light ACURA TL 1995 Service Manual PDF

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 769 of 1771

Valves, Valv e Spring s an d

Valv e Seal s

Valv e Installatio n

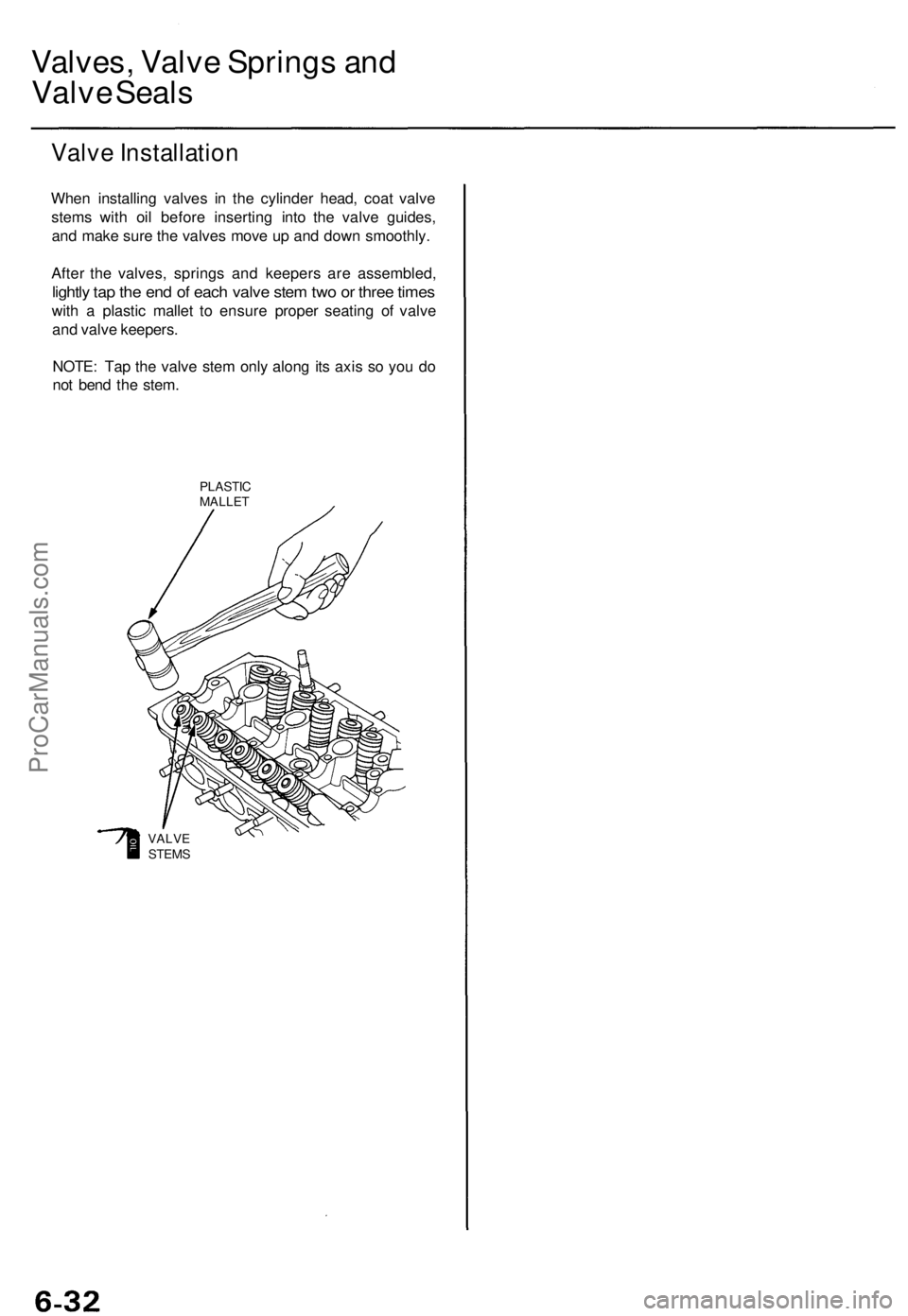

When installin g valve s i n th e cylinde r head , coa t valv e

stem s wit h oi l befor e insertin g int o th e valv e guides ,

an d mak e sur e th e valve s mov e u p an d dow n smoothly .

Afte r th e valves , spring s an d keeper s ar e assembled ,

lightly ta p th e en d o f eac h valv e ste m tw o o r thre e time s

with a plasti c malle t t o ensur e prope r seatin g o f valv e

an d valv e keepers .

NOTE : Ta p th e valv e ste m onl y alon g it s axi s s o yo u d o

no t ben d th e stem .

PLASTI CMALLET

VALVESTEMS

ProCarManuals.com

Page 770 of 1771

Camshaft/Rocker Arms and

Camshaft Seal

Installation

CAUTION:

• Make sure that all rockers are in alignment with their

valves when torquing the rocker assembly bolts.

• Valve locknuts should be loosened and adjusting

screws backed off before installation.

• To prevent the rocker arm assembly from coming

apart, leave the camshaft holder bolts in the holes.

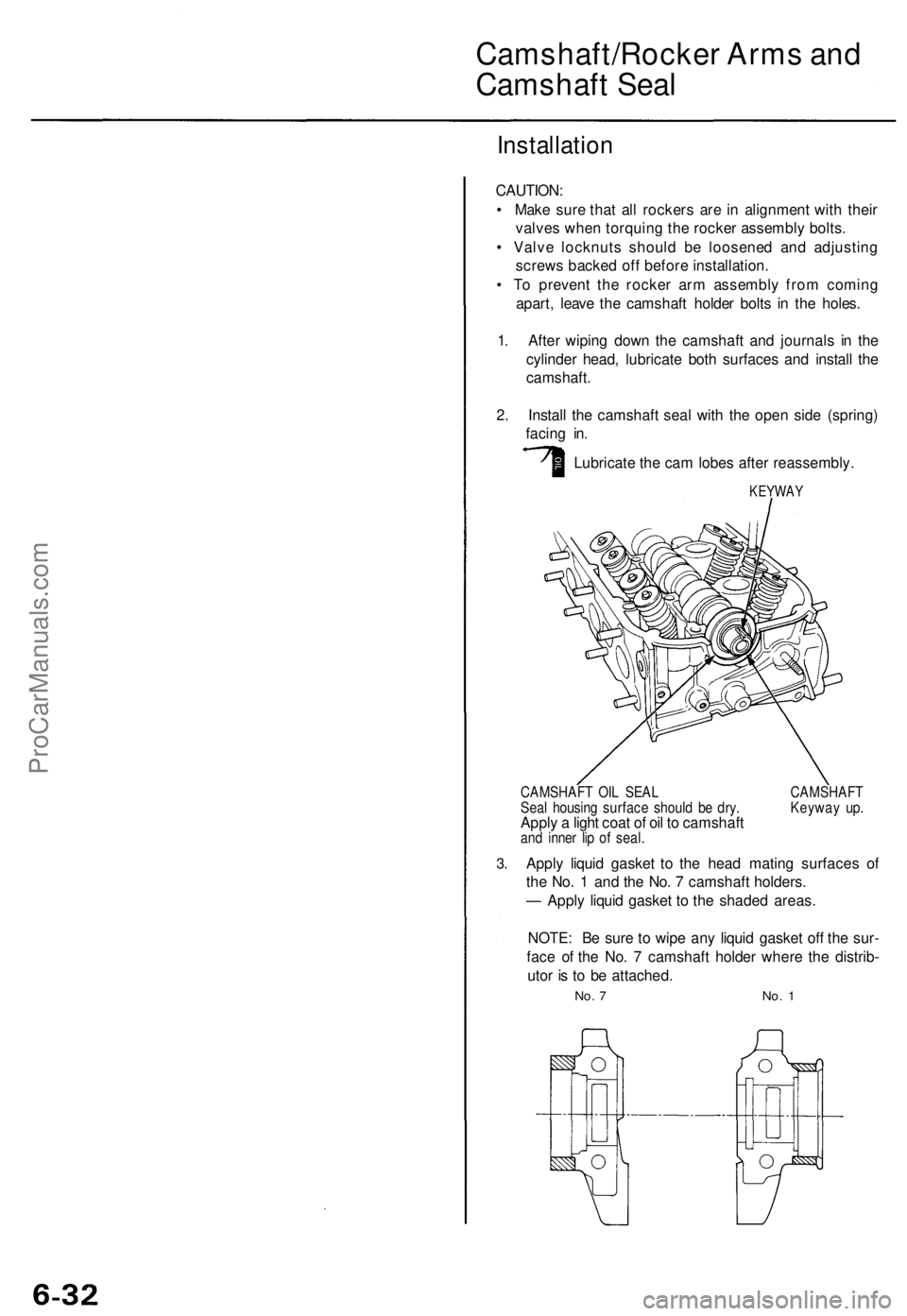

1. After wiping down the camshaft and journals in the

cylinder head, lubricate both surfaces and install the

camshaft.

2. Install the camshaft seal with the open side (spring)

facing in.

Lubricate the cam lobes after reassembly.

KEYWAY

3.

CAMSHAFT OIL SEAL CAMSHAFT

Seal housing surface should be dry. Keyway up.

Apply a light coat of oil to camshaft

and inner lip of seal.

Apply liquid gasket to the head mating surfaces of

the No. 1 and the No. 7 camshaft holders.

— Apply liquid gasket to the shaded areas.

NOTE: Be sure to wipe any liquid gasket off the sur-

face of the No. 7 camshaft holder where the distrib-

utor is to be attached.

No. 7 No. 1ProCarManuals.com

Page 775 of 1771

Cylinder Head

Installation (cont'd)

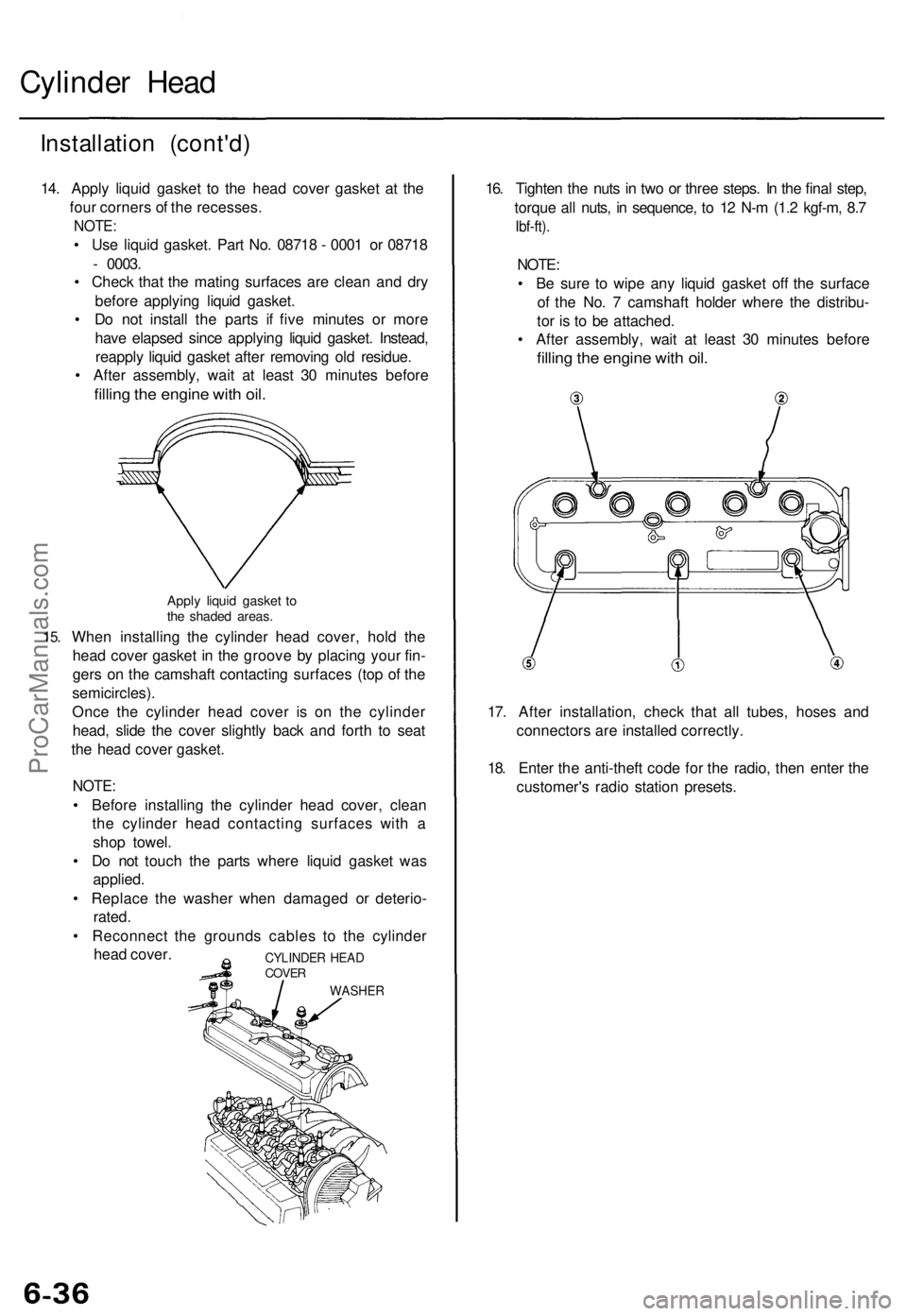

14. Apply liquid gasket to the head cover gasket at the

four corners of the recesses.

NOTE:

• Use liquid gasket. Part No. 08718 - 0001 or 08718

- 0003.

• Check that the mating surfaces are clean and dry

before applying liquid gasket.

• Do not install the parts if five minutes or more

have elapsed since applying liquid gasket. Instead,

reapply liquid gasket after removing old residue.

• After assembly, wait at least 30 minutes before

filling the engine with oil.

15.

Apply liquid gasket to

the shaded areas.

When installing the cylinder head cover, hold the

head cover gasket in the groove by placing your fin-

gers on the camshaft contacting surfaces (top of the

semicircles).

Once the cylinder head cover is on the cylinder

head, slide the cover slightly back and forth to seat

the head cover gasket.

NOTE:

• Before installing the cylinder head cover, clean

the cylinder head contacting surfaces with a

shop towel.

• Do not touch the parts where liquid gasket was

applied.

• Replace the washer when damaged or deterio-

rated.

• Reconnect the grounds cables to the cylinder

head cover.

16. Tighten the nuts in two or three steps. In the final step,

torque all nuts, in sequence, to 12 N-m (1.2 kgf-m, 8.7

Ibf-ft).

NOTE:

• Be sure to wipe any liquid gasket off the surface

of the No. 7 camshaft holder where the distribu-

tor is to be attached.

• After assembly, wait at least 30 minutes before

filling the engine with oil.

17. After installation, check that all tubes, hoses and

connectors are installed correctly.

18. Enter the anti-theft code for the radio, then enter the

customer's radio station presets.

CYLINDER HEAD

COVER

WASHERProCarManuals.com

Page 808 of 1771

Oil Filter

Replacement

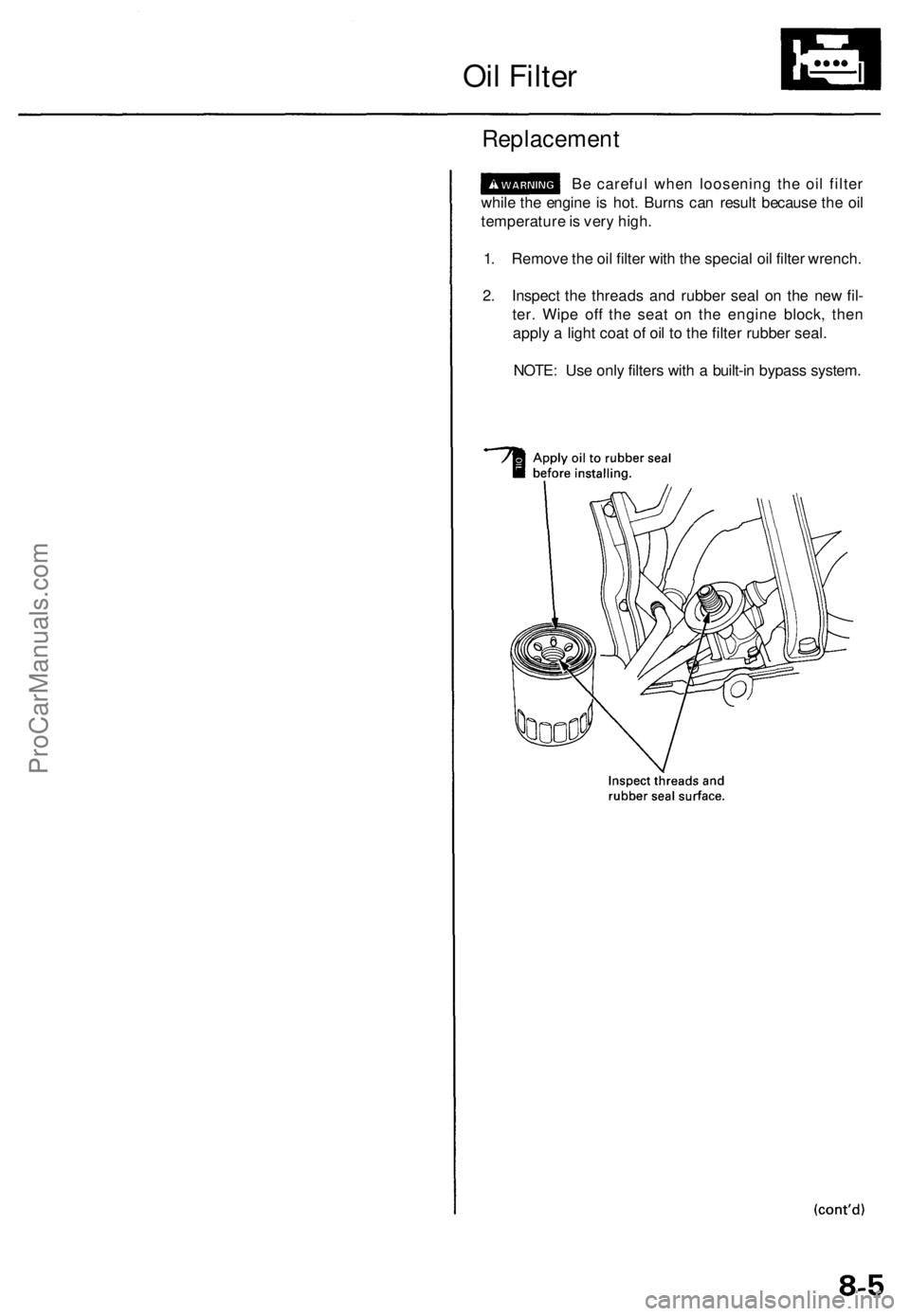

Be careful when loosening the oil filter

while the engine is hot. Burns can result because the oil

temperature is very high.

1. Remove the oil filter with the special oil filter wrench.

2. Inspect the threads and rubber seal on the new fil-

ter. Wipe off the seat on the engine block, then

apply a light coat of oil to the filter rubber seal.

NOTE: Use only filters with a built-in bypass system.ProCarManuals.com

Page 819 of 1771

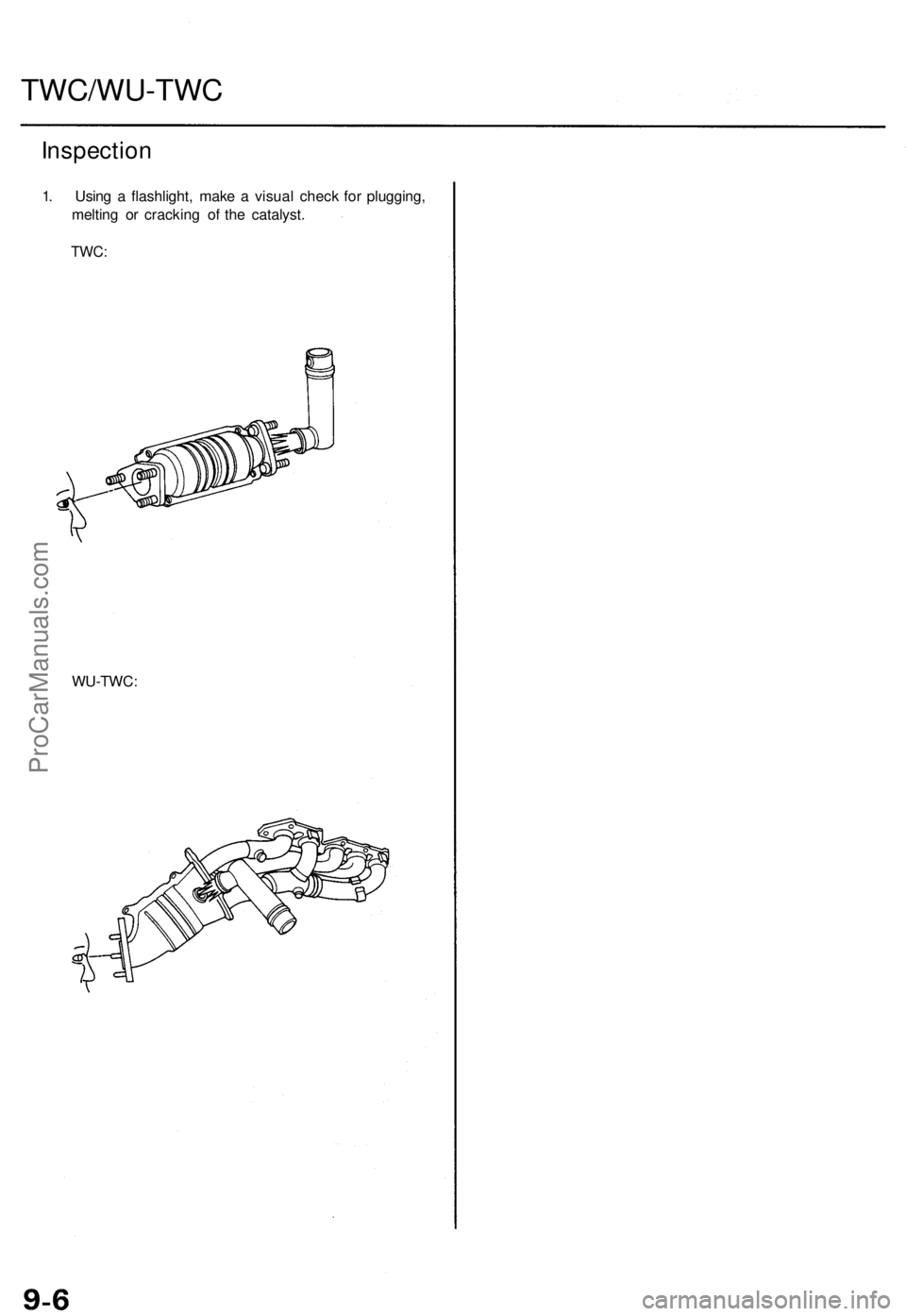

TWC/WU-TWC

Inspection

1. Usin g a flashlight , mak e a visua l chec k fo r plugging ,

meltin g o r crackin g o f th e catalyst .

TWC:

WU-TWC :

ProCarManuals.com

Page 864 of 1771

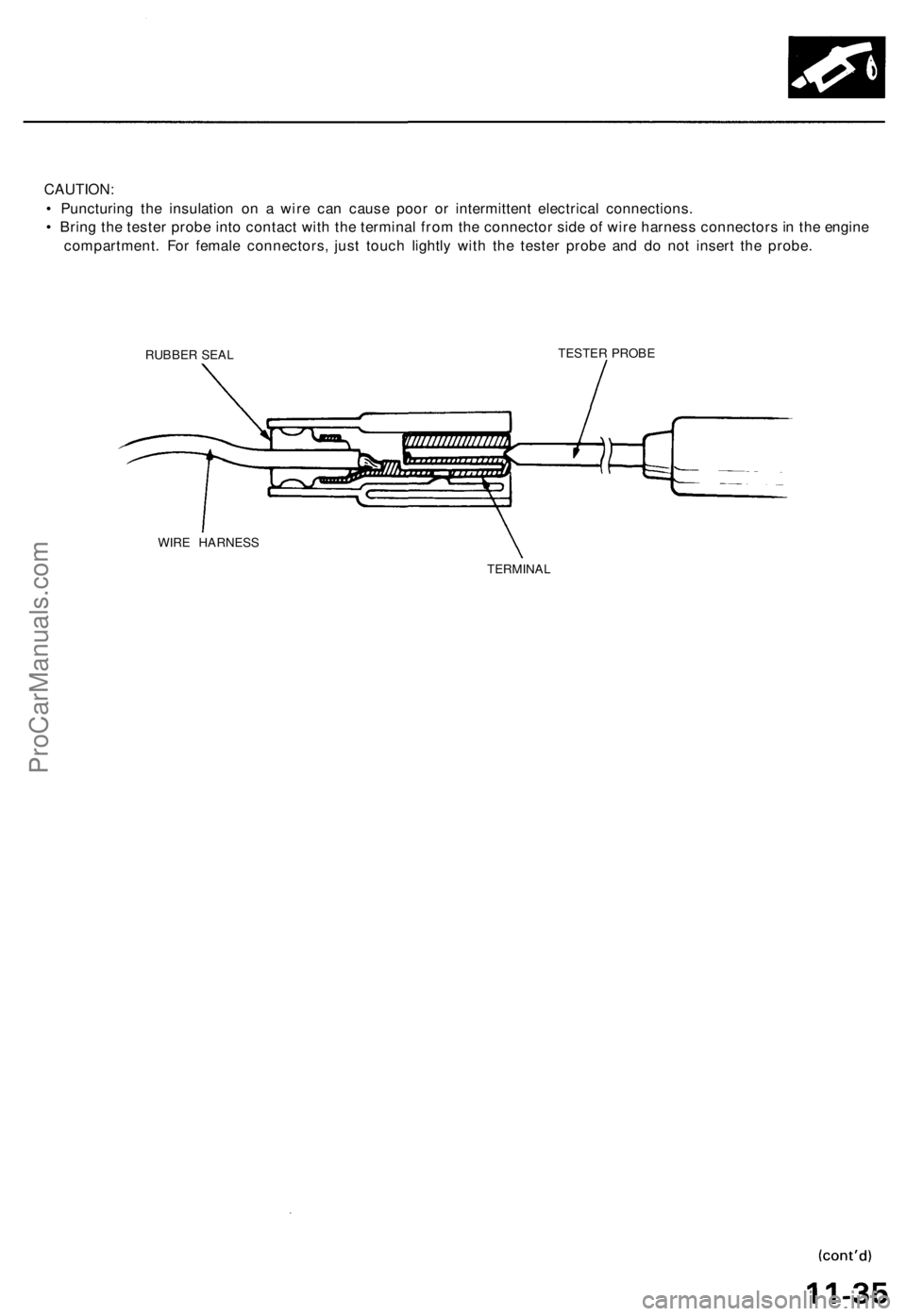

CAUTION:

• Puncturing the insulation on a wire can cause poor or intermittent electrical connections.

• Bring the tester probe into contact with the terminal from the connector side of wire harness connectors in the engine

compartment. For female connectors, just touch lightly with the tester probe and do not insert the probe.

RUBBER SEAL

TESTER PROBE

WIRE HARNESS

TERMINALProCarManuals.com

Page 878 of 1771

4. A/ C Compresso r Clutc h Rela y

When th e EC M receive s a deman d fo r coolin g fro m th e ai r conditionin g system , i t delay s th e compresso r fro m bein g

energized , an d enriche s th e mixtur e to assur e smoot h transitio n to th e A/ C mode .

5 . Evaporativ e Emissio n (EVAP ) Purg e Contro l Solenoi d Valv e

Whe n th e engin e coolan t temperatur e i s belo w 167° F (75°C ) ('9 7 - 9 8 models : 158° F (70°C) , th e EC M control s th e

EVA P purg e contro l solenoi d valv e whic h cut s vacuu m to th e EVA P purg e contro l caniste r diaphragm .

6 . Intak e Ai r Bypas s (IAB ) Contro l Solenoi d Valv e

Whe n th e engin e spee d i s belo w 4,80 0 rpm , th e IA B contro l solenoi d valv e i s activate d b y a signa l fro m th e ECM ,

intak e ai r flow s throug h th e smalle r chamber , the n hig h torqu e i s delivered. At speed s highe r tha n 4,80 0 rpm , th e

solenoi d valv e i s deactivate d b y th e ECM , an d intak e ai r flow s throug h th e large r chambe r i n orde r t o reduc e th e

resistanc e in airflow .

7 . Exhaus t Ga s Recirculatio n (EGR ) Contro l Solenoi d Valv e

Whe n th e EG R is require d fo r contro l o f oxide s o f nitroge n (NOx ) emissions , th e EC M control s th e EG R contro l

solenoi d valv e whic h supplie s regulate d vacuu m to th e EG R valve .

8 . Alternato r Contro l

Th e syste m control s th e voltag e generate d a t th e alternato r i n accordanc e wit h th e electrica l loa d an d drivin g mode ,

whic h reduce s th e engin e loa d to improv e th e fue l economy .

ECM Fail-safe/Back-u p Function s

1. Fail-saf e Functio n

Whe n a n abnormalit y occur s in a signa l fro m a sensor , th e EC M ignore s tha t signa l an d assume s a pre-programme d

valu e fo r tha t senso r tha t allow s th e engin e to continu e to run .

2 . Back-u p Functio n

Whe n a n abnormalit y occur s in th e EC M itself , th e fue l injector s ar e controlle d b y a back-u p circui t independen t o f th e

syste m in orde r t o permi t minima l driving .

3 . Self-diagnosi s Functio n [Malfunctio n Indicato r Lam p (MIL) ]

Whe n a n abnormalit y occur s i n a signa l fro m a sensor , th e EC M supplie s groun d fo r th e MI L an d store s th e DT C in

erasable memory . Whe n th e ignitio n i s initiall y turne d on , th e EC M supplie s ground for th e MI L fo r tw o second s t o

chec k th e MI L bul b condition .

4 . Tw o Tri p Detectio n Metho d ('9 5 - 9 6 models )

T o preven t fals e indications , th e Tw o Tri p Detectio n Metho d is use d fo r th e MA F sensor , H02S , fue l metering-related ,

idl e contro l system , EC T sensor , an d EG R syste m self-diagnosti c functions . Whe n a n abnormalit y occurs , th e EC M

store s i t i n it s memory . Whe n th e sam e abnormalit y recur s afte r th e ignitio n switc h i s turne d OF F an d O N (II ) again ,

th e EC M inform s th e drive r b y lightin g th e MIL .

However ,

to eas e troubleshooting , thi s functio n is cancelle d when you shor t the servic e check connector . The MI L will

the n blin k immediatel y whe n a n abnormalit y occurs .

5 . Tw o (o r Three ) Drivin g Cycl e Detectio n Metho d ('9 5 - 9 6 models )

A "Drivin g Cycle " consist s o f startin g th e engine , beginnin g close d loo p operation , an d stoppin g th e engine . I f misfir -

in g tha t increase s emission s o r EVA P contro l syste m malfunctio n i s detecte d i n tw o consecutiv e drivin g cycles , o r

TW C deterioratio n is detecte d in thre e consecutiv e drivin g cycles , th e EC M turn s th e MI L on .

However , t o eas e troubleshooting , thi s functio n is cancelle d whe n yo u shor t th e servic e chec k connector . Th e MI L wil l

the n blin k immediatel y whe n a n abnormalit y occurs .

6 . Tw o Drivin g Cycl e Detectio n Metho d ('9 7 - 9 8 models )

T o preven t fals e indications , th e "tw o drivin g cycl e detectio n method " i s use d fo r th e H02S , fue l metering-related ,

idl e contro l system , EC T sensor , EG R system , TW C an d EVA P contro l syste m an d othe r self-diagnosti c functions .

Whe n a n abnormalit y occurs , th e EC M store s i t i n it s memory . Whe n th e sam e abnormalit y recur s afte r switc h i s

turne d OF F an d O N (II ) again , th e EC M inform s th e drive r b y turnin g o n th e MIL .

ProCarManuals.com

Page 879 of 1771

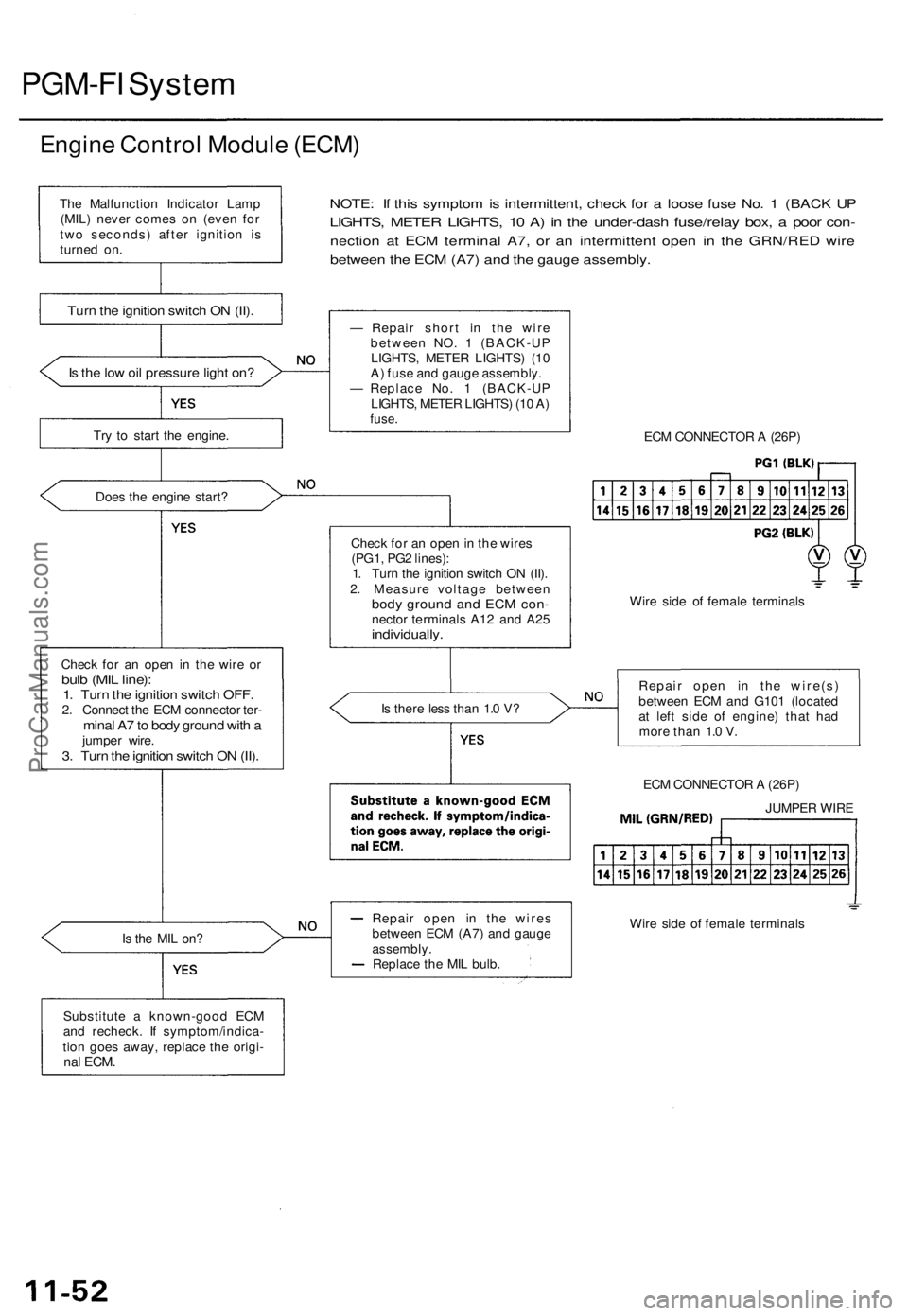

PGM-FI System

Engine Control Module (ECM)

Is the low oil pressure light on?

Try to start the engine.

Does the engine start?

Check for an open in the wire or

bulb (MIL line):

1. Turn the ignition switch OFF.

2. Connect the ECM connector ter-

minal A7 to body ground with a

jumper wire.

3. Turn the ignition switch ON (II).

NOTE: If this symptom is intermittent, check for a loose fuse No. 1 (BACK UP

LIGHTS, METER LIGHTS, 10 A) in the under-dash fuse/relay box, a poor con-

nection at ECM terminal A7, or an intermittent open in the GRN/RED wire

between the ECM (A7) and the gauge assembly.

Is the MIL on?

Substitute a known-good ECM

and recheck. If symptom/indica-

tion goes away, replace the origi-

nal

ECM.

— Repair short in the wire

between NO. 1 (BACK-UP

LIGHTS, METER LIGHTS) (10

A) fuse and gauge assembly.

— Replace No. 1 (BACK-UP

LIGHTS, METER LIGHTS) (10 A)

fuse.

Check for an open in the wires

(PG1, PG2 lines):

1. Turn the ignition switch ON (II).

2. Measure voltage between

body ground and ECM con-

nector terminals A12 and A25

individually.

Is there less than 1.0 V?

Repair open in the wires

between ECM (A7) and gauge

assembly.

Replace the MIL bulb.

ECM CONNECTOR A (26P)

Wire side of female terminals

Repair open in the wire(s)

between ECM and G101 (located

at left side of engine) that had

more than 1.0 V.

ECM CONNECTOR A (26P)

Wire side of female terminals

The Malfunction Indicator Lamp

(MIL) never comes on (even for

two seconds) after ignition is

turned on.

Turn the ignition switch ON (II).

JUMPER WIREProCarManuals.com

Page 888 of 1771

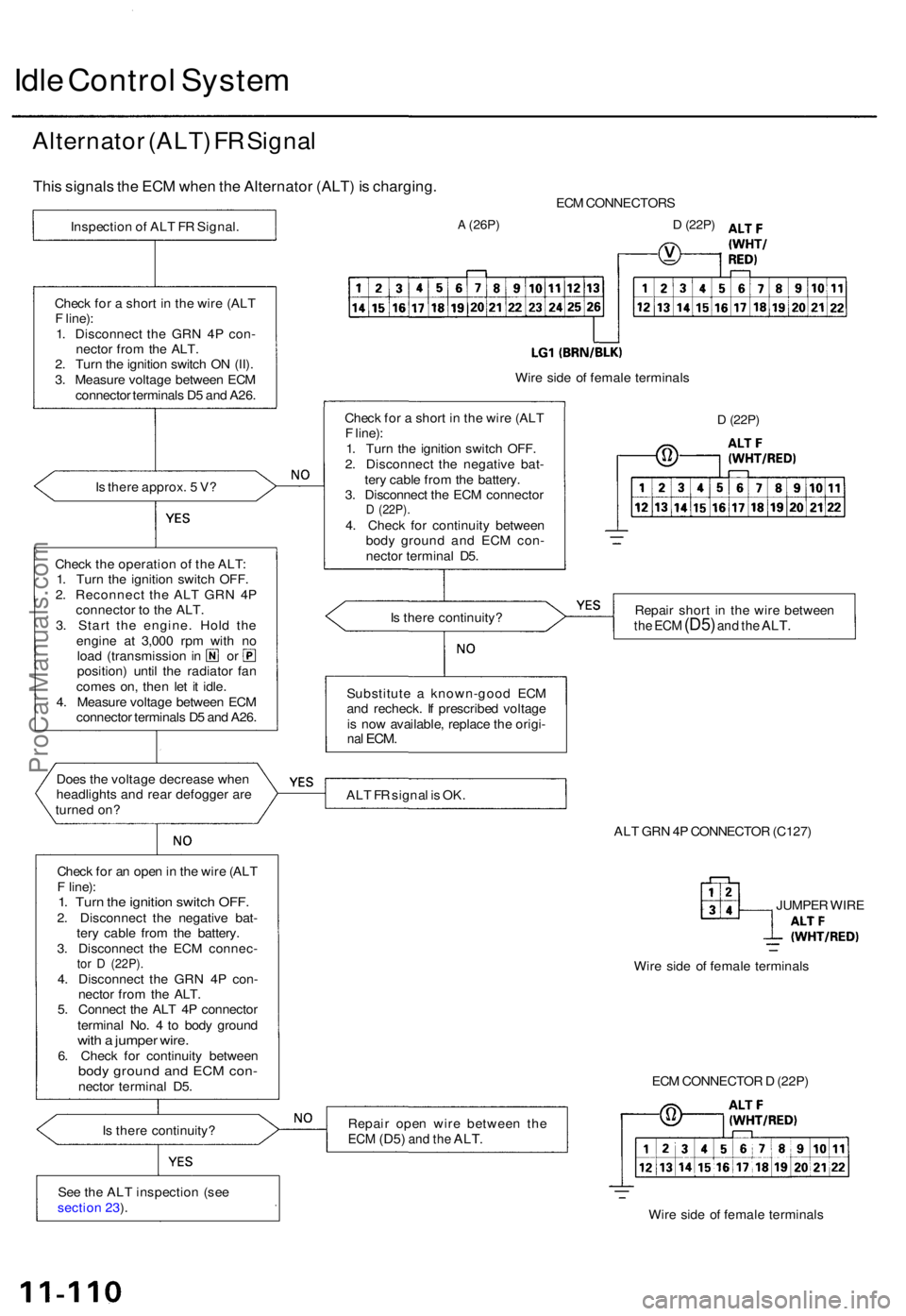

Idle Contro l Syste m

Alternato r (ALT ) F R Signa l

This signal s th e EC M whe n th e Alternato r (ALT ) i s charging .

Is ther e approx . 5 V ?

Chec k th e operatio n o f th e ALT :

1 . Tur n th e ignitio n switc h OFF .

2 . Reconnec t th e AL T GR N 4 P

connecto r t o th e ALT .

3 . Star t th e engine . Hol d th e

engin e a t 3,00 0 rp m wit h n o

loa d (transmissio n in o r

position ) unti l th e radiato r fa n

come s on , the n le t i t idle .

4 . Measur e voltag e betwee n EC M

connecto r terminal s D 5 an d A26 .

Doe s th e voltag e decreas e whe n

headlight s an d rea r defogge r ar e

turne d on ?

Chec k fo r a n ope n in th e wir e (AL T

F line) :

1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e negativ e bat -

ter y cabl e fro m th e battery .

3 . Disconnec t th e EC M connec -

tor D (22P) .4. Disconnec t th e GR N 4 P con -

necto r fro m th e ALT .

5 . Connec t th e AL T 4 P connecto r

termina l No . 4 to bod y groun d

with a jumpe r wire .6. Chec k fo r continuit y betwee nbody groun d an d EC M con -necto r termina l D5 .

I s ther e continuity ?

Se e th e AL T inspectio n (se e

sectio n 23 ). EC

M CONNECTOR S

A (26P)D (22P)

Wire sid e o f femal e terminal s

D (22P)

Repai r shor t i n th e wir e betwee nthe EC M (D5 ) and th e ALT .

ALT F R signa l i s OK .

ALT GR N 4P CONNECTO R (C127 )

JUMPE R WIR E

Wir e sid e o f femal e terminal s

Repai r ope n wir e betwee n th e

ECM (D5 ) and th e ALT .

ECM CONNECTO R D (22P )

Wir e sid e o f femal e terminal s

Substitut

e a known-goo d EC M

an d recheck . I f prescribe d voltag e

i s no w available , replac e th e origi -

nal ECM .

Is ther e continuity ?

Chec

k fo r a shor t i n th e wir e (AL T

F line) :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e negativ e bat -

ter y cabl e fro m th e battery .

3 . Disconnec t th e EC M connecto r

D (22P) .4. Chec k fo r continuit y betwee n

bod y groun d an d EC M con -

necto r termina l D5 .

Chec

k fo r a shor t i n th e wir e (AL T

F line) :

1 . Disconnec t th e GR N 4 P con -

necto r fro m th e ALT .

2 . Tur n th e ignitio n switc h O N (II) .

3 . Measur e voltag e betwee n EC M

connecto r terminal s D 5 an d A26 .

Inspectio

n o f AL T F R Signal .

ProCarManuals.com

Page 889 of 1771

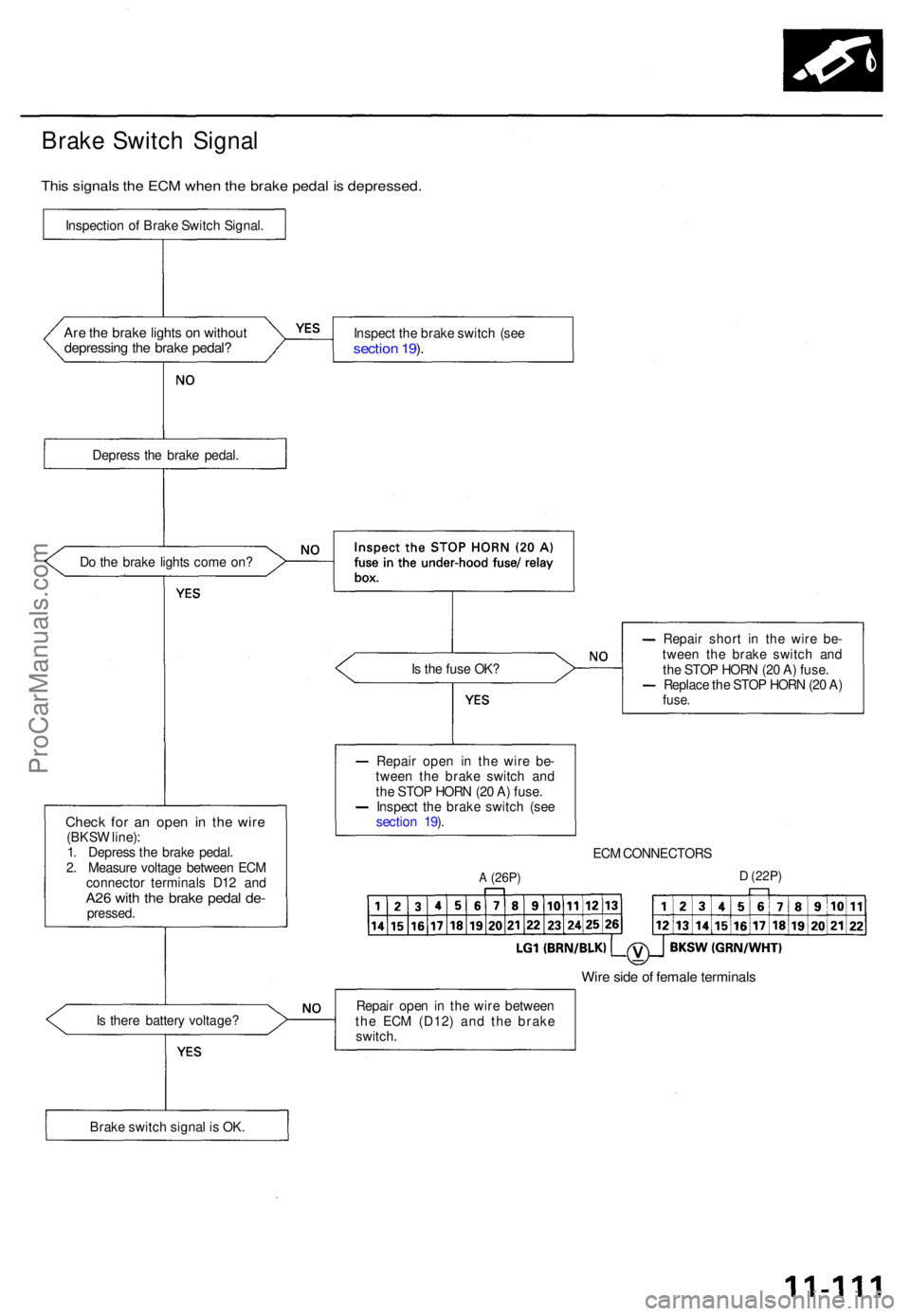

Brake Switc h Signa l

This signal s th e EC M whe n th e brak e peda l i s depressed .

Inspection o f Brak e Switc h Signal .

Are th e brak e light s o n withou tdepressin g th e brak e pedal ?Inspec t th e brak e switc h (se e sectio n 19 ).

Depres s th e brak e pedal .

D o th e brak e light s com e on ?

Is th e fus e OK ?

Chec k fo r a n ope n i n th e wir e(BKS W line) :

1 . Depres s th e brak e pedal .

2 . Measur e voltag e betwee n EC M

connecto r terminal s D1 2 an d

A26 wit h th e brak e peda l de -pressed . Repai

r shor t i n th e wir e be -

twee n th e brak e switc h an d

th e STO P HOR N (2 0 A ) fuse .

Replac e th e STO P HOR N (2 0 A )

fuse .

ECM CONNECTOR S

A (26P)D (22P )

Wire sid e o f femal e terminal s

Is ther e batter y voltage ? Repai

r ope n i n th e wir e betwee n

th e EC M (D12 ) an d th e brak e

switch .

Brak e switc h signa l i s OK . Repai

r ope n i n th e wire be-

twee n th e brak e switc h an d

th e STO P HOR N (2 0 A ) fuse .

Inspec t th e brak e switc h (se e

sectio n 19 ).

ProCarManuals.com