radiator ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 48 of 1771

Engine Removal/Installatio n

Removal (cont'd )

30. Remov e th e radiato r cap .

Us e car e whe n removin g th e radiato r

ca p to avoi d scaldin g b y ho t coolan t o r steam .

31 . Rais e th e hois t t o ful l height .

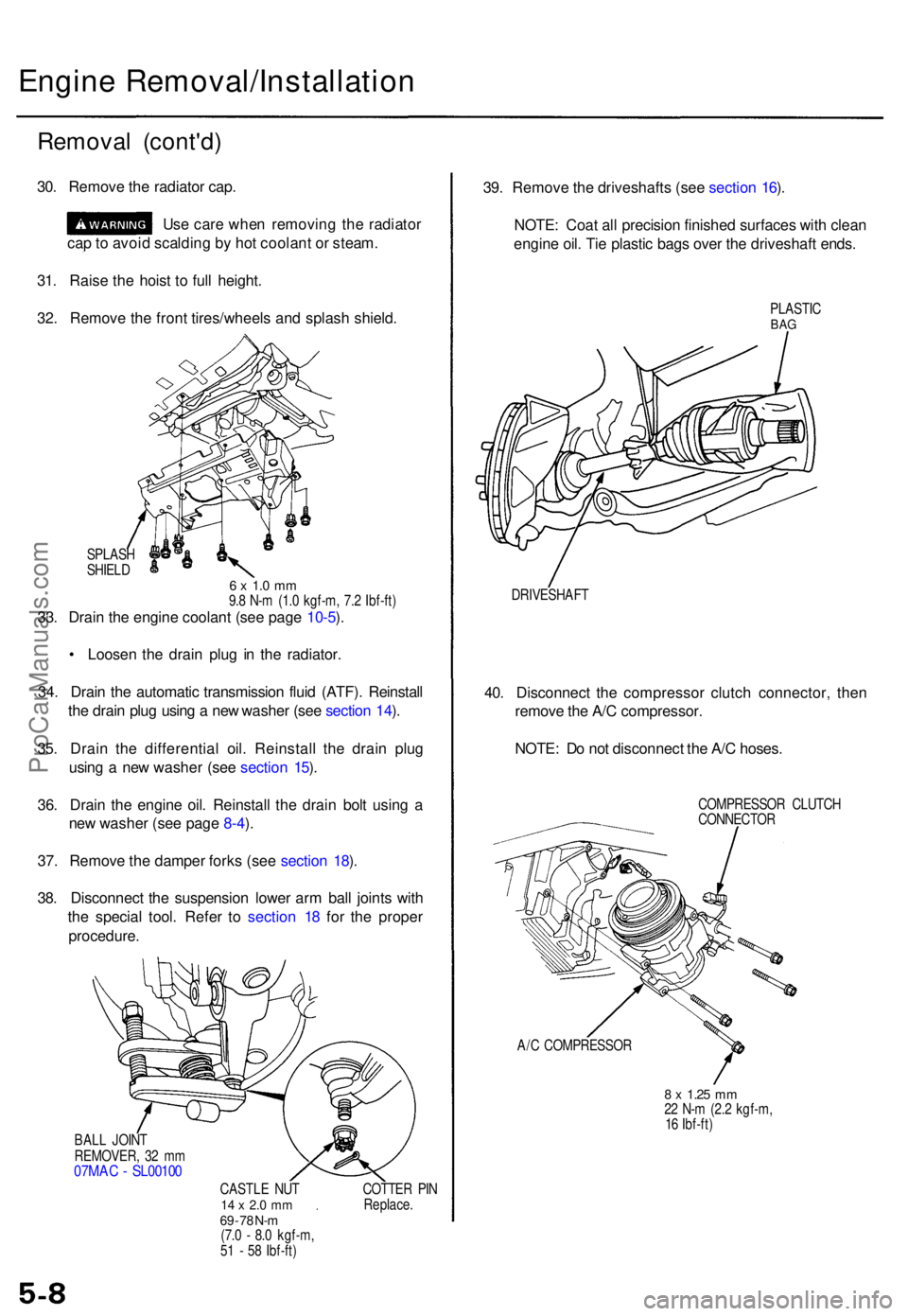

32 . Remov e th e fron t tires/wheel s an d splas h shield .

SPLAS H

SHIEL D

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )33. Drai n th e engin e coolan t (se e pag e 10-5 ).

• Loose n th e drai n plu g i n th e radiator .

34 . Drai n th e automati c transmissio n flui d (ATF) . Reinstal l

th e drai n plu g usin g a ne w washe r (se e sectio n 14 ).

35 . Drai n th e differentia l oil . Reinstal l th e drai n plu g

usin g a ne w washe r (se e sectio n 15 ).

36 . Drai n th e engin e oil . Reinstal l th e drai n bol t usin g a

ne w washe r (se e pag e 8-4 ).

37 . Remov e th e dampe r fork s (se e sectio n 18 ).

38 . Disconnec t th e suspensio n lowe r ar m bal l joint s wit h

th e specia l tool . Refe r t o sectio n 1 8 fo r th e prope r

procedure .

BALL JOIN T

REMOVER , 3 2 m m

07MA C - SL0010 0

CASTLE NU T14 x 2. 0 m m69 - 7 8 N- m(7. 0 - 8. 0 kgf-m ,

5 1 - 5 8 Ibf-ft ) COTTE

R PI N

Replace .

39. Remov e th e driveshaft s (se e sectio n 16 ).

NOTE : Coa t al l precisio n finishe d surface s wit h clea n

engin e oil . Ti e plasti c bag s ove r th e driveshaf t ends .

PLASTI CBAG

DRIVESHAF T

40. Disconnec t th e compresso r clutc h connector , the n

remov e th e A/ C compressor .

NOTE : D o no t disconnec t th e A/ C hoses .

COMPRESSO R CLUTC H

CONNECTO R

A/ C COMPRESSO R

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

ProCarManuals.com

Page 141 of 1771

Radiator

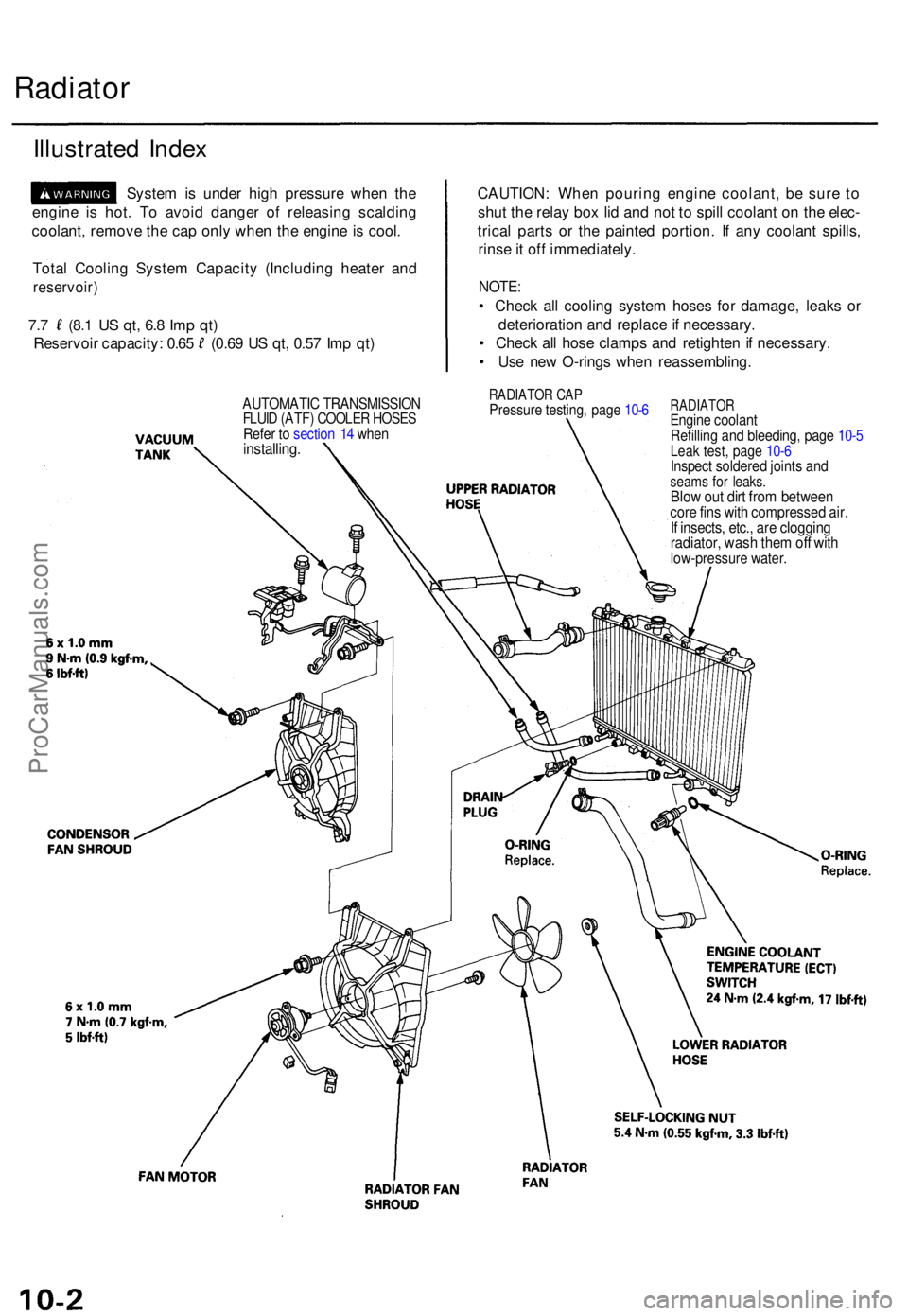

Illustrate d Inde x

Syste m is unde r hig h pressur e whe n th e

engin e i s hot . T o avoi d dange r o f releasin g scaldin g

coolant , remov e th e ca p onl y whe n th e engin e is cool .

Tota l Coolin g Syste m Capacit y (Includin g heate r an d

reservoir )

7.7 (8. 1 US qt , 6. 8 Im p qt )

Reservoi r capacity : 0.6 5 (0.6 9 U S qt , 0.5 7 Im p qt ) CAUTION

: Whe n pourin g engin e coolant , b e sur e t o

shu t th e rela y bo x li d an d no t t o spil l coolan t o n th e elec -

trica l part s o r th e painte d portion . I f an y coolan t spills ,

rins e it of f immediately .

NOTE:

• Chec k al l coolin g syste m hose s fo r damage , leak s o r

deterioratio n an d replac e if necessary .

• Chec k al l hos e clamp s an d retighte n if necessary .

• Us e ne w O-ring s whe n reassembling .

RADIATOR CA PPressur e testing , pag e 10- 6RADIATO REngine coolan t

Refillin g an d bleeding , pag e 10- 5

Leak test , pag e 10- 6Inspec t soldere d joint s an dseam s fo r leaks .Blow ou t dir t fro m betwee ncore fin s wit h compresse d air .If insects , etc. , ar e cloggin gradiator , was h the m of f wit hlow-pressur e water .

AUTOMATI C TRANSMISSIO NFLUID (ATF ) COOLE R HOSE SRefer t o sectio n 1 4 whe ninstalling .

ProCarManuals.com

Page 143 of 1771

Radiator

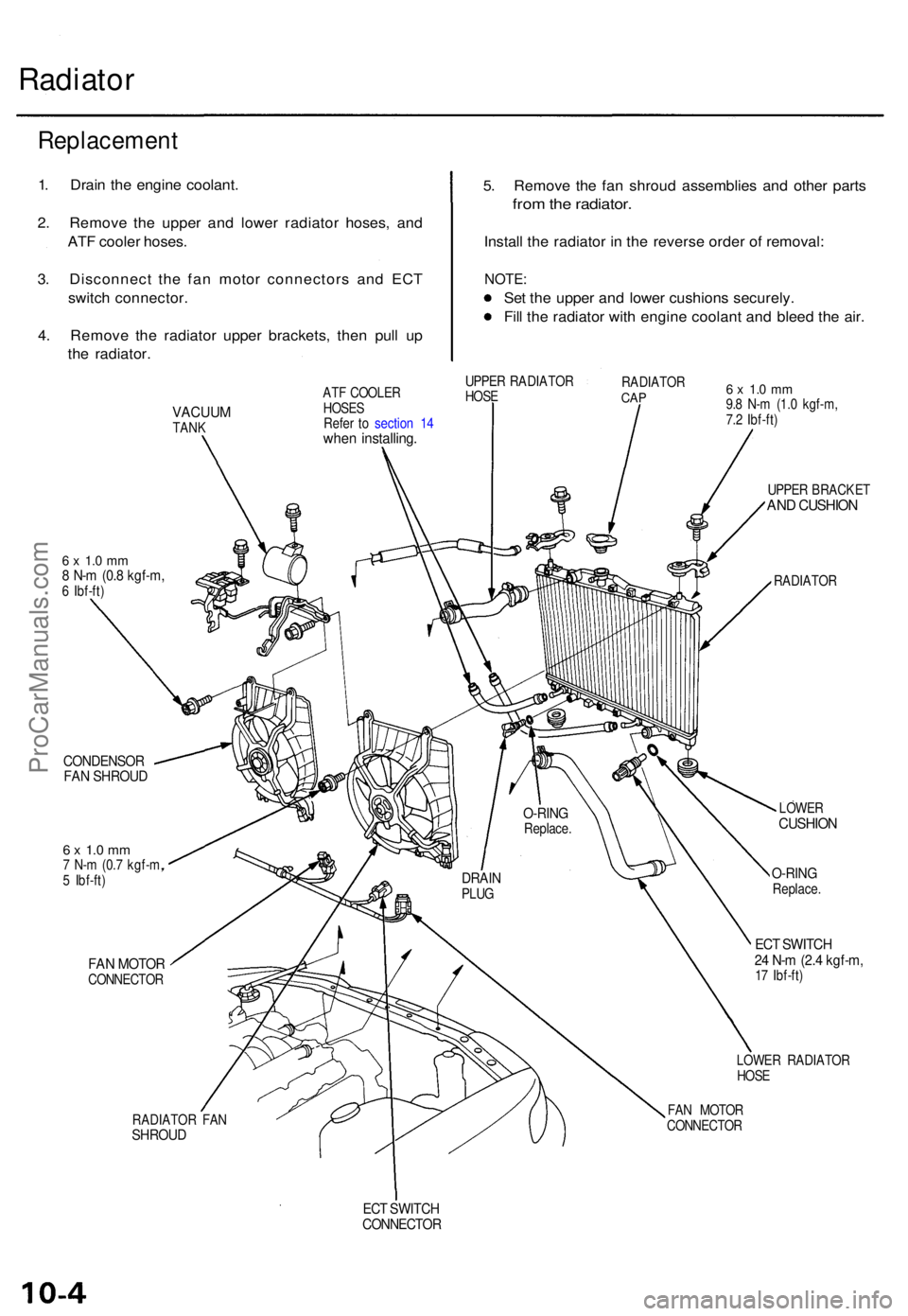

5. Remov e th e fa n shrou d assemblie s an d othe r part s

from th e radiator .

Install th e radiato r i n th e revers e orde r o f removal :

NOTE:

Set th e uppe r an d lowe r cushion s securely .

Fil l th e radiato r wit h engin e coolan t an d blee d th e air .

VACUU MTANK

6 x 1. 0 m m8 N- m (0. 8 kgf-m ,6 Ibf-ft )

CONDENSO RFAN SHROU D

6 x 1. 0 m m7 N- m (0. 7 kgf-m ,

5 Ibf-ft )

FAN MOTO RCONNECTO R

RADIATO R FA N

SHROU D

ATF COOLE R

HOSE S

Refe r t o sectio n 1 4

whe n installing .

UPPER RADIATO R

HOS E RADIATO

RCAP6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

UPPE R BRACKE T

AND CUSHIO N

RADIATO R

LOWE R

CUSHIO N

O-RINGReplace .

ECT SWITC H24 N- m (2. 4 kgf-m ,17 Ibf-ft )

LOWE R RADIATO R

HOS E

FA N MOTO R

CONNECTO R

ECT SWITC HCONNECTO R

DRAINPLUG

O-RIN GReplace .

Replacemen t

1. Drai n th e engin e coolant .

2 . Remov e th e uppe r an d lowe r radiato r hoses , an d

AT F coole r hoses .

3 . Disconnec t th e fa n moto r connector s an d EC T

switc h connector .

4 . Remov e th e radiato r uppe r brackets , the n pul l u p

th e radiator .

ProCarManuals.com

Page 145 of 1771

Radiator

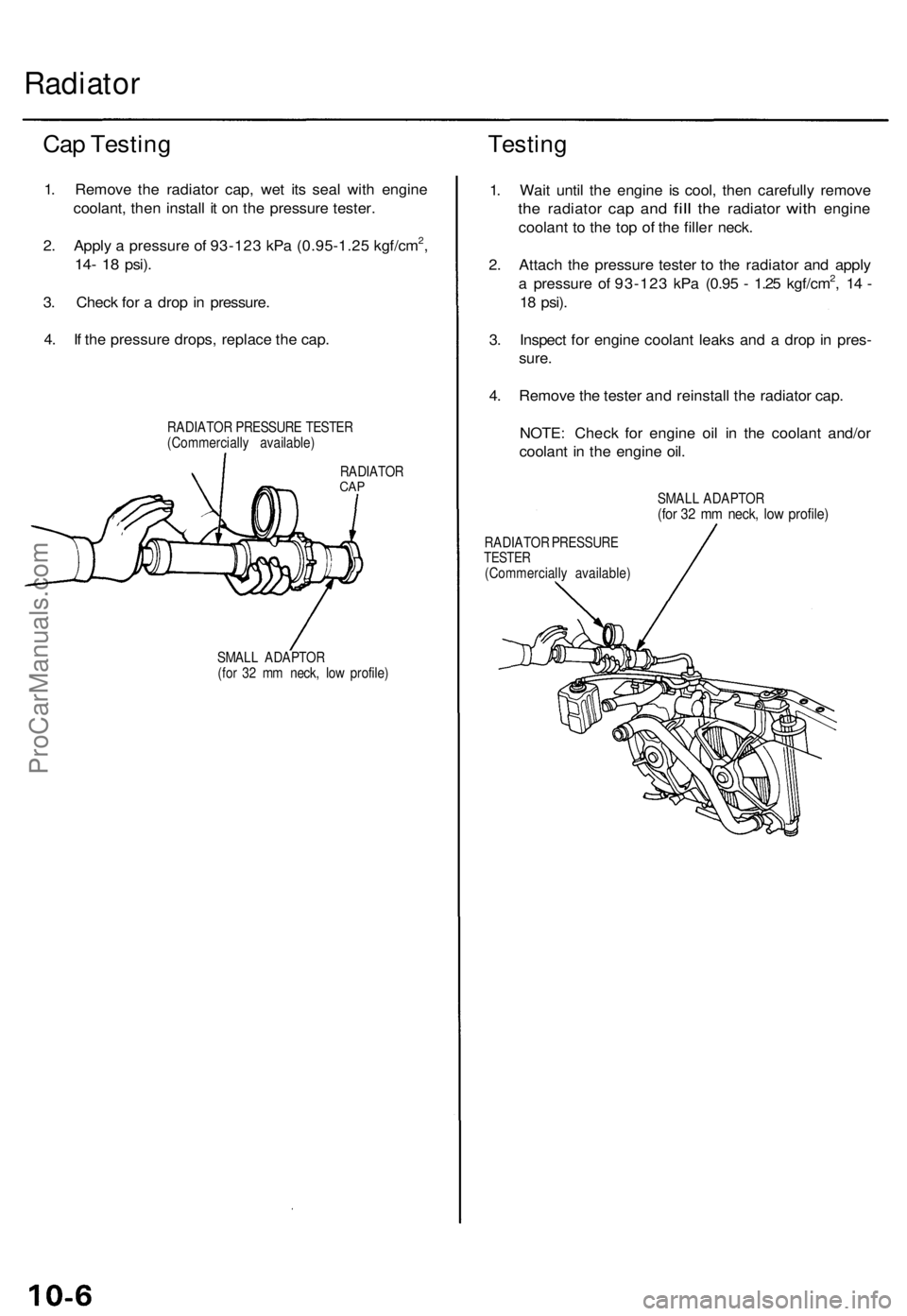

Cap Testing

1. Remove the radiator cap, wet its seal with engine

coolant, then install it on the pressure tester.

2. Apply a pressure of 93-123 kPa (0.95-1.25 kgf/cm2,

14- 18

psi).

3. Check for a drop in pressure.

4. If the pressure drops, replace the cap.

RADIATOR PRESSURE TESTER

(Commercially available)

Testing

RADIATOR

CAP

SMALL ADAPTOR

(for 32 mm neck, low profile)

1. Wait until the engine is cool, then carefully remove

the

radiator

cap and

fill

the

radiator

with

engine

coolant to the top of the filler neck.

2. Attach the pressure tester to the radiator and apply

a pressure of 93-123 kPa (0.95 - 1.25 kgf/cm2, 14 -

18

psi).

3. Inspect for engine coolant leaks and a drop in pres-

sure.

4. Remove the tester and reinstall the radiator cap.

NOTE: Check for engine oil in the coolant and/or

coolant in the engine oil.

SMALL ADAPTOR

(for 32 mm neck, low profile)

RADIATOR PRESSURE

TESTER

(Commercially available)ProCarManuals.com

Page 241 of 1771

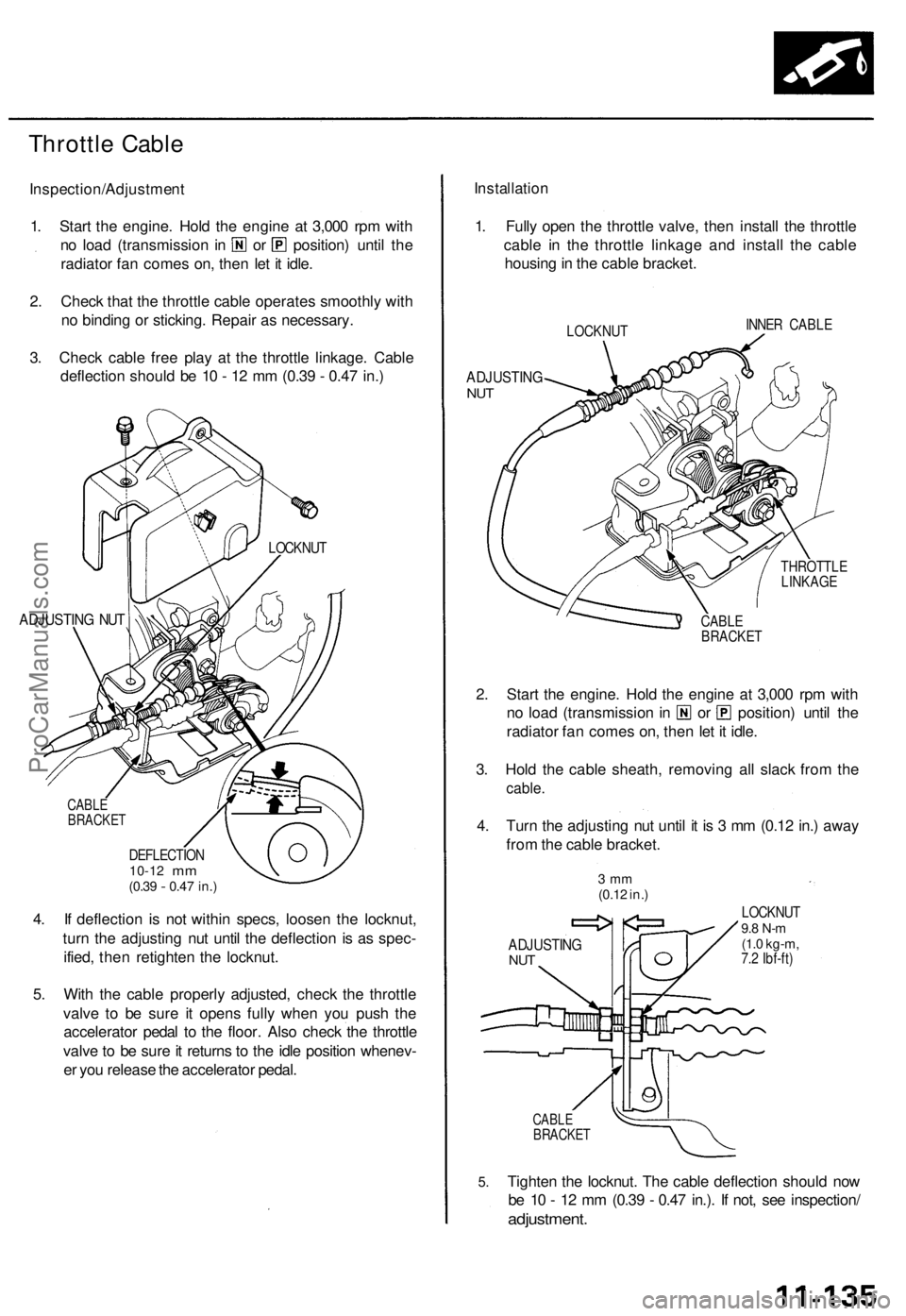

Throttle Cable

Inspection/Adjustment

1. Start the engine. Hold the engine at 3,000 rpm with

no load (transmission in or position) until the

radiator fan comes on, then let it idle.

2. Check that the throttle cable operates smoothly with

no binding or sticking. Repair as necessary.

3. Check cable free play at the throttle linkage. Cable

deflection should be 10 - 12 mm (0.39 - 0.47 in.)

ADJUSTING NUT

CABLE

BRACKET

DEFLECTION

10-12

mm

(0.39

-

0.47 in.)

4. If deflection is not within specs, loosen the locknut,

turn the adjusting nut until the deflection is as spec-

ified, then retighten the locknut.

5. With the cable properly adjusted, check the throttle

valve to be sure it opens fully when you push the

accelerator pedal to the floor. Also check the throttle

valve to be sure it returns to the idle position whenev-

er you release the accelerator pedal.

Installation

1. Fully open the throttle valve, then install the throttle

cable in the throttle linkage and install the cable

housing in the cable bracket.

LOCKNUT

INNER CABLE

ADJUSTING

NUT

THROTTLE

LINKAGE

CABLE

BRACKET

2. Start the engine. Hold the engine at 3,000 rpm with

no load (transmission in or position) until the

radiator fan comes on, then let it idle.

3. Hold the cable sheath, removing all slack from the

cable.

4. Turn the adjusting nut until it is 3 mm (0.12 in.) away

from the cable bracket.

3 mm

(0.12 in.)

ADJUSTING

NUT

LOCKNUT

9.8 N-m

(1.0 kg-m,

7.2 Ibf-ft)

5.

CABLE

BRACKET

Tighten the locknut. The cable deflection should now

be 10 - 12 mm (0.39 - 0.47 in.). If not, see inspection/

adjustment.

LOCKNUTProCarManuals.com

Page 327 of 1771

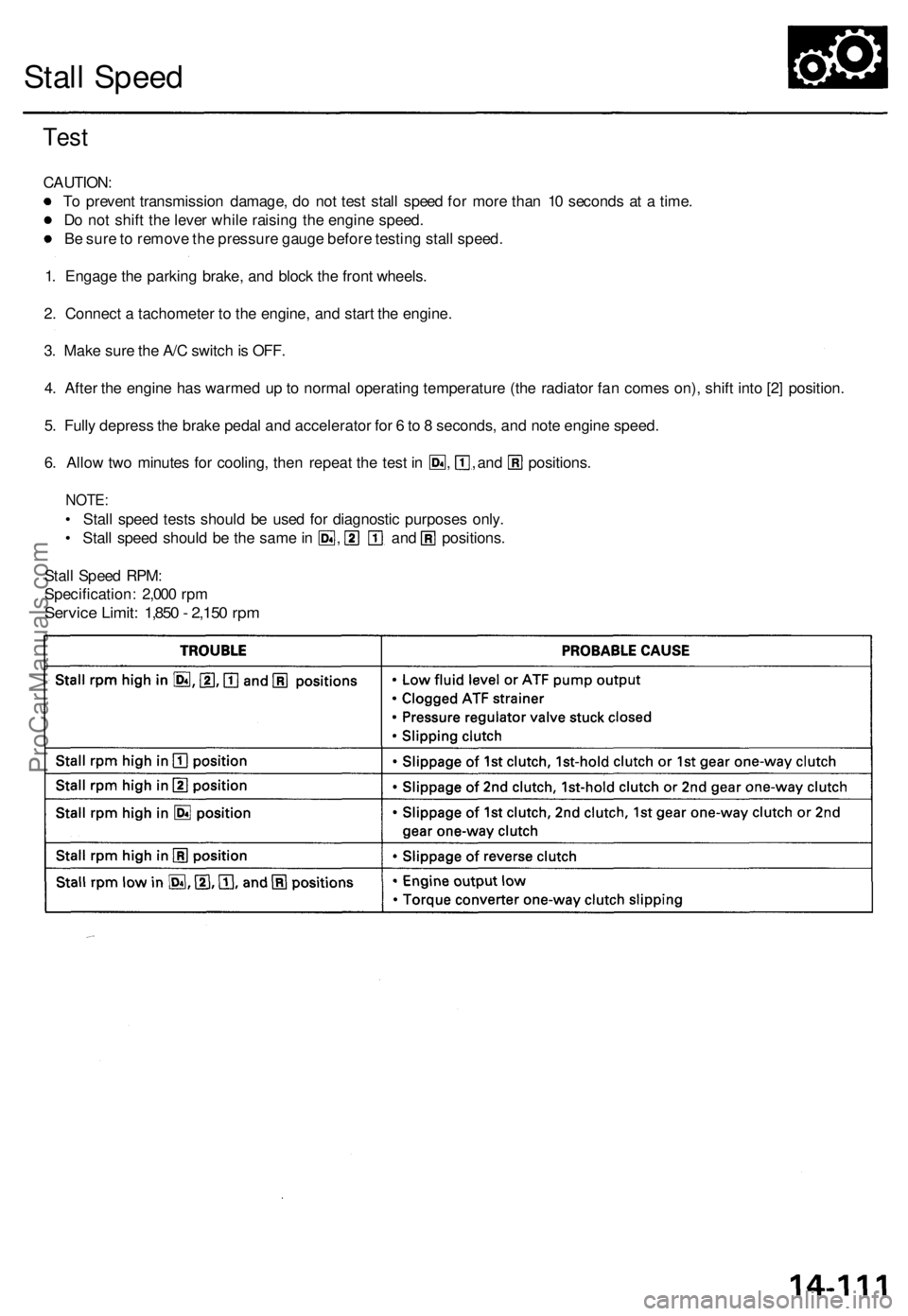

Stall Speed

Test

CAUTION:

To prevent transmission damage, do not test stall speed for more than 10 seconds at a time.

Do not shift the lever while raising the engine speed.

Be sure to remove the pressure gauge before testing stall speed.

1. Engage the parking brake, and block the front wheels.

2. Connect a tachometer to the engine, and start the engine.

3. Make sure the A/C switch is OFF.

4. After the engine has warmed up to normal operating temperature (the radiator fan comes on), shift into [2] position.

5. Fully depress the brake pedal and accelerator for 6 to 8 seconds, and note engine speed.

6. Allow two minutes for cooling, then repeat the test in , , and positions.

NOTE:

• Stall speed tests should be used for diagnostic purposes only.

• Stall speed should be the same in , and positions.

Stall Speed RPM:

Specification: 2,000 rpm

Service Limit: 1,850 - 2,150 rpmProCarManuals.com

Page 328 of 1771

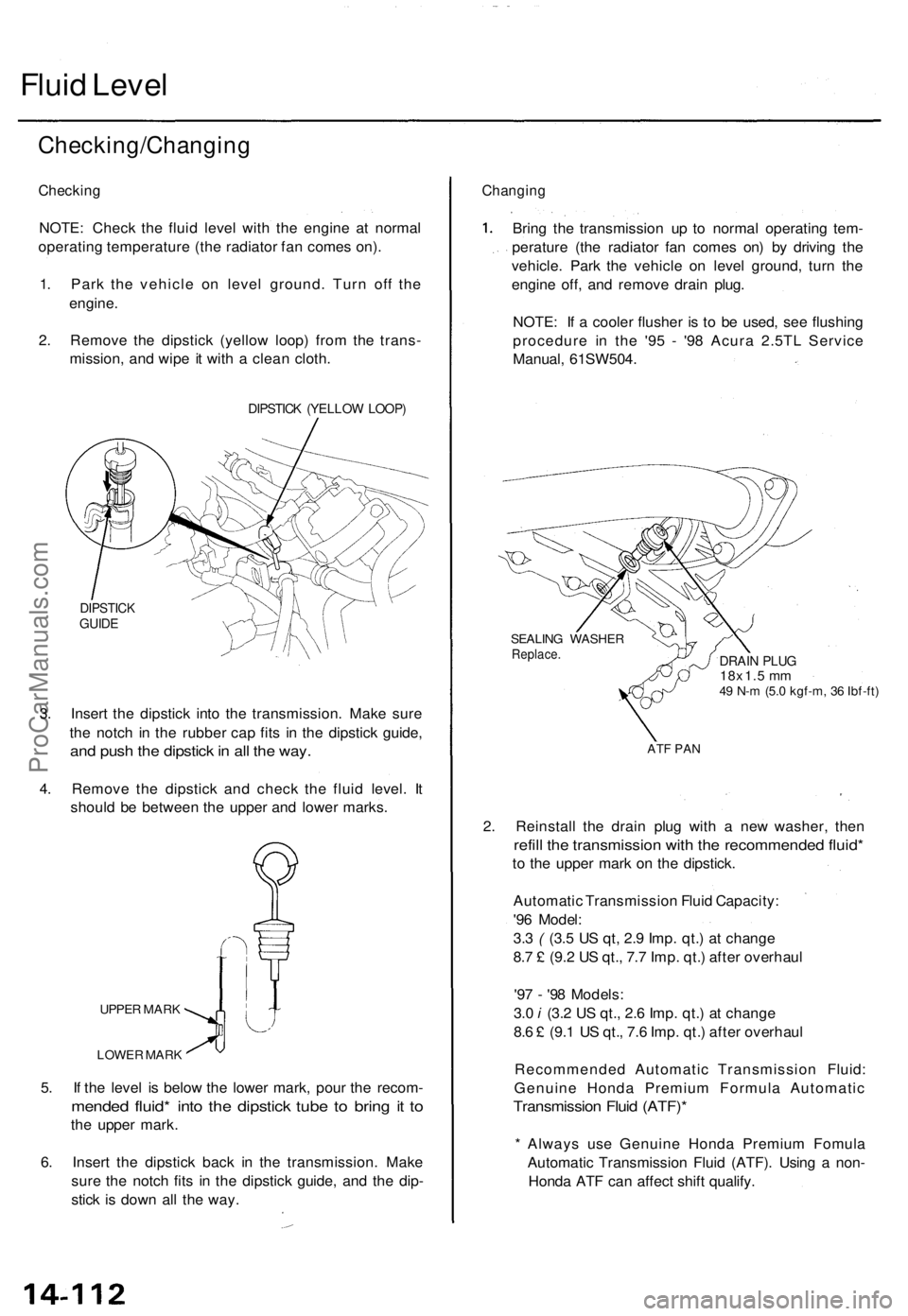

Fluid Level

Checking/Changing

Checking

NOTE: Check the fluid level with the engine at normal

operating temperature (the radiator fan comes on).

1. Park the vehicle on level ground. Turn off the

engine.

2. Remove the dipstick (yellow loop) from the trans-

mission, and wipe it with a clean cloth.

DIPSTICK (YELLOW LOOP)

DIPSTICK

GUIDE

3. Insert the dipstick into the transmission. Make sure

the notch in the rubber cap fits in the dipstick guide,

and push the dipstick in all the way.

4. Remove the dipstick and check the fluid level. It

should be between the upper and lower marks.

UPPER MARK

LOWER MARK

5. If the level is below the lower mark, pour the recom-

mended fluid* into the dipstick tube to bring it to

the upper mark.

6. Insert the dipstick back in the transmission. Make

sure the notch fits in the dipstick guide, and the dip-

stick is down all the way.

Changing

Bring the transmission up to normal operating tem-

perature (the radiator fan comes on) by driving the

vehicle. Park the vehicle on level ground, turn the

engine off, and remove drain plug.

NOTE: If a cooler flusher is to be used, see flushing

procedure in the '95 - '98 Acura 2.5TL Service

Manual, 61SW504.

SEALING WASHER

Replace.

DRAIN PLUG

18x1.5 mm

49 N-m (5.0 kgf-m, 36 Ibf-ft)

ATF PAN

2. Reinstall the drain plug with a new washer, then

refill the transmission with the recommended fluid*

to the upper mark on the dipstick.

Automatic Transmission Fluid Capacity:

'96 Model:

3.3 ( (3.5 US qt, 2.9 Imp. qt.) at change

8.7 £ (9.2 US qt., 7.7 Imp. qt.) after overhaul

'97 - '98 Models:

3.0 i (3.2 US qt., 2.6 Imp. qt.) at change

8.6 £ (9.1 US qt., 7.6 Imp. qt.) after overhaul

Recommended Automatic Transmission Fluid:

Genuine Honda Premium Formula Automatic

Transmission Fluid (ATF)*

* Always use Genuine Honda Premium Fomula

Automatic Transmission Fluid (ATF). Using a non-

Honda ATF can affect shift qualify.ProCarManuals.com

Page 562 of 1771

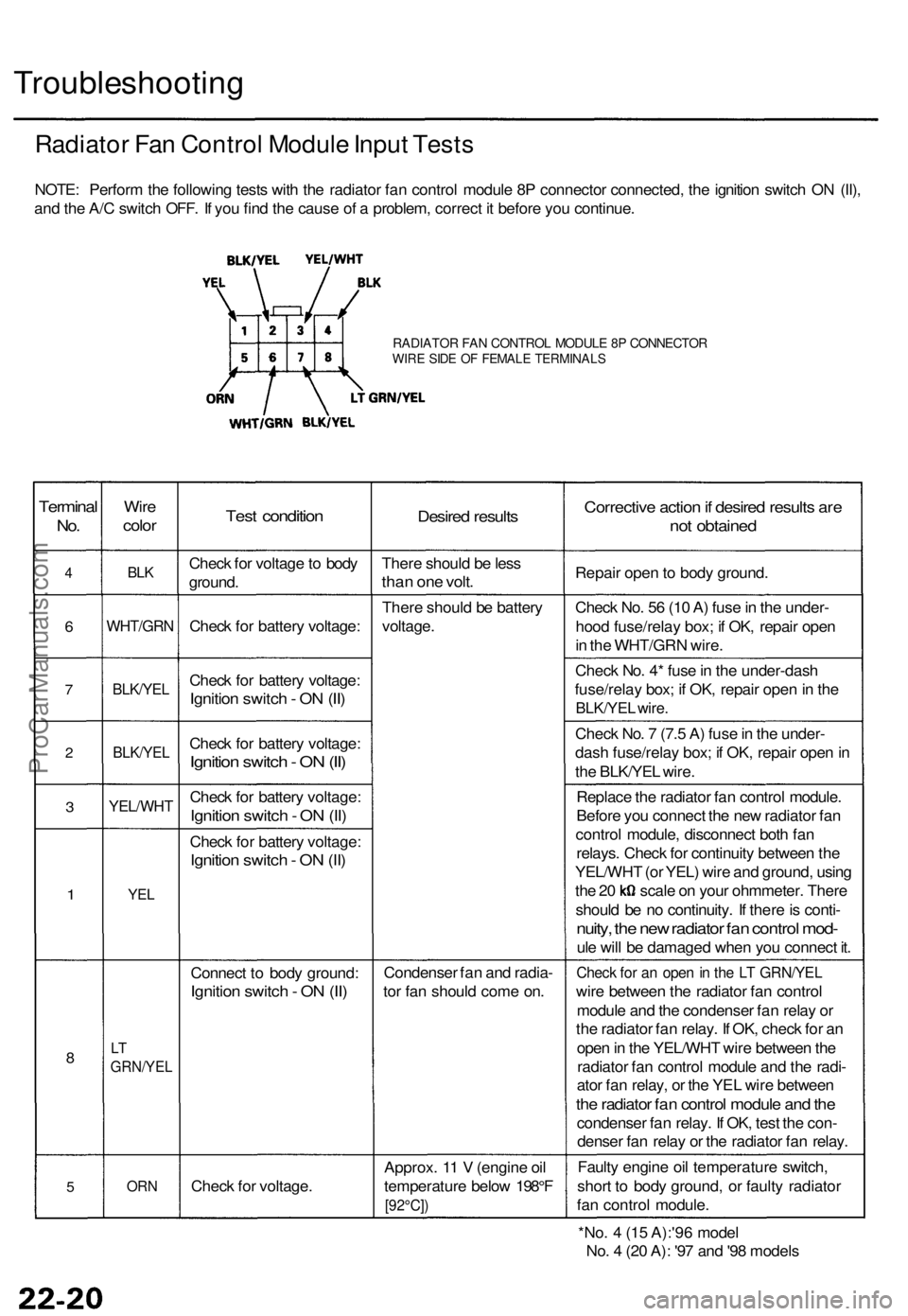

Troubleshooting

Radiator Fan Control Module Input Tests

NOTE: Perform the following tests with the radiator fan control module 8P connector connected, the ignition switch ON (II),

and the A/C switch OFF. If you find the cause of a problem, correct it before you continue.

RADIATOR FAN CONTROL MODULE 8P CONNECTOR

WIRE SIDE OF FEMALE TERMINALS

Terminal

No.

4

6

7

2

3

1

8

5

Wire

color

BLK

WHT/GRN

BLK/YEL

BLK/YEL

YEL/WHT

YEL

LT

GRN/YEL

ORN

Test condition

Check for voltage to body

ground.

Check for battery voltage:

Check for battery voltage:

Ignition switch - ON (II)

Check for battery voltage:

Ignition switch - ON (II)

Check for battery voltage:

Ignition switch - ON (II)

Check for battery voltage:

Ignition switch - ON (II)

Connect to body ground:

Ignition switch - ON (II)

Check for voltage.

Desired results

There should be less

than one volt.

There should be battery

voltage.

Condenser fan and radia-

tor fan should come on.

Approx. 11 V (engine oil

temperature below 198°F

[92°C])

Corrective action if desired results are

not obtained

Repair open to body ground.

Check No. 56 (10 A) fuse in the under-

hood fuse/relay box; if OK, repair open

in the WHT/GRN wire.

Check No. 4* fuse in the under-dash

fuse/relay box; if OK, repair open in the

BLK/YEL wire.

Check No. 7 (7.5 A) fuse in the under-

dash fuse/relay box; if OK, repair open in

the BLK/YEL wire.

Replace the radiator fan control module.

Before you connect the new radiator fan

control module, disconnect both fan

relays. Check for continuity between the

YEL/WHT (or YEL) wire and ground, using

the 20 scale on your ohmmeter. There

should be no continuity. If there is conti-

nuity, the new radiator fan control mod-

ule will be damaged when you connect it.

Check for an open in the LT GRN/YEL

wire between the radiator fan control

module and the condenser fan relay or

the radiator fan relay. If OK, check for an

open in the YEL/WHT wire between the

radiator fan control module and the radi-

ator fan relay, or the YEL wire between

the radiator fan control module and the

condenser fan relay. If OK, test the con-

denser fan relay or the radiator fan relay.

Faulty engine oil temperature switch,

short to body ground, or faulty radiator

fan control module.

*No. 4 (15 A):'96 model

No. 4 (20 A): '97 and '98 modelsProCarManuals.com

Page 610 of 1771

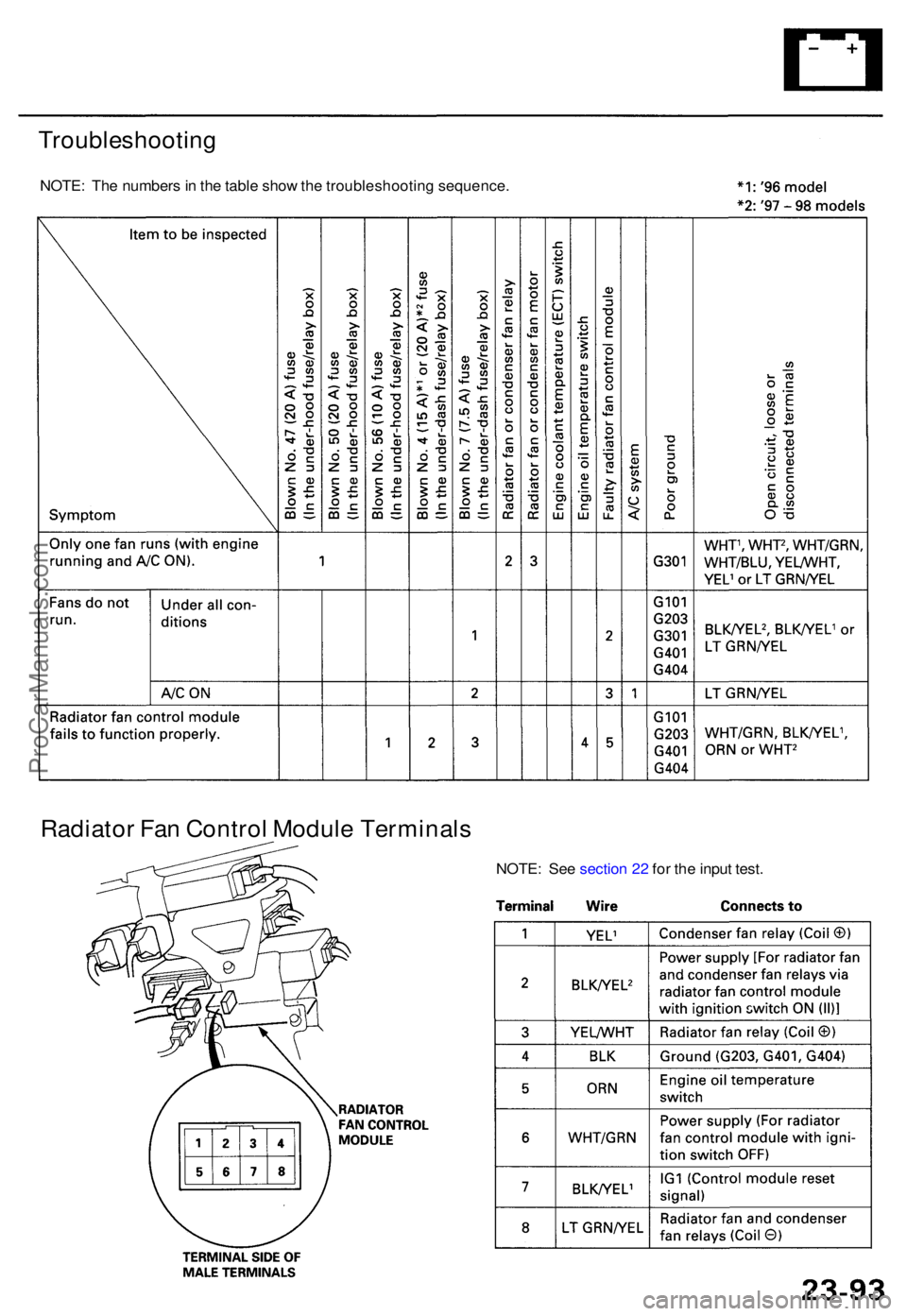

Troubleshooting

NOTE: Th e number s in th e tabl e sho w th e troubleshootin g sequence .

Radiator Fa n Contro l Modul e Terminal s

NOTE: Se e sectio n 2 2 fo r th e inpu t test .

ProCarManuals.com

Page 822 of 1771

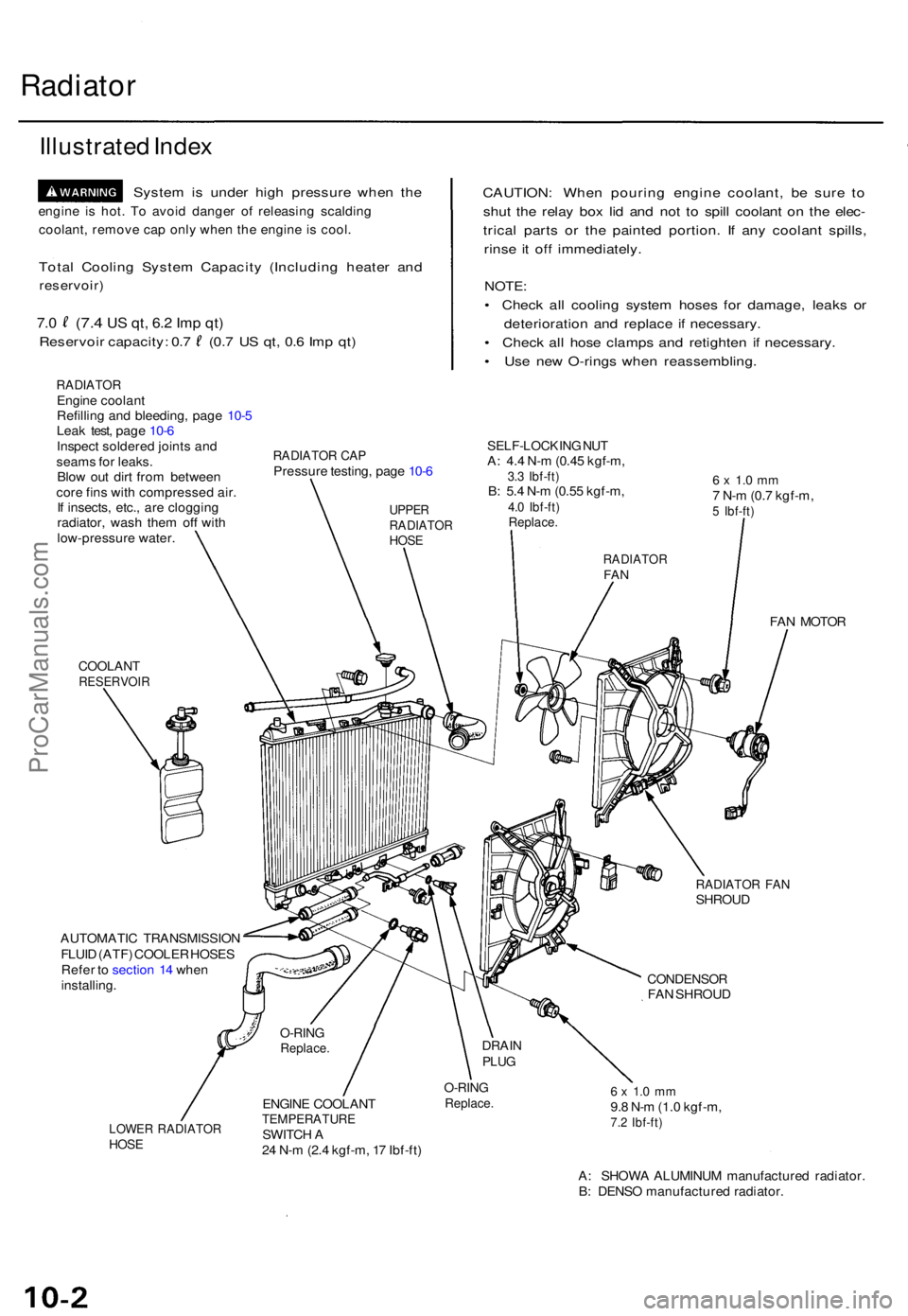

Radiator

Illustrate d Inde x

Syste m is unde r hig h pressur e whe n th e

engin e i s hot . T o avoi d dange r o f releasin g scaldin g

coolant , remov e ca p onl y whe n th e engin e i s cool .

Total Coolin g Syste m Capacit y (Includin g heate r an d

reservoir )

7.0 (7. 4 US qt , 6. 2 Im p qt )

Reservoi r capacity : 0. 7 (0. 7 U S qt , 0. 6 Im p qt )

RADIATO REngine coolan t

Refillin g an d bleeding , pag e 10- 5

Lea k test , pag e 10- 6

Inspec t soldere d joint s an d

seam s fo r leaks .

Blo w ou t dir t fro m betwee n

cor e fin s wit h compresse d air .

I f insects , etc. , ar e cloggin g

radiator , was h the m of f wit h

low-pressur e water .

CAUTION : Whe n pourin g engin e coolant , b e sur e t o

shu t th e rela y bo x li d an d no t t o spil l coolan t o n th e elec -

trica l part s o r th e painte d portion . I f an y coolan t spills ,

rins e i t of f immediately .

NOTE:

• Chec k al l coolin g syste m hose s fo r damage , leak s o r

deterioratio n an d replac e i f necessary .

• Chec k al l hos e clamp s an d retighte n i f necessary .

• Us e ne w O-ring s whe n reassembling .

RADIATOR CA PPressur e testing , pag e 10- 6

SELF-LOCKIN G NU TA: 4. 4 N- m (0.4 5 kgf-m ,3.3 Ibf-ft )B: 5. 4 N- m (0.5 5 kgf-m ,4.0 Ibf-ft )Replace .

6 x 1. 0 m m7 N- m (0. 7 kgf-m ,5 Ibf-ft )

COOLAN TRESERVOI R

FAN MOTO R

RADIATO R FA NSHROU D

AUTOMATI C TRANSMISSIO N

FLUI D (ATF ) COOLE R HOSE S

Refe r t o sectio n 1 4 whe n

installing .

CONDENSO RFAN SHROU D

LOWER RADIATO RHOSE

ENGIN E COOLAN TTEMPERATUR ESWITCH A

2 4 N- m (2. 4 kgf-m , 1 7 Ibf-ft )

O-RIN GReplace .6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,7.2 Ibf-ft )

A: SHOW A ALUMINU M manufacture d radiator .

B : DENS O manufacture d radiator .

O-RINGReplace .DRAINPLUG

UPPE RRADIATO RHOSE

RADIATO RFAN

ProCarManuals.com