heating ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 442 of 1771

Differential Assembl y

Disassembl y (cont'd )

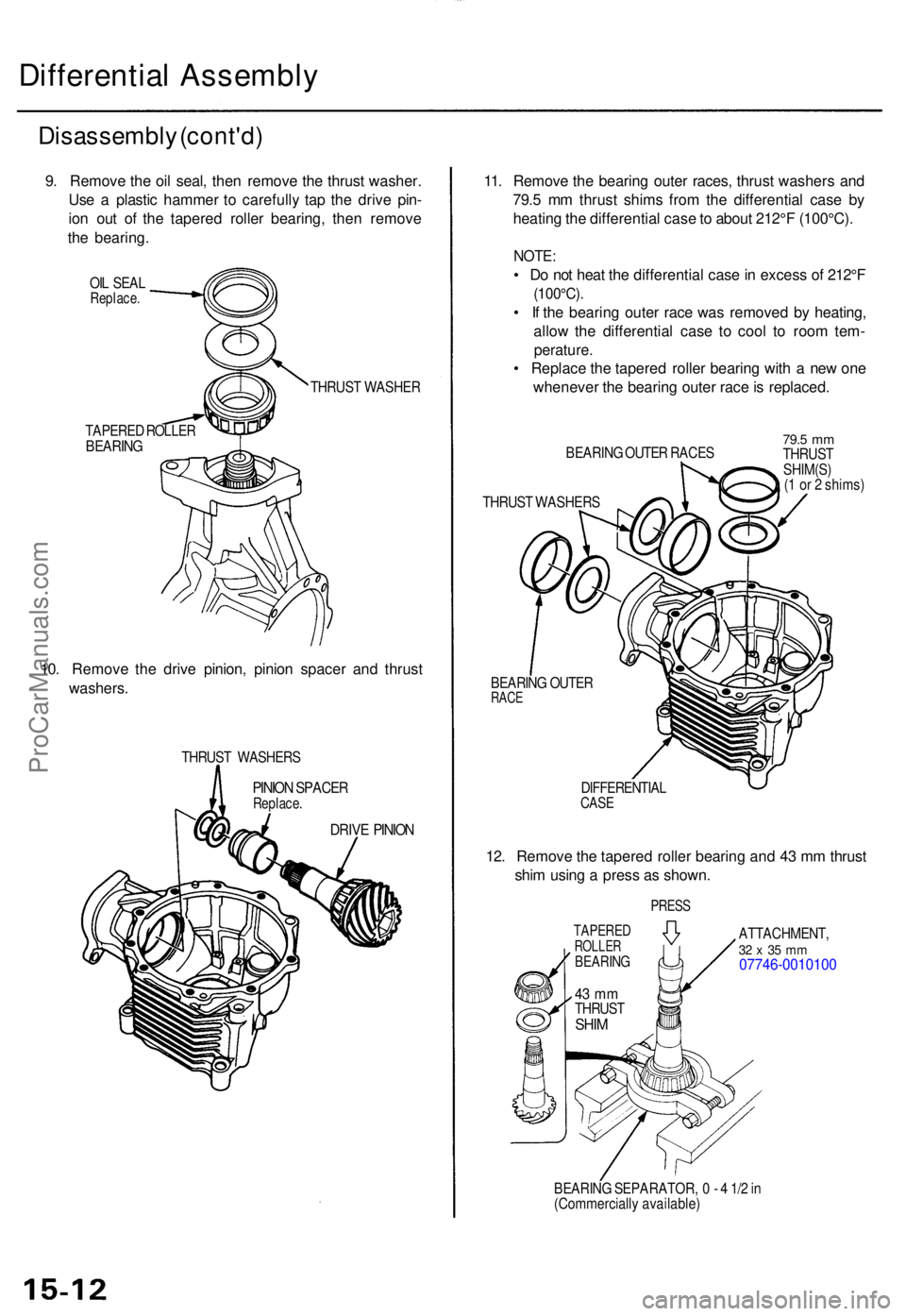

9. Remov e th e oi l seal , the n remov e th e thrus t washer .

Us e a plasti c hamme r t o carefull y ta p th e driv e pin -

io n ou t o f th e tapere d rolle r bearing , the n remov e

th e bearing .

OIL SEA LReplace .

TAPERE D ROLLE RBEARIN G

THRUST WASHE R

10. Remov e th e driv e pinion , pinio n space r an d thrus t

washers .

THRUST WASHER S

PINION SPACE RReplace .

DRIVE PINIO N

11. Remov e th e bearin g oute r races , thrus t washer s an d

79. 5 m m thrus t shim s fro m th e differentia l cas e b y

heatin g th e differentia l cas e to abou t 212° F (100°C) .

NOTE:

• D o no t hea t th e differentia l cas e in exces s o f 212° F

(100°C) .

• I f th e bearin g oute r rac e wa s remove d b y heating ,

allo w th e differentia l cas e t o coo l t o roo m tem -

perature .

• Replac e th e tapere d rolle r bearin g wit h a ne w on e

wheneve r th e bearin g oute r rac e is replaced .

BEARING OUTE R RACE S79.5 mmTHRUS T

SHIM(S )

( 1 o r 2 shims )

THRUS T WASHER S

BEARIN G OUTE R

RACE

DIFFERENTIA LCASE

12. Remov e th e tapere d rolle r bearin g an d 4 3 m m thrus t

shi m usin g a pres s a s shown .

ATTACHMENT ,32 x 35 m m07746-001010 0

BEARING SEPARATOR , 0 - 4 1/ 2 in

(Commerciall y available )

TAPEREDROLLERBEARIN G

43 m mTHRUS TSHIM

PRES S

ProCarManuals.com

Page 470 of 1771

Inspection an d Adjustmen t

Pump Pressur e Chec k (cont'd )

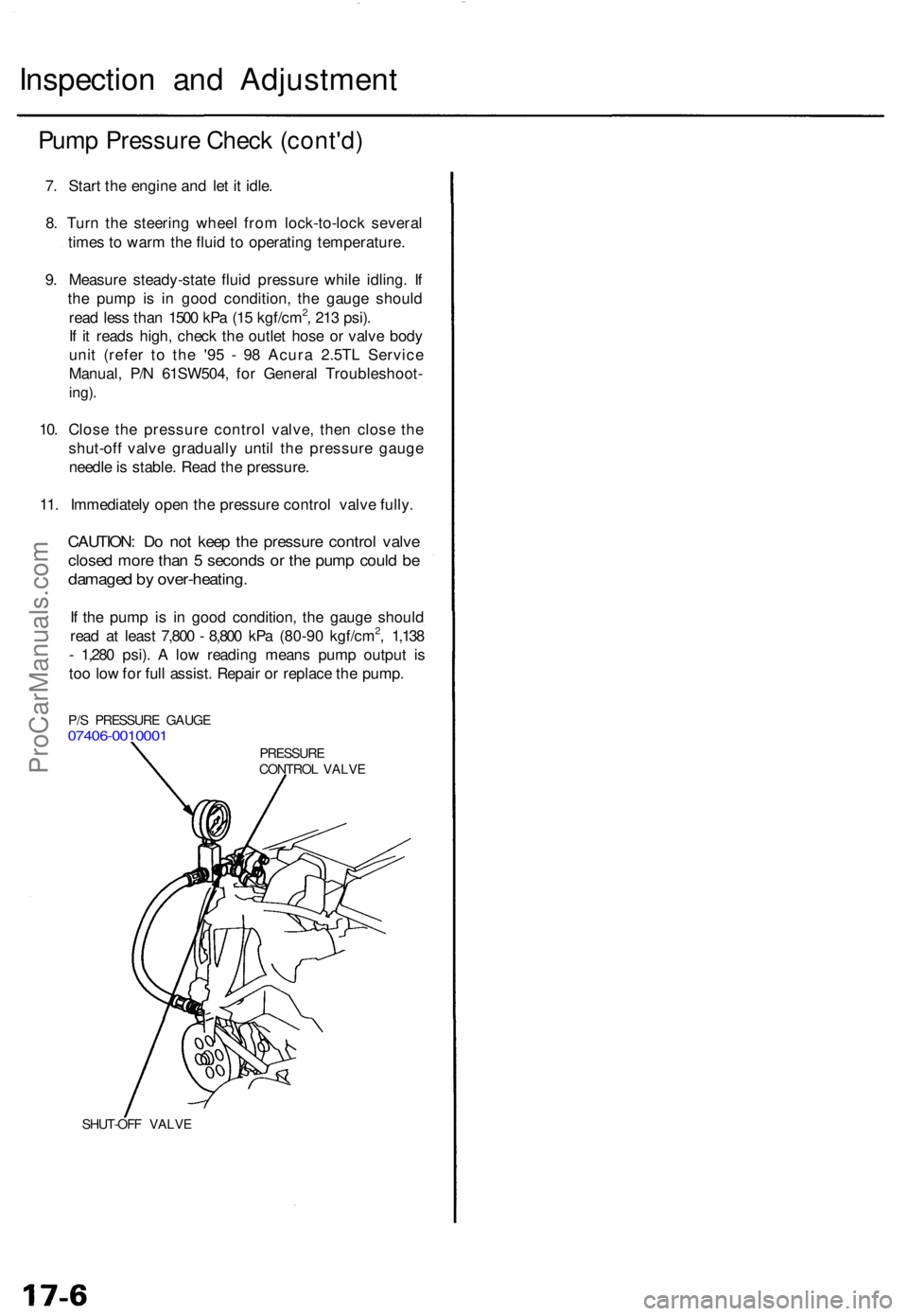

7. Star t th e engin e an d le t i t idle .

8 . Tur n th e steerin g whee l fro m lock-to-loc k severa l

time s to war m th e flui d to operatin g temperature .

9 . Measur e steady-stat e flui d pressur e whil e idling . I f

th e pum p i s i n goo d condition , th e gaug e shoul d

rea d les s tha n 150 0 kP a (1 5 kgf/cm

2, 21 3 psi) .

I f i t read s high , chec k th e outle t hos e o r valv e bod y

uni t (refe r t o th e '9 5 - 9 8 Acur a 2.5T L Servic e

Manual , P/ N 61SW504 , fo r Genera l Troubleshoot -

ing).

10. Clos e th e pressur e contro l valve , the n clos e th e

shut-of f valv e graduall y unti l th e pressur e gaug e

needl e is stable . Rea d th e pressure .

11 . Immediatel y ope n th e pressur e contro l valv e fully .

CAUTION : D o no t kee p th e pressur e contro l valv e

close d mor e tha n 5 second s o r th e pum p coul d b e

damage d b y over-heating .

If th e pum p i s i n goo d condition , th e gaug e shoul d

rea d a t leas t 7,80 0 - 8,80 0 kP a (80-9 0 kgf/cm2, 1,13 8

- 1,28 0 psi) . A lo w readin g mean s pum p outpu t i s

to o lo w fo r ful l assist . Repai r o r replac e th e pump .

SHUT-OF F VALV E

PRESSUR ECONTROL VALV E

P/

S PRESSUR E GAUG E

07406-001000 1

ProCarManuals.com

Page 671 of 1771

General Info

Specifications

Maintenance

Engine

Cooling

Fuel and Emissions

2.5L

3.2L

* Transaxle

SteeringSuspension

* Brakes (Including ABS)

* Body

* Heating, Ventilation

and Air Conditioning

* Body Electrical

* Engine Electrical

* SRS2.5L

3.2L

1995±98 TL Main Menu

As sections w/ * include SRS components, special precautions are required when servicing.

ProCarManuals.com

Page 1167 of 1771

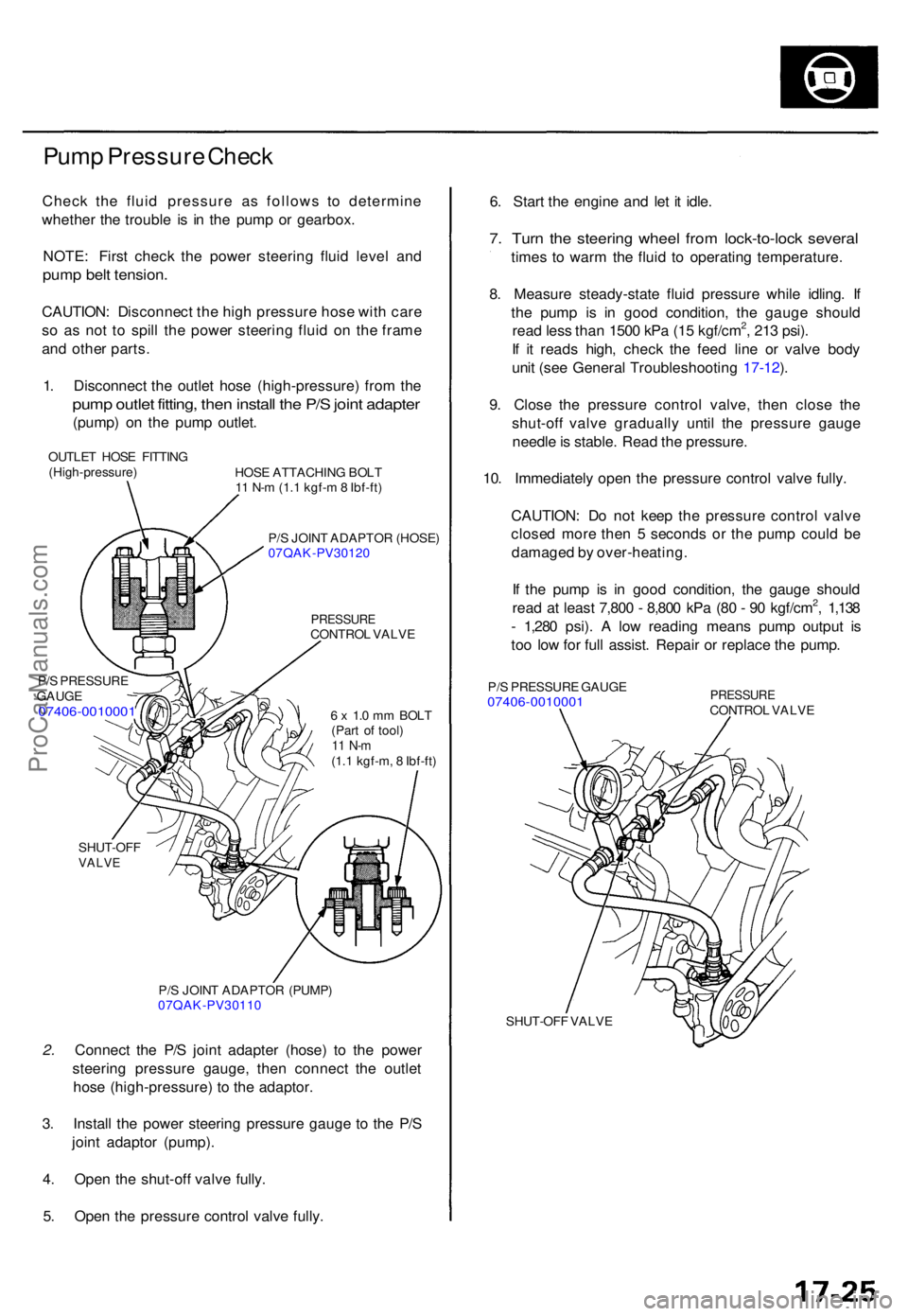

Pump Pressur e Chec k

Chec k th e flui d pressur e a s follow s t o determin e

whethe r th e troubl e i s i n th e pum p o r gearbox .

NOTE : Firs t chec k th e powe r steerin g flui d leve l an d

pum p bel t tension .

CAUTION : Disconnec t th e hig h pressur e hos e wit h car e

s o a s no t t o spil l th e powe r steerin g flui d o n th e fram e

an d othe r parts .

1 . Disconnec t th e outle t hos e (high-pressure ) fro m th e

pum p outle t fitting , the n instal l th e P/ S join t adapte r

(pump) o n th e pum p outlet .

OUTLE T HOS E FITTIN G

(High-pressure )

P/ S PRESSUR E

GAUG E

07406-001000 1

HOSE ATTACHIN G BOL T

1 1 N- m (1. 1 kgf- m 8 Ibf-ft )

P/ S JOIN T ADAPTO R (HOSE )

07QAK-PV3012 0

PRESSURECONTROL VALV E

6 x 1. 0 m m BOL T

(Par t o f tool )

11 N- m(1.1 kgf-m , 8 Ibf-ft )

SHUT-OF F

VALVE

P/S JOIN T ADAPTO R (PUMP )

07QAK-PV3011 0

2. Connec t th e P/ S join t adapte r (hose ) t o th e powe r

steerin g pressur e gauge , the n connec t th e outle t

hos e (high-pressure ) t o th e adaptor .

3 . Instal l th e powe r steerin g pressur e gaug e t o th e P/ S

join t adapto r (pump) .

4 . Ope n th e shut-of f valv e fully .

5 . Ope n th e pressur e contro l valv e fully . 6

. Star t th e engine and le t i t idle .

7. Tur n th e steerin g whee l fro m lock-to-loc k severa l

times t o war m th e flui d t o operating temperature .

8 . Measur e steady-stat e flui d pressur e whil e idling . I f

th e pum p i s i n goo d condition , th e gaug e shoul d

rea d les s tha n 150 0 kP a (1 5 kgf/cm

2, 21 3 psi) .

I f i t read s high , chec k th e fee d lin e o r valv e bod y

uni t (se e Genera l Troubleshootin g 17-12 ).

9 . Clos e th e pressur e contro l valve , the n clos e th e

shut-of f valv e graduall y unti l th e pressur e gaug e

needl e is stable . Rea d th e pressure .

10 . Immediatel y ope n th e pressur e contro l valv e fully .

CAUTION : D o no t kee p th e pressur e contro l valv e

close d mor e the n 5 second s o r th e pum p coul d b e

damage d b y over-heating .

I f th e pum p i s i n goo d condition , th e gaug e shoul d

rea d a t leas t 7,80 0 - 8,80 0 kP a (8 0 - 9 0 kgf/cm

2, 1,13 8

- 1,28 0 psi) . A lo w readin g mean s pum p outpu t i s

to o lo w fo r ful l assist . Repai r o r replac e th e pump .

P/S PRESSUR E GAUG E07406-001000 1 PRESSUR ECONTROL VALV E

SHUT-OF F VALV E

ProCarManuals.com

Page 1462 of 1771

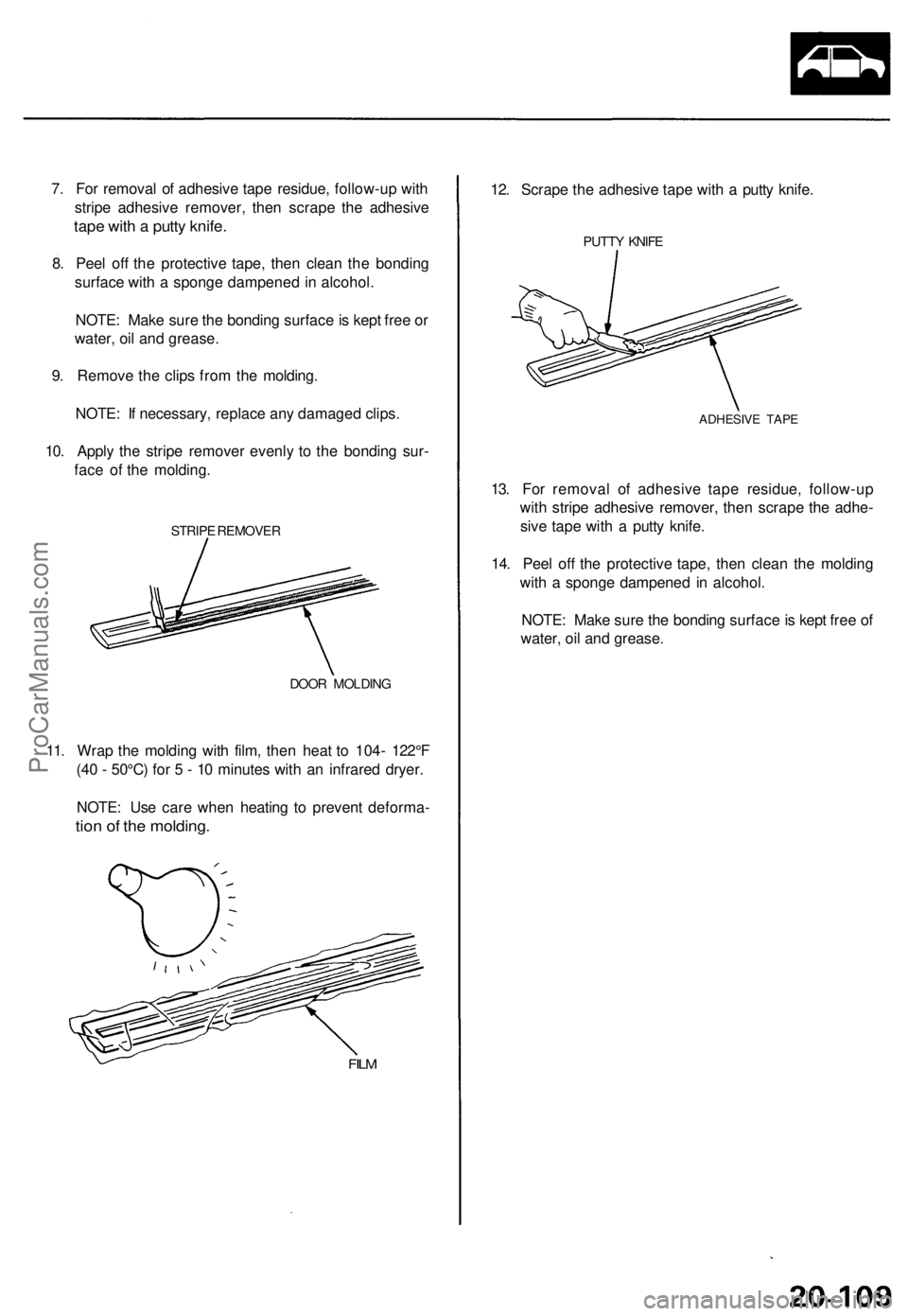

7. For removal of adhesive tape residue, follow-up with

stripe adhesive remover, then scrape the adhesive

tape with a putty knife.

8. Peel off the protective tape, then clean the bonding

surface with a sponge dampened in alcohol.

NOTE: Make sure the bonding surface is kept free or

water, oil and grease.

9. Remove the clips from the molding.

NOTE: If necessary, replace any damaged clips.

10. Apply the stripe remover evenly to the bonding sur-

face of the molding.

STRIPE REMOVER

DOOR MOLDING

11. Wrap the molding with film, then heat to 104- 122°F

(40 - 50°C) for 5 - 10 minutes with an infrared dryer.

NOTE: Use care when heating to prevent deforma-

tion of the molding.

FILM

12. Scrape the adhesive tape with a putty knife.

PUTTY KNIFE

ADHESIVE TAPE

13. For removal of adhesive tape residue, follow-up

with stripe adhesive remover, then scrape the adhe-

sive tape with a putty knife.

14. Peel off the protective tape, then clean the molding

with a sponge dampened in alcohol.

NOTE: Make sure the bonding surface is kept free of

water, oil and grease.ProCarManuals.com

Page 1463 of 1771

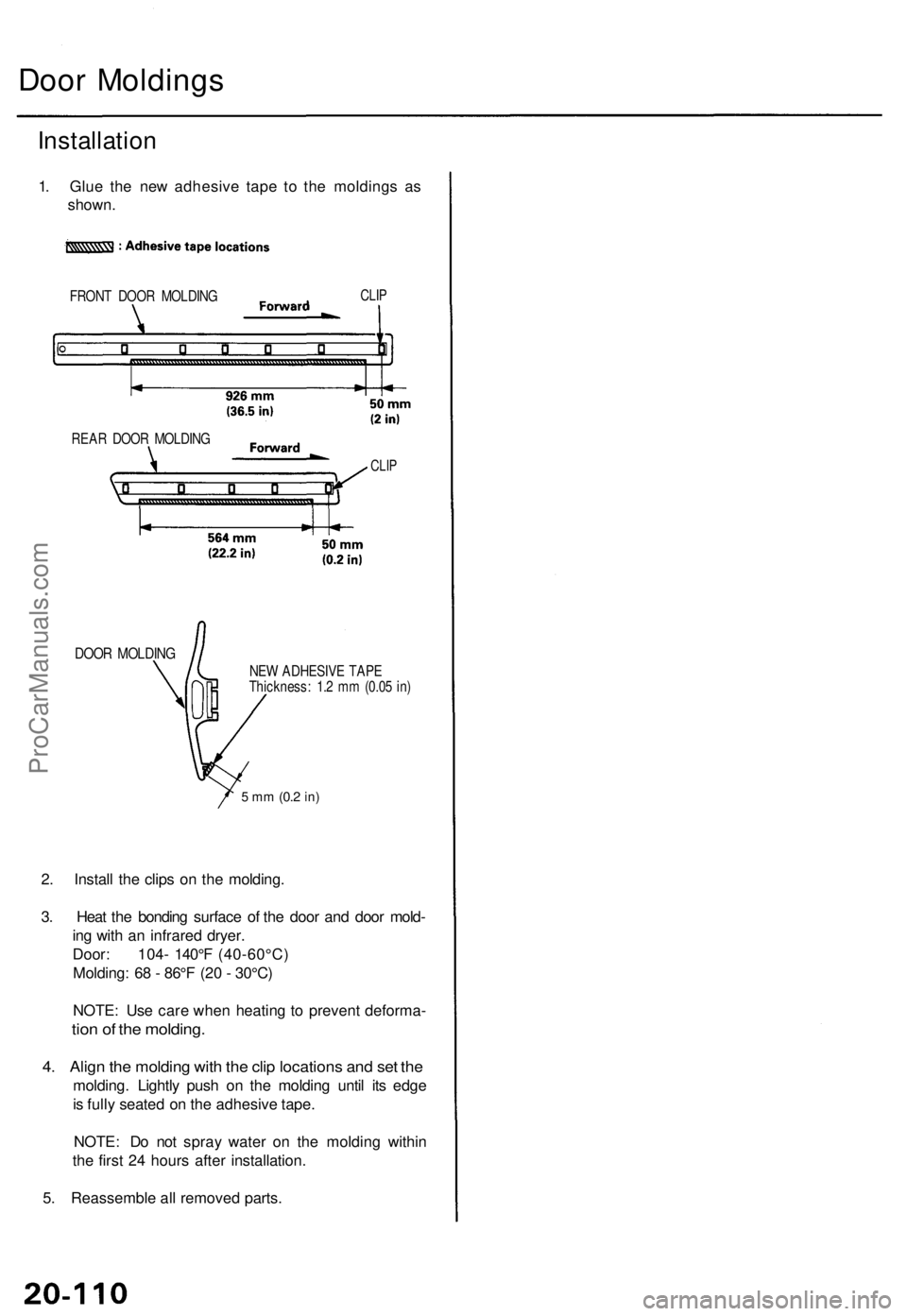

Door Moldings

Installation

1. Glue the new adhesive tape to the moldings as

shown.

FRONT DOOR MOLDING

CLIP

DOOR MOLDING

NEW ADHESIVE TAPE

Thickness: 1.2 mm (0.05 in)

5 mm

(0.2

in)

2. Install the clips on the molding.

3. Heat the bonding surface of the door and door mold-

ing with an infrared dryer.

Door: 104- 140°F (40-60°C)

Molding: 68 - 86°F (20 - 30°C)

NOTE: Use care when heating to prevent deforma-

tion of the molding.

4. Align the molding with the clip locations and set the

molding. Lightly push on the molding until its edge

is fully seated on the adhesive tape.

NOTE: Do not spray water on the molding within

the first 24 hours after installation.

5. Reassemble all removed parts.

REAR DOOR MOLDING

CLIPProCarManuals.com