gearbox ACURA TL 1995 Service Owner's Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1192 of 1771

Steering Gearbo x

Remova l (cont'd )

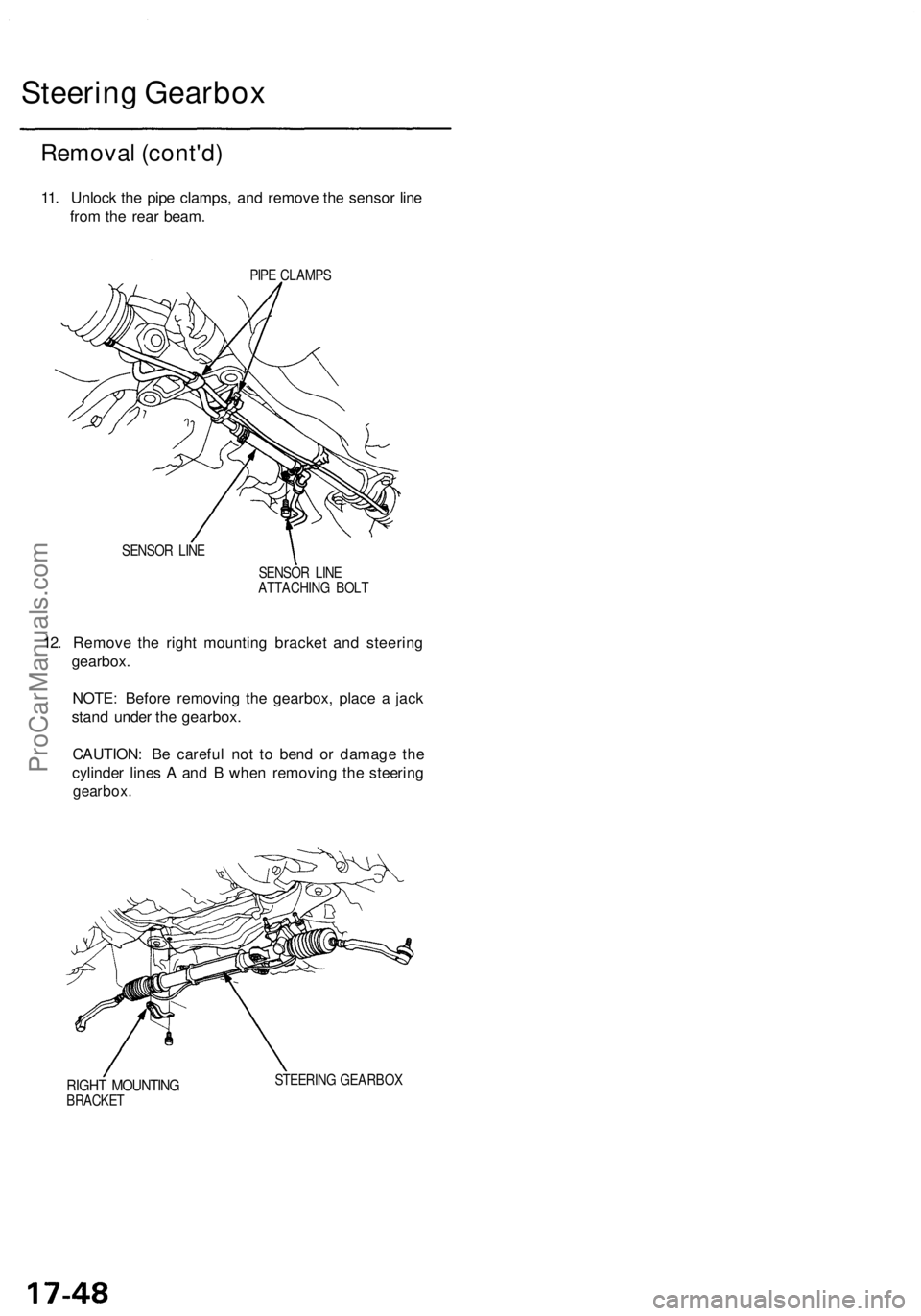

11. Unloc k th e pip e clamps , an d remov e th e senso r lin e

fro m th e rea r beam .

PIPE CLAMP S

SENSO R LIN E

SENSOR LIN E

ATTACHIN G BOL T

12. Remov e th e righ t mountin g bracke t an d steerin g

gearbox .

NOTE : Befor e removin g th e gearbox , plac e a jac k

stan d unde r th e gearbox .

CAUTION : B e carefu l no t t o ben d o r damag e th e

cylinde r line s A an d B whe n removin g th e steerin g

gearbox .

RIGHT MOUNTIN GBRACKET STEERIN

G GEARBO X

ProCarManuals.com

Page 1193 of 1771

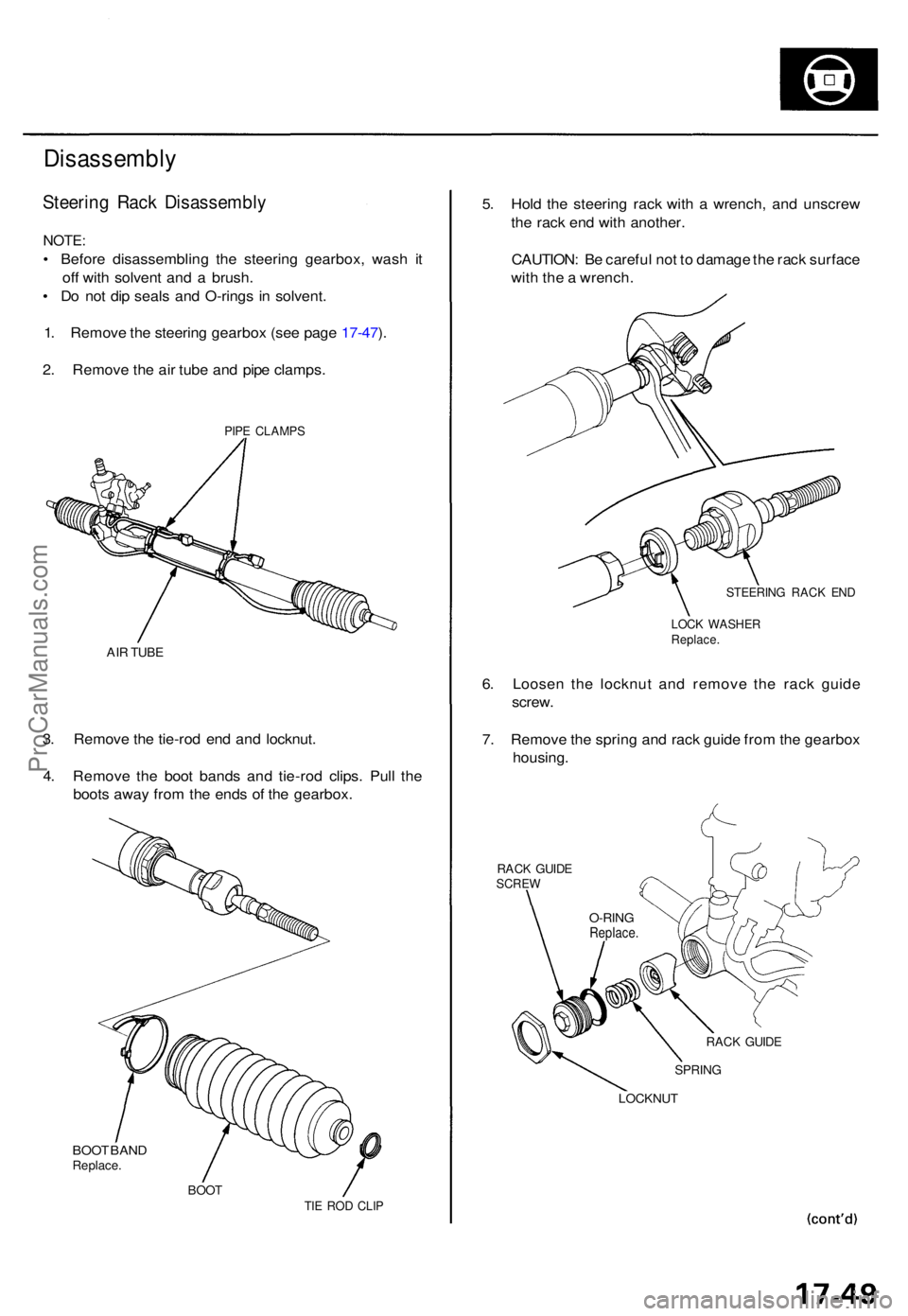

Disassembly

Steering Rac k Disassembl y

NOTE:

• Befor e disassemblin g th e steerin g gearbox , was h i t

of f wit h solven t an d a brush .

• D o no t di p seal s an d O-ring s i n solvent .

1 . Remov e th e steerin g gearbo x (se e pag e 17-47 ).

2 . Remov e th e ai r tub e an d pip e clamps .

PIPE CLAMP S

AIR TUB E

3. Remov e th e tie-ro d en d an d locknut .

4 . Remov e th e boo t band s an d tie-ro d clips . Pul l th e

boot s awa y fro m th e end s o f th e gearbox.

BOO T BAN DReplace .

BOOTTIE RO D CLI P

5. Hol d th e steerin g rac k wit h a wrench , an d unscre w

th e rac k en d wit h another .

CAUTION : B e carefu l no t t o damag e th e rac k surfac e

wit h th e a wrench .

STEERIN G RAC K EN D

LOC K WASHE RReplace.

6. Loose n th e locknu t an d remov e th e rac k guid e

screw .

7 . Remov e th e sprin g an d rac k guid e fro m th e gearbo x

housing .

RACK GUID ESCRE W

RACK GUID E

SPRIN G

LOCKNU T

O-RINGReplace .

ProCarManuals.com

Page 1194 of 1771

Steering Gearbo x

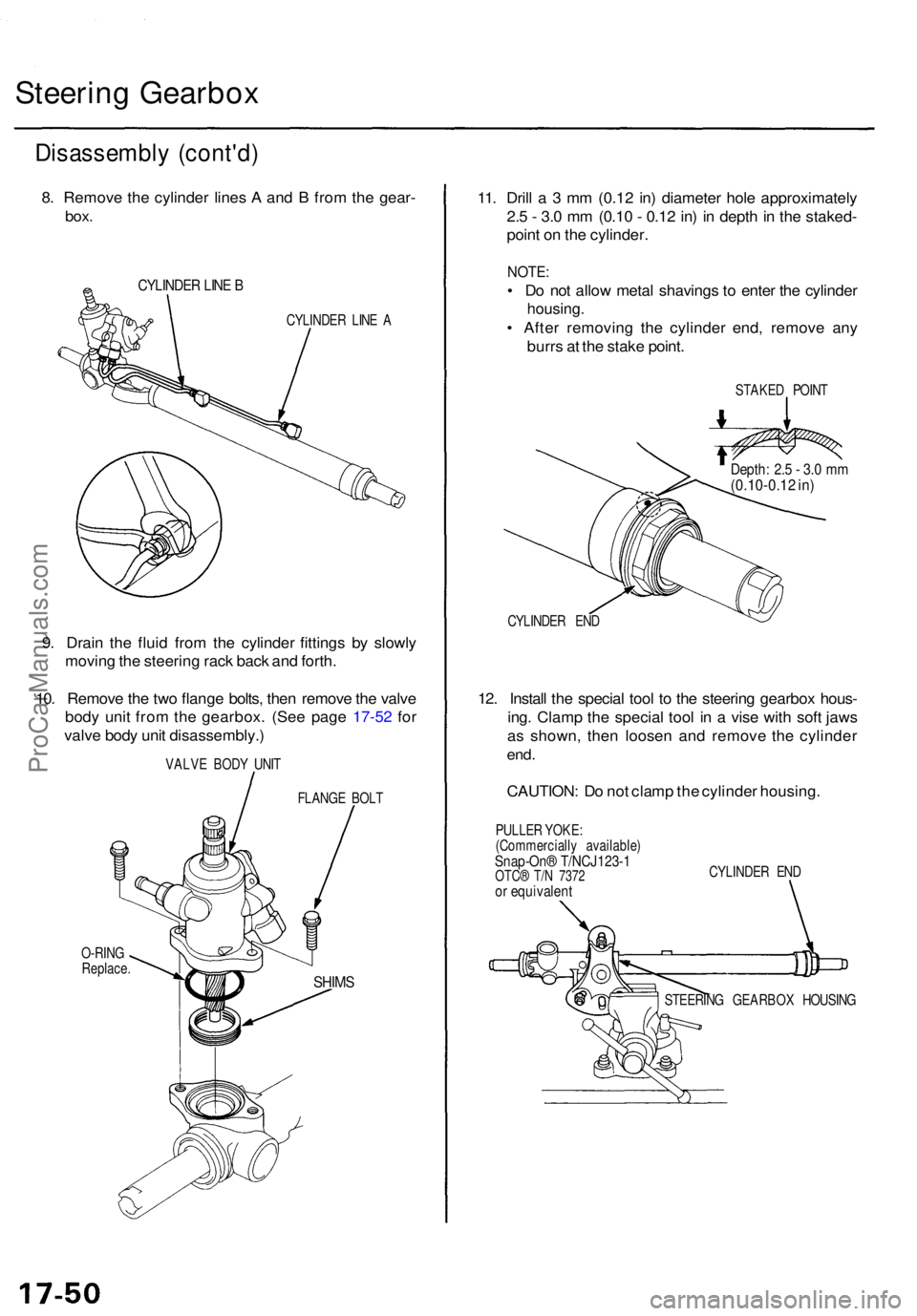

Disassembl y (cont'd )

8. Remov e th e cylinde r line s A an d B fro m th e gear -

box.

CYLINDE R LIN E B

CYLINDE R LIN E A

9. Drai n th e flui d fro m th e cylinde r fitting s b y slowl y

movin g th e steerin g rac k bac k an d forth .

10 . Remov e th e tw o flang e bolts , the n remov e th e valv e

bod y uni t fro m th e gearbox . (Se e pag e 17-5 2 fo r

valv e bod y uni t disassembly. )

VALVE BOD Y UNI T

FLANG E BOL T

O-RIN G

Replace .

11. Dril l a 3 mm (0.1 2 in ) diamete r hol e approximatel y

2. 5 - 3. 0 m m (0.1 0 - 0.1 2 in ) i n dept h in th e staked -

poin t o n th e cylinder .

NOTE:

• D o no t allo w meta l shaving s t o ente r th e cylinde r

housing .

• Afte r removin g th e cylinde r end , remov e an y

burr s a t th e stak e point .

STAKE D POIN T

CYLINDE R EN D

12. Instal l th e specia l too l t o th e steerin g gearbo x hous -

ing . Clam p th e specia l too l i n a vis e wit h sof t jaw s

a s shown , the n loose n an d remov e th e cylinde r

end.

CAUTION : D o no t clam p th e cylinde r housing .

PULLER YOKE :

(Commerciall y available )

Snap-On® T/NCJ123- 1OTC® T/ N 737 2or equivalen t

CYLINDER EN D

STEERIN G GEARBO X HOUSIN G

SHIMS

Depth : 2. 5 - 3. 0 m m(0.10-0.1 2 in )

ProCarManuals.com

Page 1195 of 1771

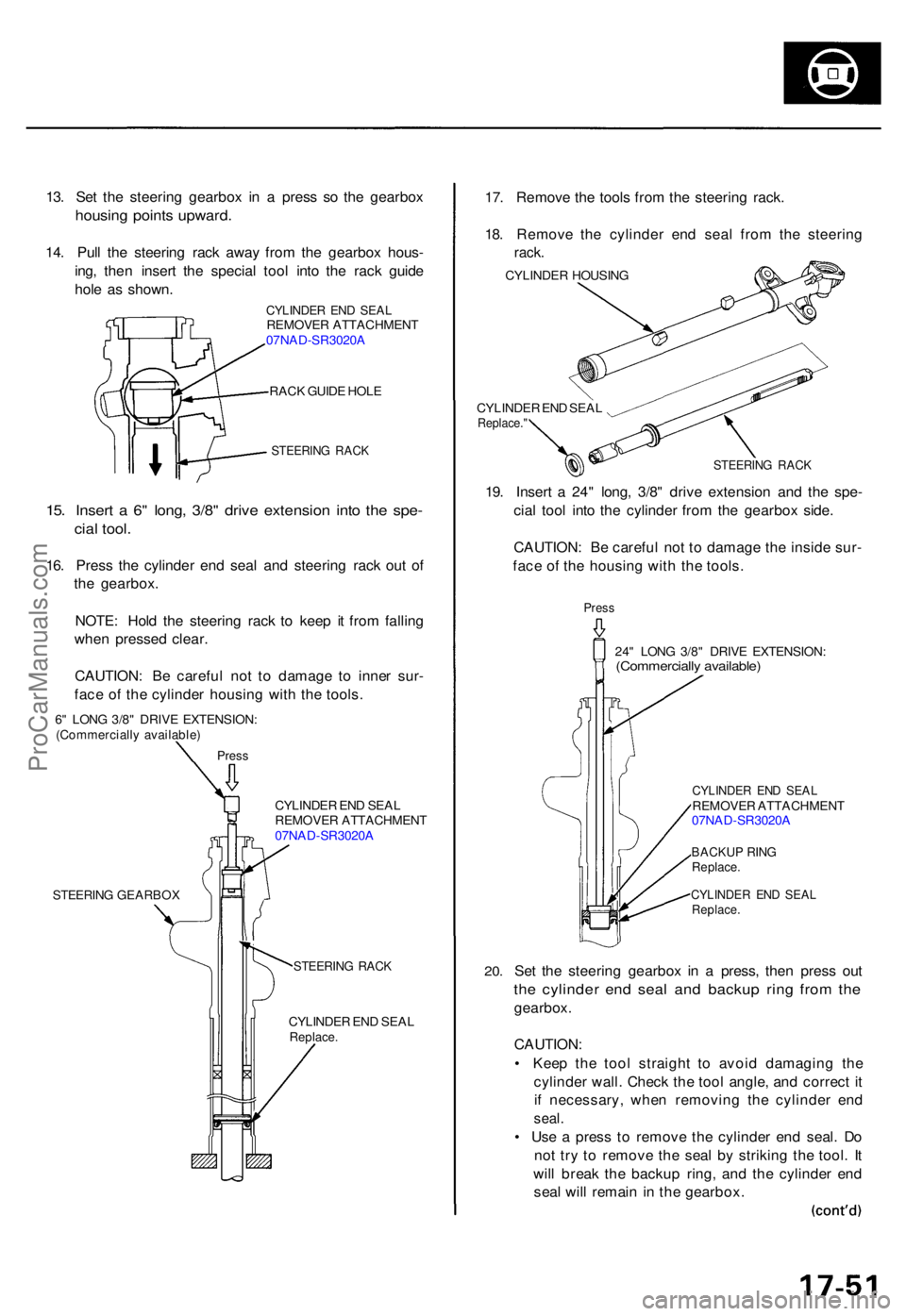

13. Se t th e steerin g gearbo x i n a pres s s o th e gearbo x

housing point s upward .

14. Pul l th e steerin g rac k awa y fro m th e gearbo x hous -

ing , the n inser t th e specia l too l int o th e rac k guid e

hol e a s shown .

CYLINDE R EN D SEA LREMOVE R ATTACHMEN T

07NA D-SR3020 A

RAC K GUID E HOL E

STEERIN G RAC K

15. Inser t a 6 " long , 3/8 " driv e extensio n int o th e spe -

cial tool .

16. Pres s th e cylinde r en d sea l an d steerin g rac k ou t o f

th e gearbox .

NOTE : Hol d th e steerin g rac k t o kee p i t fro m fallin g

whe n presse d clear .

CAUTION : B e carefu l no t t o damag e t o inne r sur -

fac e o f th e cylinde r housin g wit h th e tools .

6" LON G 3/8 " DRIV E EXTENSION :(Commerciall y available )

Press

CYLINDE R EN D SEA L

REMOVE R ATTACHMEN T

07NA D-SR3020 A

STEERIN G GEARBO X

STEERING RAC K

CYLINDE R EN D SEA LReplace .

17. Remov e th e tool s fro m th e steerin g rack .

18 . Remov e th e cylinde r en d sea l fro m th e steerin g

rack.

CYLINDE R HOUSIN G

CYLINDE R EN D SEA L

Replace. "

STEERIN G RAC K

19. Inser t a 24 " long , 3/8 " driv e extensio n an d th e spe -

cia l too l int o th e cylinde r fro m th e gearbo x side .

CAUTION : B e carefu l no t t o damag e th e insid e sur -

fac e o f th e housin g wit h th e tools .

Press

24" LON G 3/8 " DRIV E EXTENSION :(Commercially available )

20.

CYLINDE R EN D SEA LREMOVE R ATTACHMEN T

07NA D-SR3020 A

BACKU P RIN GReplace .

CYLINDE R EN D SEA LReplace .

Set th e steerin g gearbo x i n a press , the n pres s ou t

the cylinde r en d sea l an d backu p rin g fro m th e

gearbox .

CAUTION :

• Kee p th e too l straigh t t o avoi d damagin g th e

cylinde r wall . Chec k th e too l angle , an d correc t i t

i f necessary , whe n removin g th e cylinde r en d

seal .

• Us e a pres s t o remov e th e cylinde r en d seal . D o

no t tr y t o remov e th e sea l b y strikin g th e tool . I t

wil l brea k th e backu p ring , an d th e cylinde r en d

sea l wil l remai n in th e gearbox .

ProCarManuals.com

Page 1206 of 1771

Steering Gearbo x

Reassembl y (cont'd )

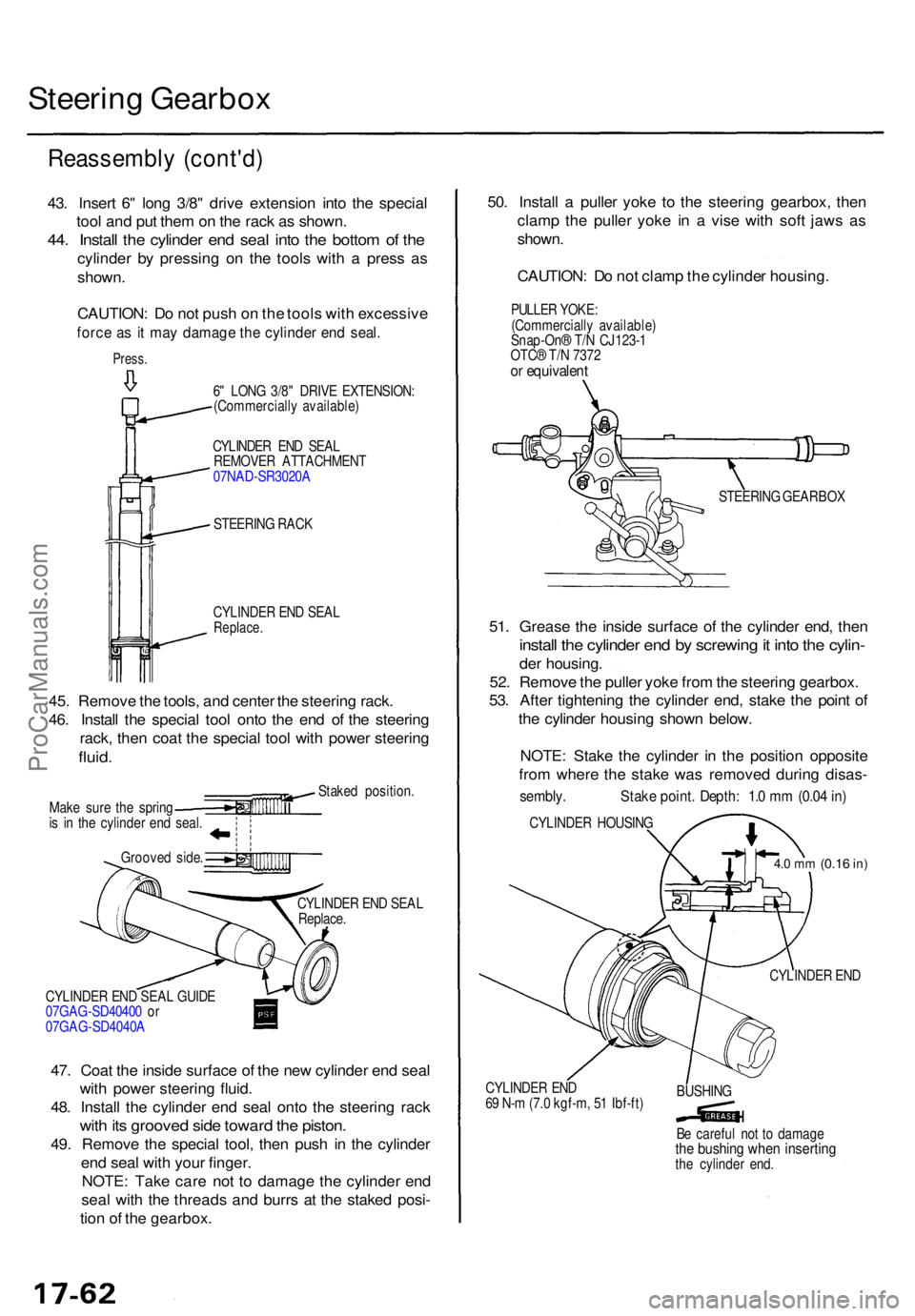

43. Inser t 6 " lon g 3/8 " driv e extensio n int o th e specia l

too l an d pu t the m on th e rac k a s shown .

44. Instal l th e cylinde r en d sea l int o th e botto m o f th e

cylinde r b y pressin g o n th e tool s wit h a pres s a s

shown .

CAUTION : D o no t pus h o n th e tool s wit h excessiv e

force a s i t ma y damag e th e cylinde r en d seal .

Press .

STEERIN G RAC K

CYLINDE R EN D SEA L

Replace .

a

45. Remov e th e tools , an d cente r th e steerin g rack .

46 . Instal l th e specia l too l ont o th e en d o f th e steerin g

rack , the n coa t th e specia l too l wit h powe r steerin g

fluid.

Stake d position .

Mak e sur e th e sprin g

i s i n th e cylinde r en d seal .

Groove d side .

CYLINDER EN D SEA L

Replace .

CYLINDE R EN D SEA L GUID E

07GA G-SD4040 0 o r

07GA G-SD4040 A

47. Coa t th e insid e surfac e o f th e ne w cylinde r en d sea l

wit h powe r steerin g fluid .

48 . Instal l th e cylinde r en d sea l ont o th e steerin g rac k

with it s groove d sid e towar d th e piston .

49. Remov e th e specia l tool , the n pus h i n th e cylinde r

en d sea l wit h you r finger.

NOTE : Tak e car e no t t o damag e th e cylinde r en d

sea l wit h th e thread s an d burr s a t th e stake d posi -

tio n o f th e gearbox . 50

. Instal l a pulle r yok e t o th e steerin g gearbox , the n

clam p th e pulle r yok e i n a vis e wit h sof t jaw s a s

shown .

CAUTION : D o no t clam p th e cylinde r housing .

51 . Greas e th e insid e surfac e o f th e cylinde r end , the n

instal l th e cylinde r en d b y screwin g it int o th e cylin -

der housing .

52 . Remov e th e pulle r yok e fro m th e steerin g gearbox .

53 . Afte r tightenin g th e cylinde r end , stak e th e poin t o f

th e cylinde r housin g show n below .

NOTE : Stak e th e cylinde r i n th e positio n opposit e

fro m wher e th e stak e wa s remove d durin g disas -

sembly . Stak e point . Depth : 1. 0 m m (0.0 4 in )

CYLINDE R HOUSIN G

4.0 m m (0.1 6 in)

CYLINDE R EN D

CYLINDE R EN D

6 9 N- m (7. 0 kgf-m , 5 1 Ibf-ft ) BUSHIN

G

B e carefu l no t t o damag e

the bushin g whe n insertin gthe cylinde r end .

CYLINDE

R EN D SEA L

REMOVE R ATTACHMEN T

07NA D-SR3020 A

6

" LON G 3/8 " DRIV E EXTENSION :

(Commerciall y available ) PULLE

R YOKE :

(Commerciall y available )

Snap-On ® T/ N CJ123- 1

OTC ® T/ N 737 2

or equivalen t

STEERING GEARBO X

ProCarManuals.com

Page 1207 of 1771

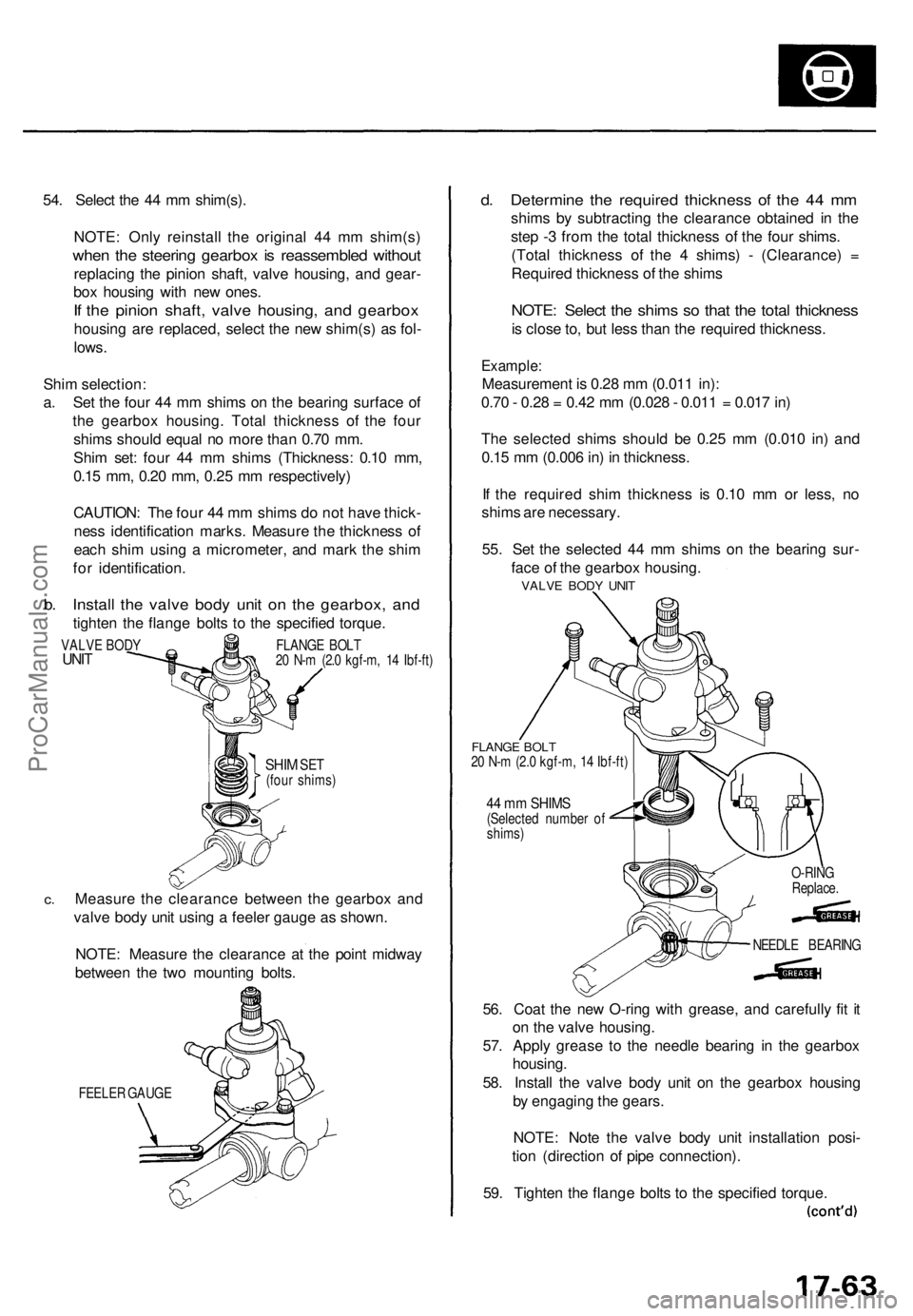

54. Selec t th e 4 4 m m shim(s) .

NOTE : Onl y reinstal l th e origina l 4 4 m m shim(s )

when th e steerin g gearbo x i s reassemble d withou t

replacin g th e pinio n shaft , valv e housing , an d gear -

bo x housin g wit h ne w ones .

If th e pinio n shaft , valv e housing , an d gearbo x

housing ar e replaced , selec t th e ne w shim(s ) a s fol -

lows .

Shi m selection :

a . Se t th e fou r 4 4 m m shim s o n th e bearin g surfac e o f

th e gearbo x housing . Tota l thicknes s o f th e fou r

shim s shoul d equa l n o mor e tha n 0.7 0 mm .

Shi m set : fou r 4 4 m m shim s (Thickness : 0.1 0 mm ,

0.1 5 mm , 0.2 0 mm , 0.2 5 m m respectively )

CAUTION : Th e fou r 4 4 m m shim s d o no t hav e thick -

nes s identificatio n marks . Measur e th e thicknes s o f

eac h shi m usin g a micrometer , an d mar k th e shi m

fo r identification .

b. Instal l th e valv e bod y uni t o n th e gearbox , an d

tighte n th e flang e bolt s t o th e specifie d torque .

SHIM SET(fou r shims )

c.Measur e th e clearanc e betwee n th e gearbo x an d

valv e bod y uni t usin g a feele r gaug e a s shown .

NOTE : Measur e th e clearanc e a t th e poin t midwa y

betwee n th e tw o mountin g bolts .

FEELE R GAUG E

d. Determin e th e require d thicknes s o f th e 4 4 m m

shim s b y subtractin g th e clearanc e obtaine d i n th e

ste p - 3 fro m th e tota l thicknes s o f th e fou r shims .

(Tota l thicknes s o f th e 4 shims ) - (Clearance ) =

Require d thicknes s o f th e shim s

NOTE : Selec t th e shim s s o tha t th e tota l thicknes s

is clos e to , bu t les s tha n th e require d thickness .

Example:

Measuremen t i s 0.2 8 m m (0.01 1 in) :

0.7 0 - 0.2 8 = 0.4 2 m m (0.02 8 - 0.01 1 = 0.01 7 in )

Th e selecte d shim s shoul d b e 0.2 5 m m (0.01 0 in ) an d

0.1 5 m m (0.00 6 in ) i n thickness .

I f th e require d shi m thicknes s i s 0.1 0 m m o r less , n o

shim s ar e necessary .

55 . Se t th e selecte d 4 4 m m shim s o n th e bearin g sur -

fac e o f th e gearbo x housing .

FLANGE BOL T20 N- m (2. 0 kgf-m , 1 4 Ibf-ft )

44 m m SHIM S(Selecte d numbe r o f

shims )

56. Coa t th e ne w O-rin g wit h grease , an d carefull y fi t i t

o n th e valv e housing .

57 . Appl y greas e t o th e needl e bearin g i n th e gearbo x

housing .

58 . Instal l th e valv e bod y uni t o n th e gearbo x housin g

b y engagin g th e gears .

NOTE : Not e th e valv e bod y uni t installatio n posi -

tio n (directio n o f pip e connection) .

59 . Tighte n th e flang e bolt s t o th e specifie d torque .

VALVE BOD YUNITFLANG E BOL T

2 0 N- m (2. 0 kgf-m , 1 4 Ibf-ft )

NEEDLE BEARIN G

O-RIN

G

Replace .

VALVE BOD Y UNI T

ProCarManuals.com

Page 1211 of 1771

Steering Gearbo x

Installatio n

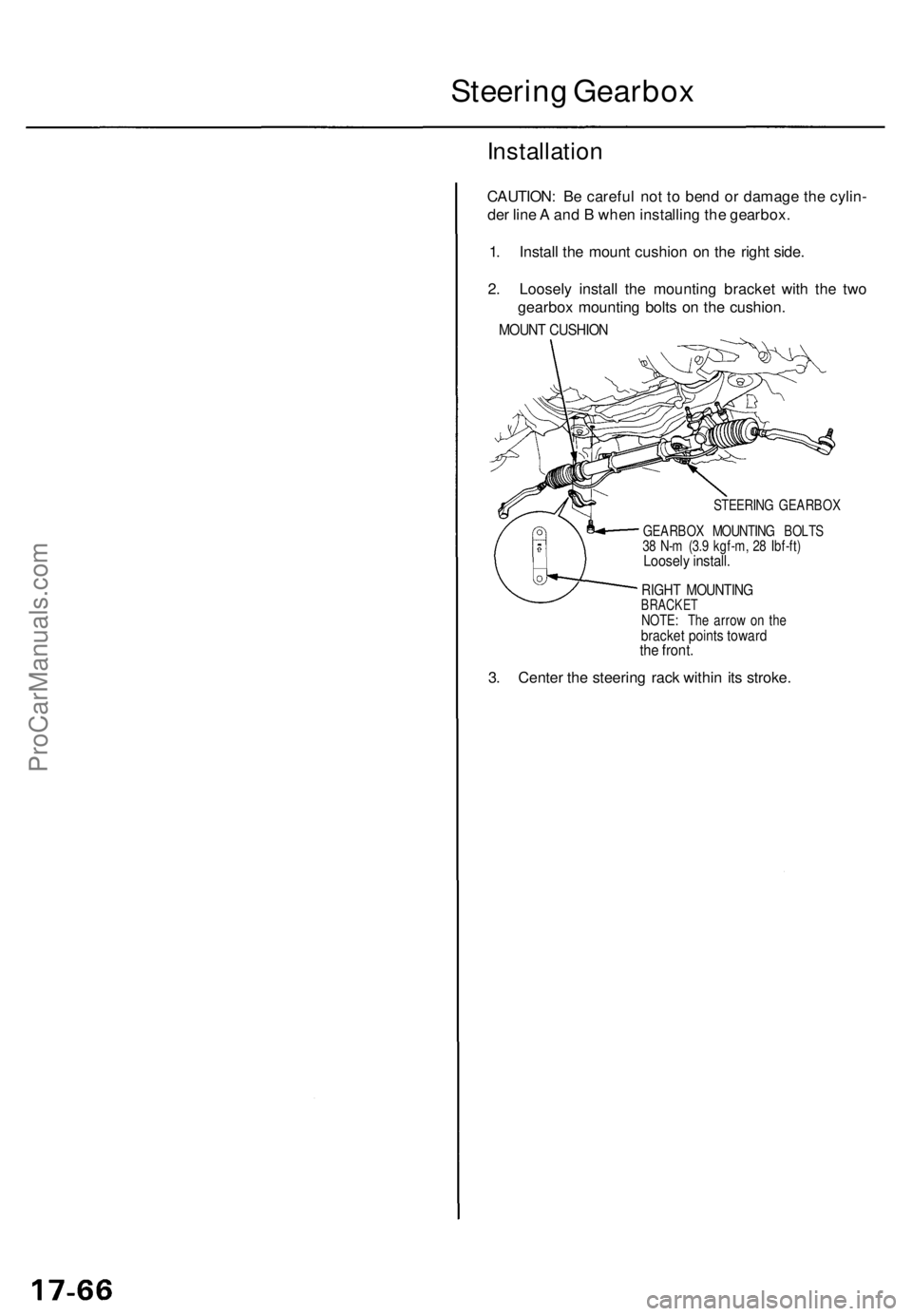

CAUTION: B e carefu l no t t o ben d o r damag e th e cylin -

de r lin e A an d B whe n installin g th e gearbox .

1 . Instal l th e moun t cushio n o n th e righ t side .

2 . Loosel y instal l th e mountin g bracke t wit h th e tw o

gearbo x mountin g bolt s o n th e cushion .

MOUNT CUSHIO N

STEERIN G GEARBO X

GEARBO X MOUNTIN G BOLT S

3 8 N- m (3. 9 kgf-m , 2 8 Ibf-ft )

Loosel y install .

RIGHT MOUNTIN GBRACKETNOTE: Th e arro w o n th ebracke t point s towar dthe front .

3. Cente r th e steerin g rac k withi n it s stroke .

ProCarManuals.com

Page 1213 of 1771

Steering Gearbo x

Installatio n (cont'd )

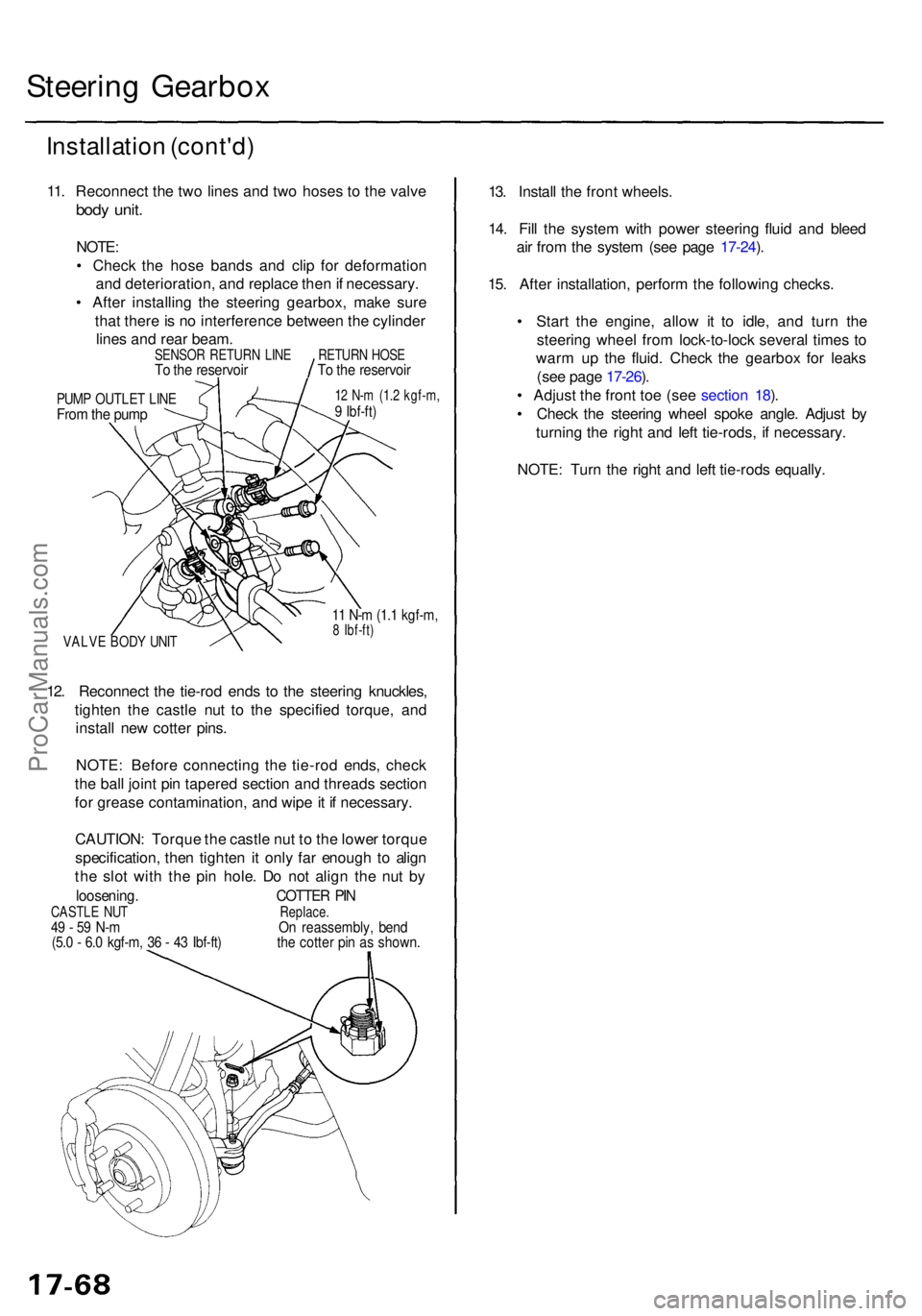

11. Reconnec t th e tw o line s an d tw o hose s t o th e valv e

body unit .

NOTE :

• Chec k th e hos e band s an d cli p fo r deformatio n

an d deterioration , an d replac e the n if necessary .

• Afte r installin g th e steerin g gearbox , mak e sur e

tha t ther e is n o interferenc e betwee n th e cylinde r

line s an d rea r beam .

PUMP OUTLE T LIN EFrom th e pum p

12 N- m (1. 2 kgf-m ,9 Ibf-ft )

VALV E BOD Y UNI T

11 N- m (1. 1 kgf-m ,8 Ibf-ft )

12. Reconnec t th e tie-ro d end s t o th e steerin g knuckles ,

tighte n th e castl e nu t t o th e specifie d torque , an d

instal l ne w cotte r pins .

NOTE : Befor e connectin g th e tie-ro d ends , chec k

th e bal l join t pi n tapere d sectio n an d thread s sectio n

fo r greas e contamination , an d wip e it i f necessary .

CAUTION : Torqu e th e castl e nu t t o th e lowe r torqu e

specification , the n tighte n it onl y fa r enoug h t o alig n

th e slo t wit h th e pi n hole . D o no t alig n th e nu t b y

loosening . COTTER PI NCASTL E NU T Replace.49 - 5 9 N- m O n reassembly , ben d(5.0 - 6. 0 kgf-m , 3 6 - 4 3 Ibf-ft ) th e cotte r pi n a s shown .

13. Instal l th e fron t wheels .

14 . Fil l th e syste m wit h powe r steerin g flui d an d blee d

ai r fro m th e syste m (se e pag e 17-24 ).

15 . Afte r installation , perfor m th e followin g checks .

• Star t th e engine , allo w i t t o idle , an d tur n th e

steerin g whee l fro m lock-to-loc k severa l time s t o

war m u p th e fluid . Chec k th e gearbo x fo r leak s

(se e pag e 17-26 ).

• Adjus t th e fron t to e (se e sectio n 18 ).

• Chec k th e steerin g whee l spok e angle . Adjus t b y

turnin g th e righ t an d lef t tie-rods , i f necessary .

NOTE : Tur n th e righ t an d lef t tie-rod s equally .

SENSO R RETUR N LIN ETo th e reservoi rRETURN HOS ETo th e reservoi r

ProCarManuals.com

Page 1436 of 1771

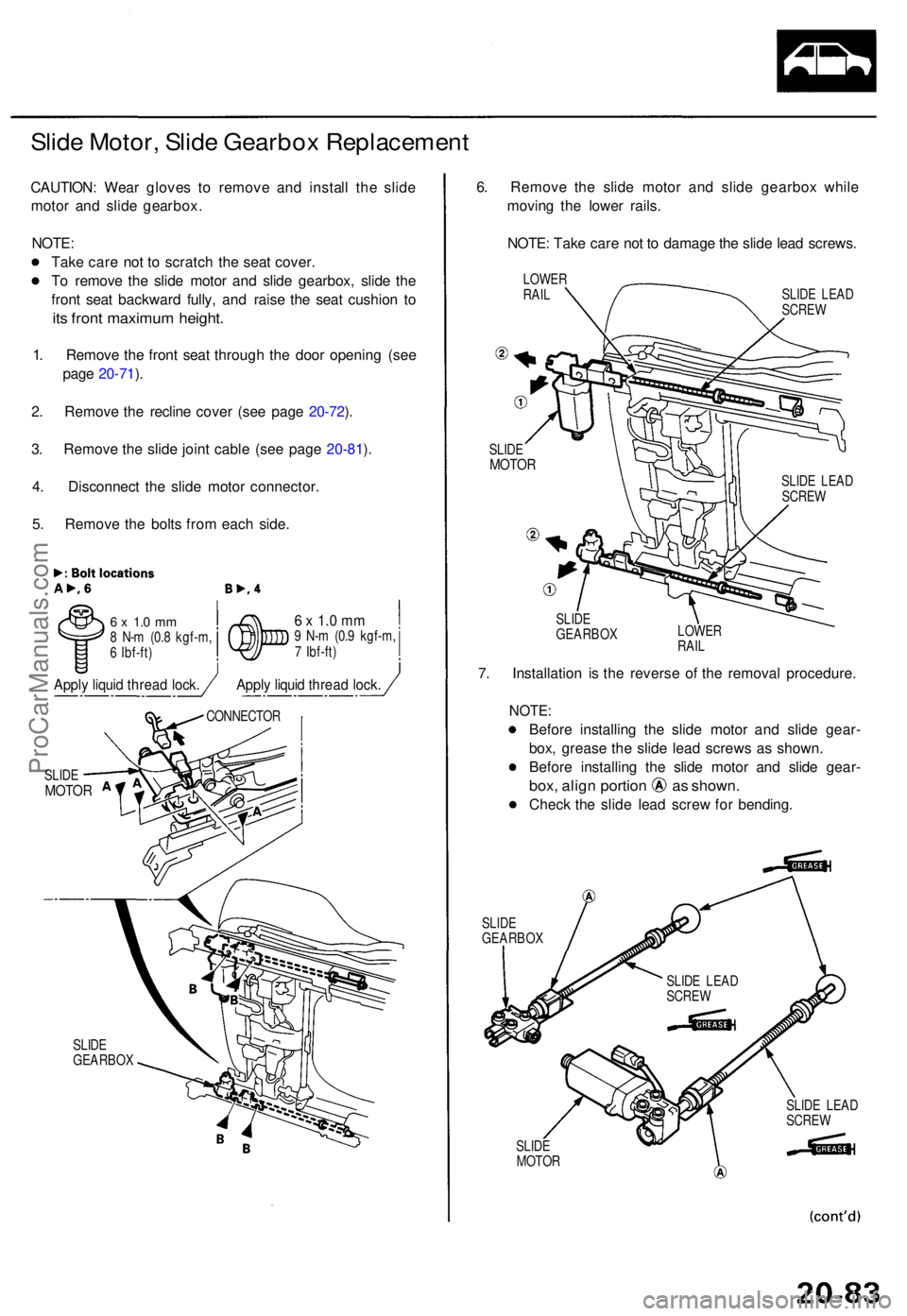

Slide Motor , Slid e Gearbo x Replacemen t

CAUTION: Wea r glove s t o remov e an d instal l th e slid e

moto r an d slid e gearbox .

NOTE :

Tak e car e no t t o scratc h th e sea t cover .

T o remov e th e slid e moto r an d slid e gearbox , slid e th e

fron t sea t backwar d fully , an d rais e th e sea t cushio n t o

its fron t maximu m height .

1. Remov e th e fron t sea t throug h th e doo r openin g (se e

pag e 20-71 ).

2 . Remov e th e reclin e cove r (se e pag e 20-72 ).

3 . Remov e th e slid e join t cabl e (se e pag e 20-81 ).

4 . Disconnec t th e slid e moto r connector .

5 . Remov e th e bolt s fro m eac h side .

6 x 1. 0 m m8 N- m (0. 8 kgf-m ,

6 Ibf-ft )6 x 1. 0 m m9 N- m (0. 9 kgf-m ,

7 Ibf-ft )

SLID E

GEARBO X

6. Remov e th e slid e moto r an d slid e gearbo x whil e

movin g th e lowe r rails .

NOTE : Tak e car e no t t o damag e th e slid e lea d screws .

LOWERRAILSLID E LEA D

SCRE W

SLID E

MOTO R

SLIDE

GEARBO X LOWE

R

RAIL

7. Installatio n i s th e revers e o f th e remova l procedure .

NOTE:

Before installin g th e slid e moto r an d slid e gear -

box , greas e th e slid e lea d screw s a s shown .

Befor e installin g th e slid e moto r an d slid e gear -

box, alig n portio n a s shown .

Check th e slid e lea d scre w fo r bending .

SLIDEGEARBO X

SLIDE

MOTO R SLID

E LEA D

SCRE W

SLID E

MOTO R

CONNECTO R

SLIDE LEA D

SCRE W

SLIDE LEA D

SCRE W

Apply liqui d threa d lock .Apply liqui d threa d lock .

ProCarManuals.com

Page 1437 of 1771

Front Seat

Slide Motor, Slide Gearbox

Replacement (cont'd)

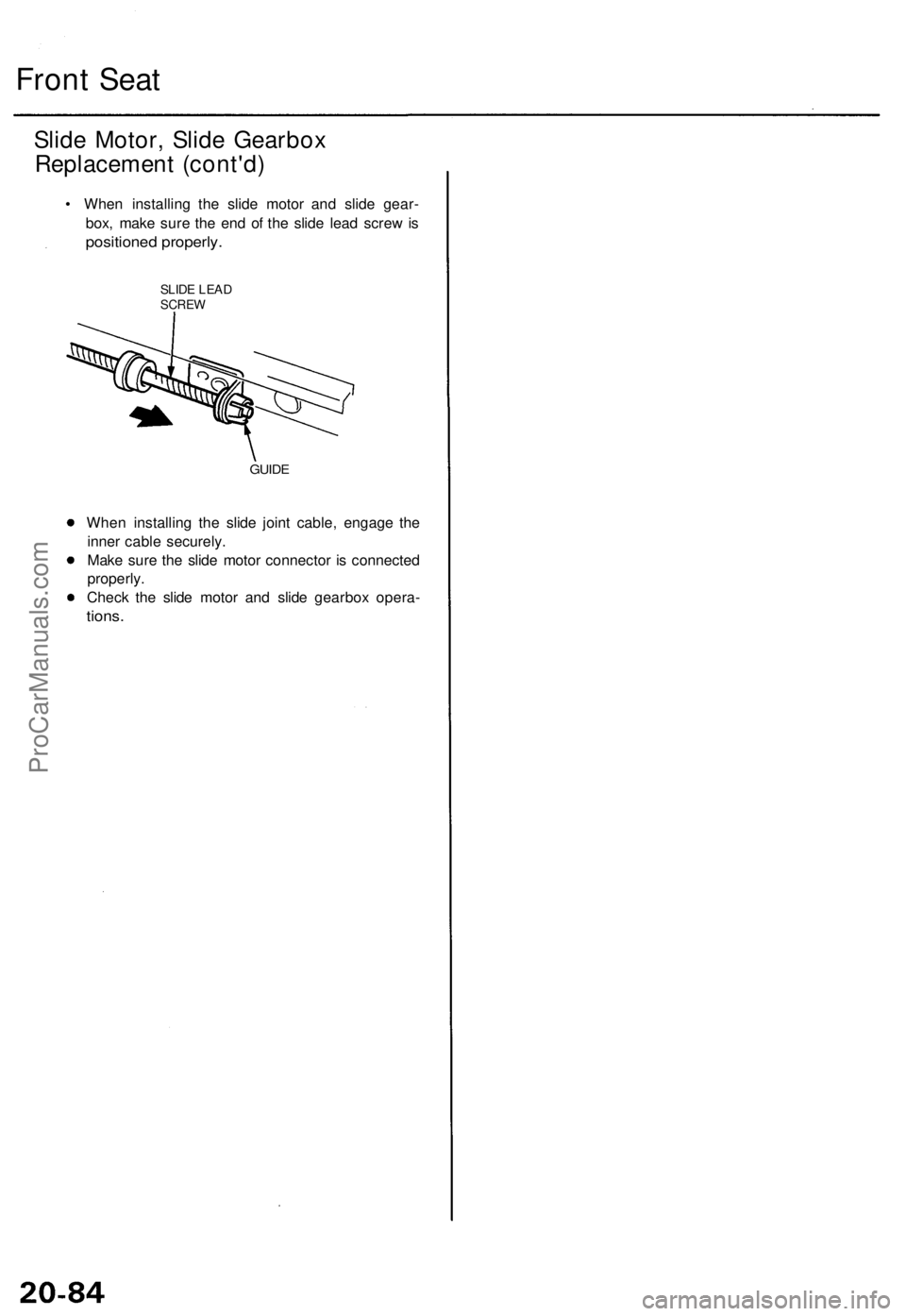

• When installing the slide motor and slide gear-

box, make sure the end of the slide lead screw is

positioned properly.

SLIDE LEAD

SCREW

GUIDE

When installing the slide joint cable, engage the

inner cable securely.

Make sure the slide motor connector is connected

properly.

Check the slide motor and slide gearbox opera-

tions.ProCarManuals.com