oil ASTON MARTIN DB7 1997 Owner's Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 290 of 421

^2?

Air Conditioning

General System Procedures

Evacuating the System

This process, the removal of unwanted air and moisture, is critical to the correct operation of the air conditioning

system.

The procedures depends on the characteristics of the recovery-recycle-recharge equipment and must be

carried out exactly in accordance with the manufacturers instructions.

Moisture can be highly destructive and may cause internal blockages due to freezing, but more importantly, water

suspended in the PAG oil will damage the compressor. Once the system has been opened for repairs, or the

refrigerant charge recovered, all traces oi moisture must be removed before recharging with new or recycled

refrigerant.

Adding Compressor Lubricating Oil

Oil can be added by three methods, two of which are direct into the system

• via the recovery-recycle-recharge station

• by proprietary oil injector.

Equipment manufacturer's instructions must be adhered to when using direct oil introduction.

The third method may be required because of rectification work to the existing compressor, or the need to fit a new

compressor. From an existing compressor, drain the oil into a measuring cylinder and record the amount. Flush the

unit out with fresh PAG oil and drain thoroughly. Refill the compressor with the same amount of PAG oil that was

drained out originally and plug all orifices immediately ready for refitting to the vehicle. The transit lubricating oil

must be drained and discarded from a new compressor before it may be fitted. An adjustment should be made to

the system oil level by taking into account:

• the quantity found in the original compressor

• the quantity deposited in the recovery equipment oil separator from the charge recovery operation.

Typically, 80 ml can be drained from the original compressor and 30 ml found in the oil separator; the sum of these

volumes (80 + 30 = 110 ml) is the amount of fresh PAG oil that must be put into the new compressor prior to fitting.

Hote:

The

discrepancy

between

this

figure

and

the

nominal capacity of

135

ml is

caused

by normally not

recoverable

oil being

trapped in

components

such

as

the receiver-drier or

evaporator.

The above statements are only true if there is no evidence of a leak. Where a leak has been detected and rectified,

the compressor must be refilled with the specified quantity.

Caution: Always decant

fresh

oil from a sealed container and do not leave oil exposed to the

atmosphere.

PAG oil is very

hygroscopic

(absorbs

water) and rapidly

attracts

atmospheric moisture.

PAG oil must

NEVER

be mixed with mineral

based

oils.

Do not

reuse

oil following a recovery cycle,

dispose

of it

safely.

Depending on the state of the air conditioning system immediately prior to charge recovery and the rate of recovery,

an amount of oil is drawn out with the refrigerant. The quantity is approximately 30 to 40 mi; this may vary, and

the figure is given only for guidance. It is most important that the oil separator vessel in the recovery equipment is

clean and empty at the start of the process so that the amount drawn out may be accurately measured.

May 1996 8-13

Page 291 of 421

Air Conditioning //—->> "^^Izz^^ • ^ ^

General System Procedures L ^—/ ' —^ ^./^

Adding Refrigerant

In order that the air conditioning system may operate efficiently it must contain a full refrigerant charge. The

indications of some system defects, and the results of certain tests, shows that

a

low charge

is

the most probable cause

of the fault. In such cases the charge shou

Id

be recovered from the

system,

the weight noted, and the correct amount

installed.

Note: Never attempt to

guess the

amount of refrigerant in

a

system.

Always recover and

recharge

with

the

correct

charge

weight,

this is the only

accurate

method.

Caution: If oil is drawn out during the recovery

process,

the correct amount can be added directly from your

recovery-recycle-

recharge station

(if so

equipped)

prior to the charging

process.

It must be

stressed

that the need to protect

compressor

oil from

moisture is vital, observe

the procedures

in Handling Lubricating Oil.

Warning: Liquid refrigerant boils at -29°C (-20°F) at atmospheric pressure. Serious injury, even blindness, can occur if

the refrigerant comes into contact with the eyes.

Goggles and gloves must be warn while working with refrigerant.

First Aid

If refrigerant should contact the eyes or

skin,

bathe the eyes or affected area with cold water for several minutes. Do

not rub. As soon as possible thereafter, obtain treatment from a doctor or eye specialist.

8-14 May 1996

Page 294 of 421

^=2?

Air Conditioning

System Trouble Shooting

System Trouble Shooting

There are five basic symptoms associated with air conditioning fault diagnosis. It is very important to identify the area of

concern before starting a rectification procedure. Spend time with your customer on problem identification, and use the

following trouble shooting guide.

The following conditions are not in order of priority.

No Cooling

1.

Is the electrical circuit to the compressor clutch functional?

2.

Is the electrical circuit to the blower motor(s) functional?

3. Slack or broken compressor drive belt.

4.

Compressor partially or completely seized.

5. Compressor shaft seal leak (see 9).

6. Compressor valve or piston damag^ (may be indicated by small variation between HIGH & LOW side pressures

relative to engine speed).

7. Broken refrigerant pipe (causing total loss of refrigerant).

8. Leak in system (causing total loss of refrigerant).

9. Blocked filter in the receiver drier.

10.

Evaporator sensor disconnected?

11.

Dual pressure switch faulty?

Note:

Should a

leak or low

refrigerant be established as

the

cause,

follow

the procedures

for

Recovery-Recycle

-Recharge,

and

observe all refrigerant and oil handling instructions.

insufficient Cooing

1.

Blower motor(s) sluggish.

2.

Restricted blower inlet or outlet passage

3. Blocked or partially restricted condenser matrix or fins.

4.

Blocked or partially restricted evaporator matrix.

5. Blocked or partially restricted filter in the receiver drier.

6. Blocked or partially restricted expansion valve.

7. Partially collapsed flexible pipe.

8. Expansion valve temperature sensor faulty (this sensor is integral with valve and is not serviceable).

9. Excessive moisture in the system.

10.

Air in the system.

11.

Low refrigerant charge.

May 1996 8-17

Page 295 of 421

Air Conditioning

/J=y>f^^^

—p )

System Trouble Shooting

12.

Compressor clutch slipping.

13.

Blower flaps or distribution vents closed or partially seized.

14.

Water valve not closed.

15.

Evaporator sensor detached from evaporator.

Intermittent Cooling

Is the electrical circuit to the compressor clutch consistent?

2.

Is the electrical circuit to the blower motor(s) consistent?

3. Compressor clutch slipping.

4.

Faulty air distribution flap potentiometer or motor.

5. Motorised in-car aspirator or evaporator temperature sensor faulty, causing temperature variations.

6. Blocked or partially restricted evaporator or condenser.

Noisy System

1.

Loose or damaged compressor drive belt.

2.

Loose or damaged compressor mountings.

3. Compressor oil level low, look for evidence of leakage.

4.

Compressor damage caused by low oil level or internal debris.

5. Blower(s) motor(s) noisy.

6. Excessive refrigerant charge, witnessed by vibration and 'thumping' in the high pressure line (may be indicated by

high HIGH & high LOW side pressures).

7. Low refrigerant charge causing 'hissing' at the expansion valve (may be indicated by low HIGH side pressure).

8. Excessive moisture in the system causing expansion valve noise.

Note;

Electrical faults

may

be more rapidly traced using PDU.

Insufficient Heating

1.

Water valve stuck in the closed position.

2.

Motorised in-car aspirator seized.

3. Blend flaps stuck or seized.

4.

Blocked or restricted blower inlet or outlet.

5. Low coolant level.

6. Blower fan speed low.

7. Coolant thermostat faulty or seized open.

8-18 May 1996

Page 311 of 421

Air Conditioning

Refrigeration /s:s^°27

Refrigeration

Safety Precautions

The air conditioning system is designed to use only

Refrigerant E134A (dichlorodifluoromethane). Extreme

care must betaken NOT to use

a

methylchloride refrigerant.

The chemical reaction between methylchloride and the

aluminium parts ofthe compressor results in the formation

ofproductswhich burn spontaneously on exposure toair,

or decompose with violence in the presence of moisture.

The suitable refrigerant is supplied under the following

names.

El 34A KLEA or equivalent

Warning: Take care when handling refrigerant. Serious

damage will occur if it is allowed to come into

contact with the eyes. Always wear with goggles

and gloves when working with refrigerant

First Aid

If refrigerant should come into contact with the

eyes or

skin,

splash the eyes or affected area with

cold water for several minutes. DO NOT RUB. As

soon as possible thereafter, obtain treatment from a

Doctor or an eye specialist.

Good Practice

1.

Protective sealing plugs must be fitted to all

disconnected pipes and units.

2.

Theprotectivesealingpiugsmustremain inposition

on ail replacement components and pipes until

immediately before assembly.

3. Any part arriving for assembly without sealing

plugs in position must be returned to the supplier as

defective.

4.

It is essential that a second backing spanner is

always used when tightening or loosening all joints.

This minimises distortion or strain on components

or connecting hoses.

5. Components must not be lifted by connecting

pipes,

hoses or capillary tubes.

6. Care must be taken not to damage fins on the

condenser or evaporator matrices. Any damage

must be rectified by the use of fin combs.

7. Before assembly oftube and hosejoints, use

a

small

amount of clean new refrigerant oil on the sealing

seat.

8. Refrigerant oil for any purpose must be kept very

clean and capped at all times. This prevents the oil

absorbing moisture.

9. Before assembly the condition of joints and flares

must be examined. Dirt and even minor damage

will cause leaks at the high pressure points

encountered in the system.

10.

Dirty end fitting can only be cleaned using a cloth

wetted with alcohol.

11.

Afterremovingsealingplugsand immediatelybefore

assembly, visually check the bore of pipes and

components. Where any dirt or moisture is

discovered,

the part must be rejected.

12. Ail components must be allowed to reach room

temperature before sealing plugs are removed.

This prevents condensation should the component

be cold initially.

13.

Before finally tightening hose connections ensure

that the hose lies in the correct position, is not

kinked or twisted and will not be trapped by

subsequent operations, e.g., refitting or closing

bonnet.

14.

Check that hoses are correctly fitted in clips or

straps.

15.

The compressor must be stored horizontally with

the sump down. It must not be rotated before fitting

and charging. Do not remove the shipping plate

until immediately before assembly. Always use

new "O" ring seals in those joints that incorporate

them.

"O" ring seals should be coated with

compressor oil before fitting.

16.

Components or hoses removed must be sealed

immediately after removal.

1 7. Afterthe system has been opened the receiver-drier

must be renewed.

18.

Before

testing,

run the engine until normal running

temperature is reached. This ensures that sufficient

vacuum is available for test. For cooling tests the

engine must be running for the compressor clutch

to operate.

8-34 May 1996

Page 312 of 421

'^T?

Air Conditioning

Compressors

Compressors

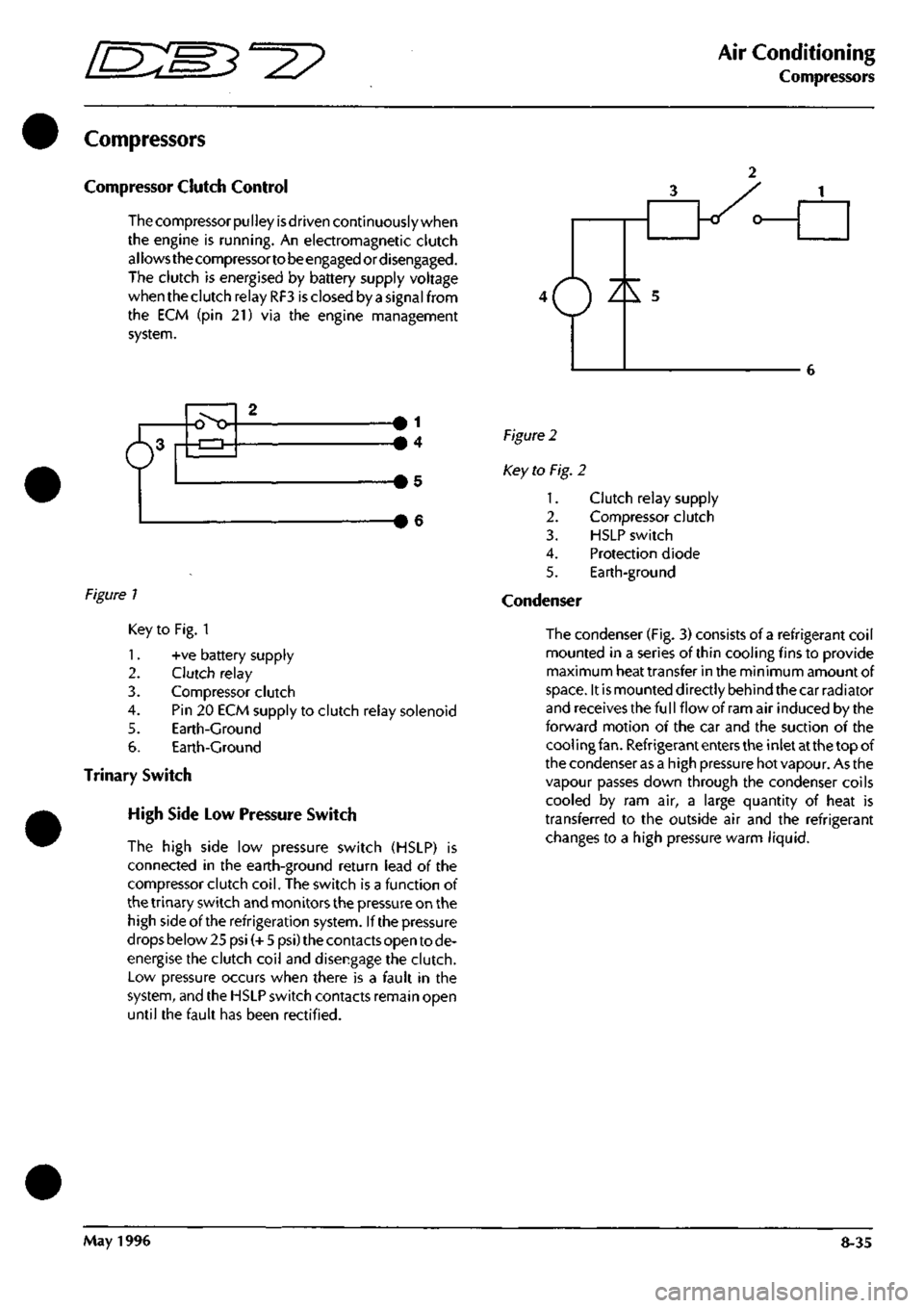

Compressor Clutch Control

The compressor

pu I

ley

is

driven continuously when

the engine is running. An electromagnetic clutch

allows the compressortobeengagedordisengaged.

The clutch is energised by battery supply voltage

when the clutch relay RF3 is closed by a signal from

the ECM (pin 21) via the engine management

system.

6^

o>o 1

4

Figure 1

Figure 2

Key to Fig. 2

1.

2.

3.

4.

5.

Condenser

Clutch relay supply

Compressor clutch

HSLP switch

Protection diode

Earth-ground

Key to Fig. 1

1.

+ve battery supply

2.

Clutch relay

3. Compressor clutch

4.

Pin 20 ECM supply to clutch relay solenoid

5. Earth-Ground

6. Earth-Ground

Trinary Switch

High Side Low Pressure Switch

The high side low pressure switch (HSLP) is

connected in the earth-ground return lead of the

compressor clutch

coil.

The switch is a function of

the trinary switch and monitors the pressure on the

high side of the refrigeration system. If the pressure

drops below 25 psi (+ 5 psi) the contacts open to de-

energise the clutch coil and disengage the clutch.

Low pressure occurs when there is a fault in the

system,

and the HSLP switch contacts remain open

until the fault has been rectified.

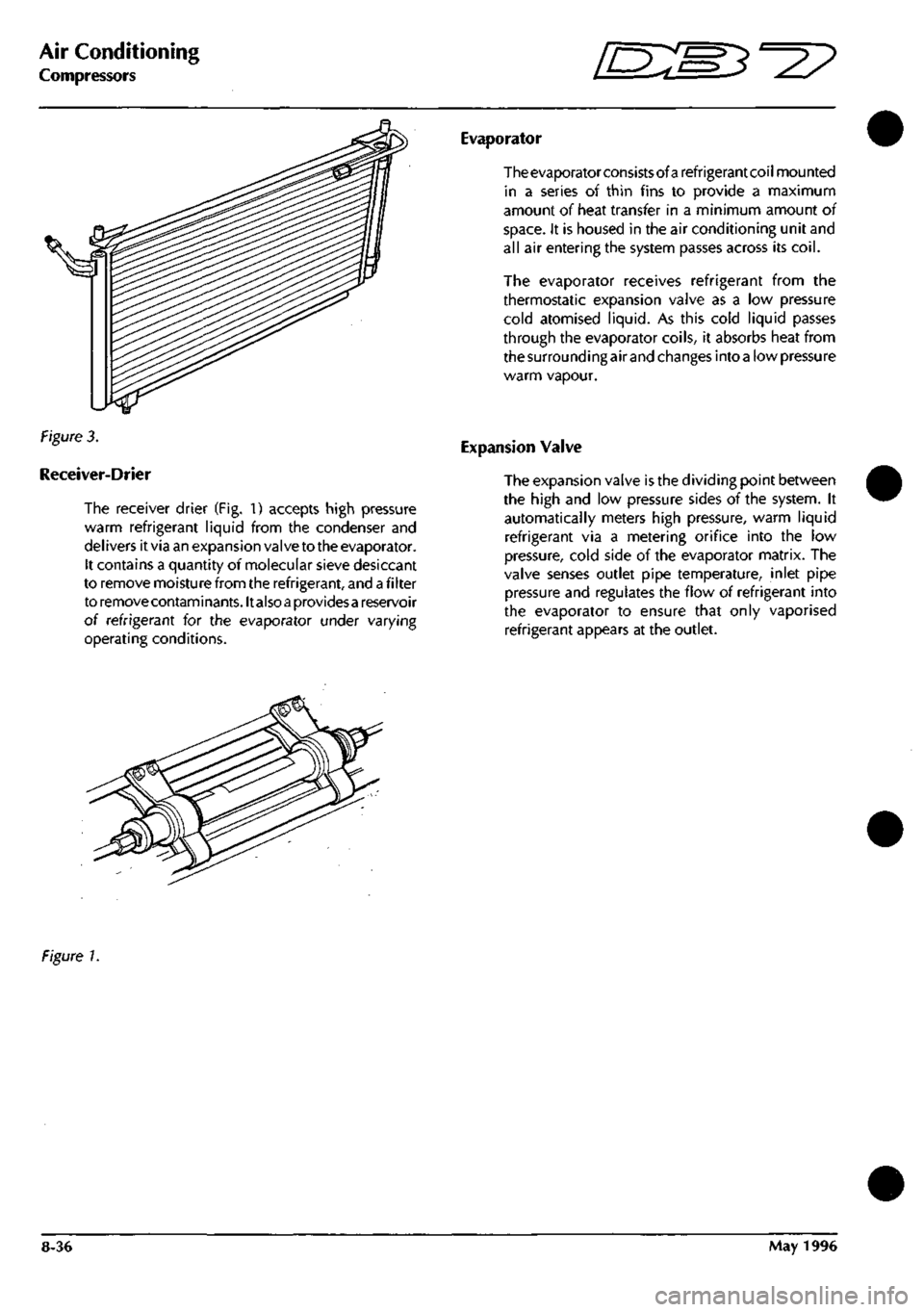

The condenser (Fig, 3) consists of a refrigerant coil

mounted in a series of thin cooling fins to provide

maximum heat transfer in the minimum amount of

space.

It is mounted directly behind the car radiator

and receives the fu

11

flow of ram air induced by the

forward motion of the car and the suction of the

cool ing

fan.

Refrigerant enters the inlet at the top of

the condenser as a high pressure hot vapour. As the

vapour passes down through the condenser coils

cooled by ram air, a large quantity of heat is

transferred to the outside air and the refrigerant

changes to a high pressure warm liquid.

May 1996 8-35

Page 313 of 421

Air Conditioning

Compressors ^?

Evaporator

Figure 3.

Receiver-Drier

The receiver drier (Fig. 1) accepts high pressure

warm refrigerant liquid from the condenser and

del ivers it via an expansion valve to the evaporator.

It contains a quantity of molecular sieve desiccant

to remove moisture from the refrigerant, and

a

fi Iter

to removecontaminants.lt also

a

providesa reservoir

of refrigerant for the evaporator under varying

operating conditions.

The evaporator consists of a refrigerant coil mounted

in a series of thin fins to provide a maximum

amount of heat transfer in a minimum amount of

space.

It is housed in the air conditioning unit and

all air entering the system passes across its

coil.

The evaporator receives refrigerant from the

thermostatic expansion valve as a low pressure

cold atomised liquid. As this cold liquid passes

through the evaporator coils, it absorbs heat from

the surrounding air and changes into

a

low pressure

warm vapour.

Expansion Valve

The expansion valve is the dividing point between

the high and low pressure sides of the system. It

automatically meters high pressure, warm liquid

refrigerant via a metering orifice into the low

pressure, cold side of the evaporator matrix. The

valve senses outlet pipe temperature, inlet pipe

pressure and regulates the flow of refrigerant into

the evaporator to ensure that only vaporised

refrigerant appears at the outlet.

Figure 1.

8-36 May 1996

Page 314 of 421

^?

Air Conditioning

Sanden Compressor SD7H15

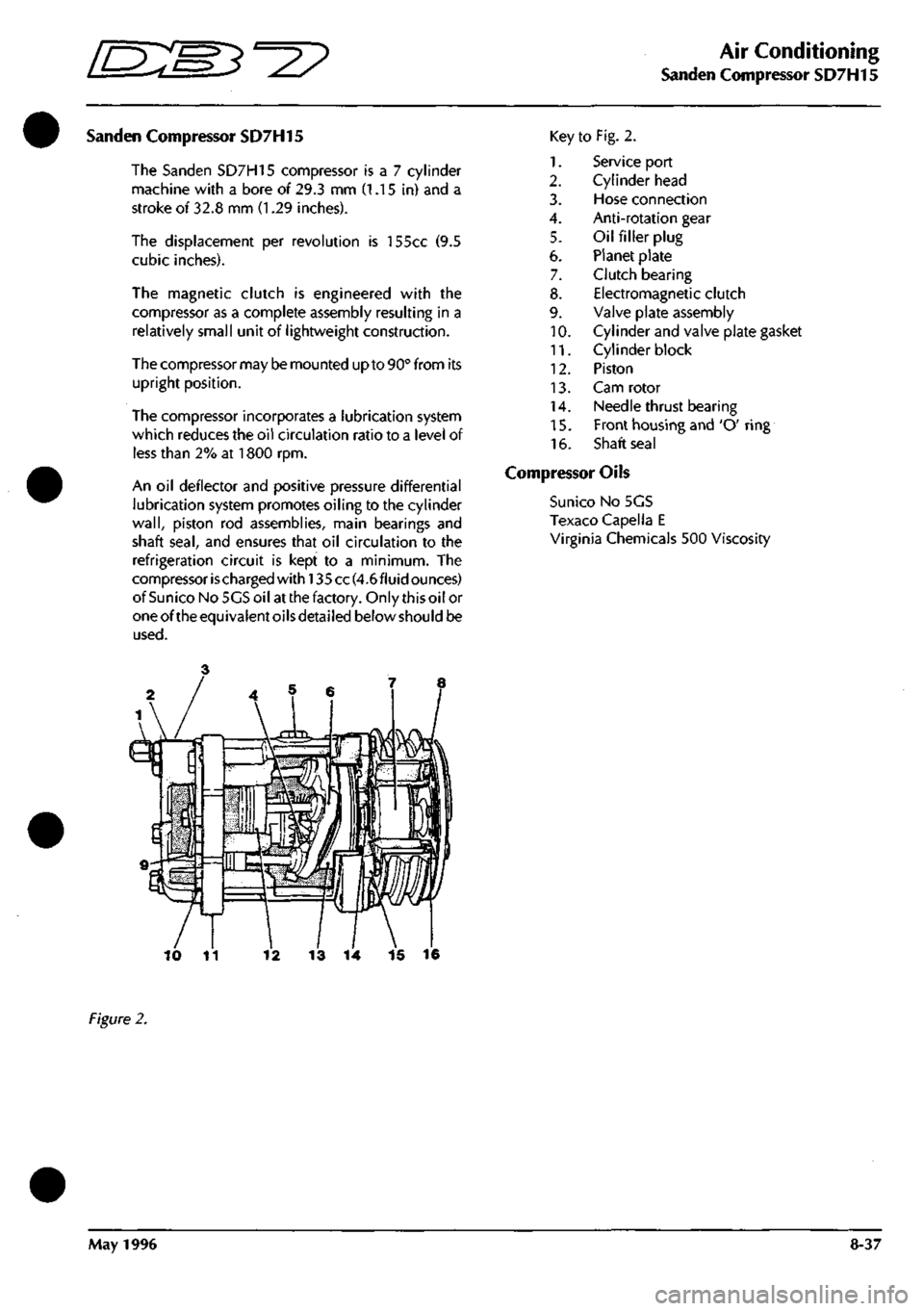

Sanden Compressor SD7H15

The Sanden SD7H15 compressor

is a 7

cylinder

machine with

a

bore

of

29.3

mm (1.15 in) and a

stroke

of

32.8

mm (1.29

inches).

The displacement

per

revolution

is

155cc

(9.5

cubic inches).

The magnetic clutch

is

engineered with

the

compressor

as a

complete assembly resulting

in a

relatively small unit

of

lightweight construction.

The compressor may be mounted up to 90° from

its

upright position.

The compressor incorporates

a

lubrication system

which reduces the

oil

circulation ratio

to a

level

of

less than

2% at 1800 rpm.

An

oil

deflector

and

positive pressure differential

lubrication system promotes oiling

to the

cylinder

wall,

piston

rod

assemblies, main bearings

and

shaft

seal,

and

ensures that

oil

circulation

to the

refrigeration circuit

is

kept

to a

minimum.

The

compressor ischarged

with!

35 cc(4.6fluid ounces)

ofSunico NoSGSoil at the factory. Only this oil

or

oneoftheequivalentoilsdetailed below should

be

used.

Key

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

to Fig. 2.

Service port

Cylinder head

Hose connection

Anti-rotation gear

Oil filler plug

Planet plate

Clutch bearing

Electromagnetic clutch

Valve plate assembly

Cylinder and valve plate gasket

Cylinder block

Piston

Cam rotor

Needle thrust bearing

Front housing and 'O' ring

Shaft seal

Compressor Oils

Suni

CO

No 5GS

Texaco Capella E

Virginia Chemicals 500 Viscosity

13

14 15 16

Figure

2.

May

1996

8-37

Page 317 of 421

Air Conditioning

System Checking with the Manifold Gauge Set D'^?

Purging the Test Hoses

1.

With the manifold test set attached to the system.

2.

Purge the high pressure test hose by cracking open

the high pressure side hand valve on the manifold

gauge set for 3 to 5 seconds. This allows the system

refrigerant to purge the air from the test hose and

discharge through the manifold centre test hose.

Immediately cl ose the high pressure side hand

valve.

3. Purge the low pressure test hose in the same manner

by cracking open the low pressure side hand valve

manifold gauge

set

for 3 to 5 seconds, then close the

hand valve.

Stabilising the System

The manifold gauge set is now attached to the

system and the test hoses purged of air. With both

hand valves closed, the system must be operated

for a few minutes to stabilise all pressures and

temperatures throughout the system in order to

obtain accurate test gauge readings.

Proceed as follows:

1.

Place all test hoses, gauge set and other equipment

away from all engine moving parts. Also keep the

hoses from touching the hot engine manifold.

2.

Start the engine and adjust engine speed to fast idle

3. Turn on the air conditioning and set for maximum

cooling with blower fans on high speed

4.

Open the car doors and/or windows (to quickly

eliminate car interior heat).

5. Operate the system under these conditions for 5 to

10 minutes to stabilise the system ready for testing.

6. Check the system for full refrigerant by noting the

sightglass indications. Some refrigerant loss occurs

over a period of time.

Note: The air conditioning

system

must contain a full

refrigerant

charge

before an accurate

system

check can

be

made.

An insufficient

charge

is indicated by

a stream

of

bubbles

or

foam.

If

the

refrigerant charge is low, the

system

must

be

fullydischarged into

a

refrigerant recovery

station and recharged with the correct weight of refrigerant

82.30.08. Do not top up a

system

with refrigerant.

Leak Test

A high proportion of ail air conditioning work

consists of locating and repairing leaks.

Many leaks are located at connections and are

caused by vibration. They may only require the re-

tightening of a connection or clamp.

Occasionally a hose rubs on a structural part of the

vehicle and creates a leak, or a hose deteriorates

which will require a replacement.

The specified maximum leakage rate at each fitting

is 0.5 kg of R 134a in 40 years and a leak detector

capable of operating to this accuracy must be

provided.

To check place the leak detector probe at

the lowest pointofeach joint, pausefortwo seconds.

Do not wave the probe about as refrigerant is

heavier than air and flows to the lowest point. If a

leak is greater than 0-5 kg in forty years is detected

identify the leak point for rectification.

Check that the leaking fitting has been tightened to

the correct torque. If the torque is low, rectify and

repeat leak test. If the torque is satisfactory,

depressurise the system, dismantle the leaking

connection and check the quality of the fitting.

If the fitting is satisfactory, clean and reassemble

after applying a thin film of refrigerant to the seat of

aflarefitting, ora newoiled "O" ring to an "O" ring

fitting.

Tighten to the correct torque.

Charge the system with 200 g of El 34A and leak test

the rectified system. If the system is satisfactory,

depressurise, evacuate and recharge the system.

If the system is unsatisfactory, i.e. leakage greater

than 0.5 kg in forty years, depressurise and replace

the leaking assembly.

8-40 May 1996

Page 318 of 421

=2?

Air Conditioning

System Checking with the Manifold Gauge Set

Pressure Temperature Relationship.

Note:

Pressures

shown are under exact conditions

(see

test

conditions) and

are

not

necessary

true for every

car

checked.

Ambient Temperature is given as the air

surrounding the

condenser

and

is

taken 5 cm in front of

the

condenser.

Test Conditions.

Use a large fan to substitute for normal ram air through the

condenser. Engine adjusted to fast idle speed.

All conditions equivalent to 30 m.p.h. or 48 km/h.

Ambient

Evaporator

Temp °C

16

18

21

24

27

29

32

35

38

41

43

46

49

High

Pressure

Gauge

Reading

Ibf/in2

95-115

105-125

115-125

130-150

1

50-170

165-185

175-195

185-205

210-230

230-250

250-270

265-285

280-310

Low

Pressure

Gauge

Reading

Ibf/in2

10

12

4

16

18

20

22

24

26

28

30

35

40

45

50

55

60

65

70

Ten

-16

-14

-12

-10

-8

-6

-5

-4

-3

-1

0

2

5

9

11

14

17

19

21

Normal operating ambient temperature range is:

-24 to 43°C.

Normal operating evaporator temperature range

is:-12toO°C.

Under normal running conditions system pressure

should be, as follows:

Lowside:1.05to2.10kgf/cm21.034to2.06bar15

to 30 ibf/in2

High side: 13.00 to 14.40 kgf/cm2 12.75 to 14.34

bar185to205lbf/in2

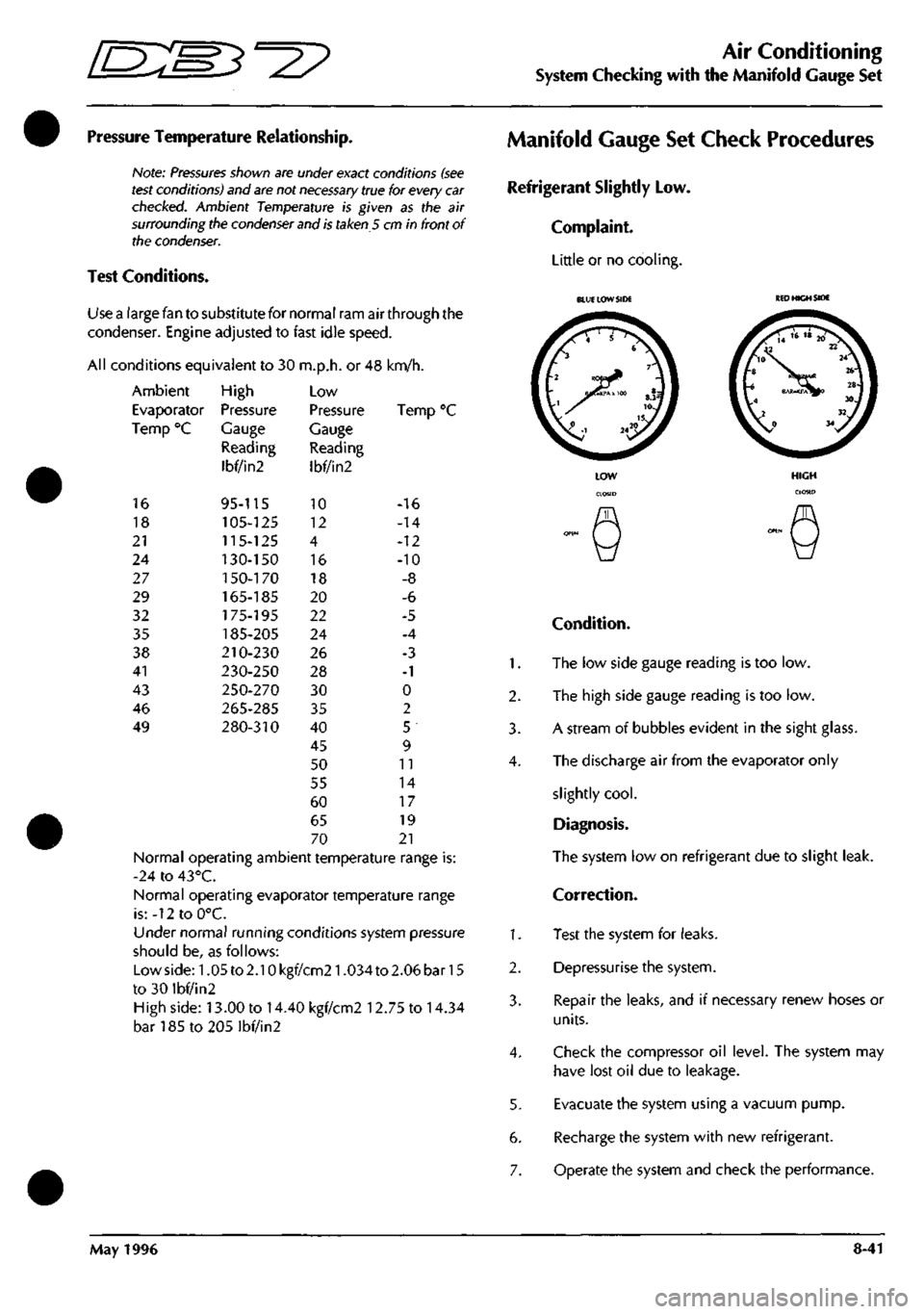

Manifold Gauge Set Check Procedures

Refrigerant Slightly Low.

Complaint.

Little or no cooling.

1.

2.

3.

4.

1.

2.

3.

4.

5.

6.

7.

BLUE LOW SIDE

KED

HIGH SIDE

Condition.

The low side gauge reading is too low.

The high side gauge reading is too low.

A stream of bubbles evident in the sight glass.

The discharge air from the evaporator only

slightly

cool.

Diagnosis.

The system low on refrigerant due to slight leak.

Correction.

Test the system for leaks.

Depressurise the system.

Repair the leaks, and if necessary renew hoses or

units.

Check the compressor oil level. The system may

have lost oil due to leakage.

Evacuate the system using a vacuum pump.

Recharge the system with new refrigerant.

Operate the system and check the performance.

May 1996 8-41