heater ASTON MARTIN DB7 1997 User Guide

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 180 of 421

NO

COLOUR

ms 8

909

NG

999

BK

2160

B

995

NK

PIN

1 ? i 4

5

7

S 9 10 tl 12

AREA

A3

86

06

A3 86

RQ

SEAT HEATER

SWITC

NO

COLOUf

2155

R

749

OU

2161

0

2162

OR

2159

B

996

P

2163

KR

2164

K

2165

S

2166

SN

362

RW

i

PAC

PIN 1 2 3 4 5 6 / e

9 10 II 12 13

14

K

AREA B4-2I5

06 01 01 A3 86 Dl 01 01

01

86

NO

2157

?l5fl

2159 2160

COLOUR

B B B B

AREA

A4 Al 81 Al

NO

COLOUR

PIN

2157

8 1

2154

R 2 J 4

AREA

A3

84-215

NO

COLOUR

998

WK

2166

SN

2165

S

2162

OR

2164

K

2163

KR

997

BP

2161

0

PIN 1 4 B 9 1? 13 ?8 37

AREA

86 CI 81 81 81 81 86 ei

c/a

24 48

NO

COLOUf

995 NK

362

RW

996 PN

909 NG 997 8S 998 WK 904 OW 750 OS 749

OU

999 8K

PIN

1 2 3 4

5

6 7

8 9 10 II 12 13

14 15 16

AREA

Al

CI Bl

Al Dl 01

C3-2I4

03 81 Al

SHEET 12 AREA D6

NO

COLOUR

750

OS

2156

OW

2157

R

2158

OW

PIN 85 RR

87 87A

30

AREA

C6

C4-2I4 84-215

C4-2I4

HEATER RELAY

'"^P Wiring Diagram

Model - Aston Martin DB7

Harness Title - Passengers Sill

Part No. - B37-84649

Revision - 0 Sheet 24 of 26 - 97 MY

Page 184 of 421

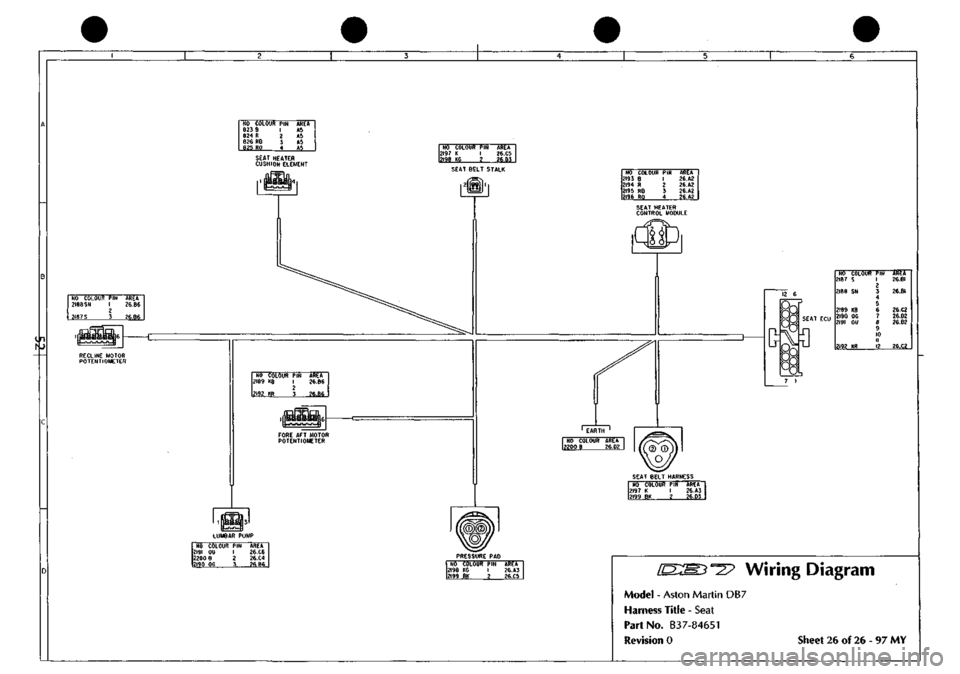

NO COLOUR

PIN

823

8 1

824

R

2

826 RB

3

825 RO

4

AREA

A5 A5 A5 AS

SEAT HEATER

CUSHION

ELEMENT

NO COLOUR

PIN

2193

e 1

2194

R 2

2195

RB 3

2196

RO 4

AREA 26.A2 26.A2 26.A2 26.A2

in

NO COLOUR

PIN

AREA 2188

SN

1

26.B6 2 2187

S

3

26.B6

16

NO COLOUf 2187

S

2186

SN

2189

KB

2190

OG

2191

OU

2192

KR

PIN

1 ? 3 4 S

6 1

e

9 10 11

12

AREA 26.BI

26.BI

2e.C2 26.D2 26.02

26.02 RECLINE MOTOR POTENTIOMETER

Wiring Diagram

Model - Aston Martin DB7

Harness Title - Seat

Part No. B37-84651

Revision 0 Sheet 26 of 26 - 97 MY

Page 217 of 421

5^^?

Electrics

Seat Belt Pretensioner

The Seat Belt Pretensioner System (where fitted)

Description

The DB7 seat belt pretensioner system operates the drivers seat belt pretensioner in conjunction with the Airbag

system.

The seat belt pretensioner control module is located under the right hand seat, beside the right hand seat

control module.

The pretensioner control module calculates changes in vehicle speed using an input signal from an accelerometer.

When a collision is detected (Rapid reduction in vehicle speed) and the safing sensor in the airbag system is also

activated,

the pretensioner charge

is

fi red usingelectrical energy stored in a capacitor within the pretensioner control

module. Firing of the pretensioner charge applies additional tension to the drivers seat belt.

The airbag and seat belt pretensioner systems share the SRS (Airbag) warning lamp. Any fault detected by the

pretensioner control module is indicated by constant illumination ofthe

SRS

(Airbag) warning lamp. Flashing of the

SRS warning lamp indicates a fault in the airbag system.

Should both systems develop faults, the pretensioner system will permanently illuminate the warning lamp. This

would mask the airbag system warning indication. Therefore, rectify the pretensioner fault and then retest for faults

in the airbag system

The pretensioner control module can log up to 10 diagnostic trouble codes together with a time since each fault was

alerted to the driver. Each

fau It

wi

11

be identified as 'Permanent' or 'Intermittent' on the PDU diagnostic trouble codes

screen.

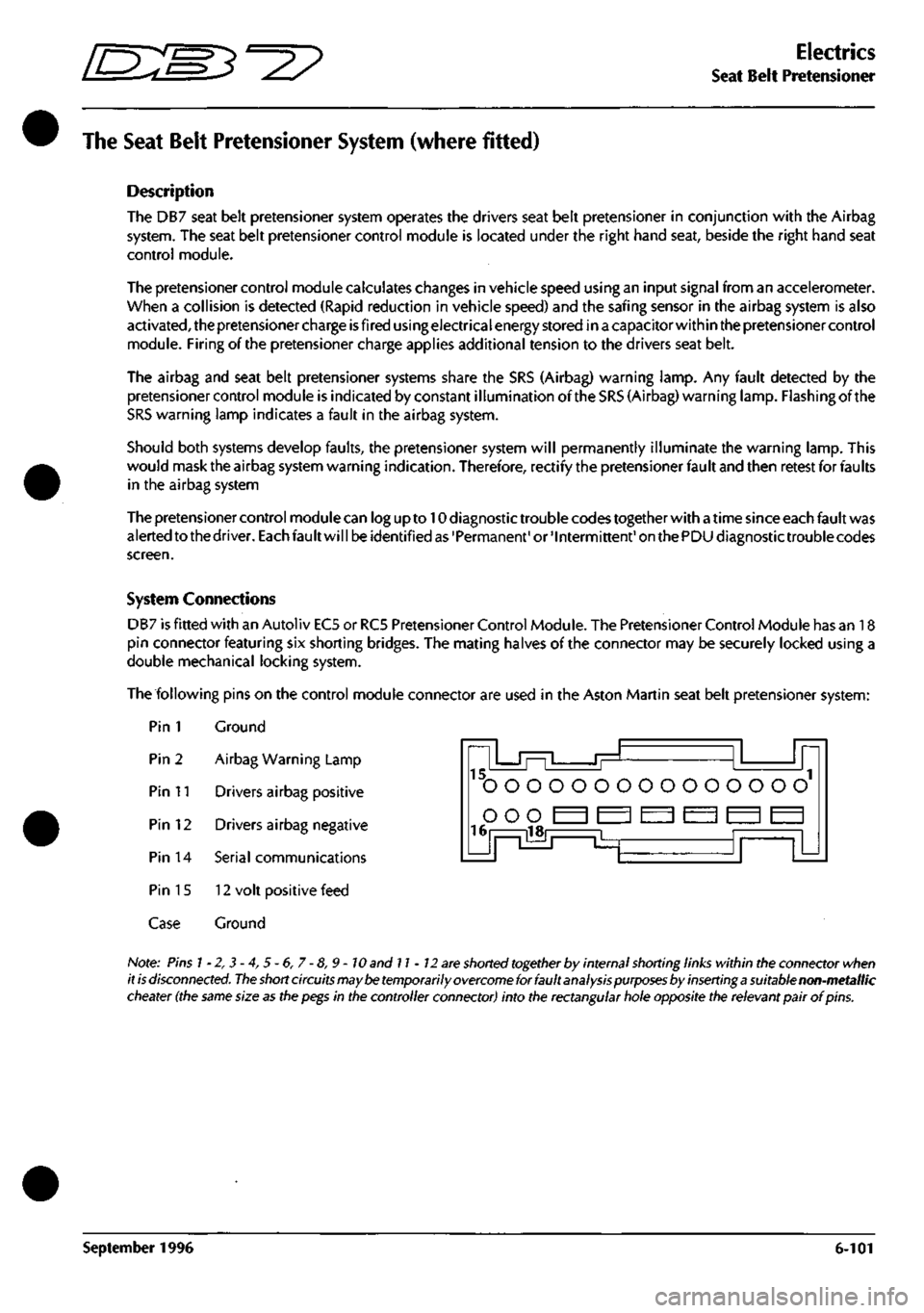

System Connections

DB7 is fitted with an Autoliv ECS or RC5 Pretensioner Control Module. The Pretensioner Control Module has an 18

pin connector featuring six shorting bridges. The mating halves of the connector may be securely locked using a

double mechanical locking system.

The following pins on the control module connector are used in the Aston Martin seat belt pretensioner system:

Pin 1 Ground

' ' "L Pin 2 Airbag Warning Lamp

Pin 11 Drivers airbag positive

Pin 12 Drivers airbag negative

Pin 14 Serial communications

Pin 15 12 volt positive feed

Case Ground

15.

rrj ^

ooooooooooooooo

16 illn

^

Note: Pins

1

-2, 3 -4, 5 -6, 7 -8,9 -

10

and 11-12

are

shorted

together

by internal shorting links within the connector when

it

is

disconnected.

The

short circuits may

be

temporarily

overcome

for fault analysis

purposes

by inserting

a

suitable non-metallic

cheater

(the

sBfTiG

size

3s

the

p€gs

in the controller connector) into the rectsngul^r hole opposite the relevsnt p3ir of pins.

September 1996 6-101

Page 221 of 421

^^

Electrics

Seat Belt Pretensioner

Diagnostic Trouble Codes

050A Pretensioner squib leak to battery positive

050B Pretensioner squib leak to ground

050C Pretensioner squib high resistance

050D Pretensioner squib low resistance

0D13 Capacitor voltage error

0D14 Capacitor capacitance

0D09 Energy reserve sv^^itch

0D1

E

Energy shutdown switch

050E Seatbelt pretensioner switch error

0109 Accelerometer function

01OA Acceleration out of range

01 OB

Accelerometer offset

0209 Safing sensor error

030A Temperature sensor error

060C Warning lamp short circuit

060D Warning lamp open circuit

060E Warning lamp driver error

OAOC Analogue voltage error

0A09 Communications error

090A EEPROM not programmed

0909 EEPROM checksum

OAOA External watchdog error

OAOB External watchdog time out

020A Safing sensor not closed

090C RAM check error

Seat Beit Pretensioner Diagnostics

WARNING: To avoid the possibility of personal

injury caused by accidental deployment of the

pretensioner, disconnect the vehicle battery and

iva/f at least 10 minutes for all voltages to fully

discharge before working on the pretensioner

system. This covers the possibility of the normal

capacitor discharge circuits being inoperative and

failing to discharge the capacitor when instructed

to do

so.

WARNING: Do not make any electrical

measurements on the pretensioner

squib.

Electrical

measurement devices

can

induce sufficient voltage

to cause unintentional firing of the pretensioner

assembly

050 A Pretensioner Squib Leak to Battery

Positive

050A will be logged if the resistance of the

pretensioner squib feed or return line to a positive

potential falls below

1

k£2.

Procedure

1.

Read the warnings given at the start of this

pretensioner diagnostics section.

2.

Connect the PDU to the lower diagnostic socket

and access the pretensioner control module. Verify

that an 050A code is logged and note if the fault is

shown as intermittent. Note any other codes in the

DTC log and then clear all codes.

3. Switch off the ignition and wait at least 10 minutes

for the pretensioner squib firing capacitors to fully

discharge before continuing with this procedure.

4.

Disconnect the pretensioner squib connector at the

rearward harness. Disconnect the pretensioner

control module and temporarily cheat the squib

shorting link.

Note: The control module harness connector has a

shorting

link which short circuits

the

squib

lines together

when the connector is displaced. Carefully insert a

suitable non-metallic cheater to remove the short

circuit

between pins 11 and 12 before continuing with fault

diagnosis.

i"o

o o b 6 o ooooooooo'

I

ooo

Inserr cheater here

September 1996 6-105

Page 222 of 421

Electrics

Seat Belt Pretensioner 5^^?

Switch on the ignition and check for a positive

potential on the squib feed or return lines at the two

pins of the squib harness connector (activating

circuits in the rearward harness in turn may assist in

identifyingthe voltage

source).

Ifa positive potential

is detected, switch off and repair the circuit fault.

If no short circuit is detected in the rearward

harness, go to step 6.

With the ignition switched off and the pretensioner

squib disconnected, check the squib harness for

physical damage.

If any damage is detected, replace the complete

pretensioner squib assembly.

If no damage is detected, the fault is possibly in the

pretensioner control module. Replace the control

module.

Remove the cheater from the control module

connector.

'o o 0080 000000000' 000 ™ ^^ ^^^

ir Insert cheater here

Reconnect all components. Switch on the ignition

and test the vehicle to ensure that the problem is

resolved.

050B Pretensioner

Squib

Leakto Ground

050B will be logged if the resistance of the

pretensioner squib feed or return line to ground

falls below

Ikfi.

Procedure

1.

Read the warnings given at the start of this

pretensioner diagnostics section.

2.

Connect the PDU to the lower diagnostic socket

and access the pretensioner control module. Verify

that an 050B code is logged and note if the fault is

shown as intermittent. Note any other codes in the

DTC log and then clear all codes.

3. Switch offthe ignition and wait at least 10 minutes

for the pretensioner squib firing capacitors to fully

discharge before continuing with this procedure.

4.

Disconnect the pretensioner squib connector at the

rearward harness. Disconnect the pretensioner

control module and temporarily cheat the squib

shorting link.

Note: The control module harness connector has a

shorting link which

short

circuits

the squib lines together

when the connector is displaced. Carefully insert a

suitable non-metallic cheater to remove the

short circuit

between pins 11 and 12 before continuing with fault

diagnosis.

'o

o 00 8 o 000000000' 000

Insert cheater here

Check for a short circuit to vehicle ground on the

squib feed or return lines at the two pins of the squib

harness connector. If a short circuit is detected,

switch off and repair the circuit fault.

If no short circuit is detected in the rearward

harness, go to step 6.

With the ignition switched off and the pretensioner

squib disconnected, check the squib harness for

physical damage.

If any damage is detected, replace the complete

pretensioner squib assembly.

If no damage is detected, the fault is possibly in the

pretensioner control module. Replace the control

module.

Remove the cheater from the control module

connector. Reconnect all components. Switch on

the ignition and test the vehicle to ensure that the

problem is resolved.

6-106 September 1996

Page 223 of 421

D=27

Electrics

Seat Belt Pretensioner

050C Pretensioner Squib High Resistance 050D Pretensioner squib low resistance

050C will be logged if the resistance of the

pretensioner squib circuit rises above 4.5 ±0.5C2

050D will be logged if the resistance of the

pretensioner squib circuit falls below 1.4 ±0.4Q

Procedure

Read the warnings given at the start of this

pretensioner diagnostics section.

Connect the PDU to the lower diagnostic socket

and access the pretensioner control module. Verify

that an 050C code is logged and note if the fault is

shown as internnittent. Note any other codes in the

DTC log and then clear ail codes.

Switch off the ignition and wait at least 10 minutes

for the pretensioner squib firing capacitors to fully

discharge before continuing with this procedure.

Disconnect the pretensioner squib connector at the

rearward harness. Disconnect the pretensioner

control module and temporarily cheat the squib

shorting link.

3.

Procedure

Read the warnings given at the start of this

pretensioner diagnostics section.

Connect the PDU to the lower diagnostic socket

and accessthe pretensioner control module. Verify

that an 050D code is logged and note if the fault is

shown as intermittent. Note any other codes in the

DTC log and then clear all codes.

Switch off the ignition and wait at least 10 minutes

for the pretensioner squib firing capacitors to fully

discharge before continuing with this procedure.

Disconnect the pretensioner squib connector atthe

rearward harness. Disconnect the pretensioner

control module and temporarily cheat the squib

shorting link.

Note: The control module harness connector has a

shorting link which

short

circuits the squib

lines together

when the connector is displaced. Carefully insert a

suitable non-metallic

cheater to

remove

the short

circuit

between pins 11 and 12 before continuing with fault

diagnosis.

.j^ 'o o ob bo oooooooo

O O O

iV ^3 ^3 ^3 ^3 ^3 ^

lU Insert cheater here

Check the continuity of the squib feed and return

lines.

If any significant resistance is measured,

service the wiring as necessary.

Also check the condition of the connector pins for

damage or lack of tension and service

as

necessary.

If the circuit resistance is acceptable and the

connector pins are good, go to step 6.

If any defects are identified and serviced, go to step

7.

If the checks in step 4 are good, the high circuit

resistance must be in the pretensioner squib or in

thecontrol module. Replace the pretensioner squib

and reconnect all components.

Clearall logged DTCs from the pretensioner control

module and then test the vehicle.

If the 050C code is logged again, replace the

control module.

Note: The control module harness connector has a

shorting link which

short

circuits the squib

lines together

when the connector is displaced. Carefully insert a

suitable non-metallic

cheater to remove the

short circuit

between pins 11 and 12 before continuing with fault

diagnosis.

Insert cheater here

Check the continuity from the squib feed line to the

squib return line. With the shorting link cheated,

the resistance should be more than lOkQ. If the

resistance is less than 10kQ, service the wiring as

necessary.

Also check the connector pins for any damage

which could cause an unintentional short circuit.

If the checks in step 5 are good, the low circuit

resistance must be in the pretensioner squib or in

thecontrol module. Replace the pretensioner squib

and reconnect all components.

Clearall logged DTCs from the pretensioner control

module and then test the vehicle.

If the 050D code is logged again, replace the

control module.

September 1996 6-107

Page 224 of 421

Electrics

Seat Belt Pretensioner ^?

060C Warning Lamp Short Circuit

060C will be logged if the nnonitor current flow

through the SRS/Airbag warning lamp is excessive.

The warning lamp circuit is normally at 12 volts and

is switched to ground by the airbag control module

or by the pretensioner control module when one of

these control modules detects a fault.

If either control module connector is displaced and

the ignition is switched on, the warning lamp will

be illuminated via the ground shorting link between

pins!

and 2 ofthe pretensioner controller connector

or pins 4 and 5 of the airbag controller connector,

both control modules must be checked for the

appropriate DTC to isolate which circuit is at fault.

Procedure

1.

Connect the PDU to the lower diagnostic socket

and access the pretensioner control module. Verify

that an 060C code is logged and note if the fault is

shown as intermittent. Note any other codes in the

DTC log and then clear all codes. Go to step 2.

If fault code 060C is not logged, go to the diagnostics

section of the airbag system.

2.

Check the security of the pretensioner control

module connector.

If the connector is secure, go to step 3.

If the connector isdisplaced,resecu re theconnector.

Clear all logged DTCs and retest the vehicle to

ensure that the problem is resolved.

3. Access the SRS/Airbag warning lamp and check the

lamp resistance.

If the resistance is approximately

120£2,

the lamp is

good.

Refit the lamp and go to step 4.

If the resistance of the lamp is significantly less than

approximately 120^, fit a new lamp and refit the

instrument panel. Clear the logged DTCs from the

pretensioner control module and retest the vehicle

to ensure that the problem is resolved.

4.

If the checks in step 3 are good, the low circuit

resistance must be in the instrument pack or in the

control module. Replace the pretensioner control

module and reconnect all components.

6. Switch on the ignition and then test the vehicle.

If the 060C code is logged again, replace the

instrument pack.

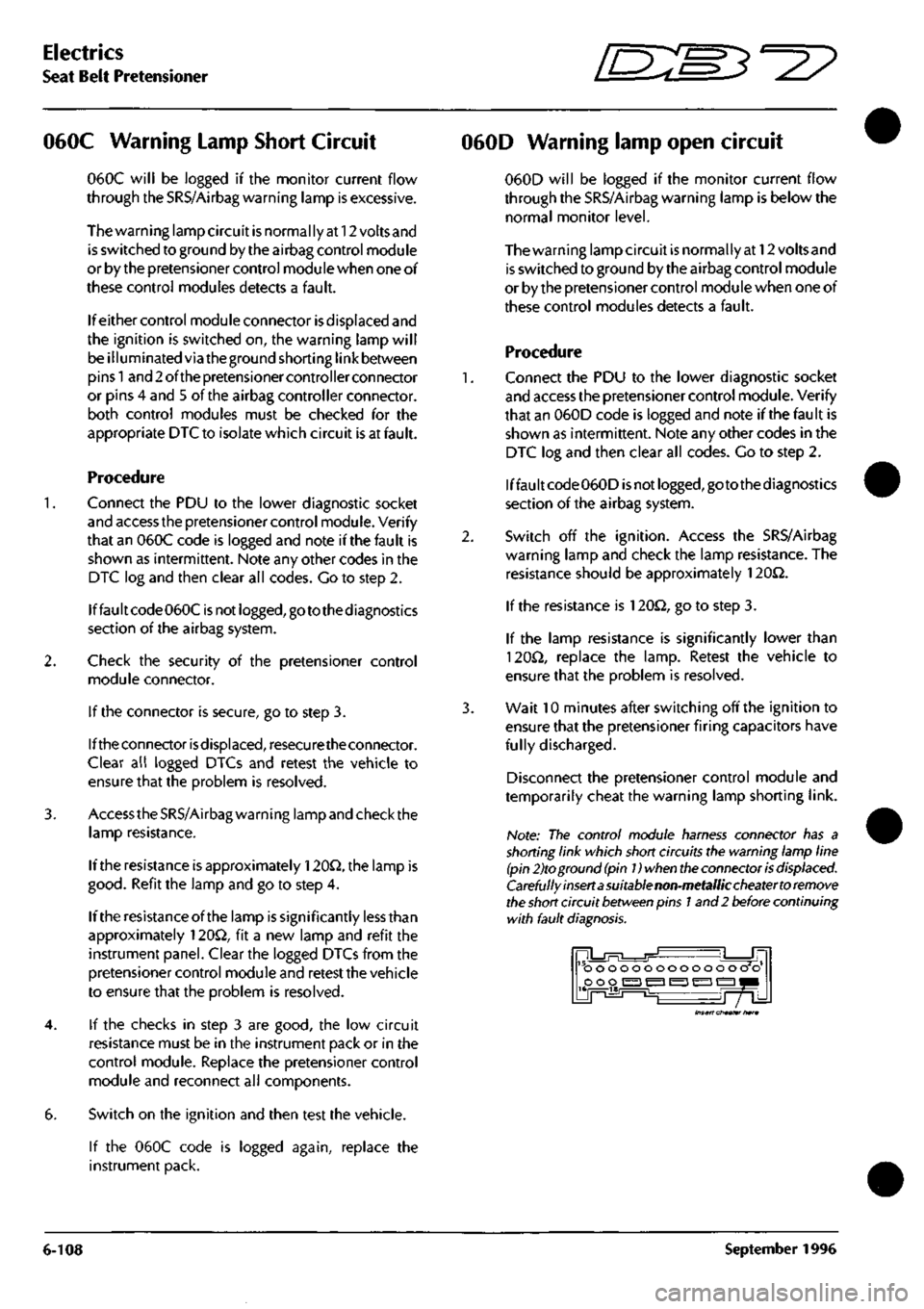

060D Warning lamp open circuit

060D will be logged if the monitor current flow

through the SRS/Airbag warning lamp is below the

normal monitor level.

The warning lampcircuit is normally at 12 voltsand

is switched to ground by the airbag control module

or by the pretensioner control module when one of

these control modules detects a fault.

Procedure

Connect the PDU to the lower diagnostic socket

and access the pretensioner control module. Verify

that an 060D code is logged and note if the fault is

shown as intermittent. Note any other codes in the

DTC log and then clear all codes. Go to step 2.

lffaultcode060D is not

logged,

gotothediagnostics

section of the airbag system.

Switch off the ignition. Access the SRS/Airbag

warning lamp and check the lamp resistance. The

resistance should be approximately 120Q.

If the resistance is 120i2, go to step 3.

If the lamp resistance is significantly lower than

120^2,

replace the lamp. Retest the vehicle to

ensure that the problem is resolved.

Wait 10 minutes after switching off the ignition to

ensure that the pretensioner firing capacitors have

fully discharged.

Disconnect the pretensioner control module and

temporarily cheat the warning lamp shorting link.

Note: The control module harness connector has a

shorting link which short circuits the warning lamp line

(pin 2)to ground

(pin

Dwhen

the

connector

is

displaced.

Carefully insert a suitable non-metallic cheater to remove

the

short

circuit

between

pins

1

and 2 before continuing

with fault

diagnosis.

ooooooooooooo o o poo

i^i

^ ^ ^ 1^1

Insert cheater hare

6-108

September

1996

Page 227 of 421

3-^?

Electrics

Seat Removal/Replacement 97.5 MY

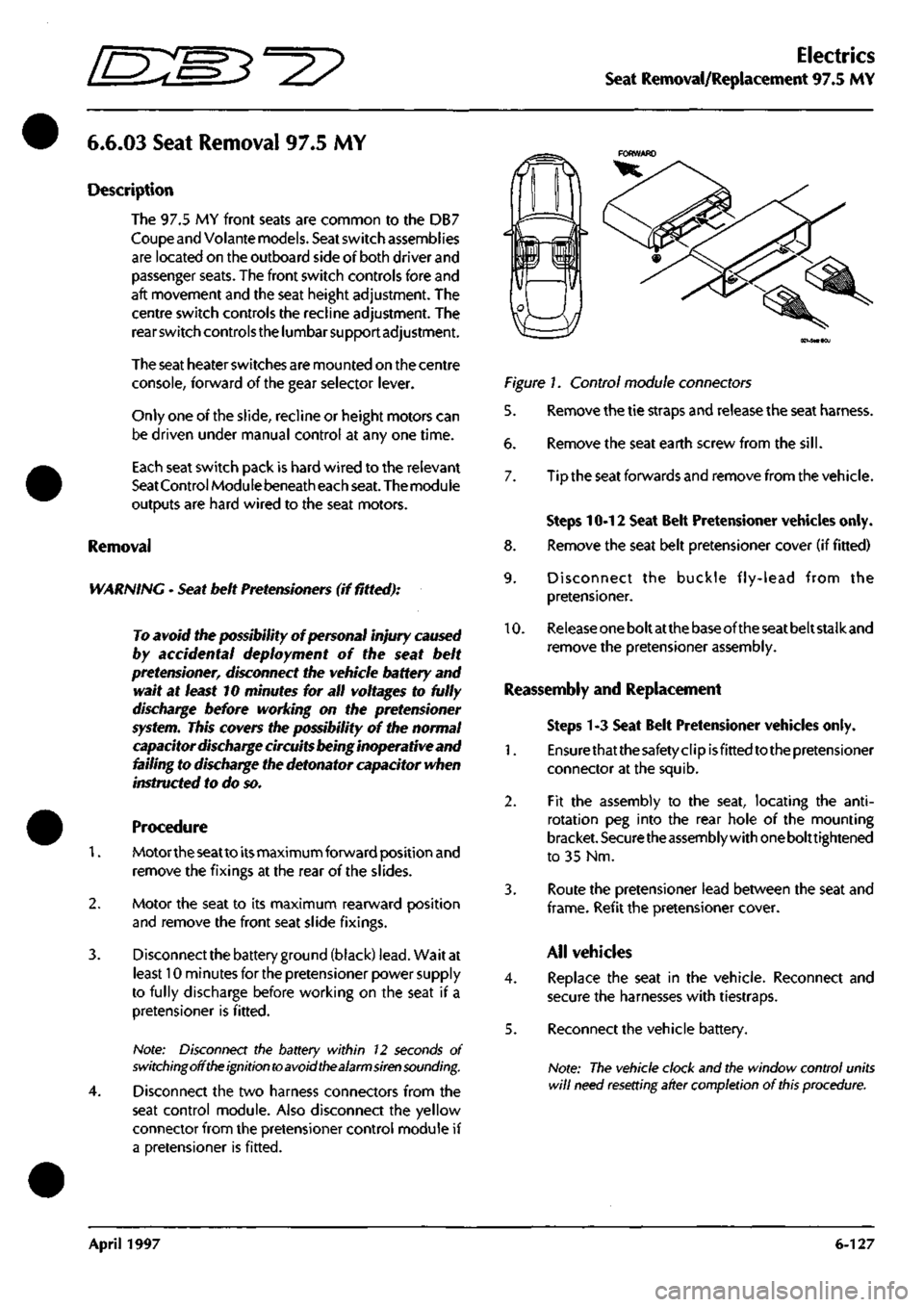

6.6.03

Seat Removal 97.5 MY

Description

The 97.5 MY front seats are common to the DB7

Coupe

and

Volante

models.

Seat

switch

assembi ies

are located on the outboard side of both driver and

passenger

seats.

The front switch controls fore and

aft movement and the seat height adjustment. The

centre switch controls the recline adjustment. The

rear switch

controls

the

lumbar support adjustment.

The seat

heater switches are mounted on the centre

console, forward of the gear selector

lever.

Only one of

the

slide,

recline or height motors can

be driven under manual control at any one time.

Each seat switch pack is hard wired to the relevant

Seat Control

Module

beneath each

seat.

The

module

outputs are hard wired to the seat motors.

Removal

WARNING -

Seat

belt

Pretensioners

(if fitted):

To avoid the possibility

of

personal

injury

caused

by accidental deployment of the seat belt

pretensioner,

disconnect

the

vehicle battery and

wait at

least

10

minutes

for all

voltages

to fully

discharge

before working on the

pretensioner

system.

This covers the possibility

of

the normal

capacitor

discharge

circuits being inoperative and

failing to discharge the detonator capacitor when

instructed

to

do

so.

Procedure

1.

Motortheseatto

its

maximum forward position and

remove the fixings at the rear of the slides.

2.

Motor the seat to its maximum rearward position

and remove the front seat slide fixings.

3. Disconnect the battery

ground

(black)

lead.

Wait at

least 10 minutes for the pretensioner power supply

to fully discharge before working on the seat if a

pretensioner is fitted.

Note: Disconnect the battery within 12 seconds of

switching off the ignition to avoid the alarm siren sounding.

4.

Disconnect the two harness connectors from the

seat control module. Also disconnect the yellow

connector from the pretensioner control module if

a pretensioner is fitted.

Figure 1. Control module connectors

5. Remove the tie straps and release the seat harness.

6. Remove the seat earth screw from the

sill.

7. Tip the seat forwards and remove from the vehicle.

Steps 10-12 Seat Belt Pretensioner vehicles only.

8. Remove the seat belt pretensioner cover (if fitted)

9. Disconnect the buckle fly-lead from the

pretensioner.

10.

Release

one

bolt at

the

base of the

seat

belt stalk and

remove the pretensioner assembly.

Reassembly and Replacement

Steps 1-3 Seat Belt Pretensioner vehicles only.

1.

Ensurethatthesafetyclipisfittedtothepretensioner

connector at the squib.

2.

Fit the assembly to the seat, locating the

anti-

rotation peg into the rear hole of the mounting

bracket.

Securethe

assembly with

one

bolttightened

to 35 Nm.

3. Route the pretensioner lead between the seat and

frame.

Refit the pretensioner

cover.

All vehicles

4.

Replace the seat in the vehicle. Reconnect and

secure the harnesses with tiestraps.

5. Reconnect the vehicle battery.

Note:

The vehicle clock and the window control units

will

need resetting after completion

of

this

procedure.

April 1997 6-127

Page 229 of 421

O" D^?

Body and Trim

Contents

Contents

Body and Trim

Body Repair

Potential Risks

Precautions

General Repair Notes

Steel Body Parts - Repair, Remove and Replace

RTM Body Parts

Body Panel and Trim Removal

Front Apron

Front Undertray

Wheel Arch Liners

Side Sills (top fixings)

Side Sills (bottom fixings)

Rear Bumper

Doors

Door Liners

Door Liner (components)

Steering Wheel

Column Switches

Instrument Panel (surround)

Instrument Panel

Facia Underscuttles

Glove Box

Facia Mountings (1)

Facia Mountings (2)

Console Instruments

Radio

Front Seats

Ashtray

Centre Console

Seat ECU Covers

Rear Console

Rear Seats and C Post Trim

Quarter Panels, B Post Panels, Parcel Shelf

Headlining

Roof System Description and Repair Procedures

Vol ante Roof

Roof and Rear Quarter Light Control

Roof Component Location

Roof Control System

9.0.02.1

Roof Removal/Replacement

9.0.02.3

Roof Hydrailic Control System

9.0.02.5

Bleeding the Roof Hydraulic System

9.1.01.1

Rear Quarter Window Renewal

9.1.01.2

Rear Quarter Glass Adjustment

9.1.01.4

Rear Quarter Window Lift Motor - LH

9.1.01.5

Rear Quarter Window Lift Motor - RH

Roof Sealing and Wind Noise

9.2.01.5

'A' Post/Header Sealing and Lock Adj

9.2.01.6

Roof Seals - Adjustment

9.2.01.7

Cheater Plate Seals - Adjust/Renew

9.2.01.8

Door Glass Adjustment

Alcantara Cleaning

7-1

7-2

7-2

7-3

7-3

7-4

7-5

7-6

Sheet 1

Sheet 2

Sheet 3

Sheet 4

Sheet 5

Sheet 6

Sheet 7

Sheet 8

Sheet 9

Sheet 10

Sheet 11

Sheet 12

Sheet 13

Sheet 14

Sheet 15

Sheet 16

Sheet 17

Sheet 18

Sheet 19

Sheet 20

Sheet 21

Sheet 22

Sheet 23

Sheet 24

Sheet 25

Sheet 26

Sheet 27

7-7

7-7

7-8

7-9

7-10

7-11

7-12

7-13

7-14

7-15

7-16

7-17

7-17

7-18

7-19

7-20

7-21

May 1996 7-1

Page 272 of 421

^^2?

Body and Trim

Roof Sealing and Wind Noise

Roof Sealing and Wind Noise

Roof seals and side windows have been provided

with

a range

ofadjustments capable ofdealing with

any leaks which may occur.

The following information is divided into five

sections:

1.

A post and header sealing/roof lock adjustment

2.

Roof seals - adjustment

3. Cheater plate seals - adjustment/renewal

4.

Door glass - adjustment

5. Rear quarter glass - adjustment (9.1.01.2)

When a leak is

reported,

either wind noise or water

ingress, try to pinpoint the actual leak path using

any of the following methods:

• An ultrasonic leak detector

• An air flow

detector,

e.g.

Drager

smoke

tube

• Paper test strips at seal contact areas

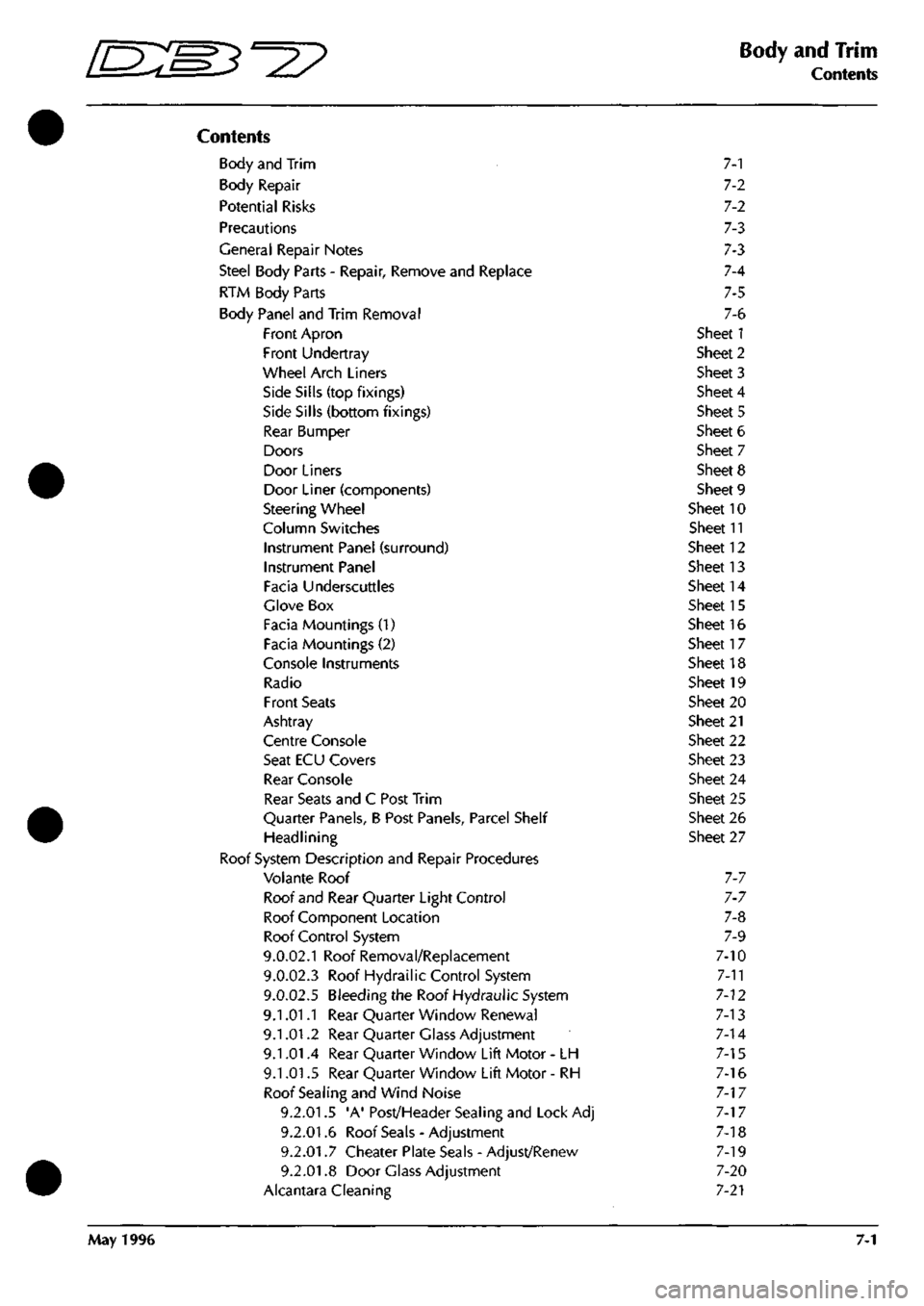

9.2.01.5 - 'A' Post/Header Sealing and

Lock Adjustment

when a leak is detected at the top of the 'A' post

adjacent to the header rail

seal,

first

ensure

that the

roof lock is correctly adjusted.

If the lock is difficult to operate, it is probably

overtensioned. Release the retaining hook locknut

and extend

the hook

one full

turn.

Checkand repeat

the adjustment as necessary.

If the locking handle is loose, it is undertensioned.

Release the retaining hook locknut and screw the

hook inwards one full

turn.

Check and repeat the

adjustment as necessary.

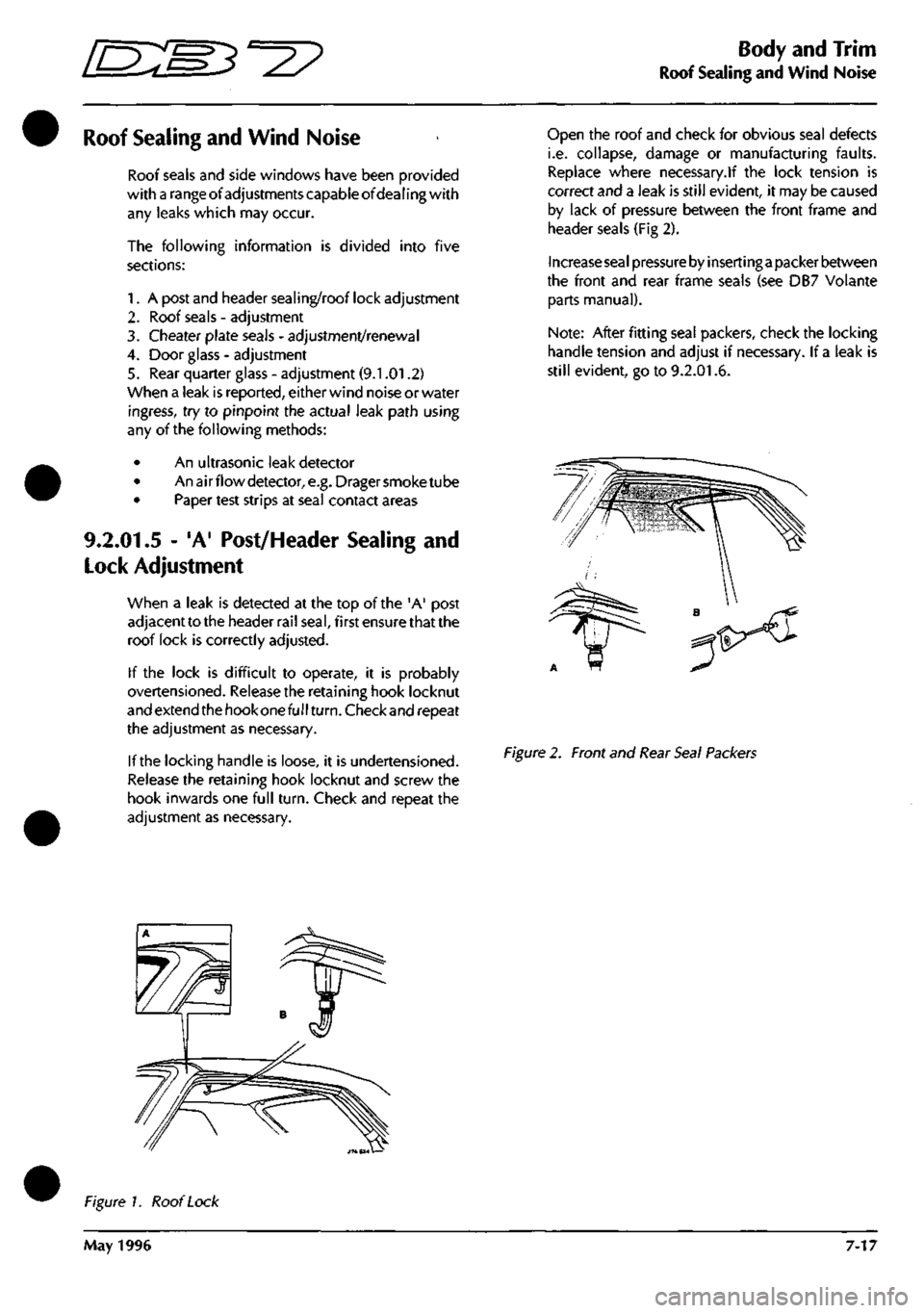

Open the roof and check for obvious seal defects

i.e. collapse, damage or manufacturing faults.

Replace where necessary.lf the lock tension is

correct and a leak is still evident, it may be caused

by lack of pressure between the front frame and

header seals (Fig 2).

Increase seal pressure by inserting a

packer between

the front and rear frame seals (see DB7 Volante

parts manual).

Note:

After fitting

sea!

packers, check the locking

handle tension and adjust if necessary. If

a

leak is

still evident, go to 9.2.01.6.

Figure

2. Front and

Rear Seal Packers

Figure 1. Roof

Lock

May 1996 7-17