light ASTON MARTIN DB7 1997 Owner's Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 158 of 421

CIGAR LIGHTER

NO COLOUR 735 B 347 RW

746 8 818 RG 819 OR RH

1

1 4 5

AREA l3.B3-2ieA 15.B5-JI9A

I3.B3-2I84 13.86 I3.B6 WINDOW SWITCH

NO COLOUR PIN AREA 730 8 I l3.B3-2ieA 820 GP 2 13.86 329 RW I3.B5-2I9AI

0 0

[D

CRUISE ON/OFF SWITCH

•*• NO COLOUR 725 B 2203 YO 2201 LGY 2204 YO 307 RW

PIN 1 2 3 4

AREA 13.B3-2I8A 13.B4-2I9 I3.B4-2I8 13.84-219 I3.B5-2I9A

NO COLOUR AREA 729 8 I3.C3-2I8A

RIP

D

CRUISE SET SWITCH

•*• NO COLOUR 230 U 825 BP 2205 LGY 177 Y 343 RW

PIN 1 2 3 4

AREA I3.B3 I3.B6 I3.B4-2I8 13.86 I3.B5-2I9A

NO COLOUR AREA 734 B 13.C3-219A

0

D

NO COLOUR 817 YO 818 RG 819 GR 379 RU 380 GU 820 6P S2I RW 177 Y 825 BP 731 U 2202 LGY

332 8

PIN 1 ? 3 4 5 6 7 8 9 10 II 12 13 14 15 16

AREA 13.84-219 I3.A2 I3.A2 I3.D2 13.02 I3.A3 I3,B5-2I9A I3.A5 I3.B5 I3.B3 I3.B4-2I8

IS.B3-2I8A

SHEET II AREA Dl

GEAR SELECTOR ILLUMINATION

LH WINDOW SWITCH

NO COLOUR PIN AREA 331 RW I 13.B5-219A 705 6 2 l3.B3-2ieA NO COLOUR PIN 748 B 342 RW

778

B

379 RU 380 GU

AREA l3.B3-2ieA I3.B5-2I9A

I3.B3-2I8A 13.66 13.86 ^7 Wiring Diagram

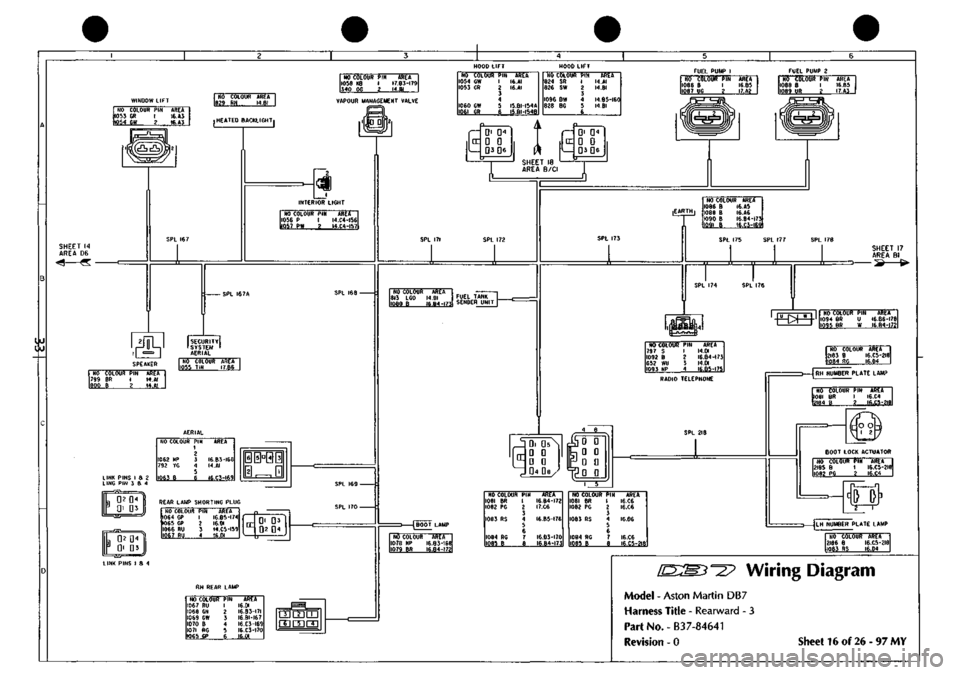

Model - Aston Martin DB7

Harness Title - Console

Part No. - B37-84638

Revision - 0 Sheet 13 of 26-97 MY

Page 164 of 421

NO

COLOUR

PIN

AREA I0S8

KB I

I7.B3-I79 JAO

OC 2 H.BI

WINDOW LIFT NO COLOUR

PIN

AREA I0S3

GR I

I6.A3 1051

GW 2

I6.A3

I

NO

COLOUR AREA 1829

RN

I4.BI

I HEATED BACKLIGHTi

VAPOUR MANAGEMENT VALVE

HOOD LIFT NO COLOUR 1054

GW

1053

GR

1060 GW lOEl

GR

1

I

4

I

AREA I6.AI le.AI

I5.ei-I54A I5.BI-I54B

NO COLOUR

PIN

1096 BW 828

BG

AREA I4.AI I4.BI

I4.B5-I60 I4.BI

FUEL PUMP

I

NO COLOUR

PIN

1086

B 1

1087 UG

2

AREA I6.B3 I7.A2

NO COLOUR

PIN

AREA 16.85 I7.A3

INTERIOR LIGHT NO COLOUR

PIN

AREA

1056 P I I4.C4-I56 1057 PW 2 I4.C4-I57

m

fsD

1ST SECURITY STEM

I

AERIAL

I

NO

COLOUR

PIN

799

BR I

1800

B 2

AREA 14.Al 14.Al

I

NO

COLOUR ||055

TIN

AREA I7.B6

LINK PINS

I a 2

LING

PIN 3 a 4

NO COLOUR

PIN

AREA

1062

NP

792

VG

I6.B3-I68 I4.AI

6)[5]o[4)|3J

02 01 Qi 03

REAR LAMP

SHORTING

PLUG

02 01 Ql 03

NO COLOUR PINAREA

1064

GP I

IG.B5-I74

1065 GP

2 16.01 1066 RU 3 I4.C5-I59

1067

RU 4 16,01

Ql D3 D2 01

LINK PINS

I 8 4

RH REAR LAMP

NO COLOUR 1067

RU

1068

ON

1069 CW 1070

B

1071

RG

1065

GP

PIN 1 ? ^ 4 •) 6

AREA 16.01 I6.B3-I7I I6.BI-I67 I6.C3-IG9 I6.C3-I70 16.01

mmra CEIinnn

(—\ Qi 01

cr

D 0 I—I 03 06 SHEET 18 '• AREA B/CI

0

01 Qi 0 D 03 06

NO COLOUR AREA 813

LGO 14.01

1080

B

I6.B4-I73 FUEL TANK SENDER UNIT

NO COLOUR AREA 1086

B

1088

B

1090

B

1091

B

I6.A5 I6.A6 16.84-173 I6.C3-I69

TH^

SHEET 17 AREA Bl

-» ^

-F^Pl-'

NO COLOUR

PIN

AREA

1094

BR U

16.86-178

1095 BR W 16.84-172

NO COLOUR PIN 797 S I

1092

B 2

652

WU 3

1093

HP 4

AREA 14.01

I6.B4-I73 14.01 I6.B5-I75

NO COLOUR AREA 2183

B

I6.C5-2I8 1084 RG

16.04

RADIO TELEPHONE

E

Di 05 D 0 D D 04 08/

4

8

J^Q a

£o 0 PO 0

T?D 0 ^ 1 S ^

NO COLOUR

PIN

1081

BR I

1082 PG

2

3

NO COLOUR AREA

1078

NP

I6.B3-I68 1079

BR

I6.B4-I72

AREA I6.B4-I72 I7.C6

1084

RG 1085 B 16.03-170 I6.B4-I73

NO COLOUR

PIN

1081

BR I

1082

PG 2

3 i

RS 4

5 6 1084 RG

7

1085

B 8

AREA le.CG 16.CG

I6.C6 I6.C5-2I8

Zl

1

RH NUMBER PLATE LAMP

NO COLOUR

PIN

AREA 1081

BR I

I6.C4 2184

B 2

l6.C5-2ia

BOOT LOCK ACTUATOR NO COLOUR

PIN

AREA 2185

B I

I6.C5-2I8 1082

PG 2

I6.C4

^[}

[}

JLH

NUMBER

PLATE LAMP

NO COLOUR AREA 2186

B

I6.C5-2I6 ;I083

RS

I6.D4

Wiring Diagram

Model - Aston Martin DB7

Harness Title - Rearward - 3

Part No. -

B3

7-84641

Revision - 0 Sheet 16 of 26-97 MY

Page 187 of 421

^=2?

Electrics

Airbag System

Eye Protection

Chemical protective goggles are recommended

where there is a possibility of eye contact with the

propellant. Safety glasses with side shields are

recommended for all other operations.

Protective Clothing

Approved protective gloves, overalls and shoes/

boots should be worn.

Handling and Storage Precautions

Do not store airbag modules near live electrical

equipment or circuitry. Store in a dry environment

at ambient temperatures.

Good housekeeping and engineering practices

should be employed to prevent the generation and

accumulation of

dusts.

Store in compliance with all

local state and federal regulations.

Driver and Passenger Airbag Modules

Assembly/Removal/Service Instructions

WARNING: In the event of a vehicle impact where the

airbags and the seatbeltpretensioner (if fitted) are

deployed, the following actions MUST be

performed:

Check the condition of the seatbelts, steering

wheel,

steering column, all connections to airbags,

and the column switchgear connectors for integrity

and damage. If in any

doubt,

replace suspected

parts for new parts.

Replace both crash

sensors,

the

safing sensor

and

the seatbelt pretensioner module (if fitted).

On completion of all repair procedures, switch on

the ignition and check that the

Airbag/SRS

warning

light comes on when the ignition is switched on

and extinguishes after approximately six seconds

indicating satisfactory completion of the airbag

and pretensioner

system

self

tests.

WARNING: Before starting

work,

ensure

that the ignition

switch is in position 'O' and the ignition key is

removed.

Disconnect the battery negative lead

within 12 seconds of switching off the ignition to

prevent the alarm system triggering.

As the airbag control module is equipped with a

back-up power source and due to the risk of the

airbag being inadvertently deployed, wait one

minute or longer after disconnecting the battery

before starting work on the airbag module.

• Disconnectingthe battery negative cable cancels

the memory for the 'one-touch' window down

system and stops the vehicle clock. Reset the

window memory and the clock when work is

completed.

• Never use airbags from other vehicles, always

use new parts.

• After work is completed, reconnect the battery

and perform the airbag warning light check

• Never use electrical probes to check voltage or

electrical resistance of the airbag modules.

• Disconnect the airbag before carrying out any

work on, or in the vicinity of the module, or

when using electric welding equipment.

• Always ensure that the battery negative lead has

been disconnected for at least one minute before

commencing any removal procedure.

September 1996 6-71

Page 196 of 421

Electrics

Airbag System ^2?

6.4.21.4

Airbag Disarming/Arming

Procedures

WARNINGS AND CAUTIONS:

WARNINGS:

Disarm the airbags by disconnecting the battery

ground (black)

lead,

waiting one minute and then

removing the airbag modules before servicing of

any airbag or steering column component.

After disconnecting the battery ground

lead,

allow

a minimum of one minute delay for the back-up

power supply to discharge before servicing the

airbag system.

The system components are non-serviceable, if

faults are

suspected,

change components for new

items

only.

Failure to observe the above procedures may

result in accidental deployment of the airbags.

Always wear safety

glasses

when working on airbag

equipped vehicles.

Personnel carrying an airbag module must ensure

that the module and trim cover are pointing away

from the

body.

When positioning on a bench or

work surface, ensure that the airbag module and

trim cover face upwards to limit motion on

accidental deployment.

Always wear

gloves

when handling deployed airbag

modules. Deposits of sodium hydroxide may be

presenton the module surface. If sodium hydroxide

contacts any area of the skin, wash the affected

area immediately with mild soap and

water.

Dispose of the deployed airbag using the correct

procedures referred to in this section.

Cautions:

When scrapping vehicles,

ensure

that the

airbags

have

been deployed (see

Scrapping Vehicles

with Live

Airbags).

If a component

has been

renewed and the fault

does

not

clear,

refit the original item and repeat the diagnostic

procedure.

After

servicing,

repeatthe diagnostic

procedures

to ensure

correct

system

operation.

Renew

the airbag module if the surrounding trim

panels

are

damaged.

Do not attempt to repaint trim covers as

paint may

damage

cover material.

Disarming the Airbags

3.

4.

WARNING: Carry out the following disarming

procedure before attempting any work on the

vehicles electrical

systems.

Note: The battery ground (black) lead must be

disconnected within 12 seconds of switching off the

ignition to avoid the alarm siren sounding.

Disconnect the battery ground

lead.

Allow a

minimum of one minute delay for the back-up

power supply to discharge.

Remove the drivers side airbag module and replace

it with an airbag simulatorfrom the simulator kit (Pt

No.

43.27028).

Remove the passengers airbag module and replace

it with an airbag simulator from the simulator kit.

Reconnect the battery ground.

Rearming the Airbags

WARNING: Carry out the following procedure to

rearm and check the airbags after completing all

work on the vehicles electrical

systems.

Note: The vehicle battery

must be

disconnected within

12

seconds

of switching off

the

ignition

to

avoid the alarm

siren sounding.

^. Disconnect the battery ground

lead.

Allow a

minimum of one minute delay for the back-up

power supply to discharge.

2.

Removethedriverssideairbagsimulatorand replace

it with the drivers airbag module. Secure the airbag

module with the two captive torx screws.

3. Remove the passengers side airbag simulator and

replace it with the passenger side airbag module.

Secure the module with four nuts and washers.

Close the passenger side airbag door.

4.

Reconnect the battery ground.

5. Switch on the ignition and check for correct

indications from the SRS/AIRBAG warning light.

TheSRS/AIRBAC lamp should come on after

a

brief

delay and remain on for approximately six seconds

during the airbag system self check. The lamp will

extinguish upon satisfactory completion of the self

check, or will flash a diagnostic code if an airbag

system fault is detected. Continuous illumination of

the warning lamp may indicate a seatbelt

pretensioner fault

Note:

Reset the

clock and window

ECUs

on completion.

6-80 September 1996

Page 199 of 421

"^p

Electrics

Airbag System

No Airbag Warning Lamp

I

noperative lamp, lamp ci rcu it or no ign ition voltage

to the diagnostics module

Normal Operation

The airbag warning lamp is designed to illuminate

for approximately six seconds when the ignition is

switched

on.

This period

is

allocated for satisfactory

performance of the airbag system self test.

Note: The a irbag warning lamp is

driven

by

the instrument

pack and not directly by the airbag diagnostic module.

The airbag diagnostic module requires an ignition

supply to pin

1

to energise the airbag warning lamp

circuit. If the warning lamp circuit is open, or the

diagnostic module does not receive an ignition

voltageatpini, the warning lamp will not illuminate.

Open circuit in the warning lamp supply, in

conjunction with another system fault, will cause

the diagnostic module to emit five tones every 30

minutes while the ignition is switched on. Repair

the faulty circuit before further diagnosis.

Note:

The

diagnostic module will not emit

the

five tone

signal if the warning lamp

is

open circuit and

there

is no

system

fault.

Possible Causes

Defective airbag warning lamp

Faulty wiring in the airbag warning lamp circuit

Loss of ignition voltage at diagnostic module pin 1.

Loss of ground at diagnostic module pin 3

Instrument pack fault

Fault Analysis

WARNING: Read and adhere to all warnings and

safety procedures at the start of this section when

working on the airbag

systent.

1.

Remove the instrument pack and check the airbag

warning lamp.

If the lamp is good, go to step 2.

If the lamp is defective, replace it, switch on the

ignition and check that the lamp is now on for

approximately six seconds after ignition on.

2.

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

9.

Connect the PDU. Switch on the ignition. Measure

the 12V ignition supply voltage from airbag

diagnostic connector pin

1 -1

{+) to chassis ground.

If ignition voltage is present, go to step 6. If ignition

voltage is not present, go to step 4.

Checkfuse F15passengersidefuseboxRHDorF17

passenger side fusebox LHD (Ignition supply to the

diagnostic module pin

1

-1). If the fuse is good, go

to step 5. If the fuse is replaced, go to step 6.

Check for an open circuit on the YW wire from fuse

F15 passenger sidefusebox(F17 LHD)todiagnostic

module pin 1-1. If continuity is good, isolate the

fault in the 12V supply to fuse Fl 5 (Fl 7) and then

go to step 9.

Measure the voltage from diagnostic module pin

1

-

1 to diagnostic module pin 1-3. If 12V is not

present, isolate and service the open circuit in the

diagnostic module ground to pin 1-3. Then go to

step 7.

Switch the ignition off. Set up to measure the

voltage from DM pin

1

-4 to DM pin

1

-5 during the

first six seconds after ignition on.

Switch on the ignition, the warning light signal to

the instrument pack should switch for six seconds

after a brief delay.

If the signal does not switch, the diagnostic module

is

fau Ity. Replace the modu

le,

switch on the ign ition

and check that the airbag warning lamp does light

for six seconds after ignition on.

If the signal does switch for approx. six seconds

after ignition on, the fault is in the instrument pack

or wiring, go to step 8.

Check continuity of the YW wire from diagnostic

module pin

1

-4 to instrument pack 16 way plug pin

2.

If continuity is good, service the instrument pack

and then retesttoensure correct indication from the

airbag warning lamp at ignition on.

If continuity is defective, service the wire and then

retest to ensure correct indication from the airbag

warning lamp at ignition on.

Disconnect the PDU, and rearm the airbags

(6.4.21.4). Switch on the ignition and check for

correct indications from the airbag warning lamp.

September 1996 6-83

Page 200 of 421

Electrics

Airbag System [EE:^^^?

Continuous Airbag Warning Lamp

Inoperative lamp circuit or no ignition supply to the

airbag diagnostic module.

Normal Operation

The airbag warning lamp is designed to illuminate

for approximately six seconds when the ignition is

switched

on.

This period isallocated for satisfactory

performance of the airbag system self test. If after

this period, the diagnostic module detects a fault

within the system, the airbag warning lamp will

begin to flash.

Note:

The seat

belt

pretensioner system

(if fitted)

shares

the

airbag/SRS

warning lamp with

the airbag

system.

If a

seat belt pretensioner fault is

detected,

the

Airbag/SRS

warning lamp will be permanently illuminated. Ensure

thata permanently lit

lamp

is nottheresultof a pretensioner

fault before carrying out fault analysis on the airbag

system.

Poor connection or disconnection of the diagnostic

module harness may cause a short circuit from DM

pin 4 (warning lamp control) to pin 5 (ground) and

cause permanent illumination ofthe warning lamp.

Faulty operation of the diagnostic module internal

logic may fail to turn off the warning lamp control

circuit and cause constant illumination of the

warning lamp.

Fault Analysis

WARNING: Read and adhere to all warnings and

safety procedures at the start of this section when

working on the airbag system.

1.

Disarm the airbag system and fit airbag simulators

(6.4.21.4). Reconnect the battery.

2.

Inspectthe instrument pack and diagnostic module

connectors for damaged, pushed out pins, proper

location etc.

If any defects are identified, service as necessary.

Retest to ensure correct operation of the airbag

warning light.

If the connector condition and security are good,

reconnect the connectors and go to step 3.

5.

Connect the PDU to the upper diagnostic socket

and monitorthe airbag warning lamp

signal.

Switch

on the ignition.

If the signal is permanently low, suspect a short

circuit to ground on the airbag warning lamp

control line within the diagnostic module or from

diagnostic module pin

1

-4 to earth. Co to step 4.

If the signal switches low for six seconds after

ignition on but the airbag warning lamp is

permanently illuminated, suspect a fault in the

output side of the instrument pack to the airbag

warning lamp.

Disconnect diagnostic module plug 1 (slate) and

withdraw the plastic locking wedge to prevent

shorts to other circuits. Check continuity from pin

1-1 to ground.

If a short circuit to ground is detected, service the

wiring

as

necessary. Replacethe locking

wedge,

re

insert the connector. Switch on the ignition and

check that the airbag warning lamp signal atpin 1-

4 goes high six seconds after switching on the

ignition and that the warning lamp extinguishes.

If no short circuitto ground isdetected,thediagnostic

module is faulty. Replace the diagnostic module.

Switch on the ignition and check that the airbag

warning lamp signal at pin

1

-4 goes high six seconds

after switching on the ignition and that the warning

lamp extinguishes.

Switch off the ignition. Disconnect the battery.

Rearm the airbags (6.4.21.4). Switch on the

ign

ition

and check for correct indications from the airbag

warning lamp.

6-84 September 1996

Page 215 of 421

in:[M3^?

Electrics

Airbag System

Airbag DM Fault Code 52

Back-up power supply - voltage boost fault.

Normal Operation

A back-up power supply consisting of a capacitor

and voltage booster is contained within the

diagnostic module. The voltage booster charges

the capacitor to 24 ±

1

volt when the ignition is on.

The back-up power supply is connected to

diagnostic module pin 1-9 via a diode. Since the

resistance of pin 1-9 to ground is infinite, the

capacitor has no discharge path and the back-up

supply

is

maintained ata high

voltage.

Thediagnostic

module monitors this voltage and will flag a code

52 if a minimum of 23V is not achieved within 45

seconds of switching on the ignition.

Possible Causes

Low back-up supply voltage may be caused by:

• Partial or total short circuit of pin 1-9 to ground.

• Boost circuit failure within the diagnostic

module.

Fault Analysis

1.

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

2.

Disconnect the diagnostic module. Check for a

partial or permanent short circuit to ground from

diagnostic module harness connector pin 1-9.

If no short circuit is detected, go to step 3.

If a short circuit is detected, service the wiring as

necessary. Reconnectthediagnostic module. Clear

the code 52. Rearm the airbags.

3. Using a high resistance digital multimeter, set up to

measure the voltage from diagnostic module pin

1

-

9 to ground. Switch on the ignition.

If the voltage is in the range 24 ± 1 volt, the back

up power supply is good. Suspect an intermittent

short circuit to ground and recheck the output

circuit from pin 1-9.

Ifthe voltage is below the range 24 ±

1

volt, replace

the diagnostic module.

4.

Rearm the airbags (6.4.21.4).

Airbag DM Fault Code 53

internal diagnostic module failure.

Normal Operation

The diagnostic module constantly measures the

voltage on pins

1

-2,

1

-6,

1 -11

and

1

-12. It should

be 10

±1

volt. The voltage is regulated by a resistor

within the diagnostic module and the resistance to

ground ofpins

1-2,6,11

and 12 should be infinite.

The resistance across the normally open contacts of

the crash sensors should also be infinite. If the

resistance of the pins to ground or across the crash

sensors becomes measurable, the voltage wi

11

drop.

At between 5V and lOVthe diagnostic module will

recognise an internal voltage regulation failure and

flag a code 53 fault and the airbag warning light will

be illuminated.

Notes: A dead short to ground in the

crash

sensor circuits

will drop the voltage below 5V and the diagnostic

module will flag

a

code

14

fault.

The

diagnostic module

performs several self-tests as

the

ignition is switched on. If it fails any

test,

fault code 53

will be flagged.

Possible Causes

• A decrease in resistance from infinity between

the primary crash sensor circuits and ground.

• An internal diagnostic module self-test failure.

Fault Analysis

1.

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

2.

Check each of pins 1-2, 1-6, 1-11 and 1-12 for

continuity to ground.

If resistance of all circuits is infinity, go to step 3.

If any resistance other than infinity is detected,

service the circuit wiring as necessary. Reconnect

all connectors and switch on and clear all fault

codes.

Switch off the ignition and then switch on again.

Check that the airbag warning lamp comes on at

'ignition on' and extinguishes after approximately

six seconds on satisfactory completion of the airbag

system self-check.

3. Rearm the airbags (6.4.21.4).

September 1996 6-99

Page 216 of 421

Electrics

Airbag System [n:M^^^?

Airbag DM Fault Code 99

Rapid continuous flashing of the airbag warning

light - Both front crash sensors disconnected.

Normal Operation

Each crash sensor has three wires. Two deploy the

airbag and monitor the sensors connection to the

diagnostic monitor. The third wire monitors the

mounting of the sensor to the vehicle bodywork. A

code99isdeclaredifbothsensorsaredisconnected

and not properly grounded.

Fault Analysis

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

Check continuity of all circuits listed below and

service as necessary.

LH Crash Sensor

DM Pin

1-6

1-12

2-9

RH Crash Sensor

DM Pin

1-2

1-11

2-8

Sensor Pin

1

2

4

Sensor Pin

1

2

4

Also check for correct grounding of the diagnostic

module and the sensor cases.

Reconnect all connectors, clear fault code 99.

Switch off the ignition and then switch on again.

Check that the airbag warning lamp comes on at

'ignition on' and extinguishes after approximately

six seconds on satisfactory completion of the airbag

system self-check.

Rearm the airbags (6.4.21.4).

6-100 September 1996

Page 218 of 421

Electrics //—>> ^^^^^^ • >^

Seat Belt Pretensioner I'•—

-"i-t.

^-^

JH—X

System Fault Strategy

No single fault may cause an unexpected deployment. The controller will supervise the pretensioner electrical

system in order to warn the driver should a fault occur. Any fault detected by the self diagnostics shall cause the SRS/

airbag warning lamp to be activated, and in some cases the pretensioner control module to enter shutdown mode.

In shutdown mode, the energy of the reserve capacitors shall be discharged to avoid unintended deployment.

As the ignition is switched on, the pretensioner controller will directly discharge the energy capacitors. When the

start up procedure is completed without detecting any faults, the DC/DC converter will be activated allowing the

capacitors to be charged. The system shall be fully active within

11

secondsafterswitchingthe ignition on providing

that no faults are detected.

All system faults monitored by the controller are filtered in software to avoid fault warnings due to transient electrical

disturbances.

If a fault which could lead to inadvertent deployment is detected by the microprocessor, a software shutdown will

be generated. However, a leakage to an earth or positive potential in the pretensioner output circuit shall not cause

the controller to enter shutdown mode.

If a permanent short of the ignition transistor occurs, a shutdown shall be generated by the hardware circuit. If a

shutdown occurs, the system shall be unable to deploy the pretensioner after a period of 3 seconds (i.e. capacitors

discharged to under minimum deployment voltage).

WARNING: To avoid the possibility of personal injury caused by accidental deployment of the pretensioner,

disconnect the vehicle battery and wait at least 10 minutes for all voltages to fully discharge before working on

the pretensioner

system.

This

covers the possibility of the normal capacitor discharge circuits being inoperative

and failing to discharge the capacitor when instructed to do so.

WA RNING: Do not make any electrical measurements on the pretensioner squib. Electrical measurement devices

can induce sufficient voltage to cause unintentional firing of the pretensioner assembly

If the module enters shutdown mode, all diagnostic functions are stopped, but the communications link remains

active.

A fault code corresponding to the cause of the problem may be read by the PDU.

Assembly/Removal/Service I nstructions

WARNING: In the event of a vehicle impact where the airbags and the seatbelt pretensioner (if fitted) are

deployed, the following actions MUST be performed:

Check the condition of the

seatbelts,

steering wheel, steering column, all connections to airbags, and the column

switchgear connectors for integrity and damage. If in any doubt, replace suspected parts for new parts.

Replace both crash

sensors,

the safing sensor and the seatbelt pretensioner module (if fitted).

On completion of all repair procedures, switch on the ignition and check that the Airbag/SRS warning light

comes

on when the ignition is switched on and extinguishes after approximately six seconds indicating satisfactory

completion of the airbag and pretensioner

system

self

tests.

Vehicles for the North American, Australian and Japanese markets are fitted with drivers seat belt pretensioner

systems and are fitted with a shorting plug in the yellow connector adjacent to the pretensioner control module.

Vehicles for other markets do not have drivers seat belt pretensioners fitted but have a blanking plug in the yellow

connector adjacent to the pretensioner control module.

6-102 September 1996

Page 229 of 421

O" D^?

Body and Trim

Contents

Contents

Body and Trim

Body Repair

Potential Risks

Precautions

General Repair Notes

Steel Body Parts - Repair, Remove and Replace

RTM Body Parts

Body Panel and Trim Removal

Front Apron

Front Undertray

Wheel Arch Liners

Side Sills (top fixings)

Side Sills (bottom fixings)

Rear Bumper

Doors

Door Liners

Door Liner (components)

Steering Wheel

Column Switches

Instrument Panel (surround)

Instrument Panel

Facia Underscuttles

Glove Box

Facia Mountings (1)

Facia Mountings (2)

Console Instruments

Radio

Front Seats

Ashtray

Centre Console

Seat ECU Covers

Rear Console

Rear Seats and C Post Trim

Quarter Panels, B Post Panels, Parcel Shelf

Headlining

Roof System Description and Repair Procedures

Vol ante Roof

Roof and Rear Quarter Light Control

Roof Component Location

Roof Control System

9.0.02.1

Roof Removal/Replacement

9.0.02.3

Roof Hydrailic Control System

9.0.02.5

Bleeding the Roof Hydraulic System

9.1.01.1

Rear Quarter Window Renewal

9.1.01.2

Rear Quarter Glass Adjustment

9.1.01.4

Rear Quarter Window Lift Motor - LH

9.1.01.5

Rear Quarter Window Lift Motor - RH

Roof Sealing and Wind Noise

9.2.01.5

'A' Post/Header Sealing and Lock Adj

9.2.01.6

Roof Seals - Adjustment

9.2.01.7

Cheater Plate Seals - Adjust/Renew

9.2.01.8

Door Glass Adjustment

Alcantara Cleaning

7-1

7-2

7-2

7-3

7-3

7-4

7-5

7-6

Sheet 1

Sheet 2

Sheet 3

Sheet 4

Sheet 5

Sheet 6

Sheet 7

Sheet 8

Sheet 9

Sheet 10

Sheet 11

Sheet 12

Sheet 13

Sheet 14

Sheet 15

Sheet 16

Sheet 17

Sheet 18

Sheet 19

Sheet 20

Sheet 21

Sheet 22

Sheet 23

Sheet 24

Sheet 25

Sheet 26

Sheet 27

7-7

7-7

7-8

7-9

7-10

7-11

7-12

7-13

7-14

7-15

7-16

7-17

7-17

7-18

7-19

7-20

7-21

May 1996 7-1