tires ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 12 of 1771

Towing

If the vehicle needs to be towed, call a professional tow-

ing service. Never tow the vehicle behind another vehi-

cle with just a rope or chain. It is very dangerous.

Emergency Towing

There are three popular methods of towing a vehicle:

Flat-bed Equipment — The operator loads the vehicle on

the back of a truck. This is the best way of transporting the

vehicle.

Wheel Lift Equipment — The tow truck uses two pivoting

arms that go under the tires (front or rear) and lifts them

off the ground. The other two wheels remain on the

ground.

Sling-type Equipment — The tow truck uses metal cables

with hooks on the ends. These hooks go around parts of

the frame or suspension and the cables lift that end of

the vehicle off the ground. The vehicle's suspension and

body can be seriously damaged if this method of towing

is attempted.

If the vehicle cannot be transported by flat-bed, it should

be towed with the front wheels off the ground. If due to

damage, the vehicle must be towed with the front

wheels on the ground, do the following:

Release the parking brake.

Start the engine.

Shift to position, then position.

Turn off the engine.

CAUTION:

Improper towing preparation will damage the trans-

mission. Follow the above procedure exactly. If you

cannot shift the transmission or start the engine, the

vehicle must be transported on a flat-bed.

It is best to tow the vehicle no farther than 50 miles

(80 km), and keep the speed below 35 mph (55 km/h).

Trying to lift or tow the vehicle by the bumpers will

cause serious damage. The bumpers are not designed

to support the vehicle's weight.

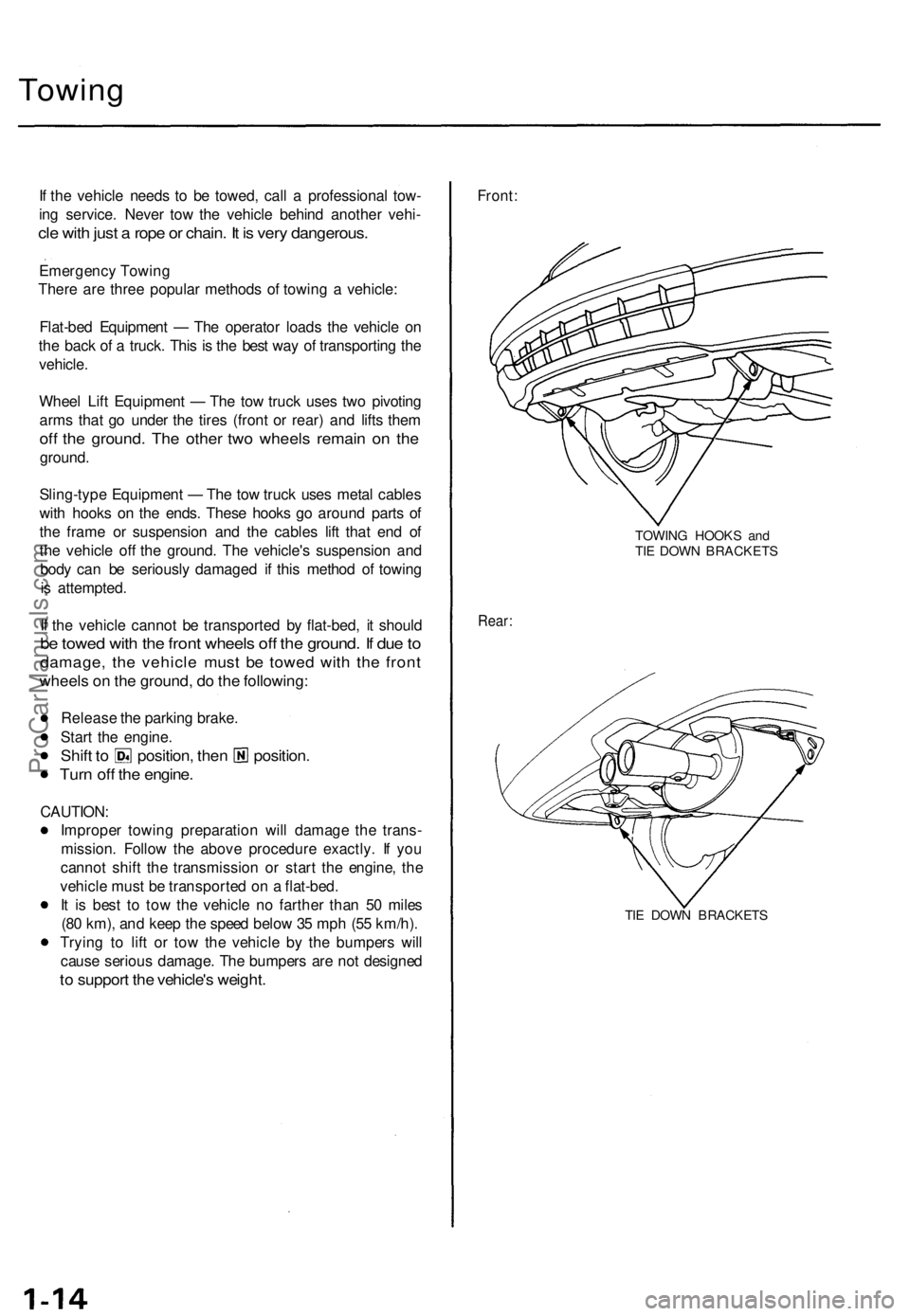

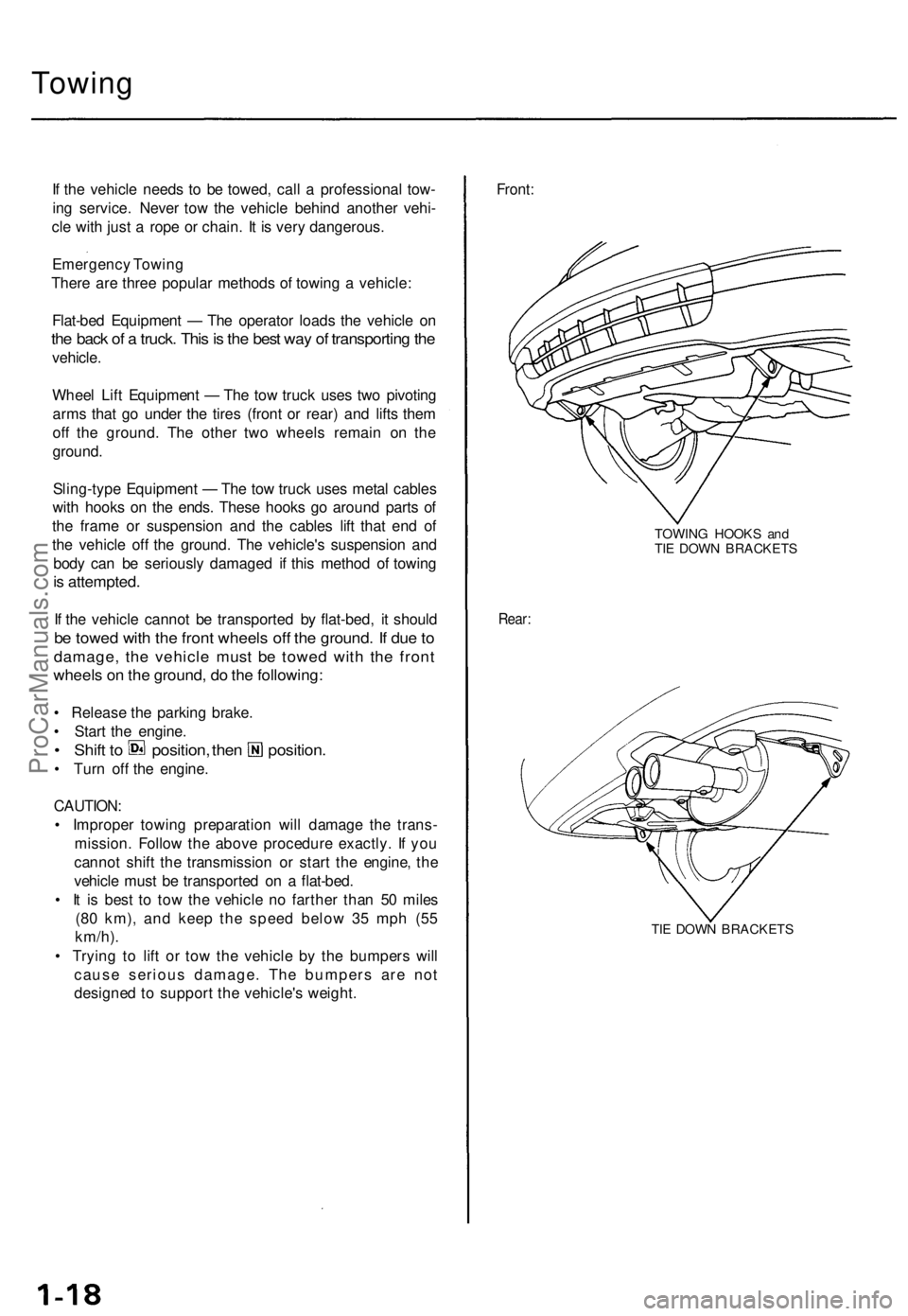

Front:

TOWING HOOKS and

TIE DOWN BRACKETS

Rear:

TIE DOWN BRACKETSProCarManuals.com

Page 48 of 1771

Engine Removal/Installatio n

Removal (cont'd )

30. Remov e th e radiato r cap .

Us e car e whe n removin g th e radiato r

ca p to avoi d scaldin g b y ho t coolan t o r steam .

31 . Rais e th e hois t t o ful l height .

32 . Remov e th e fron t tires/wheel s an d splas h shield .

SPLAS H

SHIEL D

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )33. Drai n th e engin e coolan t (se e pag e 10-5 ).

• Loose n th e drai n plu g i n th e radiator .

34 . Drai n th e automati c transmissio n flui d (ATF) . Reinstal l

th e drai n plu g usin g a ne w washe r (se e sectio n 14 ).

35 . Drai n th e differentia l oil . Reinstal l th e drai n plu g

usin g a ne w washe r (se e sectio n 15 ).

36 . Drai n th e engin e oil . Reinstal l th e drai n bol t usin g a

ne w washe r (se e pag e 8-4 ).

37 . Remov e th e dampe r fork s (se e sectio n 18 ).

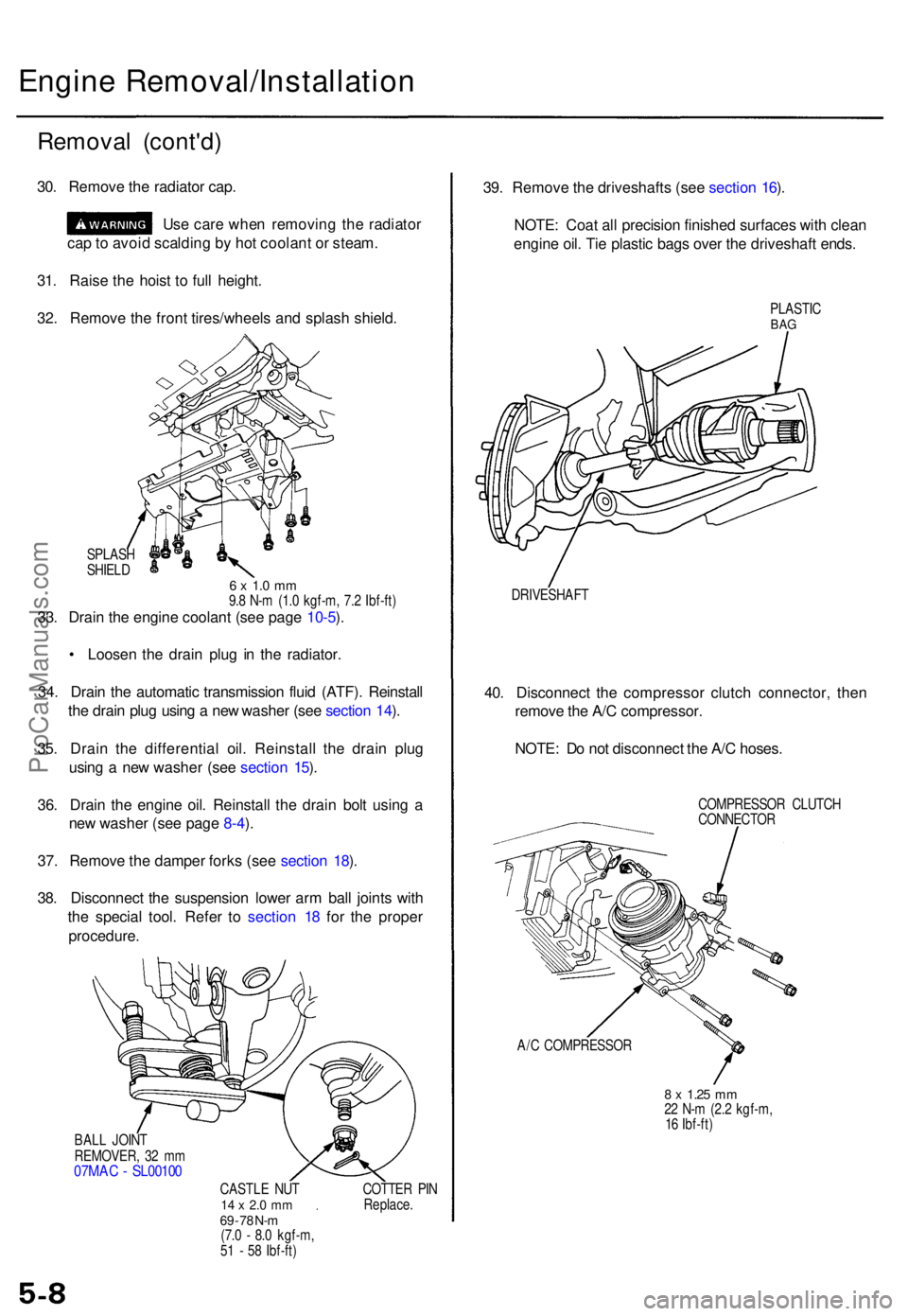

38 . Disconnec t th e suspensio n lowe r ar m bal l joint s wit h

th e specia l tool . Refe r t o sectio n 1 8 fo r th e prope r

procedure .

BALL JOIN T

REMOVER , 3 2 m m

07MA C - SL0010 0

CASTLE NU T14 x 2. 0 m m69 - 7 8 N- m(7. 0 - 8. 0 kgf-m ,

5 1 - 5 8 Ibf-ft ) COTTE

R PI N

Replace .

39. Remov e th e driveshaft s (se e sectio n 16 ).

NOTE : Coa t al l precisio n finishe d surface s wit h clea n

engin e oil . Ti e plasti c bag s ove r th e driveshaf t ends .

PLASTI CBAG

DRIVESHAF T

40. Disconnec t th e compresso r clutc h connector , the n

remov e th e A/ C compressor .

NOTE : D o no t disconnec t th e A/ C hoses .

COMPRESSO R CLUTC H

CONNECTO R

A/ C COMPRESSO R

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

ProCarManuals.com

Page 492 of 1771

Component Location s Whee

l Alignmen t

Index

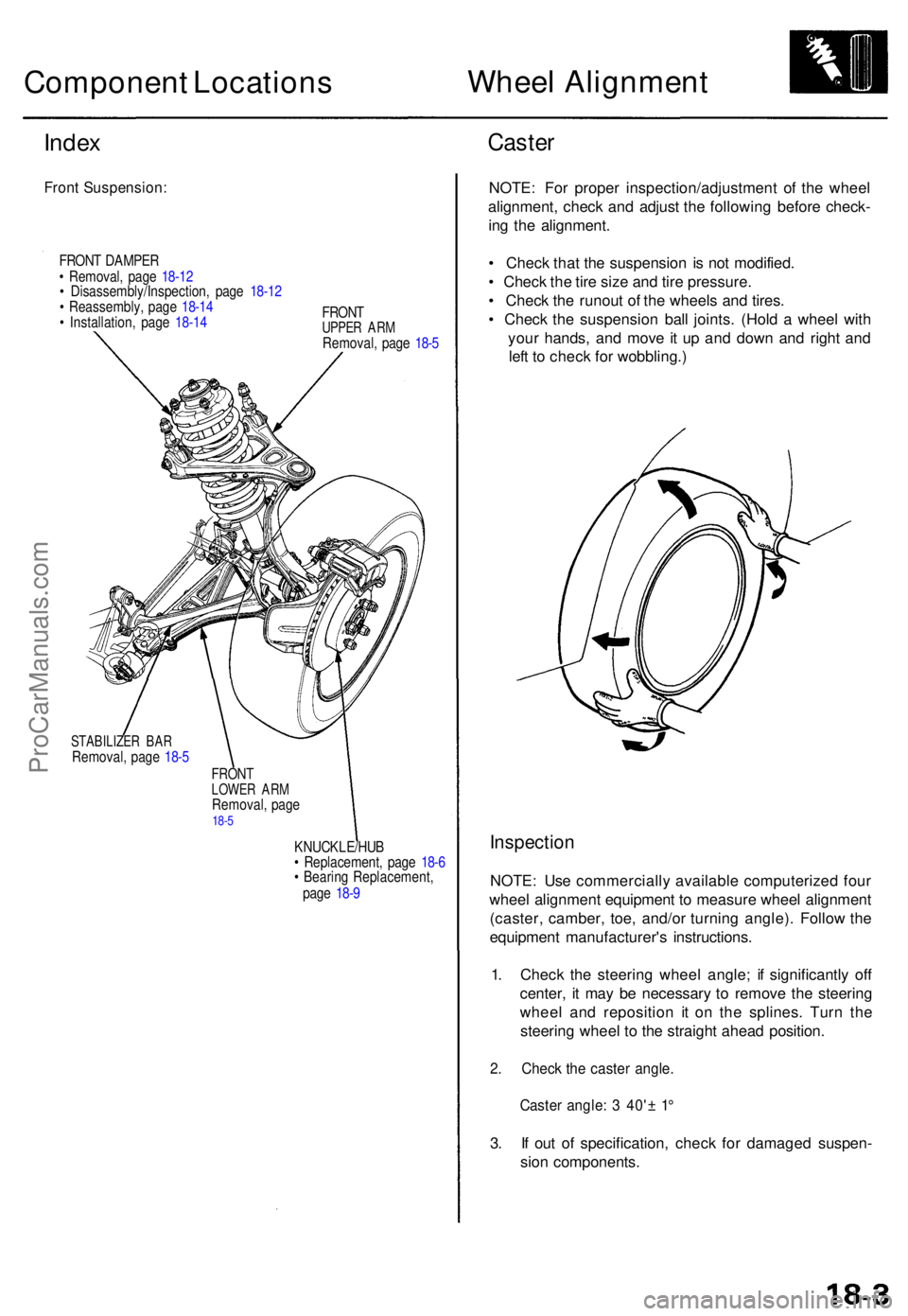

Fron t Suspension :

FRONT DAMPE R

• Removal , pag e 18-1 2

• Disassembly/Inspection , pag e 18-1 2

• Reassembly , pag e 18-1 4

• Installation , pag e 18-1 4 FRON

T

UPPER AR MRemoval , pag e 18- 5

STABILIZE R BA RRemoval , pag e 18- 5

FRON TLOWE R AR MRemoval , pag e18-5

KNUCKLE/HU B

• Replacement , pag e 18- 6

• Bearin g Replacement ,

pag e 18- 9

Caste r

NOTE : Fo r prope r inspection/adjustmen t of the whee l

alignment , chec k an d adjus t th e followin g befor e check -

in g th e alignment .

• Chec k tha t th e suspensio n i s no t modified .

• Chec k th e tir e siz e an d tir e pressure .

• Chec k th e runou t o f th e wheel s an d tires .

• Chec k th e suspensio n bal l joints . (Hol d a whee l wit h

you r hands , an d mov e i t u p an d dow n an d righ t an d

lef t t o chec k fo r wobbling. )

Inspection

NOTE: Us e commerciall y availabl e computerize d fou r

whee l alignmen t equipmen t t o measur e whee l alignmen t

(caster , camber , toe , and/o r turnin g angle) . Follo w th e

equipmen t manufacturer' s instructions .

1 . Chec k th e steerin g whee l angle ; i f significantl y of f

center , i t ma y b e necessar y t o remov e th e steerin g

whee l an d repositio n i t o n th e splines . Tur n th e

steerin g whee l t o th e straigh t ahea d position .

2. Chec k th e caste r angle .

Caster angle : 3 40' ± 1 °

3. I f ou t o f specification , chec k fo r damage d suspen -

sio n components .

ProCarManuals.com

Page 530 of 1771

Construction and Function

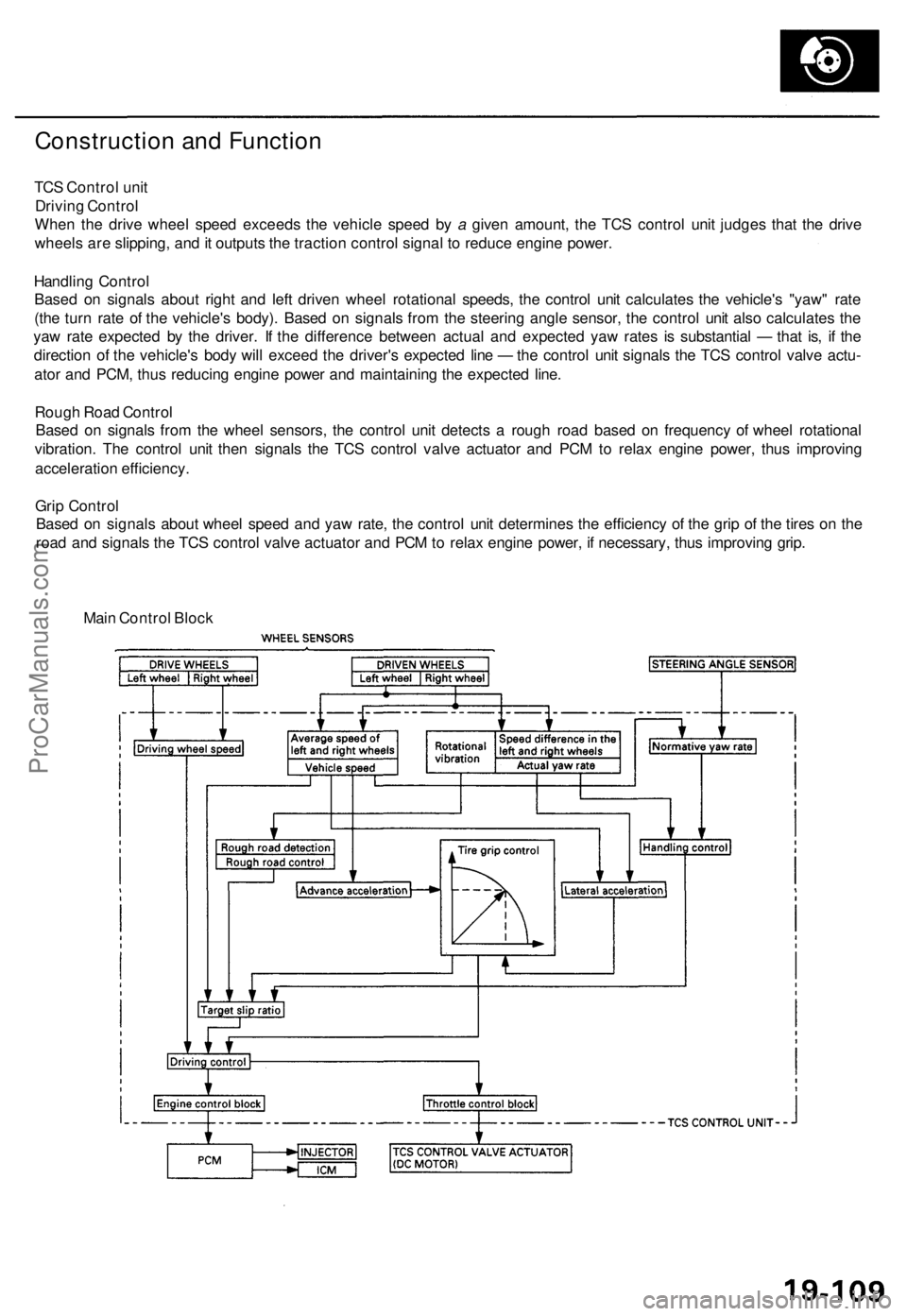

TCS Control unit

Driving Control

When the drive wheel speed exceeds the vehicle speed by a given amount, the TCS control unit judges that the drive

wheels are slipping, and it outputs the traction control signal to reduce engine power.

Handling Control

Based on signals about right and left driven wheel rotational speeds, the control unit calculates the vehicle's "yaw" rate

(the turn rate of the vehicle's body). Based on signals from the steering angle sensor, the control unit also calculates the

yaw rate expected by the driver. If the difference between actual and expected yaw rates is substantial — that is, if the

direction of the vehicle's body will exceed the driver's expected line — the control unit signals the TCS control valve actu-

ator and PCM, thus reducing engine power and maintaining the expected line.

Rough Road Control

Based on signals from the wheel sensors, the control unit detects a rough road based on frequency of wheel rotational

vibration. The control unit then signals the TCS control valve actuator and PCM to relax engine power, thus improving

acceleration efficiency.

Grip Control

Based on signals about wheel speed and yaw rate, the control unit determines the efficiency of the grip of the tires on the

road and signals the TCS control valve actuator and PCM to relax engine power, if necessary, thus improving grip.

Main Control BlockProCarManuals.com

Page 688 of 1771

Towing

If the vehicle needs to be towed, call a professional tow-

ing service. Never tow the vehicle behind another vehi-

cle with just a rope or chain. It is very dangerous.

Emergency Towing

There are three popular methods of towing a vehicle:

Flat-bed Equipment — The operator loads the vehicle on

the back of a truck. This is the best way of transporting the

vehicle.

Wheel Lift Equipment — The tow truck uses two pivoting

arms that go under the tires (front or rear) and lifts them

off the ground. The other two wheels remain on the

ground.

Sling-type Equipment — The tow truck uses metal cables

with hooks on the ends. These hooks go around parts of

the frame or suspension and the cables lift that end of

the vehicle off the ground. The vehicle's suspension and

body can be seriously damaged if this method of towing

is attempted.

If the vehicle cannot be transported by flat-bed, it should

be towed with the front wheels off the ground. If due to

damage, the vehicle must be towed with the front

wheels on the ground, do the following:

• Release the parking brake.

• Start the engine.

• Shift to position, then position.

• Turn off the engine.

CAUTION:

• Improper towing preparation will damage the trans-

mission. Follow the above procedure exactly. If you

cannot shift the transmission or start the engine, the

vehicle must be transported on a flat-bed.

• It is best to tow the vehicle no farther than 50 miles

(80 km), and keep the speed below 35 mph (55

km/h).

• Trying to lift or tow the vehicle by the bumpers will

cause serious damage. The bumpers are not

designed to support the vehicle's weight.

Front:

TOWING HOOKS and

TIE DOWN BRACKETS

Rear:

TIE DOWN BRACKETSProCarManuals.com

Page 723 of 1771

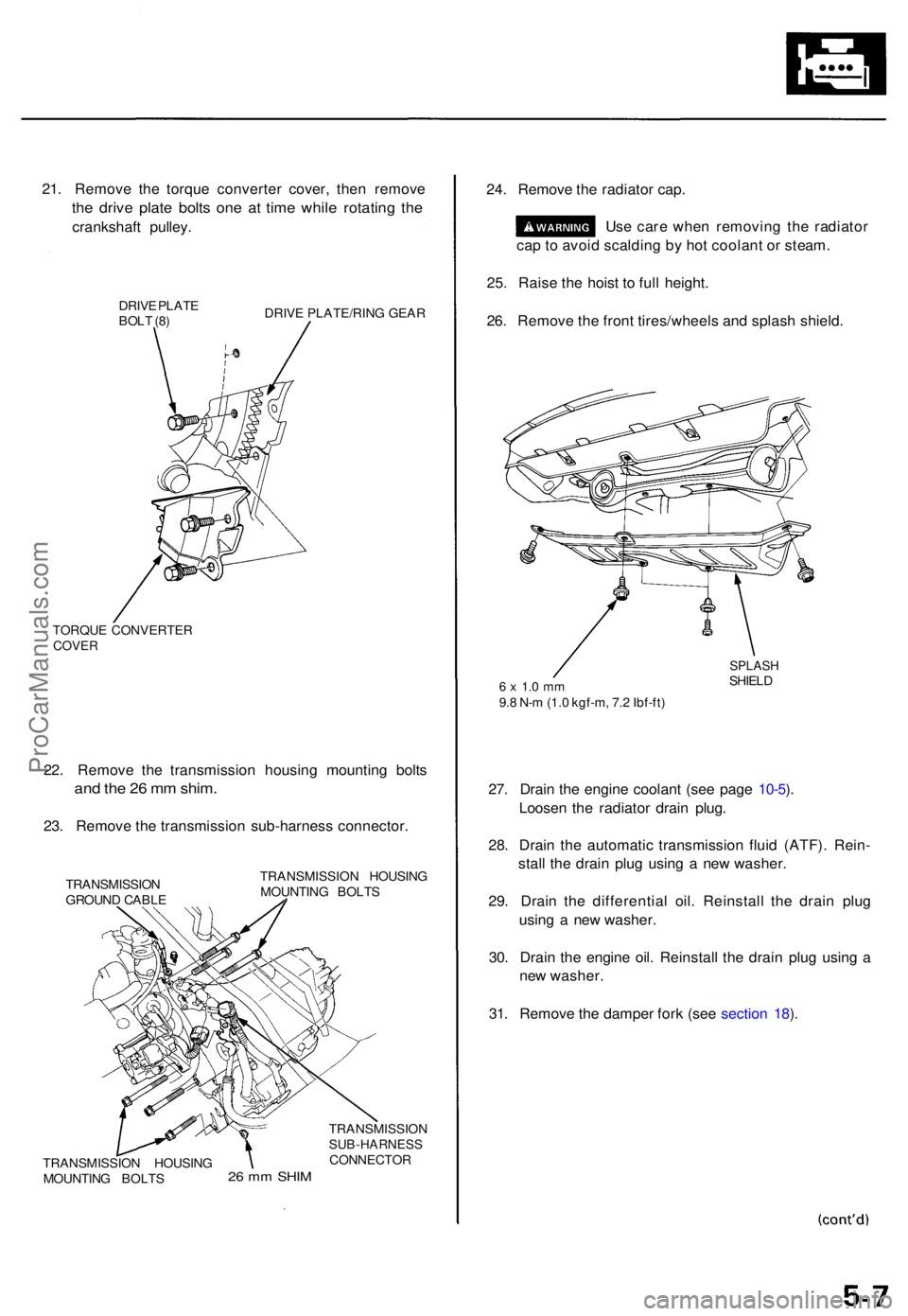

21. Remov e th e torqu e converte r cover , the n remov e

the driv e plat e bolt s on e a t tim e whil e rotatin g th e

crankshaf t pulley .

DRIVE PLAT E

BOL T (8 ) DRIV

E PLATE/RIN G GEA R

TORQU E CONVERTE R

COVER

22. Remov e th e transmissio n housin g mountin g bolt s

and th e 2 6 m m shim .

23. Remov e th e transmissio n sub-harnes s connector .

TRANSMISSIO N

GROUN D CABL E TRANSMISSIO

N HOUSIN G

MOUNTIN G BOLT S

24. Remov e th e radiato r cap .

Us e car e whe n removin g th e radiato r

ca p to avoi d scaldin g b y ho t coolan t o r steam .

25 . Rais e th e hois t t o ful l height .

26 . Remov e th e fron t tires/wheel s an d splas h shield .

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

SPLAS HSHIELD

27. Drai n th e engin e coolan t (se e pag e 10-5 ).

Loose n th e radiato r drai n plug .

28 . Drai n th e automati c transmissio n flui d (ATF) . Rein -

stal l th e drai n plu g usin g a ne w washer .

29 . Drai n th e differentia l oil . Reinstal l th e drai n plu g

usin g a ne w washer .

30 . Drai n th e engin e oil . Reinstal l th e drai n plu g usin g a

ne w washer .

31 . Remov e th e dampe r for k (se e sectio n 18 ).

2 6 m m SHI M

TRANSMISSIO NSUB-HARNESSCONNECTOR

TRANSMISSIO N HOUSIN G

MOUNTIN G BOLT S

ProCarManuals.com

Page 1218 of 1771

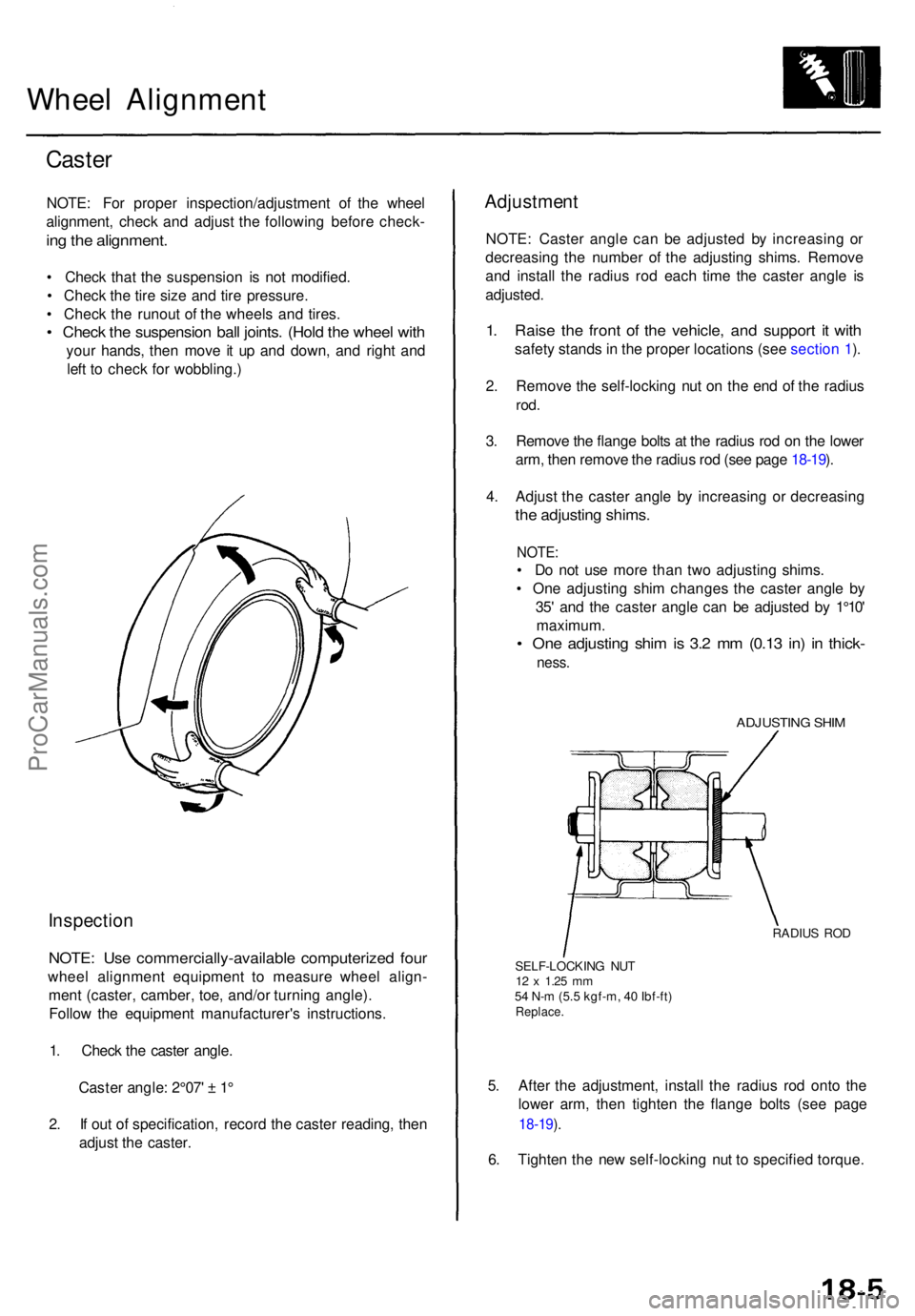

Wheel Alignmen t

Caster

NOTE : Fo r prope r inspection/adjustmen t o f th e whee l

alignment , chec k an d adjus t th e followin g befor e check -

ing th e alignment .

• Chec k tha t th e suspensio n i s no t modified .

• Chec k th e tir e siz e an d tir e pressure .

• Chec k th e runou t o f th e wheel s an d tires .

• Chec k th e suspensio n bal l joints . (Hol d th e whee l wit h

you r hands , the n mov e i t u p an d down , an d righ t an d

lef t t o chec k fo r wobbling. )

Inspection

NOTE: Us e commercially-availabl e computerize d fou r

whee l alignmen t equipmen t t o measur e whee l align -

men t (caster , camber , toe , and/o r turnin g angle) .

Follo w th e equipmen t manufacturer' s instructions .

1 . Chec k th e caste r angle .

Caste r angle : 2°07 ' ± 1 °

2 . I f ou t o f specification , recor d th e caste r reading , the n

adjus t th e caster .

Adjustmen t

NOTE: Caste r angl e ca n b e adjuste d b y increasin g o r

decreasin g th e numbe r o f th e adjustin g shims . Remov e

an d instal l th e radiu s ro d eac h tim e th e caste r angl e i s

adjusted .

1. Rais e th e fron t o f th e vehicle , an d suppor t i t wit h

safet y stand s in th e prope r location s (se e sectio n 1 ).

2 . Remov e th e self-lockin g nu t o n th e en d o f th e radiu s

rod.

3. Remov e th e flang e bolt s a t th e radiu s ro d o n th e lowe r

arm , the n remov e th e radiu s ro d (se e pag e 18-19 ).

4 . Adjus t th e caste r angl e b y increasin g o r decreasin g

the adjustin g shims .

NOTE:

• D o no t us e mor e tha n tw o adjustin g shims .

• On e adjustin g shi m change s th e caste r angl e b y

35 ' an d th e caste r angl e ca n b e adjuste d b y 1°10 '

maximum .

• On e adjustin g shi m is 3. 2 m m (0.1 3 in ) i n thick -

ness.

ADJUSTIN G SHI M

RADIU S RO D

SELF-LOCKIN G NU T

12 x 1.2 5 mm54 N- m (5. 5 kgf-m , 4 0 Ibf-ft )Replace .

5. Afte r th e adjustment , instal l th e radiu s ro d ont o th e

lowe r arm , the n tighte n th e flang e bolt s (se e pag e

18-19 ).

6 . Tighte n th e ne w self-lockin g nu t t o specifie d torque .

ProCarManuals.com

Page 1323 of 1771

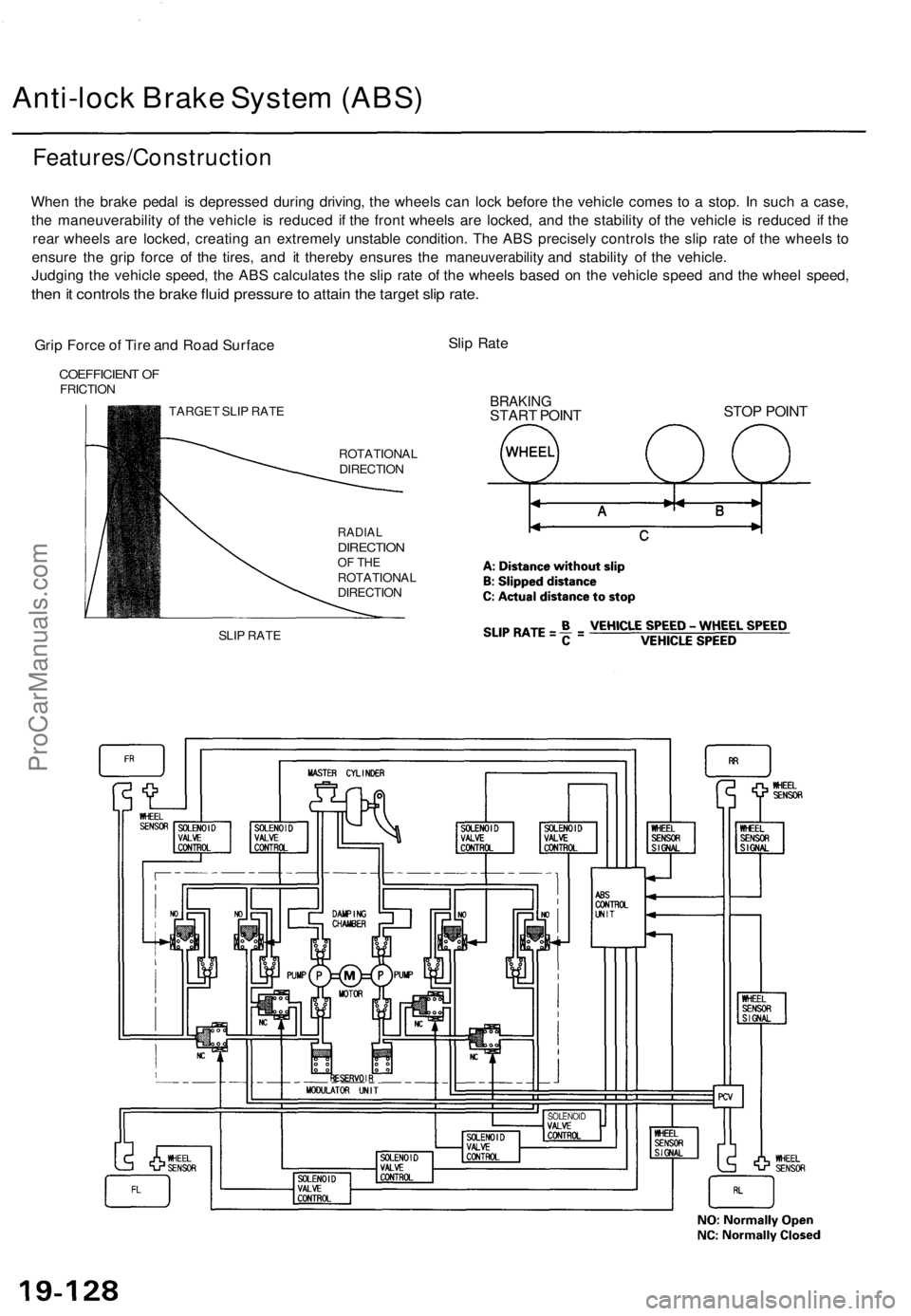

Anti-lock Brak e Syste m (ABS )

Features/Constructio n

When th e brak e peda l i s depresse d durin g driving , th e wheel s ca n loc k befor e th e vehicl e come s t o a stop . I n suc h a case ,

th e maneuverabilit y o f th e vehicl e i s reduce d i f th e fron t wheel s ar e locked , an d th e stabilit y o f th e vehicl e i s reduce d i f th e

rea r wheel s ar e locked , creatin g a n extremel y unstabl e condition . Th e AB S precisel y control s th e sli p rat e o f th e wheel s t o

ensur e th e gri p forc e o f th e tires , an d i t thereb y ensure s th e

maneuverability an d stabilit y o f th e vehicle .

Judgin g th e vehicl e speed , th e AB S calculate s th e sli p rat e o f th e wheel s base d o n th e vehicl e spee d an d th e whee l speed ,

then it control s th e brak e flui d pressur e to attai n th e targe t sli p rate .

Grip Forc e o f Tir e an d Roa d Surfac e Sli

p Rat e

COEFFICIEN T O FFRICTIO N

TARGET SLI P RAT E

SLI P RAT E ROTATIONA

L

DIRECTIO N

RADIALDIRECTIO NOF TH EROTATIONA L

DIRECTIO N

BRAKINGSTART POIN T STO

P POIN T

SOLENOI D

ProCarManuals.com