power steering ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 28 of 1771

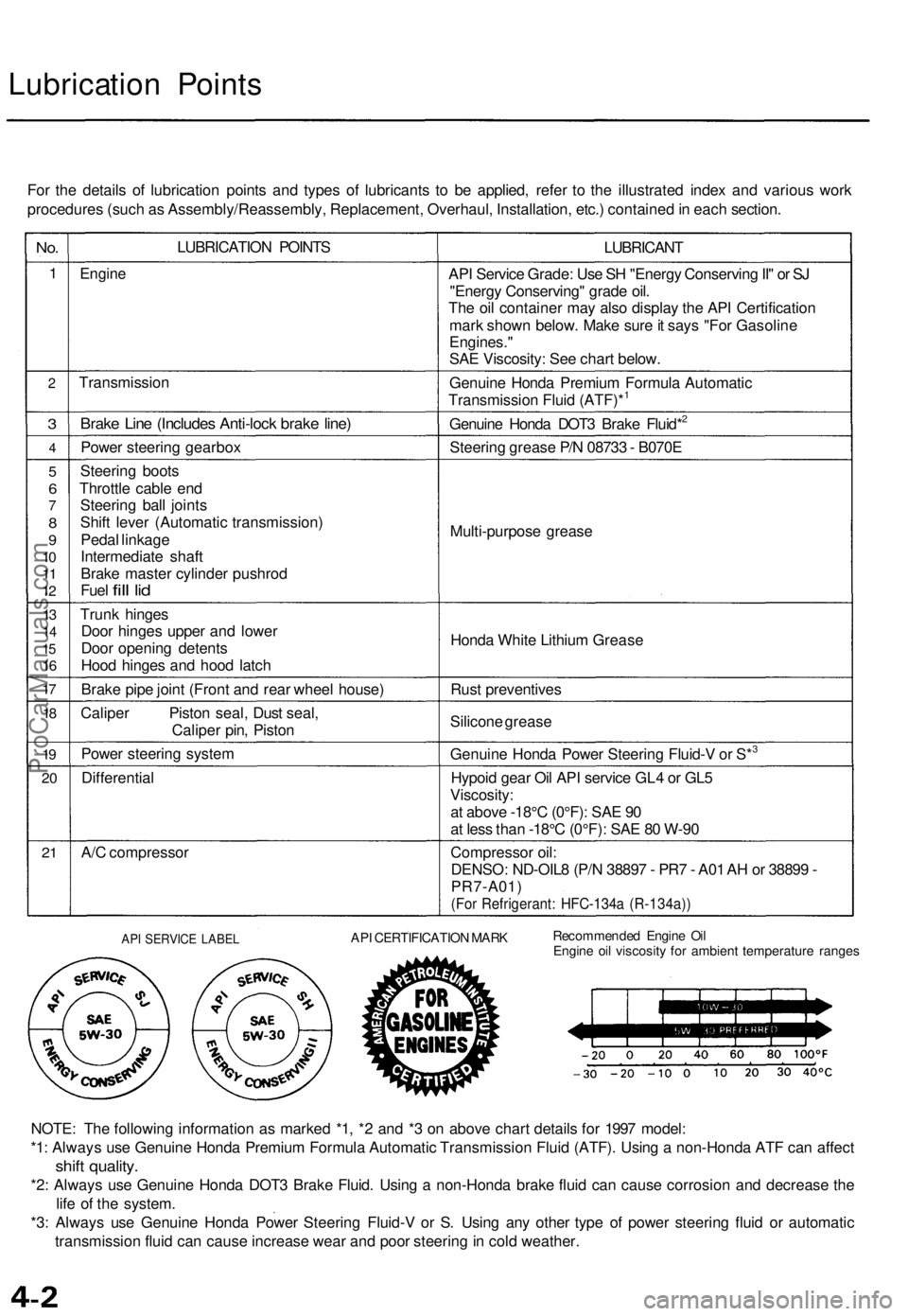

Lubrication Points

For the details of lubrication points and types of lubricants to be applied, refer to the illustrated index and various work

procedures (such as Assembly/Reassembly, Replacement, Overhaul, Installation, etc.) contained in each section.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

LUBRICATION POINTS

Engine

Transmission

Brake Line (Includes Anti-lock brake line)

Power steering gearbox

Steering boots

Throttle cable end

Steering ball joints

Shift lever (Automatic transmission)

Pedal linkage

Intermediate shaft

Brake master cylinder pushrod

Fuel

fill

lid

Trunk hinges

Door hinges upper and lower

Door opening detents

Hood hinges and hood latch

Brake pipe joint (Front and rear wheel house)

Caliper Piston seal, Dust seal,

Caliper pin, Piston

Power steering system

Differential

A/C compressor

LUBRICANT

API Service Grade: Use SH "Energy Conserving II" or SJ

"Energy Conserving" grade oil.

The oil container may also display the API Certification

mark shown below. Make sure it says "For Gasoline

Engines."

SAE Viscosity: See chart below.

Genuine Honda Premium Formula Automatic

Transmission Fluid (ATF)*1

Genuine Honda DOT3 Brake Fluid*2

Steering grease P/N 08733 - B070E

Multi-purpose grease

Honda White Lithium Grease

Rust preventives

Silicone grease

Genuine Honda Power Steering Fluid-V or S*3

Hypoid gear Oil API service GL4 or GL5

Viscosity:

at above -18°C (0°F): SAE 90

at less than -18°C (0°F): SAE 80 W-90

Compressor oil:

DENSO: ND-OIL8 (P/N 38897 - PR7 - A01 AH or 38899 -

PR7-A01)

(For Refrigerant: HFC-134a (R-134a))

API SERVICE LABEL

API CERTIFICATION MARK

Recommended Engine Oil

Engine oil viscosity for ambient temperature ranges

NOTE: The following information as marked *1, *2 and *3 on above chart details for 1997 model:

*1: Always use Genuine Honda Premium Formula Automatic Transmission Fluid (ATF). Using a non-Honda ATF can affect

shift quality.

*2: Always use Genuine Honda DOT3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease the

life of the system.

*3: Always use Genuine Honda Power Steering Fluid-V or S. Using any other type of power steering fluid or automatic

transmission fluid can cause increase wear and poor steering in cold weather.ProCarManuals.com

Page 45 of 1771

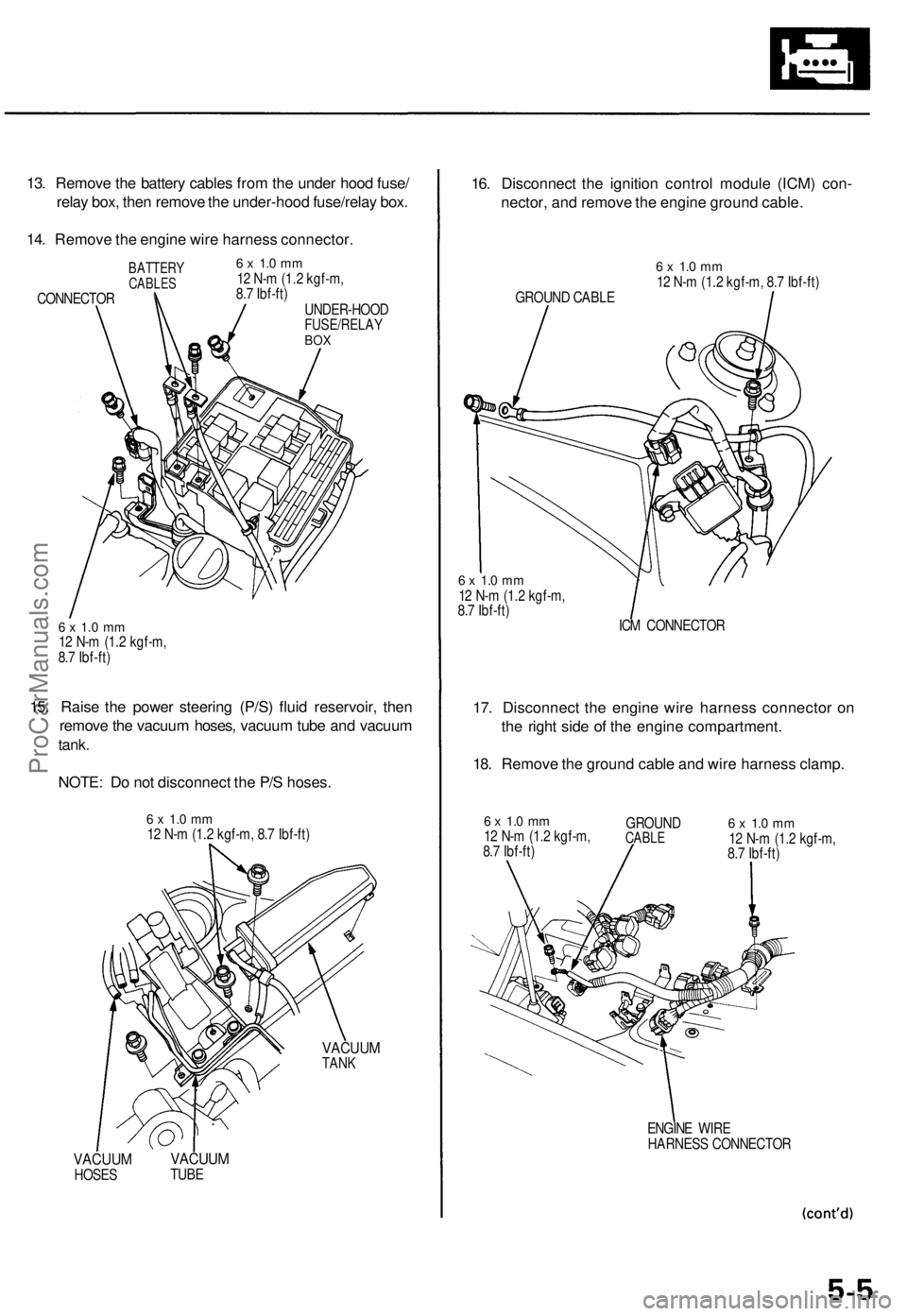

13. Remove the battery cables from the under hood fuse/

relay box, then remove the under-hood fuse/relay box.

14. Remove the engine wire harness connector.

BATTERY

CABLES

CONNECTOR

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

UNDER-HOOD

FUSE/RELAY

BOX

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

15. Raise the power steering (P/S) fluid reservoir, then

remove the vacuum hoses, vacuum tube and vacuum

tank.

NOTE: Do not disconnect the P/S hoses.

6 x 1.0 mm

12 N-m (1.2 kgf-m, 8.7 Ibf-ft)

VACUUM

TANK

VACUUM

HOSES

VACUUM

TUBE

16. Disconnect the ignition control module (ICM) con-

nector, and remove the engine ground cable.

GROUND CABLE

6 x 1.0 mm

12 N-m (1.2 kgf-m, 8.7 Ibf-ft)

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

ICM CONNECTOR

17. Disconnect the engine wire harness connector on

the right side of the engine compartment.

18. Remove the ground cable and wire harness clamp.

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

GROUND

CABLE

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

ENGINE WIRE

HARNESS CONNECTORProCarManuals.com

Page 47 of 1771

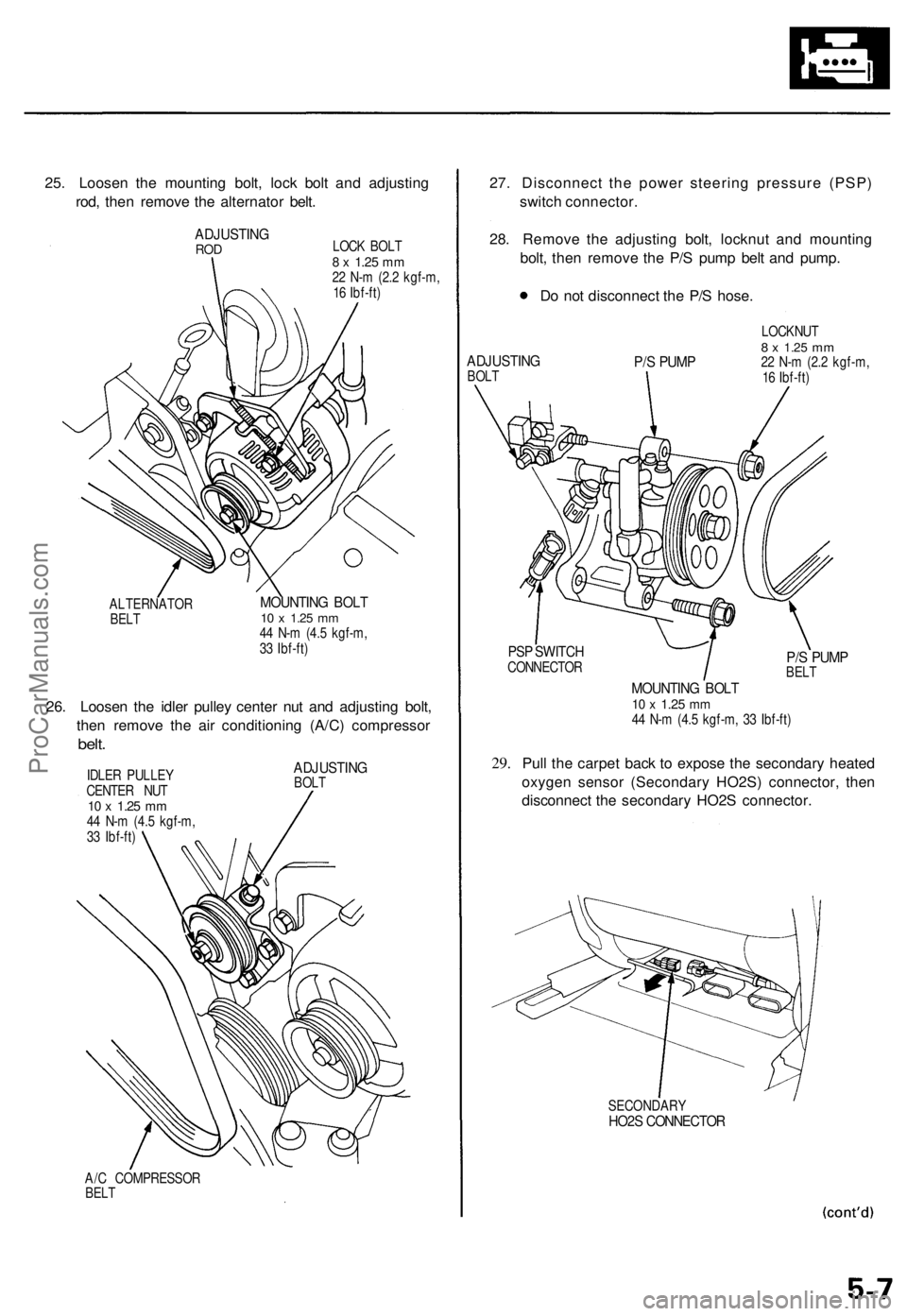

25. Loosen the mounting bolt, lock bolt and adjusting

rod, then remove the alternator belt.

ADJUSTING

ROD

LOCK BOLT

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

ALTERNATOR

BELT

MOUNTING BOLT

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

26. Loosen the idler pulley center nut and adjusting bolt,

then remove the air conditioning (A/C) compressor

belt.

IDLER PULLEY

CENTER NUT

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

ADJUSTING

BOLT

A/C COMPRESSOR

BELT

27. Disconnect the power steering pressure (PSP)

switch connector.

28. Remove the adjusting bolt, locknut and mounting

bolt, then remove the P/S pump belt and pump.

Do not disconnect the P/S hose.

ADJUSTING

BOLT

P/S PUMP

LOCKNUT

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

PSP SWITCH

CONNECTOR

29.

P/S PUMP

BELT

MOUNTING BOLT

10 x

1.25

mm

44 N-m (4.5 kgf-m, 33 Ibf-ft)

Pull the carpet back to expose the secondary heated

oxygen sensor (Secondary HO2S) connector, then

disconnect the secondary HO2S connector.

SECONDARY

HO2S CONNECTORProCarManuals.com

Page 49 of 1771

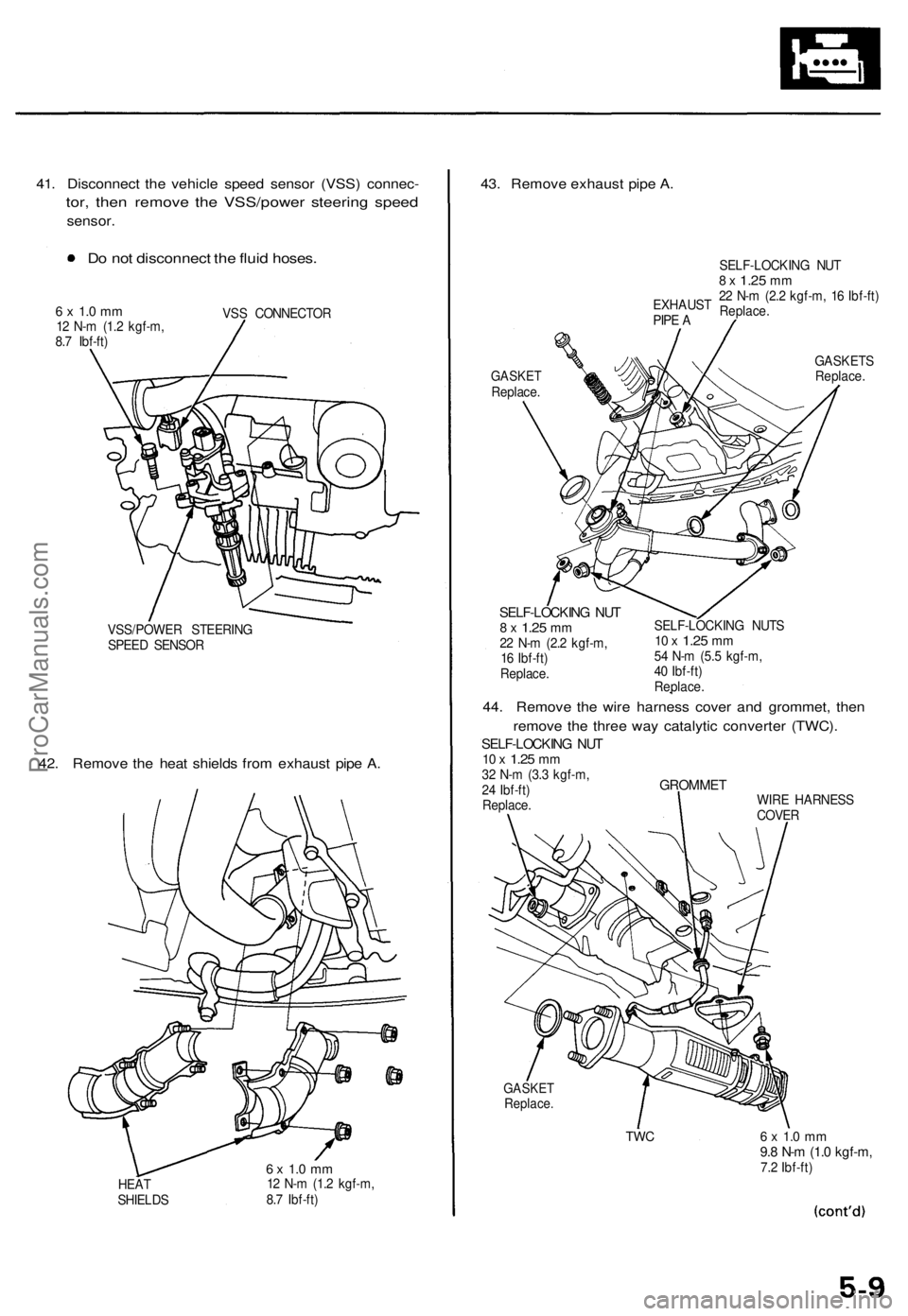

41. Disconnect the vehicle speed sensor (VSS) connec-

tor, then remove the VSS/power steering speed

sensor.

Do not disconnect the fluid hoses.

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

VSS CONNECTOR

VSS/POWER STEERING

SPEED SENSOR

42. Remove the heat shields from exhaust pipe A.

HEAT

SHIELDS

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

43. Remove exhaust pipe A.

EXHAUST

PIPE A

GASKET

Replace.

SELF-LOCKING NUT

8 x

1.25

mm

22 N-m (2.2 kgf-m, 16 Ibf-ft)

Replace.

GASKETS

Replace.

GASKET

Replace.

TWC

6 x 1.0 mm

9.8 N-m (1.0 kgf-m,

7.2 Ibf-ft)

SELF-LOCKING NUT

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

Replace.

SELF-LOCKING NUTS

10 x

1.25

mm

54 N-m (5.5 kgf-m,

40 Ibf-ft)

Replace.

44. Remove the wire harness cover and grommet, then

remove the three way catalytic converter (TWC).

SELF-LOCKING NUT

10 x

1.25

mm

32 N-m (3.3 kgf-m,

24 Ibf-ft)

Replace.

GROMMET

WIRE HARNESS

COVERProCarManuals.com

Page 468 of 1771

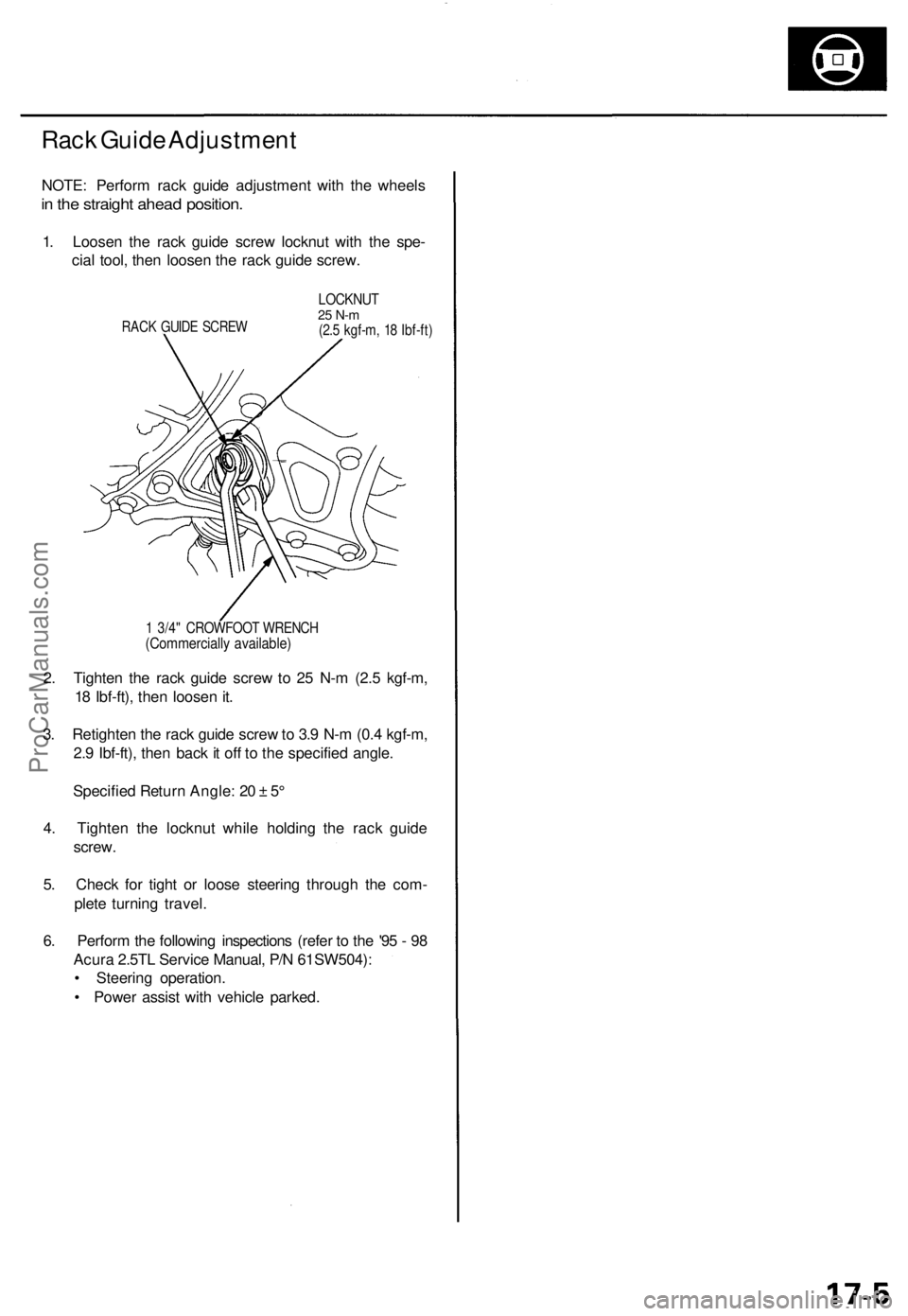

Rack Guide Adjustment

NOTE: Perform rack guide adjustment with the wheels

in the straight ahead position.

1. Loosen the rack guide screw locknut with the spe-

cial tool, then loosen the rack guide screw.

RACK GUIDE SCREW

LOCKNUT

25 N-m

(2.5 kgf-m, 18 Ibf-ft)

1 3/4" CROWFOOT WRENCH

(Commercially available)

2. Tighten the rack guide screw to 25 N-m (2.5 kgf-m,

18 Ibf-ft), then loosen it.

3. Retighten the rack guide screw to 3.9 N-m (0.4 kgf-m,

2.9 Ibf-ft), then back it off to the specified angle.

Specified Return Angle: 20 ± 5°

4. Tighten the locknut while holding the rack guide

screw.

5. Check for tight or loose steering through the com-

plete turning travel.

6. Perform the following inspections (refer to the '95 - 98

Acura 2.5TL Service Manual, P/N 61SW504):

• Steering operation.

• Power assist with vehicle parked.ProCarManuals.com

Page 471 of 1771

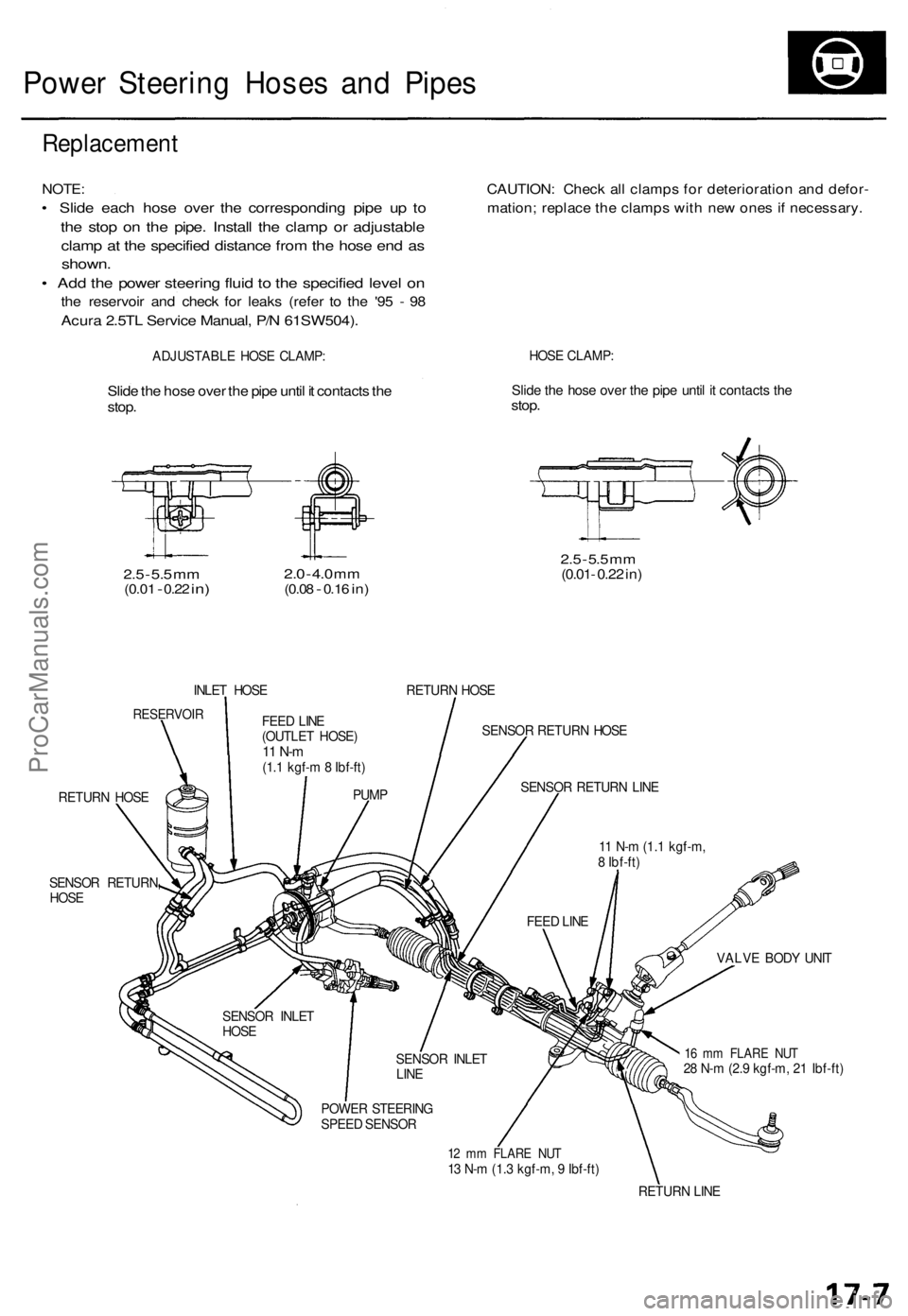

Power Steering Hoses and Pipes

Replacement

NOTE:

• Slide each hose over the corresponding pipe up to

the stop on the pipe. Install the clamp or adjustable

clamp at the specified distance from the hose end as

shown.

• Add the power steering fluid to the specified level on

the reservoir and check for leaks (refer to the '95 - 98

Acura 2.5TL Service Manual, P/N 61SW504).

CAUTION: Check all clamps for deterioration and defor-

mation; replace the clamps with new ones if necessary.

ADJUSTABLE HOSE CLAMP:

HOSE CLAMP:

Slide the hose over the pipe until it contacts the

stop.

Slide the hose over the pipe until it contacts the

stop.

2.5

-

5.5

mm

(0.01

-

0.22

in)

2.0

-

4.0

mm

(0.08

-

0.16

in)

2.5

-

5.5

mm

(0.01- 0.22 in)

INLET HOSE

RETURN HOSE

RESERVOIR

SENSOR RETURN HOSE

RETURN HOSE

SENSOR RETURN

HOSE

VALVE BODY UNIT

16 mm FLARE NUT

28 N-m (2.9 kgf-m, 21 Ibf-ft)

12 mm FLARE NUT

13 N-m (1.3 kgf-m, 9 Ibf-ft)

RETURN LINE

FEED LINE

(OUTLET HOSE)

11 N-m

(1.1 kgf-m 8 Ibf-ft)

PUMP

SENSOR INLET

HOSE

SENSOR INLET

LINE

POWER STEERING

SPEED SENSOR

FEED LINE

11 N-m (1.1 kgf-m,

8 Ibf-ft)

SENSOR RETURN LINEProCarManuals.com

Page 479 of 1771

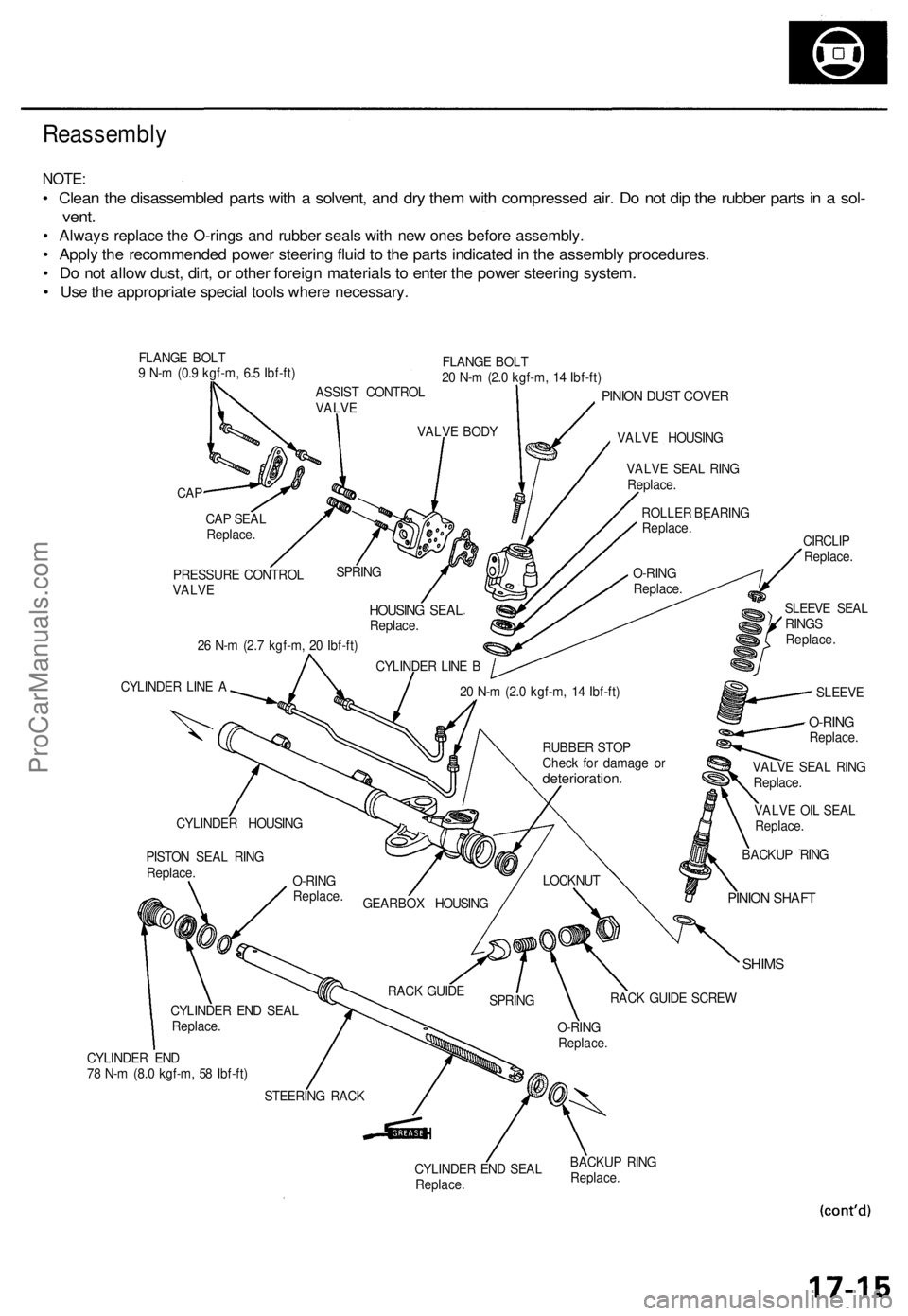

Reassembly

NOTE:

• Clean the disassembled parts with a solvent, and dry them with compressed air. Do not dip the rubber parts in a sol-

vent.

• Always replace the O-rings and rubber seals with new ones before assembly.

• Apply the recommended power steering fluid to the parts indicated in the assembly procedures.

• Do not allow dust, dirt, or other foreign materials to enter the power steering system.

• Use the appropriate special tools where necessary.

FLANGE BOLT

9 N-m (0.9 kgf-m, 6.5 Ibf-ft)

FLANGE BOLT

20 N-m (2.0 kgf-m, 14 Ibf-ft)

CAP

PINION DUST COVER

VALVE HOUSING

26 N-m (2.7 kgf-m, 20 Ibf-ft)

CYLINDER LINE A

VALVE OIL SEAL

Replace.

SHIMS

CYLINDER END

78 N-m (8.0 kgf-m, 58 Ibf-ft)

CYLINDER END SEAL

Replace.

BACKUP RING

Replace.

CAP SEAL

Replace.

PRESSURE CONTROL

VALVE

SPRING

HOUSING SEAL

Replace.

CYLINDER LINE B

VALVE BODY

ASSIST CONTROL

VALVE

VALVE SEAL RING

Replace.

ROLLER BEARING

Replace.

O-RING

Replace.

SLEEVE SEAL

RINGS

Replace.

CIRCLIP

Replace.

SLEEVE

20 N-m (2.0 kgf-m, 14 Ibf-ft)

BACKUP RING

PINION SHAFT

LOCKNUT

RACK GUIDE SCREW

O-RING

Replace.

SPRING

RACK GUIDE

STEERING RACK

CYLINDER END SEAL

Replace.

PISTON SEAL RING

Replace.

CYLINDER HOUSING

GEARBOX HOUSING

O-RING

Replace.

RUBBER STOP

Check for damage or

deterioration.

VALVE SEAL RING

Replace.

O-RING

Replace.ProCarManuals.com

Page 482 of 1771

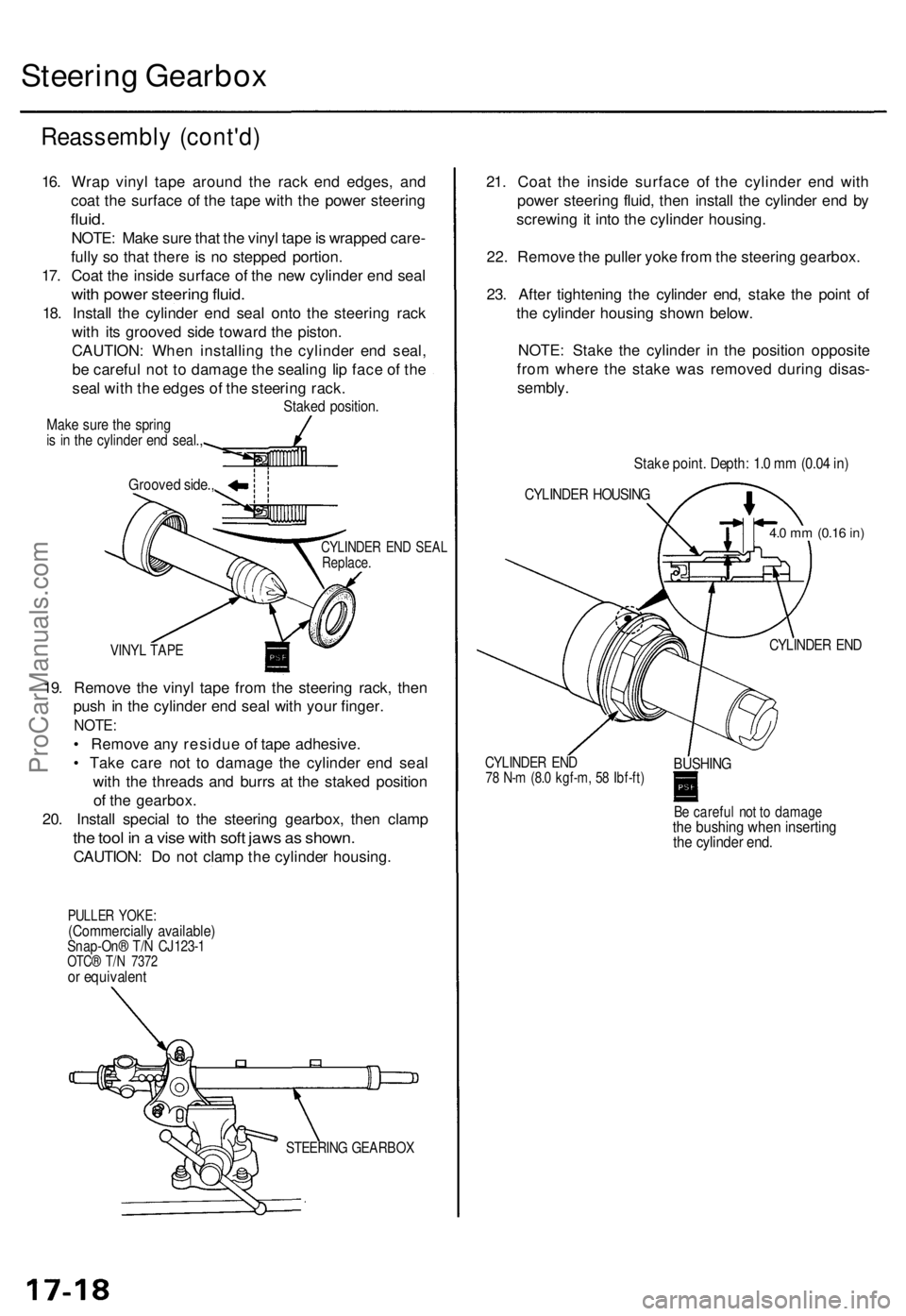

Steering Gearbox

Reassembly (cont'd)

CYLINDER END SEAL

Replace.

VINYL TAPE

19. Remove the vinyl tape from the steering rack, then

push in the cylinder end seal with your finger.

NOTE:

• Remove any residue of tape adhesive.

• Take care not to damage the cylinder end seal

with the threads and burrs at the staked position

of the gearbox.

20. Install special to the steering gearbox, then clamp

the tool in a vise with soft jaws as shown.

CAUTION: Do not clamp the cylinder housing.

PULLER YOKE:

(Commercially available)

Snap-On® T/N CJ123-1

OTC® T/N 7372

or equivalent

21. Coat the inside surface of the cylinder end with

power steering fluid, then install the cylinder end by

screwing it into the cylinder housing.

22. Remove the puller yoke from the steering gearbox.

23. After tightening the cylinder end, stake the point of

the cylinder housing shown below.

NOTE: Stake the cylinder in the position opposite

from where the stake was removed during disas-

sembly.

CYLINDER END

CYLINDER END

78 N-m (8.0 kgf-m, 58 Ibf-ft)

BUSHING

Be careful not to damage

the bushing when inserting

the cylinder end.

Grooved side.,

Stake point. Depth: 1.0 mm (0.04 in)

CYLINDER HOUSING

4.0 mm

(0.16

in)

STEERING GEARBOX

16. Wrap vinyl tape around the rack end edges, and

coat the surface of the tape with the power steering

fluid.

NOTE: Make sure that the vinyl tape is wrapped care-

fully so that there is no stepped portion.

17. Coat the inside surface of the new cylinder end seal

with power steering fluid.

18. Install the cylinder end seal onto the steering rack

with its grooved side toward the piston.

CAUTION: When installing the cylinder end seal,

be careful not to damage the sealing lip face of the

seal with the edges of the steering rack.

Staked position.

Make sure the spring

is in the cylinder end seal.,ProCarManuals.com

Page 530 of 1771

Construction and Function

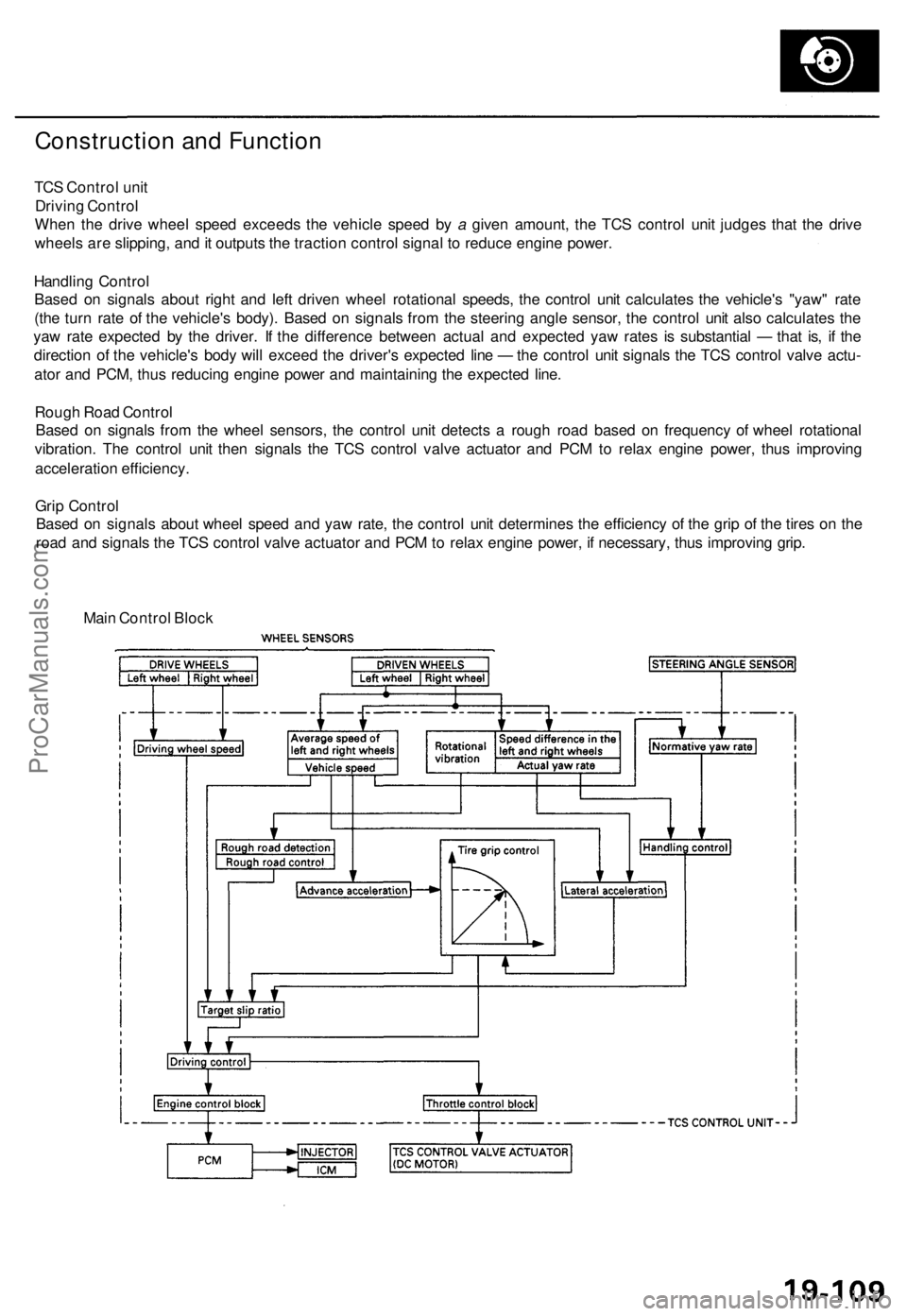

TCS Control unit

Driving Control

When the drive wheel speed exceeds the vehicle speed by a given amount, the TCS control unit judges that the drive

wheels are slipping, and it outputs the traction control signal to reduce engine power.

Handling Control

Based on signals about right and left driven wheel rotational speeds, the control unit calculates the vehicle's "yaw" rate

(the turn rate of the vehicle's body). Based on signals from the steering angle sensor, the control unit also calculates the

yaw rate expected by the driver. If the difference between actual and expected yaw rates is substantial — that is, if the

direction of the vehicle's body will exceed the driver's expected line — the control unit signals the TCS control valve actu-

ator and PCM, thus reducing engine power and maintaining the expected line.

Rough Road Control

Based on signals from the wheel sensors, the control unit detects a rough road based on frequency of wheel rotational

vibration. The control unit then signals the TCS control valve actuator and PCM to relax engine power, thus improving

acceleration efficiency.

Grip Control

Based on signals about wheel speed and yaw rate, the control unit determines the efficiency of the grip of the tires on the

road and signals the TCS control valve actuator and PCM to relax engine power, if necessary, thus improving grip.

Main Control BlockProCarManuals.com

Page 720 of 1771

Engine Removal/Installation

Removal (cont'd)

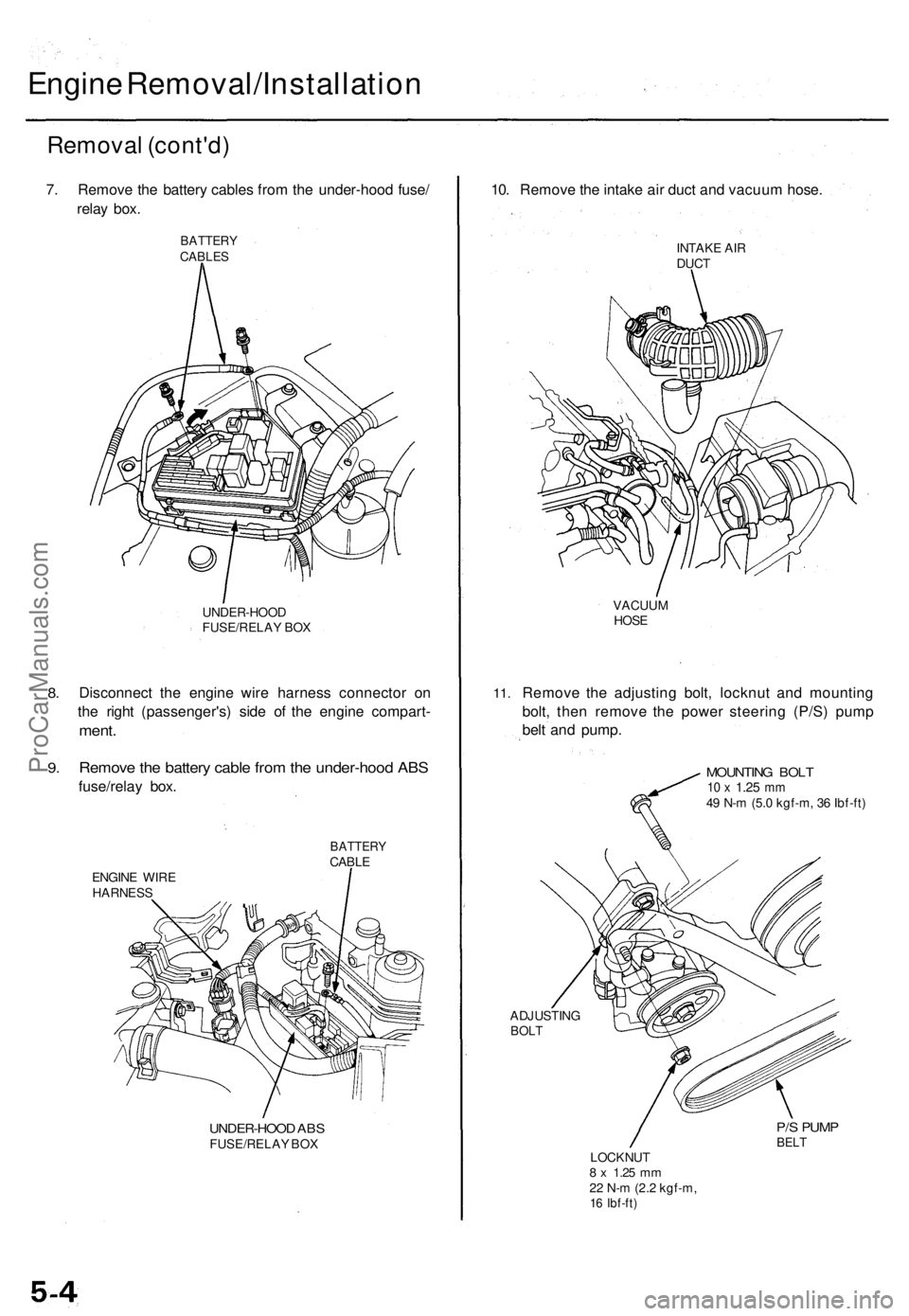

7. Remove the battery cables from the under-hood fuse/

relay box.

BATTERY

CABLES

8.

9.

UNDER-HOOD

FUSE/RELAY BOX

Disconnect the engine wire harness connector on

the right (passenger's) side of the engine compart-

ment.

Remove the battery cable from the under-hood ABS

fuse/relay box.

BATTERY

CABLE

ENGINE WIRE

HARNESS

UNDER-HOOD ABS

FUSE/RELAY BOX

10. Remove the intake air duct and vacuum hose.

INTAKE AIR

DUCT

11.

VACUUM

HOSE

Remove the adjusting bolt, locknut and mounting

bolt, then remove the power steering (P/S) pump

belt and pump.

MOUNTING BOLT

10 x

1.25

mm

49 N-m (5.0 kgf-m, 36 Ibf-ft)

ADJUSTING

BOLT

P/S PUMP

BELT

LOCKNUT

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)ProCarManuals.com