light ASTON MARTIN DB7 1997 Service Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 322 of 421

=2?

Air Conditioning

System Checking with the Manifold Gauge Set

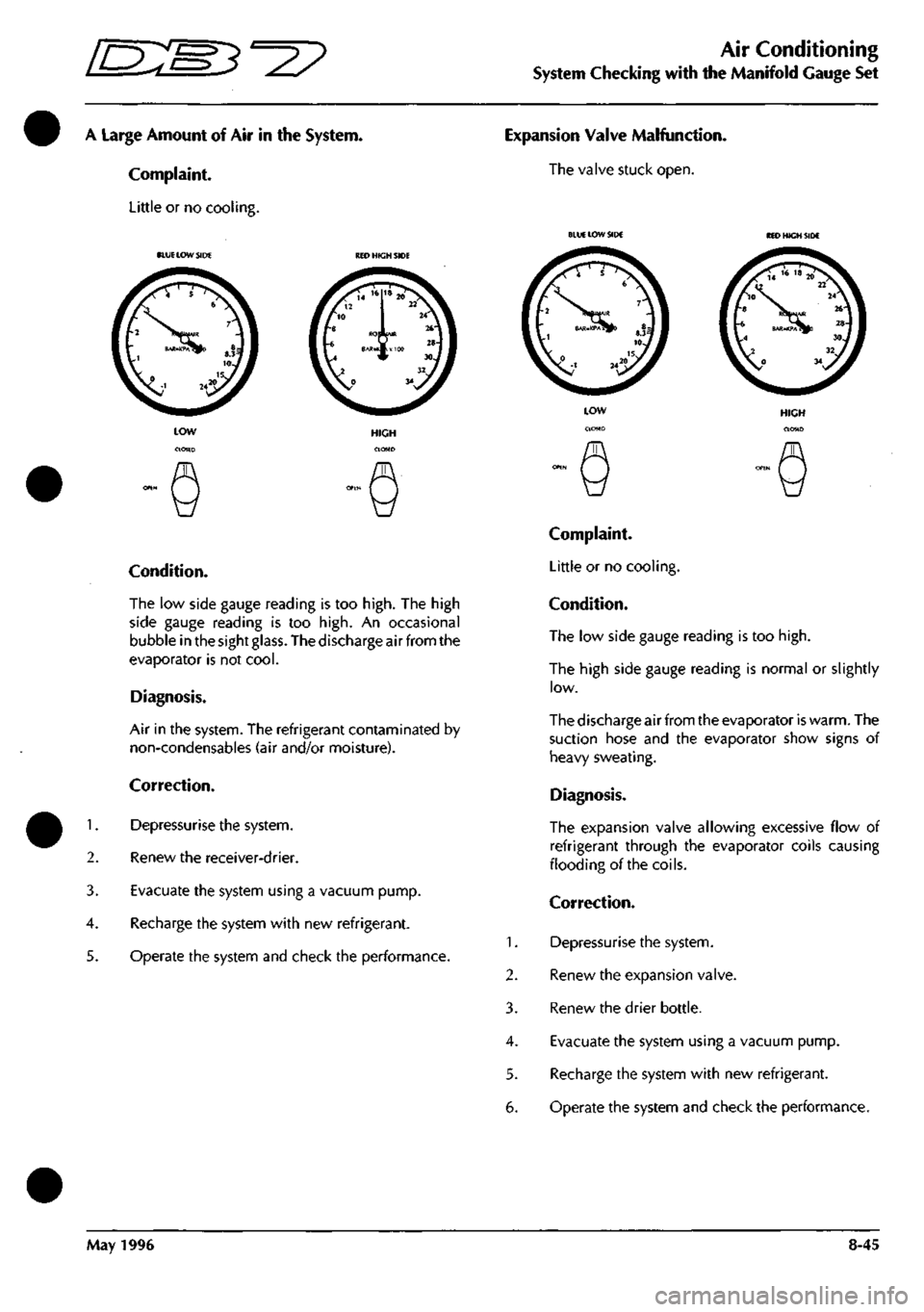

A Large Amount of Air in the System.

Complaint.

Little or no cooling.

1.

2.

3.

4.

5.

BLUE

LOW SIDE RED HIGH SIDE

Condition.

The low side gauge reading is too

high.

The high

side gauge reading is too

high.

An occasional

bubble in the sight

glass.

The discharge air from the

evaporator is not

cool.

Diagnosis.

Air in the system. The refrigerant contaminated by

non-condensables (air and/or moisture).

Correction.

Depressurise the system.

Renew the receiver-drier.

Evacuate the system using a vacuum pump.

Recharge the system with new refrigerant.

Operate the system and check the performance.

Expansion Valve Malfunction.

The valve stuck open.

1.

2.

3.

4.

5.

6.

BLUE LOW SIDE

HIGH

Complaint.

Little or no cooling.

Condition.

The low side gauge reading is too

high.

The high side gauge reading is normal or slightly

low.

The discharge air from the evaporator is warm. The

suction hose and the evaporator show signs of

heavy sweating.

Diagnosis.

The expansion valve allowing excessive flow of

refrigerant through the evaporator coils causing

flooding of the coils.

Correction.

Depressurise the system.

Renew the expansion valve.

Renew the drier bottle.

Evacuate the system using a vacuum pump.

Recharge the system with new refrigerant.

Operate the system and check the performance.

May 1996 8-45

Page 323 of 421

Air Conditioning

System Checking with the Manifold Gauge Set ^^?

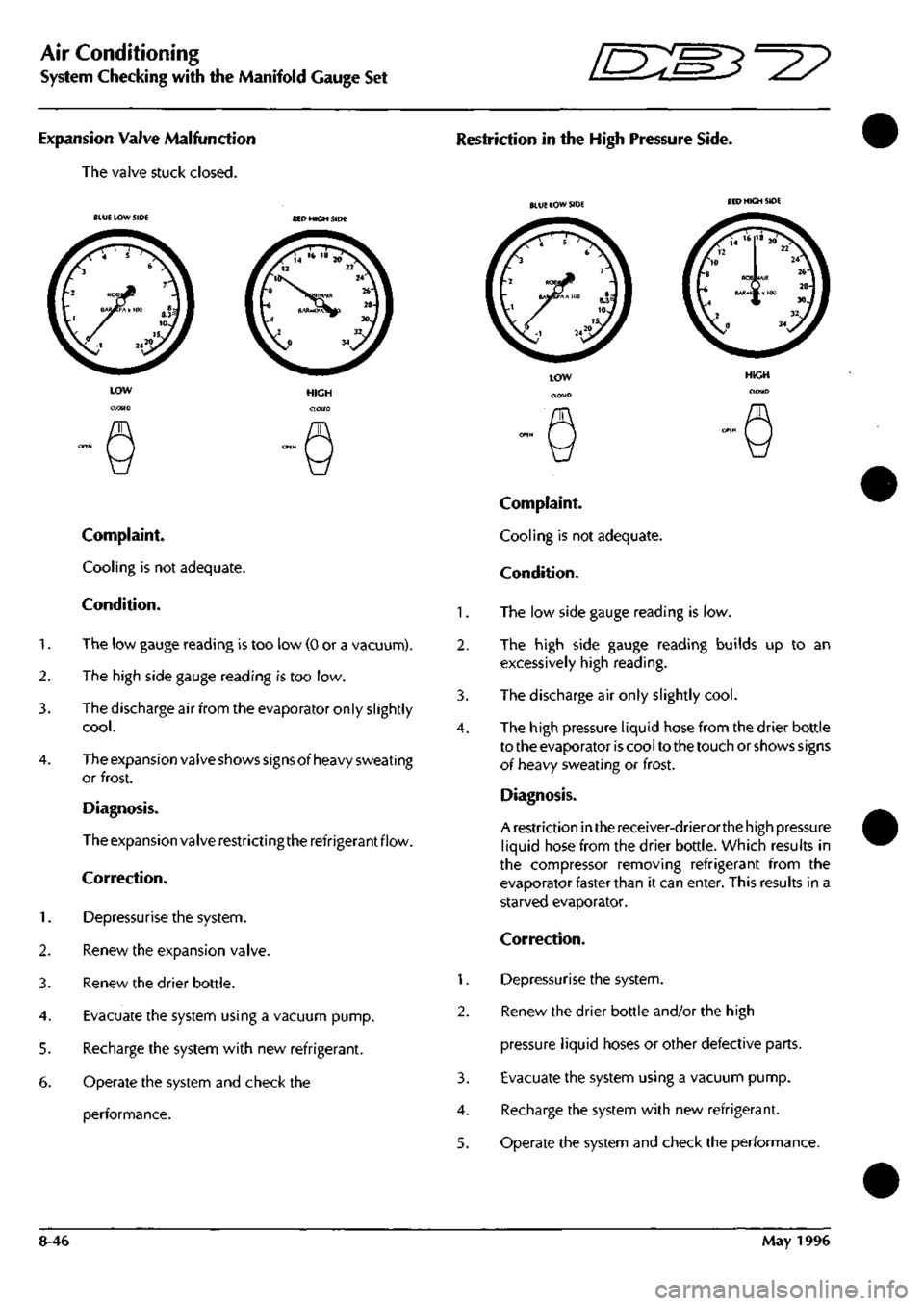

Expansion Valve Malfunction

The valve stuck closed.

Restriction in the High Pressure Side.

BLUE LOW SIDE SED HIGH SIDE

Complaint.

Cooling is not adequate.

Condition.

1.

The low gauge reading is too low (0 or a vacuunn).

2.

The high side gauge reading is too low.

3. The discharge air from the evaporator only slightly

cool.

4.

The expansion valve shows signs of heavy sweating

or frost.

Diagnosis.

The expansion valve restrictingthe refrigerant flow.

Correction.

1.

Depressurise the system.

2.

Renew the expansion valve.

3. Renew the drier bottle.

4.

Evacuate the system using a vacuum pump.

5. Recharge the system with new refrigerant.

6. Operate the system and check the

performance.

1.

2.

3.

4.

1.

2.

3.

4.

5.

BLUE LOW SIDE

Complaint.

Cooling is not adequate.

Condition.

The low side gauge reading is low.

The high side gauge reading builds up to an

excessively high reading.

The discharge air only slightly

cool.

The high pressure liquid hose from the drier bottle

to the evaporator is cool to the touch or shows signs

oi heavy sweating or frost.

Diagnosis.

A restriction in the receiver-drier orthe high pressure

liquid hose from the drier bottle. Which results in

the compressor removing refrigerant from the

evaporator faster than it can enter. This results in a

starved evaporator.

Correction.

Depressurise the system.

Renew the drier bottle and/or the high

pressure liquid hoses or other defective parts.

Evacuate the system using a vacuum pump.

Recharge the system with new refrigerant.

Operate the system and check the performance.

8-46 May 1996

Page 328 of 421

^?

Air Conditioning Repair Procedures

Compressor Removal

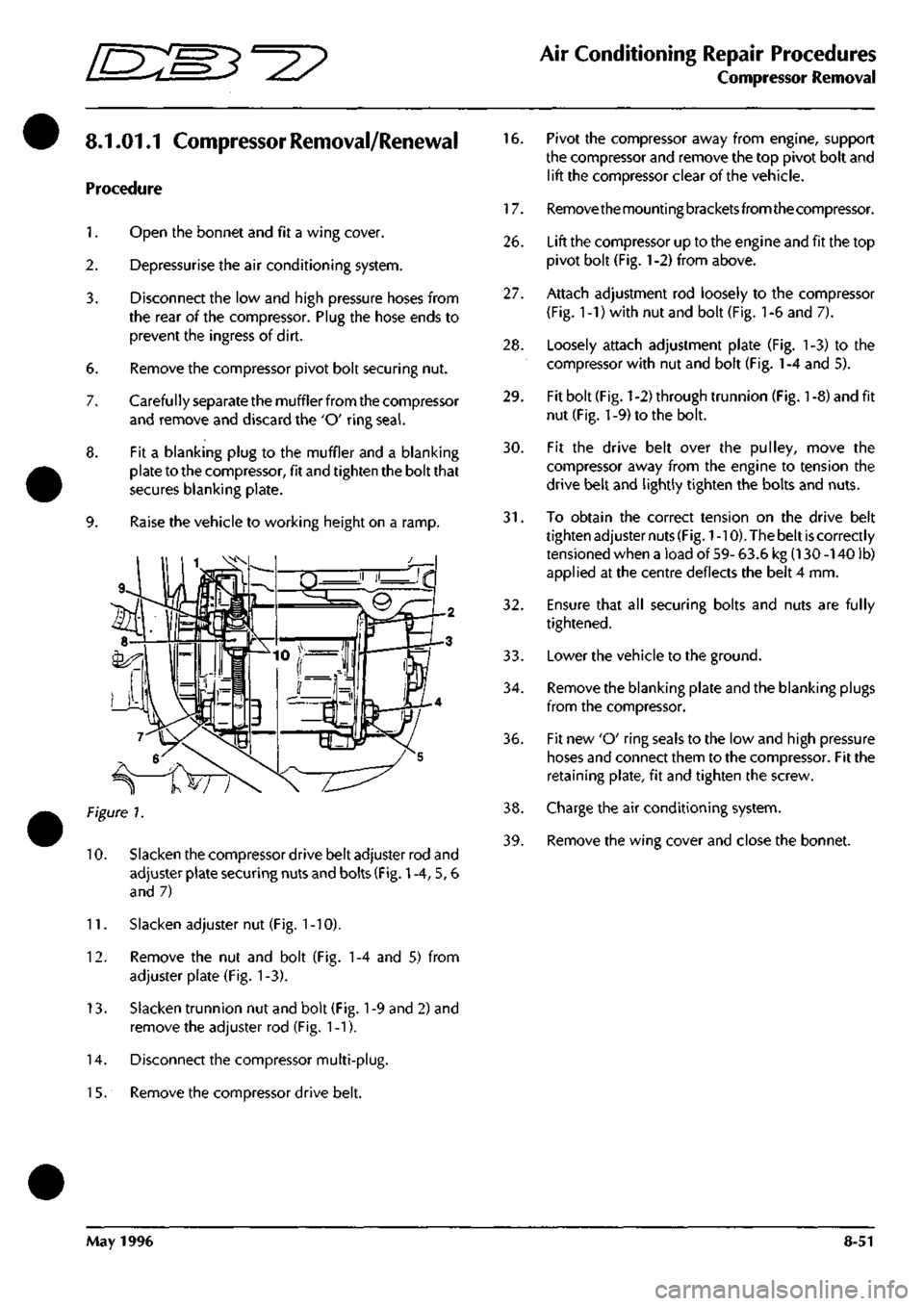

8.1.01.1 Compressor Removal/Renewal

Procedure

1.

Open the bonnet and fit a wing cover.

2.

Depressurise the air conditioning system.

3.

6.

7.

8.

9.

Disconnect the low and high pressure hoses from

the rear of the compressor. Plug the hose ends to

prevent the ingress of dirt.

Remove the compressor pivot bolt securing nut.

Carefully separate the muffler from the compressor

and remove and discard the 'O' ring

seal.

Fit a blanking plug to the muffler and a blanking

plate to the compressor, fit and tighten the bolt that

secures blanking plate.

Raise the vehicle to working height on a ramp.

Figure 7.

10.

Slacken the compressor drive belt adjuster rod and

adjuster plate securing nuts and bolts (Fig.

1

-4, 5, 6

and 7)

11.

Slacken adjuster nut (Fig.

1

-10).

12.

Remove the nut and bolt (Fig. 1-4 and 5) from

adjuster plate (Fig. 1-3).

13.

Slacken trunnion nut and bolt (Fig.

1

-9 and 2) and

remove the adjuster rod (Fig. 1-1).

14.

Disconnect the compressor multi-plug.

1

5. Remove the compressor drive belt.

16.

Pivot the compressor away from engine, support

the compressor and remove the top pivot bolt and

lift the compressor clear of the vehicle.

17.

Removethemountingbracketsfromthecompressor.

26.

Lift the compressor up to the engine and fit the top

pivot bolt (Fig.

1

-2) from above.

27.

Attach adjustment rod loosely to the compressor

(Fig.

1

-1) with nut and bolt (Fig.

1

-6 and 7).

28.

Loosely attach adjustment plate (Fig. 1-3) to the

compressor with nut and bolt (Fig.

1

-4 and 5).

29.

Fit bolt (Fig.

1

-2) through trunnion (Fig.

1

-8) and fit

nut (Fig. 1-9) to the bolt.

30.

Fit the drive belt over the pulley, move the

compressor away from the engine to tension the

drive belt and lightly tighten the bolts and nuts.

31.

To obtain the correct tension on the drive belt

tighten adjuster nuts

(Fig.

1

-10). The belt

is

correctly

tensioned when a load of 59- 63.6 kg (130 -140 lb)

applied at the centre deflects the belt 4 mm.

32.

Ensure that all securing bolts and nuts are fully

tightened.

33.

Lowerthe vehicle to the ground.

34.

Remove the blanking plate and the blanking plugs

from the compressor.

36.

Fit new 'O' ring seals to the low and high pressure

hoses and connect them to the compressor. Fit the

retaining plate, fit and tighten the screw.

38.

Charge the air conditioning system.

39.

Remove the wing cover and close the bonnet.

May 1996 8-51

Page 353 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions E:MB^^?

Introduction The Aston Martin Diagnostic System

This guide contains instructions for the installation

of the Portable Diagnostic Unit hardware in Aston

Martin Dealer workshops. To achieve maxinnum

benefit from the system, please follow the

instructions carefully. The following System

Diagram shows the principal system components

and panel details.

This introduction briefly describes the system and

its capabilities. This is followed by the Installation

and Power-Up procedures which give detailed

instruaions on how to start the system and access

the self-contained Interactive

Training

Programme.

The subsequent sections detail the fault diagnosis

and maintenance procedures.

WARNING:

The equipment must

only

be used by

trained

personnel.

Care should

be taken to use the

equipment in accordance with the operating

procedures.

Observe

all safety

warnings

in this

guide.

If any part of

the system is damaged do not

use it. Call your local CenRad

Service

Centre

immediately

for a

substitute

part.

Refer to

'Parts

Ordering'.

The Aston Martin Diagnostic System is a new

generation diagnostic

tool

which fulfils

a

number of

functions in aiding the technician to quickly and

accurately locate faults. The heart of the system is

the Portable Diagnostic

Unit,

a

lightweight powerful

computer/measurement system providing a step-

by-step user friendly interface for the technician.

PDU functions include:

Data Logger - The ability to monitor and record

control module signals even whilst the vehicle is

being driven.

On-Line Help-Containing detailed descriptions in

the

operation

ofthevehicleselectroniccomponents.

Vehicle Setup - The ability to setup various

adjustable parameters to their optimum settings.

Diagnostic Trouble Codes - The ability to extract

recorded fault information from the DB7's control

modules.

Each of

these

funaions is described in detail in the

PDU Users Guide.

WARNING: If

the system is used to measure high

voltages,

these voltages can appear on the pins of

other

connectors in

the

system.

Ensure

that socket

covers

are

fitted

on

unused

sockets.

Ensure

that all

connections

are

made

prior to

applying the high

voltage to

the

probes.

Do not

leave the equipment

unattended

in

this

state.

The maximum

voltage

that may be applied

between the

test

probes is 150

volts

AC or DC.

Radio Interference Statements

This digital apparatus does not exceed the Class A

limits for radio noiseemissionsfromdigital apparatus

as set

out

in

the radio interference regulations of the

Canadian Department of Communications.

This equipment has been tested and found to

comply with the limits for Class A digital device

pursuant to part 15 of the Federal Communications

Commission (FCC) rules. However, operation in

close proximity to domestic communication

equipment may cause interference. It is the

responsibility of the user to avoid or correct this

condition.

9-2 May 1996

Page 354 of 421

'=^

The Aston Martin Lagonda Diagnostic System

Installation Instructions

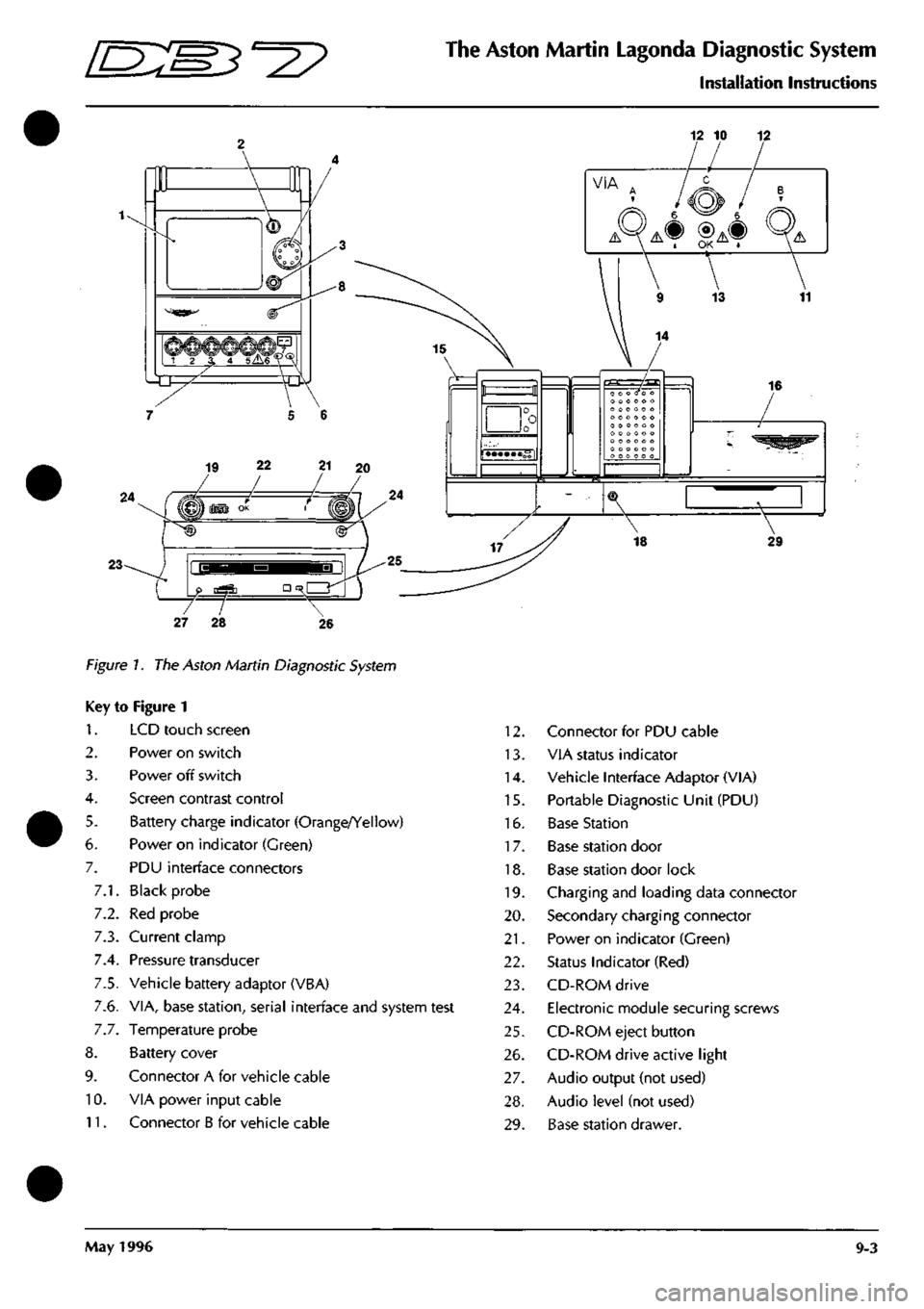

12 10

19 22 21 20

VIA A / /^^>^ I B T

A-XA^I'A® QA

13

16

18 29

Figure 7. The Aston Martin Diagnostic System

Key to Figure 1

1.

2.

3.

4.

5.

6.

7.

7.1.

7.2.

7.3.

7.4.

7.5.

7.6.

7.7.

8.

9.

10.

11.

LCD touch screen

Power on switch

Power off switch

Screen contrast control

Battery charge indicator (Orange/Yellow)

Power on indicator (Green)

PDU interface connectors

Black probe

Red probe

Current clamp

Pressure transducer

Vehicle battery adaptor (VBA)

VIA, base station, serial interface and system test

Temperature probe

Battery cover

Connector A for vehicle cable

VIA power input cable

Connector B for vehicle cable

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

Connector for PDU cable

VIA status indicator

Vehicle Interface Adaptor (VIA)

Portable Diagnostic Unit (PDU)

Base Station

Base station door

Base station door lock

Charging and loading data connector

Secondary charging connector

Power on indicator (Green)

Status Indicator (Red)

CD-ROM drive

Electronic module securing screws

CD-ROM eject button

CD-ROM drive active light

Audio output (not used)

Audio level (not used)

Base station drawer.

May 1996 9-3

Page 355 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions "^P

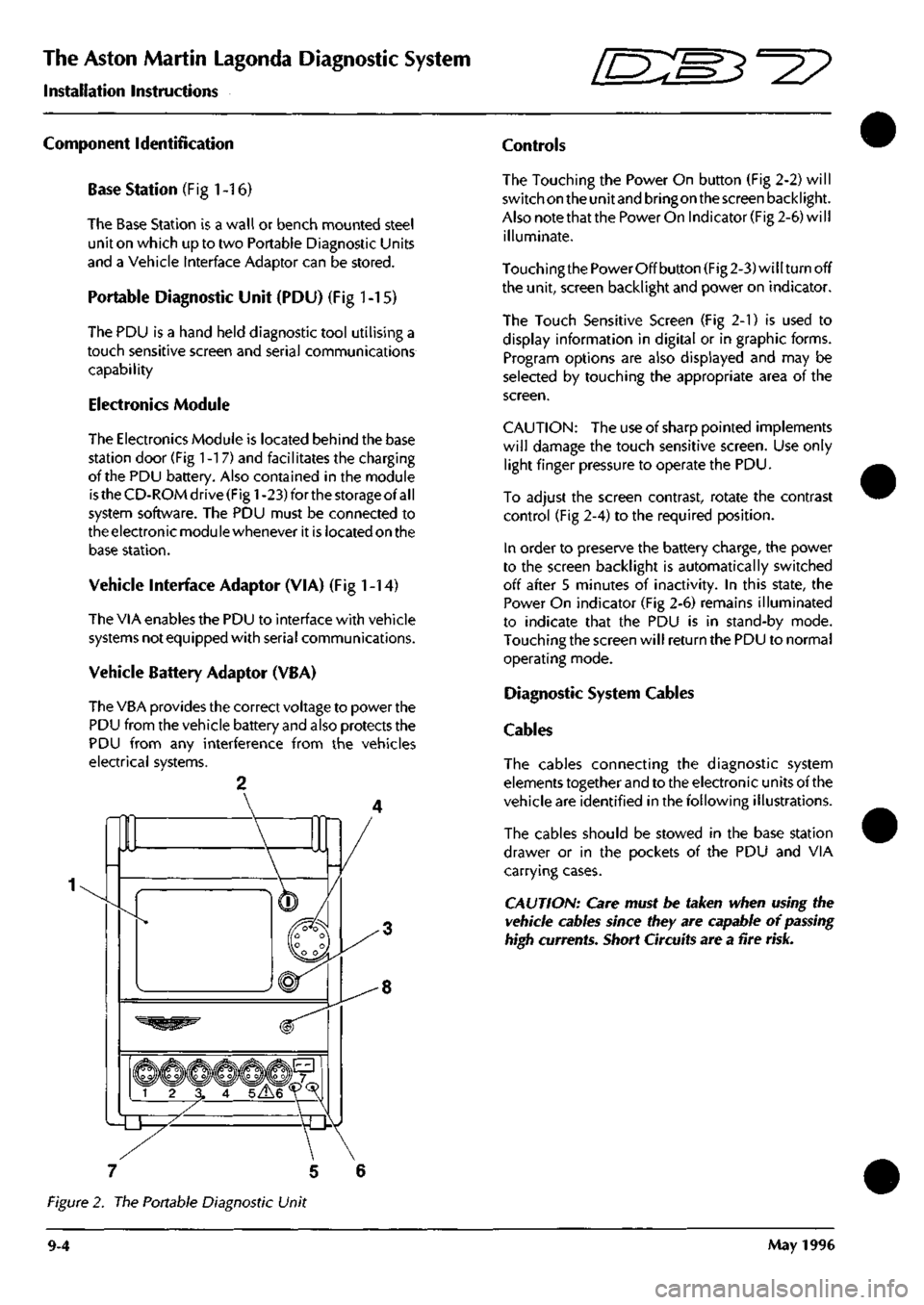

Component Identification

Base Station (Fig

1

-16)

The Base Station is a wall or bench mounted steel

unit on which up to two Portable Diagnostic Units

and a Vehicle Interface Adaptor can be stored.

Portable Diagnostic Unit (PDU) (Fig 1-15)

The PDU is a hand held diagnostic tool utilising a

touch sensitive screen and serial communications

capability

Electronics Module

The Electronics Module is located behind the base

station door (Fig

1

-17) and facilitates the charging

of the PDU battery. Also contained in the module

is

the CD-ROM drive (Fig

1

-23) for the storage of

al I

system software. The PDU must be connected to

the electronic modu le whenever it is located on the

base station.

Vehicle interface Adaptor (VIA) (Fig

1

-14)

The VIA enables the PDU to interface with vehicle

systems not equipped with serial communications.

Vehicle Battery Adaptor (VBA)

The VBA provides the correct voltage to power the

PDU from the vehicle battery and also protects the

PDU from any interference from the vehicles

electrical systems.

Controls

The Touching the Power On button (Fig 2-2) will

switch on the unit and bringon the screen backlight.

Also note that the Power On Indicator (Fig 2-6) will

illuminate.

Touching the Power Off button (Fig 2-3) will turn off

the unit, screen backlight and power on indicator.

The Touch Sensitive Screen (Fig 2-1) is used to

display information in digital or in graphic forms.

Program options are also displayed and may be

selected by touching the appropriate area of the

screen.

CAUTION:

The use of sharp pointed implements

will damage the touch sensitive screen. Use only

light finger pressure to operate the PDU.

To adjust the screen contrast, rotate the contrast

control (Fig 2-4) to the required position.

In order to preserve the battery charge, the power

to the screen backlight is automatically switched

off after 5 minutes of inactivity. In this state, the

Power On indicator (Fig 2-6) remains illuminated

to indicate that the PDU is in stand-by mode.

Touching the screen will return the PDU to normal

operating mode.

Diagnostic System Cables

Cables

The cables connecting the diagnostic system

elements together and to the electronic units of the

vehicle are identified in the following illustrations.

The cables should be stowed in the base station

drawer or in the pockets of the PDU and VIA

carrying cases.

CAUTION: Care must be taken when using the

vehicle cables since they are capable of

passing

high currents. Short Circuits are a fire

risk.

7 5 6

Figure 2. The Portable Diagnostic Unit

9-4 May 1996

Page 360 of 421

^^?

The Aston Martin Lagonda Diagnostic System

I nstal lation I nstructions

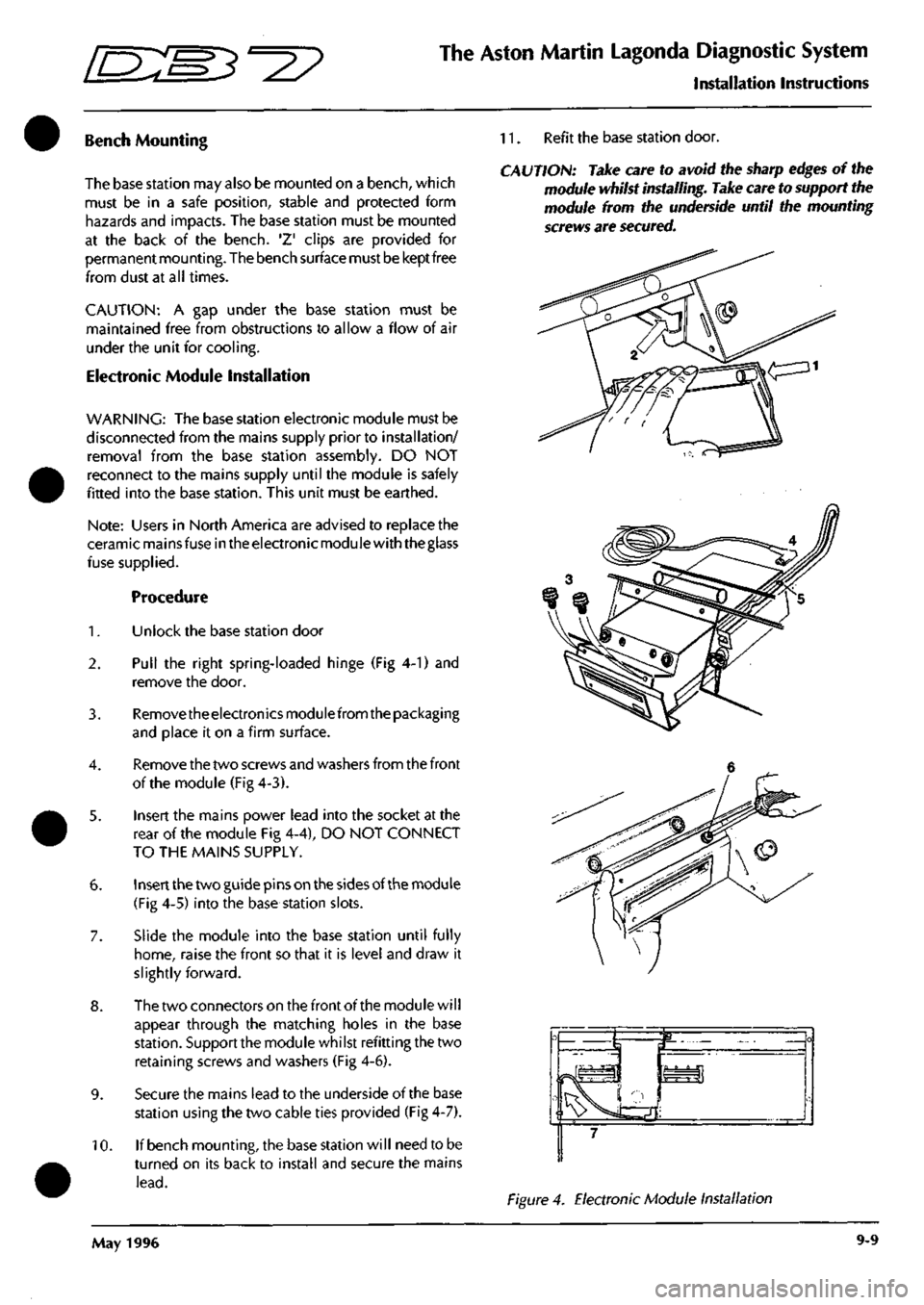

Bench Mounting

The base station may also be mounted on a bench, which

must be in a safe position, stable and protected form

hazards and impacts. The base station must be mounted

at the back of the bench. 'Z' clips are provided for

permanent mounting. The bench surface must be kept free

from dust at all times.

CAUTION:

A gap under the base station must be

maintained free from obstructions to allow a flow of air

under the unit for cooling.

Electronic Module installation

WARNING: The base station electronic module must be

disconnected from the mains supply prior to installation/

removal from the base station assembly. DO NOT

reconnect to the mains supply until the module is safely

fitted into the base station. This unit must be earthed.

Note:

Users in North America are advised to replace the

ceramic mains fuse in the electronic module with theglass

fuse supplied.

Procedure

1.

Unlock the base station door

2.

Pull the right spring-loaded hinge (Fig 4-1) and

remove the door.

3. Removetheelectronicsmodulefrom the packaging

and place it on a firm surface.

4.

Remove the two screws and washers from the front

of the module (Fig 4-3).

5. Insert the mains power lead into the socket at the

rear of the module Fig 4-4), DO NOT CONNECT

TO THE MAINS SUPPLY.

6. Insert the two guide pins on the sides of the module

(Fig 4-5) into the base station slots.

7. Slide the module into the base station until fully

home,

raise the front so that it is level and draw it

slightly forward.

8. The two connectors on the front of the module will

appear through the matching holes in the base

station.

Support the module whilst refitting the two

retaining screws and washers (Fig 4-6).

9. Secure the mains lead to the underside of the base

station using the two cable ties provided (Fig 4-7).

10.

If bench mounting, the base station will need to be

turned on its back to install and secure the mains

lead.

11.

Refit the base station door.

CAUTION: Take care to avoid the sharp edges of the

module whilst installing. Take care to support the

module from the underside until the mounting

screws are secured.

Figure 4. Electronic Module Installation

May 1996 9-9

Page 366 of 421

r^ ' ^ ^ The Aston Martin Lagonda Diagnostic System

Installation Instructions

Finishing the Test

When data analysis is finished, switch off the PDU

and disconnect it from the vehicle. Store the PDU

and cables in the carrying case and refit the case to

the base station.

Connect the PDU to the base station using cable

0064.

The base station will keep the PDU batteries

fully charged at all times (Fig 15).

Figure 15. PDU connected for recharging

Care of the Equipment

CAUTION: With the exception of those parts

referred to in the Servicing and Maintenance

section, there are no user serviceable parts. All

servicing must be carried out by GenRad Service

Centres.

Switch offthe power before cleaningtheequipment.

The Aston Martin Diagnostic System should only

be cleaned using a non-abrasive, mild cleaning

agent. Dust and other particles should be lightly

brushed from the surface before

cleaning.

Cleaning

agent should be applied to a soft lint-free cleaning

cloth and never directly to the unit. Do not soak the

cleaning cloth and take care not to allow cleaning

fluid to enter connectors.

CAUTION: Ifany liquid is spilt on theequipment,

switch off immediately.

Ensure

that the equipment

has

dried out completely before operating it again,

especially in connectors where fluid can lodge.

May 1996 9-15

Page 378 of 421

^^?

The Aston Martin Lagonda Diagnostic System

Users Guide

The Aston Martin Lagonda Diagnostic System

The Aston Martin Lagonda Diagnostic System fulfils a number of functions in aiding the technician to quickly and

accurately locate

faults.

The heart ofthe

system is the

Portable Diagnostic Unit

(PDU),

a

lightweight powerful computer/

measurement system providing a step-by-step user friendly interface for the technician.

September 1996 9-27

Page 379 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide o: "3^^?

PDU Functions

The PDU main menu provides access into the following functions:

Diagnostics

Training

Digital Multimeter

User Self Test

Diagnostics

On selecting'Diagnostics'from the main

menu,

the user will be prompted to enter the features and market specification

of the vehicle to be tested. Use of the diagnostics in each of the above areas is described later in this guide.

Diagnostics Menu - 95 Model Year

Engine

Anti-Lock Braking System

Vlenu - 97 Model Year

Engine Diagnostics

OBD II Scan Tool

Airbag

Seat Belt Pretensioner

•

•

•

•

Transmission

Engine Datalogger

Climate Control

PATS System

Climate Control

Transmission

Anti-Lock Braking System

Security

Digital Multimeter

The Digital Multimeter function provides the capabilityto measure voltage, current, resistance, frequency, pulse width,

pulse period, and duty cycle. These measurements are usually made using the PDU measurement probes. Measurements

may also be made using the module pin selection function on the Teves Mk

II

braking system and on the Air Conditioning

system.

Training

An on-screen programme is provided to train new users in the use of screen icons and in the use of the digital multi

meter and datalogger functions.

User Self Test

In order to prove that the equpment is functioning correctly, a complete user self test is incorporated. The user is directed

to test the PDU and then to progressively connect each part of the PDU system which will be tested by the software.

Any fault identified during the test is notified to the user. If no faults are identified, the user is advised on the correct

functioning of the system.

PDU Power

Power for the PDU is supplied via an internal rechargeable battery pack which can keep the PDU operational for

approximately one hour when disconnected from the base station and the vehicle. In order to preserve PDU battery

charge, power to the screen backlight is automatically cut after five minutes of inactivity. The power ON indicator

remains lit, indicating that the PDU is in 'stand-by' mode. One touch of the screen will restore backlight power.

When connected to the base station, power is supplied to the PDU from the Electronic Module to recharge the PDU

battery pack as necessary.

On 95 MY vehicles, the Vehicle Battery Adaptor (VBA) is used to maintain PDU power.

On 97 MY vehicles, when connected via the MPA to either diagnostic socket on the vehicle, power is supplied via pin

4 (chassis ground) and pin 16 (battery power) to maintain PDU power at all times even when the vehicle ignition is

switched off.

On all model years, when connected to the air conditioning system using the VIA, the vehicle battery adaptor (VBA)

must also be used to maintain PDU power.

9-28 September 1996