recommended oil ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 28 of 1771

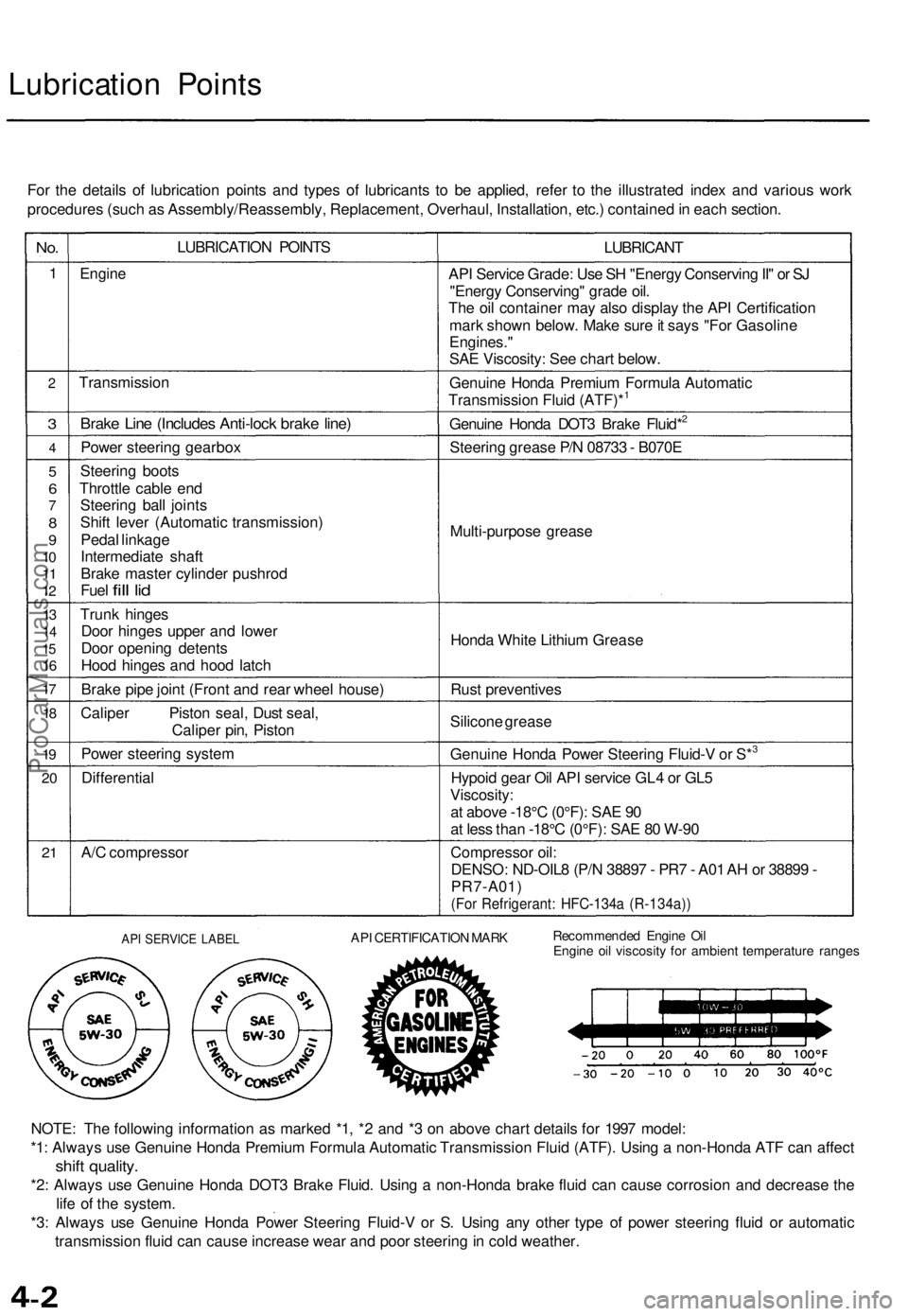

Lubrication Points

For the details of lubrication points and types of lubricants to be applied, refer to the illustrated index and various work

procedures (such as Assembly/Reassembly, Replacement, Overhaul, Installation, etc.) contained in each section.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

LUBRICATION POINTS

Engine

Transmission

Brake Line (Includes Anti-lock brake line)

Power steering gearbox

Steering boots

Throttle cable end

Steering ball joints

Shift lever (Automatic transmission)

Pedal linkage

Intermediate shaft

Brake master cylinder pushrod

Fuel

fill

lid

Trunk hinges

Door hinges upper and lower

Door opening detents

Hood hinges and hood latch

Brake pipe joint (Front and rear wheel house)

Caliper Piston seal, Dust seal,

Caliper pin, Piston

Power steering system

Differential

A/C compressor

LUBRICANT

API Service Grade: Use SH "Energy Conserving II" or SJ

"Energy Conserving" grade oil.

The oil container may also display the API Certification

mark shown below. Make sure it says "For Gasoline

Engines."

SAE Viscosity: See chart below.

Genuine Honda Premium Formula Automatic

Transmission Fluid (ATF)*1

Genuine Honda DOT3 Brake Fluid*2

Steering grease P/N 08733 - B070E

Multi-purpose grease

Honda White Lithium Grease

Rust preventives

Silicone grease

Genuine Honda Power Steering Fluid-V or S*3

Hypoid gear Oil API service GL4 or GL5

Viscosity:

at above -18°C (0°F): SAE 90

at less than -18°C (0°F): SAE 80 W-90

Compressor oil:

DENSO: ND-OIL8 (P/N 38897 - PR7 - A01 AH or 38899 -

PR7-A01)

(For Refrigerant: HFC-134a (R-134a))

API SERVICE LABEL

API CERTIFICATION MARK

Recommended Engine Oil

Engine oil viscosity for ambient temperature ranges

NOTE: The following information as marked *1, *2 and *3 on above chart details for 1997 model:

*1: Always use Genuine Honda Premium Formula Automatic Transmission Fluid (ATF). Using a non-Honda ATF can affect

shift quality.

*2: Always use Genuine Honda DOT3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease the

life of the system.

*3: Always use Genuine Honda Power Steering Fluid-V or S. Using any other type of power steering fluid or automatic

transmission fluid can cause increase wear and poor steering in cold weather.ProCarManuals.com

Page 479 of 1771

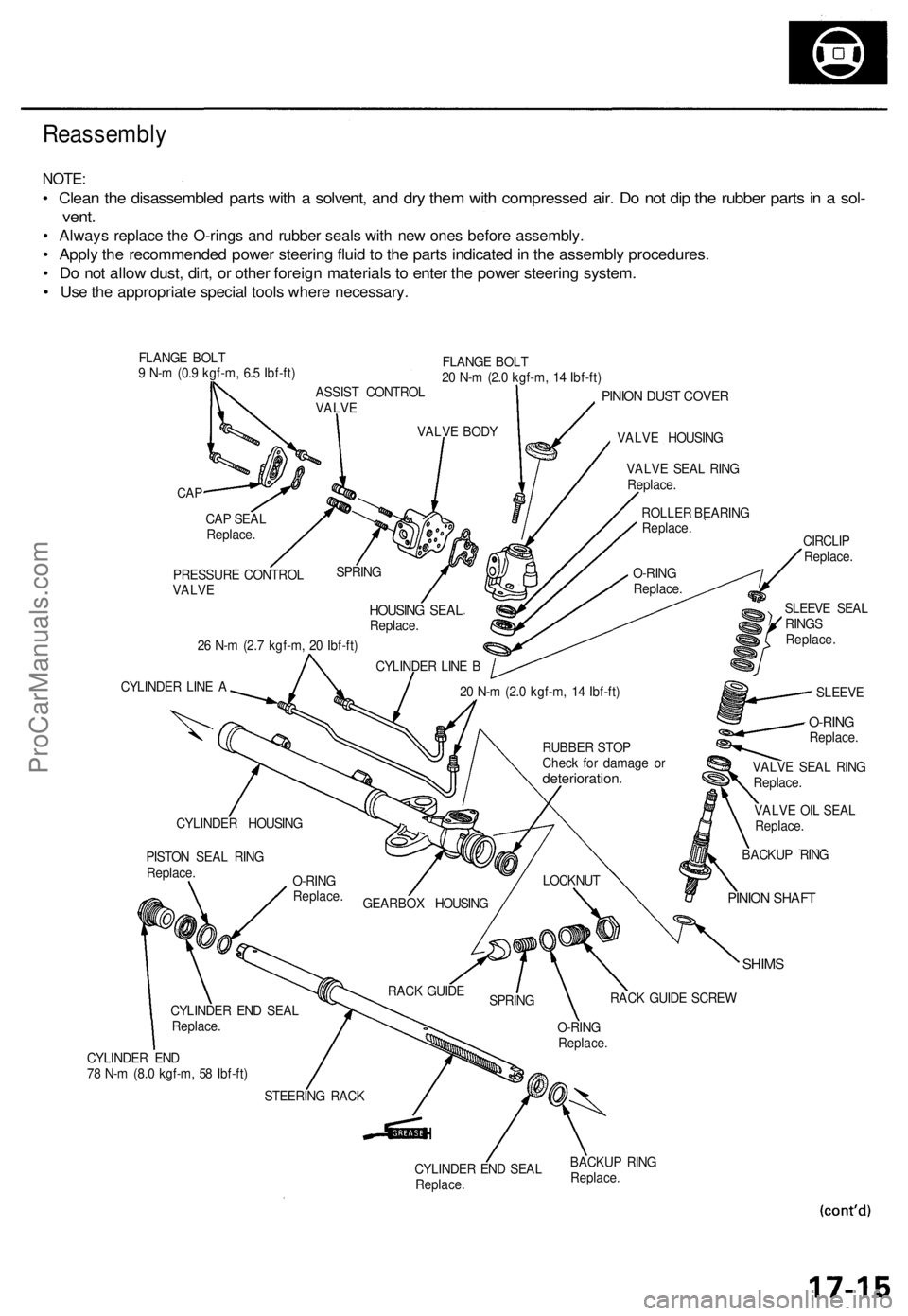

Reassembly

NOTE:

• Clean the disassembled parts with a solvent, and dry them with compressed air. Do not dip the rubber parts in a sol-

vent.

• Always replace the O-rings and rubber seals with new ones before assembly.

• Apply the recommended power steering fluid to the parts indicated in the assembly procedures.

• Do not allow dust, dirt, or other foreign materials to enter the power steering system.

• Use the appropriate special tools where necessary.

FLANGE BOLT

9 N-m (0.9 kgf-m, 6.5 Ibf-ft)

FLANGE BOLT

20 N-m (2.0 kgf-m, 14 Ibf-ft)

CAP

PINION DUST COVER

VALVE HOUSING

26 N-m (2.7 kgf-m, 20 Ibf-ft)

CYLINDER LINE A

VALVE OIL SEAL

Replace.

SHIMS

CYLINDER END

78 N-m (8.0 kgf-m, 58 Ibf-ft)

CYLINDER END SEAL

Replace.

BACKUP RING

Replace.

CAP SEAL

Replace.

PRESSURE CONTROL

VALVE

SPRING

HOUSING SEAL

Replace.

CYLINDER LINE B

VALVE BODY

ASSIST CONTROL

VALVE

VALVE SEAL RING

Replace.

ROLLER BEARING

Replace.

O-RING

Replace.

SLEEVE SEAL

RINGS

Replace.

CIRCLIP

Replace.

SLEEVE

20 N-m (2.0 kgf-m, 14 Ibf-ft)

BACKUP RING

PINION SHAFT

LOCKNUT

RACK GUIDE SCREW

O-RING

Replace.

SPRING

RACK GUIDE

STEERING RACK

CYLINDER END SEAL

Replace.

PISTON SEAL RING

Replace.

CYLINDER HOUSING

GEARBOX HOUSING

O-RING

Replace.

RUBBER STOP

Check for damage or

deterioration.

VALVE SEAL RING

Replace.

O-RING

Replace.ProCarManuals.com

Page 1493 of 1771

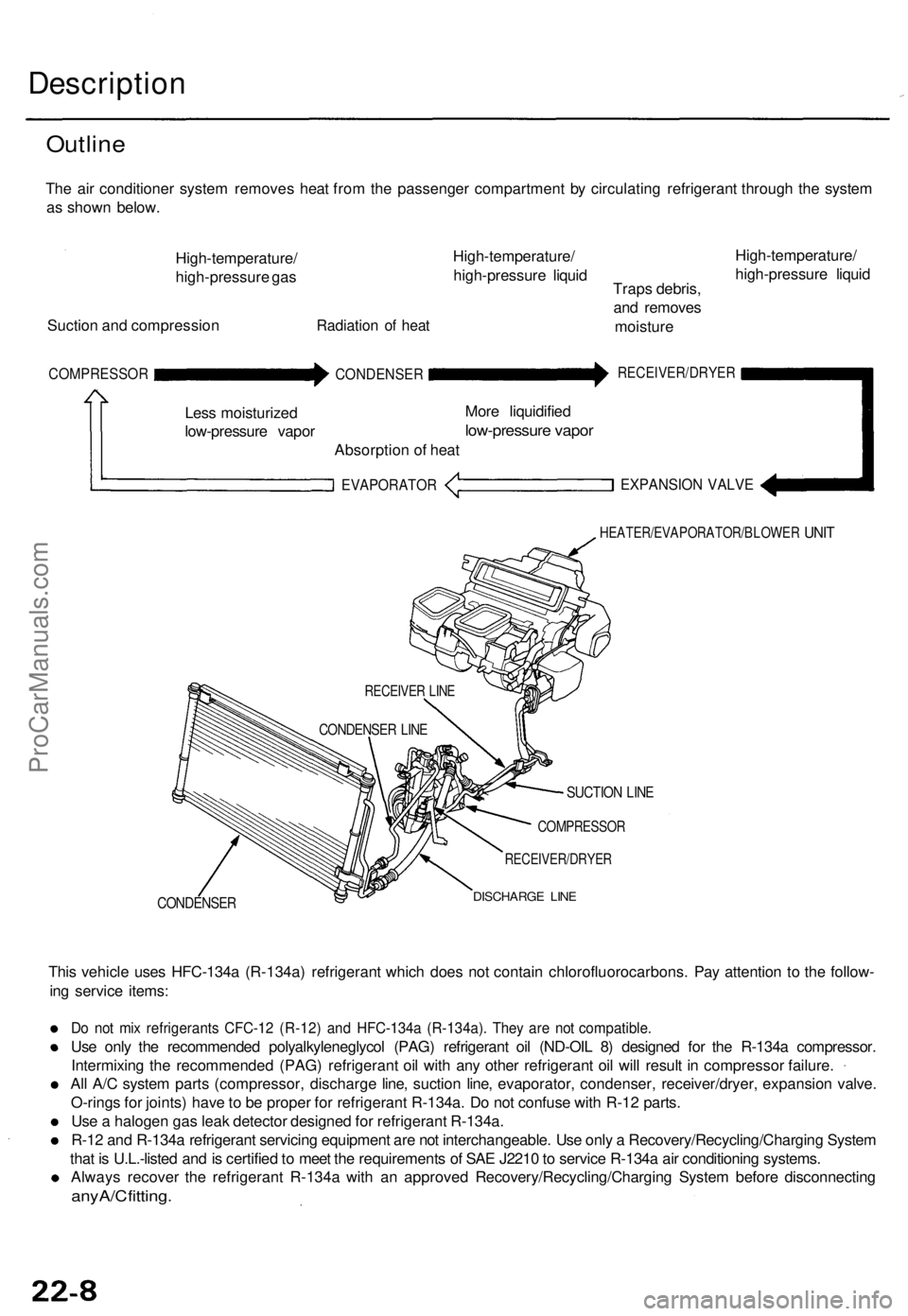

Description

Outline

The air conditioner system removes heat from the passenger compartment by circulating refrigerant through the system

as shown below.

High-temperature/

high-pressure gas

Suction and compression

Radiation of heat

High-temperature/

high-pressure liquid

Traps debris,

and removes

moisture

High-temperature/

high-pressure liquid

COMPRESSOR

Less moisturized

low-pressure vapor

CONDENSER

Absorption of heat

EVAPORATOR

More liquidified

low-pressure vapor

RECEIVER/DRYER

EXPANSION VALVE

HEATER/EVAPORATOR/BLOWER

UNIT

CONDENSER

SUCTION LINE

COMPRESSOR

RECEIVER/DRYER

DISCHARGE LINE

This vehicle uses HFC-134a (R-134a) refrigerant which does not contain chlorofluorocarbons. Pay attention to the follow-

ing service items:

Do not mix refrigerants CFC-12 (R-12) and HFC-134a (R-134a). They are not compatible.

Use only the recommended polyalkyleneglycol (PAG) refrigerant oil (ND-OIL 8) designed for the R-134a compressor.

Intermixing the recommended (PAG) refrigerant oil with any other refrigerant oil will result in compressor failure.

All A/C system parts (compressor, discharge line, suction line, evaporator, condenser, receiver/dryer, expansion valve.

O-rings for joints) have to be proper for refrigerant R-134a. Do not confuse with R-12 parts.

Use a halogen gas leak detector designed for refrigerant R-134a.

R-12 and R-134a refrigerant servicing equipment are not interchangeable. Use only a Recovery/Recycling/Charging System

that is U.L.-listed and is certified to meet the requirements of SAE J2210 to service R-134a air conditioning systems.

Always recover the refrigerant R-134a with an approved Recovery/Recycling/Charging System before disconnecting

any A/C fitting.

RECEIVER LINE

CONDENSER LINEProCarManuals.com