alternator ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 47 of 1771

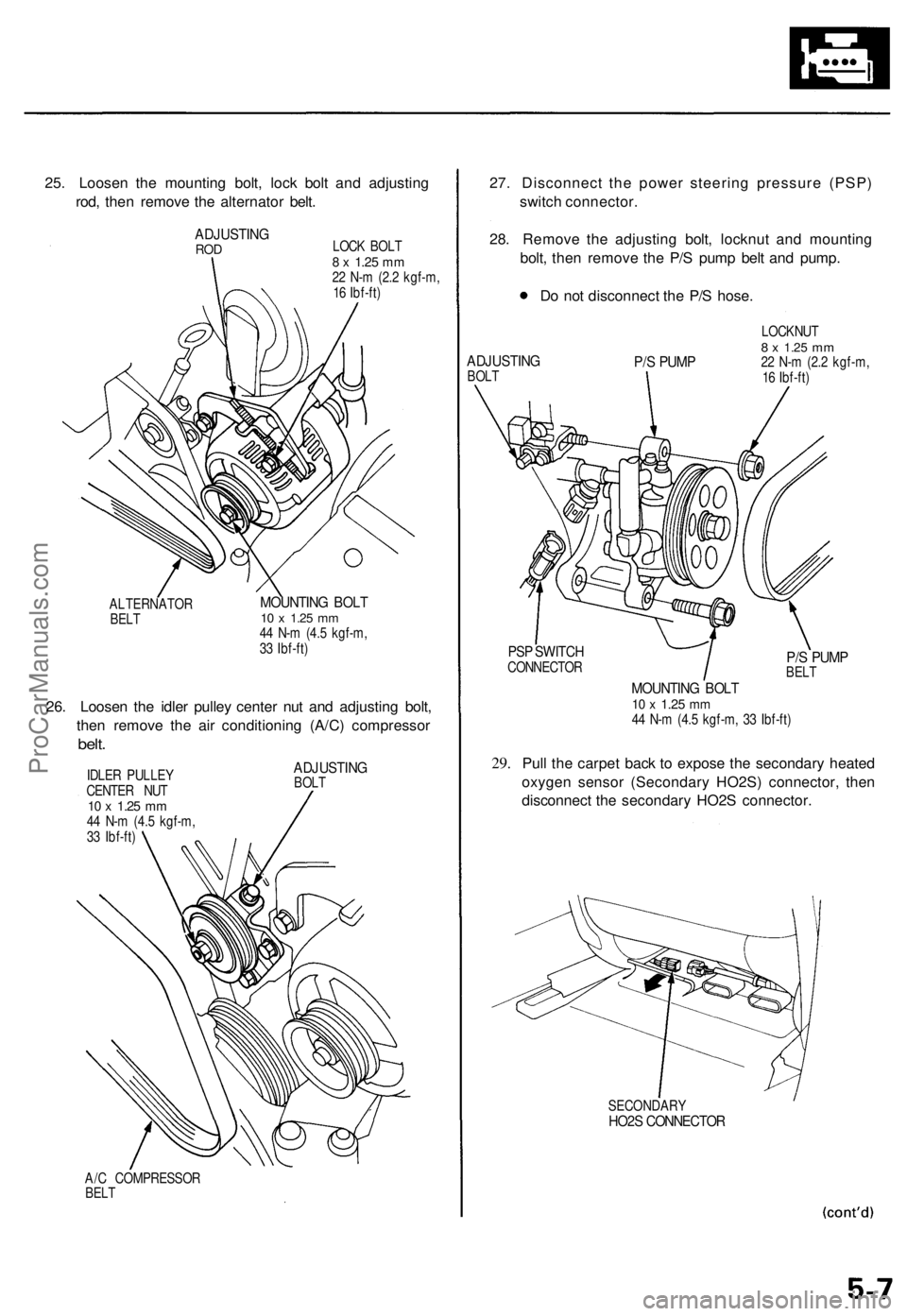

25. Loosen the mounting bolt, lock bolt and adjusting

rod, then remove the alternator belt.

ADJUSTING

ROD

LOCK BOLT

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

ALTERNATOR

BELT

MOUNTING BOLT

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

26. Loosen the idler pulley center nut and adjusting bolt,

then remove the air conditioning (A/C) compressor

belt.

IDLER PULLEY

CENTER NUT

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

ADJUSTING

BOLT

A/C COMPRESSOR

BELT

27. Disconnect the power steering pressure (PSP)

switch connector.

28. Remove the adjusting bolt, locknut and mounting

bolt, then remove the P/S pump belt and pump.

Do not disconnect the P/S hose.

ADJUSTING

BOLT

P/S PUMP

LOCKNUT

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

PSP SWITCH

CONNECTOR

29.

P/S PUMP

BELT

MOUNTING BOLT

10 x

1.25

mm

44 N-m (4.5 kgf-m, 33 Ibf-ft)

Pull the carpet back to expose the secondary heated

oxygen sensor (Secondary HO2S) connector, then

disconnect the secondary HO2S connector.

SECONDARY

HO2S CONNECTORProCarManuals.com

Page 54 of 1771

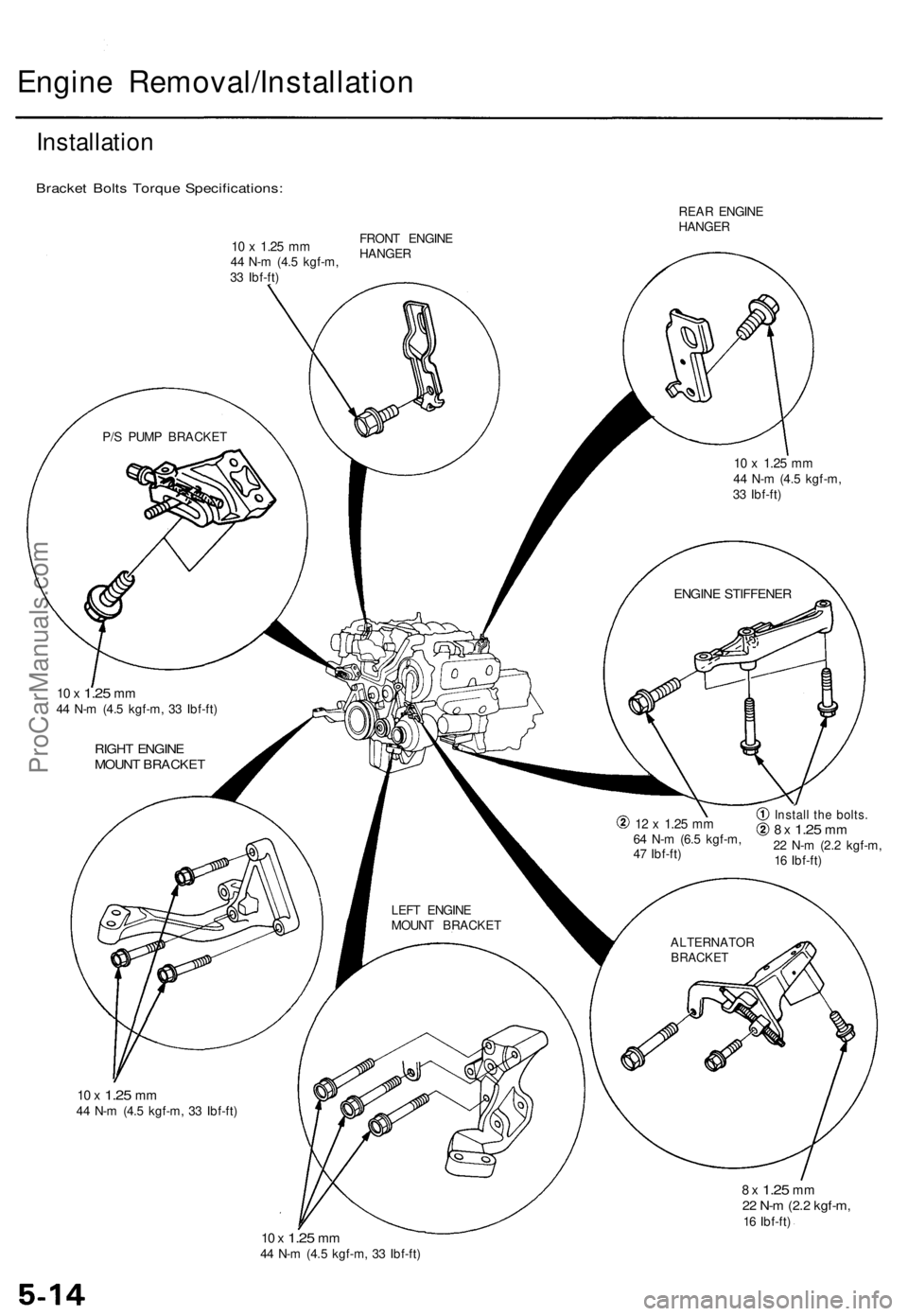

Engine Removal/Installation

Installation

Bracket Bolts Torque Specifications:

REAR ENGINE

HANGER

P/S PUMP BRACKET

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

ENGINE STIFFENER

10 x

1.25

mm

44 N-m (4.5 kgf-m, 33 Ibf-ft)

RIGHT ENGINE

MOUNT BRACKET

LEFT ENGINE

MOUNT BRACKET

12 x

1.25

mm

64 N-m (6.5 kgf-m,

47 Ibf-ft)

Install the bolts.

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

ALTERNATOR

BRACKET

10 x

1.25

mm

44 N-m (4.5 kgf-m, 33 Ibf-ft)

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

10 x

1.25

mm

44 N-m (4.5 kgf-m, 33 Ibf-ft)

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

FRONT ENGINE

HANGERProCarManuals.com

Page 78 of 1771

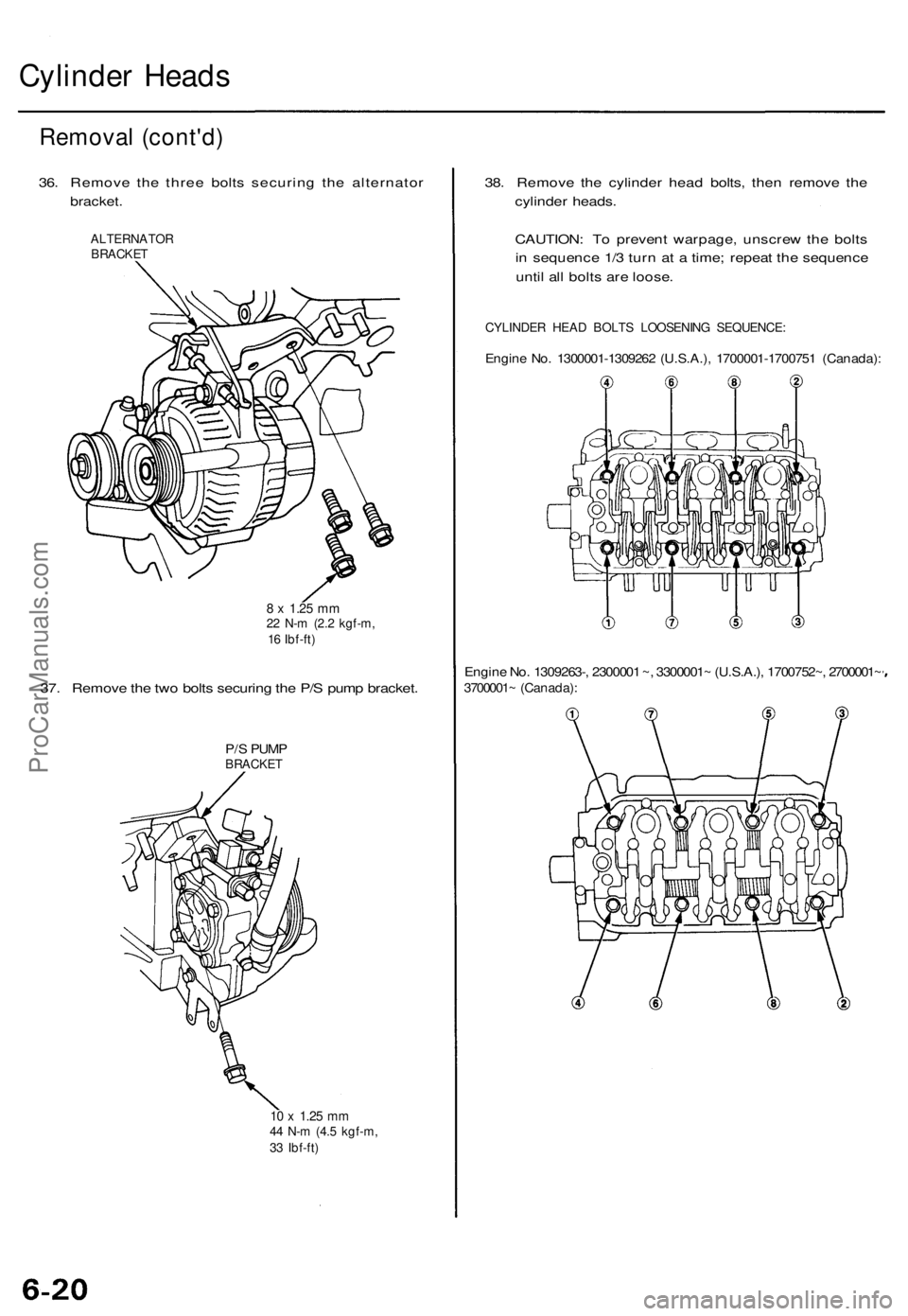

Cylinder Heads

Removal (cont'd)

36. Remove the three bolts securing the alternator

bracket.

ALTERNATOR

BRACKET

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

37. Remove the two bolts securing the P/S pump bracket.

P/S PUMP

BRACKET

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

38. Remove the cylinder head bolts, then remove the

cylinder heads.

CAUTION: To prevent warpage, unscrew the bolts

in sequence 1/3 turn at a time; repeat the sequence

until all bolts are loose.

CYLINDER HEAD BOLTS LOOSENING SEQUENCE:

Engine No. 1300001-1309262 (U.S.A.), 1700001-1700751 (Canada):

Engine No. 1309263-, 2300001 ~, 3300001~ (U.S.A.), 1700752~, 2700001~

3700001~ (Canada):ProCarManuals.com

Page 601 of 1771

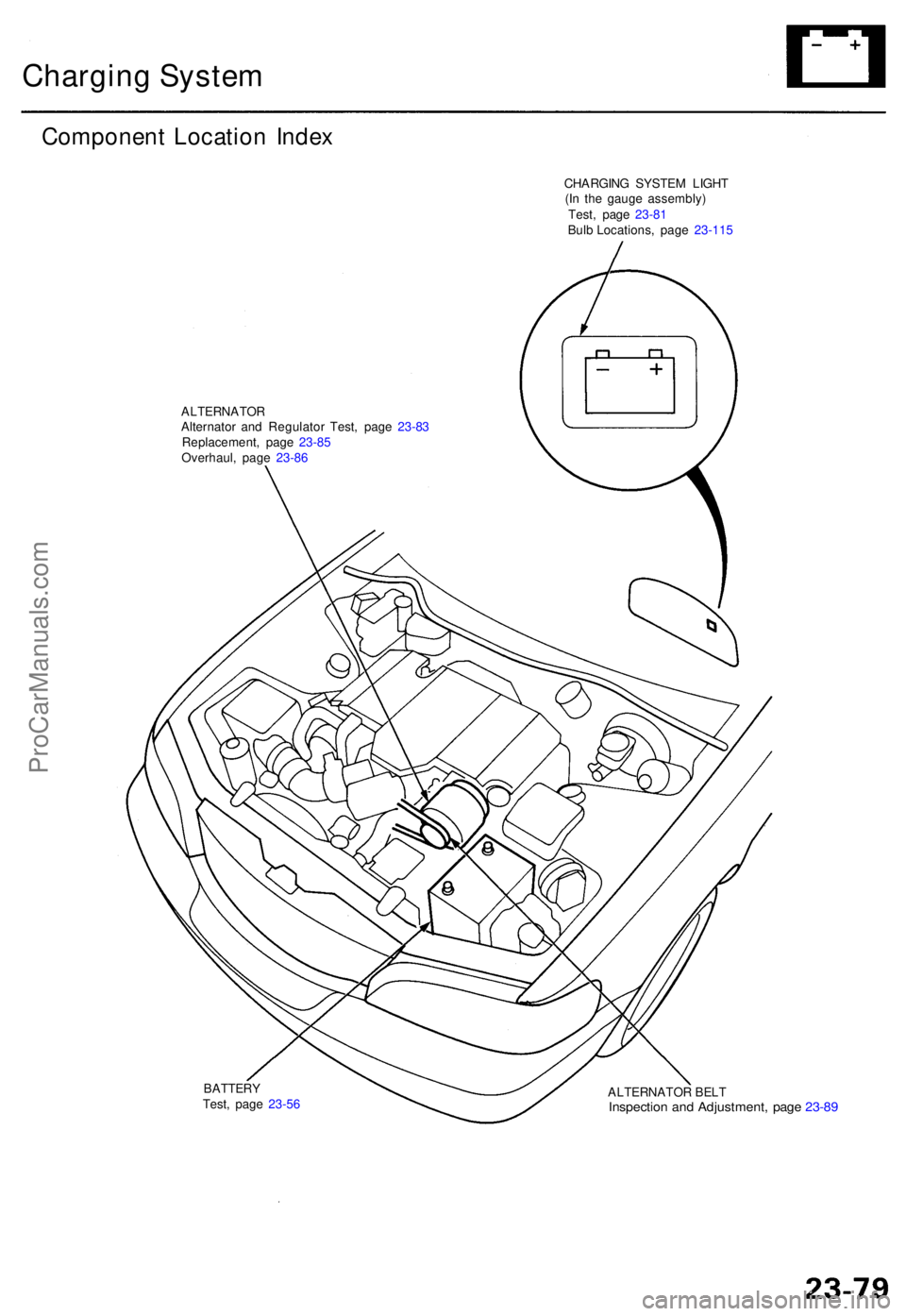

Charging Syste m

Componen t Locatio n Inde x

CHARGIN G SYSTE M LIGH T

(I n th e gaug e assembly )

ALTERNATO RAlternator an d Regulato r Test , pag e 23-8 3

Replacement , pag e 23-8 5

Overhaul , pag e 23-8 6

ALTERNATOR BEL T

Inspectio n an d Adjustment , pag e 23-8 9

BATTER YTest, pag e 23-5 6 Test

, pag e 23-8 1

Bulb Locations , pag e 23- 115

ProCarManuals.com

Page 602 of 1771

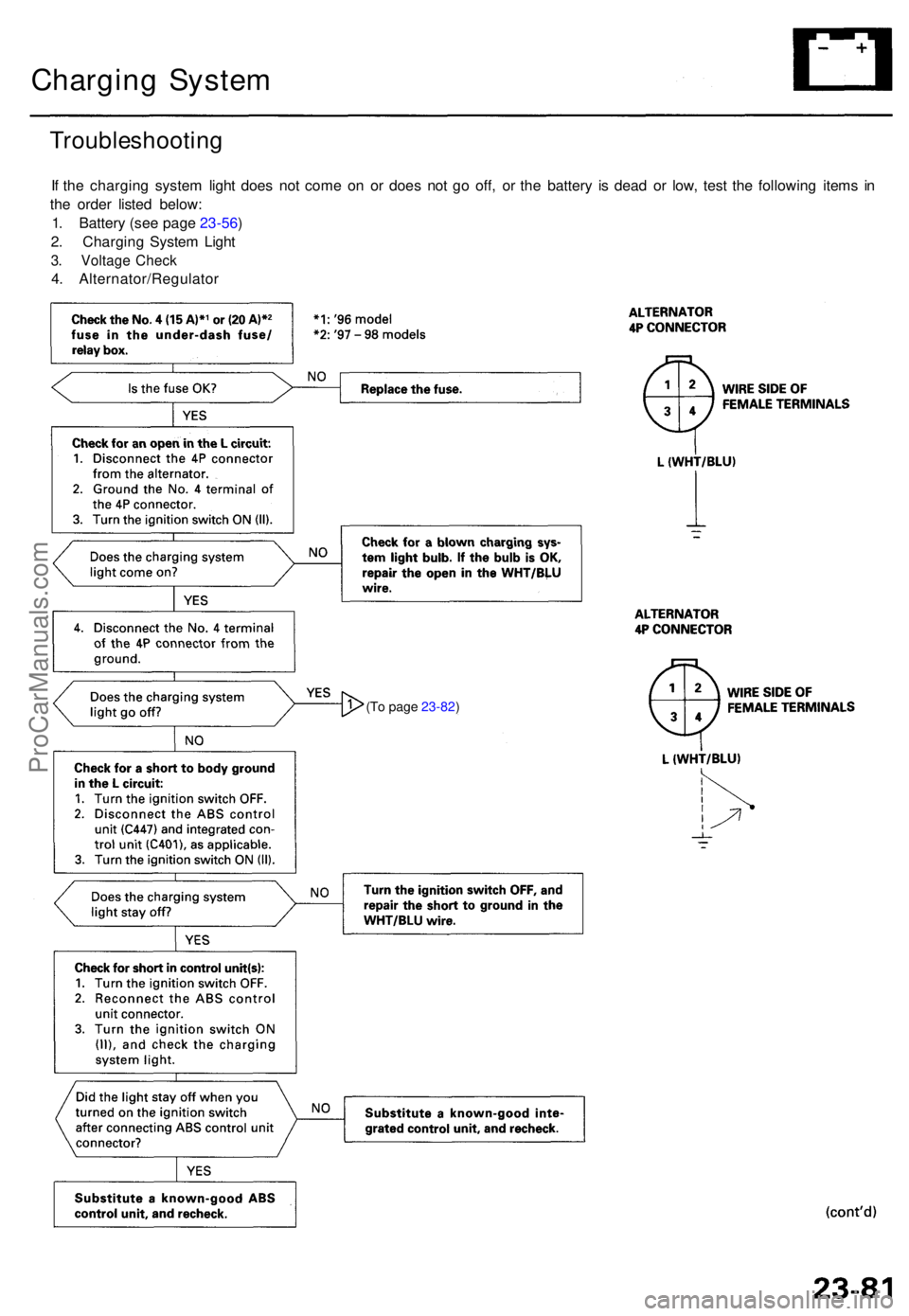

Charging Syste m

Troubleshootin g

If th e chargin g syste m ligh t doe s no t com e o n o r doe s no t g o off , o r th e batter y i s dea d o r low , tes t th e followin g item s i n

th e orde r liste d below :

1 . Batter y (se e pag e 23-56 )

2 . Chargin g Syste m Ligh t

3. Voltag e Chec k

4. Alternator/Regulato r

(To page 23-82 )

ProCarManuals.com

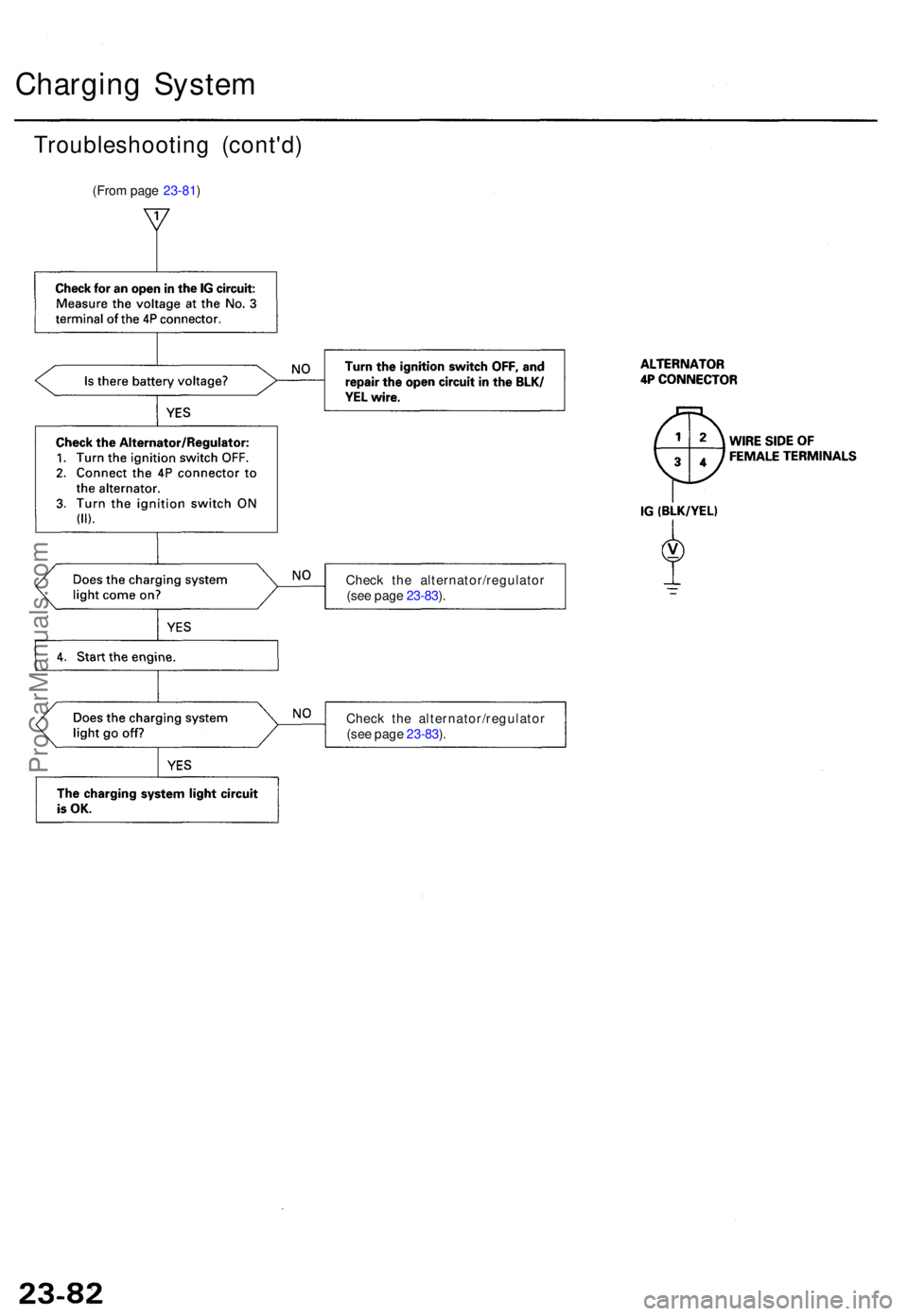

Page 603 of 1771

Charging Syste m

Troubleshootin g (cont'd )

(From page 23-81 )

Check th e alternator/regulato r

(se e pag e 23-83 ).

Chec k th e alternator/regulato r

(se e pag e 23-83 ).

ProCarManuals.com

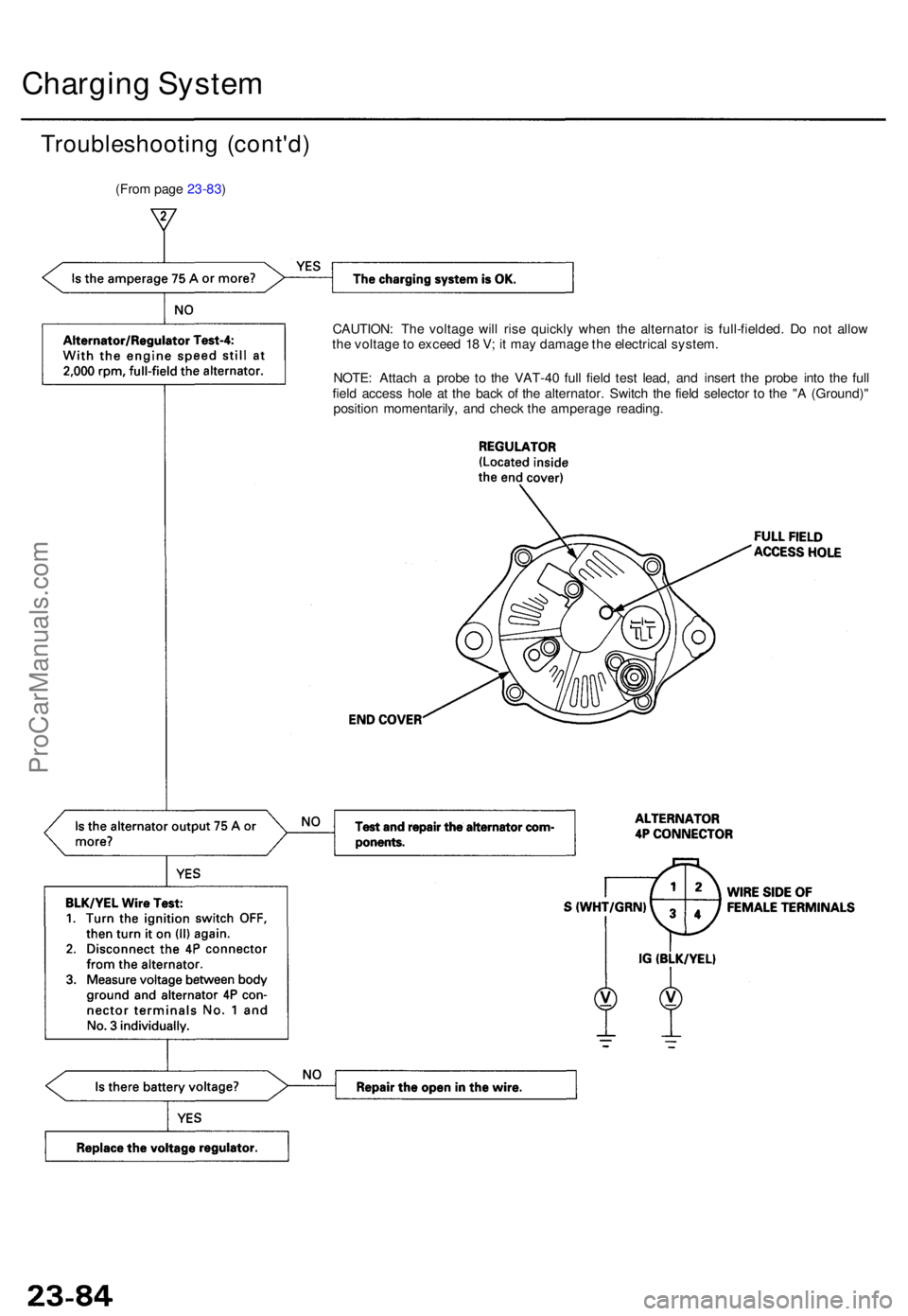

Page 605 of 1771

Charging Syste m

Troubleshootin g (cont'd )

(From page 23-83 )

CAUTION: Th e voltag e wil l ris e quickl y whe n th e alternato r i s full-fielded . D o no t allo w

th e voltag e to excee d 1 8 V ; i t ma y damag e th e electrica l system .

NOTE : Attac h a prob e t o th e VAT-4 0 ful l fiel d tes t lead , an d inser t th e prob e int o th e ful l

fiel d acces s hol e a t th e bac k o f th e alternator . Switc h th e fiel d selecto r t o th e " A (Ground) "

positio n momentarily , an d chec k th e amperag e reading .

ProCarManuals.com

Page 606 of 1771

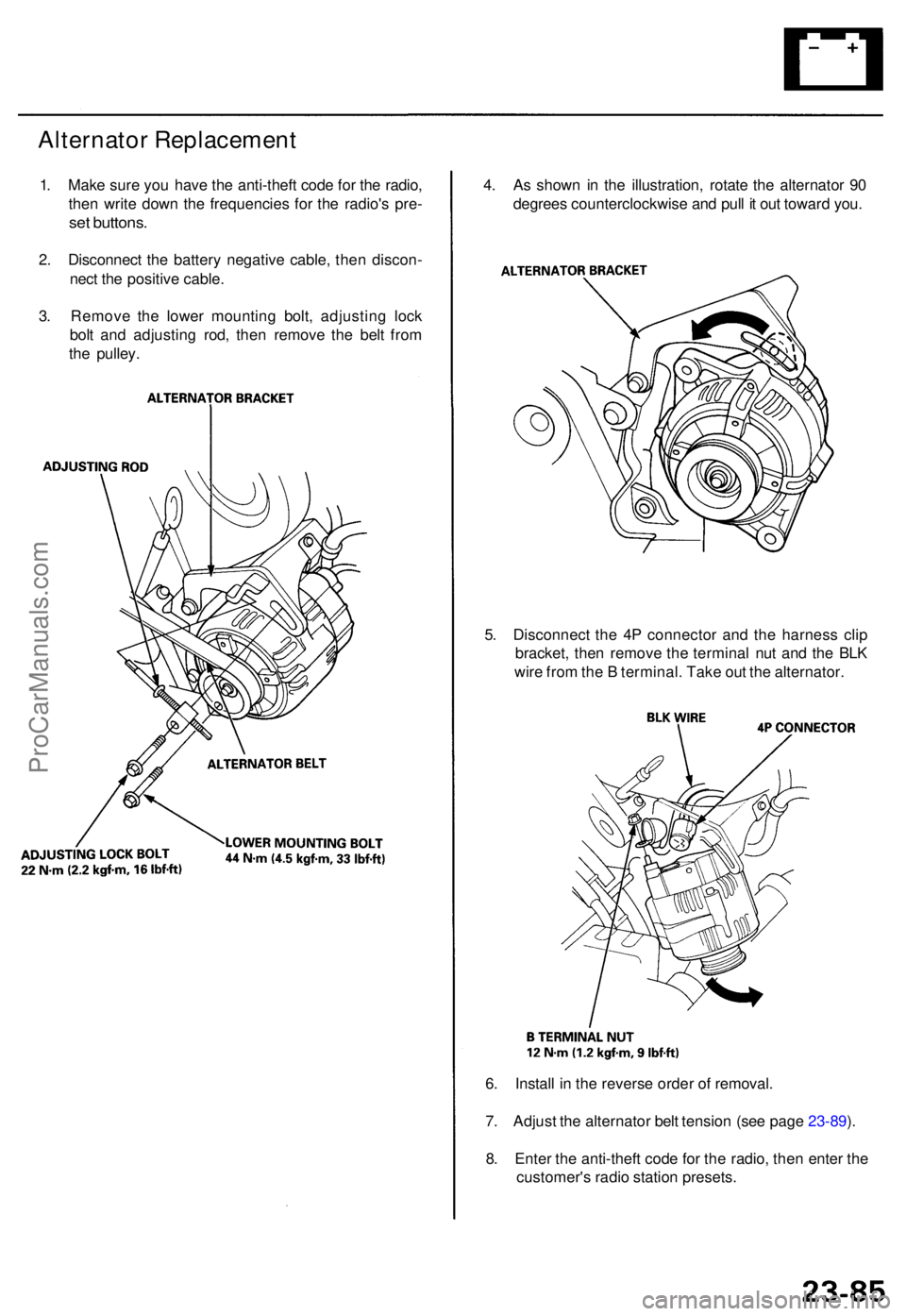

Alternator Replacemen t

1. Mak e sur e yo u hav e th e anti-thef t cod e fo r th e radio ,

the n writ e dow n th e frequencie s fo r th e radio' s pre -

set buttons .

2. Disconnec t th e batter y negativ e cable , the n discon -

nec t th e positiv e cable .

3 . Remov e th e lowe r mountin g bolt , adjustin g loc k

bol t an d adjustin g rod , the n remov e th e bel t fro m

th e pulley . 4

. A s show n i n th e illustration , rotat e th e alternato r 9 0

degree s counterclockwis e an d pul l i t ou t towar d you .

5 . Disconnec t th e 4 P connecto r an d th e harnes s cli p

bracket , the n remov e th e termina l nu t an d th e BL K

wir e fro m th e B terminal . Tak e ou t th e alternator .

6 . Instal l i n th e revers e orde r o f removal .

7 . Adjus t th e alternato r bel t tensio n (se e pag e 23-89 ).

8 . Ente r th e anti-theft code fo r th e radio , the n ente r th e

customer' s radi o statio n presets .

ProCarManuals.com

Page 608 of 1771

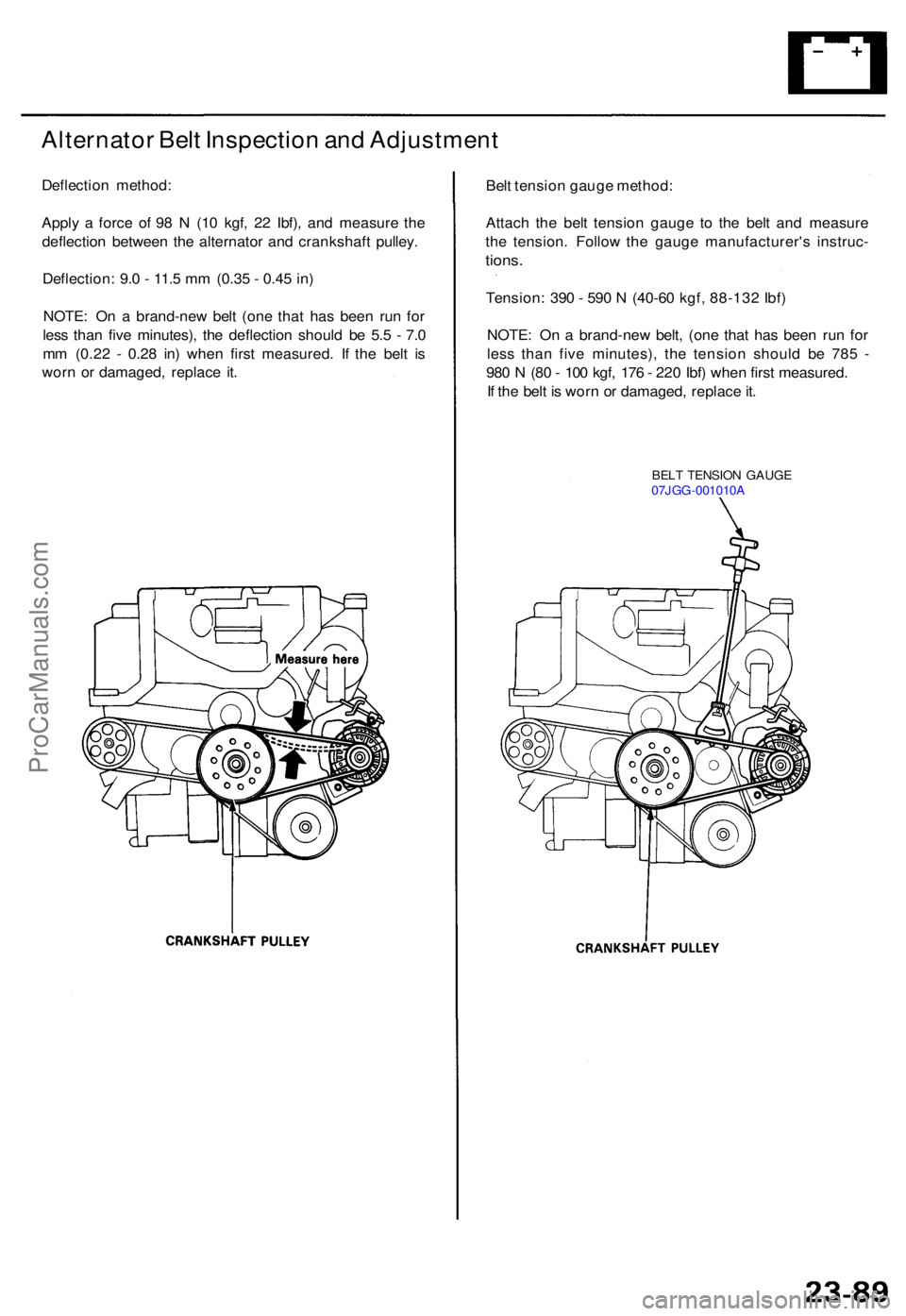

Alternator Bel t Inspectio n an d Adjustmen t

Deflection method :

Appl y a forc e o f 9 8 N (1 0 kgf , 2 2 Ibf) , an d measur e th e

deflectio n betwee n th e alternato r an d crankshaf t pulley .

Deflection : 9. 0 - 11. 5 m m (0.3 5 - 0.4 5 in )

NOTE : O n a brand-ne w bel t (on e tha t ha s bee n ru n fo r

les s tha n fiv e minutes) , th e deflectio n shoul d b e 5. 5 - 7. 0

m m (0.2 2 - 0.2 8 in ) whe n firs t measured . I f th e bel t i s

wor n o r damaged , replac e it . Bel

t tensio n gaug e method :

Attac h th e bel t tensio n gaug e t o th e bel t an d measur e

th e tension . Follo w th e gaug e manufacturer' s instruc -

tions.

Tension : 39 0 - 59 0 N (4 0-6 0 kgf , 88-13 2 Ibf )

NOTE : O n a brand-ne w belt , (on e tha t ha s bee n ru n fo r

les s tha n fiv e minutes) , th e tensio n shoul d b e 78 5 -

98 0 N (8 0 - 10 0 kgf , 17 6 - 22 0 Ibf ) whe n firs t measured .

I f th e bel t i s wor n o r damaged , replac e it .

BEL T TENSIO N GAUG E

07JG G-001010 A

ProCarManuals.com

Page 877 of 1771

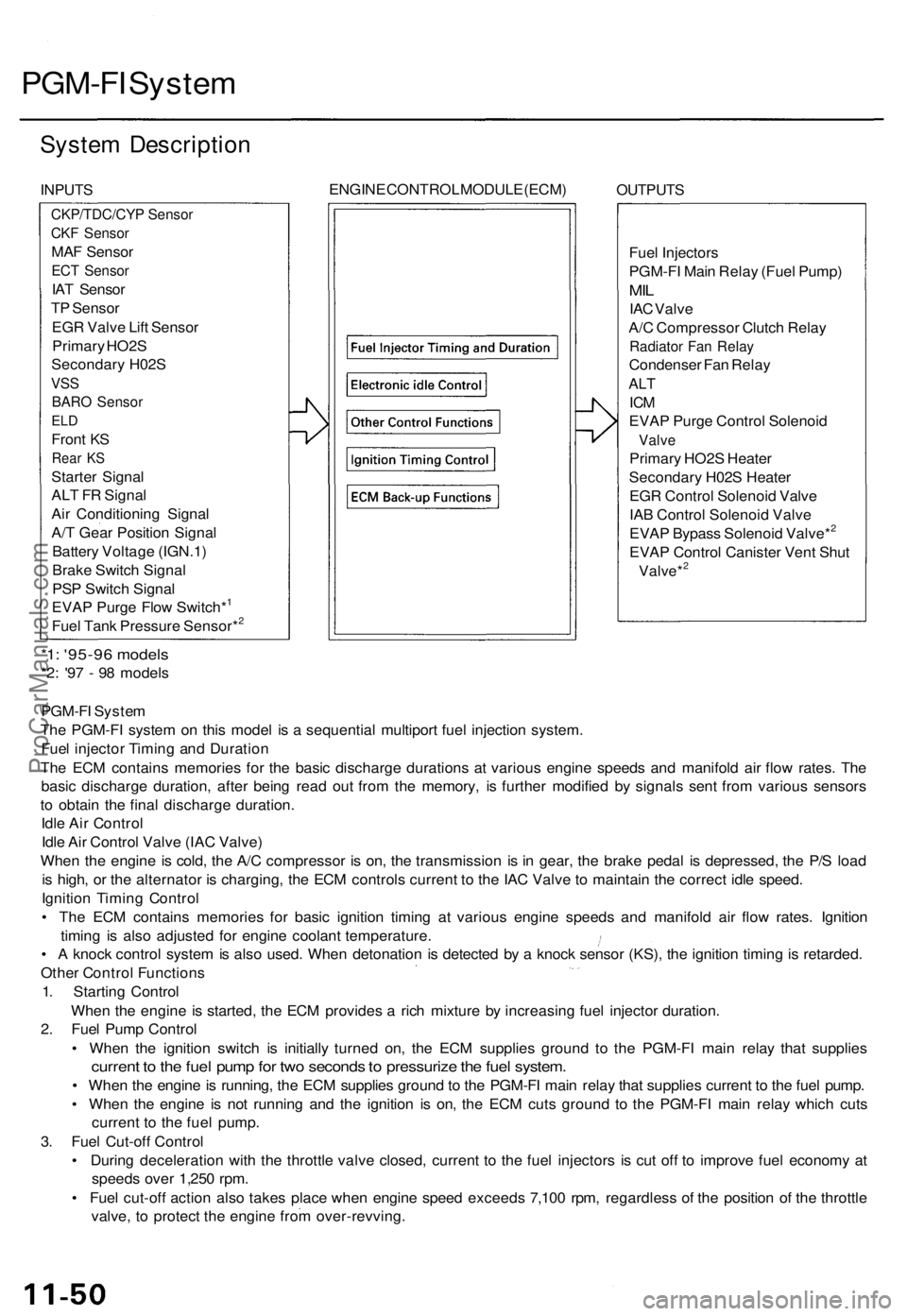

PGM-FI System

System Description

INPUTS

ENGINE CONTROL MODULE (ECM)

OUTPUTS

Fuel Injectors

PGM-FI Main Relay (Fuel Pump)

MIL

IAC Valve

A/C Compressor Clutch Relay

Radiator Fan Relay

Condenser Fan Relay

ALT

ICM

EVAP Purge Control Solenoid

Valve

Primary HO2S Heater

Secondary H02S Heater

EGR Control Solenoid Valve

IAB Control Solenoid Valve

EVAP Bypass Solenoid Valve*2

EVAP Control Canister Vent Shut

Valve*2

*1: '95-96 models

*2: '97 - 98 models

PGM-FI System

The PGM-FI system on this model is a sequential multiport fuel injection system.

Fuel injector Timing and Duration

The ECM contains memories for the basic discharge durations at various engine speeds and manifold air flow rates. The

basic discharge duration, after being read out from the memory, is further modified by signals sent from various sensors

to obtain the final discharge duration.

Idle Air Control

Idle Air Control Valve (IAC Valve)

When the engine is cold, the A/C compressor is on, the transmission is in gear, the brake pedal is depressed, the P/S load

is high, or the alternator is charging, the ECM controls current to the IAC Valve to maintain the correct idle speed.

Ignition Timing Control

• The ECM contains memories for basic ignition timing at various engine speeds and manifold air flow rates. Ignition

timing is also adjusted for engine coolant temperature.

• A knock control system is also used. When detonation is detected by a knock sensor (KS), the ignition timing is retarded.

Other Control Functions

1. Starting Control

When the engine is started, the ECM provides a rich mixture by increasing fuel injector duration.

2. Fuel Pump Control

• When the ignition switch is initially turned on, the ECM supplies ground to the PGM-FI main relay that supplies

current to the fuel pump for two seconds to pressurize the fuel system.

• When the engine is running, the ECM supplies ground to the PGM-FI main relay that supplies current to the fuel pump.

• When the engine is not running and the ignition is on, the ECM cuts ground to the PGM-FI main relay which cuts

current to the fuel pump.

3. Fuel Cut-off Control

• During deceleration with the throttle valve closed, current to the fuel injectors is cut off to improve fuel economy at

speeds over 1,250 rpm.

• Fuel cut-off action also takes place when engine speed exceeds 7,100 rpm, regardless of the position of the throttle

valve, to protect the engine from over-revving.

CKP/TDC/CYP Sensor

CKF Sensor

MAF Sensor

ECT Sensor

IAT Sensor

TP Sensor

EGR Valve Lift Sensor

Primary HO2S

Secondary H02S

VSS

BARO Sensor

ELD

Front KS

Rear KS

Starter Signal

ALT FR Signal

Air Conditioning Signal

A/T Gear Position Signal

Battery Voltage (IGN.1)

Brake Switch Signal

PSP Switch Signal

EVAP Purge Flow Switch*1

Fuel Tank Pressure Sensor*2ProCarManuals.com