brake sensor ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 275 of 1771

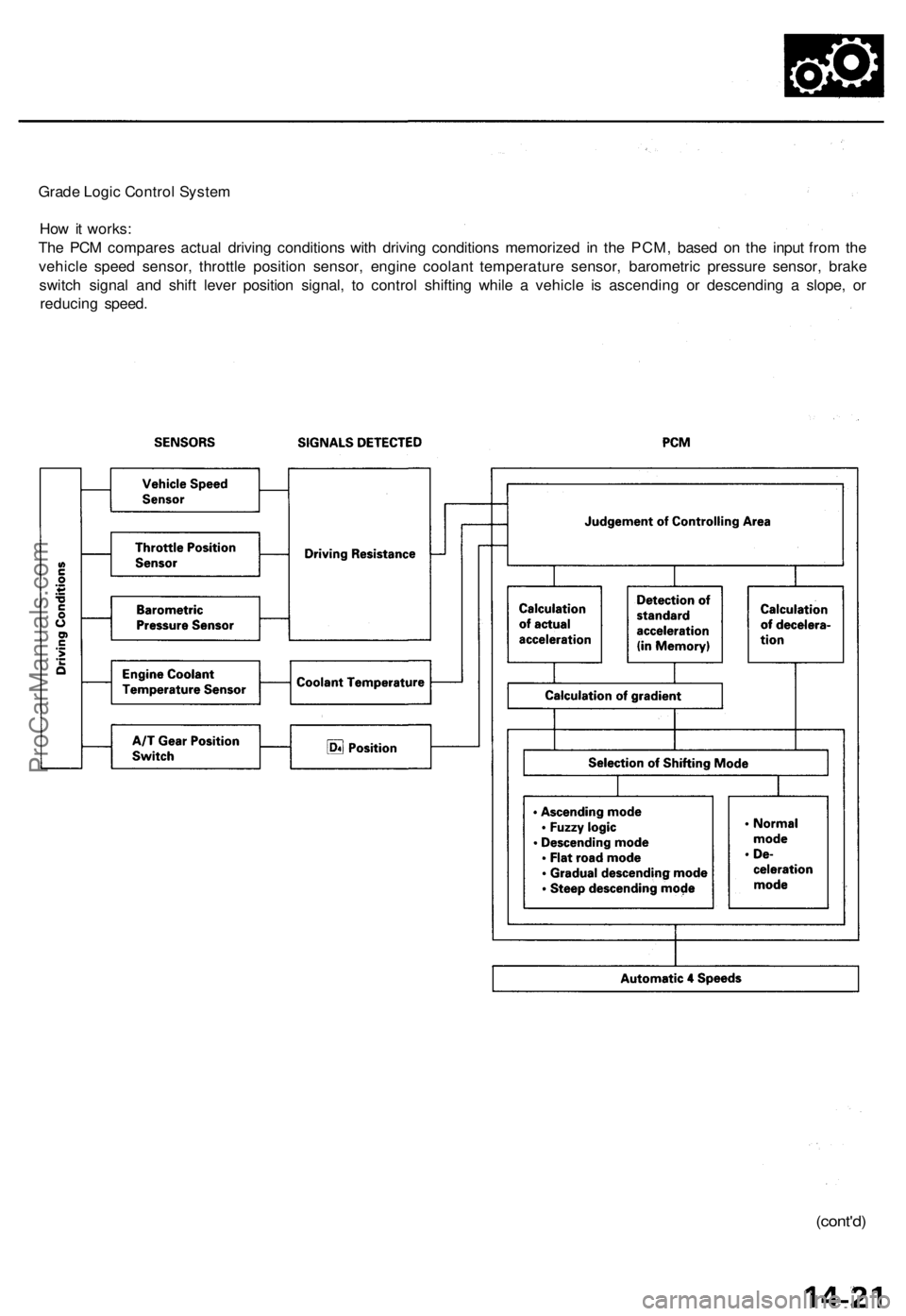

Grade Logic Control System

How it works:

The PCM compares actual driving conditions with driving conditions memorized in the PCM, based on the input from the

vehicle speed sensor, throttle position sensor, engine coolant temperature sensor, barometric pressure sensor, brake

switch signal and shift lever position signal, to control shifting while a vehicle is ascending or descending a slope, or

reducing speed.

(cont'd)ProCarManuals.com

Page 877 of 1771

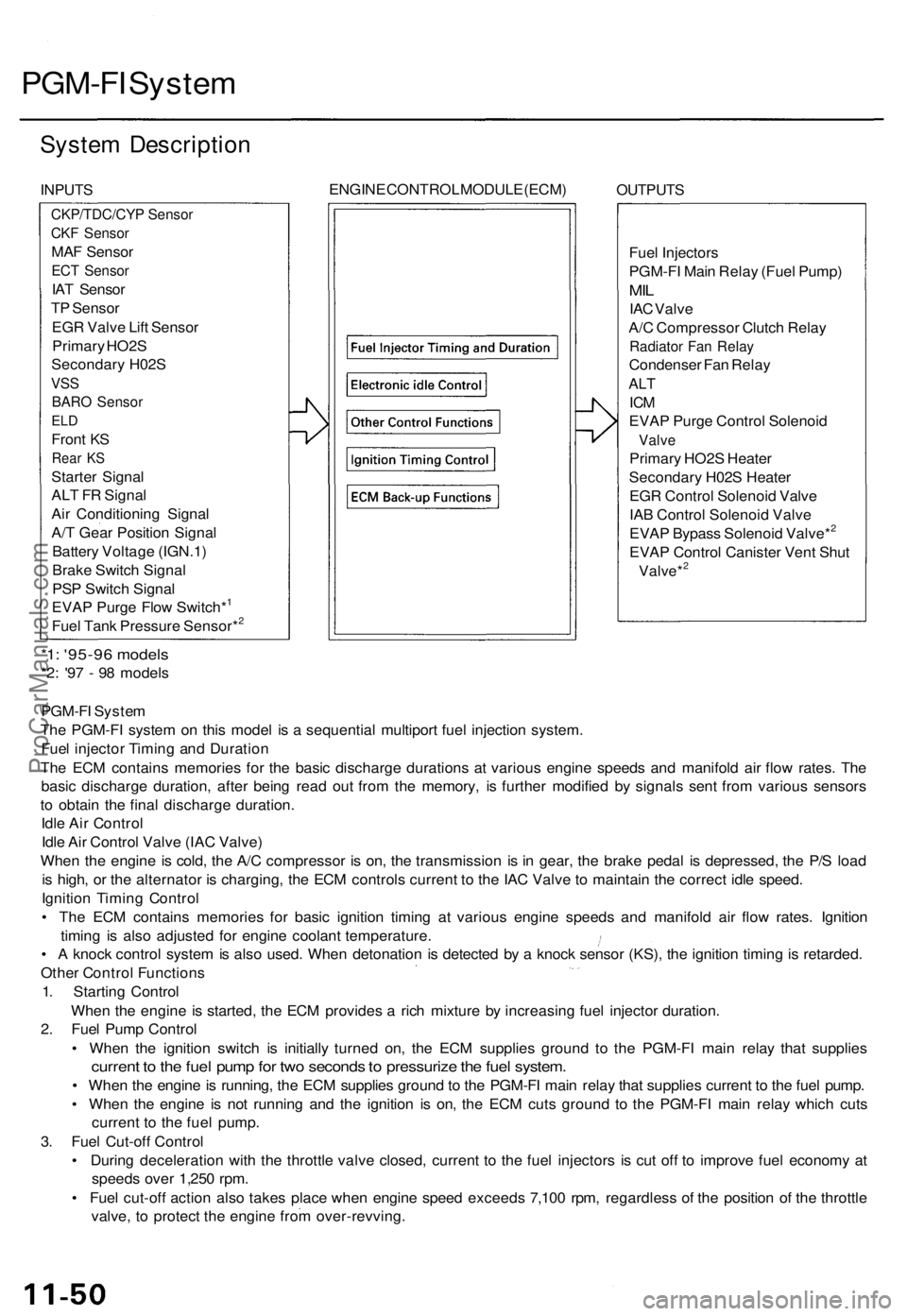

PGM-FI System

System Description

INPUTS

ENGINE CONTROL MODULE (ECM)

OUTPUTS

Fuel Injectors

PGM-FI Main Relay (Fuel Pump)

MIL

IAC Valve

A/C Compressor Clutch Relay

Radiator Fan Relay

Condenser Fan Relay

ALT

ICM

EVAP Purge Control Solenoid

Valve

Primary HO2S Heater

Secondary H02S Heater

EGR Control Solenoid Valve

IAB Control Solenoid Valve

EVAP Bypass Solenoid Valve*2

EVAP Control Canister Vent Shut

Valve*2

*1: '95-96 models

*2: '97 - 98 models

PGM-FI System

The PGM-FI system on this model is a sequential multiport fuel injection system.

Fuel injector Timing and Duration

The ECM contains memories for the basic discharge durations at various engine speeds and manifold air flow rates. The

basic discharge duration, after being read out from the memory, is further modified by signals sent from various sensors

to obtain the final discharge duration.

Idle Air Control

Idle Air Control Valve (IAC Valve)

When the engine is cold, the A/C compressor is on, the transmission is in gear, the brake pedal is depressed, the P/S load

is high, or the alternator is charging, the ECM controls current to the IAC Valve to maintain the correct idle speed.

Ignition Timing Control

• The ECM contains memories for basic ignition timing at various engine speeds and manifold air flow rates. Ignition

timing is also adjusted for engine coolant temperature.

• A knock control system is also used. When detonation is detected by a knock sensor (KS), the ignition timing is retarded.

Other Control Functions

1. Starting Control

When the engine is started, the ECM provides a rich mixture by increasing fuel injector duration.

2. Fuel Pump Control

• When the ignition switch is initially turned on, the ECM supplies ground to the PGM-FI main relay that supplies

current to the fuel pump for two seconds to pressurize the fuel system.

• When the engine is running, the ECM supplies ground to the PGM-FI main relay that supplies current to the fuel pump.

• When the engine is not running and the ignition is on, the ECM cuts ground to the PGM-FI main relay which cuts

current to the fuel pump.

3. Fuel Cut-off Control

• During deceleration with the throttle valve closed, current to the fuel injectors is cut off to improve fuel economy at

speeds over 1,250 rpm.

• Fuel cut-off action also takes place when engine speed exceeds 7,100 rpm, regardless of the position of the throttle

valve, to protect the engine from over-revving.

CKP/TDC/CYP Sensor

CKF Sensor

MAF Sensor

ECT Sensor

IAT Sensor

TP Sensor

EGR Valve Lift Sensor

Primary HO2S

Secondary H02S

VSS

BARO Sensor

ELD

Front KS

Rear KS

Starter Signal

ALT FR Signal

Air Conditioning Signal

A/T Gear Position Signal

Battery Voltage (IGN.1)

Brake Switch Signal

PSP Switch Signal

EVAP Purge Flow Switch*1

Fuel Tank Pressure Sensor*2ProCarManuals.com

Page 951 of 1771

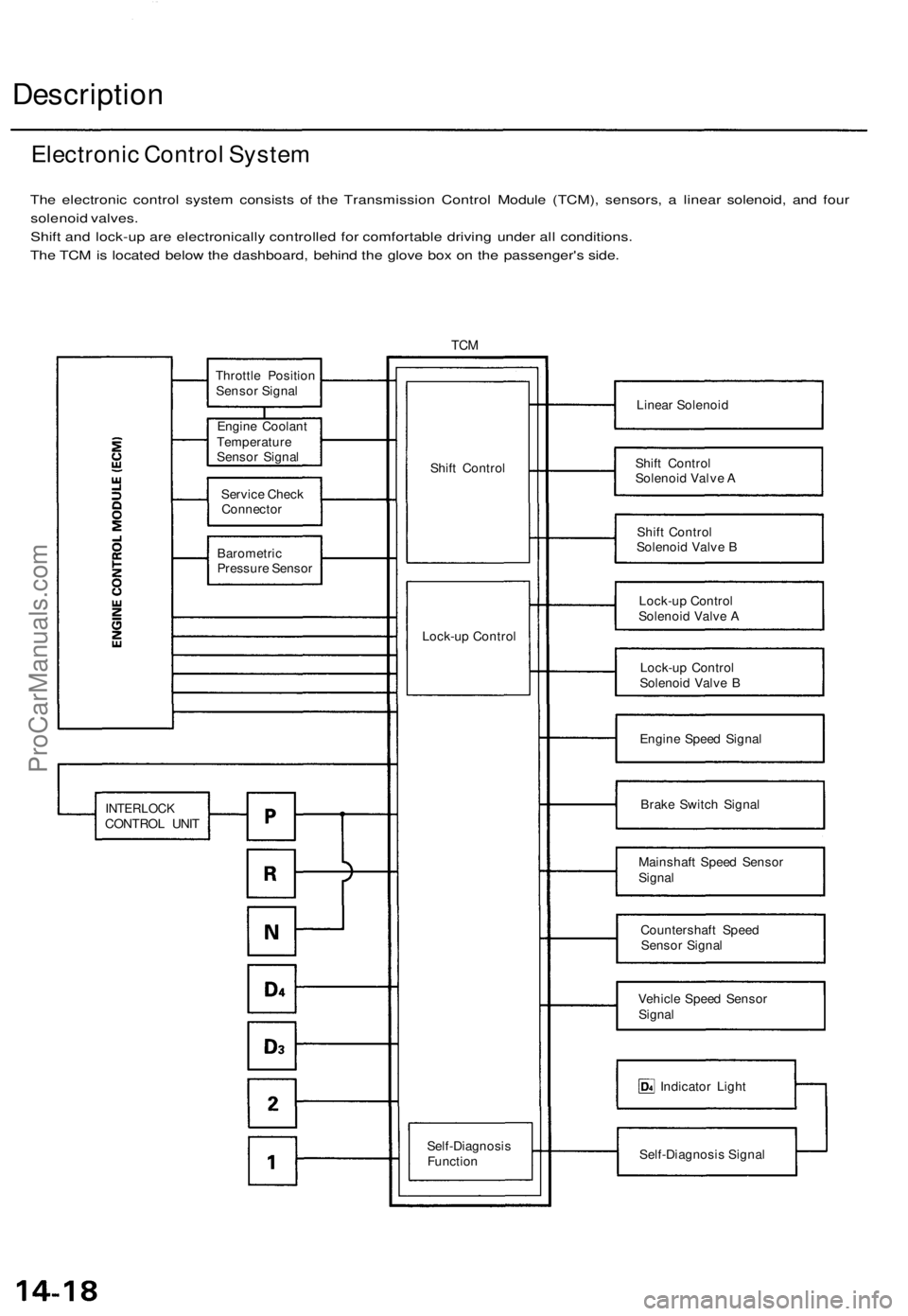

Description

The electronic control system consists of the Transmission Control Module (TCM), sensors, a linear solenoid, and four

solenoid valves.

Shift and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located below the dashboard, behind the glove box on the passenger's side.

TCM

Linear Solenoid

Shift Control

Solenoid Valve A

Shift Control

Solenoid Valve B

Lock-up Control

Solenoid Valve A

Lock-up Control

Solenoid Valve B

Engine Speed Signal

Brake Switch Signal

Mainshaft Speed Sensor

Signal

Countershaft Speed

Sensor Signal

Vehicle Speed Sensor

Signal

Indicator Light

Self-Diagnosis Signal

Electronic Control System

Shift Control

Lock-up Control

Throttle Position

Sensor Signal

Engine Coolant

Temperature

Sensor Signal

Service Check

Connector

Barometric

Pressure Sensor

INTERLOCK

CONTROL UNIT

Self-Diagnosis

FunctionProCarManuals.com

Page 953 of 1771

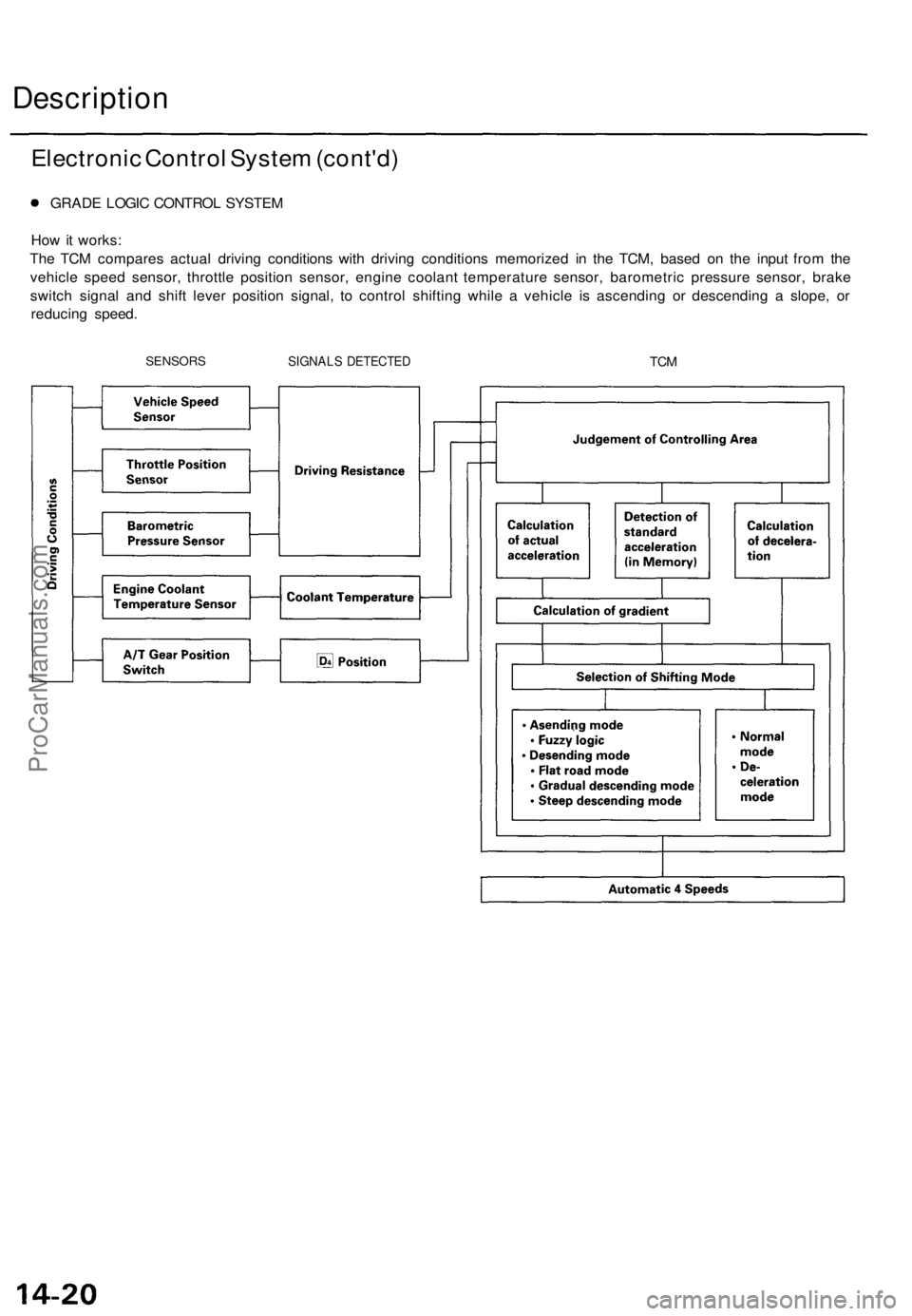

Description

GRADE LOGIC CONTROL SYSTEM

How it works:

The TCM compares actual driving conditions with driving conditions memorized in the TCM, based on the input from the

vehicle speed sensor, throttle position sensor, engine coolant temperature sensor, barometric pressure sensor, brake

switch signal and shift lever position signal, to control shifting while a vehicle is ascending or descending a slope, or

reducing speed.

SENSORS

SIGNALS DETECTED

TCM

Electronic Control System (cont'd)ProCarManuals.com

Page 972 of 1771

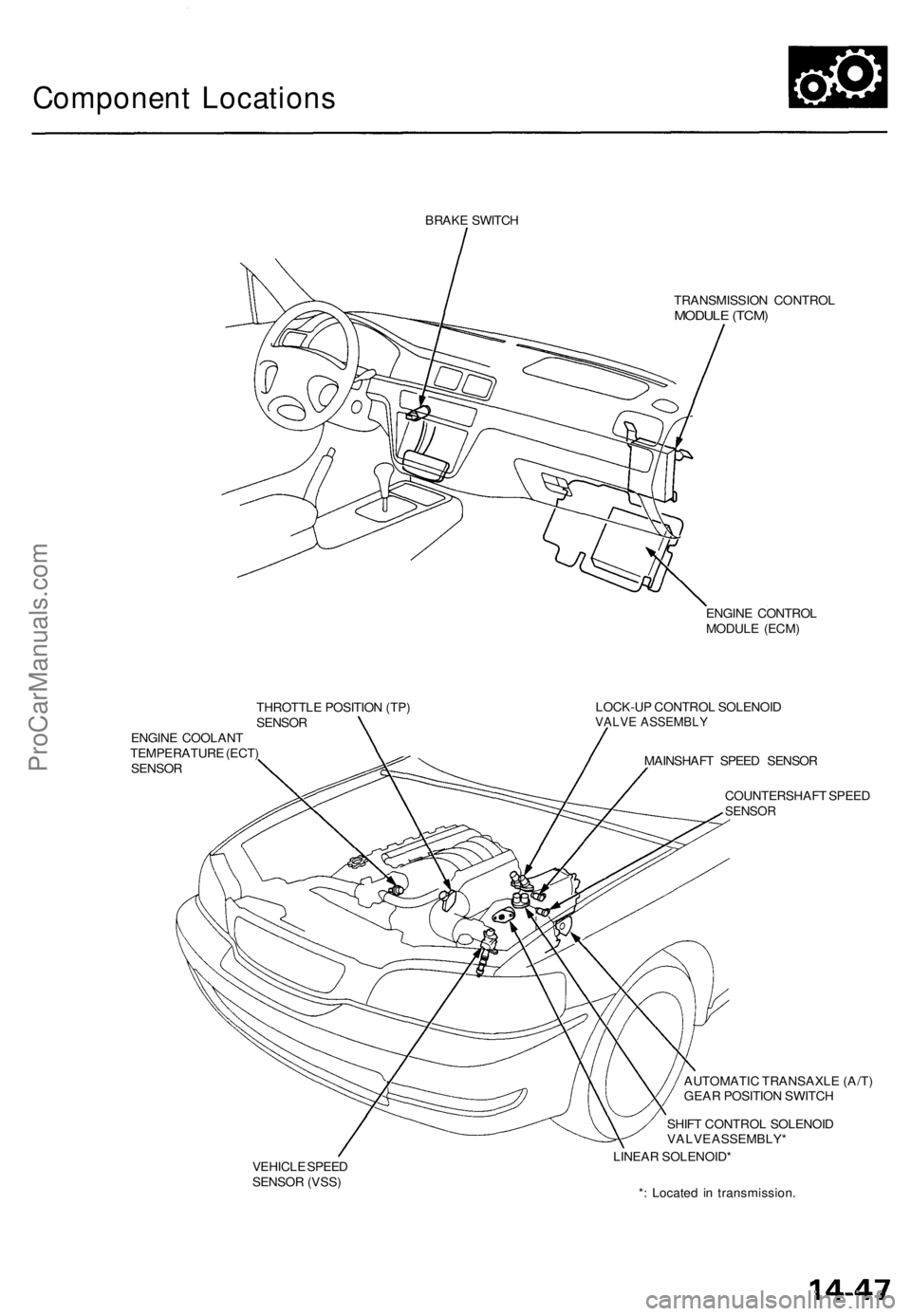

Component Locations

BRAKE SWITCH

TRANSMISSION CONTROL

MODULE (TCM)

ENGINE CONTROL

MODULE (ECM)

THROTTLE POSITION (TP)

SENSOR

ENGINE COOLANT

TEMPERATURE (ECT)

SENSOR

LOCK-UP CONTROL SOLENOID

VALVE ASSEMBLY

MAINSHAFT SPEED SENSOR

COUNTERSHAFT SPEED

SENSOR

VEHICLE SPEED

SENSOR (VSS)

AUTOMATIC TRANSAXLE (A/T)

GEAR POSITION SWITCH

SHIFT CONTROL SOLENOID

VALVE ASSEMBLY*

LINEAR SOLENOID*

*: Located in transmission.ProCarManuals.com

Page 985 of 1771

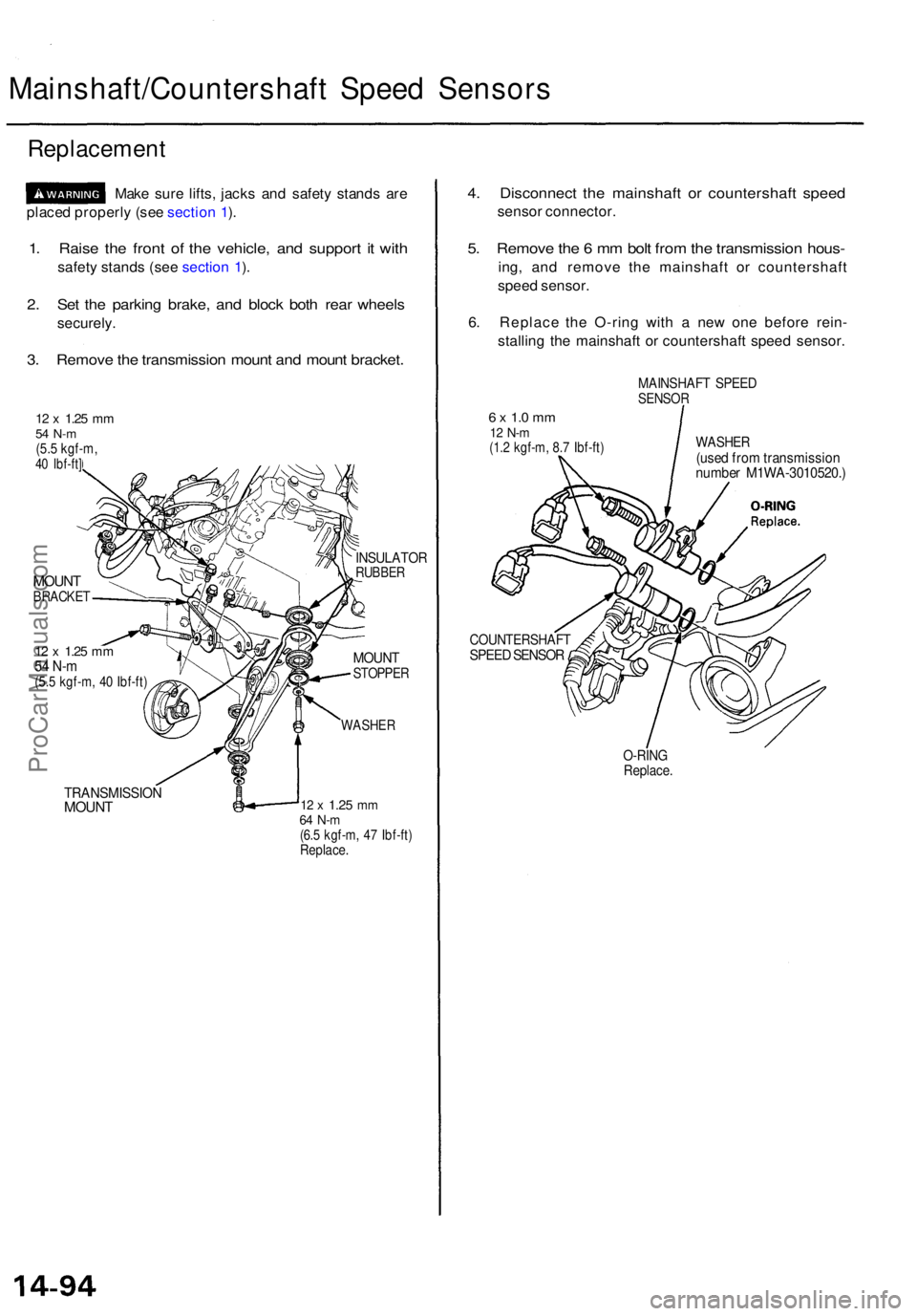

Mainshaft/Countershaft Spee d Sensor s

Replacemen t

Make sur e lifts , jack s an d safet y stand s ar e

place d properl y (se e sectio n 1 ).

1 . Rais e th e fron t o f th e vehicle , an d suppor t i t wit h

safet y stand s (se e sectio n 1 ).

2 . Se t th e parkin g brake , an d bloc k bot h rea r wheel s

securely .

3. Remov e th e transmissio n moun t an d moun t bracket .

12 x 1.2 5 mm54 N- m(5.5 kgf-m ,40 Ibf-ft ]

MOUN TBRACKE T

12 x 1.2 5 mm54 N- m(5.5 kgf-m , 4 0 Ibf-ft )

TRANSMISSIO NMOUNT

INSULATO RRUBBER

MOUNTSTOPPE R

WASHER

12 x 1.2 5 mm64 N- m(6.5 kgf-m , 4 7 Ibf-ft )Replace .

4. Disconnec t th e mainshaf t o r countershaf t spee d

senso r connector .

5. Remov e th e 6 m m bol t fro m th e transmissio n hous -

ing, an d remov e th e mainshaf t o r countershaf t

spee d sensor .

6 . Replac e th e O-rin g wit h a ne w on e befor e rein -

stallin g th e mainshaf t o r countershaf t spee d sensor .

MAINSHAF T SPEE DSENSO R

6 x 1. 0 m m12 N- m(1.2 kgf-m , 8. 7 Ibf-ft )WASHE R(used fro m transmissio n

numbe r M1WA-3010520. )

COUNTERSHAFTSPEED SENSO R

O-RINGReplace .

ProCarManuals.com

Page 1286 of 1771

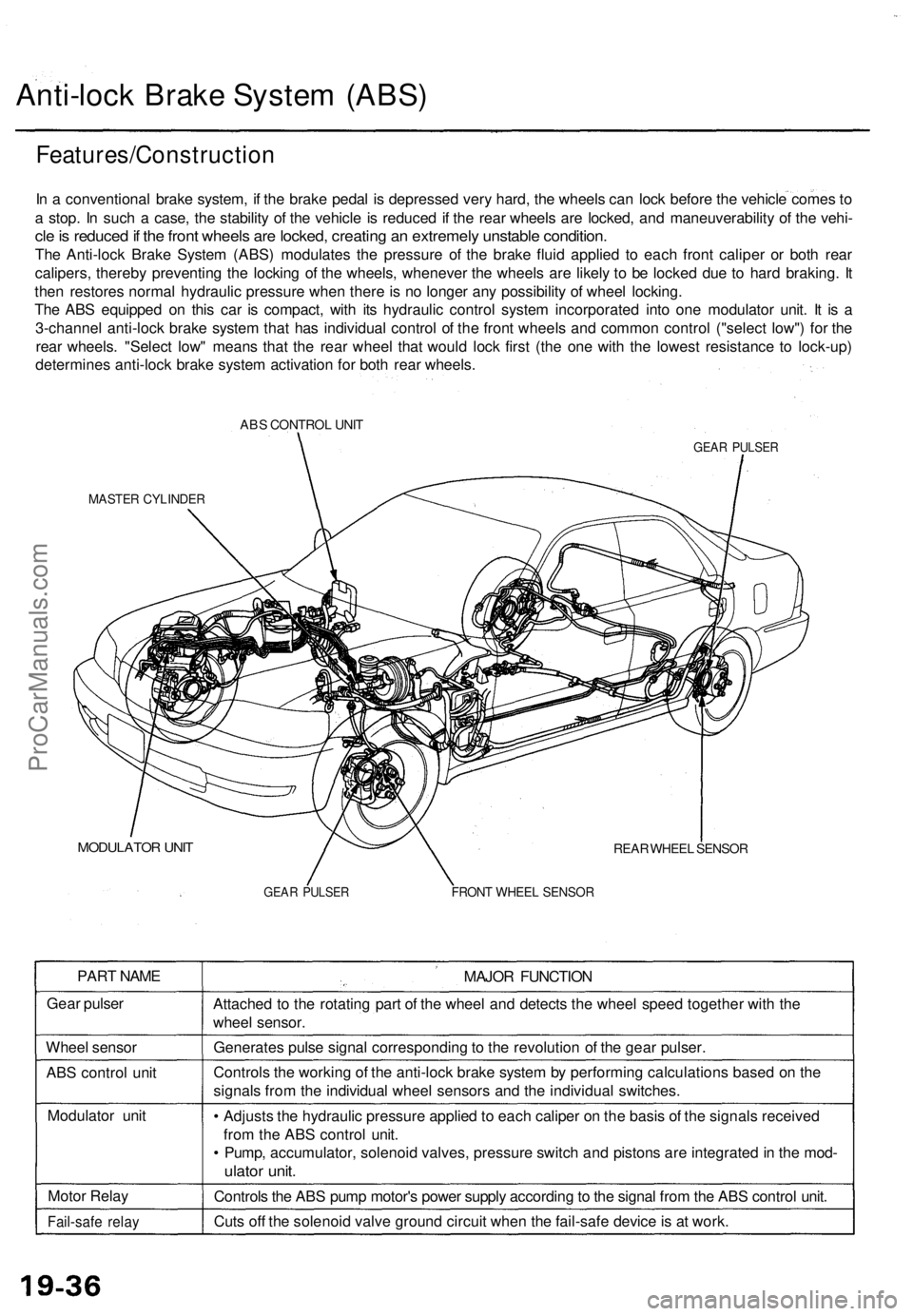

Anti-lock Brake System (ABS)

Features/Construction

In a conventional brake system, if the brake pedal is depressed very hard, the wheels can lock before the vehicle comes to

a stop. In such a case, the stability of the vehicle is reduced if the rear wheels are locked, and maneuverability of the vehi-

cle is reduced if the front wheels are locked, creating an extremely unstable condition.

The Anti-lock Brake System (ABS) modulates the pressure of the brake fluid applied to each front caliper or both rear

calipers, thereby preventing the locking of the wheels, whenever the wheels are likely to be locked due to hard braking. It

then restores normal hydraulic pressure when there is no longer any possibility of wheel locking.

The ABS equipped on this car is compact, with its hydraulic control system incorporated into one modulator unit. It is a

3-channel anti-lock brake system that has individual control of the front wheels and common control ("select low") for the

rear wheels. "Select low" means that the rear wheel that would lock first (the one with the lowest resistance to lock-up)

determines anti-lock brake system activation for both rear wheels.

ABS CONTROL UNIT

GEAR PULSER

MASTER CYLINDER

MODULATOR UNIT

REAR WHEEL SENSOR

GEAR PULSER

FRONT WHEEL SENSOR

PART NAME

Gear pulser

Wheel sensor

ABS control unit

Modulator unit

Motor Relay

Fail-safe relay

MAJOR FUNCTION

Attached to the rotating part of the wheel and detects the wheel speed together with the

wheel sensor.

Generates pulse signal corresponding to the revolution of the gear pulser.

Controls the working of the anti-lock brake system by performing calculations based on the

signals from the individual wheel sensors and the individual switches.

• Adjusts the hydraulic pressure applied to each caliper on the basis of the signals received

from the ABS control unit.

• Pump, accumulator, solenoid valves, pressure switch and pistons are integrated in the mod-

ulator unit.

Controls the ABS pump motor's power supply according to the signal from the ABS control unit.

Cuts off the solenoid valve ground circuit when the fail-safe device is at work.ProCarManuals.com

Page 1290 of 1771

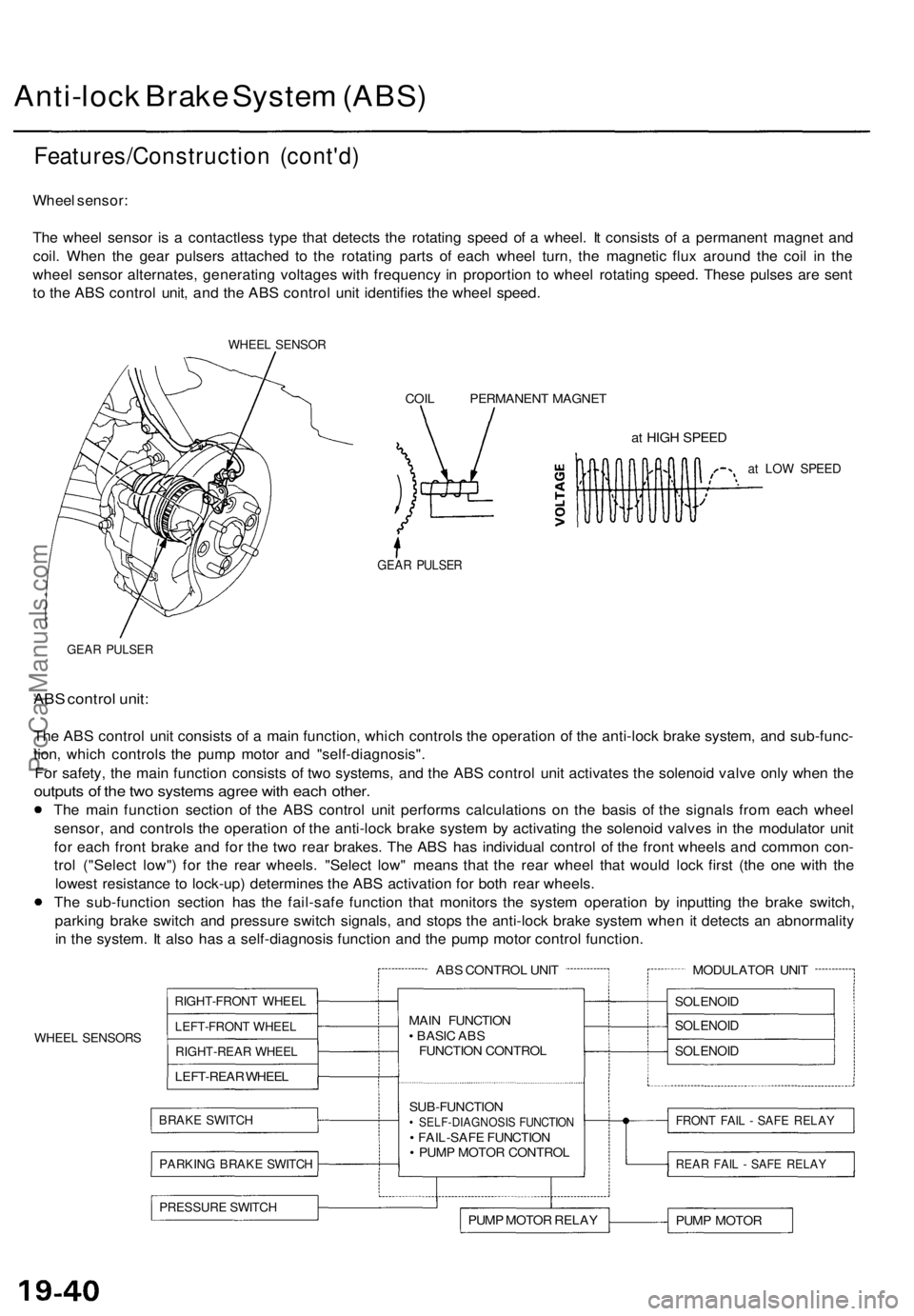

Anti-lock Brake System (ABS)

Features/Construction (cont'd)

Wheel sensor:

The wheel sensor is a contactless type that detects the rotating speed of a wheel. It consists of a permanent magnet and

coil. When the gear pulsers attached to the rotating parts of each wheel turn, the magnetic flux around the coil in the

wheel sensor alternates, generating voltages with frequency in proportion to wheel rotating speed. These pulses are sent

to the ABS control unit, and the ABS control unit identifies the wheel speed.

WHEEL SENSOR

COIL PERMANENT MAGNET

at HIGH SPEED

at LOW SPEED

GEAR PULSER

GEAR PULSER

ABS control unit:

The ABS control unit consists of a main function, which controls the operation of the anti-lock brake system, and sub-func-

tion, which controls the pump motor and "self-diagnosis".

For safety, the main function consists of two systems, and the ABS control unit activates the solenoid valve only when the

outputs of the two systems agree with each other.

The main function section of the ABS control unit performs calculations on the basis of the signals from each wheel

sensor, and controls the operation of the anti-lock brake system by activating the solenoid valves in the modulator unit

for each front brake and for the two rear brakes. The ABS has individual control of the front wheels and common con-

trol ("Select low") for the rear wheels. "Select low" means that the rear wheel that would lock first (the one with the

lowest resistance to lock-up) determines the ABS activation for both rear wheels.

The sub-function section has the fail-safe function that monitors the system operation by inputting the brake switch,

parking brake switch and pressure switch signals, and stops the anti-lock brake system when it detects an abnormality

in the system. It also has a self-diagnosis function and the pump motor control function.

WHEEL SENSORS

ABS CONTROL UNIT

RIGHT-FRONT WHEEL

LEFT-FRONT WHEEL

RIGHT-REAR WHEEL

LEFT-REAR WHEEL

BRAKE SWITCH

PARKING BRAKE SWITCH

MAIN FUNCTION

• BASIC ABS

FUNCTION CONTROL

SUB-FUNCTION

• SELF-DIAGNOSIS FUNCTION

• FAIL-SAFE FUNCTION

• PUMP MOTOR CONTROL

PRESSURE SWITCH

PUMP MOTOR RELAY

MODULATOR UNIT

SOLENOID

SOLENOID

SOLENOID

FRONT FAIL - SAFE RELAY

REAR FAIL - SAFE RELAY

PUMP MOTORProCarManuals.com

Page 1291 of 1771

Pump motor control:

The ABS control unit monitors the brake fluid pressure in the accumulator by the pressure switch ON/OFF signals. The

ABS control unit turns the pump on when the pressure in the accumulator drops, and stops the pump when the pressure

rises to the specified value.

If the pressure does not reach the specified value after the motor has operated continuously for a specified period, the

ABS control unit stops the motor and activates the ABS indicator light.

Self-diagnosis function:

The self-diagnosis function, provided in the sub-function of the ABS control unit, monitors the main system functions by

constantly transmitting the data between the two Central Processing Units (CPUs). When an abnormality is detected, the

ABS control unit turns the ABS indicator light on and stops the ABS, although the basic brake system continues to operate

normally.

When the ABS control unit detects an abnormality with the ABS and turns the ABS indicator light on, the diagnostic trou-

ble code (DTC), which shows the problem part or unit, is recorded in the control unit. The DTC can be read by the blinking

frequency of the ABS indicator light.

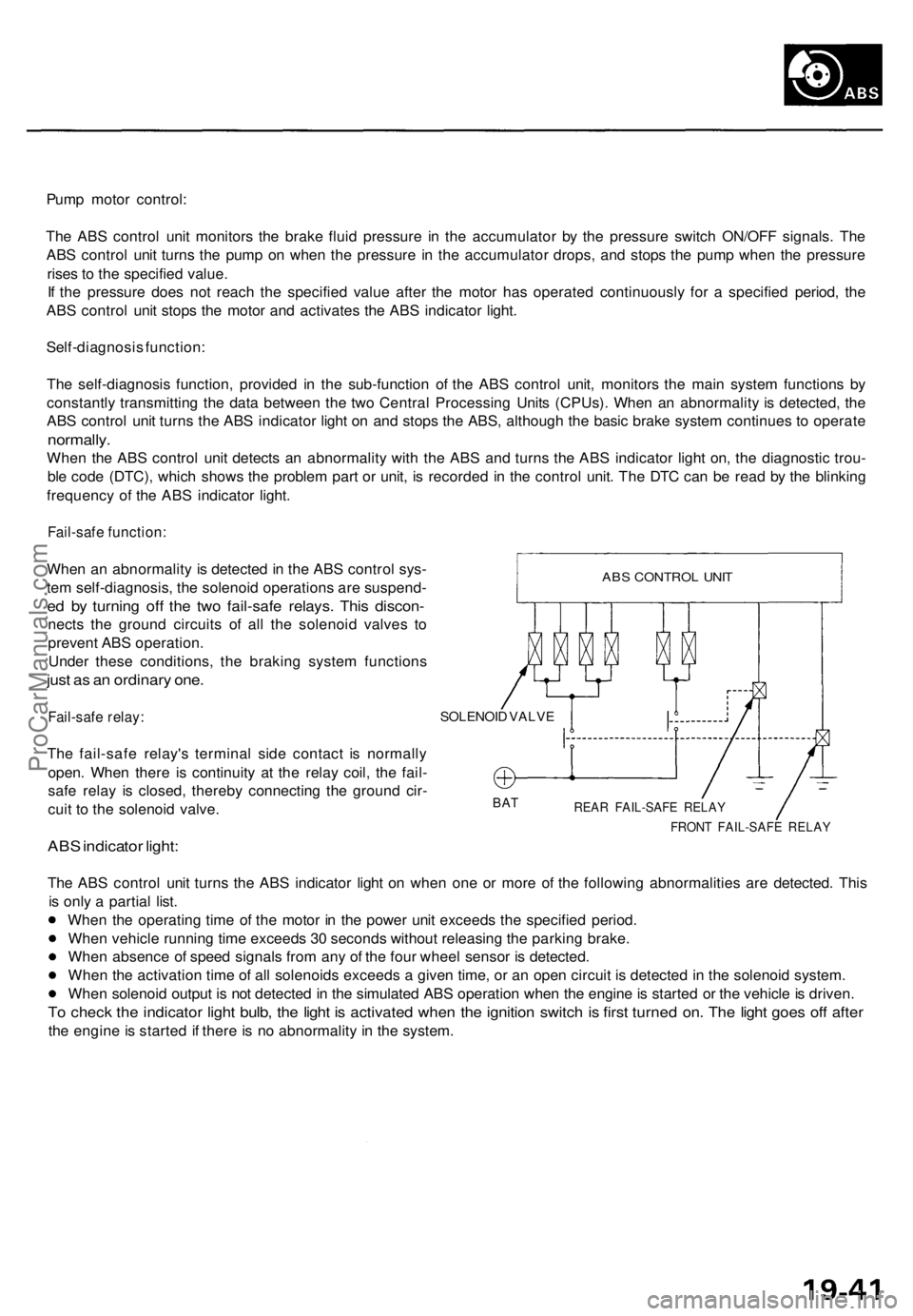

Fail-safe function:

When an abnormality is detected in the ABS control sys-

tem self-diagnosis, the solenoid operations are suspend-

ed by turning off the two fail-safe relays. This discon-

nects the ground circuits of all the solenoid valves to

prevent ABS operation.

Under these conditions, the braking system functions

just as an ordinary one.

Fail-safe relay:

The fail-safe relay's terminal side contact is normally

open. When there is continuity at the relay coil, the fail-

safe relay is closed, thereby connecting the ground cir-

cuit to the solenoid valve.

ABS indicator light:

SOLENOID VALVE

BAT

REAR FAIL-SAFE RELAY

FRONT FAIL-SAFE RELAY

The ABS control unit turns the ABS indicator light on when one or more of the following abnormalities are detected. This

is only a partial list.

When the operating time of the motor in the power unit exceeds the specified period.

When vehicle running time exceeds 30 seconds without releasing the parking brake.

When absence of speed signals from any of the four wheel sensor is detected.

When the activation time of all solenoids exceeds a given time, or an open circuit is detected in the solenoid system.

When solenoid output is not detected in the simulated ABS operation when the engine is started or the vehicle is driven.

To check the indicator light bulb, the light is activated when the ignition switch is first turned on. The light goes off after

the engine is started if there is no abnormality in the system.

ABS CONTROL UNITProCarManuals.com

Page 1295 of 1771

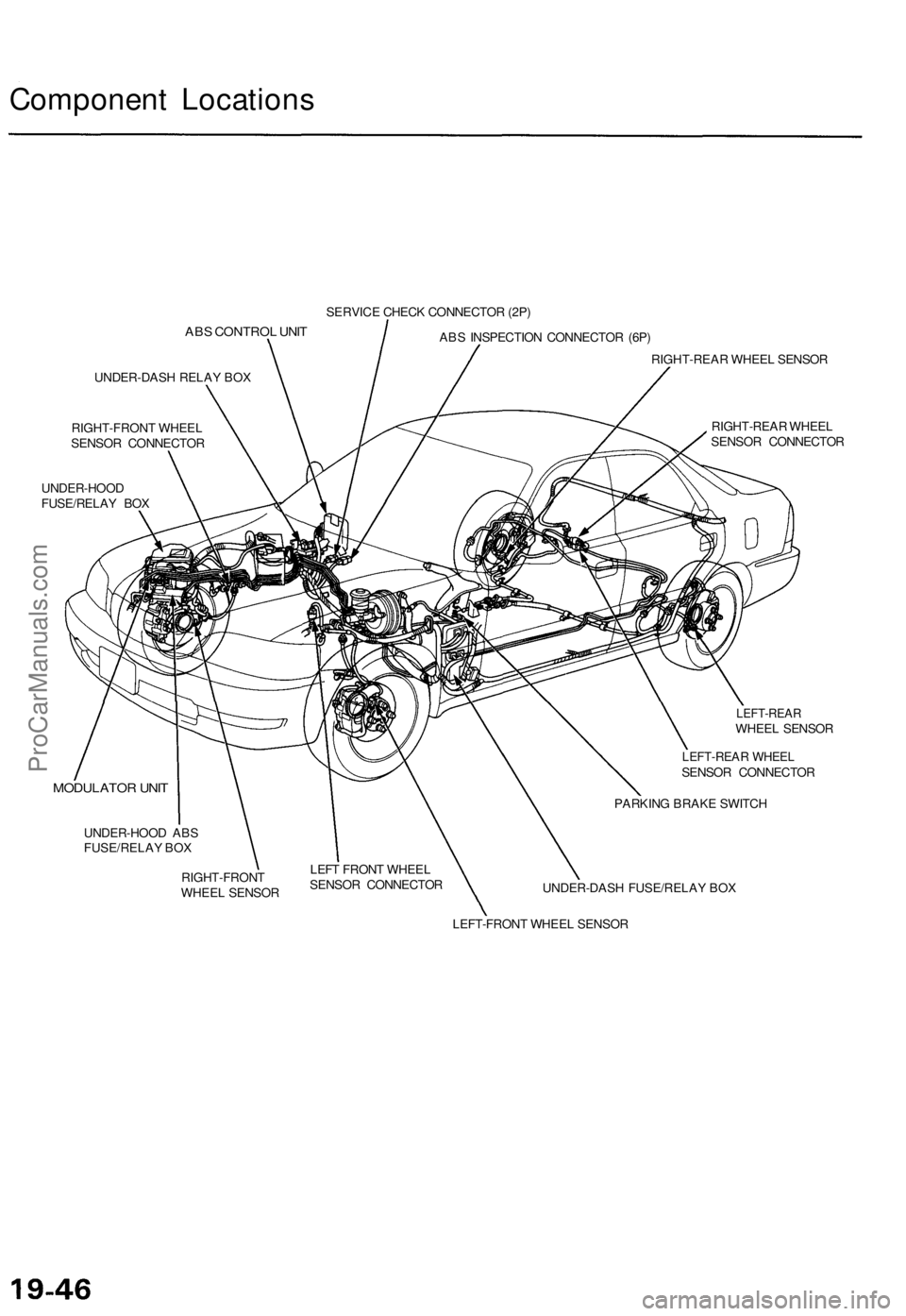

Component Locations

ABS CONTROL UNIT

UNDER-DASH RELAY BOX

RIGHT-FRONT WHEEL

SENSOR CONNECTOR

UNDER-HOOD

FUSE/RELAY BOX

SERVICE CHECK CONNECTOR (2P)

ABS INSPECTION CONNECTOR (6P)

MODULATOR UNIT

UNDER-HOOD ABS

FUSE/RELAY BOX

RIGHT-REAR WHEEL SENSOR

RIGHT-REAR WHEEL

SENSOR CONNECTOR

LEFT-REAR

WHEEL SENSOR

LEFT-REAR WHEEL

SENSOR CONNECTOR

RIGHT-FRONT

WHEEL SENSOR

LEFT FRONT WHEEL

SENSOR CONNECTOR

PARKING BRAKE SWITCH

UNDER-DASH FUSE/RELAY BOX

LEFT-FRONT WHEEL SENSORProCarManuals.com