wheel ASTON MARTIN DB7 1997 Owner's Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 394 of 421

^?

The Aston Martin Lagonda Diagnostic System

Users Guide

Climate Control Diagnostics

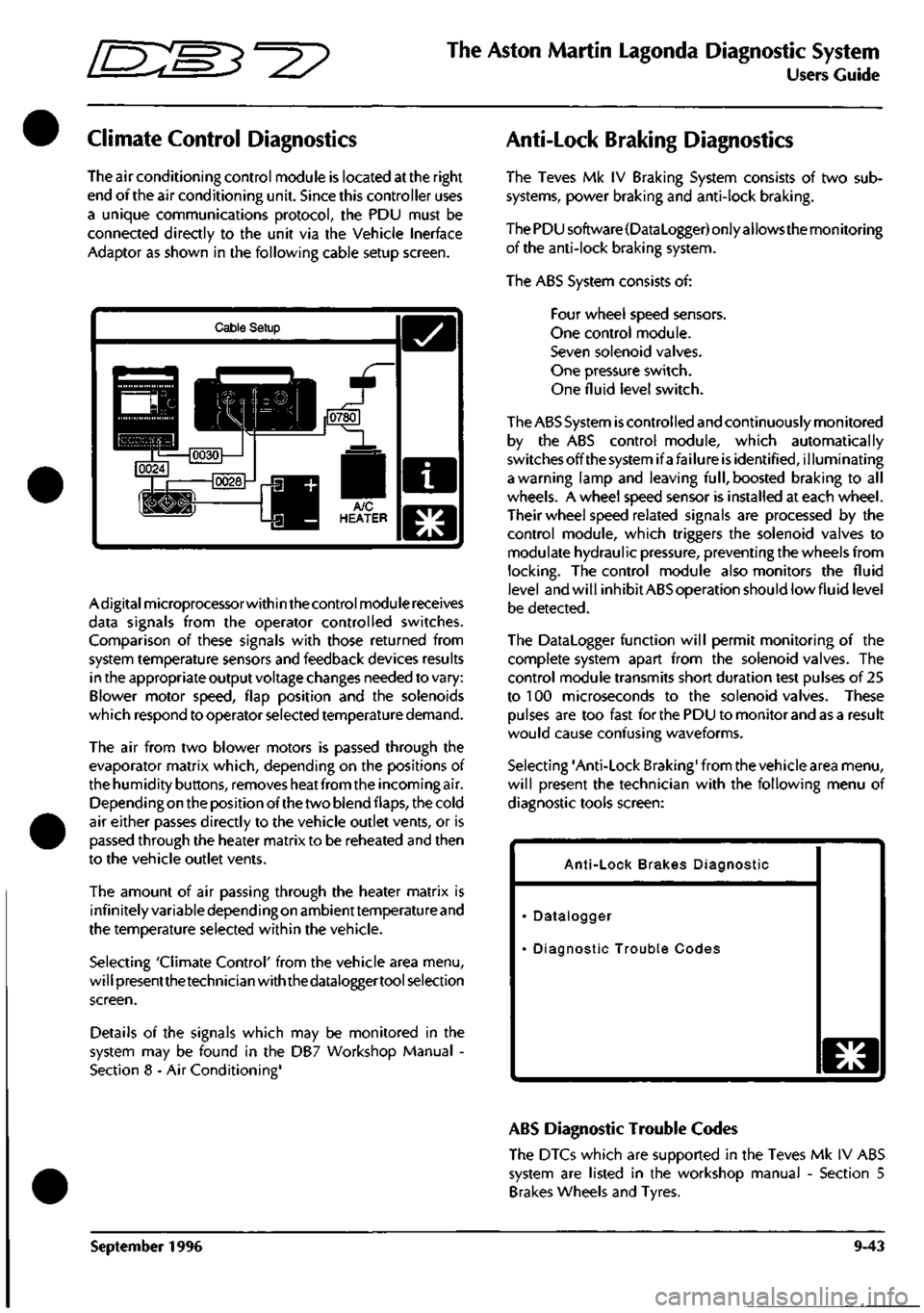

The air conditioning control module is located at the right

end of the air conditioning unit. Since this controller uses

a unique communications protocol, the PDU must be

connected directly to the unit via the Vehicle Inerface

Adaptor as shown in the following cable setup screen.

Cable Setup

Adigitalmicroprocessorwithin the control module receives

data signals from the operator controlled switches.

Comparison of these signals with those returned from

system temperature sensors and feedback devices results

in the appropriate output voltage changes needed to vary:

Blower motor speed, flap position and the solenoids

which respond to operator selected temperature demand.

The air from two blower motors is passed through the

evaporator matrix which, depending on the positions of

the humidity buttons, removes heat from the incoming air.

Dependingon the position of the two blend flaps, the cold

air either passes directly to the vehicle outlet vents, or is

passed through the heater matrix to be reheated and then

to the vehicle outlet vents.

The amount of air passing through the heater matrix is

infinitely variable depending on ambienttemperature and

the temperature selected within the vehicle.

Selecting 'Climate Control' from the vehicle area menu,

will presentthetechnician with the dataloggertool selection

screen.

Details of the signals which may be monitored in the

system may be found in the DB7 Workshop Manual -

Section 8 - Air Conditioning'

Anti-Lock Braking Diagnostics

The Teves Mk IV Braking System consists of two sub

systems, power braking and anti-lock braking.

The PDU software(DataLogger) only allows the monitoring

of the anti-lock braking system.

The ABS System consists of:

Four wheel speed sensors.

One control module.

Seven solenoid valves.

One pressure switch.

One fluid level switch.

The ABS System

is

controlled and continuously monitored

by the ABS control module, which automatically

switchesoffthesystemifafailure is identified, illuminating

a warning lamp and leaving

full,

boosted braking to all

wheels. A wheel speed sensor is installed at each wheel.

Their wheel speed related signals are processed by the

control module, which triggers the solenoid valves to

modulate hydraulic pressure, preventing the wheels from

locking.

The control module also monitors the fluid

level and will inhibit ABS operation should lowfluid level

be detected.

The Datalogger function will permit monitoring of the

complete system apart from the solenoid valves. The

control module transmits short duration test pulses of 25

to 100 microseconds to the solenoid valves. These

pulses are too fast for the PDU to monitor and as a result

would cause confusing waveforms.

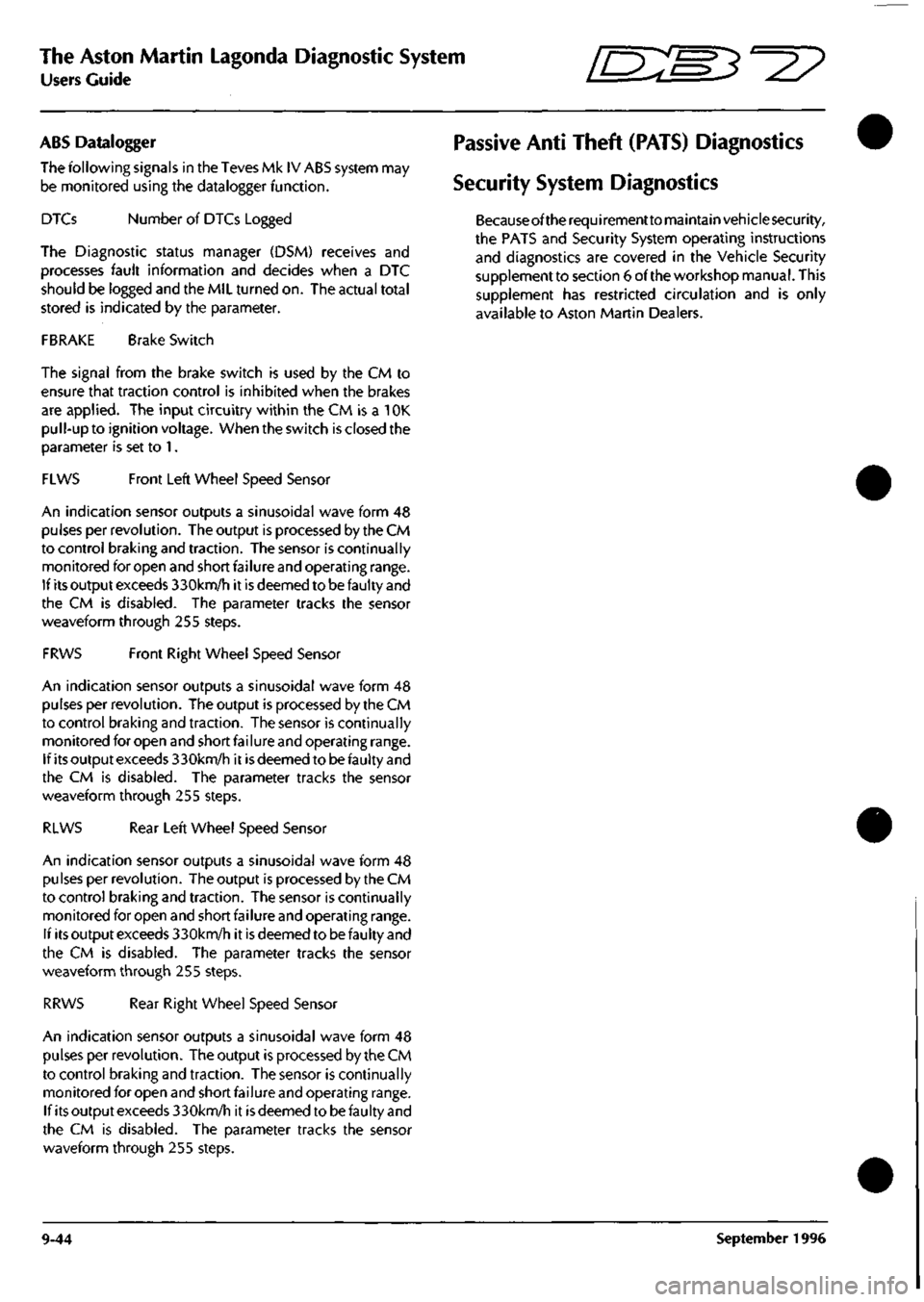

Selecting 'Anti-Lock Braking' from the vehicle area menu,

will present the technician with the following menu of

diagnostic tools screen:

Anti-Lock Brakes Diagnostic

Datalogger

Diagnostic Trouble Codes

o

ABS Diagnostic Trouble Codes

The DTCs which are supported in the Teves Mk IV ABS

system are listed in the workshop manual - Section 5

Brakes Wheels and Tyres.

September 1996 9-43

Page 395 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide

Em^'^?

ABS Datalogger

The following signals in the Teves Mk IV ABS system may

be monitored using the datalogger function.

DTCs Number of DTCs Logged

The Diagnostic status manager (DSM) receives and

processes fault information and decides when a DTC

should be logged and the MIL turned on. The actual total

stored is indicated by the parameter.

FBRAKE Brake Switch

The signal from the brake switch is used by the CM to

ensure that traction control is inhibited when the brakes

are applied. The input circuitry within the CM is a

1

OK

pull-up to ignition voltage. When the switch is closed the

parameter is set to 1.

FLWS Front Left Wheel Speed Sensor

An indication sensor outputs a sinusoidal wave form 48

pulses per revolution. The output is processed by the CM

to control braking and traction. The sensor is continually

monitored for open and short failure and operating range.

If its output exceeds 330km/h it is deemed to be faulty and

the CM is disabled. The parameter tracks the sensor

weaveform through 255 steps.

FRWS Front Right Wheel Speed Sensor

An indication sensor outputs a sinusoidal wave form 48

pulses per revolution. The output is processed by the CM

to control braking and traction. The sensor is continually

monitored for open and short failure and operating range.

If its output exceeds 330km/h it

is

deemed to be faulty and

the CM is disabled. The parameter tracks the sensor

weaveform through 255 steps.

RLWS Rear Left Wheel Speed Sensor

An indication sensor outputs a sinusoidal wave form 48

pulses per revolution. The output is processed by the CM

to control braking and traction. The sensor is continually

monitored for open and short failure and operating range.

If its output exceeds 330km/h it

is

deemed to be faulty and

the CM is disabled. The parameter tracks the sensor

weaveform through 255 steps.

RRWS Rear Right Wheel Speed Sensor

An indication sensor outputs a sinusoidal wave form 48

pulses per revolution. The output is processed by the CM

to control braking and traction. The sensor is continually

monitored for open and short failure and operating range.

If its output exceeds 330km/h it is deemed to be faulty and

the CM is disabled. The parameter tracks the sensor

waveform through 255 steps.

Passive Anti Theft (PATS) Diagnostics

Security System Diagnostics

Becauseof the requirementto maintain vehicle security,

the PATS and Security System operating instructions

and diagnostics are covered in the Vehicle Security

supplement to section 6 of the workshop manual. This

supplement has restricted circulation and is only

available to Aston Martin Dealers.

9-44 September 1996

Page 414 of 421

^?

The Aston Martin Lagonda Diagnostic System

Users Guide

Datalogger Example

A customer reported intermittent illumination of the

anti-

Lock Brakes (ABS) warning lamp.

TheABScontrolmodulewas interrogated, producing fault

code 33 (95 MY), right-rear wheel speed sensor.

The PDU was used to check the wheel speed sensor

output using the ABS warning lamp as a trigger.

The PDU was setup to the vehicle's configurations and

Datalogger was accessed.

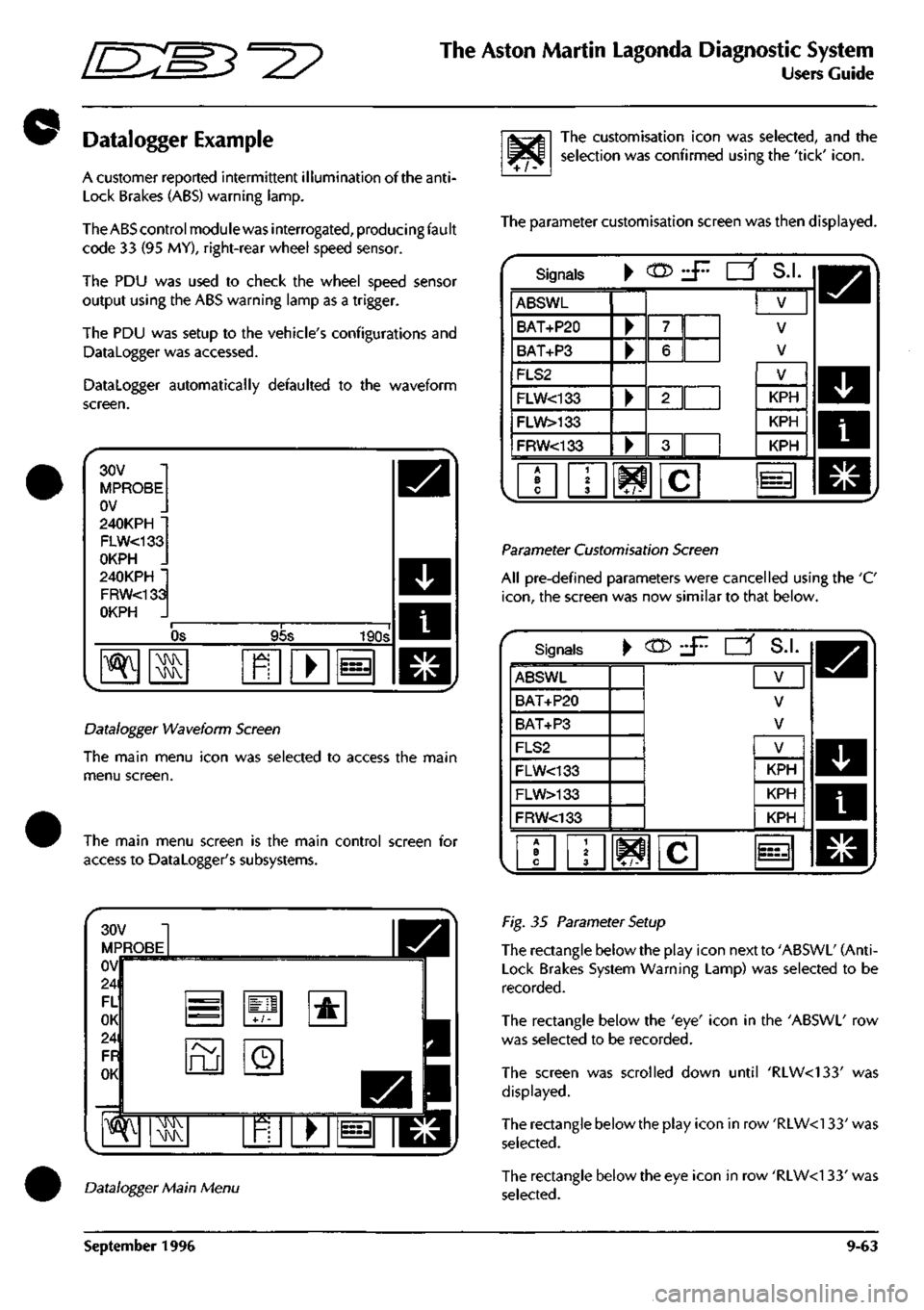

Datalogger automatically defaulted to the waveform

screen.

30V

MPROBE

OV

240KPH •

FLW<133

OKPH .

240KPH •

FRW<133

OKPH .

OS 95s 190s

^ ^ R • i=3

Datalogger Waveform Screen

The main menu icon was selected to access the main

menu screen.

The main menu screen is the main control screen for

access to Datalogger's subsystems.

^/^

The customisation icon was selected, and the

selection was confirmed using the 'tick'

icon.

The parameter customisation screen was then displayed.

Signals • c05 d^ CZf S.I.

ABSWL

BAT+P20

BAT+P3

FLS2

FLW<133

FLW>133

FRW<133

•

•

•

•

7

6

2||

3

V

V

V

1 2 3 W c

V

KPH

KPH

KPH

^=3

Parameter Customisation Screen

All pre-defined parameters were cancelled using the 'C

icon,

the screen was now similar to that below.

Signals ^ (n> •S'- rz^ S.I.

ABSWL

BAT+P20

BAT+P3

FLS2

FLW<133

FLW>133

FRW<133

V

V

V

A B C

1 2 3 ^ ^ i i C

V

KPH

KPH

KPH

Datalogger Main Menu

Fig. 35 Parameter Setup

The rectangle below the play icon next to 'ABSWl' (Anti-

lock Brakes System Warning Lamp) was selected to be

recorded.

The rectangle below the 'eye' icon in the 'ABSWl' row

was selected to be recorded.

The screen was scrolled down until 'RIW<133' was

displayed.

The rectangle below the play icon in row'RLW<133'was

selected.

The rectangle below the eye icon in row 'RLW<1 33' was

selected.

September 1996 9-63

Page 416 of 421

5'=3^

The Aston Martin Lagonda Diagnostic System

Users Guide

The 'tick' icon was selected to return to the trigger screen

which will then be as shown below.

ABSWL

Trigger

Anti-Lock Bra

^ CTD

AJUJ

^B

6V

.J7.

!•

t 1

•

S.I.

fvl

^ t

]

kes Warning Lamp

Z-.Z4

The Trigger Set-Up Screen

The 'tick' icon was then selected to return to the parameter

customisation

screen.

The screen should now look similar

to that below.

Signals • cn> J^ [Z^ S.L

RLW<133

RRW<133

BAT+P20

BAT+P3

FLS2

FLW<133

•

V

KPH

KPH

V

V

^ Kr-

i c

V

KPH

ini

Parameter Customisation - Final Setup

The 'tick' icon was pressed to access the waveform

display.

The PDU was now ready to start recording data.

The 'record' icon was selected to start recording data.

When the fault occurred, the ABS warning lamp

automatically triggered the PDU. This will place a fixed

cursor on the screen and set the time base to zero. The

PDU will stop recording after the preset record time. If no

record time has been entered, the PDU will use its default

record time of 16minutes and 40 seconds. 8m20s pre-

trigger and 8m20s post trigger.

The following figure indicates the typical waveform display

for the wheel speed sensor fault. The dotted vertical line

represents the trigger point.

16V

ABSWL

OV

240KPH "

RLW<133

OKPH .

240KPH •

RRW<133

OKPH

-55.4s

7.29s

^ 39.6s

^ MMV

\!MV

m

wheel Speed Sensor Display

September 1996 9-65