belt ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 47 of 1771

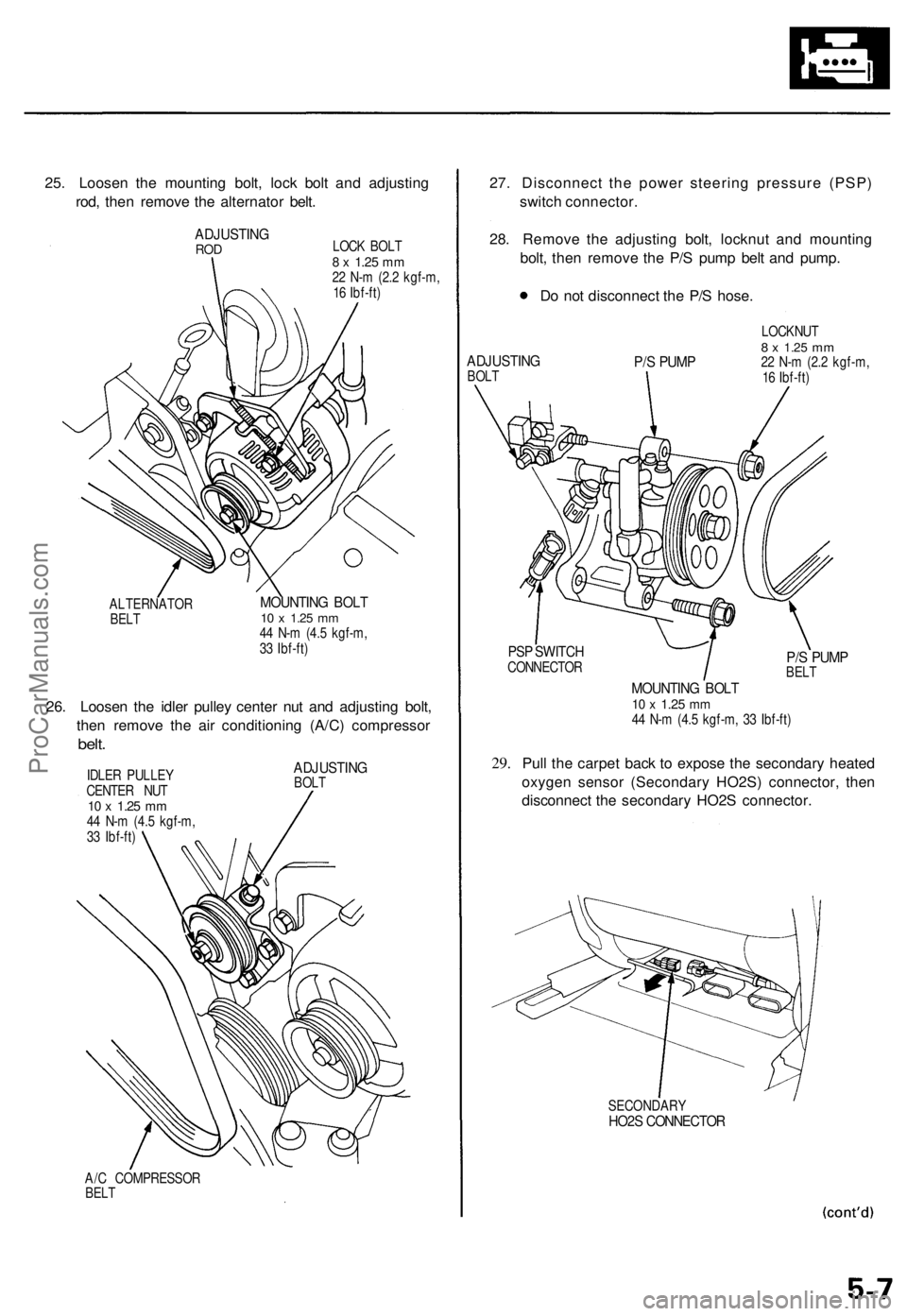

25. Loosen the mounting bolt, lock bolt and adjusting

rod, then remove the alternator belt.

ADJUSTING

ROD

LOCK BOLT

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

ALTERNATOR

BELT

MOUNTING BOLT

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

26. Loosen the idler pulley center nut and adjusting bolt,

then remove the air conditioning (A/C) compressor

belt.

IDLER PULLEY

CENTER NUT

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

ADJUSTING

BOLT

A/C COMPRESSOR

BELT

27. Disconnect the power steering pressure (PSP)

switch connector.

28. Remove the adjusting bolt, locknut and mounting

bolt, then remove the P/S pump belt and pump.

Do not disconnect the P/S hose.

ADJUSTING

BOLT

P/S PUMP

LOCKNUT

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

PSP SWITCH

CONNECTOR

29.

P/S PUMP

BELT

MOUNTING BOLT

10 x

1.25

mm

44 N-m (4.5 kgf-m, 33 Ibf-ft)

Pull the carpet back to expose the secondary heated

oxygen sensor (Secondary HO2S) connector, then

disconnect the secondary HO2S connector.

SECONDARY

HO2S CONNECTORProCarManuals.com

Page 61 of 1771

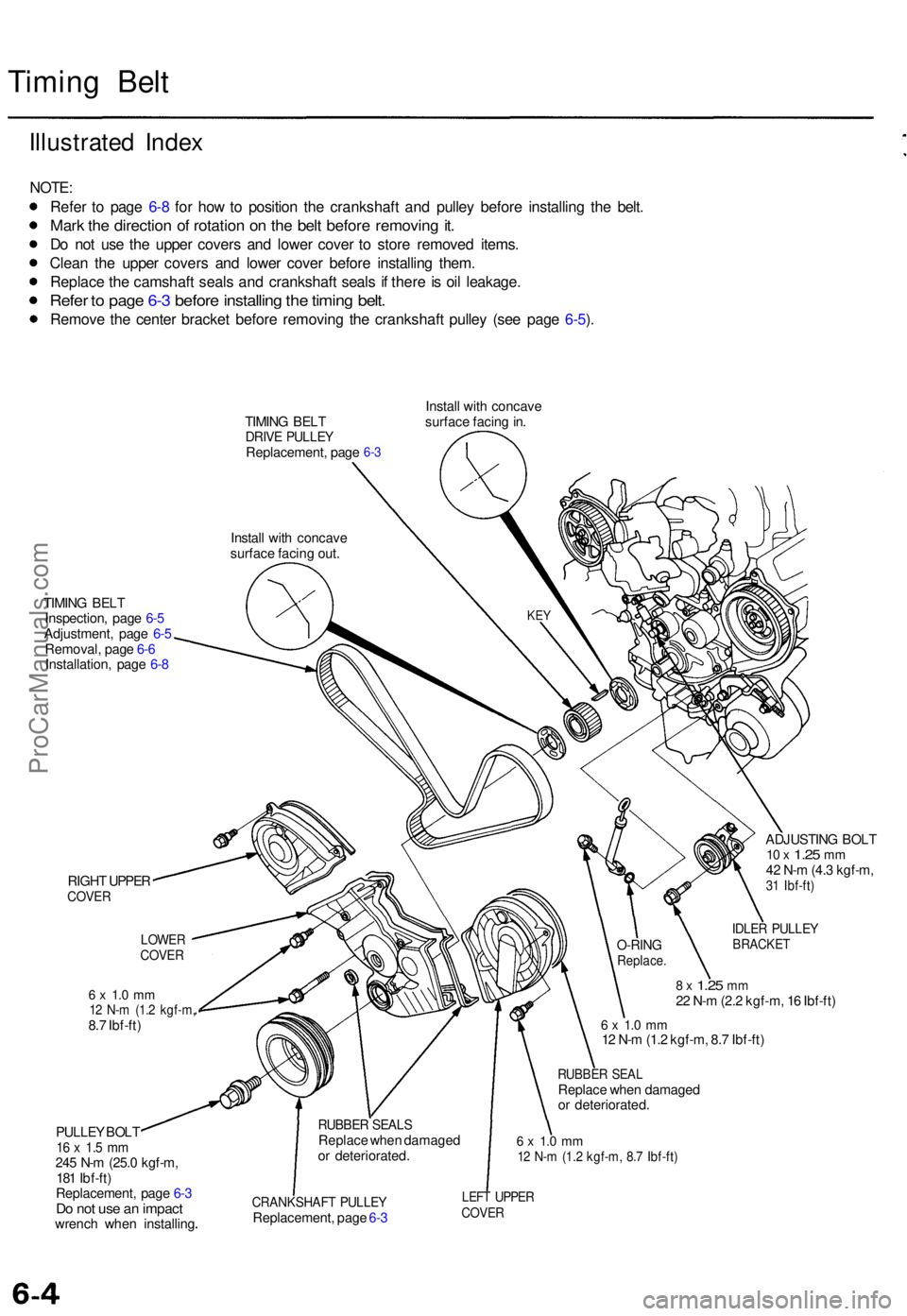

Timing Bel t

Illustrate d Inde x

NOTE :

Refe r t o pag e 6- 8 fo r ho w to positio n th e crankshaft and pulle y befor e installin g th e belt .

Mark th e directio n o f rotatio n o n th e bel t befor e removin g it .

Do no t us e th e uppe r cover s an d lowe r cove r t o stor e remove d items .

Clea n th e uppe r cover s an d lowe r cove r befor e installin g them .

Replac e th e camshaf t seal s an d crankshaf t seal s i f ther e is oi l leakage .

Refer t o pag e 6- 3 befor e installin g th e timin g belt .

Remov e th e cente r bracke t befor e removin g th e crankshaf t pulle y (se e pag e 6-5 ).

TIMIN G BEL TDRIV E PULLE YReplacement , pag e

Instal l wit h concav e

surfac e facin g out . Instal

l wit h concav e

surfac e facin g in .6-3

TIMIN G BEL T

Inspection , pag e 6- 5

Adjustment , pag e 6-5

Removal , pag e 6- 6

Installation , pag e 6- 8

RIGH T UPPE R

COVE R

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,8.7 Ibf-ft )

PULLE Y BOL T

16 x 1. 5 m m245 N- m (25. 0 kgf-m ,

18 1 Ibf-ft )

Replacement , pag e 6- 3

Do no t us e a n impac twrench whe n installin g ADJUSTIN

G BOL T

10 x 1.2 5 mm42 N- m (4. 3 kgf-m ,31 Ibf-ft )

IDLER PULLE YBRACKE T

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

RUBBE R SEA LReplac e whe n damage d

o r deteriorated .

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

CRANKSHAF T PULLE YReplacement , pag e 6- 3

LEF T UPPE RCOVER

RUBBE R SEAL SReplac e whe n damage d

o r deteriorated .

O-RINGReplace .

LOWERCOVER

KEY

ProCarManuals.com

Page 62 of 1771

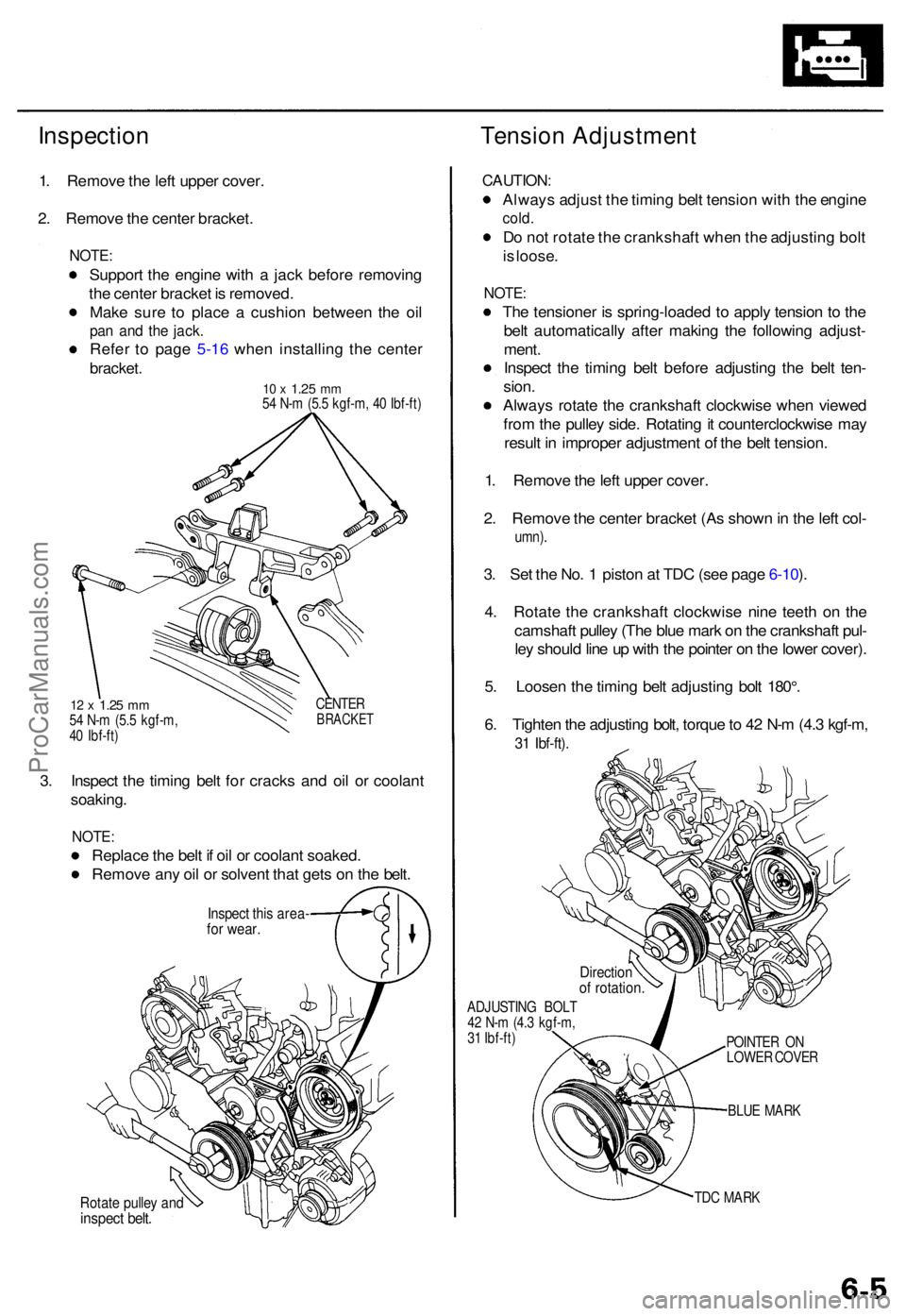

InspectionTension Adjustmen t

1. Remov e th e lef t uppe r cover .

2 . Remov e th e cente r bracket .

NOTE:

Suppor t th e engin e wit h a jac k befor e removin g

th e cente r bracke t i s removed .

Mak e sur e t o plac e a cushio n betwee n th e oi l

pan an d th e jack .

Refe r t o pag e 5-1 6 whe n installin g th e cente r

bracket .

10 x 1.2 5 mm54 N- m (5. 5 kgf-m , 4 0 Ibf-ft )

12 x 1.2 5 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft ) CENTE

RBRACKE T

3. Inspec t th e timin g bel t fo r crack s an d oi l o r coolan t

soaking .

NOTE:

Replac e th e bel t i f oi l o r coolan t soaked .

Remov e an y oi l o r solven t tha t get s o n th e belt .

Inspec t thi s area -for wear .

Rotate pulle y an dinspec t belt .

CAUTION :

Always adjus t th e timin g bel t tensio n wit h th e engin e

cold.

Do no t rotat e th e crankshaf t whe n th e adjustin g bol t

i s loose .

NOTE :

The tensione r i s spring-loade d t o appl y tensio n t o th e

bel t automaticall y afte r makin g th e followin g adjust -

ment .

Inspec t th e timin g bel t befor e adjustin g th e bel t ten -

sion .

Alway s rotat e th e crankshaf t clockwis e whe n viewe d

fro m th e pulle y side . Rotatin g it counterclockwis e ma y

resul t i n imprope r adjustmen t o f th e bel t tension .

1 . Remov e th e lef t uppe r cover .

2 . Remov e th e cente r bracke t (A s show n in th e lef t col -

umn) .

3. Se t th e No . 1 pisto n a t TD C (se e pag e 6-10 ).

4 . Rotat e th e crankshaf t clockwis e nin e teet h o n th e

camshaf t pulle y (Th e blu e mar k o n th e crankshaf t pul -

le y shoul d lin e u p wit h th e pointe r o n th e lowe r cover) .

5 . Loose n th e timin g bel t adjustin g bol t 180° .

6 . Tighte n th e adjustin g bolt , torqu e to 4 2 N- m (4. 3 kgf-m ,

31 Ibf-ft) .

ADJUSTIN G BOL T

4 2 N- m (4. 3 kgf-m ,

3 1 Ibf-ft )

BLUE MAR K

TD C MAR K

POINTE

R O N

LOWE R COVE R

Directio nof rotation .

ProCarManuals.com

Page 63 of 1771

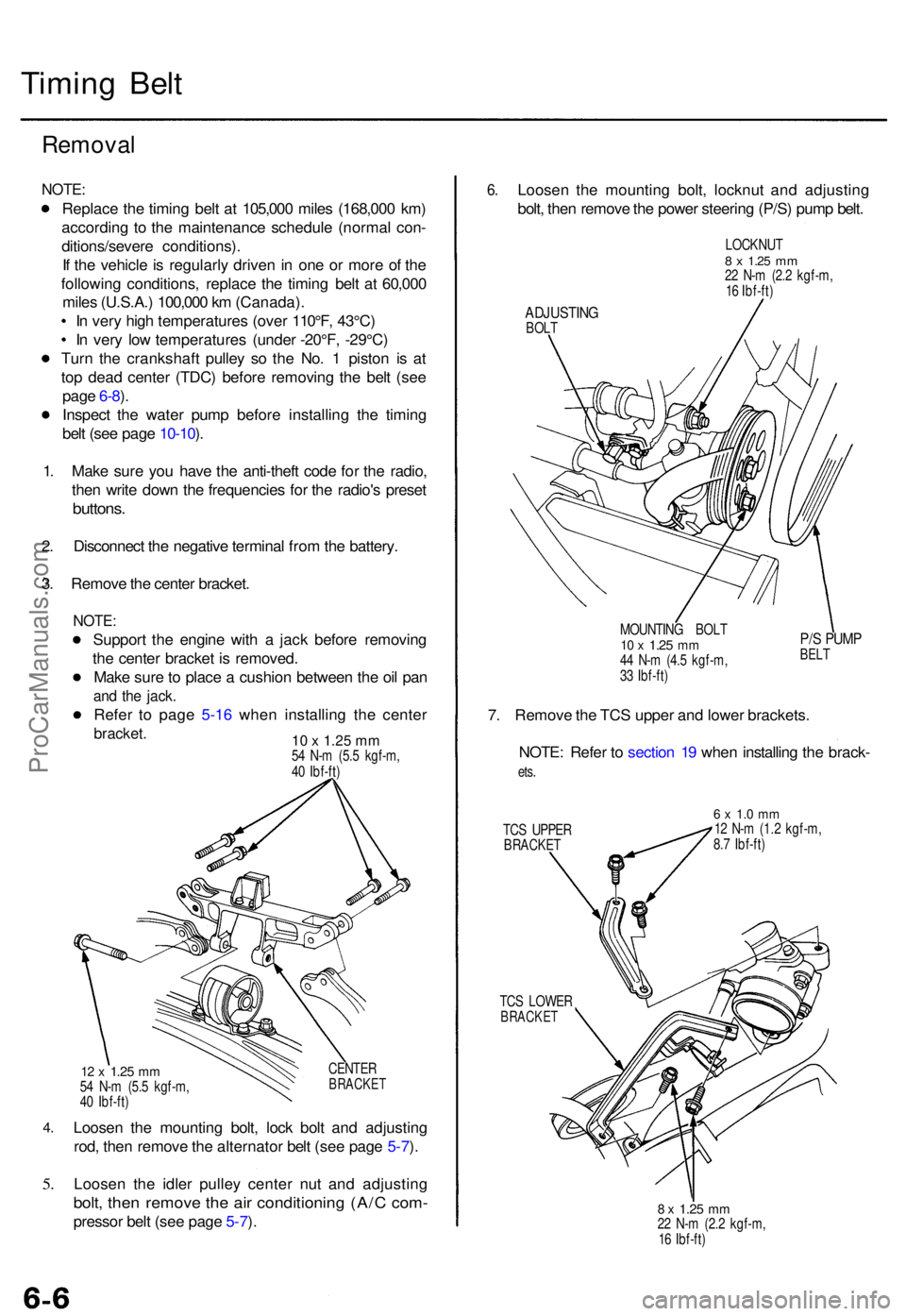

Timing Bel t

Remova l

NOTE:

Replac e th e timin g bel t a t 105,00 0 mile s (168,00 0 km )

accordin g t o th e maintenanc e schedul e (norma l con -

ditions/sever e conditions) .

I f th e vehicl e is regularl y drive n i n on e o r mor e o f th e

followin g conditions , replac e th e timin g bel t a t 60,00 0

mile s (U.S.A. ) 100,00 0 k m (Canada) .

I n ver y hig h temperature s (ove r 110°F , 43°C )

I n ver y lo w temperature s (unde r -20°F , -29°C )

Tur n th e crankshaf t pulle y s o th e No . 1 pisto n i s a t

to p dea d cente r (TDC ) befor e removin g th e bel t (se e

pag e 6-8 ).

Inspec t th e wate r pum p befor e installin g th e timin g

bel t (se e pag e 10-10 ).

1 . Mak e sur e yo u hav e th e anti-thef t cod e fo r th e radio ,

the n writ e dow n th e frequencie s fo r th e radio' s prese t

buttons .

2. Disconnec t th e negativ e termina l fro m th e battery .

3 . Remov e th e cente r bracket .

NOTE:

Suppor t th e engin e wit h a jac k befor e removin g

th e cente r bracke t i s removed .

Mak e sur e to plac e a cushio n betwee n th e oi l pa n

and th e jack .

Refer t o pag e 5-1 6 whe n installin g th e cente r

bracket. 10 x 1.25 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft )

4.

5.

CENTE RBRACKE T12 x 1.2 5 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft )

Loose n th e mountin g bolt , loc k bol t an d adjustin g

rod , the n remov e th e alternato r bel t (se e pag e 5-7 ).

Loose n th e idle r pulle y cente r nu t an d adjustin g

bolt, the n remov e th e ai r conditionin g (A/ C com -

presso r bel t (se e pag e 5-7 ).

6 .Loose n th e mountin g bolt , locknu t an d adjustin g

bolt , the n remov e th e powe r steerin g (P/S ) pum p belt .

LOCKNU T8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

ADJUSTIN GBOLT

MOUNTING BOL T

10 x 1.2 5 mm44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

P/S PUM PBELT

7. Remov e th e TC S uppe r an d lowe r brackets .

NOTE : Refe r t o sectio n 1 9 whe n installin g th e brack -

ets.

TC S UPPE RBRACKE T

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

TC S LOWE R

BRACKE T

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

ProCarManuals.com

Page 65 of 1771

Timing Belt

Removal (cont'd)

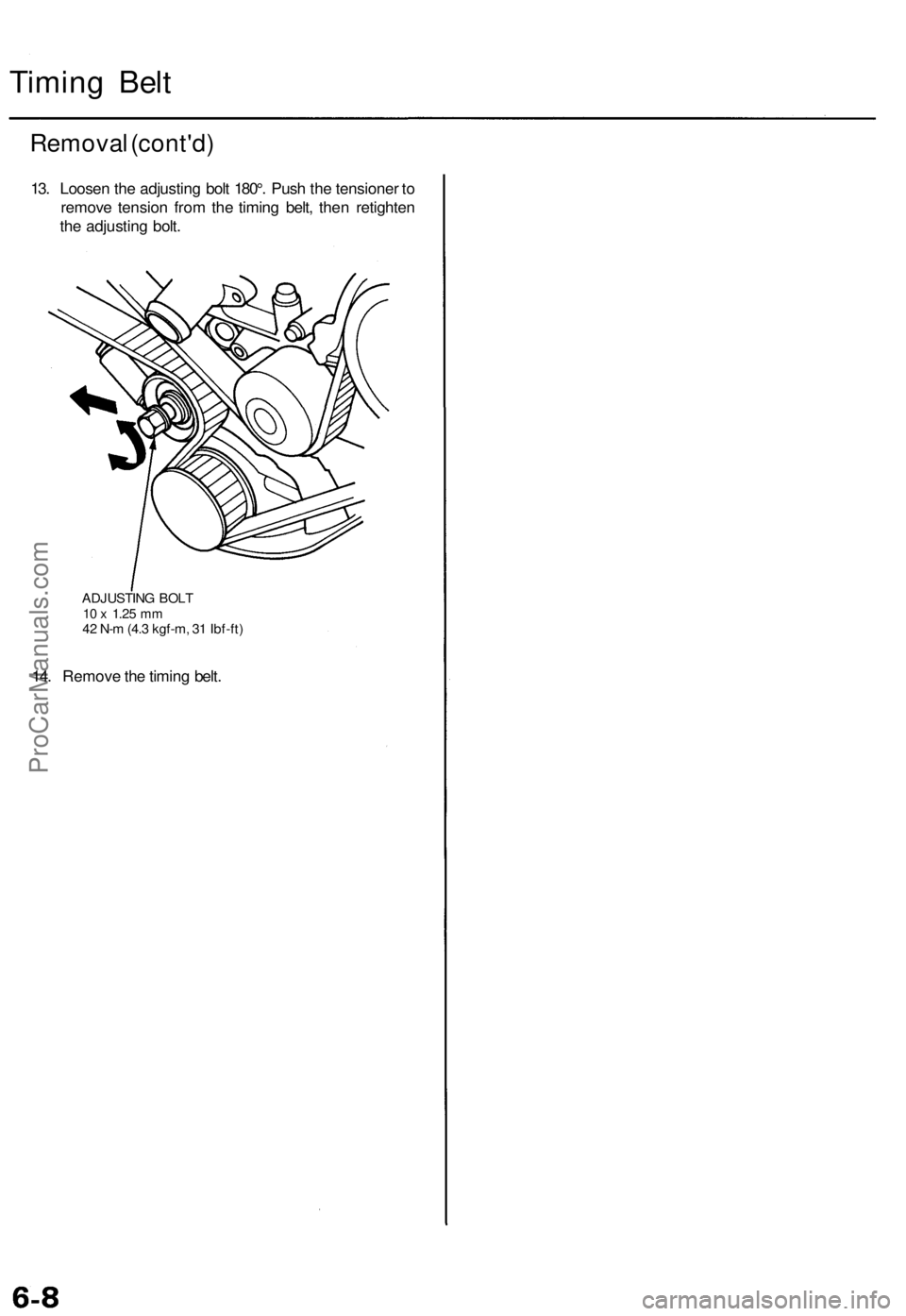

13. Loosen the adjusting bolt 180°. Push the tensioner to

remove tension from the timing belt, then retighten

the adjusting bolt.

ADJUSTING BOLT

10 x

1.25

mm

42 N-m (4.3 kgf-m, 31 Ibf-ft)

14. Remove the timing belt.ProCarManuals.com

Page 67 of 1771

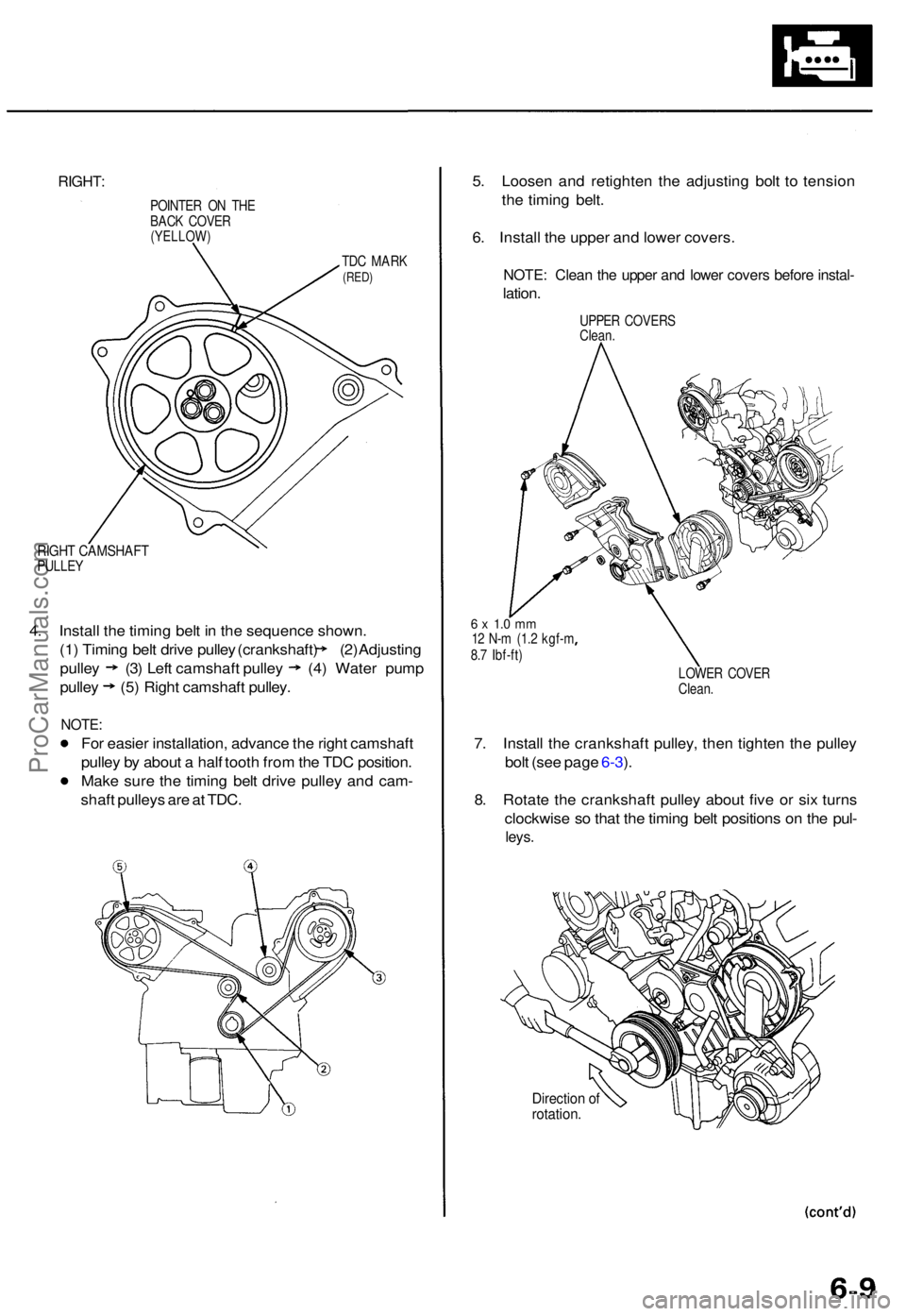

RIGHT:

POINTE R O N TH E

BAC K COVE R

(YELLOW )

TDC MAR K(RED)

RIGHT CAMSHAF TPULLEY

4. Instal l th e timin g bel t i n th e sequenc e shown .

(1) Timin g bel t driv e pulle y (crankshaft ) (2 ) Adjustin g

pulley (3 ) Lef t camshaf t pulle y (4) Wate r pum p

pulley (5) Right camshaf t pulley .

NOTE:

For easie r installation , advanc e th e righ t camshaf t

pulle y b y abou t a hal f toot h fro m th e TD C position .

Mak e sur e th e timin g bel t driv e pulle y an d cam -

shaf t pulley s ar e a t TDC . 5

. Loose n an d retighte n th e adjustin g bol t t o tensio n

th e timin g belt .

6 . Instal l th e uppe r an d lowe r covers .

NOTE: Clea n th e uppe r an d lowe r cover s befor e instal -

lation.

UPPE R COVER S

Clean .

6 x 1. 0 m m12 N- m (1. 2 kgf- m

8. 7 Ibf-ft )

LOWER COVE R

Clean .

7. Instal l th e crankshaf t pulley , the n tighte n th e pulle y

bol t (se e pag e 6-3 ).

8 . Rotat e th e crankshaf t pulle y abou t fiv e o r si x turn s

clockwis e s o tha t th e timin g bel t position s o n th e pul -

leys .

Directio n o frotation .

ProCarManuals.com

Page 68 of 1771

Timing Bel t

Installatio n (cont'd )

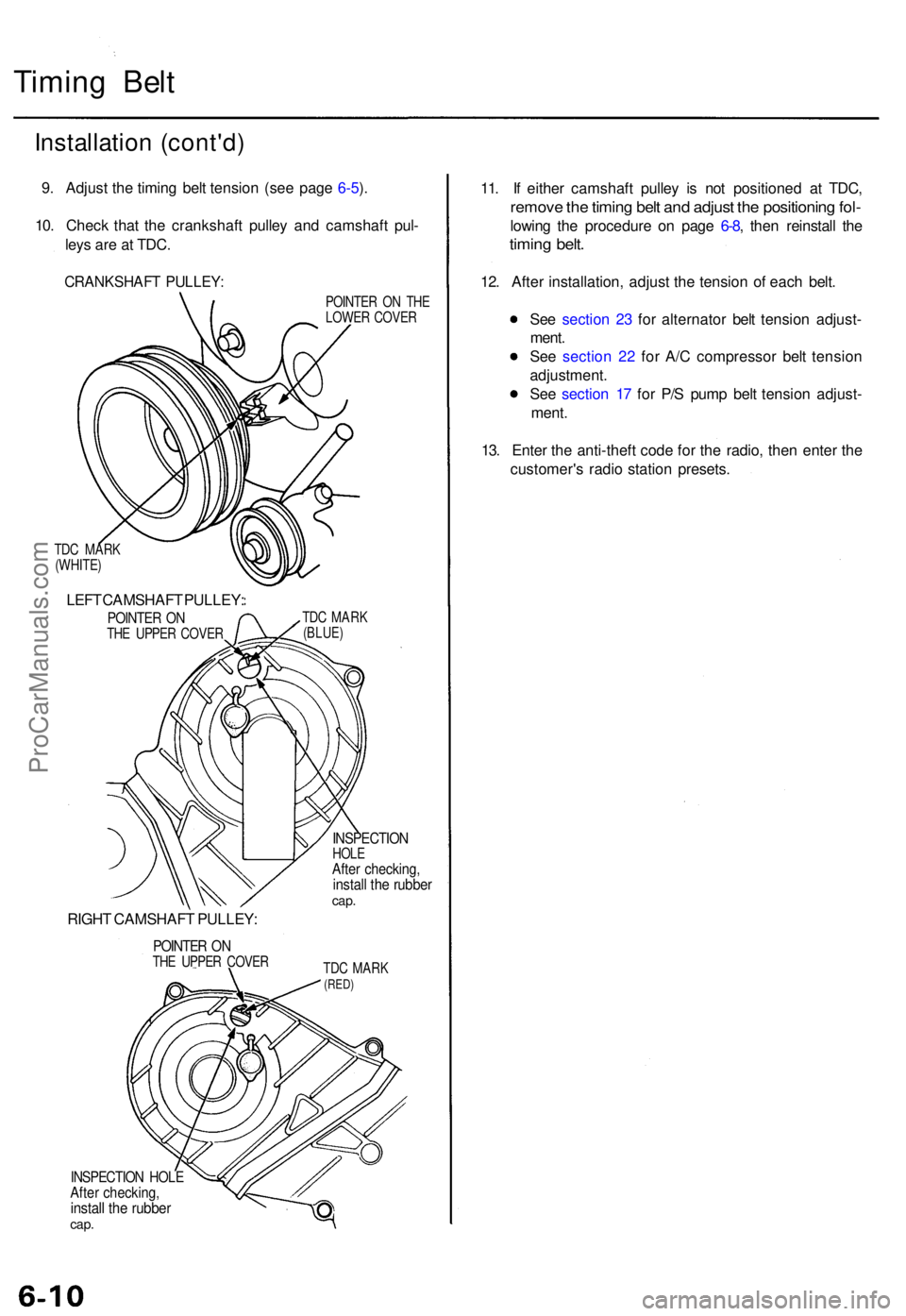

9. Adjus t th e timin g bel t tensio n (se e pag e 6-5 ).

10 . Chec k tha t th e crankshaf t pulle y an d camshaf t pul -

ley s ar e a t TDC .

CRANKSHAF T PULLEY :

TDC MAR K

(WHITE )

LEFT CAMSHAF T PULLEY :

POINTER O NTH E UPPE R COVE R

RIGHT CAMSHAF T PULLEY :

POINTER O NTH E UPPE R COVE R POINTE

R O N TH E

LOWE R COVE R

TD C MAR K

(BLUE )

INSPECTIO NHOLEAfter checking ,install th e rubbe rcap.

TDC MAR K(RED)

INSPECTIO N HOL EAfter checking ,install th e rubbe rcap.

11. I f eithe r camshaf t pulle y i s no t positione d a t TDC ,

remov e th e timin g bel t an d adjus t th e positionin g fol -

lowin g th e procedur e o n pag e 6-8 , the n reinstal l th e

timin g belt .

12. Afte r installation , adjus t th e tensio n o f eac h belt .

Se e sectio n 2 3 fo r alternato r bel t tensio n adjust -

ment .

Se e sectio n 2 2 fo r A/ C compresso r bel t tensio n

adjustment .

Se e sectio n 1 7 fo r P/ S pum p bel t tensio n adjust -

ment .

13 . Ente r th e anti-theft code fo r th e radio , the n ente r th e

customer' s radi o statio n presets .

ProCarManuals.com

Page 69 of 1771

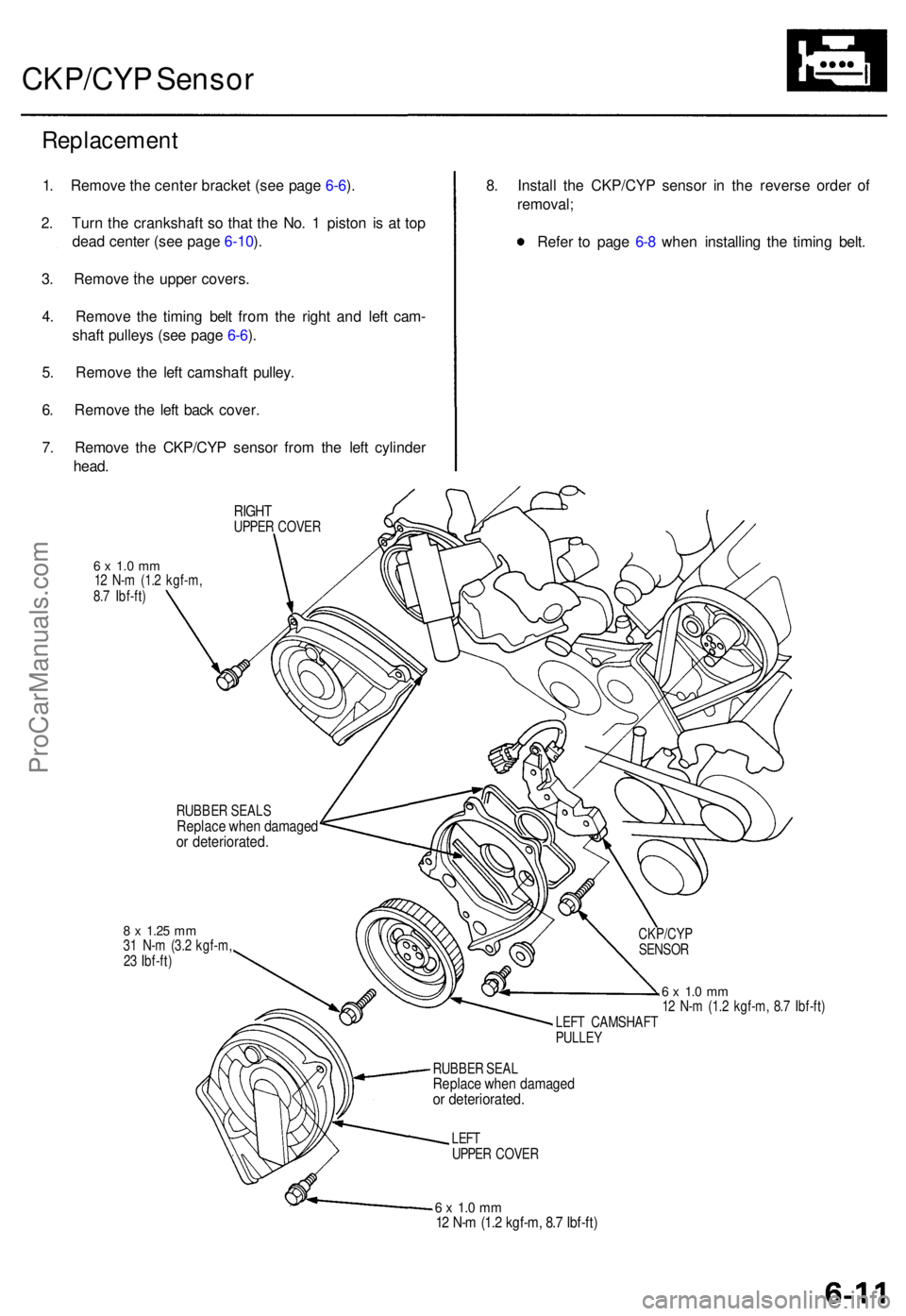

CKP/CYP Senso r

Replacemen t

1. Remov e th e cente r bracke t (se e pag e 6-6 ).

2 . Tur n th e crankshaf t s o tha t th e No . 1 pisto n i s a t to p

dea d cente r (se e pag e 6-10 ).

3 . Remov e th e uppe r covers .

4 . Remov e th e timin g bel t fro m th e righ t an d lef t cam -

shaf t pulley s (se e pag e 6-6 ).

5 . Remov e th e lef t camshaf t pulley .

6 . Remov e th e lef t bac k cover .

7 . Remov e th e CKP/CY P senso r fro m th e lef t cylinde r

head .

RIGH TUPPE R COVE R

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

8. Instal l th e CKP/CY P senso r i n th e revers e orde r o f

removal ;

Refe r t o pag e 6- 8 whe n installin g th e timin g belt .

RUBBE R SEAL SReplac e whe n damage dor deteriorated .

8 x 1.2 5 mm31 N- m (3. 2 kgf-m ,

2 3 Ibf-ft )

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

LEF T CAMSHAF T

PULLE Y

RUBBE R SEA L

Replac e whe n damage dor deteriorated .

LEFTUPPE R COVE R

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

CKP/CY P

SENSO R

ProCarManuals.com

Page 74 of 1771

Cylinder Head s

Remova l (cont'd )

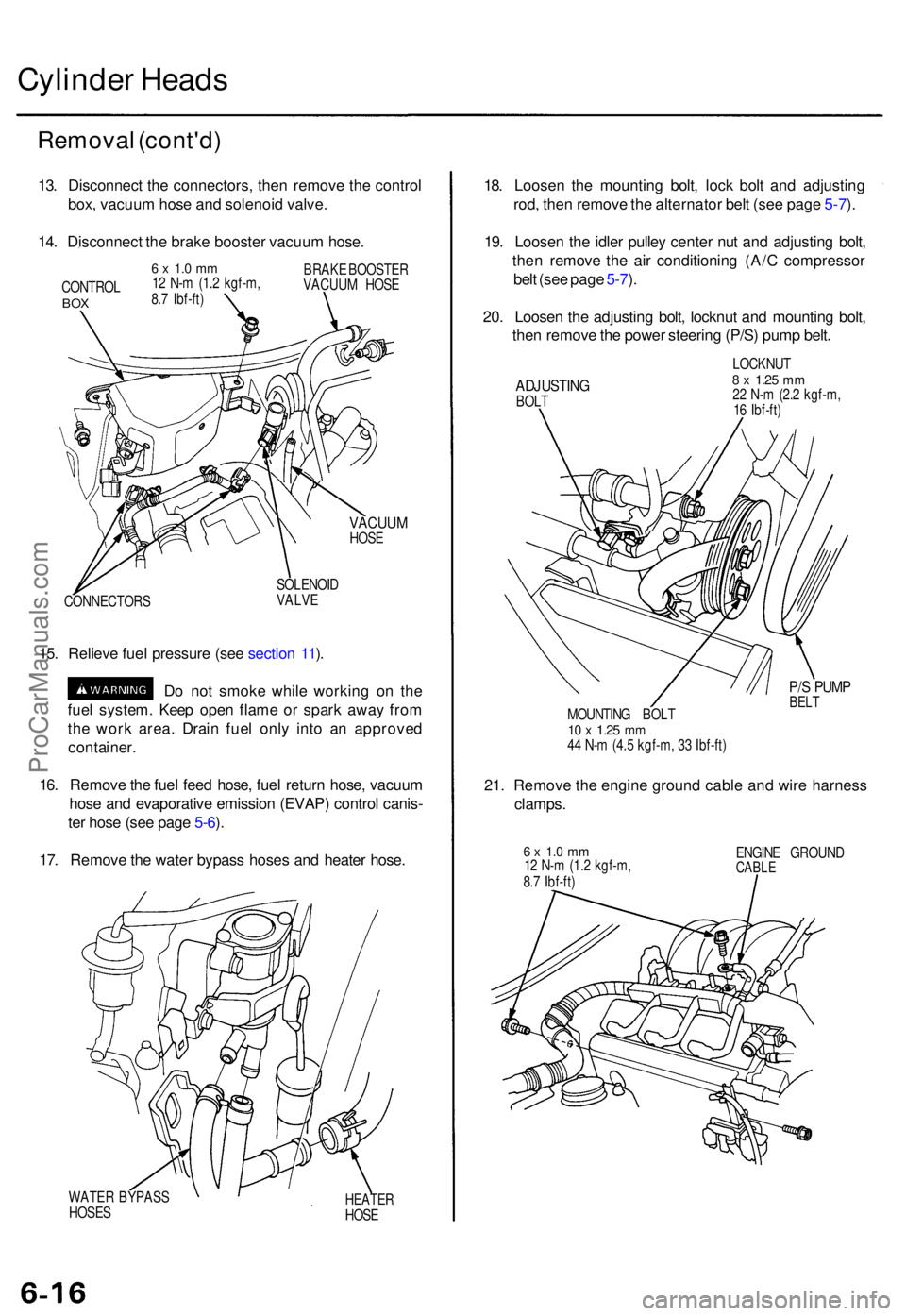

13. Disconnec t th e connectors , the n remov e th e contro l

box , vacuu m hos e an d solenoi d valve .

14 . Disconnec t th e brak e booste r vacuu m hose .

CONTRO LBOX

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft ) BRAK

E BOOSTE R

VACUU M HOS E

VACUU MHOSE

CONNECTOR S SOLENOI

D

VALVE

15. Reliev e fue l pressur e (se e sectio n 11 ).

D o no t smok e whil e workin g o n th e

fue l system . Kee p ope n flam e o r spar k awa y fro m

th e wor k area . Drai n fue l onl y int o a n approve d

container .

16 . Remov e th e fue l fee d hose , fue l retur n hose , vacuu m

hos e an d evaporativ e emissio n (EVAP ) contro l canis -

te r hos e (se e pag e 5-6 ).

17 . Remov e th e wate r bypas s hose s an d heate r hose .

WATE R BYPAS S

HOSE SHEATE RHOSE

18. Loose n th e mountin g bolt , loc k bol t an d adjustin g

rod , the n remov e th e alternato r bel t (se e pag e 5-7 ).

19 . Loose n th e idle r pulle y cente r nu t an d adjustin g bolt ,

the n remov e th e ai r conditionin g (A/ C compresso r

bel t (se e pag e 5-7 ).

20 . Loose n th e adjustin g bolt , locknu t an d mountin g bolt ,

the n remov e th e powe r steerin g (P/S ) pum p belt .

ADJUSTIN GBOLT LOCKNU

T

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

P/S PUM PBELTMOUNTIN G BOL T10 x 1.2 5 mm44 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

21. Remov e th e engine ground cabl e an d wir e harnes s

clamps.

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft ) ENGIN

E GROUN DCABLE

ProCarManuals.com

Page 116 of 1771

Pistons

Installation

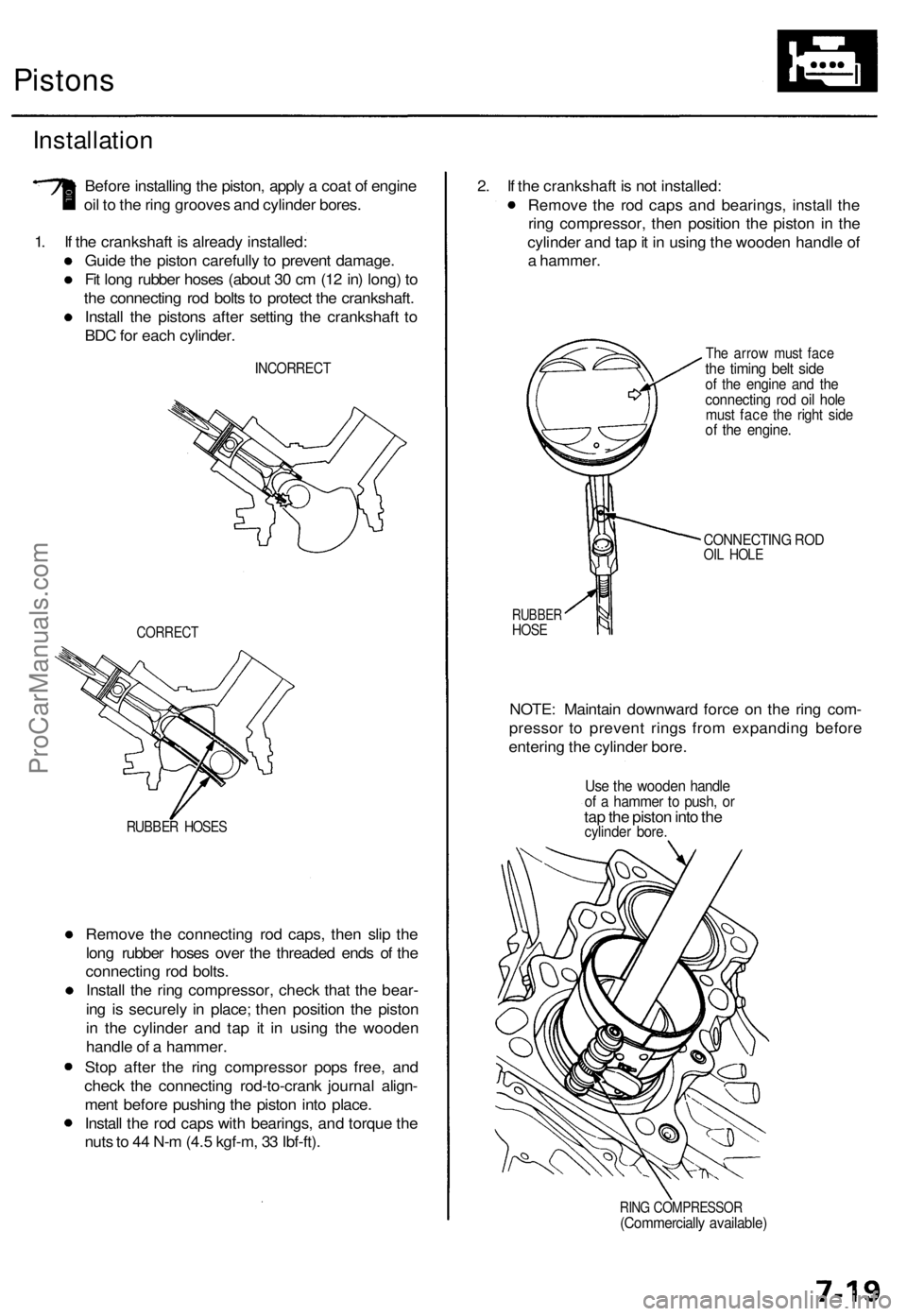

Before installing the piston, apply a coat of engine

oil to the ring grooves and cylinder bores.

1. If the crankshaft is already installed:

Guide the piston carefully to prevent damage.

Fit long rubber hoses (about 30 cm (12 in) long) to

the connecting rod bolts to protect the crankshaft.

Install the pistons after setting the crankshaft to

BDC for each cylinder.

INCORRECT

CORRECT

RUBBER HOSES

Remove the connecting rod caps, then slip the

long rubber hoses over the threaded ends of the

connecting rod bolts.

Install the ring compressor, check that the bear-

ing is securely in place; then position the piston

in the cylinder and tap it in using the wooden

handle of a hammer.

Stop after the ring compressor pops free, and

check the connecting rod-to-crank journal align-

ment before pushing the piston into place.

Install the rod caps with bearings, and torque the

nuts to 44 N-m (4.5 kgf-m, 33 Ibf-ft).

2. If the crankshaft is not installed:

Remove the rod caps and bearings, install the

ring compressor, then position the piston in the

cylinder and tap it in using the wooden handle of

a hammer.

The arrow must face

the timing belt side

of the engine and the

connecting rod oil hole

must face the right side

of the engine.

CONNECTING ROD

OIL HOLE

RUBBER

HOSE

NOTE: Maintain downward force on the ring com-

pressor to prevent rings from expanding before

entering the cylinder bore.

Use the wooden handle

of a hammer to push, or

tap the piston into the

cylinder bore.

RING COMPRESSOR

(Commercially available)ProCarManuals.com