light ACURA TL 1995 Service Owner's Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 319 of 1771

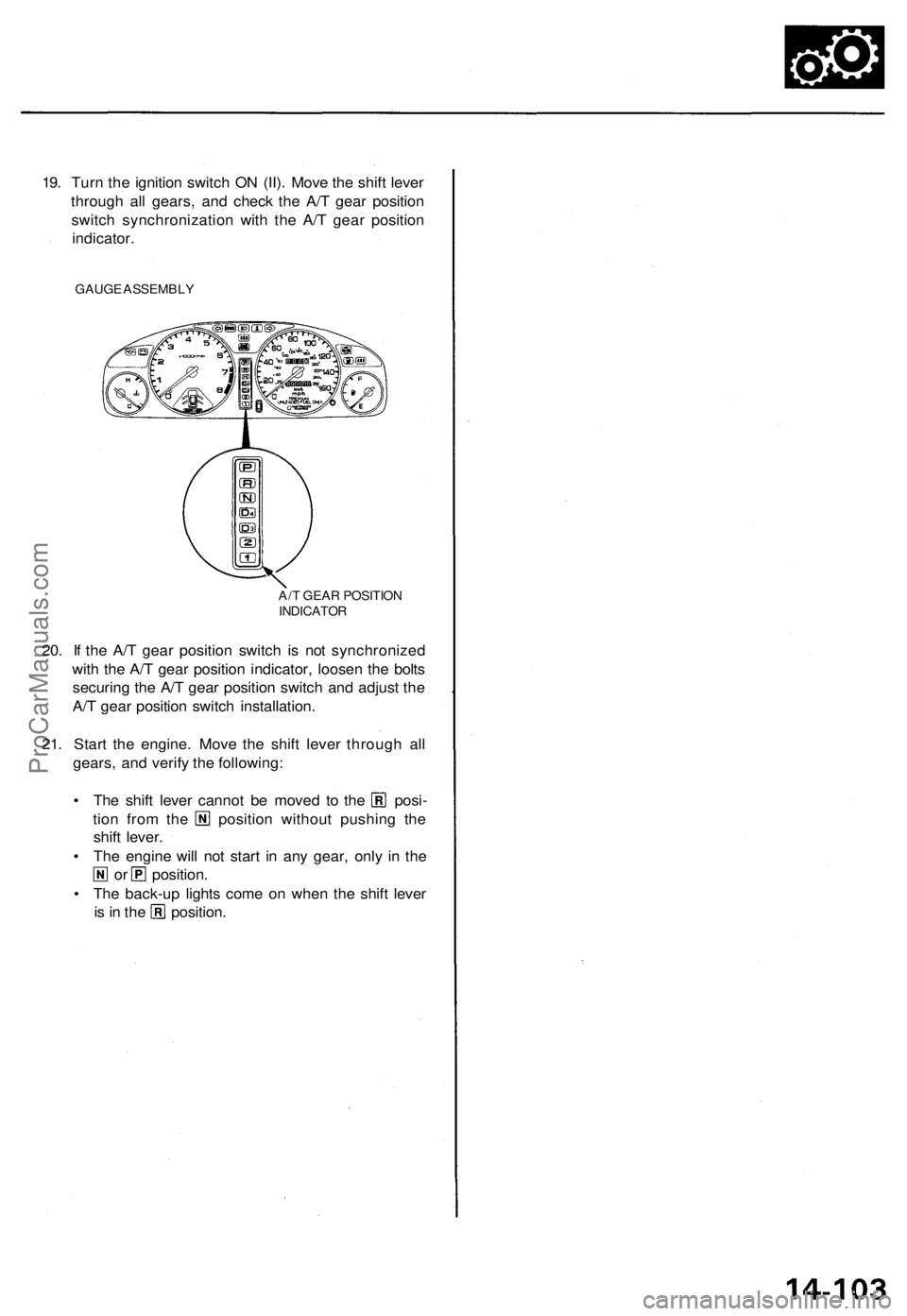

19. Turn the ignition switch ON (II). Move the shift lever

through all gears, and check the A/T gear position

switch synchronization with the A/T gear position

indicator.

GAUGE ASSEMBLY

20. If the A/T gear position switch is not synchronized

with the A/T gear position indicator, loosen the bolts

securing the A/T gear position switch and adjust the

A/T gear position switch installation.

21. Start the engine. Move the shift lever through all

gears, and verify the following:

• The shift lever cannot be moved to the posi-

tion from the position without pushing the

shift lever.

• The engine will not start in any gear, only in the

or position.

• The back-up lights come on when the shift lever

is in the position.

A/T GEAR POSITION

INDICATORProCarManuals.com

Page 320 of 1771

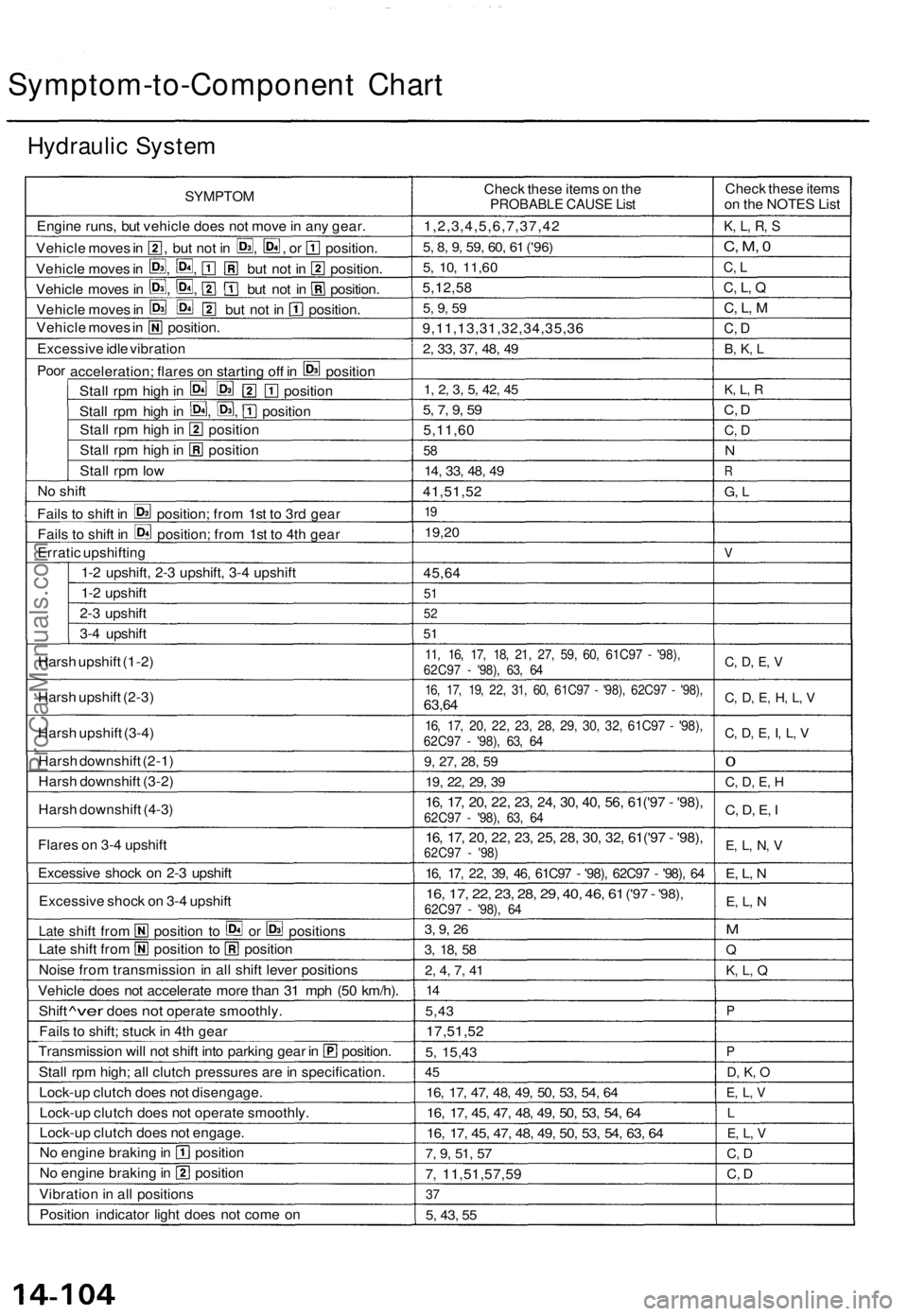

Symptom-to-Component Chart

Hydraulic System

SYMPTOM

Engine runs, but vehicle does not move in any gear.

Vehicle moves in , but not in , , or position.

Vehicle moves in , , but not in position.

Vehicle moves in , , but not in position.

Vehicle moves in but not in position.

Vehicle moves in position.

Excessive idle vibration

Poor

acceleration; flares on starting off in position

Stall rpm high in position

Stall rpm high in , , position

Stall rpm high in position

Stall rpm high in position

Stall rpm low

No shift

Fails to shift in position; from 1st to 3rd gear

Fails to shift in position; from 1st to 4th gear

Erratic upshifting

1-2 upshift, 2-3 upshift, 3-4 upshift

1-2 upshift

2-3 upshift

3-4 upshift

Harsh upshift (1-2)

Harsh upshift (2-3)

Harsh upshift (3-4)

Harsh downshift (2-1)

Harsh downshift (3-2)

Harsh downshift (4-3)

Flares on 3-4 upshift

Excessive shock on 2-3 upshift

Excessive shock on 3-4 upshift

Late

shift from position to or positions

Late shift from position to position

Noise from transmission in all shift lever positions

Vehicle does not accelerate more than 31 mph (50 km/h).

Shift

^ver

does

not

operate smoothly.

Fails to shift; stuck in 4th gear

Transmission will not shift into parking gear in position.

Stall

rpm high; all clutch pressures are in specification.

Lock-up clutch does not disengage.

Lock-up clutch does not operate smoothly.

Lock-up clutch does not engage.

No engine braking in position

No engine braking in position

Vibration in all positions

Position indicator light does not come on

Check these items on the

PROBABLE CAUSE List

1,2,3,4,5,6,7,37,42

5, 8, 9, 59, 60, 61

('96)

5, 10,

11,60

5,12,58

5, 9, 59

9,11,13,31,32,34,35,36

2, 33, 37, 48, 49

1, 2, 3, 5, 42, 45

5, 7, 9, 59

5,11,60

58

14, 33, 48, 49

41,51,52

19

19,20

45,64

51

52

51

11, 16, 17, 18, 21, 27, 59, 60, 61C97 - '98),

62C97 - '98), 63, 64

16, 17, 19, 22, 31, 60, 61C97 - '98), 62C97 - '98),

63,64

16, 17, 20, 22, 23, 28, 29, 30, 32, 61C97 - '98),

62C97 - '98), 63, 64

9, 27, 28, 59

19, 22, 29, 39

16, 17, 20, 22, 23, 24, 30, 40, 56, 61('97 - '98),

62C97 - '98), 63, 64

16, 17, 20, 22, 23, 25, 28, 30, 32, 61('97 - '98),

62C97 - '98)

16, 17, 22, 39, 46, 61C97 - '98), 62C97 - '98), 64

16, 17, 22, 23, 28, 29, 40, 46, 61

('97

-

'98),

62C97 - '98), 64

3, 9, 26

3, 18, 58

2, 4, 7, 41

14

5,43

17,51,52

5,

15,43

45

16, 17, 47, 48, 49, 50, 53, 54, 64

16, 17, 45, 47, 48, 49, 50, 53, 54, 64

16, 17, 45, 47, 48, 49, 50, 53, 54, 63, 64

7, 9, 51, 57

7, 11,51,57,59

37

5, 43, 55

Check these items

on the NOTES List

K, L, R, S

C, M, 0

C, L

C, L, Q

C, L, M

C, D

B, K, L

K, L, R

C, D

C, D

N

R

G, L

V

C, D, E, V

C, D, E, H, L, V

C, D, E, I, L, V

0

C, D, E, H

C, D, E, I

E, L, N, V

E, L, N

E, L, N

M

Q

K, L, Q

P

P

D, K, O

E, L, V

L

E, L, V

C, D

C, DProCarManuals.com

Page 361 of 1771

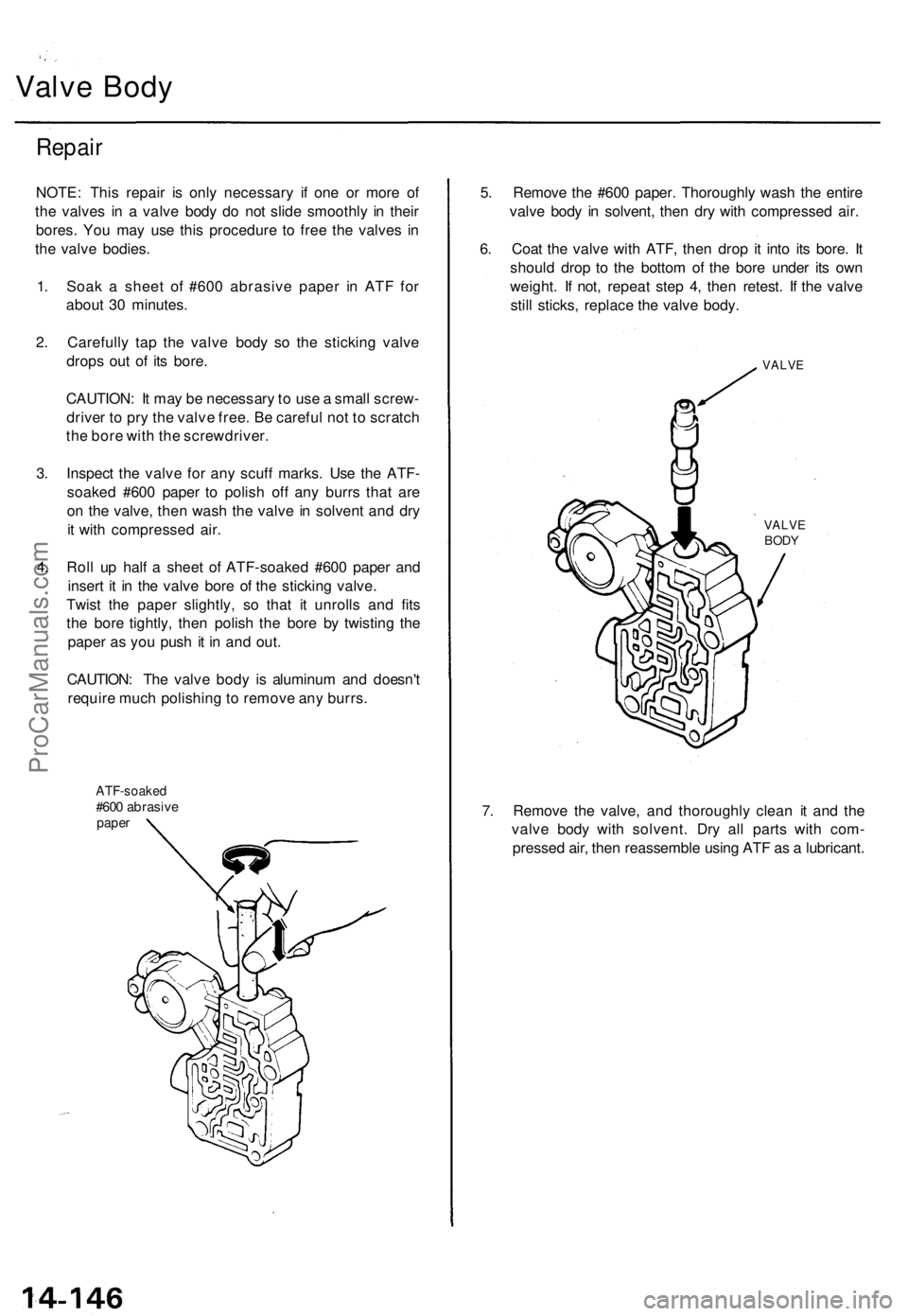

Valve Body

Repair

NOTE: This repair is only necessary if one or more of

the valves in a valve body do not slide smoothly in their

bores. You may use this procedure to free the valves in

the valve bodies.

1. Soak a sheet of #600 abrasive paper in ATF for

about 30 minutes.

2. Carefully tap the valve body so the sticking valve

drops out of its bore.

CAUTION: It may be necessary to use a small screw-

driver to pry the valve free. Be careful not to scratch

the bore with the screwdriver.

3. Inspect the valve for any scuff marks. Use the ATF-

soaked #600 paper to polish off any burrs that are

on the valve, then wash the valve in solvent and dry

it with compressed air.

4. Roll up half a sheet of ATF-soaked #600 paper and

insert it in the valve bore of the sticking valve.

Twist the paper slightly, so that it unrolls and fits

the bore tightly, then polish the bore by twisting the

paper as you push it in and out.

CAUTION: The valve body is aluminum and doesn't

require much polishing to remove any burrs.

ATF-soaked

#600 abrasive

paper

5. Remove the #600 paper. Thoroughly wash the entire

valve body in solvent, then dry with compressed air.

6. Coat the valve with ATF, then drop it into its bore. It

should drop to the bottom of the bore under its own

weight. If not, repeat step 4, then retest. If the valve

still sticks, replace the valve body.

VALVE

VALVE

BODY

7. Remove the valve, and thoroughly clean it and the

valve body with solvent. Dry all parts with com-

pressed air, then reassemble using ATF as a lubricant.ProCarManuals.com

Page 387 of 1771

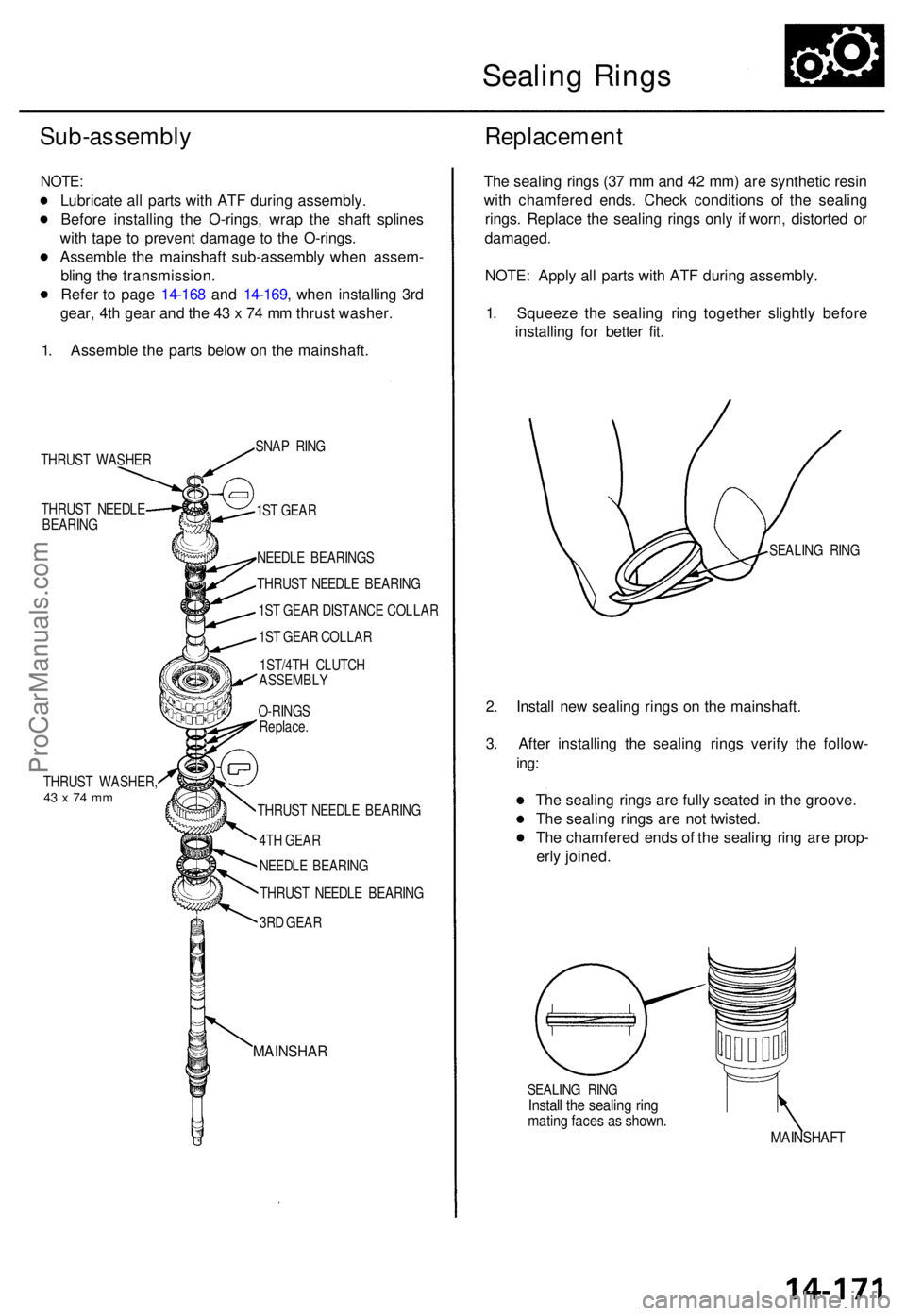

Sealing Ring s

Sub-assembl y

NOTE:

Lubricat e al l part s wit h AT F durin g assembly .

Befor e installin g th e O-rings , wra p th e shaf t spline s

wit h tap e t o preven t damag e t o th e O-rings .

Assembl e th e mainshaf t sub-assembl y whe n assem -

blin g th e transmission .

Refe r t o pag e 14-16 8 an d 14-169 , whe n installin g 3r d

gear , 4t h gea r an d th e 4 3 x 7 4 m m thrus t washer .

1 . Assembl e th e part s belo w o n th e mainshaft .

Replacemen t

THRUST WASHE R

THRUS T NEEDL E

BEARIN G

THRUS T WASHER ,

43 x 74 m m

SNA P RIN G

1S T GEA R

NEEDL E BEARING S

THRUS T NEEDL E BEARIN G

1S T GEA R DISTANC E COLLA R

1S T GEA R COLLA R

1ST/4T H CLUTC H

ASSEMBL Y

O-RING S

Replace .

THRUS T NEEDL E BEARIN G

4T H GEA R

NEEDL E BEARIN G

THRUS T NEEDL E BEARIN G

3R D GEA R

MAINSHA R

The sealin g ring s (3 7 m m an d 4 2 mm ) ar e syntheti c resi n

wit h chamfere d ends . Chec k condition s o f th e sealin g

rings . Replac e th e sealin g ring s onl y i f worn , distorte d o r

damaged .

NOTE : Appl y al l part s wit h AT F during assembly .

1 . Squeez e th e sealin g rin g togethe r slightl y befor e

installin g fo r bette r fit .

SEALIN G RIN G

2. Instal l ne w sealin g ring s o n th e mainshaft .

3 . Afte r installin g th e sealin g ring s verif y th e follow -

ing:

The sealin g ring s ar e full y seate d in th e groove .

Th e sealin g ring s ar e no t twisted .

Th e chamfere d end s o f th e sealin g rin g ar e prop -

erl y joined .

SEALIN G RIN GInstal l th e sealin g rin gmatin g face s a s shown .MAINSHAF T

ProCarManuals.com

Page 420 of 1771

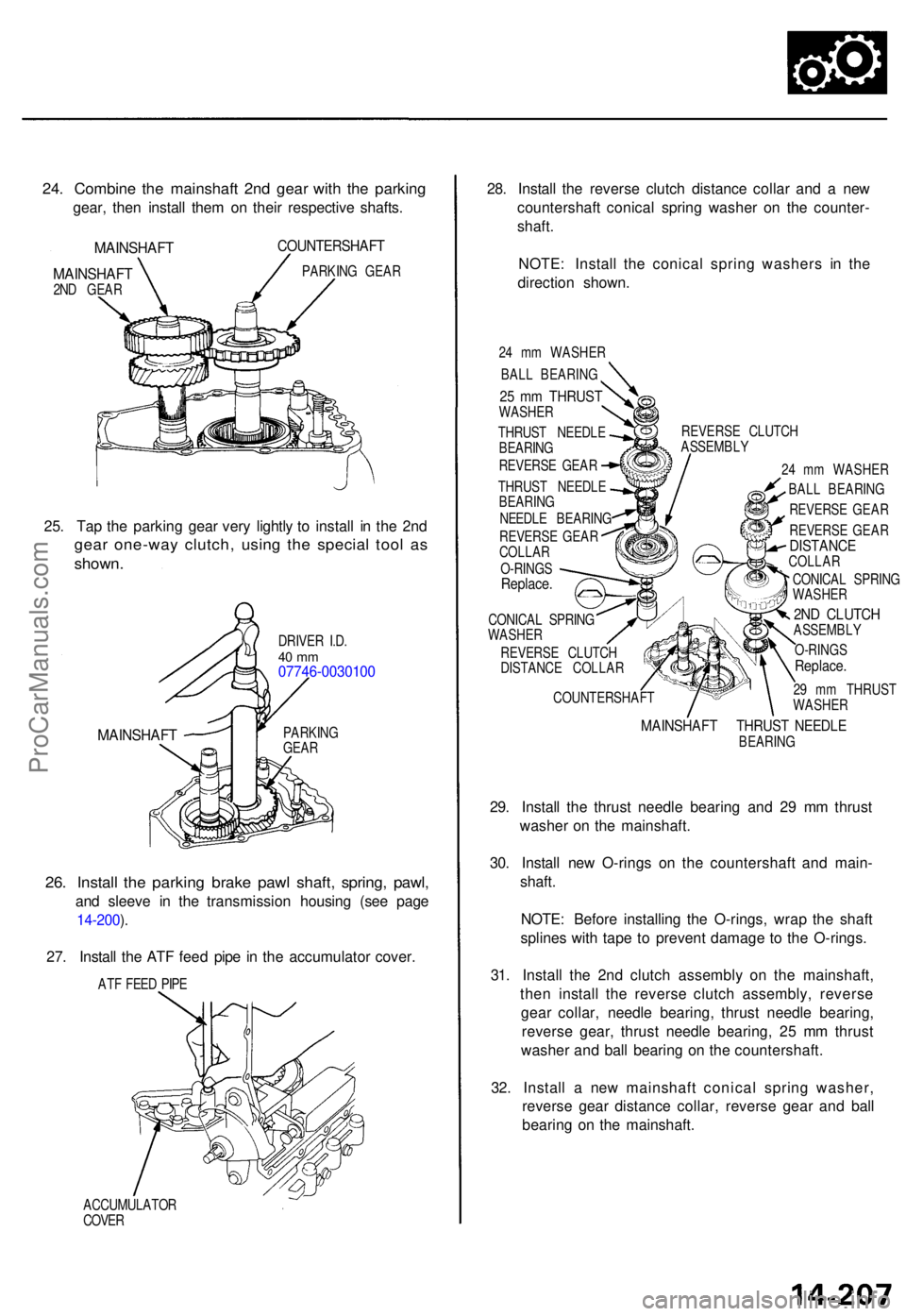

24. Combin e th e mainshaf t 2n d gea r wit h th e parkin g

gear, the n instal l the m o n thei r respectiv e shafts .

MAINSHAF T

MAINSHAF T

2ND GEA R

COUNTERSHAF T

PARKING GEA R

25. Ta p th e parkin g gea r ver y lightl y t o instal l i n th e 2n d

gea r one-wa y clutch , usin g th e specia l too l a s

shown .

DRIVE R I.D .40 m m07746-003010 0

MAINSHAFTPARKING

GEA R

26. Instal l th e parkin g brak e paw l shaft , spring , pawl ,

and sleev e i n th e transmissio n housin g (se e pag e

14-200 ).

27 . Instal l th e AT F fee d pip e i n th e accumulato r cover .

ATF FEE D PIP E

ACCUMULATO R

COVE R

28. Instal l th e revers e clutc h distanc e colla r an d a ne w

countershaf t conica l sprin g washe r o n th e counter -

shaft .

NOTE : Instal l th e conica l sprin g washer s i n th e

directio n shown .

24 m m WASHE R

BAL L BEARING

THRUS T NEEDL E

BEARIN G

REVERS E GEA R

THRUS T NEEDL E

BEARIN G

NEEDL E BEARIN G

REVERS E GEA R

COLLA R

O-RING S

Replace .

CONICA L SPRIN G

WASHE R

REVERS E CLUTC H

DISTANC E COLLA R

COUNTERSHAF TREVERS

E CLUTC H

ASSEMBL Y

24 m m WASHE R

BAL L BEARIN G

REVERS E GEA R

REVERS E GEA R

DISTANC ECOLLAR

CONICA L SPRIN G

WASHE R

2ND CLUTC HASSEMBL Y

O-RING S

Replace .

29 m m THRUS T

WASHE R

MAINSHAF T THRUS T NEEDL EBEARIN G

29. Instal l th e thrus t needl e bearin g an d 2 9 m m thrus t

washe r o n th e mainshaft .

30 . Instal l ne w O-ring s o n th e countershaf t an d main -

shaft .

NOTE : Befor e installin g th e O-rings , wra p th e shaf t

spline s wit h tap e t o preven t damag e t o th e O-rings .

31 . Instal l th e 2n d clutc h assembl y o n th e mainshaft ,

the n instal l th e revers e clutc h assembly , revers e

gea r collar , needl e bearing , thrus t needl e bearing ,

revers e gear , thrus t needl e bearing , 2 5 m m thrus t

washe r an d bal l bearin g o n th e countershaft .

32 . Instal l a ne w mainshaf t conica l sprin g washer ,

revers e gea r distanc e collar , revers e gea r an d bal l

bearin g o n th e mainshaft .

25 m m THRUS TWASHER

ProCarManuals.com

Page 439 of 1771

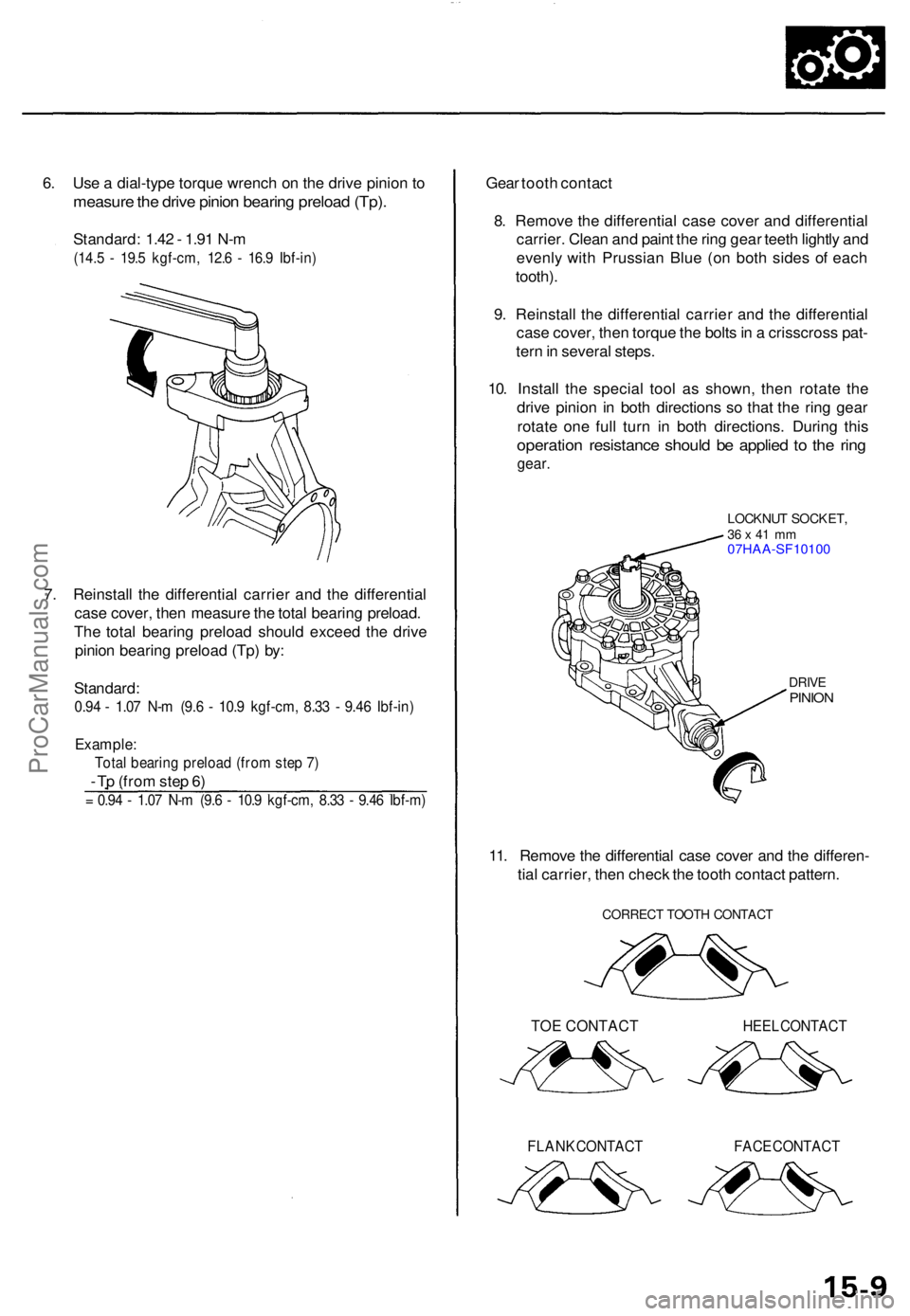

6. Us e a dial-typ e torqu e wrenc h o n th e driv e pinio n t o

measur e th e driv e pinio n bearin g preloa d (Tp) .

Standard : 1.4 2 - 1.9 1 N- m

(14. 5 - 19. 5 kgf-cm , 12. 6 - 16. 9 Ibf-in )

7. Reinstal l th e differentia l carrie r an d th e differentia l

cas e cover , the n measur e th e tota l bearin g preload .

Th e tota l bearin g preloa d shoul d excee d th e driv e

pinio n bearin g preloa d (Tp ) by :

Standard :

0.94 - 1.0 7 N- m (9. 6 - 10. 9 kgf-cm , 8.3 3 - 9.4 6 Ibf-in )

Example :

Total bearin g preloa d (fro m ste p 7 )

- T p (fro m ste p 6 )

= 0.9 4 - 1.0 7 N- m (9. 6 - 10. 9 kgf-cm , 8.3 3 - 9.4 6 Ibf-m )

Gear toot h contac t

8 . Remov e th e differentia l cas e cove r an d differentia l

carrier . Clea n an d pain t th e rin g gea r teet h lightl y an d

evenl y wit h Prussia n Blu e (o n bot h side s o f eac h

tooth) .

9 . Reinstal l th e differentia l carrie r an d th e differentia l

cas e cover , the n torqu e th e bolt s in a crisscros s pat -

ter n in severa l steps .

10 . Instal l th e specia l too l a s shown , the n rotat e th e

driv e pinio n i n bot h direction s s o tha t th e rin g gea r

rotat e on e ful l tur n i n bot h directions . Durin g thi s

operatio n resistanc e shoul d b e applie d t o th e rin g

gear .

LOCKNU T SOCKET ,36 x 41 m m07HAA-SF1010 0

DRIVEPINIO N

11. Remov e th e differentia l cas e cove r an d th e differen -

tia l carrier , the n chec k th e toot h contac t pattern .

CORREC T TOOT H CONTAC T

TOE CONTACT HEEL CONTAC T

FLANK CONTAC T FACE CONTAC T

ProCarManuals.com

Page 448 of 1771

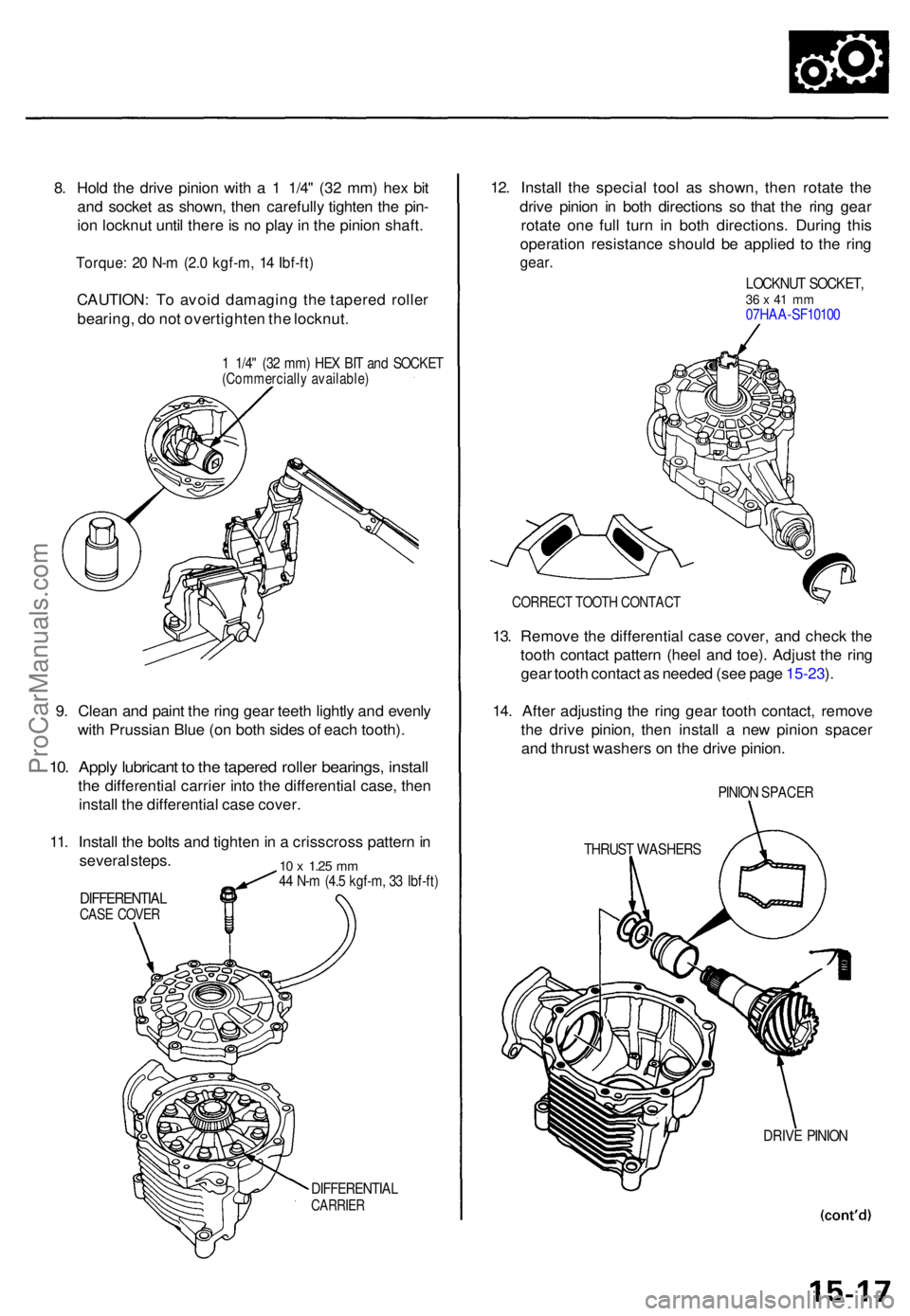

8. Hol d th e driv e pinio n wit h a 1 1/4 " (3 2 mm ) he x bi t

an d socke t a s shown , the n carefull y tighte n th e pin -

io n locknu t unti l ther e is n o pla y in th e pinio n shaft .

Torque : 2 0 N- m (2. 0 kgf-m , 1 4 Ibf-ft )

CAUTION : T o avoi d damagin g th e tapere d rolle r

bearing , d o no t overtighte n th e locknut .

1 1/4 " (3 2 mm ) HE X BI T an d SOCKE T(Commerciall y available )

9. Clea n an d pain t th e rin g gea r teet h lightl y an d evenl y

wit h Prussia n Blu e (o n bot h side s o f eac h tooth) .

10. Appl y lubrican t t o th e tapere d rolle r bearings , instal l

the differentia l carrie r int o th e differentia l case , the n

instal l th e differentia l cas e cover .

11 . Instal l th e bolt s an d tighte n in a crisscros s patter n in

severa l steps .

DIFFERENTIA LCASE COVE R

10 x 1.2 5 mm44 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

DIFFERENTIA LCARRIER

12. Instal l th e specia l too l a s shown , the n rotat e th e

driv e pinio n i n bot h direction s s o tha t th e rin g gea r

rotat e on e ful l tur n i n bot h directions . Durin g thi s

operation resistanc e shoul d b e applie d t o th e rin g

gear .

LOCKNU T SOCKET ,36 x 41 m m07HA A-SF1010 0

CORREC T TOOT H CONTAC T

13. Remov e th e differentia l cas e cover , an d chec k th e

toot h contac t patter n (hee l an d toe) . Adjus t th e rin g

gea r toot h contac t a s neede d (se e pag e 15-23 ).

14 . Afte r adjustin g th e rin g gea r toot h contact , remov e

th e driv e pinion , the n instal l a ne w pinio n space r

an d thrus t washer s o n th e driv e pinion .

PINION SPACE R

THRUST WASHER S

DRIVE PINIO N

ProCarManuals.com

Page 450 of 1771

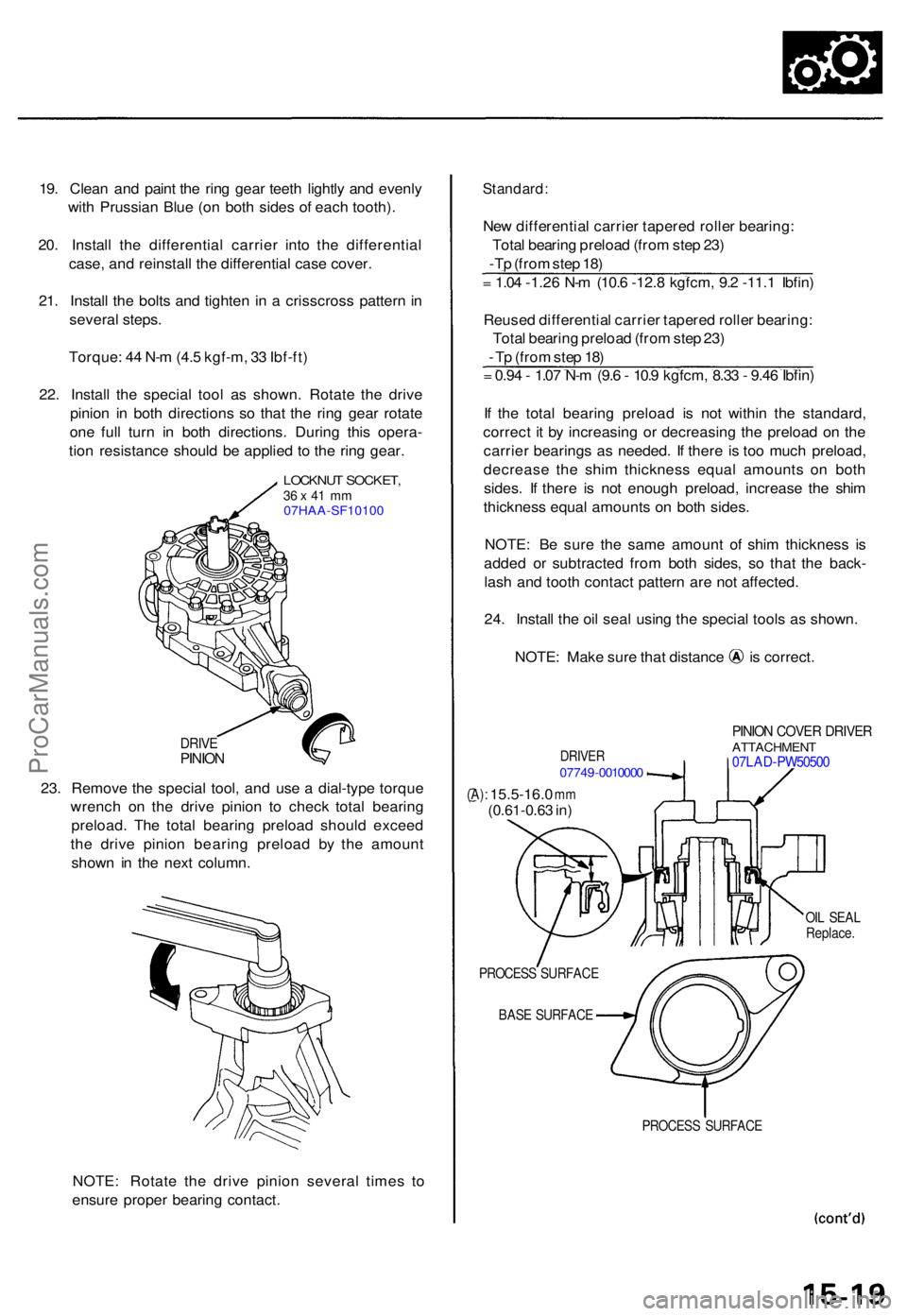

19. Clea n an d pain t th e rin g gea r teet h lightl y an d evenl y

wit h Prussia n Blu e (o n bot h side s o f eac h tooth) .

20 . Instal l th e differentia l carrie r int o th e differentia l

case , an d reinstal l th e differential case cover .

21 . Instal l th e bolt s an d tighte n i n a crisscros s patter n in

severa l steps .

Torque : 4 4 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

22 . Instal l th e specia l too l a s shown . Rotat e th e driv e

pinio n i n bot h direction s s o tha t th e rin g gea r rotat e

on e ful l tur n i n bot h directions . Durin g thi s opera -

tio n resistanc e shoul d b e applie d t o th e rin g gear .

LOCKNU T SOCKET ,36 x 41 m m07HAA-SF10100

DRIV EPINIO N

23. Remov e th e specia l tool , an d us e a dial-typ e torqu e

wrenc h o n th e driv e pinio n t o chec k tota l bearin g

preload . Th e tota l bearin g preloa d shoul d excee d

th e driv e pinio n bearin g preloa d b y th e amoun t

show n i n th e nex t column .

NOTE : Rotat e th e driv e pinio n severa l time s t o

ensur e prope r bearin g contact .

Standard :

New differentia l carrie r tapere d rolle r bearing :

Tota l bearin g preloa d (fro m ste p 23 )

-Tp (fro m ste p 18 )

= 1.0 4 -1.2 6 N- m (10. 6 -12. 8 kgfcm , 9. 2 -11. 1 Ibfin )

Reuse d differentia l carrie r tapere d rolle r bearing :

Tota l bearin g preloa d (fro m ste p 23 )

- T p (fro m ste p 18 )

= 0.9 4 - 1.0 7 N- m (9. 6 - 10. 9 kgfcm , 8.3 3 - 9.4 6 Ibfin )

I f th e tota l bearin g preloa d i s no t withi n th e standard ,

correc t i t b y increasin g o r decreasin g th e preloa d o n th e

carrie r bearing s a s needed . I f ther e i s to o muc h preload ,

decreas e th e shi m thicknes s equa l amount s o n bot h

sides . I f ther e i s no t enoug h preload , increase the shi m

thicknes s equa l amount s o n bot h sides .

NOTE : B e sur e th e sam e amoun t of shi m thicknes s i s

adde d o r subtracte d fro m bot h sides , s o tha t th e back -

las h an d toot h contac t patter n ar e no t affected .

24 . Instal l th e oi l sea l usin g th e specia l tool s a s shown .

NOTE: Mak e sur e tha t distanc e i s correct .

DRIVER07749-001000 0

PINION COVE R DRIVE RATTACHMEN T07LAD-PW5050 0

(A): 15.5-16. 0 mm(0.61-0.6 3 in )

OIL SEA L

Replace .

PROCES S SURFAC E

BAS E SURFAC E

PROCESS SURFAC E

ProCarManuals.com

Page 484 of 1771

Steering Gearbo x

Reassembl y (cont'd )

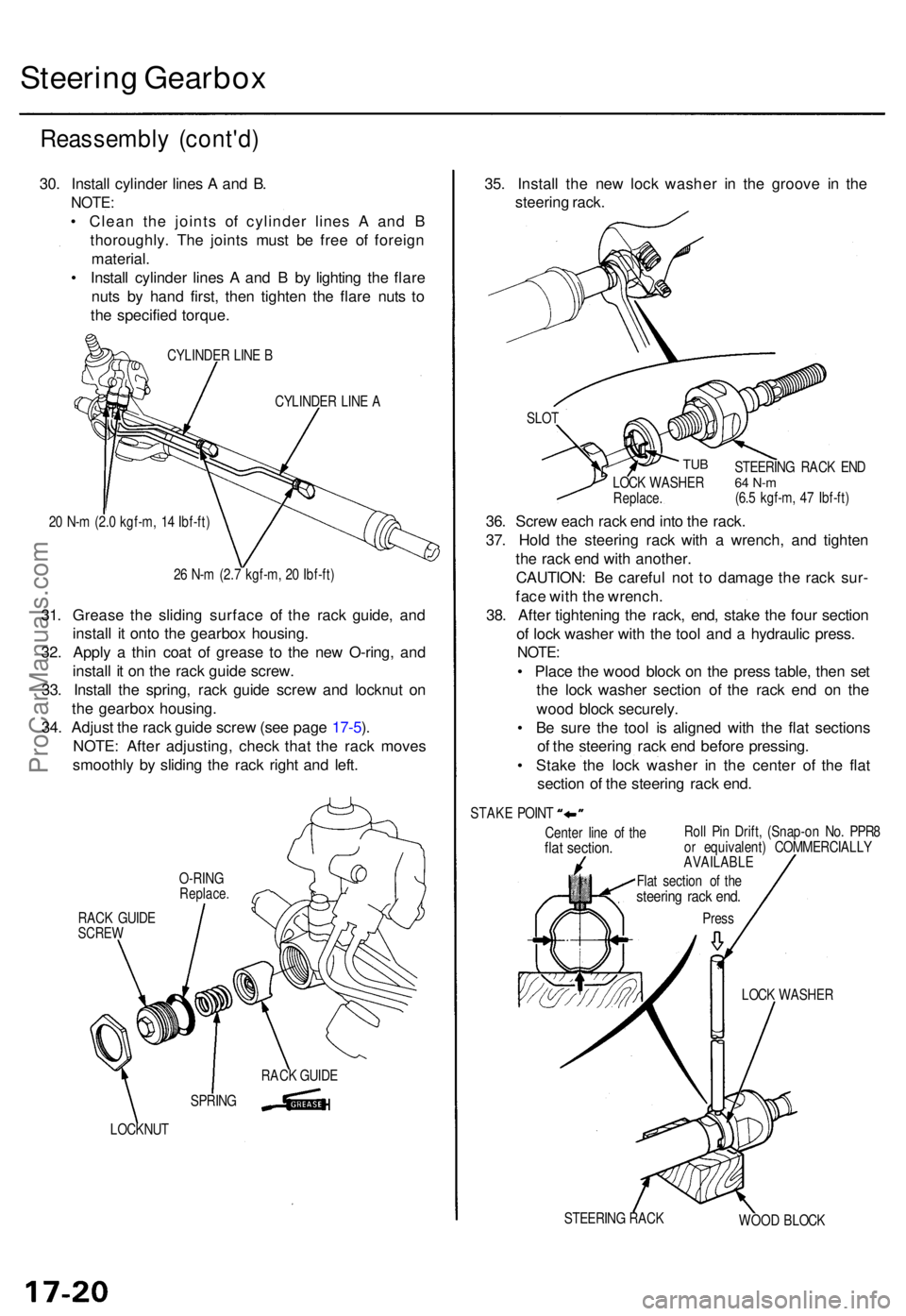

30. Instal l cylinde r line s A an d B .

NOTE :

• Clea n th e joint s o f cylinde r line s A an d B

thoroughly . Th e joint s mus t b e fre e o f foreig n

material .

• Instal l cylinde r line s A an d B by lightin g th e flar e

nut s b y han d first , the n tighte n th e flar e nut s t o

th e specifie d torque .

CYLINDE R LIN E B

CYLINDE R LIN E A

2 0 N- m (2. 0 kgf-m , 1 4 Ibf-ft )

2 6 N- m (2. 7 kgf-m , 2 0 Ibf-ft )

31. Greas e th e slidin g surfac e o f th e rac k guide , an d

instal l i t ont o th e gearbo x housing .

32 . Appl y a thi n coa t o f greas e t o th e ne w O-ring , an d

instal l i t o n th e rac k guid e screw .

33 . Instal l th e spring , rac k guid e scre w an d locknu t o n

th e gearbo x housing .

34 . Adjus t th e rac k guid e scre w (se e pag e 17-5 ).

NOTE : Afte r adjusting , chec k tha t th e rac k move s

smoothl y b y slidin g th e rac k righ t an d left .

RAC K GUID ESCRE W

LOCKNU T

35. Instal l th e ne w loc k washe r i n th e groov e i n th e

steerin g rack .

Cente r lin e o f th eflat section .Roll Pi n Drift , (Snap-o n No . PPR 8

o r equivalent ) COMMERCIALL Y

AVAILABLE

LOCK WASHE R

STEERIN G RAC K

WOOD BLOC K

SLO

T

TUB

36. Scre w eac h rac k en d int o th e rack .

37 . Hol d th e steerin g rac k wit h a wrench , an d tighte n

th e rac k en d wit h another .

CAUTION : B e carefu l no t t o damag e th e rac k sur -

fac e wit h th e wrench .

38 . Afte r tightenin g th e rack , end , stak e th e fou r sectio n

o f loc k washe r wit h th e too l an d a hydrauli c press .

NOTE:

• Plac e th e woo d bloc k o n th e pres s table , the n se t

th e loc k washe r sectio n o f th e rac k en d o n th e

woo d bloc k securely .

• B e sur e th e too l i s aligne d wit h th e fla t section s

o f th e steerin g rac k en d befor e pressing .

• Stak e th e loc k washe r i n th e cente r o f th e fla t

sectio n o f th e steerin g rac k end .

STEERIN G RAC K EN D64 N- m(6.5 kgf-m , 4 7 Ibf-ft )

LOC

K WASHE RReplace.

STAKE POIN T

Flat sectio n o f th e

steerin g rac k end .

Pres s

SPRIN GRAC

K GUID E

O-RIN

G

Replace .

ProCarManuals.com

Page 485 of 1771

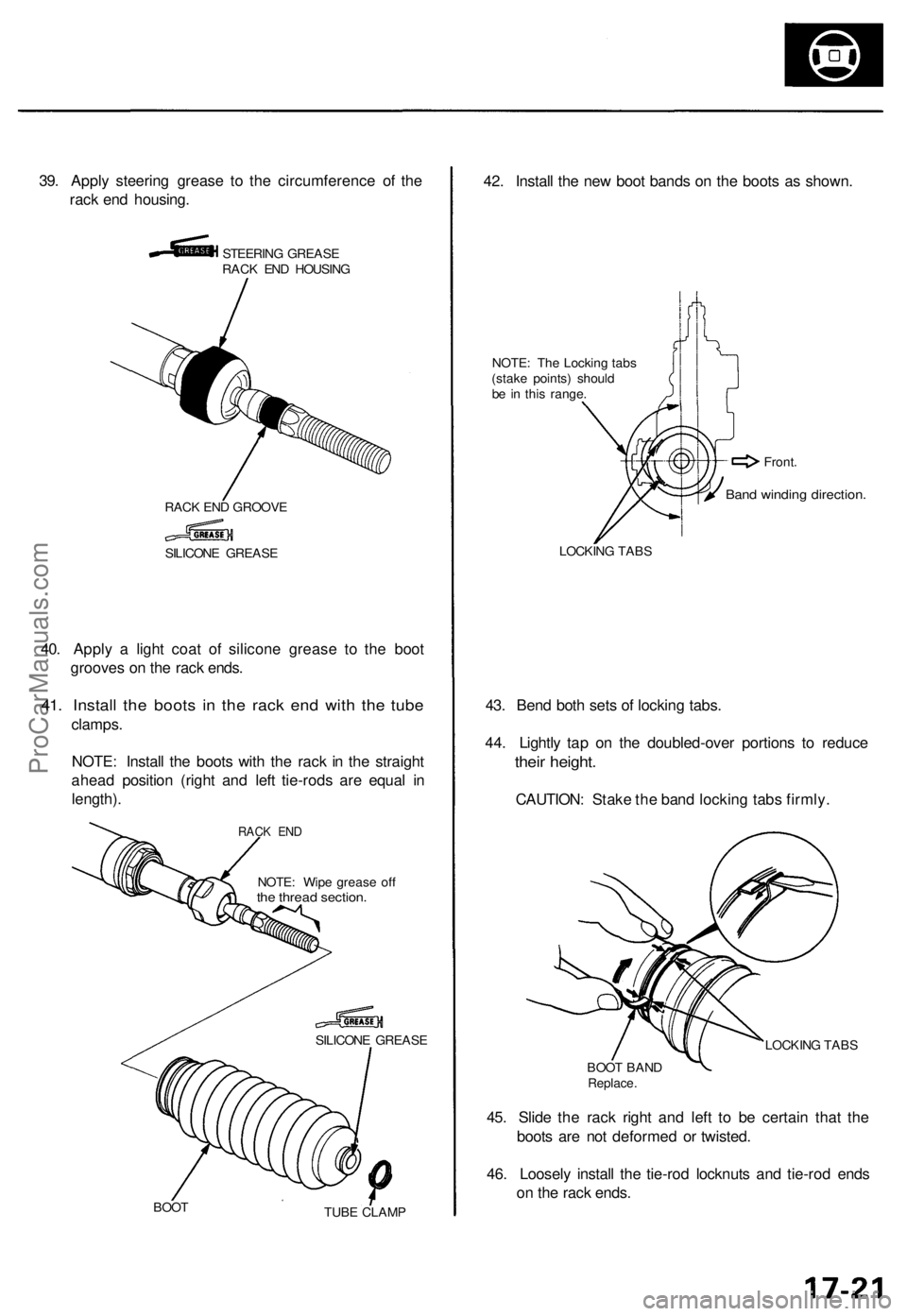

39. Appl y steerin g greas e t o th e circumferenc e o f th e

rac k en d housing .

STEERIN G GREAS E

RAC K EN D HOUSIN G

RAC K EN D GROOV E

40. Appl y a ligh t coa t o f silicon e greas e t o th e boo t

groove s o n th e rac k ends .

41. Instal l th e boot s i n th e rac k en d wit h th e tub e

clamps .

NOTE : Instal l th e boot s wit h th e rac k i n th e straigh t

ahea d positio n (righ t an d lef t tie-rod s ar e equa l i n

length) .

NOTE: Wip e greas e of fthe threa d section .

SILICON E GREAS E

BOO T

TUBE CLAM P

42. Instal l th e ne w boo t band s o n th e boot s a s shown .

NOTE: Th e Lockin g tab s

(stak e points ) shoul d

b e i n thi s range .

LOCKIN G TAB S

43. Ben d bot h set s o f lockin g tabs .

44 . Lightl y ta p o n th e doubled-ove r portion s t o reduc e

their height .

CAUTION : Stak e th e ban d lockin g tab s firmly .

LOCKIN G TAB S

BOO T BAN D

Replace .

45. Slid e th e rac k righ t an d lef t t o b e certai n tha t th e

boot s ar e no t deforme d o r twisted .

46 . Loosel y instal l th e tie-ro d locknut s an d tie-ro d end s

o n th e rac k ends .

SILICON E GREAS E

Band windin g direction .

Front.

RACK EN D

ProCarManuals.com