light ASTON MARTIN DB7 1997 Owner's Guide

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 262 of 421

y/--^^^^3^

'—-p "^ Body and Trim

Roof Description

Volante Roof

Description

The system comprises an electrically driven hydraulic pump and two hydraulic rams for raising and lowering the

roof.

The pump is powered via two heavy duty changeover relays. Two further pairs of changeover relays power

the rear quarter windows (one pair for each window). The roof hydraulic pump is protected by a 30A fuse, the

windows by circuit breakers.

An electronic control module (ECM) is actuated by the roof switch on the centre console. The ECM controls the

operation of

both

the roof

and

rear quarter window circuits

so

that they can only be operated in

a

pre-programmed

manned.

When in operation, the ECM provides signals to the roof and to the rear quarter windows.

When the roof

switch

is moved into the open (Roof Down) position, the roof

and

rear windows move together until

approximately four seconds has elapsed. At this time, the ECM will remove power from the rear window circuits,

leaving the roof motor running. The roof motor will stop after 12 seconds (i.e. a further 8 seconds after the rear

window motors stop).

The signals will be removed from the rear window relay after 4 seconds and from the roof relay after 12 seconds

if the roof switch is held in either position for longer than 12 seconds.

In order to comply with legislation, the following features are built into the system:

If the roof switch is operated in either direction and then released before that operation is complete, the roof and

rear quarter windows will stop immediately. If, whilst the system is in operation, the ignition switch

is

turned to the

off position, the system will immediately stop.

If the roof switch is pressed again after pausing during a roof movement, the timing sequence will be as follows:

1.

If the previous direction is selected, the timing recommences from where it left off and will continue to

completion. If the ignition has been turned off, the timing will start from the beginning of its cycle.

2.

If theoppositedirection

is

selected,

the timing sequence will commence

from the beginning

of the newly selected

direction and continue to completion.

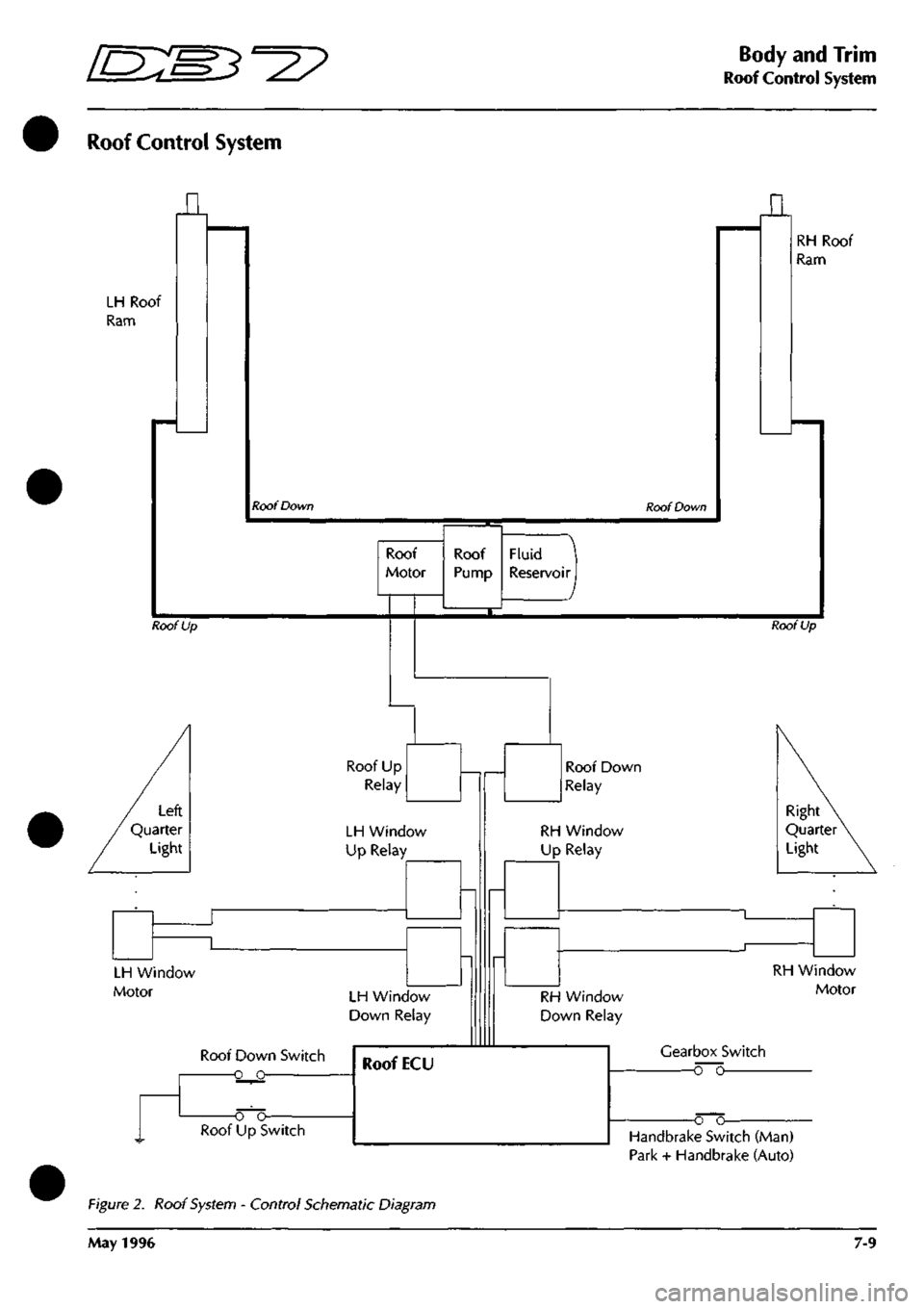

Roof and Rear Quarter Light Control

The following diagrams show the component location and the electrical control for the roof and rear quarter light

systems.

May 1996 7-7

Page 263 of 421

Body and Trim >/—^

^^^^5^

' ^ ^

Roof Components I -^' ^—^ -^-^

Roof Component Location

Roof Switch

Hydraulic Pump

ECM

Roof Up Relay

Roof Down Relay

LH Q Light Up Relay

LH Q Light Down Relay

RH Q Light Up Relay

RH Q Light Down Relay

Fuse and Circuit Breakers

Hydraulic Rams

Heated Rear Window Overide Switch

Figure 7. Roof

System

Component Location

7-8 May 1996

Page 264 of 421

5^^

Body and Trim

Roof Control System

Roof Control System

LH Roof

Ram

n

Roof Down Roof Down

n

RH Roof

Ram

Roof

Motor

Roof Up

Fluid

Reservoir I

Roof Up

Roof Up

Relay

LH Window

Up Relay

LH Window

Motor LH Window

Down Relay

Roof Down Switch

-o o-

Roof Down

Relay

RH Window

Up Relay

Right

Quarter

Light

RH Window

Down Relay

RH Window

Motor

Gearbox Switch

o~o

o o-Handbrake Switch (Man)

Park + Handbrake (Auto)

Figure 2. Roof System - Control Schematic Diagram

May 1996 7-9

Page 273 of 421

Body and Trim

Roof Seals - Adjustment

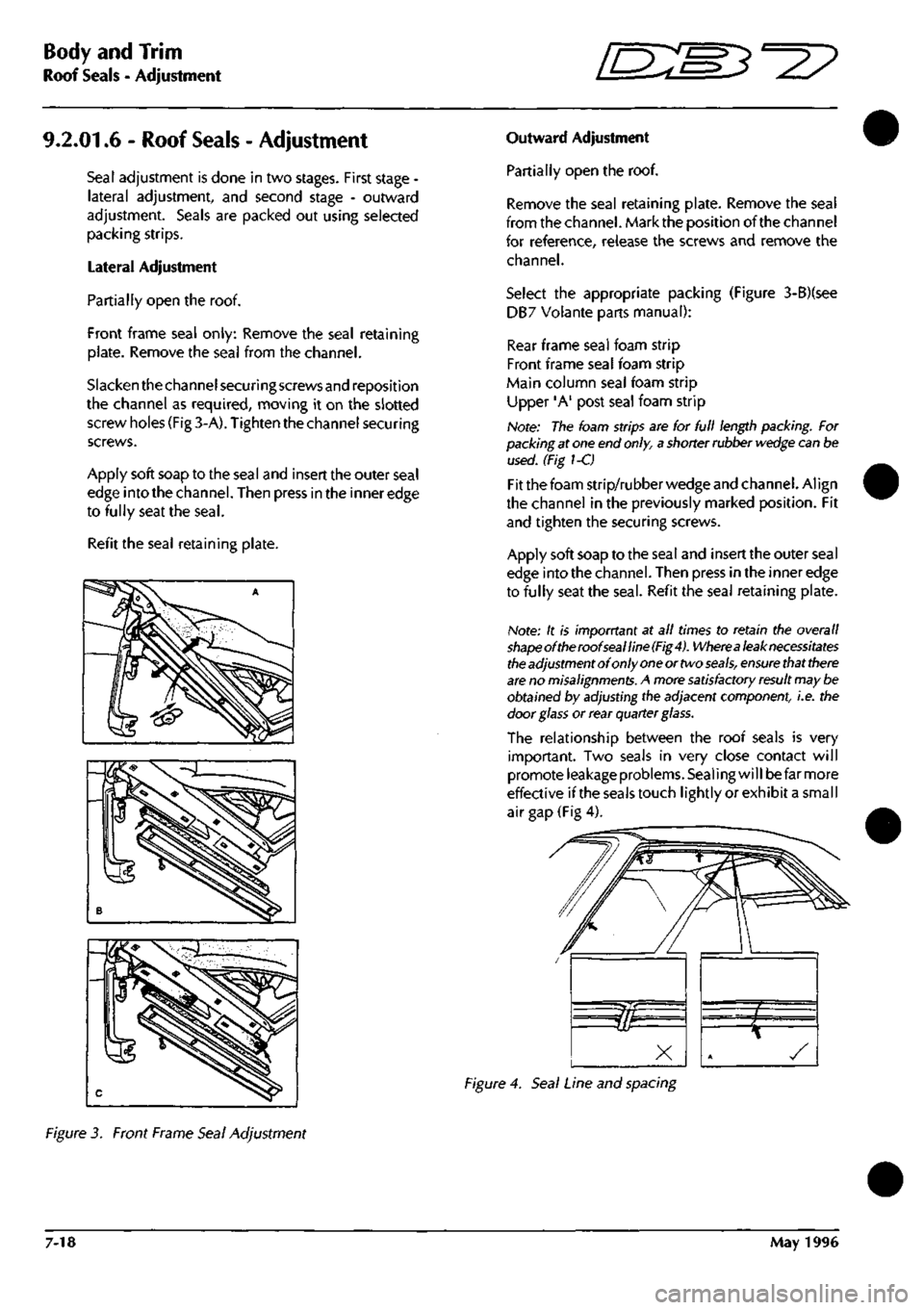

9.2.01.6 - Roof

Seals

- Adjustment

Seal adjustment is done in two stages. First stage -

lateral adjustment, and second stage - outward

adjustment. Seals are packed out using selected

packing strips.

Lateral Adjustment

Partially open the roof.

Front frame seal only: Remove the seal retaining

plate.

Remove the seal from the channel.

Slacken the channel securing screws and reposition

the channel as required, moving it on the slotted

screw holes (Fig 3-A). Tighten the channel securing

screws.

Apply soft soap to the seal and insert the outer seal

edge into the channel. Then press in the inner edge

to fully seat the

seal.

Refit the seal retaining plate.

Outward Adjustment

Partially open the roof.

Remove the seal retaining plate. Remove the seal

from the channel. Mark the position of the channel

for reference, release the screws and remove the

channel.

Select the appropriate packing (Figure 3-B)(see

DB7 Volante parts manual):

Rear frame seal foam strip

Front frame seal foam strip

Main column seal foam strip

Upper 'A' post seal foam strip

Note: The foam strips are for full length packing. For

packing at one end

only,

a shorter rubber

wedge

can be

used. (Fig 1-C)

Fit the foam strip/rubber wedge and channel. Align

the channel in the previously marked position. Fit

and tighten the securing screws.

Apply soft soap to the seal and insert the outer seal

edge into the channel. Then press in the inner edge

to fully seat the

seal.

Refit the seal retaining plate.

Note: It is imporrtant at all times to retain the overall

shapeoftheroofsealline(Fig4).

Wherea

leak necessitates

the

adjustment of only

one

or two

seals,

ensure

that

there

are

no

misalignments.

A more

satisfactory result

may be

obtained by adjusting the adjacent component, i.e. the

door

glass

or rear quarter glass.

The relationship between the roof seals is very

important. Two seals in very close contact will

promote leakage problems. Sealing will be far more

effective ifthe seals touch lightly or exhibit a small

air gap (Fig 4).

Figure 4. Seal Line and spacing

Figure 3. Front Frame Seal Adjustment

7-18 May 1996

Page 279 of 421

Air Conditioning

Contents '=2?

System Fault Diagnosis

Fault Finding

Blower Motor Test

Open Water Temperature Switch Needs

Short Water Temperature Switch Leads

Refrigeration

Compressors

Compressor Clutch Control

Trinary Switch

Condenser

Receiver-Drier

Evaporator

Expansion Valve

Sanden Compressor SD7H15

Manifold Gauge Set

System Checking with the Manifold Gauge Set

Evacuating the Manifold Gauge Set

Connecting the Manifold Gauge Set

Stabilising the System

Purging the Test Hoses

Leak Test

Manifold Gauge Set Check Procedures

Refrigerant Slightly Low.

Refrigerant Excessively Low.

Air In The System.

Compressor Malfunction

Moisture in the System

A Large Amount of Air in the System.

Expansion Valve Malfunction.

Expansion Valve Malfunction

Restriction in the High Pressure Side.

Torque Levels for the Hose Connections

8-30

8-33

8-33

8-33

8-34

8-35

8-35

8-35

8-35

8-36

8-36

8-36

8-37

8-39

8-39

8-39

8-39

8-40

8-40

8-41

8-41

8-42

8-42

8-43

8-44

8-45

8-45

8-46

8-46

8-47

Air Conditioning Procedures

Depressurising

Recovering Refrigerant

Evacuating and Recycling the Refrigerant

Recharging the System

Compressor Oil Check

8-47

8-47

8-48

8-49

8-49

8-2 May 1996

Page 292 of 421

Air Conditioning

Functional Check

Functional Check

This functional check procedure is provided as a simple system validation and is structured to augment the Portable

Diagnostic Unit (PDU).

Stage 1 (Cold engine only, if not proceed to Stage 2)

Procedure Normal System Reaction

1.

Ignition ON

Select MIN temperature, MAN, speed 3, Mid face.

(Engine Stationary) Fans Start

2.

Select MAX temperature Fans continue to run

3. Ignition OFF

Select MAX temperature and defrost

Ignition ON Fans start at maximum speed

4.

Select fan speed

1

Fan speed adjusts accordingly - system OK

Stage 2

Procedure Normal System Reaction

1.

Start up engine and warm up

Select fan speed 1, MAN, MAX TEMPERATURE

and mid face

2.

Open all vents Fans start after 3 seconds

2.

Select fan speed 2 Fan speed increases then stabilises

3. Select fan speed 3 Fan speed increases then stabilises

4.

Select defrost Fan speed steady at high

All air at screen and dash end

5. Re-select fan speed 1

Select AUX ignition key position

6. Slowly select MIN temperature Solenoids switch 1. centre vent

2.

water valve

3. Re-circulation

7. Re-select MID temperature

8. Select DEM Solenoid clicks

Air at screen

9. Select manual re-circulation Solenoid click

10.

Check flap for position

11.

Run Engine to normal temperature

12.

Select: MAN, 3/4 MAX heat and fan speed 2 Air from door vents

cool,

air temp from foot outlet slightly warm

13.

Select MAX temperature and air differential to hot face All vent outlets max temp except screen vent

14.

Select temperature

approx. 1/4 MAX heat and mid face level Cool air from centre vents

15.

Select MIN temperature Blower flaps at re-circulation position

All outlets blowing cold air except screen vent

May 1996 8-15

Page 307 of 421

Air Conditioning

System Fault Diagnosis ^=2?

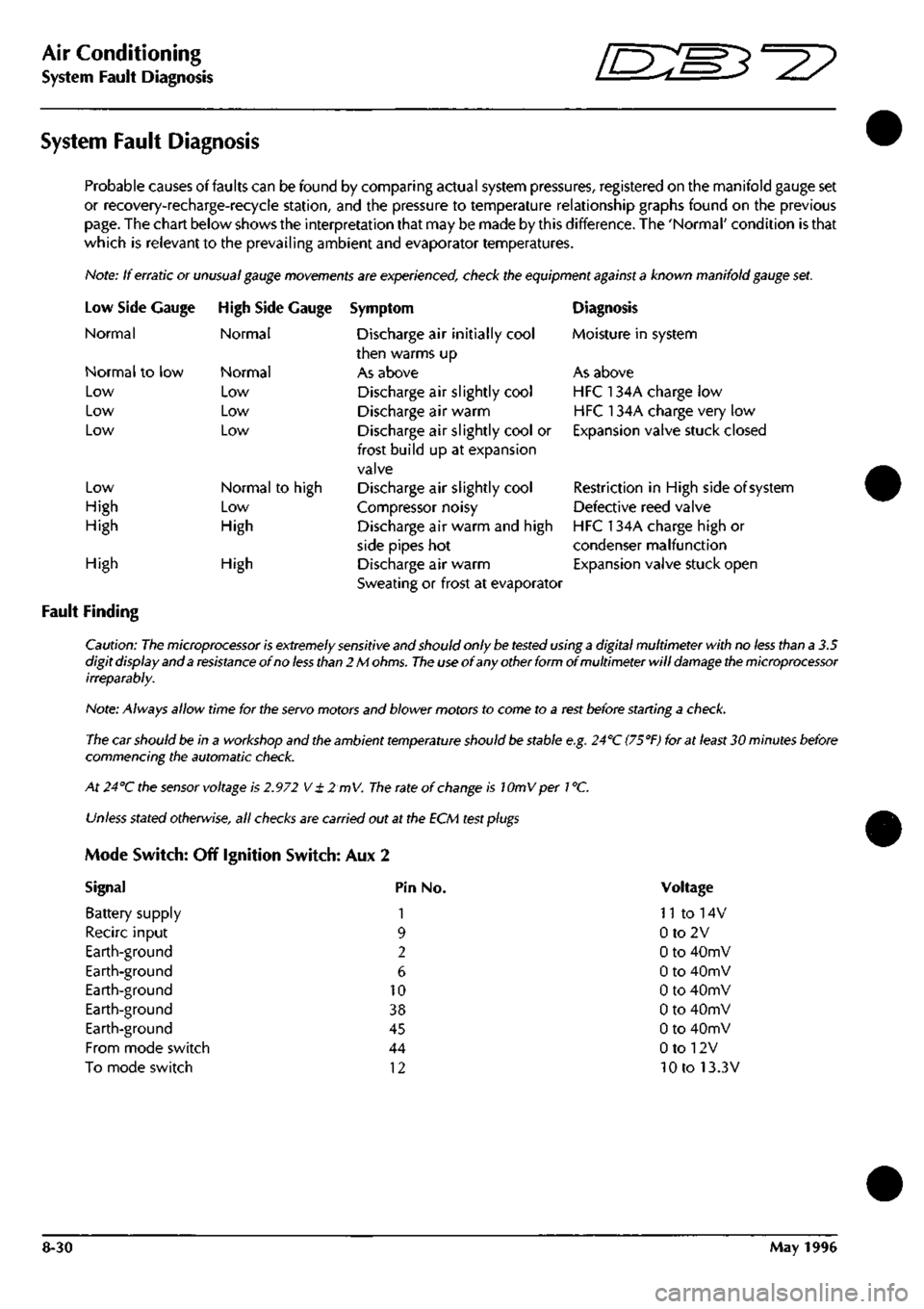

System Fault Diagnosis

Probable causes of faults can be found by comparing actual system pressures, registered on the manifold gauge set

or recovery-recharge-recycie station, and the pressure to temperature relationship graphs found on the previous

page.

The chart below shows the interpretation that may be made by this difference. The 'Normal' condition is that

which is relevant to the prevailing ambient and evaporator temperatures.

Note: If erratic or

unusual gauge movements

are experienced, check the equipment

against a

known manifold

gauge

set.

Low Side

Normal

Gauge

Normal to low

Low

Low

Low

Low

High

High

High Side Gauge

Normal

Normal

Low

Low

Low

Normal to high

Low

High

High

Fault Finding

High

Symptom

Discharge air initially cool

then warms up

As above

Discharge air slightly cool

Discharge air warm

Discharge air slightly cool or

frost build up at expansion

valve

Discharge air slightly cool

Compressor noisy

Discharge air warm and high

side pipes hot

Discharge air warm

Sweating or frost at evaporator

Diagnosis

Moisture in system

As above

HFC 134A charge low

HFC 134A charge very low

Expansion valve stuck closed

Restriction in High side of system

Defective reed valve

HFC 134A charge high or

condenser malfunction

Expansion valve stuck open

Caution:

The microprocessor is extremely sensitive

and should only

be tested

using

a

digital multimeter with no

less

than a 3.5

digit display and a

resistance

of no

less than

2 M

ohms.

The use

of any other form of multimeter will

damage the microprocessor

irreparably.

Note: Always allow time for the

servo

motors and blower motors to come to a

rest

before starting a

check.

The car should be in a workshop and the ambient

temperature

should

be

stable

e.g.

24''C

(75°F)

for at

least

30 minutes before

commencing the automatic

check.

At 24°C the

sensor

voltage is

2.972

V

± 2 mV.

The

rate of

change

is lOmVper

1

°C.

Unless

stated

otherwise,

all

checks

are carried out at the ECM

test plugs

Mode Switch: Off Ignition Switch: Aux 2

Signal Pin No.

Battery supply 1

Recirc input 9

Earth-ground 2

Earth-ground 6

Earth-ground 10

Earth-ground 38

Earth-ground 45

From mode switch 44

To mode switch 12

Voltage

n to 14v

0to2V

0 to 40mV

0 to 40mV

0 to 40mV

0 to 40mV

0 to 40mV

0 to 12V

10 to 13.3V

8-30 May 1996

Page 314 of 421

^?

Air Conditioning

Sanden Compressor SD7H15

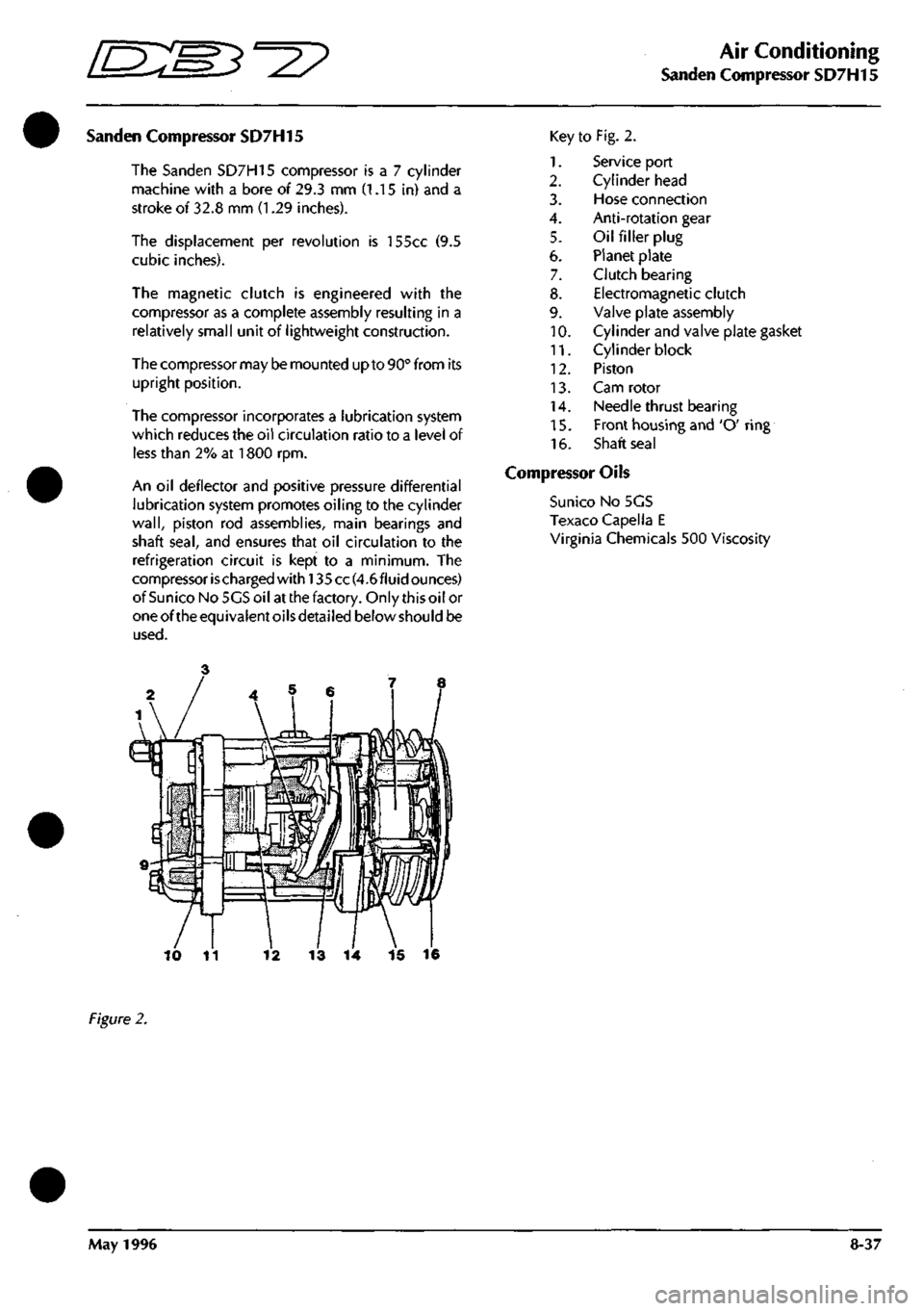

Sanden Compressor SD7H15

The Sanden SD7H15 compressor

is a 7

cylinder

machine with

a

bore

of

29.3

mm (1.15 in) and a

stroke

of

32.8

mm (1.29

inches).

The displacement

per

revolution

is

155cc

(9.5

cubic inches).

The magnetic clutch

is

engineered with

the

compressor

as a

complete assembly resulting

in a

relatively small unit

of

lightweight construction.

The compressor may be mounted up to 90° from

its

upright position.

The compressor incorporates

a

lubrication system

which reduces the

oil

circulation ratio

to a

level

of

less than

2% at 1800 rpm.

An

oil

deflector

and

positive pressure differential

lubrication system promotes oiling

to the

cylinder

wall,

piston

rod

assemblies, main bearings

and

shaft

seal,

and

ensures that

oil

circulation

to the

refrigeration circuit

is

kept

to a

minimum.

The

compressor ischarged

with!

35 cc(4.6fluid ounces)

ofSunico NoSGSoil at the factory. Only this oil

or

oneoftheequivalentoilsdetailed below should

be

used.

Key

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

to Fig. 2.

Service port

Cylinder head

Hose connection

Anti-rotation gear

Oil filler plug

Planet plate

Clutch bearing

Electromagnetic clutch

Valve plate assembly

Cylinder and valve plate gasket

Cylinder block

Piston

Cam rotor

Needle thrust bearing

Front housing and 'O' ring

Shaft seal

Compressor Oils

Suni

CO

No 5GS

Texaco Capella E

Virginia Chemicals 500 Viscosity

13

14 15 16

Figure

2.

May

1996

8-37

Page 318 of 421

=2?

Air Conditioning

System Checking with the Manifold Gauge Set

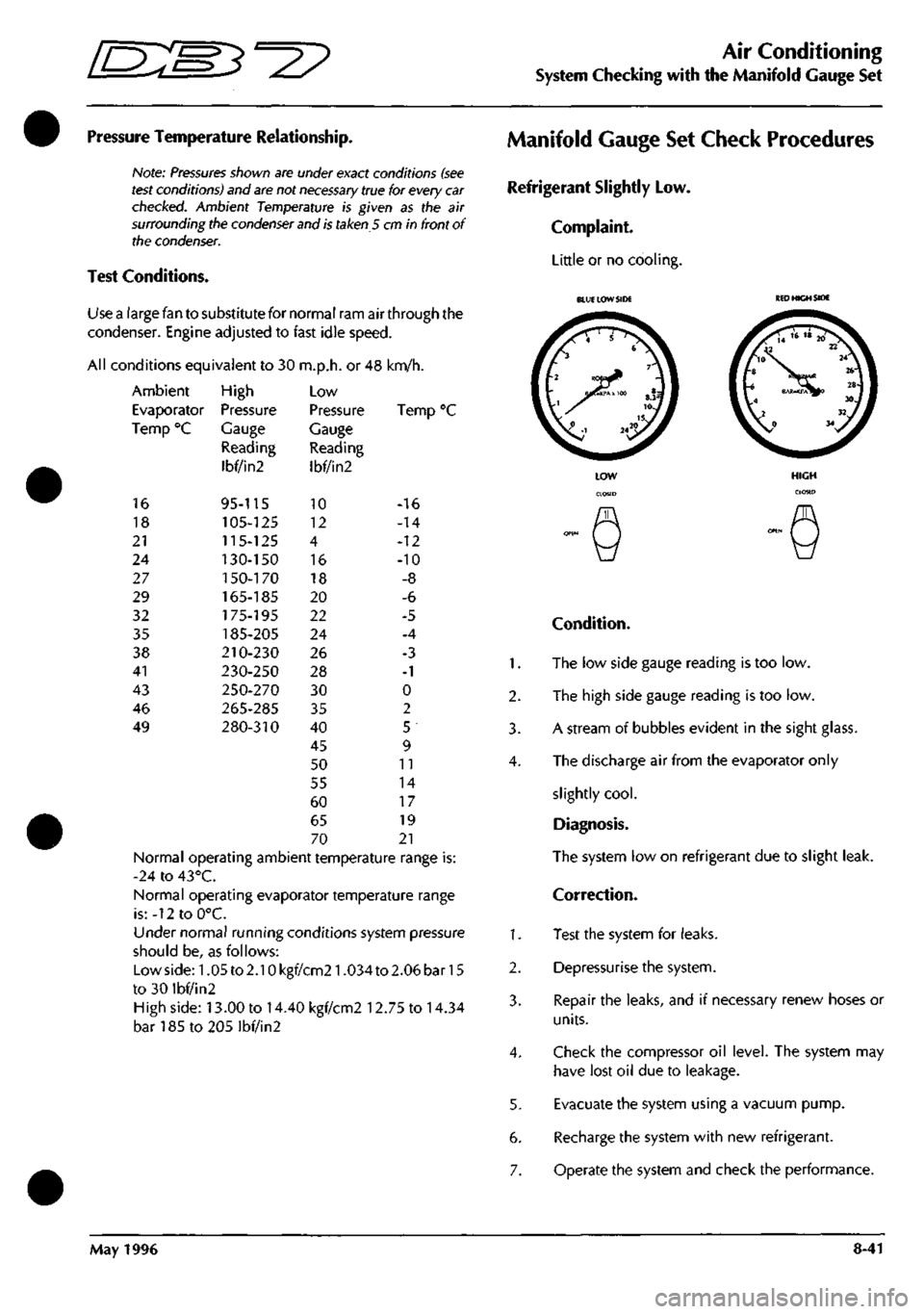

Pressure Temperature Relationship.

Note:

Pressures

shown are under exact conditions

(see

test

conditions) and

are

not

necessary

true for every

car

checked.

Ambient Temperature is given as the air

surrounding the

condenser

and

is

taken 5 cm in front of

the

condenser.

Test Conditions.

Use a large fan to substitute for normal ram air through the

condenser. Engine adjusted to fast idle speed.

All conditions equivalent to 30 m.p.h. or 48 km/h.

Ambient

Evaporator

Temp °C

16

18

21

24

27

29

32

35

38

41

43

46

49

High

Pressure

Gauge

Reading

Ibf/in2

95-115

105-125

115-125

130-150

1

50-170

165-185

175-195

185-205

210-230

230-250

250-270

265-285

280-310

Low

Pressure

Gauge

Reading

Ibf/in2

10

12

4

16

18

20

22

24

26

28

30

35

40

45

50

55

60

65

70

Ten

-16

-14

-12

-10

-8

-6

-5

-4

-3

-1

0

2

5

9

11

14

17

19

21

Normal operating ambient temperature range is:

-24 to 43°C.

Normal operating evaporator temperature range

is:-12toO°C.

Under normal running conditions system pressure

should be, as follows:

Lowside:1.05to2.10kgf/cm21.034to2.06bar15

to 30 ibf/in2

High side: 13.00 to 14.40 kgf/cm2 12.75 to 14.34

bar185to205lbf/in2

Manifold Gauge Set Check Procedures

Refrigerant Slightly Low.

Complaint.

Little or no cooling.

1.

2.

3.

4.

1.

2.

3.

4.

5.

6.

7.

BLUE LOW SIDE

KED

HIGH SIDE

Condition.

The low side gauge reading is too low.

The high side gauge reading is too low.

A stream of bubbles evident in the sight glass.

The discharge air from the evaporator only

slightly

cool.

Diagnosis.

The system low on refrigerant due to slight leak.

Correction.

Test the system for leaks.

Depressurise the system.

Repair the leaks, and if necessary renew hoses or

units.

Check the compressor oil level. The system may

have lost oil due to leakage.

Evacuate the system using a vacuum pump.

Recharge the system with new refrigerant.

Operate the system and check the performance.

May 1996 8-41

Page 319 of 421

Air Conditioning

System Checking with the Manifold Gauge Set [n::S3^^?

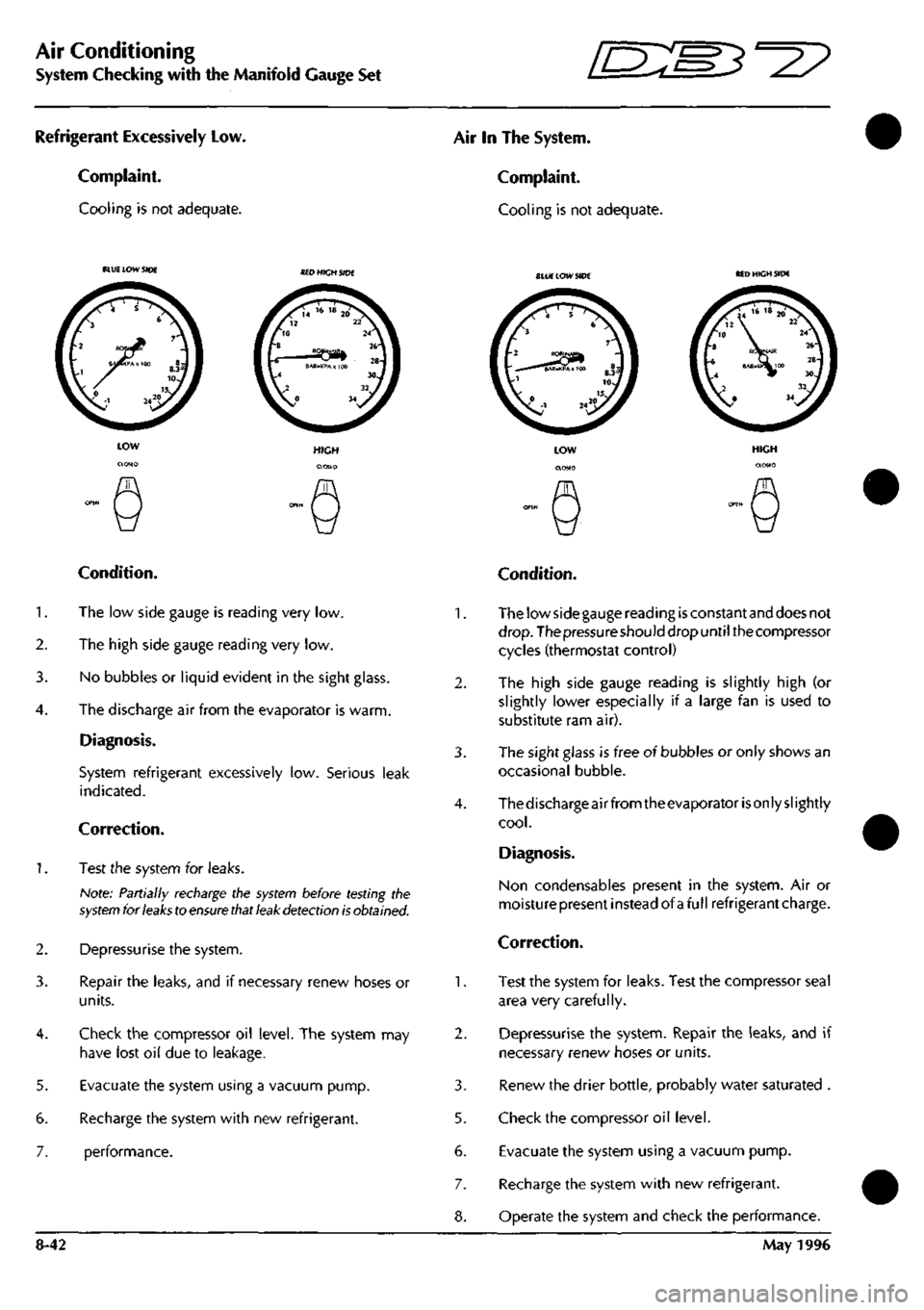

Refrigerant Excessively Low.

Complaint.

Cooling is not adequate.

Air In The System.

Complaint.

Cooling is not adequate.

BLU£ LOW SIDE SlUE LOW SIDE MD HIGH SIDE

5.

6.

7.

Condition.

1.

The low side gauge is reading very low.

2.

The high side gauge reading very low.

3. No bubbles or liquid evident in the sight glass.

4.

The discharge air from the evaporator is warm.

Diagnosis.

System refrigerant excessively low. Serious leak

indicated.

Correction.

1.

Test the system for leaks.

Note: Partially recharge the

system

before testing the

system

for

leaks

to

ensure that leak detection is

obtained.

Depressurise the system.

Repair the leaks, and if necessary renew hoses or

units.

Check the compressor oil level. The system may

have lost oil due to leakage.

Evacuate the system using a vacuum pump.

Recharge the system with new refrigerant.

performance.

2.

3.

5.

6.

7.

8-42

Condition.

The low side gauge reading

is

constant and does not

drop.

The pressure should drop until the compressor

cycles (thermostat control)

The high side gauge reading is slightly high (or

slightly lower especially if a large fan is used to

substitute ram air).

The sight glass is free of bubbles or only shows an

occasional bubble.

Thedischarge air from theevaporator

is

only slightly

cool.

Diagnosis.

Non condensables present in the system. Air or

moisturepresent instead of afullrefrigerantcharge.

Correction.

Test the system for leaks. Test the compressor seal

area very carefully.

Depressurise the system. Repair the leaks, and if

necessary renew hoses or units.

Renew the drier bottle, probably water saturated .

Check the compressor oil level.

Evacuate the system using a vacuum pump.

Recharge the system with new refrigerant.

Operate the system and check the performance.

May 1996