oil reset ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 96 of 1771

Cylinder Heads

Installation

Install th e cylinde r head s in th e revers e orde r o f removal .

NOTE:

Alway s us e ne w cylinde r hea d gaskets .

Cylinde r head s an d cylinde r bloc k surfac e mus t b e

clean .

Turn th e camshaft s s o th e pulle y locatin g pi n hole s

are a t th e top .

Turn th e crankshaf t s o th e No . 1 pisto n is a t TD C (se e

pag e 6-8 ).

Clea n th e oi l contro l orifice s befor e installing .

D o no t us e th e uppe r an d lowe r cover s t o stor e

remove d item .

Clea n th e uppe r an d lowe r cover s befor e installation .

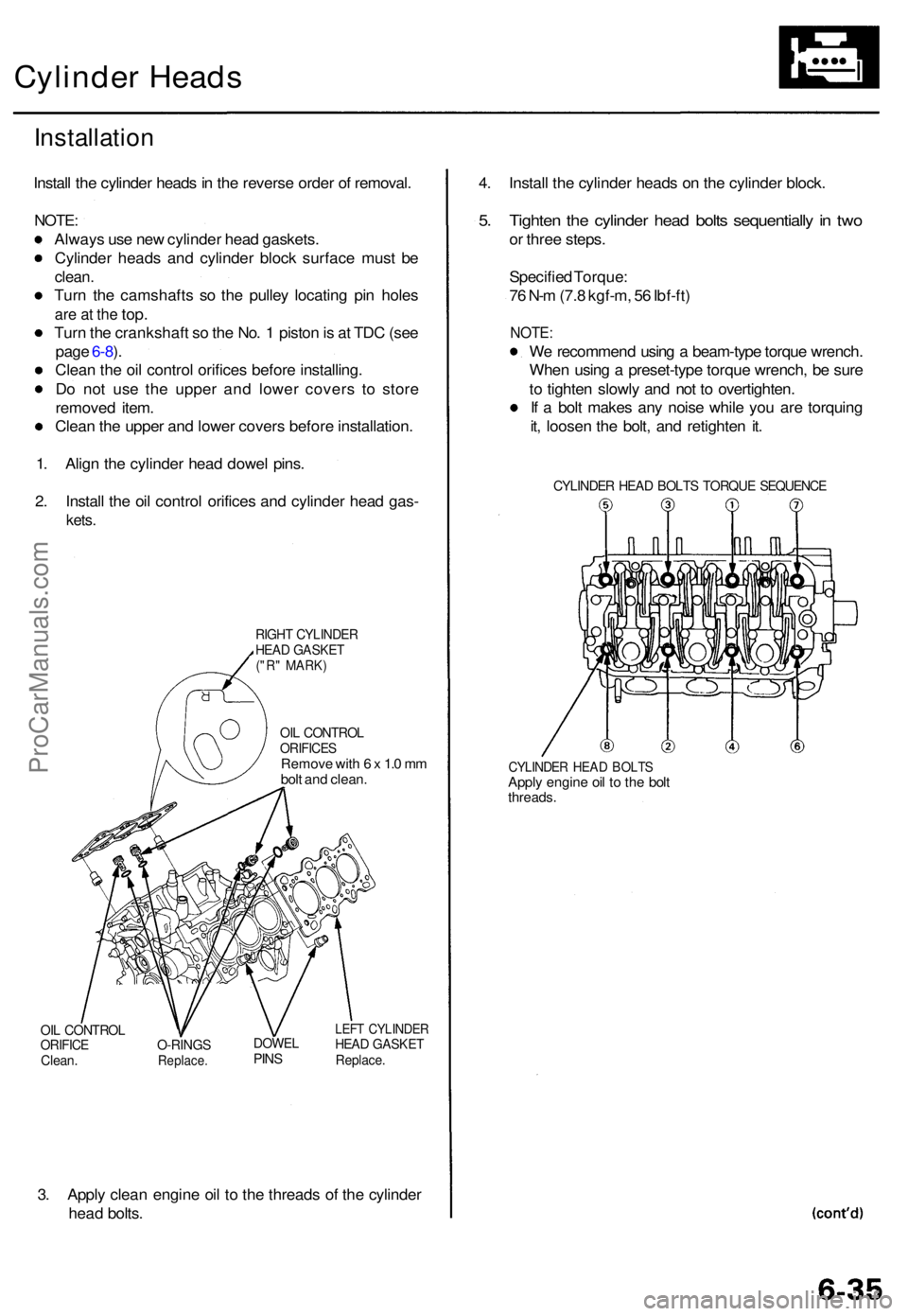

1 . Alig n th e cylinde r hea d dowe l pins .

2 . Instal l th e oi l contro l orifice s an d cylinde r hea d gas -

kets.

RIGH T CYLINDE RHEAD GASKE T("R" MARK )

OIL CONTRO LORIFICESRemove wit h 6 x 1. 0 m m

bol t an d clean .

OIL CONTRO LORIFICEClean.O-RING SReplace .

DOWELPINS

LEF T CYLINDE RHEAD GASKE TReplace.

3. Appl y clea n engin e oi l t o th e thread s o f th e cylinde r

hea d bolts . 4

. Instal l th e cylinde r head s o n th e cylinde r block .

5. Tighte n th e cylinde r hea d bolt s sequentiall y in tw o

or thre e steps .

Specifie d Torque :

7 6 N- m (7. 8 kgf-m , 5 6 Ibf-ft )

NOTE :

We recommen d usin g a beam-typ e torqu e wrench .

Whe n usin g a preset-typ e torqu e wrench , b e sur e

t o tighte n slowl y an d no t t o overtighten .

I f a bol t make s an y nois e whil e yo u ar e torquin g

it , loose n th e bolt , an d retighte n it .

CYLINDE R HEA D BOLT S TORQU E SEQUENC E

CYLINDER HEA D BOLT SApply engin e oi l t o th e bol tthreads .

ProCarManuals.com

Page 565 of 1771

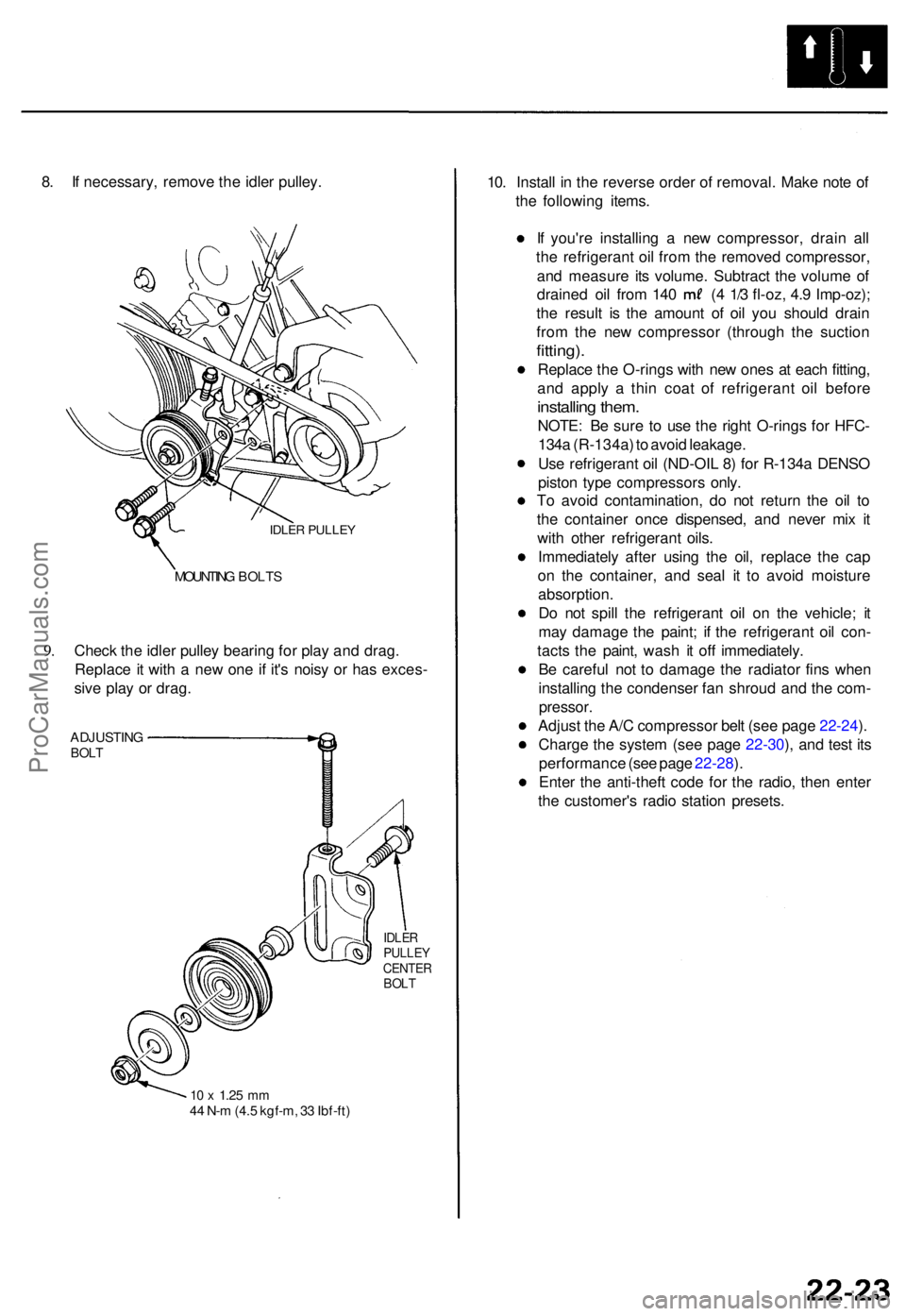

8. I f necessary , remov e th e idle r pulley .

IDLER PULLE Y

9.

MOUNTIN G BOLT S

Check th e idle r pulle y bearin g fo r pla y an d drag .

Replac e it wit h a ne w on e i f it' s nois y o r ha s exces -

siv e pla y o r drag .

ADJUSTIN GBOLT

IDLE RPULLE YCENTE RBOLT

10 x 1.2 5 mm44 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

10. Instal l i n th e revers e orde r o f removal . Mak e not e o f

th e followin g items .

I f you'r e installin g a ne w compressor , drai n al l

th e refrigeran t oi l fro m th e remove d compressor ,

an d measur e it s volume . Subtrac t th e volum e o f

draine d oi l fro m 14 0 ( 4 1/ 3 fl-oz , 4. 9 Imp-oz) ;

th e resul t i s th e amoun t o f oi l yo u shoul d drai n

fro m th e ne w compresso r (throug h th e suctio n

fitting).

Replac e th e O-rings with ne w one s a t eac h fitting ,

an d appl y a thi n coa t of refrigeran t oi l befor e

installin g them .

NOTE : B e sur e t o us e th e righ t O-ring s fo r HFC -

134 a (R-134a ) t o avoi d leakage .

Us e refrigeran t oi l (ND-OI L 8 ) fo r R-134 a DENS O

pisto n typ e compressor s only .

T o avoi d contamination , d o no t retur n th e oi l t o

th e containe r onc e dispensed , an d neve r mi x i t

wit h othe r refrigeran t oils .

Immediatel y afte r usin g th e oil , replac e th e ca p

o n th e container , an d sea l i t t o avoi d moistur e

absorption .

D o no t spil l th e refrigeran t oi l o n th e vehicle ; i t

ma y damag e th e paint ; i f th e refrigeran t oi l con -

tact s th e paint , was h i t of f immediately .

B e carefu l no t t o damag e th e radiato r fin s whe n

installin g th e condense r fa n shrou d an d th e com -

pressor .

Adjust th e A/ C compresso r bel t (se e pag e 22-24 ).

Charg e th e syste m (se e pag e 22-30 ), an d tes t it s

performanc e (se e pag e 22-28 ).

Ente r th e anti-thef t cod e fo r th e radio , the n ente r

th e customer' s radi o statio n presets .

ProCarManuals.com

Page 586 of 1771

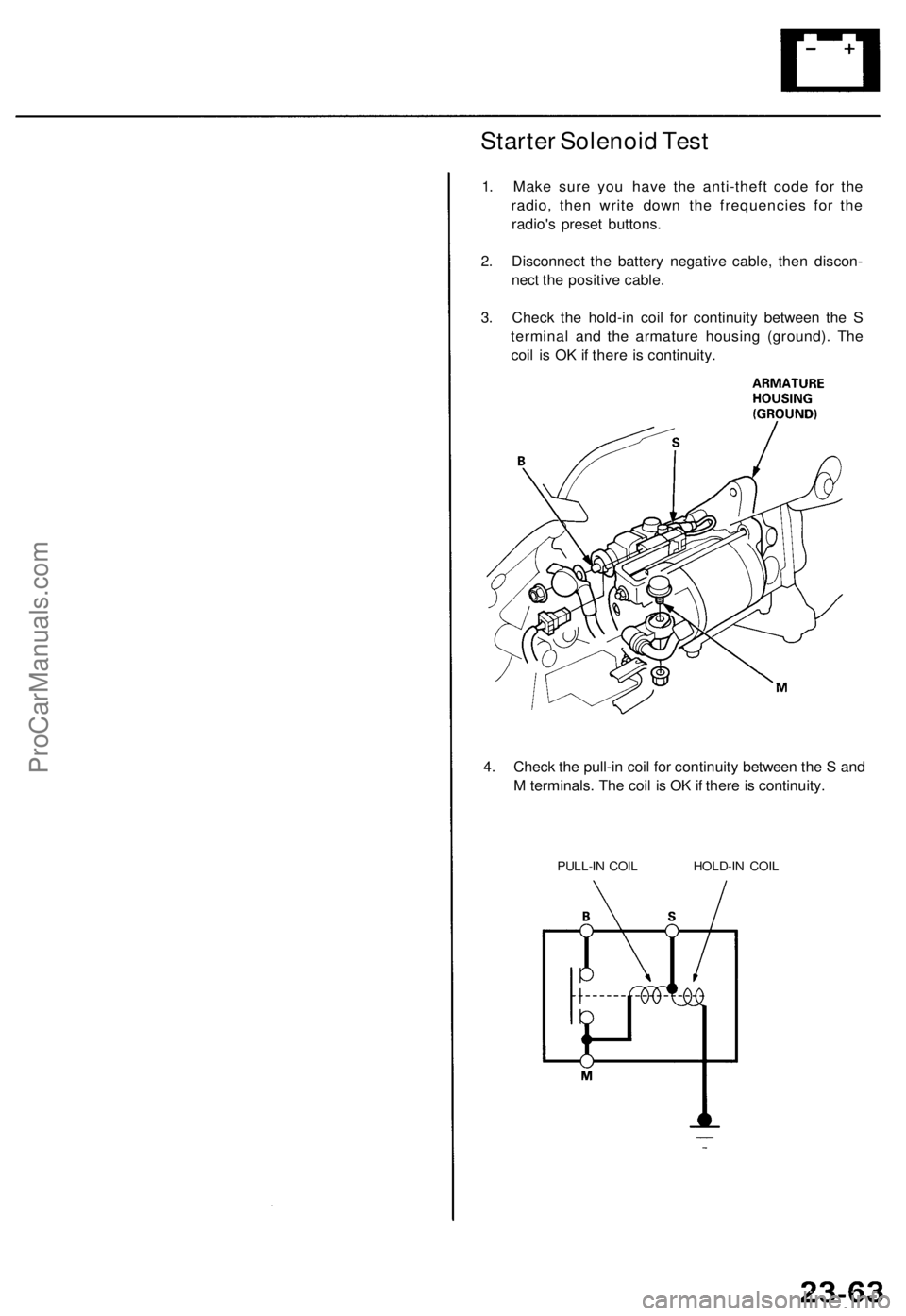

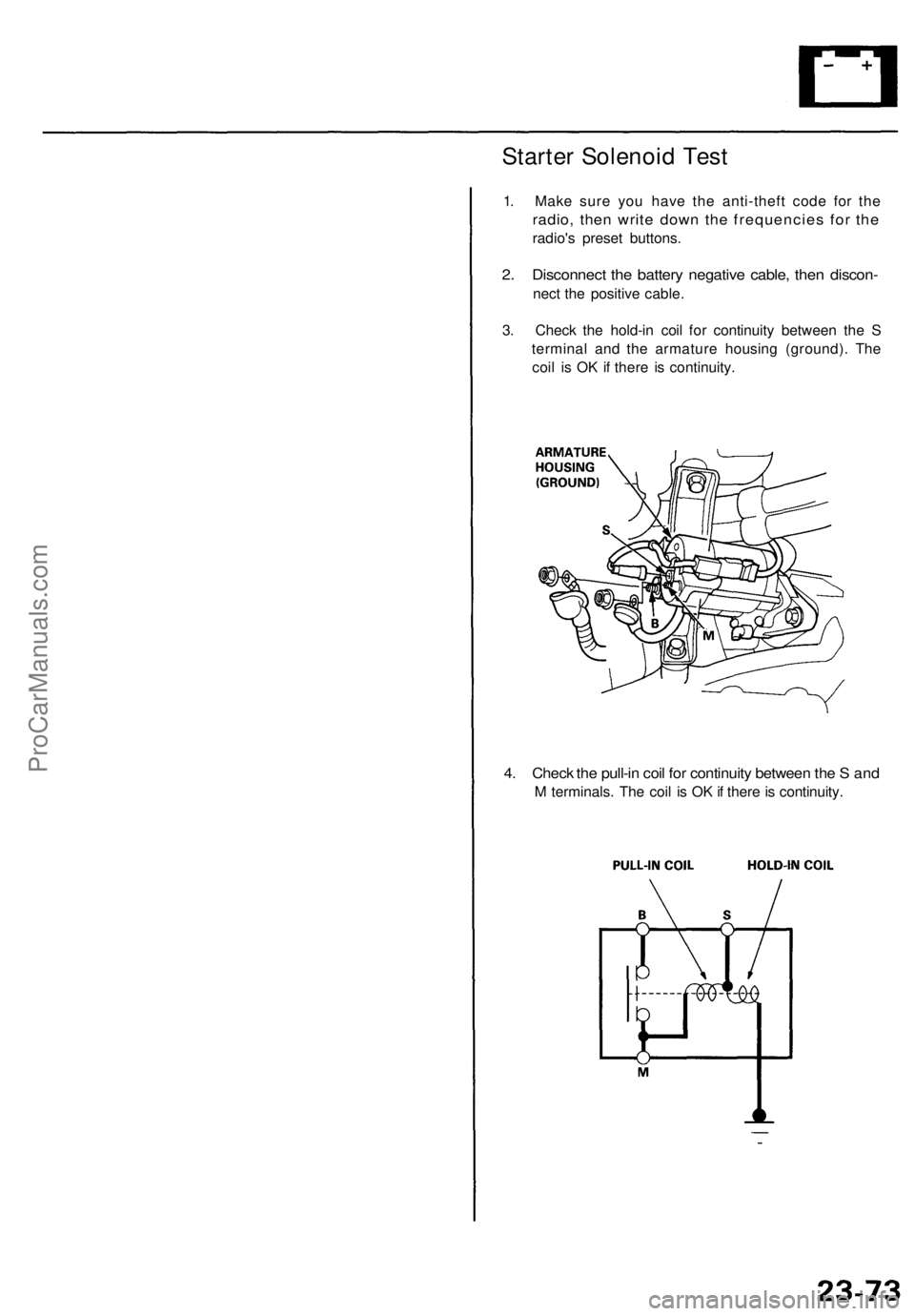

Starter Solenoid Test

1. Make sure you have the anti-theft code for the

radio, then write down the frequencies for the

radio's preset buttons.

2. Disconnect the battery negative cable, then discon-

nect the positive cable.

3. Check the hold-in coil for continuity between the S

terminal and the armature housing (ground). The

coil is OK if there is continuity.

4. Check the pull-in coil for continuity between the S and

M terminals. The coil is OK if there is continuity.

PULL-IN COIL HOLD-IN COILProCarManuals.com

Page 775 of 1771

Cylinder Head

Installation (cont'd)

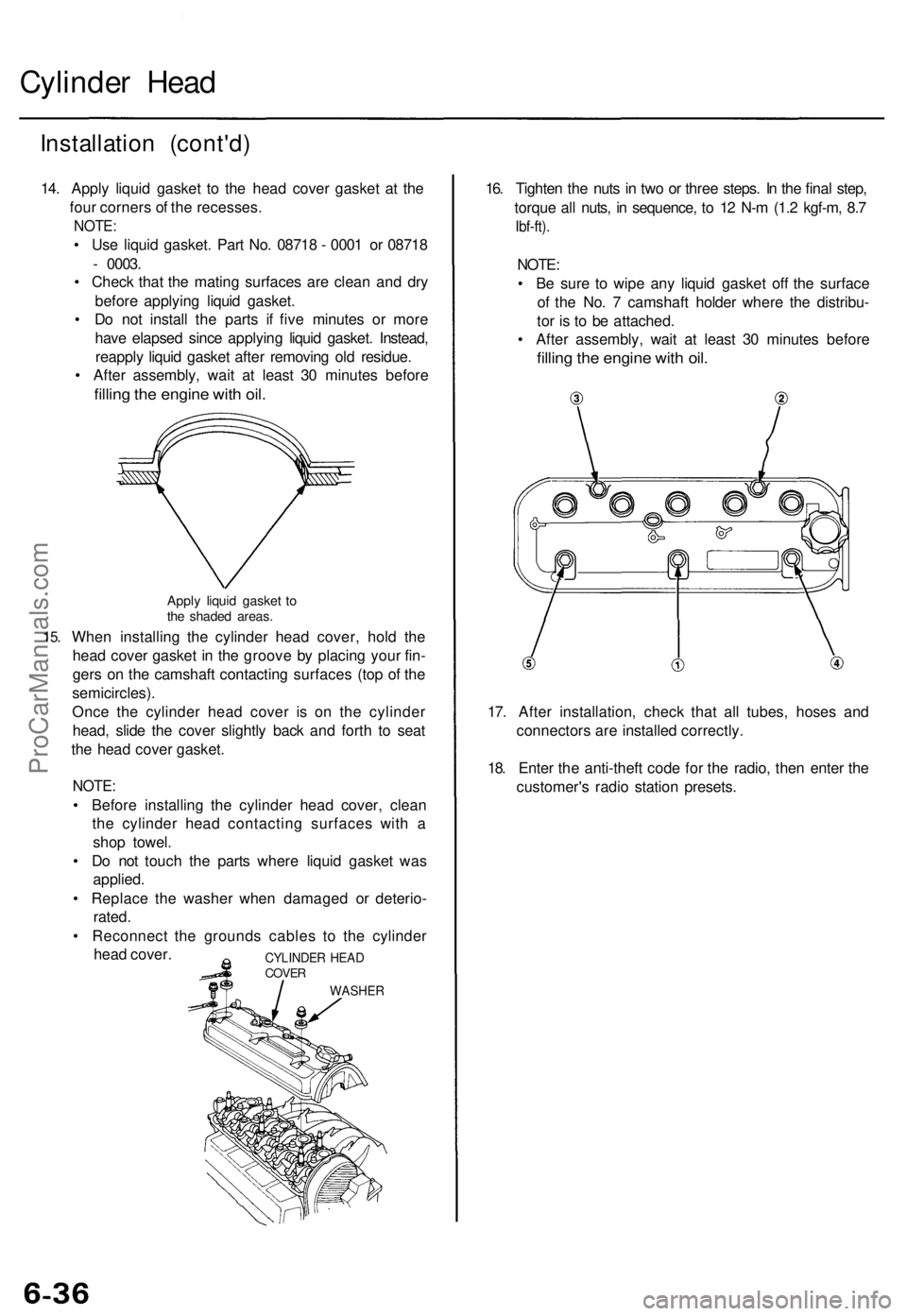

14. Apply liquid gasket to the head cover gasket at the

four corners of the recesses.

NOTE:

• Use liquid gasket. Part No. 08718 - 0001 or 08718

- 0003.

• Check that the mating surfaces are clean and dry

before applying liquid gasket.

• Do not install the parts if five minutes or more

have elapsed since applying liquid gasket. Instead,

reapply liquid gasket after removing old residue.

• After assembly, wait at least 30 minutes before

filling the engine with oil.

15.

Apply liquid gasket to

the shaded areas.

When installing the cylinder head cover, hold the

head cover gasket in the groove by placing your fin-

gers on the camshaft contacting surfaces (top of the

semicircles).

Once the cylinder head cover is on the cylinder

head, slide the cover slightly back and forth to seat

the head cover gasket.

NOTE:

• Before installing the cylinder head cover, clean

the cylinder head contacting surfaces with a

shop towel.

• Do not touch the parts where liquid gasket was

applied.

• Replace the washer when damaged or deterio-

rated.

• Reconnect the grounds cables to the cylinder

head cover.

16. Tighten the nuts in two or three steps. In the final step,

torque all nuts, in sequence, to 12 N-m (1.2 kgf-m, 8.7

Ibf-ft).

NOTE:

• Be sure to wipe any liquid gasket off the surface

of the No. 7 camshaft holder where the distribu-

tor is to be attached.

• After assembly, wait at least 30 minutes before

filling the engine with oil.

17. After installation, check that all tubes, hoses and

connectors are installed correctly.

18. Enter the anti-theft code for the radio, then enter the

customer's radio station presets.

CYLINDER HEAD

COVER

WASHERProCarManuals.com

Page 1558 of 1771

Starter Solenoid Test

1. Make sure you have the anti-theft code for the

radio, then write down the frequencies for the

radio's preset buttons.

2. Disconnect the battery negative cable, then discon-

nect the positive cable.

3. Check the hold-in coil for continuity between the S

terminal and the armature housing (ground). The

coil is OK if there is continuity.

4. Check the pull-in coil for continuity between the S and

M terminals. The coil is OK if there is continuity.ProCarManuals.com