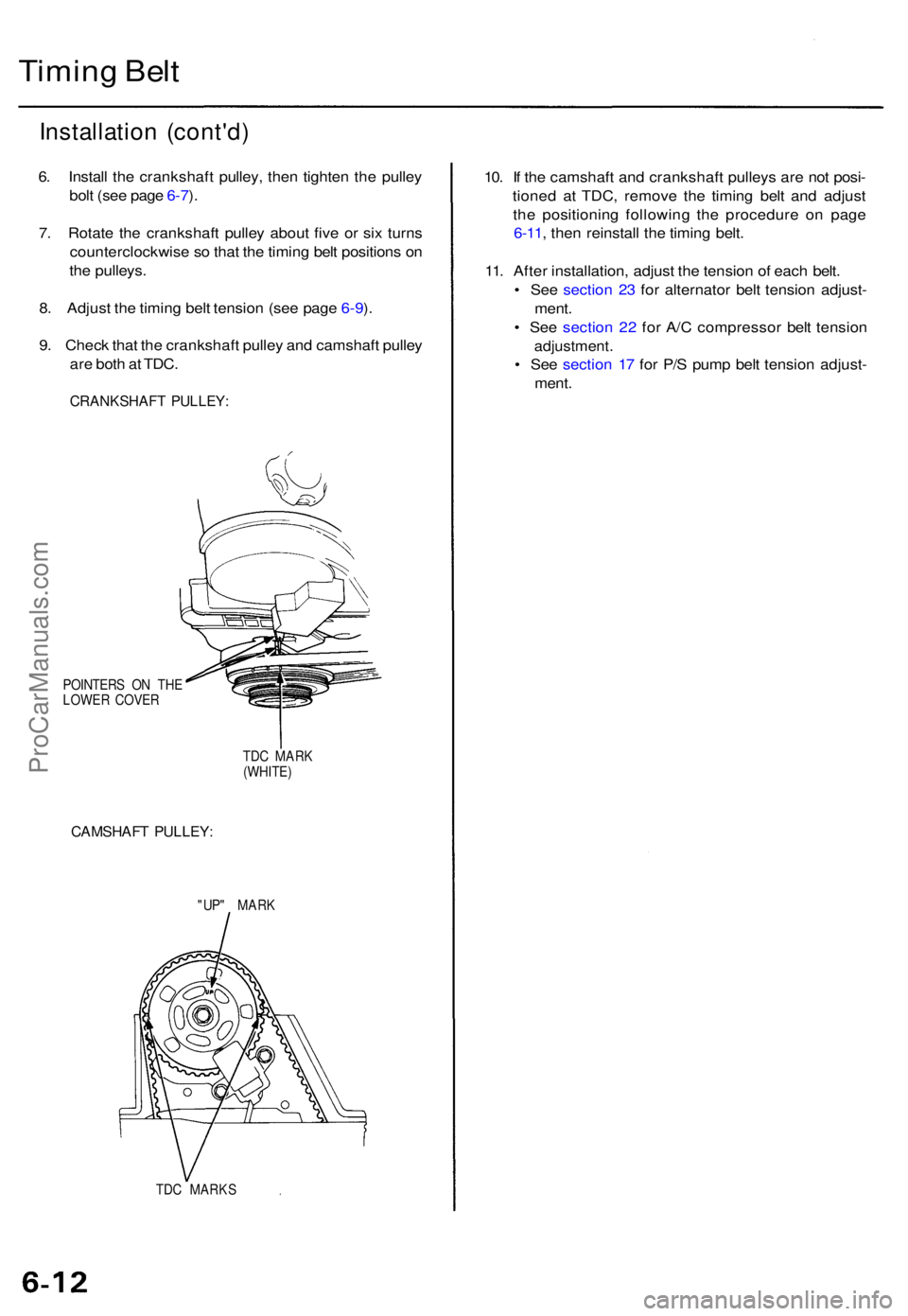

Timing Bel t

Installatio n (cont'd )

6. Instal l th e crankshaf t pulley , the n tighte n th e pulle y

bol t (se e pag e 6-7 ).

7 . Rotat e th e crankshaf t pulle y abou t fiv e o r si x turn s

counterclockwis e s o tha t th e timin g bel t position s o n

th e pulleys .

8 . Adjus t th e timin g bel t tensio n (se e pag e 6-9 ).

9 . Chec k tha t th e crankshaf t pulle y an d camshaf t pulle y

ar e bot h a t TDC .

CRANKSHAF T PULLEY :

POINTER S O N TH E

LOWE R COVE R

TDC MAR K

(WHITE )

CAMSHAF T PULLEY :

"UP" MAR K

TD C MARK S

10. I f th e camshaf t an d crankshaf t pulley s ar e no t posi -

tione d a t TDC , remov e th e timin g bel t an d adjus t

th e positionin g followin g th e procedur e o n pag e

6-11 , the n reinstal l th e timin g belt .

11 . Afte r installation , adjus t th e tensio n o f eac h belt .

• Se e sectio n 2 3 fo r alternato r bel t tensio n adjust -

ment .

• Se e sectio n 2 2 fo r A/ C compresso r bel t tensio n

adjustment .

• Se e sectio n 1 7 fo r P/ S pum p bel t tensio n adjust -

ment .

ProCarManuals.com

Page 767 of 1771

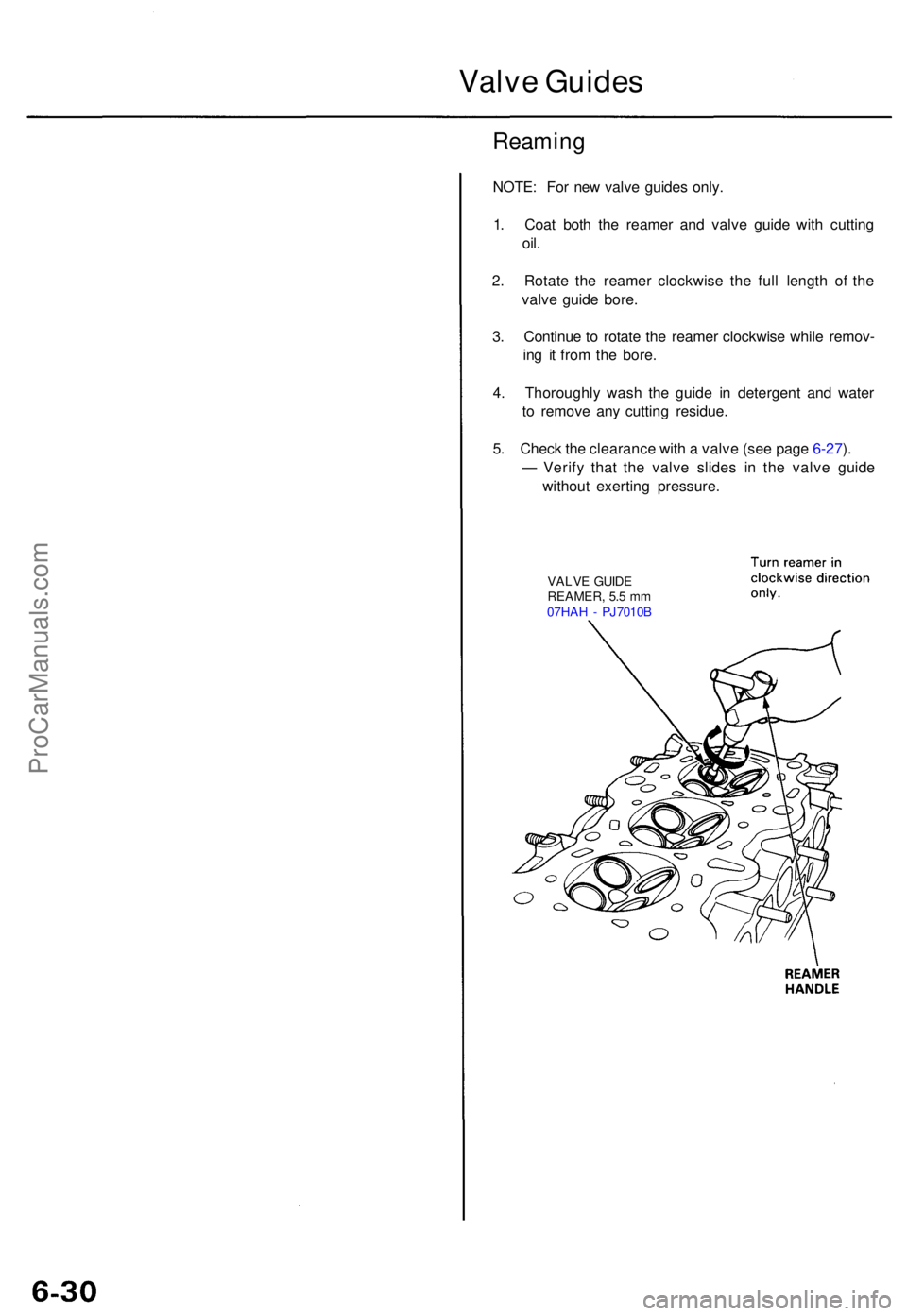

Valve Guide s

Reamin g

NOTE: Fo r ne w valv e guide s only .

1 . Coa t bot h th e reame r an d valv e guid e wit h cuttin g

oil.

2. Rotat e th e reame r clockwis e th e ful l lengt h o f th e

valv e guid e bore .

3 . Continu e t o rotat e th e reame r clockwis e whil e remov -

in g i t fro m th e bore .

4 . Thoroughl y was h th e guid e i n detergen t an d wate r

t o remov e an y cuttin g residue .

5 . Chec k th e clearanc e wit h a valv e (se e pag e 6-27 ).

— Verif y tha t th e valv e slide s i n th e valv e guid e

withou t exertin g pressure .

VALVE GUID E

REAMER , 5. 5 m m

07HA H - PJ7010 B

ProCarManuals.com

Page 799 of 1771

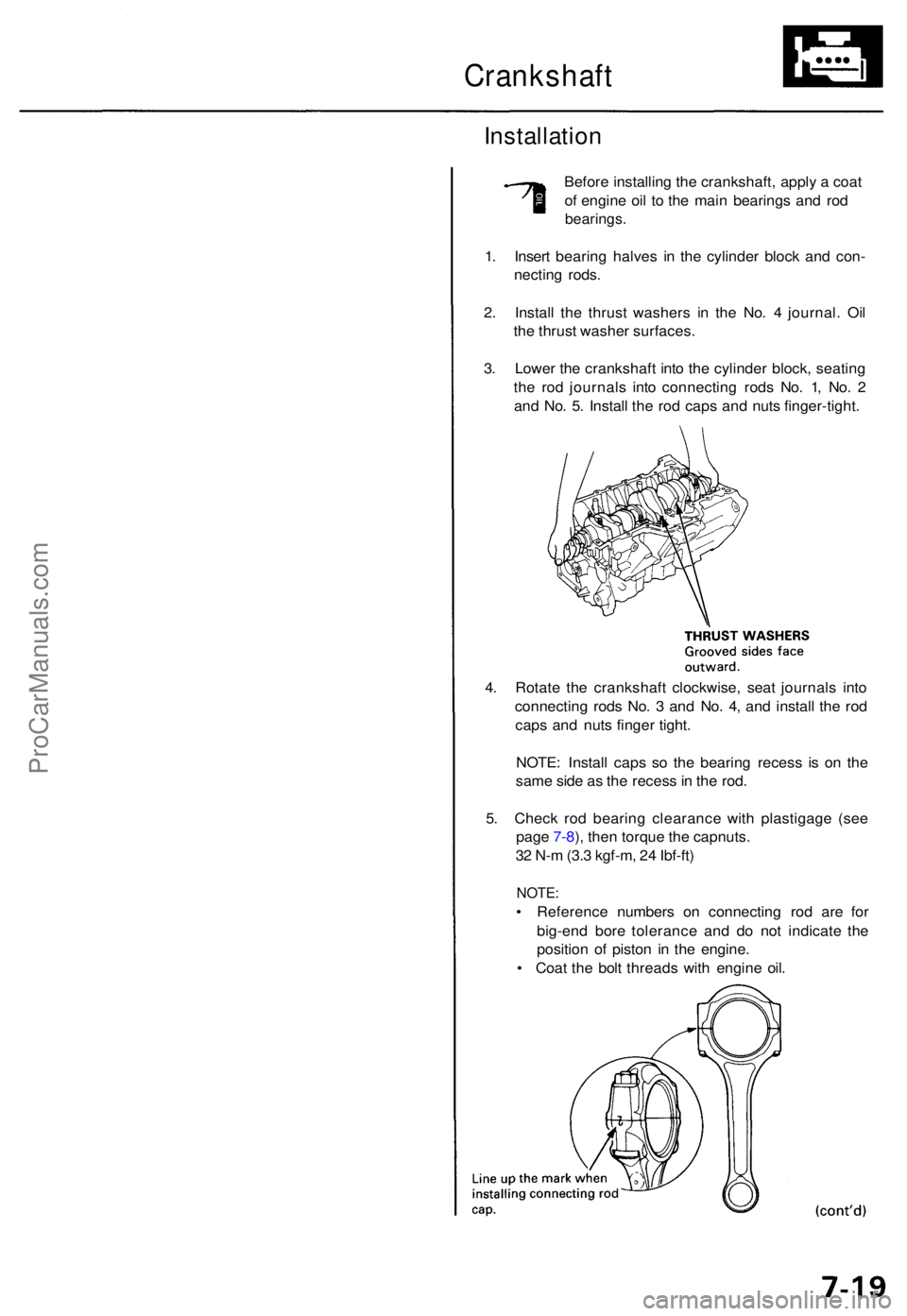

Crankshaft

Installation

Before installin g th e crankshaft , appl y a coa t

o f engin e oi l t o th e mai n bearing s an d ro d

bearings .

1. Inser t bearin g halve s i n th e cylinde r bloc k an d con -

nectin g rods .

2 . Instal l th e thrus t washer s i n th e No . 4 journal . Oi l

th e thrus t washe r surfaces .

3 . Lowe r th e crankshaf t int o th e cylinde r block , seatin g

th e ro d journal s int o connectin g rod s No . 1 , No . 2

an d No . 5 . Instal l th e ro d cap s an d nut s finger-tight .

4 . Rotat e th e crankshaf t clockwise , sea t journal s int o

connectin g rod s No . 3 an d No . 4 , an d instal l th e ro d

cap s an d nut s finge r tight .

NOTE : Instal l cap s s o th e bearin g reces s i s o n th e

sam e sid e a s th e reces s in th e rod .

5 . Chec k ro d bearin g clearanc e wit h plastigag e (se e

pag e 7-8 ), the n torqu e th e capnuts .

3 2 N- m (3. 3 kgf-m , 2 4 Ibf-ft )

NOTE :

• Referenc e number s o n connectin g ro d ar e fo r

big-en d bor e toleranc e an d d o no t indicat e th e

positio n o f pisto n i n th e engine .

• Coa t th e bol t thread s wit h engin e oil .

ProCarManuals.com

Page 809 of 1771

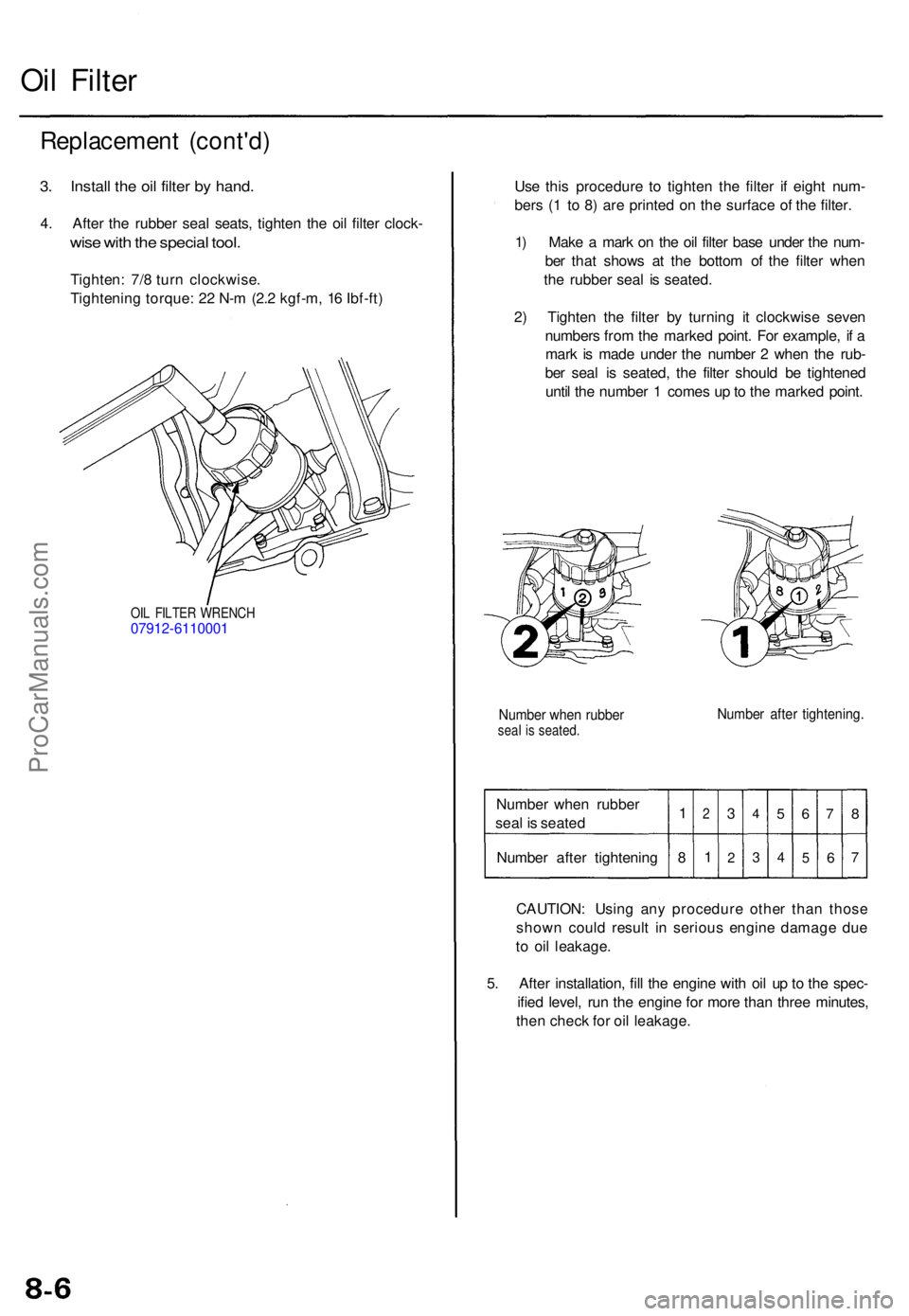

Oil Filte r

Replacemen t (cont'd )

3. Instal l th e oi l filte r b y hand .

4. Afte r th e rubbe r sea l seats , tighte n th e oi l filte r clock -

wise wit h th e specia l tool .

Tighten : 7/ 8 tur n clockwise .

Tightenin g torque : 2 2 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

OIL FILTE R WRENC H07912-611000 1

Use thi s procedur e t o tighte n th e filte r i f eigh t num -

ber s ( 1 t o 8 ) ar e printe d o n th e surfac e o f th e filter .

1 ) Mak e a mar k o n th e oi l filte r bas e unde r th e num -

be r tha t show s a t th e botto m o f th e filte r whe n

th e rubber seal i s seated .

2 ) Tighte n th e filte r b y turnin g i t clockwis e seve n

number s fro m th e marke d point . Fo r example , i f a

mar k i s mad e unde r th e numbe r 2 whe n th e rub -

be r sea l i s seated , th e filte r shoul d b e tightene d

unti l th e numbe r 1 come s u p to th e marke d point .

Numbe r whe n rubbe rseal i s seated .Number afte r tightening .

Number whe n rubbe r

sea l i s seate d

Numbe r afte r tightenin g1

8

2

1

3

2

4

3

5

4

6

5

7

6

8

7

CAUTION : Usin g an y procedur e othe r tha n thos e

show n coul d resul t i n seriou s engin e damag e du e

t o oi l leakage .

5 . Afte r installation , fil l th e engin e wit h oi l u p to th e spec -

ifie d level , ru n th e engin e fo r mor e tha n thre e minutes ,

the n chec k fo r oi l leakage .

ProCarManuals.com

Page 830 of 1771

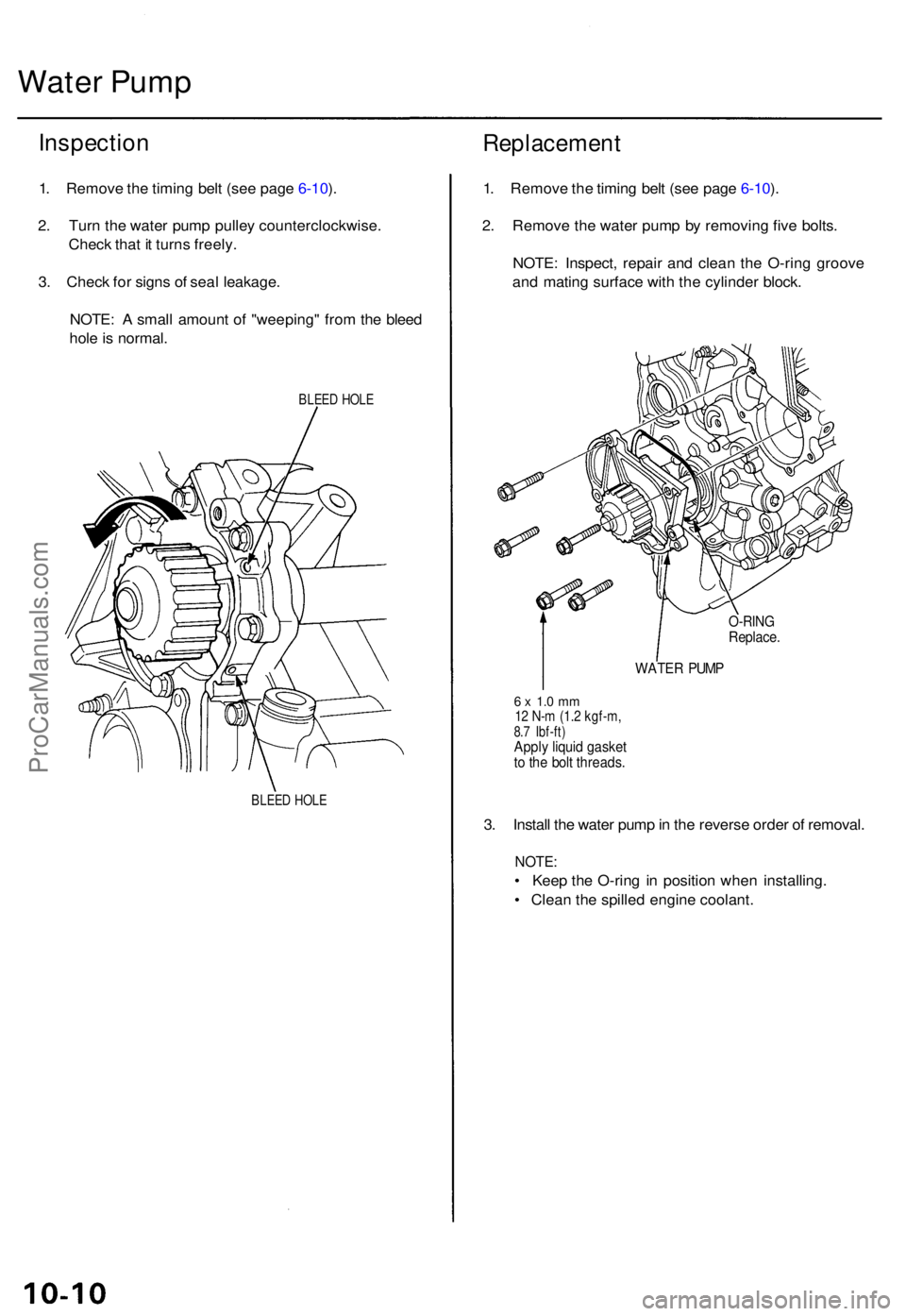

Water Pum p

Inspectio n

1. Remov e th e timin g bel t (se e pag e 6-10 ).

2 . Tur n th e wate r pum p pulle y counterclockwise .

Chec k tha t i t turn s freely .

3 . Chec k fo r sign s o f sea l leakage .

NOTE : A smal l amoun t o f "weeping " fro m th e blee d

hol e is normal .

BLEED HOL E

BLEE D HOL E

Replacemen t

1. Remov e th e timin g bel t (se e pag e 6-10 ).

2 . Remov e th e wate r pum p b y removin g fiv e bolts .

NOTE : Inspect , repai r an d clea n th e O-rin g groov e

an d matin g surfac e wit h th e cylinde r block .

O-RIN GReplace .

WATER PUM P

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,8.7 Ibf-ft )Apply liqui d gaske tto th e bol t threads .

3. Instal l th e wate r pum p in th e revers e orde r o f removal .

NOTE:

• Kee p th e O-rin g i n positio n whe n installing .

• Clea n th e spille d engin e coolant .

ProCarManuals.com

Page 975 of 1771

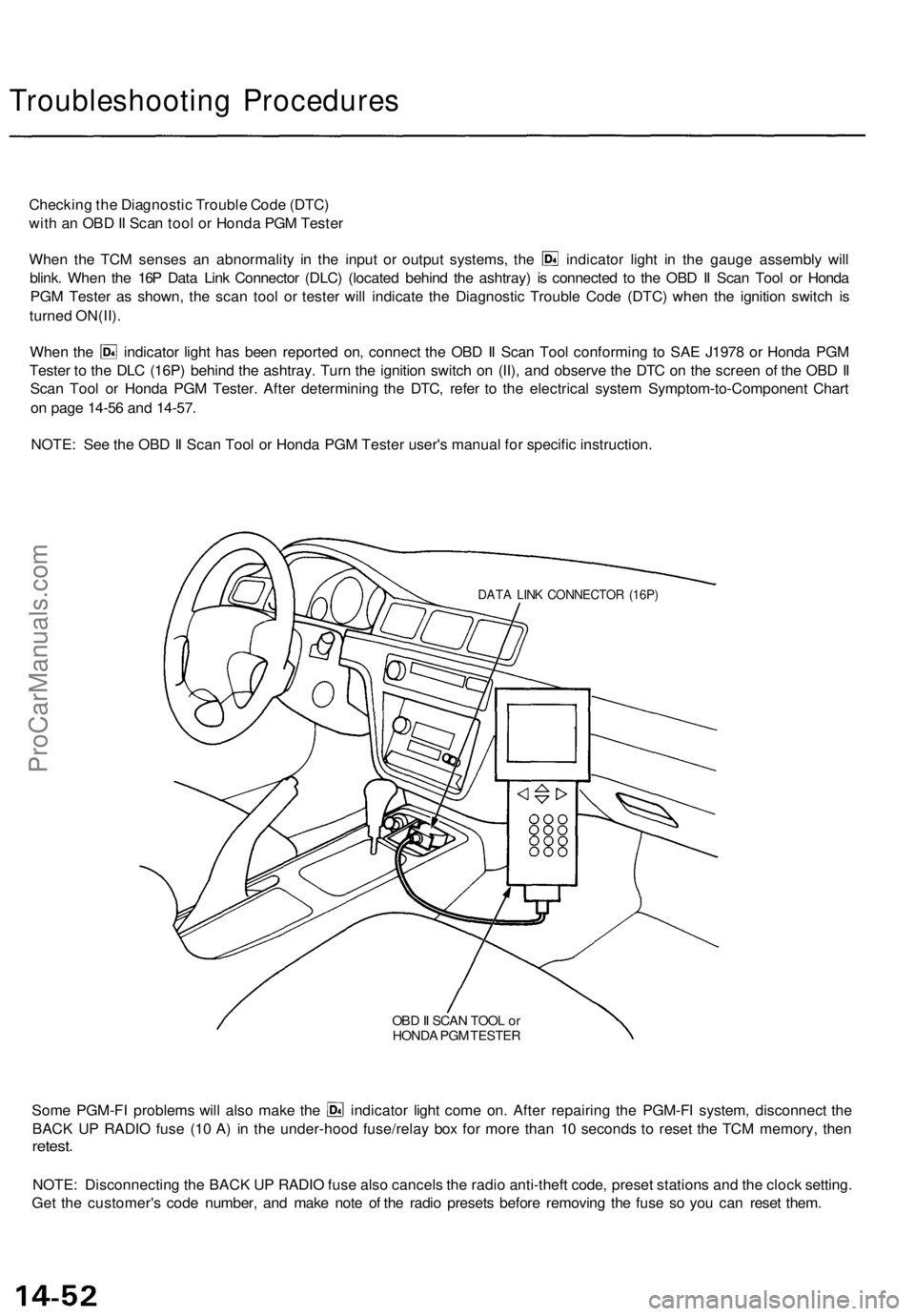

Troubleshooting Procedures

Checking the Diagnostic Trouble Code (DTC)

with an OBD II Scan tool or Honda PGM Tester

When the TCM senses an abnormality in the input or output systems, the indicator light in the gauge assembly will

blink. When the 16P Data Link Connector (DLC) (located behind the ashtray) is connected to the OBD II Scan Tool or Honda

PGM Tester as shown, the scan tool or tester will indicate the Diagnostic Trouble Code (DTC) when the ignition switch is

turned ON(II).

When the indicator light has been reported on, connect the OBD II Scan Tool conforming to SAE J1978 or Honda PGM

Tester to the DLC (16P) behind the ashtray. Turn the ignition switch on (II), and observe the DTC on the screen of the OBD II

Scan Tool or Honda PGM Tester. After determining the DTC, refer to the electrical system Symptom-to-Component Chart

on page 14-56 and 14-57.

NOTE: See the OBD II Scan Tool or Honda PGM Tester user's manual for specific instruction.

OBD II SCAN TOOL or

HONDA PGM TESTER

Some PGM-FI problems will also make the indicator light come on. After repairing the PGM-FI system, disconnect the

BACK UP RADIO fuse (10 A) in the under-hood fuse/relay box for more than 10 seconds to reset the TCM memory, then

retest.

NOTE: Disconnecting the BACK UP RADIO fuse also cancels the radio anti-theft code, preset stations and the clock setting.

Get the customer's code number, and make note of the radio presets before removing the fuse so you can reset them.

DATA LINK CONNECTOR (16P)ProCarManuals.com

Page 1172 of 1771

Installation

Airbag installation

CAUTION:

• Before installing the steering wheel, align the front

wheels straight ahead.

• Be sure to install the harness wires so that they are

not pinched or interfering with other vehicle parts.

• Do not replace the original steering wheel with any

other design, since it will make it impossible to prop-

erly install the airbag. (Only use genuine Honda

replacement parts)

• After reassembly, confirm that the wheels are still

straight ahead and that steering wheel spoke angle

is correct. If minor spoke angle adjustment is neces-

sary, do so only by adjustment of the tie-rods, not by

removing and repositioning the steering wheel.

Confirm that the airbag assembly is

securely attached to the steering wheel; otherwise,

severe personal injury could result during airbag

deployment.

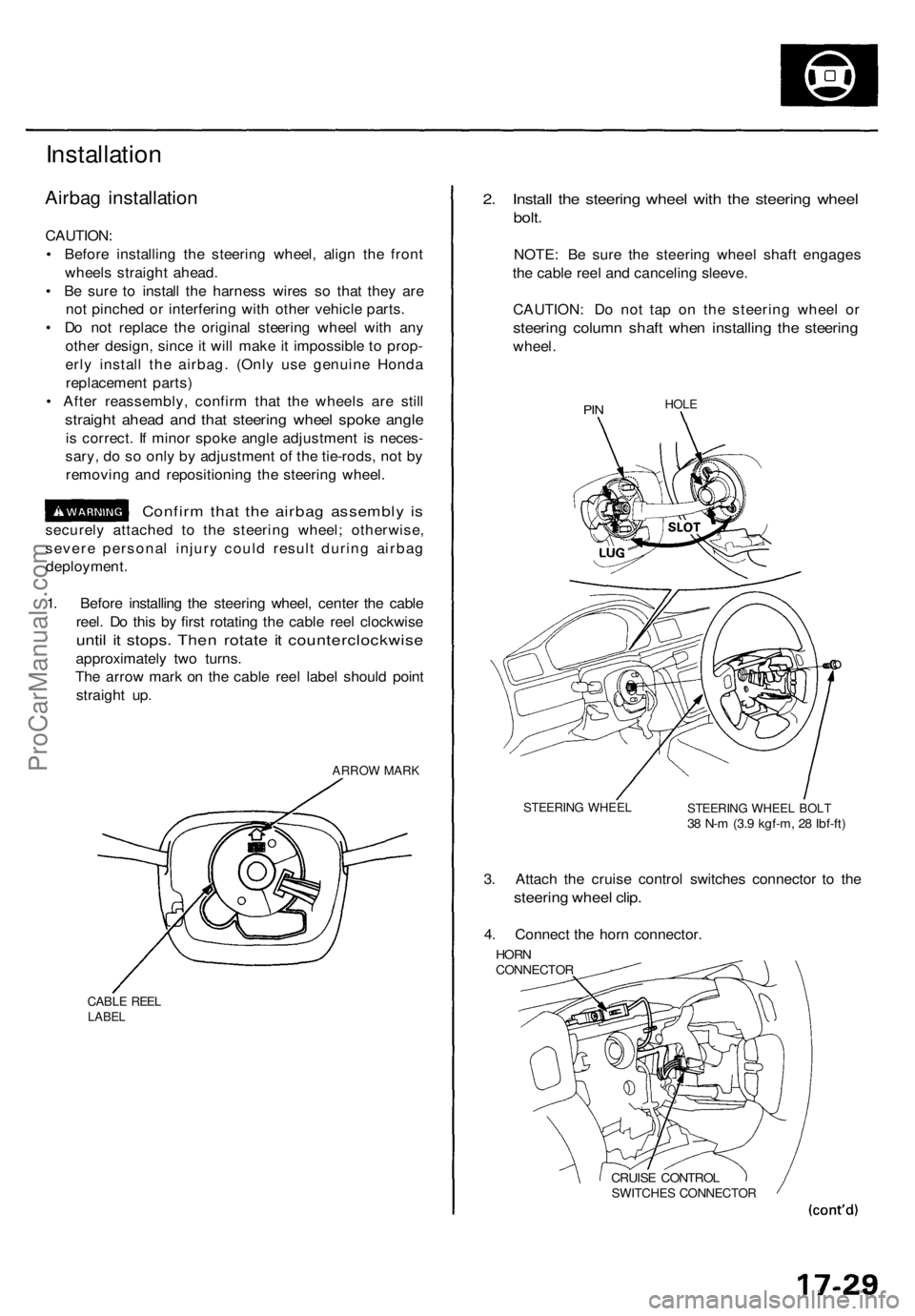

1. Before installing the steering wheel, center the cable

reel. Do this by first rotating the cable reel clockwise

until it stops. Then rotate it counterclockwise

approximately two turns.

The arrow mark on the cable reel label should point

straight up.

ARROW MARK

CABLE REEL

LABEL

2. Install the steering wheel with the steering wheel

bolt.

NOTE: Be sure the steering wheel shaft engages

the cable reel and canceling sleeve.

CAUTION: Do not tap on the steering wheel or

steering column shaft when installing the steering

wheel.

PIN

HOLE

STEERING WHEEL

STEERING WHEEL BOLT

38 N-m (3.9 kgf-m, 28 Ibf-ft)

3. Attach the cruise control switches connector to the

steering wheel clip.

4. Connect the horn connector.

HORN

CONNECTOR

CRUISE CONTROL

SWITCHES CONNECTORProCarManuals.com

Page 1212 of 1771

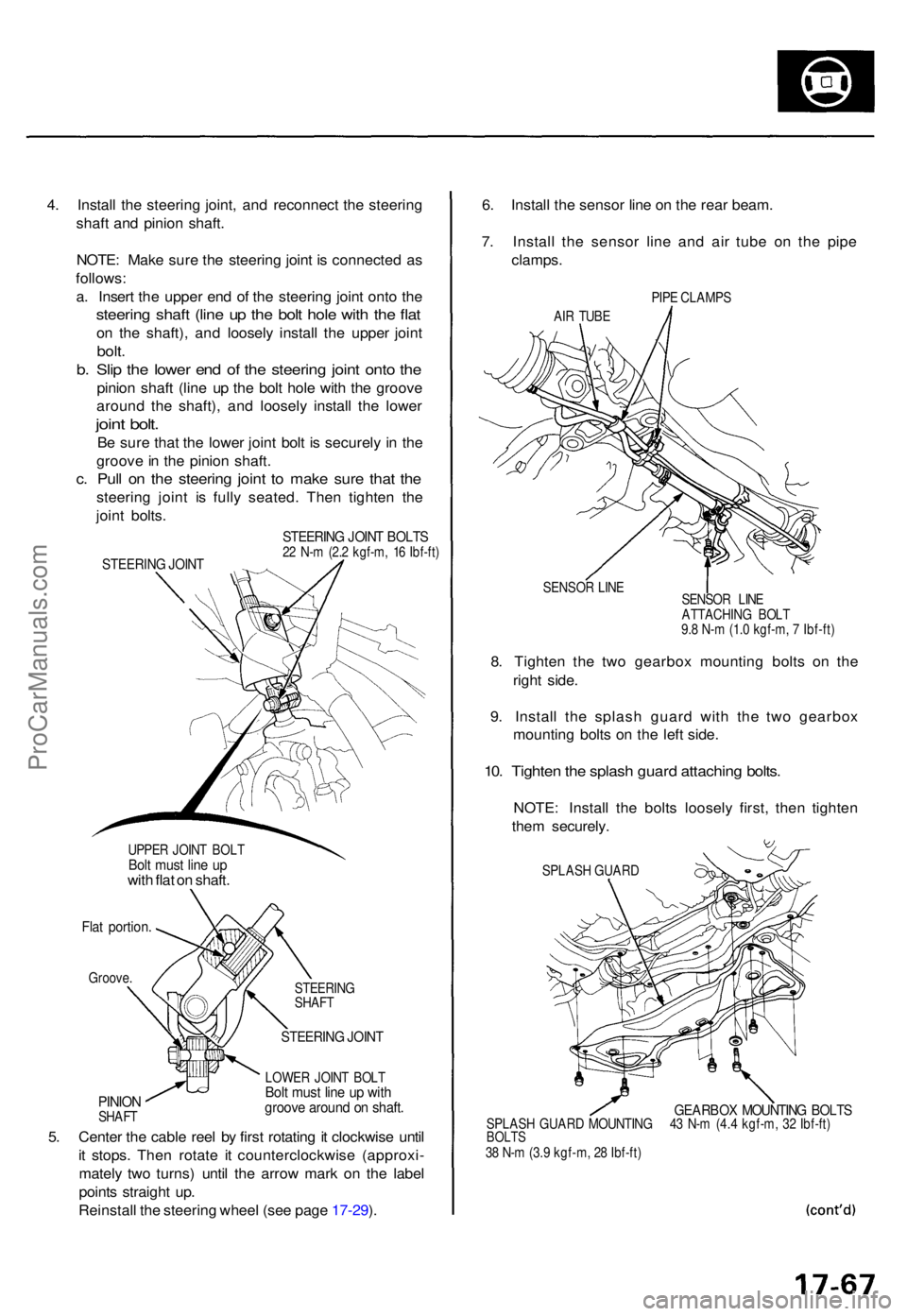

4. Instal l th e steerin g joint , an d reconnec t th e steerin g

shaf t an d pinio n shaft .

NOTE : Mak e sur e th e steerin g join t i s connecte d a s

follows :

a . Inser t th e uppe r en d o f th e steerin g join t ont o th e

steerin g shaf t (lin e u p th e bol t hol e wit h th e fla t

on th e shaft) , an d loosel y instal l th e uppe r join t

bolt.

b. Sli p th e lowe r en d o f th e steerin g join t ont o th e

pinio n shaf t (lin e u p th e bol t hol e wit h th e groov e

aroun d th e shaft) , an d loosel y instal l th e lowe r

joint bolt .

Be sur e tha t th e lowe r join t bol t i s securel y i n th e

groov e in th e pinio n shaft .

c. Pul l o n th e steerin g join t t o mak e sur e tha t th e

steerin g join t i s full y seated . The n tighte n th e

join t bolts .

UPPE R JOIN T BOL TBolt mus t lin e u pwit h fla t o n shaft .

Flat portion .

Groove.

PINIONSHAF T STEERIN

G

SHAF T

STEERIN G JOIN T

LOWE R JOIN T BOL TBolt mus t lin e u p wit hgroov e aroun d o n shaft .

5. Cente r th e cabl e ree l b y firs t rotatin g it clockwis e unti l

i t stops . The n rotat e i t counterclockwis e (approxi -

matel y tw o turns ) unti l th e arro w mar k o n th e labe l

point s straigh t up .

Reinstal l th e steerin g whee l (se e pag e 17-29 ). 6

. Instal l th e senso r lin e o n th e rea r beam .

7 . Instal l th e senso r lin e an d ai r tub e o n th e pip e

clamps .

PIPE CLAMP S

AI R TUB E

SENSO R LIN E

8. Tighte n th e tw o gearbo x mountin g bolt s o n th e

righ t side .

9 . Instal l th e splas h guar d wit h th e tw o gearbo x

mountin g bolt s o n th e lef t side .

10. Tighte n th e splas h guar d attachin g bolts .

NOTE : Instal l th e bolt s loosel y first , the n tighte n

the m securely .

SPLASH GUAR D

GEARBO X MOUNTIN G BOLT SSPLAS H GUAR D MOUNTIN G 4 3 N- m (4. 4 kgf-m , 3 2 Ibf-ft )BOLT S38 N- m (3. 9 kgf-m , 2 8 Ibf-ft )

STEERIN G JOIN T BOLT S22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )STEERIN G JOIN T

SENSO R LIN E

ATTACHIN G BOL T

9. 8 N- m (1. 0 kgf-m , 7 Ibf-ft )

ProCarManuals.com