service ASTON MARTIN DB7 1997 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 3 of 421

^?

Introduction

#

••t

*<;'..

Introduction '-^;^'^<-~'

^--"^^zfjj^^T^""

Workshop Manual Sections

The

DB7

Workshop Manual

is

divided .jnto,9seGtipnsE.a&foli

1 Engine

2.

Fuel,

Emission Control

and

Exhaust

3. Transmission

4.

Suspension

and

Steering

5. Brakes, Wheels

and

Tyres

6. Electrics

7. Chassis

and

Body

8.

Air

Conditioning

9. Aston Martin Diagnostic System

Procedure Numbering

The workshop manual procedures

are

numbered using

the

parts list numbers

as a key. The

first

two

digits

oi a

workshop manual procedure number

are

also

the

parts list number

(e.g.

1.5.01

Sump Removal relates

to PL 1.5 Oil

Pump

and

Sump). Thus when carrying

out a

procedure,

you can

quickly locate

the

relevant parts illustration

and

spare parts list.

To avoid excessive repetition, each procedure will

be

fully detailed once

in its

appropriate place

in the

manual.

In

any other location where this procedure

is

required,

it

will

be

referenced only

by its

title

and its

procedure number.

Special Tools

Where special service tools

are

required

to

perform

an

operation,

the

tool number

is

recorded

at the

point

of use

within

the

procedure.

An

index

and

illustrated list

is

provided

in

this section

for the

purpose

of

identifying special

tools.

References

References

to the

left, right, front

or

rear

of

the vehicle

or of

a component

are

always made as

if

sitting

in the

drivers

seat facing forward.

Any

such references

to

assemblies removed from

the

vehicle

are to the

normal orientation

of

the assembly when fitted

in the

vehicle.

Repairs

and

Replacements

Where replacement parts

are

required,

it is

essential that only genuine Aston Martin parts

are

used. Your attention

is drawn

to the

following points concerning repairs

and the

fitting

of

genuine Aston Martin parts

and

accessories:

• Safety features embodied

in the

vehicle

may be

impaired

if

other than genuine Aston Martin parts

are

fitted.

In certain territories, legislation prohibits

the

fitting

of

parts which

are not

produced

to the

manufacturers

specification.

• Adhere

to

torque wrench settings given

in

this manual.

• Locking devices, where specified, must

be

fitted.

If the

efficiency

of a

locking device

is

impaired during

removal,

it

must

be

renewed.

•

The

vehicle warranty

may be

invalidated

by the

fitting

of

other than genuine Aston Martin parts.

April

1997 Hi

Page 4 of 421

Introduction

/^r"^^^^^3^

'"'P ?

Safety Precautions L —^ ^^—^

Safety Precautions "

All service workshops are a source of potential danger and repair work should only be performed by technically

trained staff following the procedures in this manual. A safety conscious approach to the performance of all service

procedures must be observed at all times. Statutory requirements governing all aspects of health and safety at work

including directives for the proper use of materials and equipment must be implemented.

The following contains a list of particular safety precautions which should be observed; it is not intended to be

exhaustive.

Air Conditioning System

Do not disconnect any air conditioning refrigerant system pipes unless trained and instructed to do

so.

The refrigerant

used can cause blindness if allowed to contact your eyes.

Chemical Handling and Storage

Chemicalsusedintheservicingofmotorvehiclesincludeacids,adhesives, antifreeze, brake fluids, coolants, grease,

oil,

paint, resin and solvents. Exposure to certain chemicals through direct contact or inhalation can be

fatal.

Potential hazards may also be present through the incorrect use, storage and handling of chemicals causing a fire

risk. The following precautions should be observed.

1.

Strictly adhere to handling and safety information found on containers and labels.

2.

Do not store chemicals in unlabelled or incorrectly labelled containers.

3. Containers used for storing chemicals should not be left

open;

there is a risk of

spilling,

or evaporation of fumes

which may be inflammable or toxic.

4.

Do not mix chemicals unless instructed to do so following manufacturers guidelines.

5. Do not inhale chemical materials to determine identity, they may be toxic.

6. Do not use petrol, kerosene, diesel

fuel,

gas oil, thinners or solvents for washing

skin.

7. Containers whose capacity is over 25 litres (5 gallons) require a bund wall in order to contain spillages.

8. Chemicals based on solvents such as paint should not be sprayed in a confined space; work areas used for

such operations should be well ventilated and fume extraction equipment should be utilised.

9. Ensure that adequate ventilation is provided when volatile de-greasing agents are being used.

WARNING: Fume extraction equipment must be in operation when

solvents

are

used

e.g.

trichloroethane, white

spirit, SBP3, methylene chloride, perchlorethylene.

WARNING: Do not smoke in the vicinity of volatile de-greasing agents.

10.

Avoid splashing the

skin,

eyes and clothing.

11.

Clean chemicals from the skin and clothing as soon as possible after soiling.

12.

Wear protective clothing such as goggles, non porous gloves and apron when hand

I

ing battery acid and other

corrosive and toxic substances.

iv April 1997

Page 5 of 421

//—-^

^^^^5~^

' -^ ^ Introduction

Safety Precautions

Safety Precautions (continued)

Electrical Equipment

1.

Ensure that electrical equipment is in safe working order before use.

2.

Inspect power leads of all mains electrical equipment for damage and security, and check that it is properly

earthed.

3. Ensure that electrical equipment is protected by a fuse of the correct current rating.

4.

Disconnect the battery before commencing repair operations to the electrical system, fuel system and engine

or when working beneath the vehicle.

Exhaust Fumes

Engines should not be run in confined spaces, exhaust fumes contain harmful and toxic substances including carbon

monoxide which can prove fatal if inhaled. Engines must only be run where there is fume extraction equipment in

operation or where there is adequate ventilation.

Fire Precautions

1.

Ensure that a suitable form of fire extinguisher is conveniently located near the work area.

2.

Keep oils, solvents and combustible materials away from naked flames and other sources of ignition.

3. Ensure that NO SMOKING signs are posted around areas where combustible materials and vapour may be

present and ensure that the warnings are strictly observed.

4.

Ensure that dry sand is available to soak up any spillage of fuel or other flammable solutions.

5. Fume extraction equipment must be available and in full working order to remove combustible and toxic

vapours.

6. All personnel should be aware of the fire drill procedures and precautions.

Jacking and Lifting

1.

The recommended procedures for lifting, jacking and towing are included latefin this seetion-and must be

strictly observed to ensure personal safety.

2.

Always use a vehicle hoist, ramp or pit for working beneath the car in preferencetd^&^cking

3. Never rely on a jack to support a car independently, use axle stands or blocks carefully pJaQed at the jacking

points to provide rigid support.

4.

When working beneath a vehicle, chock the wheels as well as applying the handbrake.

5. Ensure that the vehicle is standing on firm level ground before jacking or lifting.

5. Check any lifting equipment used has adequate capacity for the load being lifted and is ih"fdll working order.

Tools and Equipment

1.

Do not leave tools, equipment, spilt oil, etc. around or on the work area.

2.

Ensure that tools and equipment used are in good condition; do not use damaged or defective tools or

equipment.

3. Do not apply heat in an attempt to free stiff nuts or fittings; as well as causing damage to protective coatings,

there is a risk of damage to electronic equipment and brake lines from stray heat.

4.

Use the recommended service tool where instructed to do so.

April 1997 v

Page 185 of 421

Electrics

Airbag System

Airbag (Supplementary Restraint System)

Repair Procedures

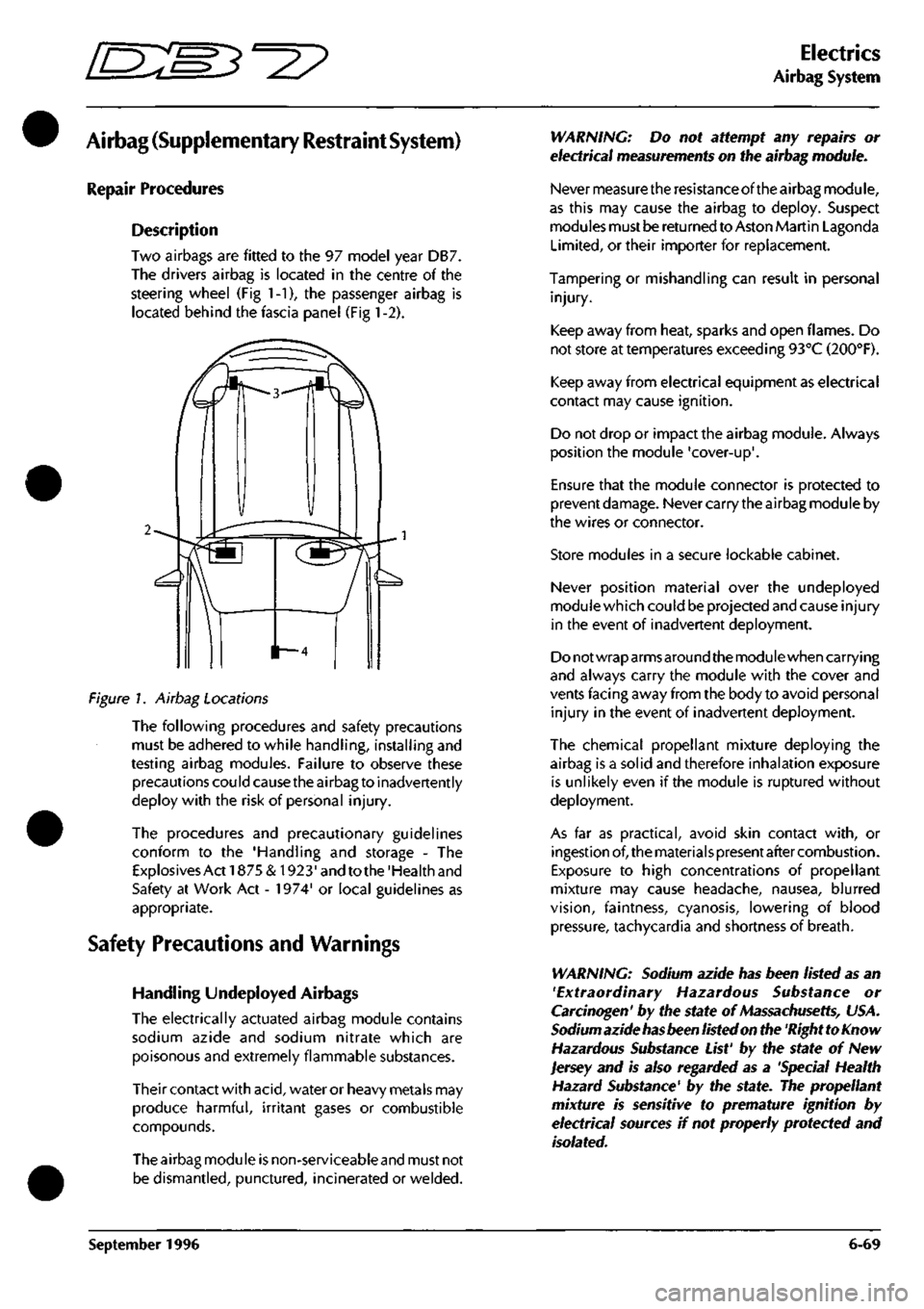

Description

Two airbaes are fitted to the 97 model year DB7.

The drivers airbag is located in the centre of the

steering wheel (Fig 1-1), the passenger airbag is

located behind the fascia panel (Fig 1-2).

Figure!. Airbag Locations

The following procedures and safety precautions

must be adhered to while handling, installing and

testing airbag modules. Failure to observe these

precautions could cause the airbag to inadvertently

deploy with the risk of personal injury.

The procedures and precautionary guidelines

conform to the 'Handling and storage - The

Explosives Act 1875 & 1923' and to the 'Health and

Safety at Work Act - 1974' or local guidelines as

appropriate.

Safety Precautions and Warnings

Handling Undeployed Airbags

The electrically actuated airbag module contains

sodium azide and sodium nitrate which are

poisonous and extremely flammable substances.

Their contact with

acid,

water or heavy metals may

produce harmful, irritant gases or combustible

compounds.

The airbag module is non-serviceable and must not

be dismantled, punctured, incinerated or welded.

WARNING: Do not attempt any repairs or

electrical measurements on the airbag module.

Never measure the resistance of the airbag module,

as this may cause the airbag to deploy. Suspect

modules must be returned to Aston Martin Lagonda

Limited,

or their importer for replacement.

Tampering or mishandling can result in personal

injury.

Keep away from heat, sparks and open flames. Do

not store at temperatures exceeding 93°C (200°F).

Keep away from electrical equipment as electrical

contact may cause ignition.

Do not drop or impact the airbag module. Always

position the module 'cover-up'.

Ensure that the module connector is protected to

prevent damage. Never carry the airbag module by

the wires or connector.

Store modules in a secure lockable cabinet.

Never position material over the undeployed

module which could be projected and cause injury

in the event of inadvertent deployment.

Do not wrap arms around the module when carrying

and always carry the module with the cover and

vents facing away from the body to avoid personal

injury in the event of inadvertent deployment.

The chemical propellant mixture deploying the

airbag is a solid and therefore inhalation exposure

is unlikely even if the module is ruptured without

deployment.

As far as practical, avoid skin contact

with,

or

ingestion of, the materials present after combustion.

Exposure to high concentrations of propellant

mixture may cause headache, nausea, blurred

vision,

faintness, cyanosis, lowering of blood

pressure, tachycardia and shortness of breath.

WARNING: Sodium azide has been listed as an

'Extraordinary Hazardous Substance or

Carcinogen' by the state of

Massachusetts,

USA.

Sodium azide has been listed on the

'Right

to Know

Hazardous Substance

List'

by the state of New

Jersey and is also regarded as a 'Special Health

Hazard Substance' by the state. The propellant

mixture is sensitive to premature ignition by

electrical sources if not properly protected and

isolated.

September 1996 6-69

Page 187 of 421

^=2?

Electrics

Airbag System

Eye Protection

Chemical protective goggles are recommended

where there is a possibility of eye contact with the

propellant. Safety glasses with side shields are

recommended for all other operations.

Protective Clothing

Approved protective gloves, overalls and shoes/

boots should be worn.

Handling and Storage Precautions

Do not store airbag modules near live electrical

equipment or circuitry. Store in a dry environment

at ambient temperatures.

Good housekeeping and engineering practices

should be employed to prevent the generation and

accumulation of

dusts.

Store in compliance with all

local state and federal regulations.

Driver and Passenger Airbag Modules

Assembly/Removal/Service Instructions

WARNING: In the event of a vehicle impact where the

airbags and the seatbeltpretensioner (if fitted) are

deployed, the following actions MUST be

performed:

Check the condition of the seatbelts, steering

wheel,

steering column, all connections to airbags,

and the column switchgear connectors for integrity

and damage. If in any

doubt,

replace suspected

parts for new parts.

Replace both crash

sensors,

the

safing sensor

and

the seatbelt pretensioner module (if fitted).

On completion of all repair procedures, switch on

the ignition and check that the

Airbag/SRS

warning

light comes on when the ignition is switched on

and extinguishes after approximately six seconds

indicating satisfactory completion of the airbag

and pretensioner

system

self

tests.

WARNING: Before starting

work,

ensure

that the ignition

switch is in position 'O' and the ignition key is

removed.

Disconnect the battery negative lead

within 12 seconds of switching off the ignition to

prevent the alarm system triggering.

As the airbag control module is equipped with a

back-up power source and due to the risk of the

airbag being inadvertently deployed, wait one

minute or longer after disconnecting the battery

before starting work on the airbag module.

• Disconnectingthe battery negative cable cancels

the memory for the 'one-touch' window down

system and stops the vehicle clock. Reset the

window memory and the clock when work is

completed.

• Never use airbags from other vehicles, always

use new parts.

• After work is completed, reconnect the battery

and perform the airbag warning light check

• Never use electrical probes to check voltage or

electrical resistance of the airbag modules.

• Disconnect the airbag before carrying out any

work on, or in the vicinity of the module, or

when using electric welding equipment.

• Always ensure that the battery negative lead has

been disconnected for at least one minute before

commencing any removal procedure.

September 1996 6-71

Page 189 of 421

^^

Electrics

Airbag System

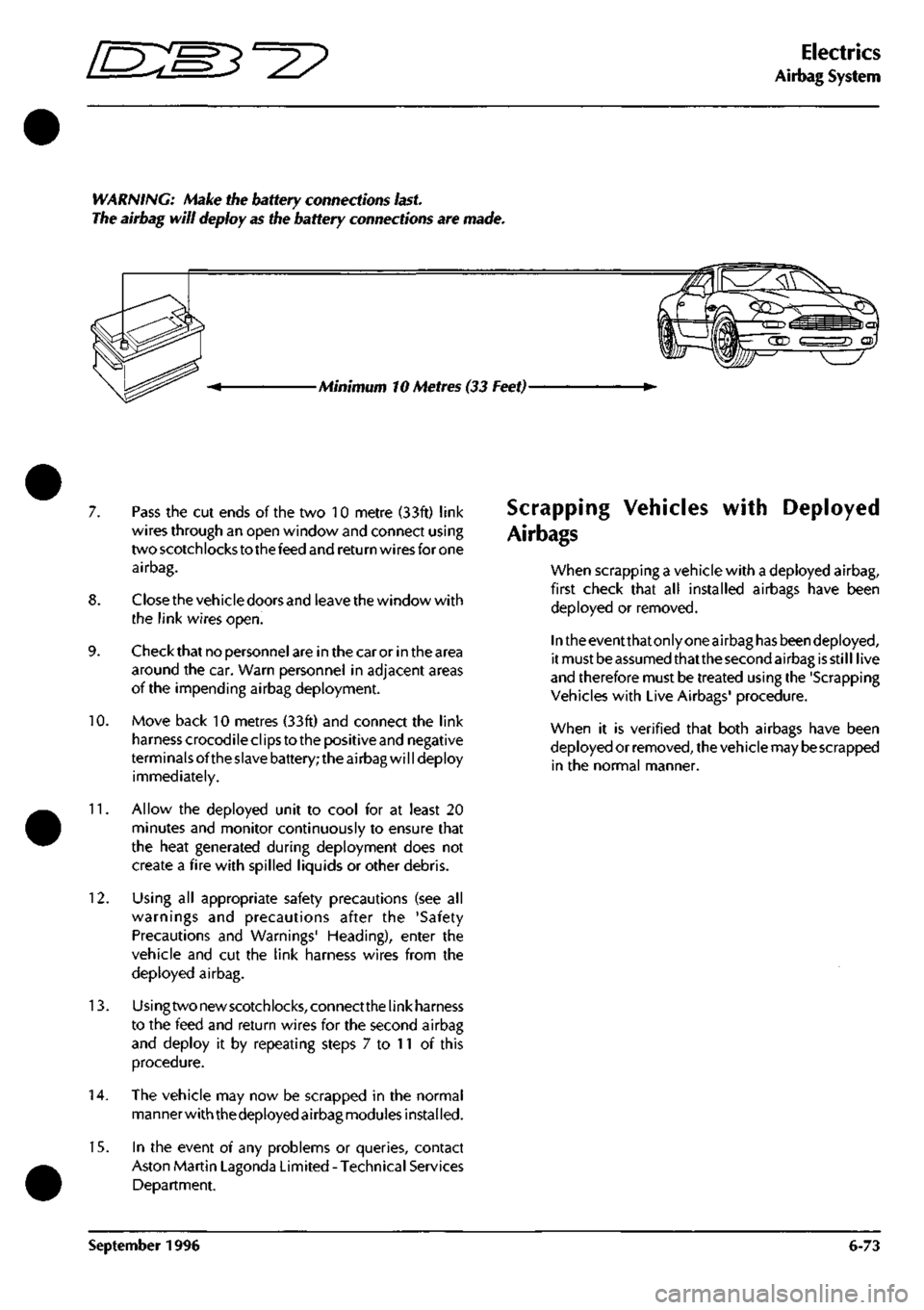

WARNING: Make the battery connections

last.

The airbag will deploy as the battery connections are made.

Minimum 10 Metres (33 Feet)-

7. Pass the cut ends of the two 10 metre (33ft) link

wires through an open window and connect using

two scotchlocks to the feed and return wires for one

airbag.

8. Closethe vehicle doors and leave the window with

the link wires open.

9. Check that no personnel are in the car or in the area

around the car. Warn personnel in adjacent areas

of the impending airbag deployment.

10.

Move back 10 metres (33ft) and connect the link

harness crocodile clips to the positive and negative

terminals ofthe slave battery; the airbag will deploy

immediately.

11.

Allow the deployed unit to cool for at least 20

minutes and monitor continuously to ensure that

the heat generated during deployment does not

create a fire with spilled liquids or other debris.

12.

Using all appropriate safety precautions (see all

warnings and precautions after the 'Safety

Precautions and Warnings' Heading), enter the

vehicle and cut the link harness wires from the

deployed airbag.

13.

Usingtwonewscotchlocks,connectthelinkharness

to the feed and return wires for the second airbag

and deploy it by repeating steps 7 to 11 of this

procedure.

14.

The vehicle may now be scrapped in the normal

manner with thedeployed airbag modules installed.

15.

In the event of any problems or queries, contact

Aston Martin Lagonda Limited - Technical Services

Department.

Scrapping Vehicles

Air bags

with Deployed

when scrapping a vehicle with a deployed airbag,

first check that all installed airbags have been

deployed or removed.

In the eventthatonly one airbag has beendeployed,

it must be assumed thatthe second airbag is still live

and therefore must be treated using the 'Scrapping

Vehicles with Live Airbags' procedure.

when it is verified that both airbags have been

deployed or removed, the vehicle may

be

scrapped

in the normal manner.

September 1996 6-73

Page 190 of 421

Electrics

Airbag System E:m3^2?

Disposal of Live Airbags

Modu

les

removed/renewed by Aston Martin dealers

are to be deployed using the following procedure.

WARNING: Never use a customer's vehicle to

deploy airbags.

Equipment Required:

Link harness

'Slave'

battery

Safety goggles to BS 2092 grade 2 or equivalent

Rubber gloves to PrEN 374 class 2 or equivalent

Ear protectors

Particulate respirator to EN 149 grade FFP 25

Deployment cage

Note: If you do not

have access

to a deployment

cage,

please

contact Aston Martin

Lagonda

Limited

Technical

Support Department for advice.

Procedure

This procedure must be performed outdoors, away

from other personnel.

Remove any loose debris from around the airbag

and ensure that no flammable liquids are present.

Assemble the disposal cabinet and fit the airbag as

shown in figure 1 in line with the following

procedures:

a) Remove the mesh guard from the rig frame.

b) Attach the guard to the frame by bolting the

hinges to the frame.

c) Ensure the relevant plate is fitted and rotate into

position.

d) Fit and secure the airbag module onto the plate.

e) Clamp the plate down using the two toggle

clamps.

f) Close the mesh guard.

Note: The harness connected between the driver's

airbag and

the

connector

has

one red

feed

wire and one

grey/orange return wire. The harness connected between

the

passenger's

airbag and the connector

has

one blue/

orange feed wire and one pink/black return wire.

Connect the 10 metre {33ft) link harness to the

airbag.

Ensure that no personnel are in the vicinity of the

cabinet.

5. Move 10 metres (33ft) and connect the link harness

crocodile clips to the 'slave' battery; the airbag will

deploy immediately.

6. Allow the unit to cool for at least 20 minutes.

7. Open the mesh guard and remove the deployed

airbag module.

Note: Should the

design

of your deployment

cage

differ

from that described above, please contact the cage

manufacturer for advice on mounting the airbag.

8. Seal the deployed module into a plastic bag ready

for disposal.

9. In the event of any problems or queries, contact

Aston Martin Lagonda Limited -Technical Services

Department.

Disposal of Deployed Airbags

Deployed airbags are to be disposed of as special

waste and disposal must comply with local

environmental requirements. If

in

any doubt, contact

the local authority for disposal instructions.

Note; The storage, transportation, disposal and/or

recycling of airbag module components must be

performed in accordance with all applicable federal,

state

and local regulations including, but not limited to,

those

governing building and fire

codes,

environmental

protection, occupational health and safety and

transportation.

Modules removed and deployed by Aston Martin

Dealers are to be returned to Aston Martin Lagonda

Limited for disposal following prior consultation.

6-74 September 1996

Page 194 of 421

Electrics

Airbag System '=2?

Airbag System Diagnostics

System Description

The airbag system installation comprises:

Airbag Diagnostic Module

Driver and passenger airbag modules

Two front impact (crash) sensors

One 'safing' sensor

Dedicated wiring harness

SRS indicator/warning lamp

The system is designed to provide protection for

both driver and front seat passenger by automatical ly

deploying airbags in the event of

a

collision during

forward travel.

In the event of a collision, the crash and safing

sensors will operate, completing the firing circuit

and causing the airbags to inflate within 32

milliseconds. At least one crash sensor and the

safing sensor must operate to fire the airbags.

Any faults in system components, installation or

wiring will be indicated by a flashing code on the

SRS/AIRBAG warning lamp. Fault code information

may also be monitored using the PDU or scan

tool.

Component Descriptions

Airbag Diagnostic Module

The airbag diagnostic module is mounted on top of

the passenger airbag mountingcage.Thediagnostic

module contains the microprocessor which is

connected to the complete airbag system. The state

of the three system sensors, the two airbag modules

and the wiring harness is constantly monitored by

the microprocessor for faults and for sensor

activation (crash) conditions.

The diagnostic module also confirms correct supply

voltage by comparing

a

direct battery voltage input

with a similar input via the ignition switch.

The diagnostic module contains a reserve power

supply, enabling the airbags to fire even if the

supply voltage is lost due to collision damage. The

reserve power charge will be retained for

approximately one minute if the positive battery

supply is lost in a collision. An auxiliary internal

circuit known as the 'dwell enhancer' provides a

temporary ground if normal system ground was lost

in a collision.

Wiring Harness

A dedicated electrical wiring harness is used to

connect all system components to the bulkhead

harness. To allow free movement of the steering

mechanism, a cable reel cassette is used to connect

the drivers airbag in the steering wheel to the airbag

harness on the steering column.

Airbag Modules

The two airbag modules contain achargeof sodium

azide/copper oxide which wi

11

generate

a

sufficient

volume of nitrogen gas to fully inflate the airbag

when ignited by an electrical impulse. The volume

of gas is greater in the passenger side airbag due to

its larger size.

Both airbag modules, including the surrounding

trim of the drivers airbag, are non-serviceable and

once deployed, must be renewed as a complete

assembly.

Crash and Safing Sensors

The two crash sensors are mounted one at either

side of the bumper mounting cross member, outside

of the bonnet hinges.

The safing sensor is mounted in the base of the

drivers side 'A' post.

The two crash sensors and the safing sensor

determine when airbag deployment is necessary in

a crash condition.

The sensor contacts will only close when the vehicle

suffers a forward impact of sufficient force. At least

one crash sensor and the safing sensor contacts

must close before the airbags will deploy. The

doubletrigger strategy

is

used to prevent deployment

during trivial impacts such as contacts during

parking.

6-78 September 1996

Page 196 of 421

Electrics

Airbag System ^2?

6.4.21.4

Airbag Disarming/Arming

Procedures

WARNINGS AND CAUTIONS:

WARNINGS:

Disarm the airbags by disconnecting the battery

ground (black)

lead,

waiting one minute and then

removing the airbag modules before servicing of

any airbag or steering column component.

After disconnecting the battery ground

lead,

allow

a minimum of one minute delay for the back-up

power supply to discharge before servicing the

airbag system.

The system components are non-serviceable, if

faults are

suspected,

change components for new

items

only.

Failure to observe the above procedures may

result in accidental deployment of the airbags.

Always wear safety

glasses

when working on airbag

equipped vehicles.

Personnel carrying an airbag module must ensure

that the module and trim cover are pointing away

from the

body.

When positioning on a bench or

work surface, ensure that the airbag module and

trim cover face upwards to limit motion on

accidental deployment.

Always wear

gloves

when handling deployed airbag

modules. Deposits of sodium hydroxide may be

presenton the module surface. If sodium hydroxide

contacts any area of the skin, wash the affected

area immediately with mild soap and

water.

Dispose of the deployed airbag using the correct

procedures referred to in this section.

Cautions:

When scrapping vehicles,

ensure

that the

airbags

have

been deployed (see

Scrapping Vehicles

with Live

Airbags).

If a component

has been

renewed and the fault

does

not

clear,

refit the original item and repeat the diagnostic

procedure.

After

servicing,

repeatthe diagnostic

procedures

to ensure

correct

system

operation.

Renew

the airbag module if the surrounding trim

panels

are

damaged.

Do not attempt to repaint trim covers as

paint may

damage

cover material.

Disarming the Airbags

3.

4.

WARNING: Carry out the following disarming

procedure before attempting any work on the

vehicles electrical

systems.

Note: The battery ground (black) lead must be

disconnected within 12 seconds of switching off the

ignition to avoid the alarm siren sounding.

Disconnect the battery ground

lead.

Allow a

minimum of one minute delay for the back-up

power supply to discharge.

Remove the drivers side airbag module and replace

it with an airbag simulatorfrom the simulator kit (Pt

No.

43.27028).

Remove the passengers airbag module and replace

it with an airbag simulator from the simulator kit.

Reconnect the battery ground.

Rearming the Airbags

WARNING: Carry out the following procedure to

rearm and check the airbags after completing all

work on the vehicles electrical

systems.

Note: The vehicle battery

must be

disconnected within

12

seconds

of switching off

the

ignition

to

avoid the alarm

siren sounding.

^. Disconnect the battery ground

lead.

Allow a

minimum of one minute delay for the back-up

power supply to discharge.

2.

Removethedriverssideairbagsimulatorand replace

it with the drivers airbag module. Secure the airbag

module with the two captive torx screws.

3. Remove the passengers side airbag simulator and

replace it with the passenger side airbag module.

Secure the module with four nuts and washers.

Close the passenger side airbag door.

4.

Reconnect the battery ground.

5. Switch on the ignition and check for correct

indications from the SRS/AIRBAG warning light.

TheSRS/AIRBAC lamp should come on after

a

brief

delay and remain on for approximately six seconds

during the airbag system self check. The lamp will

extinguish upon satisfactory completion of the self

check, or will flash a diagnostic code if an airbag

system fault is detected. Continuous illumination of

the warning lamp may indicate a seatbelt

pretensioner fault

Note:

Reset the

clock and window

ECUs

on completion.

6-80 September 1996

Page 199 of 421

"^p

Electrics

Airbag System

No Airbag Warning Lamp

I

noperative lamp, lamp ci rcu it or no ign ition voltage

to the diagnostics module

Normal Operation

The airbag warning lamp is designed to illuminate

for approximately six seconds when the ignition is

switched

on.

This period

is

allocated for satisfactory

performance of the airbag system self test.

Note: The a irbag warning lamp is

driven

by

the instrument

pack and not directly by the airbag diagnostic module.

The airbag diagnostic module requires an ignition

supply to pin

1

to energise the airbag warning lamp

circuit. If the warning lamp circuit is open, or the

diagnostic module does not receive an ignition

voltageatpini, the warning lamp will not illuminate.

Open circuit in the warning lamp supply, in

conjunction with another system fault, will cause

the diagnostic module to emit five tones every 30

minutes while the ignition is switched on. Repair

the faulty circuit before further diagnosis.

Note:

The

diagnostic module will not emit

the

five tone

signal if the warning lamp

is

open circuit and

there

is no

system

fault.

Possible Causes

Defective airbag warning lamp

Faulty wiring in the airbag warning lamp circuit

Loss of ignition voltage at diagnostic module pin 1.

Loss of ground at diagnostic module pin 3

Instrument pack fault

Fault Analysis

WARNING: Read and adhere to all warnings and

safety procedures at the start of this section when

working on the airbag

systent.

1.

Remove the instrument pack and check the airbag

warning lamp.

If the lamp is good, go to step 2.

If the lamp is defective, replace it, switch on the

ignition and check that the lamp is now on for

approximately six seconds after ignition on.

2.

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

9.

Connect the PDU. Switch on the ignition. Measure

the 12V ignition supply voltage from airbag

diagnostic connector pin

1 -1

{+) to chassis ground.

If ignition voltage is present, go to step 6. If ignition

voltage is not present, go to step 4.

Checkfuse F15passengersidefuseboxRHDorF17

passenger side fusebox LHD (Ignition supply to the

diagnostic module pin

1

-1). If the fuse is good, go

to step 5. If the fuse is replaced, go to step 6.

Check for an open circuit on the YW wire from fuse

F15 passenger sidefusebox(F17 LHD)todiagnostic

module pin 1-1. If continuity is good, isolate the

fault in the 12V supply to fuse Fl 5 (Fl 7) and then

go to step 9.

Measure the voltage from diagnostic module pin

1

-

1 to diagnostic module pin 1-3. If 12V is not

present, isolate and service the open circuit in the

diagnostic module ground to pin 1-3. Then go to

step 7.

Switch the ignition off. Set up to measure the

voltage from DM pin

1

-4 to DM pin

1

-5 during the

first six seconds after ignition on.

Switch on the ignition, the warning light signal to

the instrument pack should switch for six seconds

after a brief delay.

If the signal does not switch, the diagnostic module

is

fau Ity. Replace the modu

le,

switch on the ign ition

and check that the airbag warning lamp does light

for six seconds after ignition on.

If the signal does switch for approx. six seconds

after ignition on, the fault is in the instrument pack

or wiring, go to step 8.

Check continuity of the YW wire from diagnostic

module pin

1

-4 to instrument pack 16 way plug pin

2.

If continuity is good, service the instrument pack

and then retesttoensure correct indication from the

airbag warning lamp at ignition on.

If continuity is defective, service the wire and then

retest to ensure correct indication from the airbag

warning lamp at ignition on.

Disconnect the PDU, and rearm the airbags

(6.4.21.4). Switch on the ignition and check for

correct indications from the airbag warning lamp.

September 1996 6-83