tow ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 12 of 1771

Towing

If the vehicle needs to be towed, call a professional tow-

ing service. Never tow the vehicle behind another vehi-

cle with just a rope or chain. It is very dangerous.

Emergency Towing

There are three popular methods of towing a vehicle:

Flat-bed Equipment — The operator loads the vehicle on

the back of a truck. This is the best way of transporting the

vehicle.

Wheel Lift Equipment — The tow truck uses two pivoting

arms that go under the tires (front or rear) and lifts them

off the ground. The other two wheels remain on the

ground.

Sling-type Equipment — The tow truck uses metal cables

with hooks on the ends. These hooks go around parts of

the frame or suspension and the cables lift that end of

the vehicle off the ground. The vehicle's suspension and

body can be seriously damaged if this method of towing

is attempted.

If the vehicle cannot be transported by flat-bed, it should

be towed with the front wheels off the ground. If due to

damage, the vehicle must be towed with the front

wheels on the ground, do the following:

Release the parking brake.

Start the engine.

Shift to position, then position.

Turn off the engine.

CAUTION:

Improper towing preparation will damage the trans-

mission. Follow the above procedure exactly. If you

cannot shift the transmission or start the engine, the

vehicle must be transported on a flat-bed.

It is best to tow the vehicle no farther than 50 miles

(80 km), and keep the speed below 35 mph (55 km/h).

Trying to lift or tow the vehicle by the bumpers will

cause serious damage. The bumpers are not designed

to support the vehicle's weight.

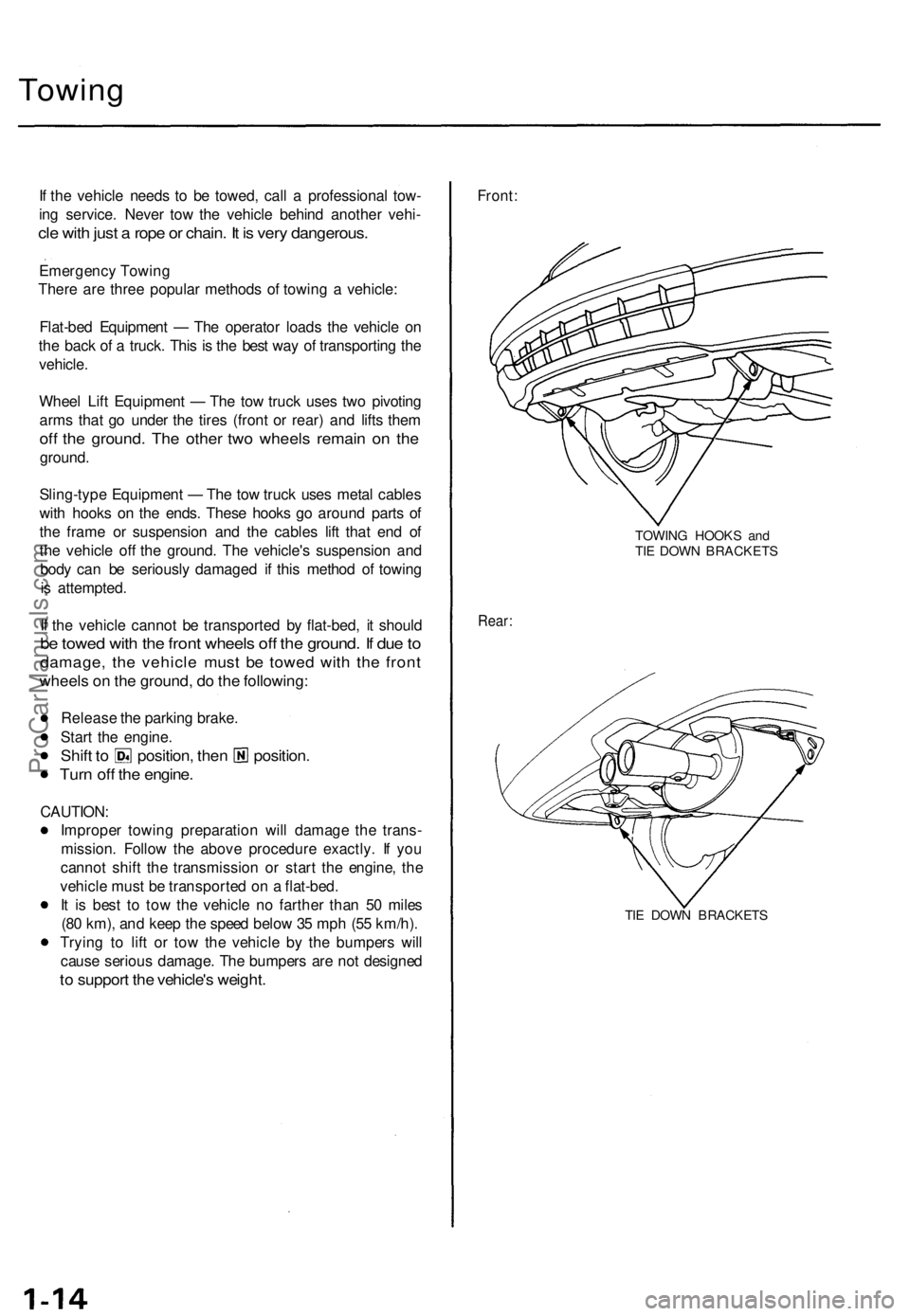

Front:

TOWING HOOKS and

TIE DOWN BRACKETS

Rear:

TIE DOWN BRACKETSProCarManuals.com

Page 33 of 1771

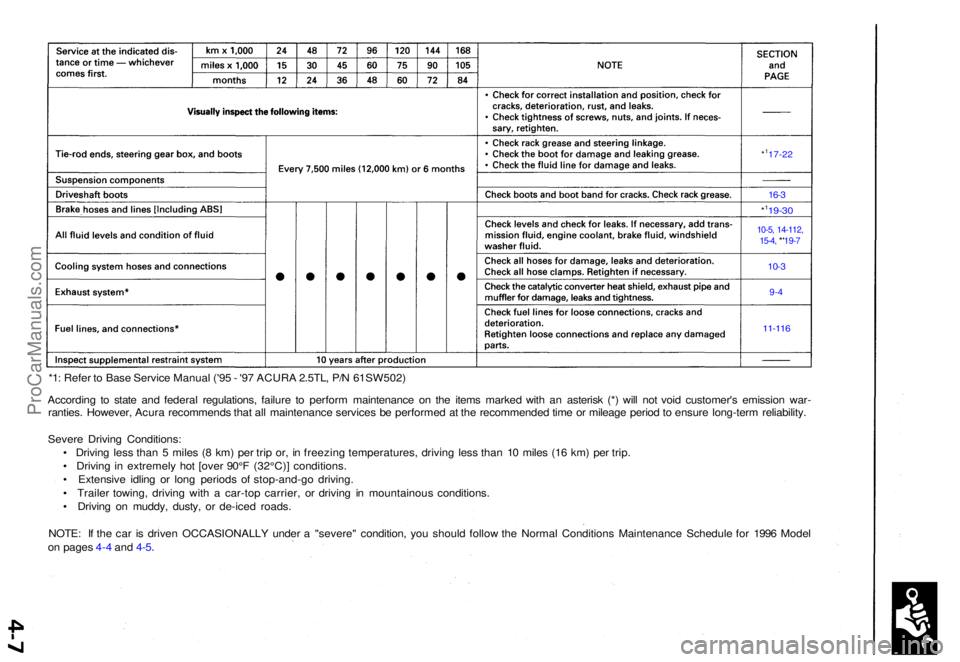

*1: Refe r t o Bas e Servic e Manua l ('9 5 - '9 7 ACUR A 2.5TL , P/ N 61SW502 )

Accordin g t o stat e an d federa l regulations , failur e t o perfor m maintenanc e o n th e item s marke d wit h a n asteris k (* ) wil l no t voi d customer' s emissio n war -

ranties . However , Acur a recommend s tha t al l maintenanc e service s b e performe d a t th e recommende d tim e o r mileag e perio d to ensur e long-ter m reliability .

Sever e Drivin g Conditions :

• Drivin g les s tha n 5 mile s ( 8 km ) pe r tri p or , i n freezin g temperatures , drivin g les s tha n 1 0 mile s (1 6 km ) pe r trip .

• Drivin g i n extremel y ho t [ove r 90° F (32°C) ] conditions .

• Extensiv e idlin g o r lon g period s o f stop-and-go driving.

• Traile r towing , drivin g wit h a car-to p carrier , o r drivin g i n mountainou s conditions .

• Drivin g o n muddy , dusty , o r de-ice d roads .

NOTE : I f th e ca r i s drive n OCCASIONALL Y unde r a "severe " condition , yo u shoul d follo w th e Norma l Condition s Maintenanc e Schedul e fo r 199 6 Mode l

o n page s 4- 4 an d 4-5 .

*117-2 2

16-3

*119-3 0

10-5, 14-112 ,

15-4 , *'19-7

10-3

9-4

11-11 6

ProCarManuals.com

Page 37 of 1771

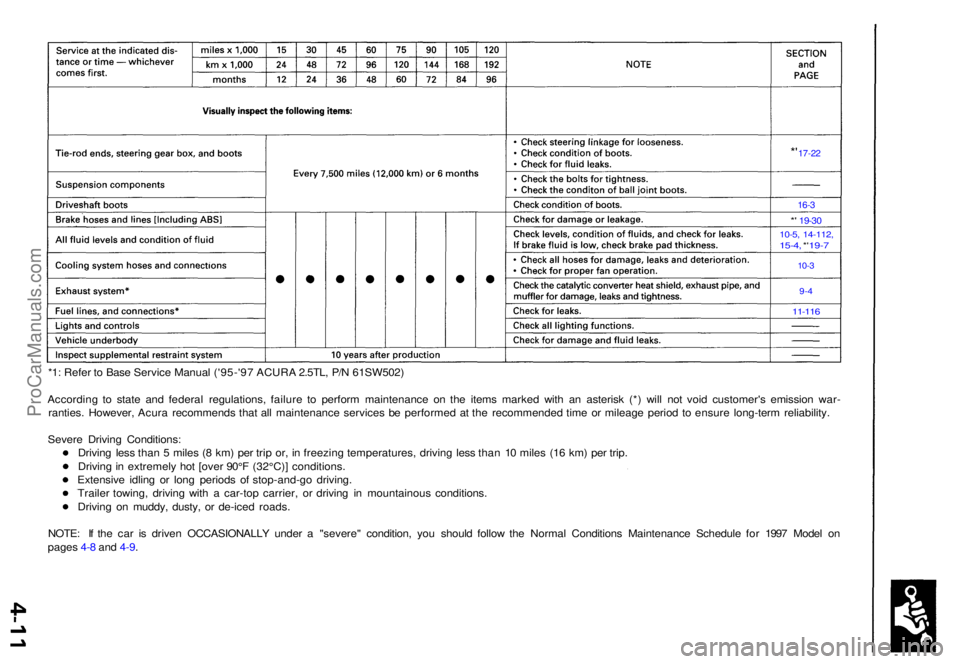

*1: Refe r t o Bas e Servic e Manua l ('95-'9 7 ACUR A 2.5TL , P/ N 61SW502 )

Accordin g t o stat e an d federa l regulations , failur e t o perfor m maintenanc e o n th e item s marke d wit h a n asteris k (* ) wil l no t voi d customer' s emissio n war -

ranties . However , Acur a recommend s tha t al l maintenanc e service s b e performe d a t th e recommende d tim e o r mileag e perio d t o ensur e long-ter m reliability .

Sever e Drivin g Conditions :

Drivin g les s tha n 5 mile s ( 8 km ) pe r tri p or , i n freezin g temperatures , drivin g les s tha n 1 0 miles (16 km ) pe r trip .

Drivin g in extremel y ho t [ove r 90° F (32°C) ] conditions .

Extensiv e idlin g o r lon g period s o f stop-and-g o driving .

Traile r towing , drivin g wit h a car-to p carrier , o r drivin g i n mountainou s conditions .

Drivin g o n muddy , dusty , o r de-ice d roads .

NOTE : I f th e ca r i s drive n OCCASIONALL Y unde r a "severe " condition , yo u shoul d follo w th e Norma l Condition s Maintenanc e Schedul e fo r 199 7 Mode l o n

page s 4- 8 an d 4-9 .

*' 17-2 2

16-3

*' 19-3 0

10-5, 14-112 ,15-4, *' 19- 7

10-3

9-4

11-11 6

ProCarManuals.com

Page 41 of 1771

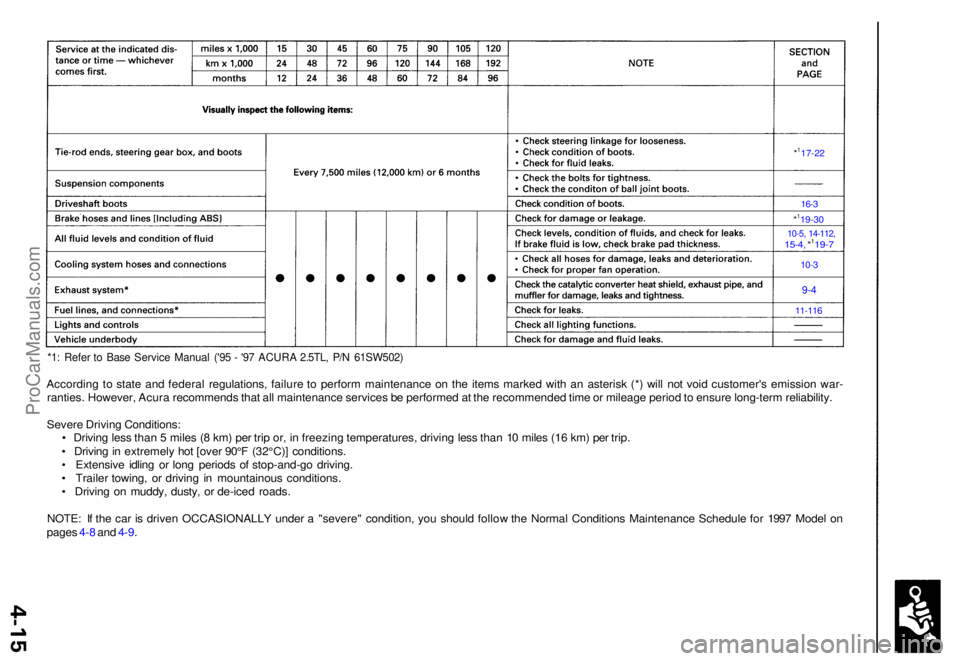

*1: Refe r t o Bas e Servic e Manua l ('9 5 - '9 7 ACUR A 2.5TL , P/ N 61SW502 )

According t o stat e an d federa l regulations , failur e t o perfor m maintenance on th e item s marke d wit h a n asteris k (* ) wil l no t voi d customer' s emissio n war -

ranties . However , Acur a recommend s tha t al l maintenanc e service s b e performe d a t th e recommende d tim e o r mileag e perio d to ensur e long-ter m reliability .

Sever e Drivin g Conditions :

• Drivin g les s tha n 5 mile s ( 8 km ) pe r tri p or , i n freezin g temperatures , drivin g les s tha n 1 0 mile s (1 6 km ) pe r trip .

• Drivin g in extremel y ho t [ove r 90° F (32°C) ] conditions .

• Extensiv e idlin g o r lon g period s o f stop-and-g o driving .

• Traile r towing , o r drivin g i n mountainou s conditions .

• Drivin g o n muddy , dusty , o r de-ice d roads .

NOTE : I f th e ca r i s drive n OCCASIONALL Y unde r a "severe " condition , yo u shoul d follo w th e Norma l Condition s Maintenanc e Schedul e fo r 199 7 Mode l o n

page s 4- 8 an d 4-9 .

*117-2 2

16-3

*119-3 0

10-5, 14-112 ,15-4, *119- 7

10-3

9-4

11-11 6

ProCarManuals.com

Page 76 of 1771

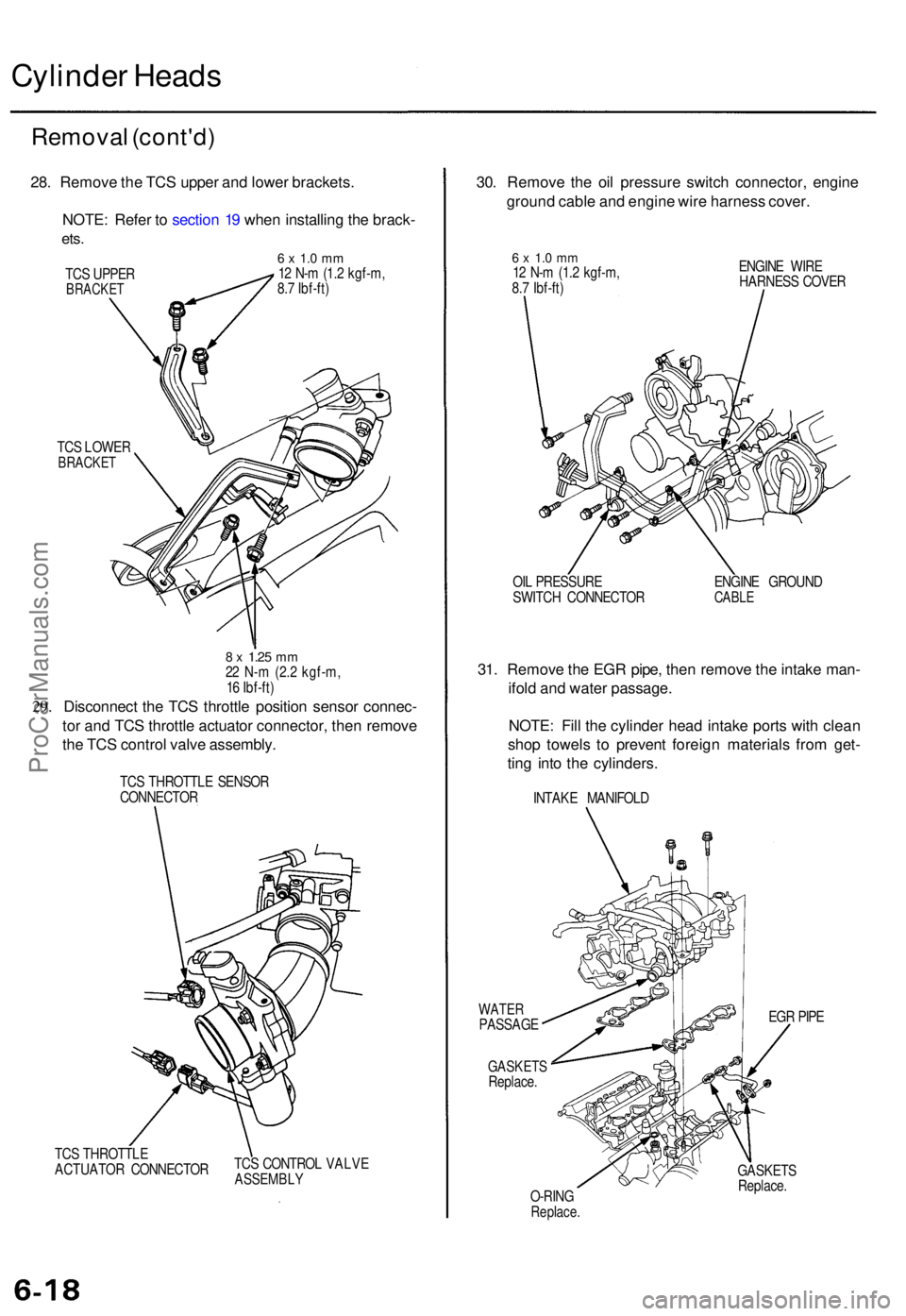

Cylinder Head s

Remova l (cont'd )

28. Remov e th e TC S uppe r an d lowe r brackets .

NOTE : Refe r t o sectio n 1 9 whe n installin g th e brack -

ets.

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

TC S LOWE R

BRACKE T

29.

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

Disconnec t th e TC S throttl e positio n senso r connec -

to r an d TC S throttl e actuato r connector , the n remov e

th e TC S contro l valv e assembly .

TCS THROTTL E SENSO R

CONNECTO R

TC S THROTTL E

ACTUATO R CONNECTO RTC

S CONTRO L VALV E

ASSEMBL Y

30. Remov e th e oi l pressur e switc h connector , engin e

groun d cabl e an d engin e wir e harnes s cover .

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft ) ENGIN

E WIR E

HARNES S COVE R

OI L PRESSUR E

SWITC H CONNECTO R ENGIN

E GROUN D

CABLE

31. Remov e th e EG R pipe , the n remov e th e intak e man -

ifol d an d wate r passage .

NOTE : Fil l th e cylinde r hea d intak e port s wit h clea n

sho p towel s t o preven t foreig n material s fro m get -

tin g int o th e cylinders .

INTAKE MANIFOL D

WATERPASSAG E

GASKETSReplace. EG

R PIP E

O-RIN G

Replace .

GASKET S

Replace .

TC

S UPPE R

BRACKE T

ProCarManuals.com

Page 82 of 1771

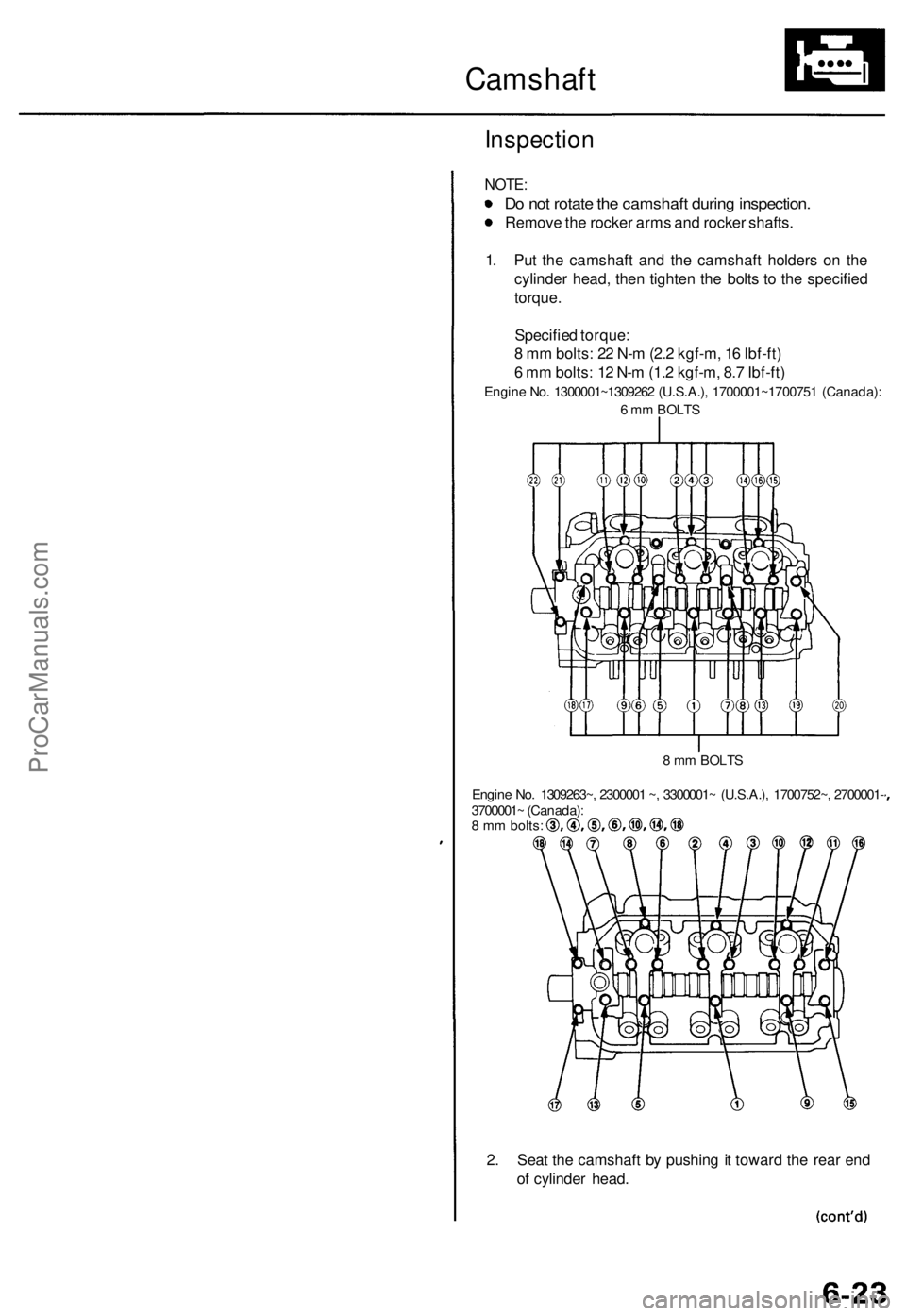

Camshaft

Inspection

NOTE:

Do not rotate the camshaft during inspection.

Remove the rocker arms and rocker shafts.

1. Put the camshaft and the camshaft holders on the

cylinder head, then tighten the bolts to the specified

torque.

Specified torque:

8 mm bolts: 22 N-m (2.2 kgf-m, 16 Ibf-ft)

6 mm bolts: 12 N-m (1.2 kgf-m, 8.7 Ibf-ft)

Engine No. 1300001~1309262 (U.S.A.), 1700001~1700751 (Canada):

6 mm BOLTS

8 mm BOLTS

Engine No. 1309263~, 2300001 ~, 3300001~ (U.S.A.), 1700752~, 2700001-

3700001~ (Canada):

8 mm bolts:

2. Seat the camshaft by pushing it toward the rear end

of cylinder head.ProCarManuals.com

Page 90 of 1771

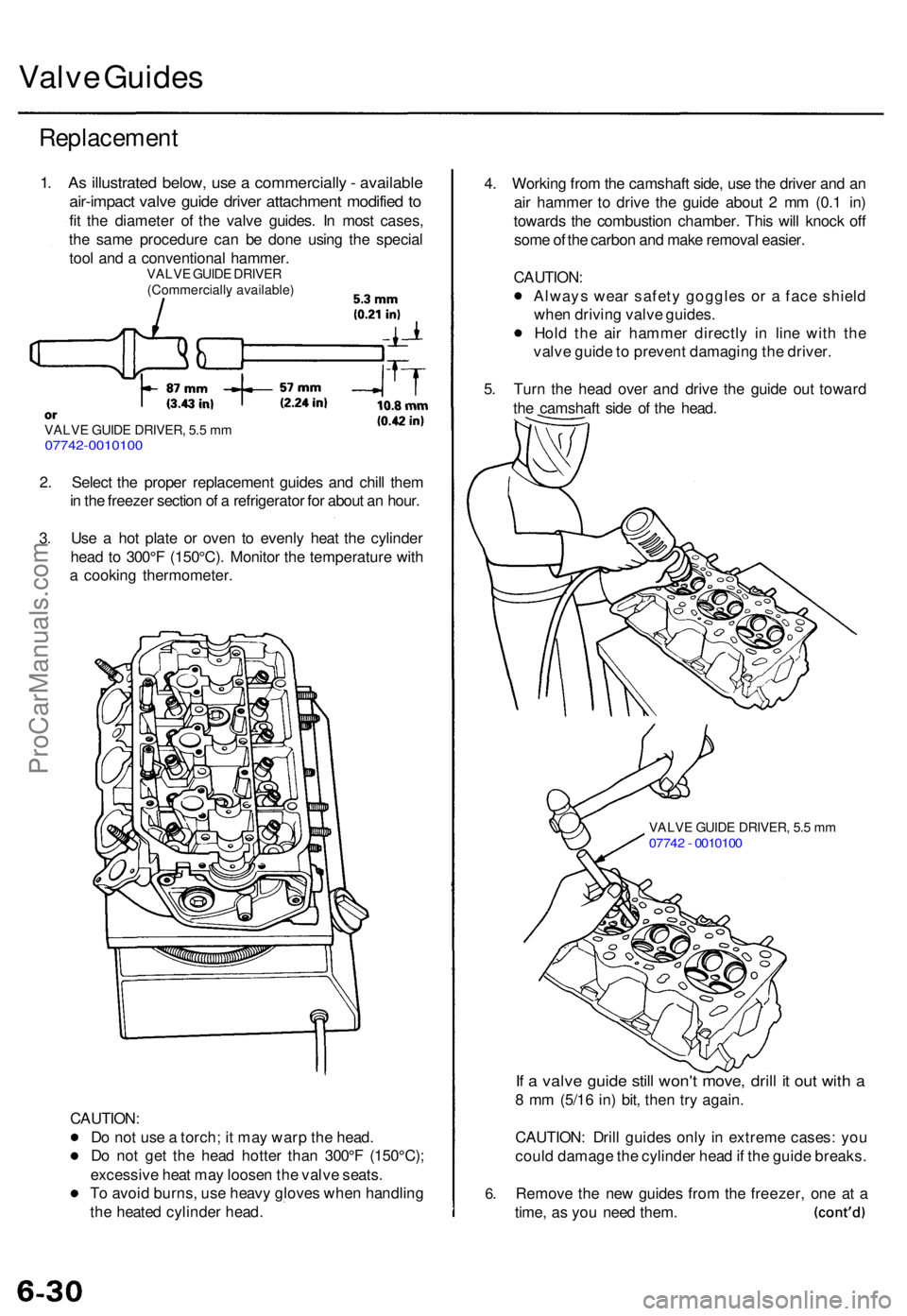

Valve Guide s

Replacemen t

1. As illustrate d below , us e a commerciall y - availabl e

air-impac t valv e guid e drive r attachmen t modifie d t o

fit th e diameter of th e valv e guides . I n mos t cases ,

th e sam e procedur e ca n b e don e usin g th e specia l

too l an d a conventiona l hammer .

VALVE GUID E DRIVE R(Commerciall y available )

VALVE GUID E DRIVER , 5. 5 m m07742-001010 0

2. Selec t th e prope r replacemen t guide s an d chil l the m

i n th e freeze r sectio n o f a refrigerato r fo r abou t a n hour .

3 . Us e a ho t plat e o r ove n t o evenl y hea t th e cylinde r

hea d t o 300° F (150°C) . Monito r th e temperatur e wit h

a cookin g thermometer .

CAUTION :

D o no t us e a torch ; i t ma y war p th e head .

D o no t ge t th e hea d hotte r tha n 300° F (150°C) ;

excessiv e hea t ma y loose n th e valv e seats .

T o avoi d burns , us e heav y glove s whe n handlin g

th e heate d cylinde r head . 4

. Workin g fro m th e camshaf t side , us e th e drive r an d a n

ai r hamme r t o driv e th e guid e abou t 2 m m (0. 1 in )

toward s th e combustio n chamber . Thi s wil l knoc k of f

som e o f th e carbo n an d mak e remova l easier .

CAUTION :

Alway s wea r safet y goggle s o r a fac e shiel d

whe n drivin g valv e guides .

Hol d th e ai r hamme r directl y i n lin e wit h th e

valv e guid e to preven t damagin g th e driver .

5 . Tur n th e hea d ove r an d driv e th e guid e ou t towar d

th e camshaf t sid e o f th e head .

VALV E GUID E DRIVER , 5. 5 m m0774 2 - 001010 0

6.

If a valv e guid e stil l won' t move , dril l i t ou t wit h a

8 m m (5/1 6 in ) bit , the n tr y again .

CAUTION : Dril l guide s onl y in extrem e cases : yo u

coul d damag e th e cylinde r hea d if th e guid e breaks .

Remov e th e ne w guide s fro m th e freezer , on e a t a

time , a s yo u nee d them .

ProCarManuals.com

Page 93 of 1771

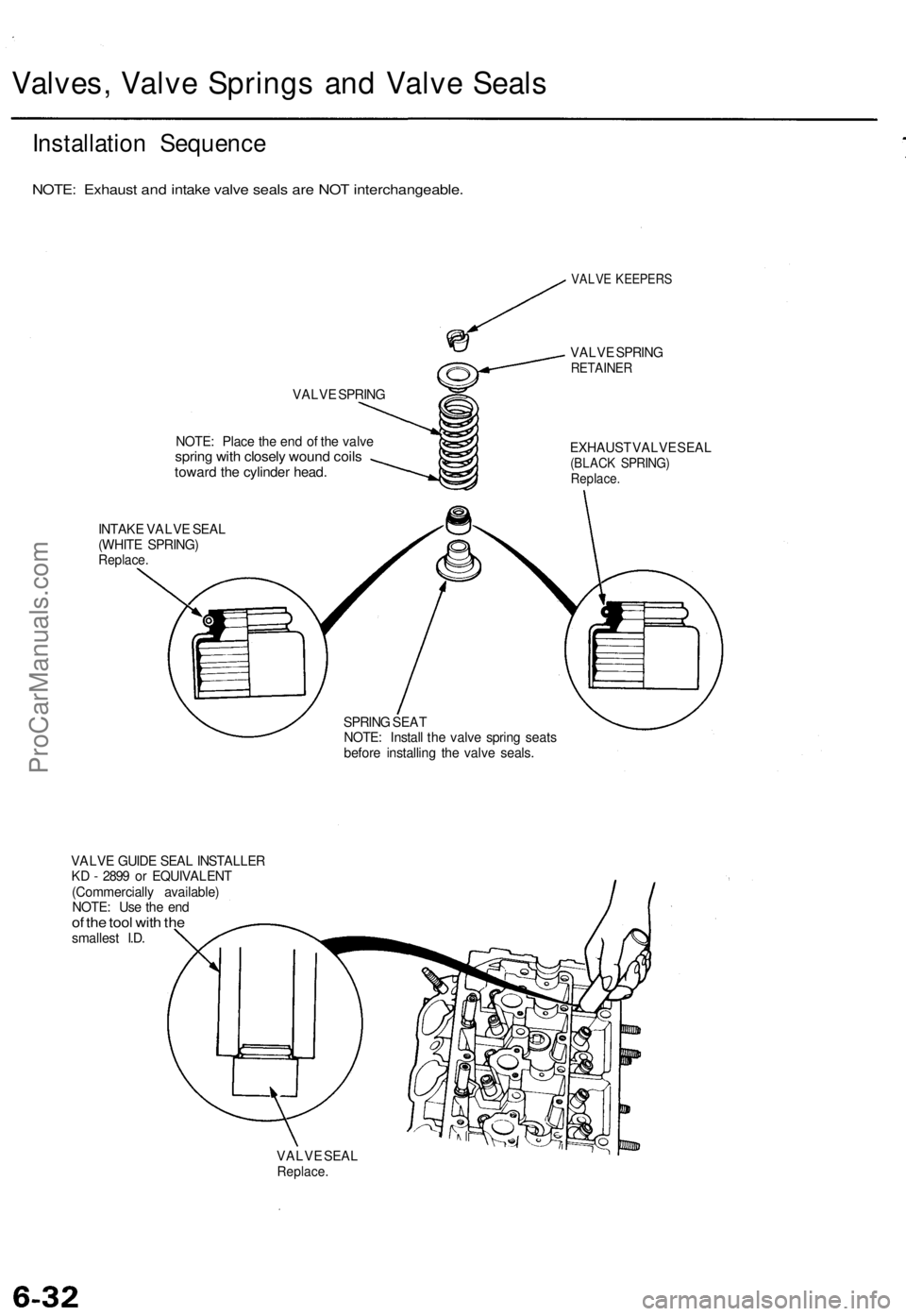

Valves, Valve Springs and Valve Seals

Installation Sequence

NOTE: Exhaust and intake valve seals are NOT interchangeable.

VALVE SPRING

NOTE: Place the end of the valve

spring with closely wound coils

toward the cylinder head.

INTAKE VALVE SEAL

(WHITE SPRING)

Replace.

VALVE KEEPERS

VALVE SPRING

RETAINER

EXHAUST VALVE SEAL

(BLACK SPRING)

Replace.

SPRING SEAT

NOTE: Install the valve spring seats

before installing the valve seals.

VALVE GUIDE SEAL INSTALLER

KD - 2899 or EQUIVALENT

(Commercially available)

NOTE: Use the end

of the tool with the

smallest I.D.

VALVE SEAL

Replace.ProCarManuals.com

Page 97 of 1771

Cylinder Heads

Installation (cont'd)

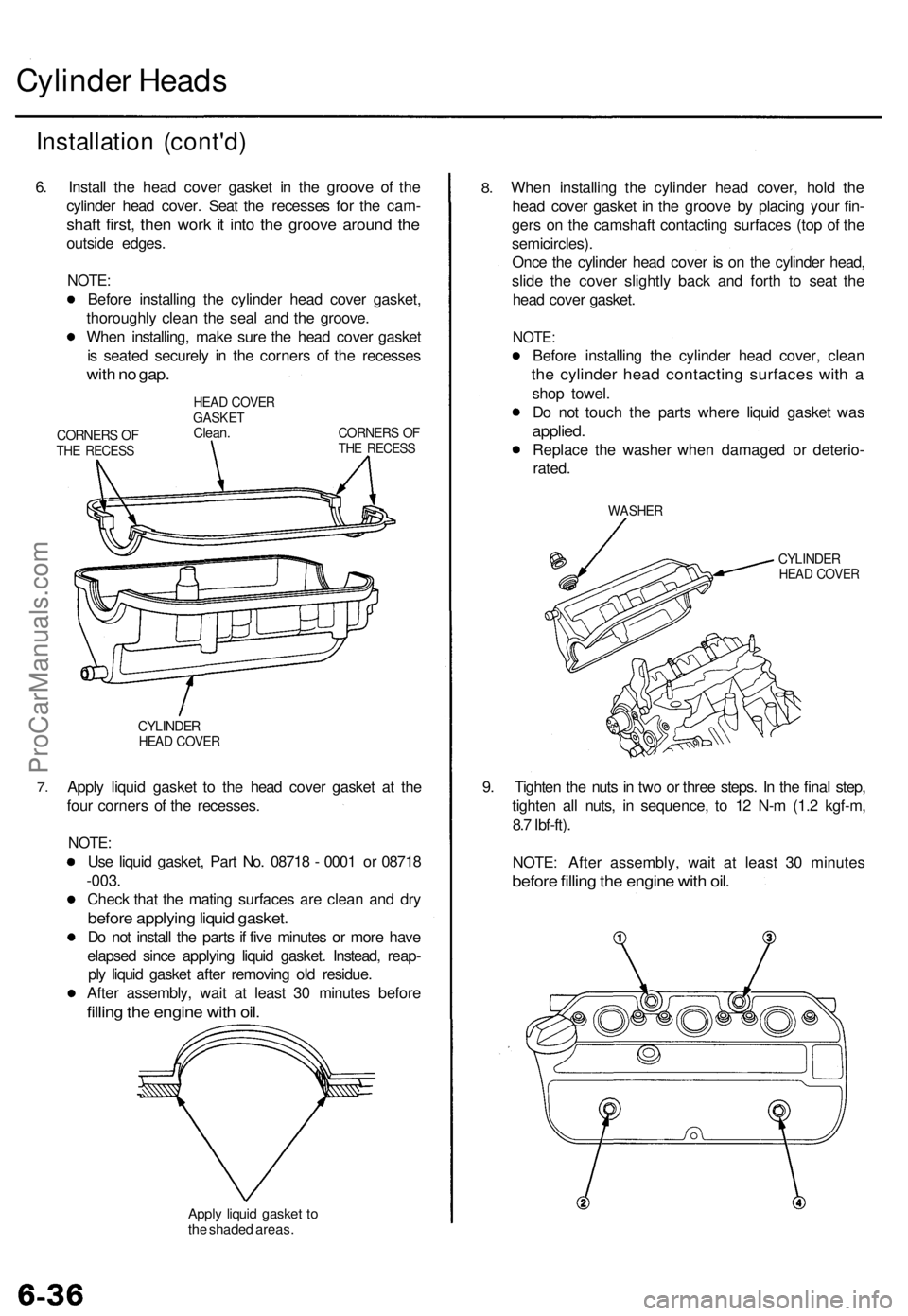

6. Install the head cover gasket in the groove of the

cylinder head cover. Seat the recesses for the cam-

shaft first, then work it into the groove around the

outside edges.

NOTE:

Before installing the cylinder head cover gasket,

thoroughly clean the seal and the groove.

When installing, make sure the head cover gasket

is seated securely in the corners of the recesses

with no gap.

CORNERS OF

THE RECESS

HEAD COVER

GASKET

Clean.

CORNERS OF

THE RECESS

7.

CYLINDER

HEAD COVER

Apply liquid gasket to the head cover gasket at the

four corners of the recesses.

NOTE:

Use liquid gasket, Part No. 08718 - 0001 or 08718

-003.

Check that the mating surfaces are clean and dry

before applying liquid gasket.

Do not install the parts if five minutes or more have

elapsed since applying liquid gasket. Instead, reap-

ply liquid gasket after removing old residue.

After assembly, wait at least 30 minutes before

filling the engine with oil.

Apply liquid gasket to

the shaded areas.

8.

When installing the cylinder head cover, hold the

head cover gasket in the groove by placing your fin-

gers on the camshaft contacting surfaces (top of the

semicircles).

Once the cylinder head cover is on the cylinder head,

slide the cover slightly back and forth to seat the

head cover gasket.

NOTE:

Before installing the cylinder head cover, clean

the cylinder head contacting surfaces with a

shop towel.

Do not touch the parts where liquid gasket was

applied.

Replace the washer when damaged or deterio-

rated.

WASHER

CYLINDER

HEAD COVER

9. Tighten the nuts in two or three steps. In the final step,

tighten all nuts, in sequence, to 12 N-m (1.2 kgf-m,

8.7 Ibf-ft).

NOTE: After assembly, wait at least 30 minutes

before filling the engine with oil.ProCarManuals.com

Page 103 of 1771

Drive Plat e Connectin

g Ro d an dCrankshaf t

Replacemen t En

d Pla y

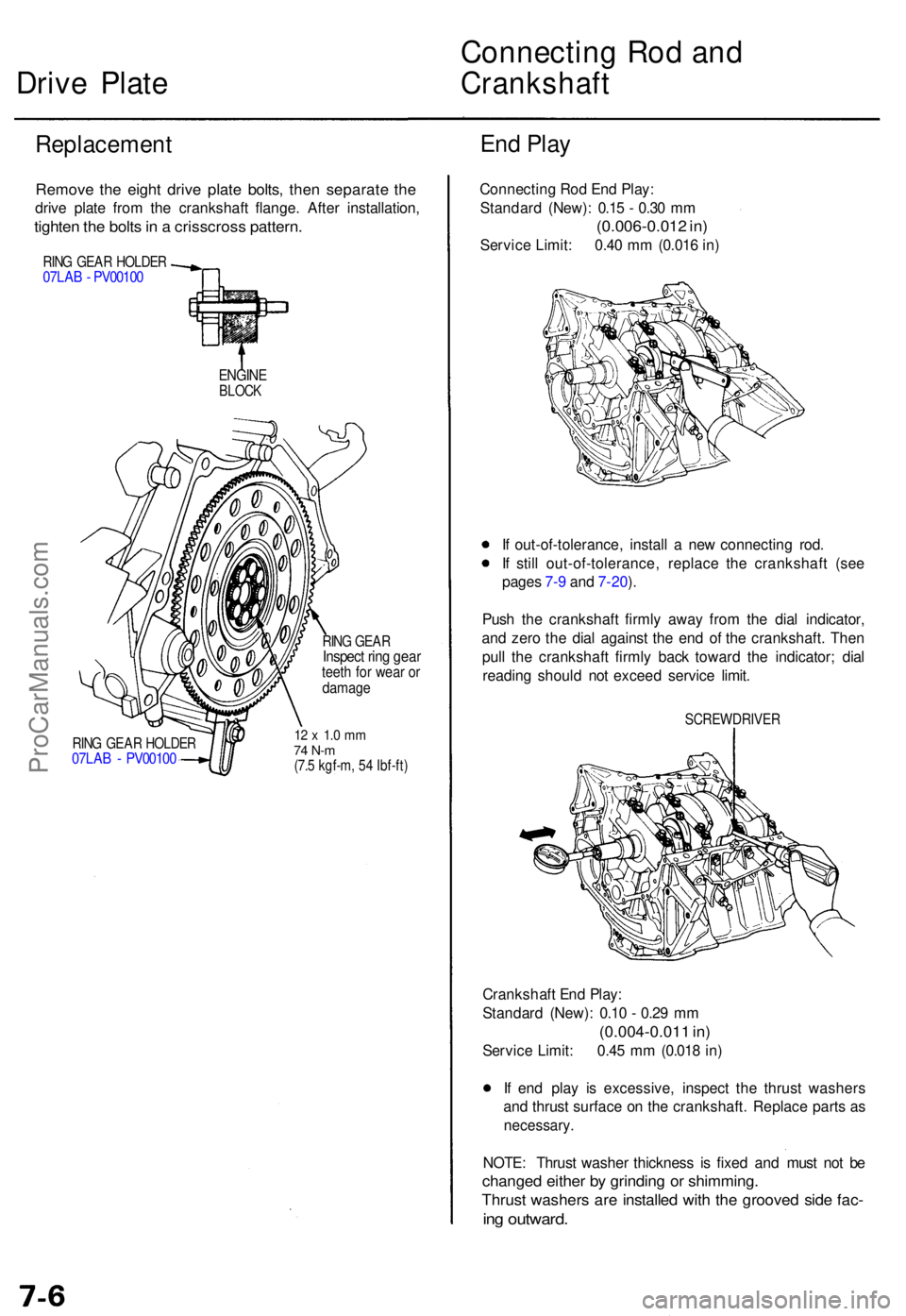

Remov e th e eigh t driv e plat e bolts , the n separat e th e

driv e plat e fro m th e crankshaf t flange . Afte r installation ,

tighten th e bolt s in a crisscros s pattern .

RING GEA R HOLDE R07LAB - PV0010 0

ENGINEBLOCK

RING GEA R HOLDE R07LAB - PV0010 0

RING GEA RInspec t rin g gea rteeth fo r wea r o rdamag e

12 x 1. 0 m m74 N- m(7.5 kgf-m , 5 4 Ibf-ft )

Connectin g Ro d En d Play :

Standar d (New) : 0.1 5 - 0.3 0 m m

(0.006-0.01 2 in )

Servic e Limit : 0.4 0 m m (0.01 6 in )

I f out-of-tolerance , instal l a ne w connectin g rod .

I f stil l out-of-tolerance , replac e th e crankshaf t (se e

page s 7- 9 an d 7-20 ).

Pus h th e crankshaf t firml y awa y fro m th e dia l indicator ,

an d zer o th e dia l agains t th e en d o f th e crankshaft . The n

pul l th e crankshaf t firml y bac k towar d th e indicator ; dia l

readin g shoul d no t excee d servic e limit .

SCREWDRIVE R

Crankshaft En d Play :

Standar d (New) : 0.1 0 - 0.2 9 m m

(0.004-0.01 1 in )

Servic e Limit : 0.4 5 m m (0.01 8 in )

I f en d pla y i s excessive , inspec t th e thrus t washer s

an d thrus t surfac e o n th e crankshaft . Replac e part s a s

necessary .

NOTE: Thrus t washe r thicknes s i s fixe d an d mus t no t b e

change d eithe r b y grindin g o r shimming .

Thrust washer s ar e installe d wit h th e groove d sid e fac -

ing outward .

ProCarManuals.com