steering ASTON MARTIN DB7 1997 User Guide

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 204 of 421

Electrics

Airbag System [D:B3-2?

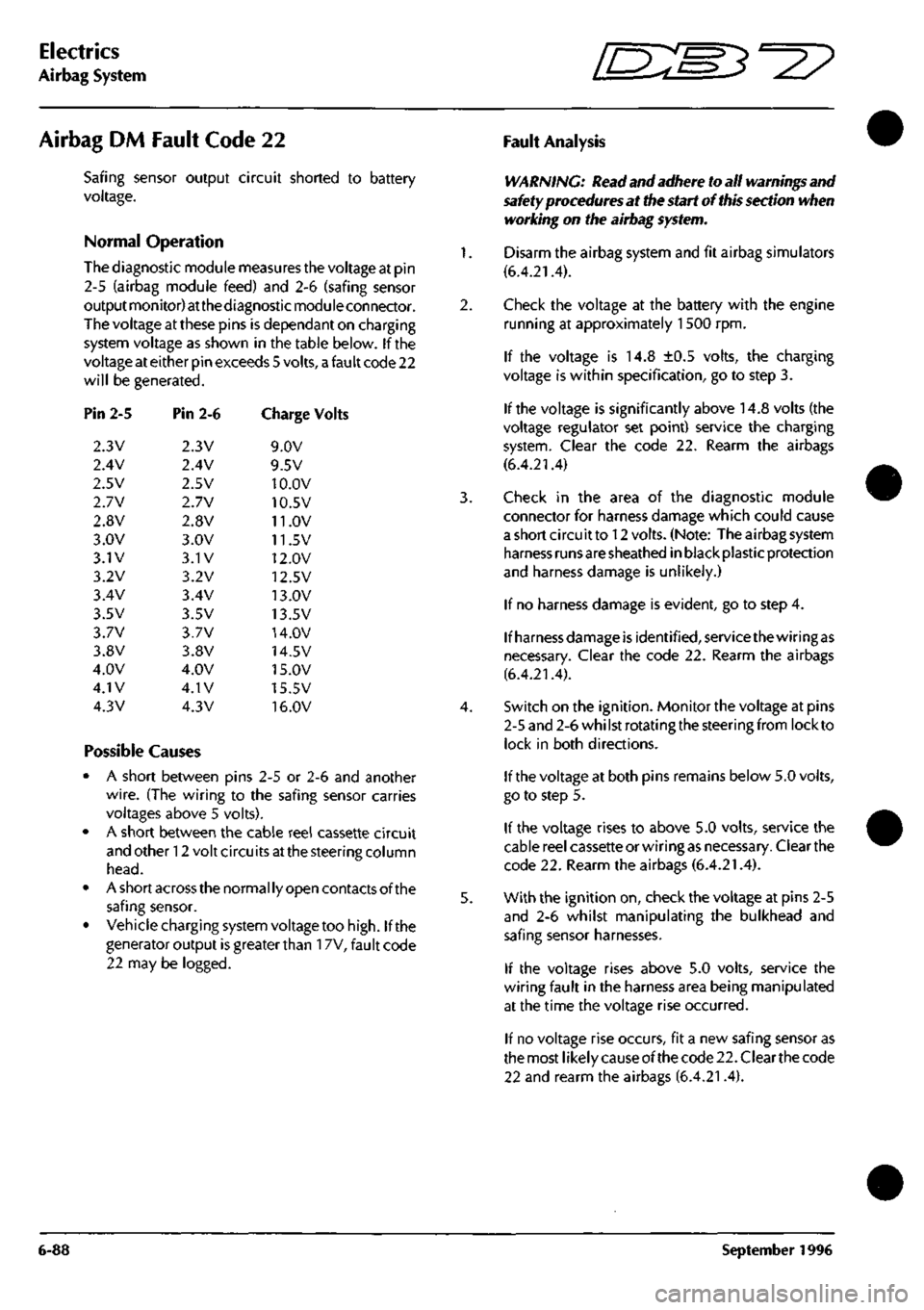

Airbag DM Fault Code 22

Safing sensor output circuit shorted to battery

voltage.

Normal Operation

The diagnostic module measures the voltage at pin

2-5 (airbag module feed) and 2-5 (safing sensor

output monitor) at thediagnosticmoduleconnector.

The voltage at these pins is dependant on charging

system voltage as shown in the table below. If the

voltage at either pin exceeds 5 volts,

a

fault code 22

will be generated.

in 2-5

2.3V

2.4V

2.5V

2.7V

2.8V

3.0V

3.1V

3.2V

3.4 V

3.5V

3.7V

3.8V

4.0V

4.1V

4.3V

Pin 2-6

2.3V

2.4V

2.5V

2.7V

2.8V

3.0V

3.1V

3.2 V

3.4 V

3.5V

3.7V

3.8V

4.0V

4.1V

4.3V

Charge Volts

9.0V

9.5V

10.0V

10.5V

11.0V

11.5V

12.0V

12.5V

13.0V

13.5V

14.0V

14.5V

15.0V

15.5V

16.0V

Possible Causes

• A short between pins 2-5 or 2-6 and another

wire.

(The wiring to the safing sensor carries

voltages above 5 volts).

• A short between the cable reel cassette circuit

and other 12 volt circu its at the steering column

head.

• A short across the normal ly open contacts of the

safmg sensor.

• Vehiclechargingsystem voltage too

high.

If the

generator output is greater than 17V, fault code

22 may be logged.

Fault Analysis

WARNING: Read and adhere to all warnings and

safety procedures at the start of this section when

working on the airbag system.

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

Check the voltage at the battery with the engine

running at approximately 1500 rpm.

If the voltage is 14.8 ±0.5 volts, the charging

voltage is within specification, go to step 3.

If the voltage is significantly above 14.8 volts (the

voltage regulator set point) service the charging

system.

Clear the code 22. Rearm the airbags

(6.4.21.4)

Check in the area of the diagnostic module

connector for harness damage which could cause

a short circu it to 12 volts. (Note: The airbag system

harness runs are sheathed in black plastic protection

and harness damage is unlikely.)

If no harness damage is evident, go to step 4.

If harness damage is identified, service the wiring as

necessary. Clear the code 22. Rearm the airbags

(6.4.21.4).

Switch on the ignition. Monitor the voltage at pins

2-5 and 2-6 whilst rotatingthe steering from lock to

lock in both directions.

If the voltage at both pins remains below 5.0 volts,

go to step 5.

If the voltage rises to above 5.0 volts, service the

cable reel cassette or wiring as necessary. Clear the

code 22. Rearm the airbags (6.4.21.4).

With the ignition on, check the voltage at pins 2-5

and 2-6 whilst manipulating the bulkhead and

safing sensor harnesses.

If the voltage rises above 5.0 volts, service the

wiring fault in the harness area being manipulated

at the time the voltage rise occurred.

If no voltage rise occurs, fit a new safing sensor as

the most likely cause of the code 22. Clear the code

22 and rearm the airbags (6.4.21.4).

6-88 September 1996

Page 209 of 421

in:m3'^?

Electrics

Airbag System

Airbag DM Fault Code 34

Drivers airbag circuit low resistance or short circuit.

Normal Operation

The diagnostic module measures the resistance

across pins 2-5 and 2-4 every time the ignition is

switched on. The resistance should be 1.6 to 1.8Q.

This value is made up of the airbag

1

.OQ and the

cable reel cassette windings 0.3-0.4£2 per winding.

If the total resistance in the passengers airbag

circuit falls below 0.7Q, fault code 34 will be

declared and the airbag lamp will be illuminated.

Note: The nominal

resistance

of the airbag simulator is

2.5Q, therefore expect

a

total circuit resistance readingof

3.1 -

3.3£2

with the simulator

fitted.

Caution: The drivers airbag connector contains

shorting bars which short circuit pins 1 and 3 of

both sides of the connector when disconnected.

DO NOT REMOVE THE AIRBAC CONNECTOR

SHORTING BAR UNDER ANY CIRCUMSTANCES.

The airbag harness shorting bar may be temporarily

disabled during the following resistance checks.

Possible Causes

• Poorly mated cable reel cassette connector. If

the connector is poorly mated, the shorting bars

may not be fully retracted.

• Faulty shorting bar may short circuit 2-4 and 2-

5 together.

• Short circuit in the cable reel cassette windings.

• A short across the airbag terminals in the airbag

module.

Fault Analysis

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

Disconnect the diagnostic module and remove the

plastic wedge from connector 2 (black). Measure

the resistance between pins 2-5 and 2-4. The

resistance should be 3.1 - 3.3Q.

If the resistance is 3.1 to 3.3Q, go to step 4.

If the resistance is below 3.1 - 3.3Q, go to step 3.

Disconnect the cable reel cassette connector at the

steering column and remove the plastic wedge.

Measure the resistance from pins 2-4 and 2-5 at the

diagnostic module connector.

If the resistance is infinity, check the cable reel

cassette for short circuits. Replace the column

switchgear assembly if necessary. Refit the plastic

wedges. Reconnect the diagnostic module. Clear

the code 34. Rearm the airbags (6.4.21.4).

If the resistance is less than infinity, replace the

main airbag harness. Refit the plastic wedges.

Reconnect the diagnostic module. Clear the code

34.

Rearm the airbags (6.4.21.4).

Since the circuit resistance is in specification, the

fault must lie in the diagnostic module or in the

airbag module.

Substitute a known good diagnostic module. If

code 34 recurs with the airbag simulator fitted,

there is still a fault in the wiring or the simulator.

If the fault code 34 does not recur, rearm the airbags

(6.4.21.4) and retest.

If fault code 34 recurs with the airbag modulefitted,

the airbag module is faulty. Replace the drivers

airbag module (4.5.01.3).

September 1996 6-93

Page 218 of 421

Electrics //—>> ^^^^^^ • >^

Seat Belt Pretensioner I'•—

-"i-t.

^-^

JH—X

System Fault Strategy

No single fault may cause an unexpected deployment. The controller will supervise the pretensioner electrical

system in order to warn the driver should a fault occur. Any fault detected by the self diagnostics shall cause the SRS/

airbag warning lamp to be activated, and in some cases the pretensioner control module to enter shutdown mode.

In shutdown mode, the energy of the reserve capacitors shall be discharged to avoid unintended deployment.

As the ignition is switched on, the pretensioner controller will directly discharge the energy capacitors. When the

start up procedure is completed without detecting any faults, the DC/DC converter will be activated allowing the

capacitors to be charged. The system shall be fully active within

11

secondsafterswitchingthe ignition on providing

that no faults are detected.

All system faults monitored by the controller are filtered in software to avoid fault warnings due to transient electrical

disturbances.

If a fault which could lead to inadvertent deployment is detected by the microprocessor, a software shutdown will

be generated. However, a leakage to an earth or positive potential in the pretensioner output circuit shall not cause

the controller to enter shutdown mode.

If a permanent short of the ignition transistor occurs, a shutdown shall be generated by the hardware circuit. If a

shutdown occurs, the system shall be unable to deploy the pretensioner after a period of 3 seconds (i.e. capacitors

discharged to under minimum deployment voltage).

WARNING: To avoid the possibility of personal injury caused by accidental deployment of the pretensioner,

disconnect the vehicle battery and wait at least 10 minutes for all voltages to fully discharge before working on

the pretensioner

system.

This

covers the possibility of the normal capacitor discharge circuits being inoperative

and failing to discharge the capacitor when instructed to do so.

WA RNING: Do not make any electrical measurements on the pretensioner squib. Electrical measurement devices

can induce sufficient voltage to cause unintentional firing of the pretensioner assembly

If the module enters shutdown mode, all diagnostic functions are stopped, but the communications link remains

active.

A fault code corresponding to the cause of the problem may be read by the PDU.

Assembly/Removal/Service I nstructions

WARNING: In the event of a vehicle impact where the airbags and the seatbelt pretensioner (if fitted) are

deployed, the following actions MUST be performed:

Check the condition of the

seatbelts,

steering wheel, steering column, all connections to airbags, and the column

switchgear connectors for integrity and damage. If in any doubt, replace suspected parts for new parts.

Replace both crash

sensors,

the safing sensor and the seatbelt pretensioner module (if fitted).

On completion of all repair procedures, switch on the ignition and check that the Airbag/SRS warning light

comes

on when the ignition is switched on and extinguishes after approximately six seconds indicating satisfactory

completion of the airbag and pretensioner

system

self

tests.

Vehicles for the North American, Australian and Japanese markets are fitted with drivers seat belt pretensioner

systems and are fitted with a shorting plug in the yellow connector adjacent to the pretensioner control module.

Vehicles for other markets do not have drivers seat belt pretensioners fitted but have a blanking plug in the yellow

connector adjacent to the pretensioner control module.

6-102 September 1996

Page 229 of 421

O" D^?

Body and Trim

Contents

Contents

Body and Trim

Body Repair

Potential Risks

Precautions

General Repair Notes

Steel Body Parts - Repair, Remove and Replace

RTM Body Parts

Body Panel and Trim Removal

Front Apron

Front Undertray

Wheel Arch Liners

Side Sills (top fixings)

Side Sills (bottom fixings)

Rear Bumper

Doors

Door Liners

Door Liner (components)

Steering Wheel

Column Switches

Instrument Panel (surround)

Instrument Panel

Facia Underscuttles

Glove Box

Facia Mountings (1)

Facia Mountings (2)

Console Instruments

Radio

Front Seats

Ashtray

Centre Console

Seat ECU Covers

Rear Console

Rear Seats and C Post Trim

Quarter Panels, B Post Panels, Parcel Shelf

Headlining

Roof System Description and Repair Procedures

Vol ante Roof

Roof and Rear Quarter Light Control

Roof Component Location

Roof Control System

9.0.02.1

Roof Removal/Replacement

9.0.02.3

Roof Hydrailic Control System

9.0.02.5

Bleeding the Roof Hydraulic System

9.1.01.1

Rear Quarter Window Renewal

9.1.01.2

Rear Quarter Glass Adjustment

9.1.01.4

Rear Quarter Window Lift Motor - LH

9.1.01.5

Rear Quarter Window Lift Motor - RH

Roof Sealing and Wind Noise

9.2.01.5

'A' Post/Header Sealing and Lock Adj

9.2.01.6

Roof Seals - Adjustment

9.2.01.7

Cheater Plate Seals - Adjust/Renew

9.2.01.8

Door Glass Adjustment

Alcantara Cleaning

7-1

7-2

7-2

7-3

7-3

7-4

7-5

7-6

Sheet 1

Sheet 2

Sheet 3

Sheet 4

Sheet 5

Sheet 6

Sheet 7

Sheet 8

Sheet 9

Sheet 10

Sheet 11

Sheet 12

Sheet 13

Sheet 14

Sheet 15

Sheet 16

Sheet 17

Sheet 18

Sheet 19

Sheet 20

Sheet 21

Sheet 22

Sheet 23

Sheet 24

Sheet 25

Sheet 26

Sheet 27

7-7

7-7

7-8

7-9

7-10

7-11

7-12

7-13

7-14

7-15

7-16

7-17

7-17

7-18

7-19

7-20

7-21

May 1996 7-1

Page 230 of 421

Body and Trim //-->> ^izz^^ ' ^ ^

Body Repair ' —^^ '-^ >^-/

Body Repair

Introduction

This section contains information for the body repair and rectification of the vehicle. Wherever possible the vehicle

must be returned to its original manufactured condition. Following repair the vehicle must be fully checked and, if

necessary, the braking system and steering must be fully reset.

Health and Safety

Ensure that the correct working practices are established before beginning work.

Observe that the correct working practices are followed whether they be legislative or common sense.

Be aware of the potential risks of using materials used in the manufacture and repair of vehicles and take the

appropriate precautions.

Warning: Make sure that the working practices for the air conditioning

system

are followed: do not vent the refrigerant

directly into the atmosphere and always use the approved recovery/recycle /recharge equipment, always wear

suitable protective garments to prevent injury to the eyes and the skin.

Potential Risks

Paint

If the organic solvents, contained in paints, are inhaled for any length of time damage can be caused to the liver,

kidneys, respiratory tract and the digestive system.

Prolonged exposure to isocyanates can cause lung sensitisation and asthma-like symtoms can develop with

subsequent re-exposure to even low concentrations.

Solvent inhilation can cause dizziness or loss of consciousness.

Inhilation of spray dust and sanding debris can cause lung damage.

Paint activatorsand additives will damage the eyesor can cause dermatitis if allowed to splash and come into contact

with these areas. Peroxide and acid catalysts can cause burns.

Applied heat

There is considerable risk of damage to the eyes and skin when welding or flame cutting.

Fire is a serious danger as many materials and fluids in the vehicle are inflammable.

Toxic and dangerous fumes can be liberated when the following are subjected to heat; expanded foam, corrosion

protection,

adhesive and sealing compounds,

trim,

seat material and paints that contain isocyanates.

When heated to

a

temperature of 300°C, polyu rethane based compounds can

1

iberate small quantities of isocyanate.

Many types of nitrogen containing chemicals may be liberated as breakdown products, these chemicals can

contain isocyanates, oxides of nitrogen and hydrogen cyanide.

Potentially toxic or asphyxiant fumes and gases are produced by welding, for example; zinc oxide with zinc coated

panels and ozone gas from the MIC process.

Metal repair

There is considerable risk of damage to the eyes, ears and skin when metal cutting, forming and dressing is being

carried out.

Soldering may be hazardous because of heat generated fumes and skin contact with the materials.

7-2 May 1996

Page 234 of 421

Body and Trim

Body Panel and Trim Removal 5^7

Body Panel and Trim Removal

The following diagrams show the fixings for all

removeable body and trim panels.

Sheet 1. Front Apron

Sheet 2. Front Undertray

Sheet 3. Wheel Arch Liners

Sheet 4. Side Sills (top fixings)

Sheets. Side Sills (bottom fixings)

Sheet 6. Rear Bumper

Sheet 7. Doors

Sheet 8. Door Liners

Sheet 9. Door Liner (components)

Sheet 10. Steering Wheel

Sheet 11. Column Switches

Sheet 12. Instrument Panel (surround)

Sheet 13. Instrument Panel

Sheet 14. Facia Underscuttles

Sheet 15. Glove Box

Sheet 16. Facia Mountings (1)

Sheet

1

7. Facia Mountings (2)

Sheet 18. Console Instruments

Sheet 19. Radio

Sheet 20. Front Seats

Sheet

21.

Ashtray

Sheet 22. Centre Console

Sheet 23. Seat ECU Covers

Sheet 24. Rear Console

Sheet 25. Rear Seats and C Post Trim

Sheet 26. Quarter Panels, B Post Panels, Parcel Shelf

Sheet 27. Headlining

7-6 May 1996

Page 332 of 421

^2?

Air Conditioning Repair Procedures

Hose - Compressor to Evaporator/Air-Con Unit Renew

8.1.06.1 Hose-Compressor

to

Evaporator

Renewal

Procedure

1.

Open the bonnet and fit a wing cover.

2.

Depressurise the air conditioning systenn.

3. Remove the hose to evaporator valve clamping

plate,

disconnect the hose from the valve, remove

and discard the 'O' ring

seal.

4.

Fit a blanking plug to the evaporator valve. Release

the evaporator hose securing clips.

5. Remove the compressor outlet port retaining bolt.

6. Disconnect the hose from the compressor, discard

the hose complete with 'O' ring seals.

7. Connect the hose to the evaporator valve and

tighten clamp onto the hose.

8. Route the hose to the compressor, fit a new 'O' ring

seal and connect it to the compressor.

9. Position the outlet port retaining plate on the

compressor, fit and tighten the securing bolt.

10.

Refit the hose to the clips.

11.

Charge the air conditioning system.

12.

Remove the wing cover and close the bonnet.

8.2.01.1 Air Conditioning Unit Renewal

1.

Disconnect the battery earth

lead.

2.

Drain the engine coolant into a suitable container.

3. Depressurise the air conditioning system.

4.

Disconnect the high and low pressure hoses and

expansion valve from the air conditioning unit (see

expansion valve renewal).

5. Slacken the coolant hose to the heater matrix pipe

securing clips and disconnect the hoses from the

matrix. (This will require the removal of the air

intake hose for access.)

6. Remove the following items from inside the car:

front seats

underscuttle panels/knee bolsters

glove box assembly

facia trim (walnut trim)

radio and ashtray

centre console switch panel assembly

instrument panel and surround trim

steering wheel and column

facia assembly complete

hoses - distribution box to door vents

facia support frame

Details and drawings of the above operations can

be found in the electrical and trim sections.

Disconnect the vacuum hoses from the blower

motors, water valve and reservoir.

Un-clip the electrical harness from the air

conditioningunit, release theelectrical connections

and reposition the harness to allow removal of the

unit.

Displace and remove the footwell ventilator ducts

and hoses (Fig. 1-1).

May 1996 8-55

Page 336 of 421

'nzm^=2?

Air Conditioning Repair Procedures

Blower Motor Renewal

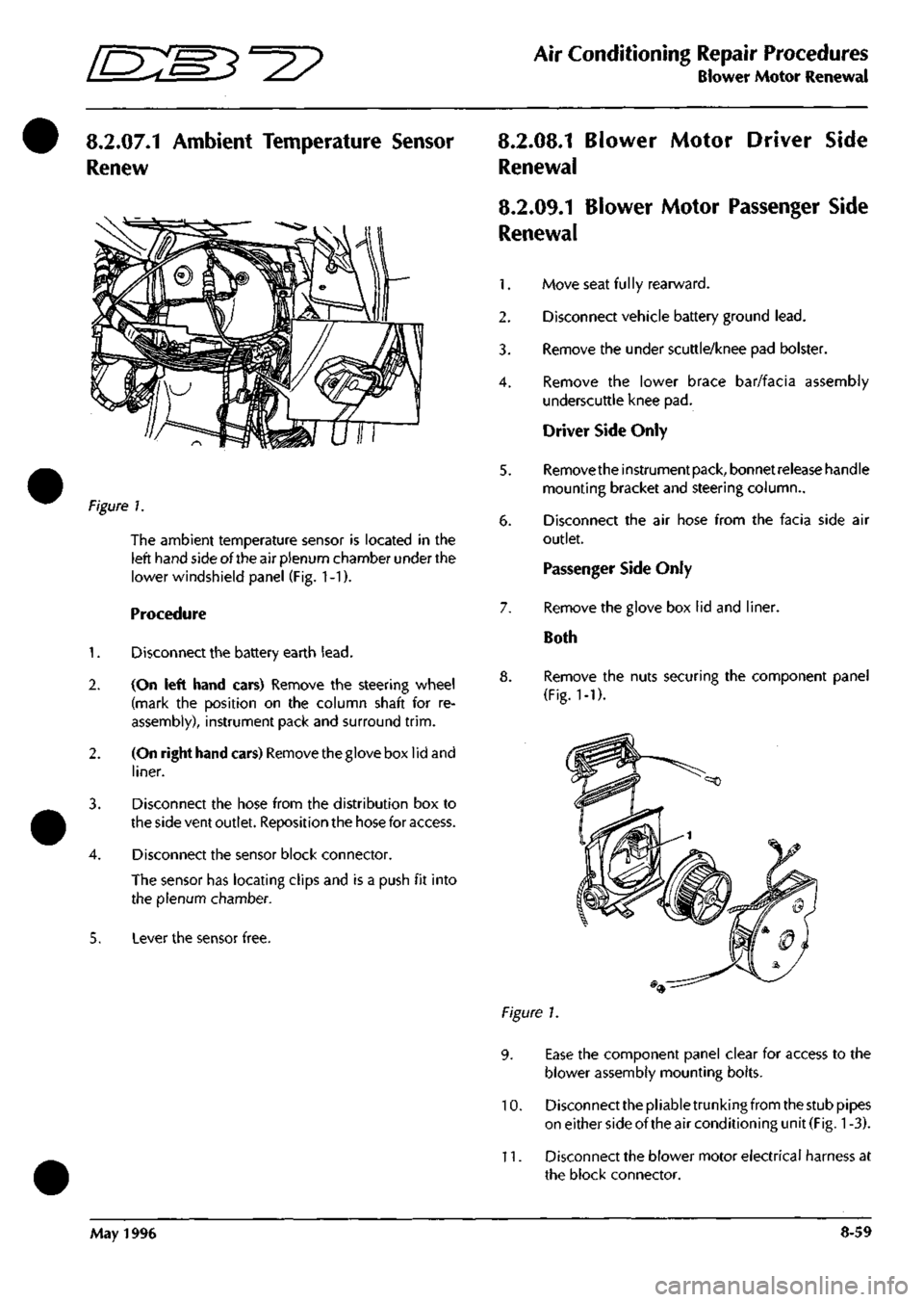

8.2.07.1 Ambient Temperature Sensor

Renew

?\gure

1.

The ambient temperature sensor is located in the

left hand side of the air plenum chamber under the

lower windshield panel (Fig. 1-1).

Procedure

1.

Disconnect the battery earth

lead.

2.

(On left hand cars) Remove the steering wheel

(mark the position on the column shaft for re

assembly), instrument pack and surround

trim.

2.

(On right hand cars) Removethegloveboxlidand

liner.

3. Disconnect the hose from the distribution box to

the side vent outlet. Reposition the hose for access.

4.

Disconnect the sensor block connector.

The sensor has locating clips and is a push fit into

the plenum chamber.

5. Lever the sensor free.

8.2.08.1 Blower Motor Driver Side

Renewal

8.2.09.1 Blower Motor Passenger Side

Renewal

1.

Move seat

fu 1

ly rearward.

2.

Disconnect vehicle battery ground

lead.

3. Remove the under scuttle/knee pad bolster.

4.

Remove the lower brace bar/facia assembly

underscuttle knee pad.

Driver Side Only

5. Removetheinstrumentpack, bonnetreieasehandle

mounting bracket and steering column..

6. Disconnect the air hose from the facia side air

outlet.

Passenger Side Only

7. Remove the glove box lid and liner.

Both

8. Remove the nuts securing the component panel

(Fig.

1-1).

Figure 1.

9. Ease the component panel clear for access to the

blower assembly mounting bolts.

10.

Disconnect the pliable trunking from the stub pipes

on either side of the air conditioning unit

(Fig.

1

-3).

11.

Disconnect the blower motor electrical harness at

the block connector.

May 1996 8-59

Page 339 of 421

Air Conditioning Repair Procedures

Water Temperature Switch/Heater Matrix Renew •=2?

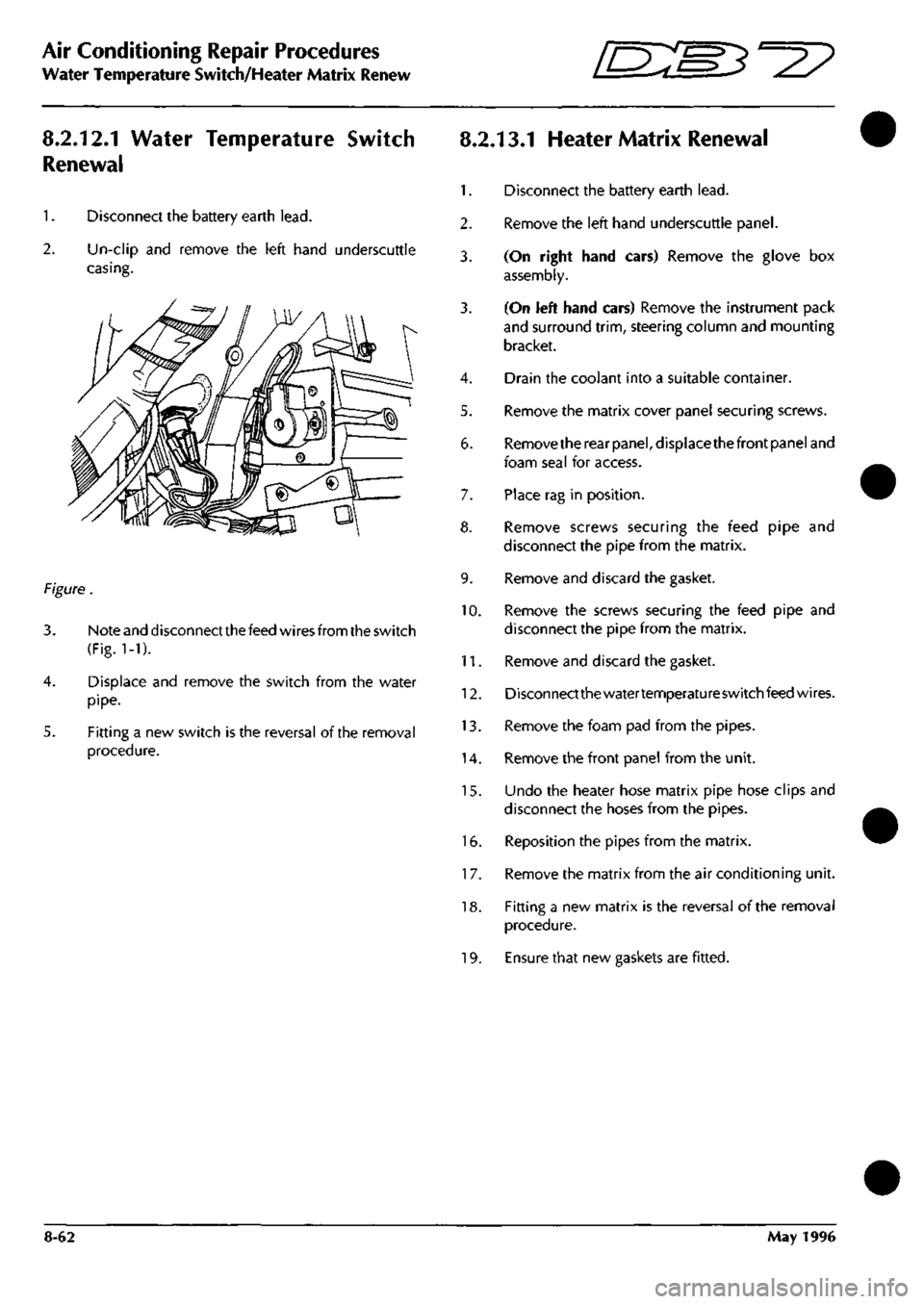

8.2.12.1 Water Temperature Switch

Renewal

1.

Disconnect the battery earth

lead.

2.

Un-clip and remove the left hand underscuttle

casing.

Figure.

3. Note and disconnect the feed wires from the switch

(Fig.

1-1).

4.

Displace and remove the switch from the water

pipe.

5. Fitting a new switch is the reversal of the removal

procedure.

8.2.13.1 Heater Matrix Renewal

1.

Disconnect the battery earth

lead.

2.

Remove the left hand underscuttle panel.

3. (On right hand cars) Remove the glove box

assembly.

3. (On left hand cars) Remove the instrument pack

and surround

trim,

steering column and mounting

bracket.

4.

Drain the coolant into a suitable container.

5. Remove the matrix cover panel securing screws.

6. Removethe rear

panel,

displacethefront panel and

foam seal for access.

7. Place rag in position.

8. Remove screws securing the feed pipe and

disconnect the pipe from the matrix.

9. Remove and discard the gasket.

10.

Remove the screws securing the feed pipe and

disconnect the pipe from the matrix.

11.

Remove and discard the gasket.

12.

Disconnectthewatertemperatureswitchfeedwires.

13.

Remove the foam pad from the pipes.

14.

Remove the front panel from the unit.

15.

Undo the heater hose matrix pipe hose clips and

disconnect the hoses from the pipes.

16.

Reposition the pipes from the matrix.

1

7. Remove the matrix from the air conditioning unit.

18.

Fitting a new matrix is the reversal of the removal

procedure.

19.

Ensure that new gaskets are fitted.

8-62 May 1996