light ASTON MARTIN DB7 1997 Repair Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 384 of 421

^27

The Aston Martin Lagonda Diagnostic System

Users Guide

Engine Diagnostics - 97 MY

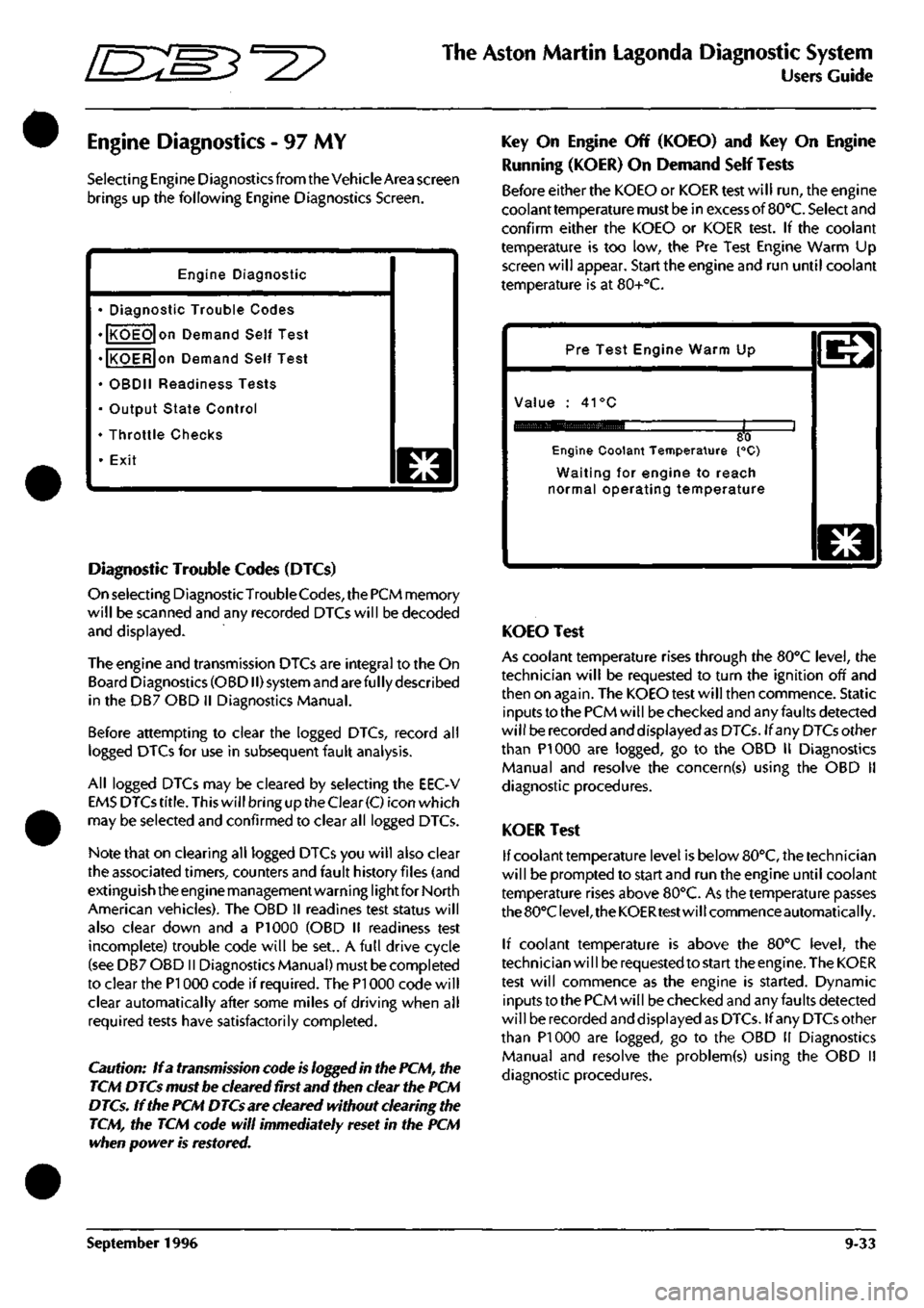

Selecting Engine Diagnostics from the Vehicle Area screen

brings up the following Engine Diagnostics Screen.

Engine Diagnostic

• Diagnostic Trouble Codes

• KOEO on Demand Self Test

• KOER on Demand Self Test

• OBDII Readiness Tests

• Output State Control

• Throttle Checks

• Exit

o

Diagnostic Trouble Codes (DTCs)

On selecting DiagnosticTrouble

Codes,

the PCM memory

will be scanned and any recorded DTCs will be decoded

and displayed.

The engine and transmission DTCs are integral to the On

Board Diagnostics (OBDII) system and are ful ly described

in the DB7 OBD II Diagnostics Manual.

Before attempting to clear the logged DTCs, record all

logged DTCs for use in subsequent fault analysis.

All logged DTCs may be cleared by selecting the EEC-V

EMS DTCs

title.

This will bring up the Clear

(C)

icon which

may be selected and confirmed to clear all logged DTCs.

Note that on clearing all logged DTCs you will also clear

the associated timers, counters and fault history files (and

extinguish the engine management warning lightfor North

American vehicles). The OBD II readines test status will

also clear down and a PI 000 (OBD II readiness test

incomplete) trouble code will be set.. A full drive cycle

(see DB7 OBD II Diagnostics Manual) must be completed

to clear the PI 000 code if required. The PI 000 code will

clear automatically after some miles of driving when all

required tests have satisfactorily completed.

Caution: If a transmission code is logged in the PCM, the

TCM DTCs must be cleared first and then clear the PCM

DTCs. If the PCM DTCs are cleared without clearing the

TCM, the TCM code will immediately reset in the PCM

when power is restored.

Key On Engine Off (KOEO) and Key On Engine

Running (KOER) On Demand Self Tests

Before either the KOEO or KOER test will run, the engine

coolant temperature must be in excess of

BO'C.

Select and

confirm either the KOEO or KOER test. If the coolant

temperature is too low, the Pre Test Engine Warm Up

screen will appear. Start the engine and run until coolant

temperature is at 80+°C.

Pre Test Engine Warm Up

Value : 41°C

80 Engine Coolant Temperature {°C)

Waiting for engine to reach

normal operating temperature

o

KOEO Test

As coolant temperature rises through the BO'C level, the

technician will be requested to turn the ignition off and

then on again. The KOEO test will then commence. Static

inputs to the PCM will be checked and any faults detected

will be recorded and displayed as DTCs. If any DTCs other

than PI 000 are logged, go to the OBD II Diagnostics

Manual and resolve the concern(s) using the OBD 11

diagnostic procedures.

KOER Test

If coolant temperature level is below 80°C, the technician

will be prompted to start and run the engine until coolant

temperature rises above 80°C. As the temperature passes

the 80°C

level,

the KOERtest will commence automatically.

If coolant temperature is above the 80°C level, the

technician wi

11

be requested to start the engine. The KOER

test will commence as the engine is started. Dynamic

inputs to the PCM will be checked and any faults detected

will be recorded and displayed as DTCs. If any DTCs other

than PI 000 are logged, go to the OBD 11 Diagnostics

Manual and resolve the problem(s) using the OBD II

diagnostic procedures.

September 1996 9-33

Page 403 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide [S:S3^2?

The PDU will then check the cable connections. Until all

connections are correct, the PDU will not allow progression

beyond this

screen.

Pressingthe'asterisk'icon and selecting

abort returns the operator to the general screen if an

incorrect system has been chosen.

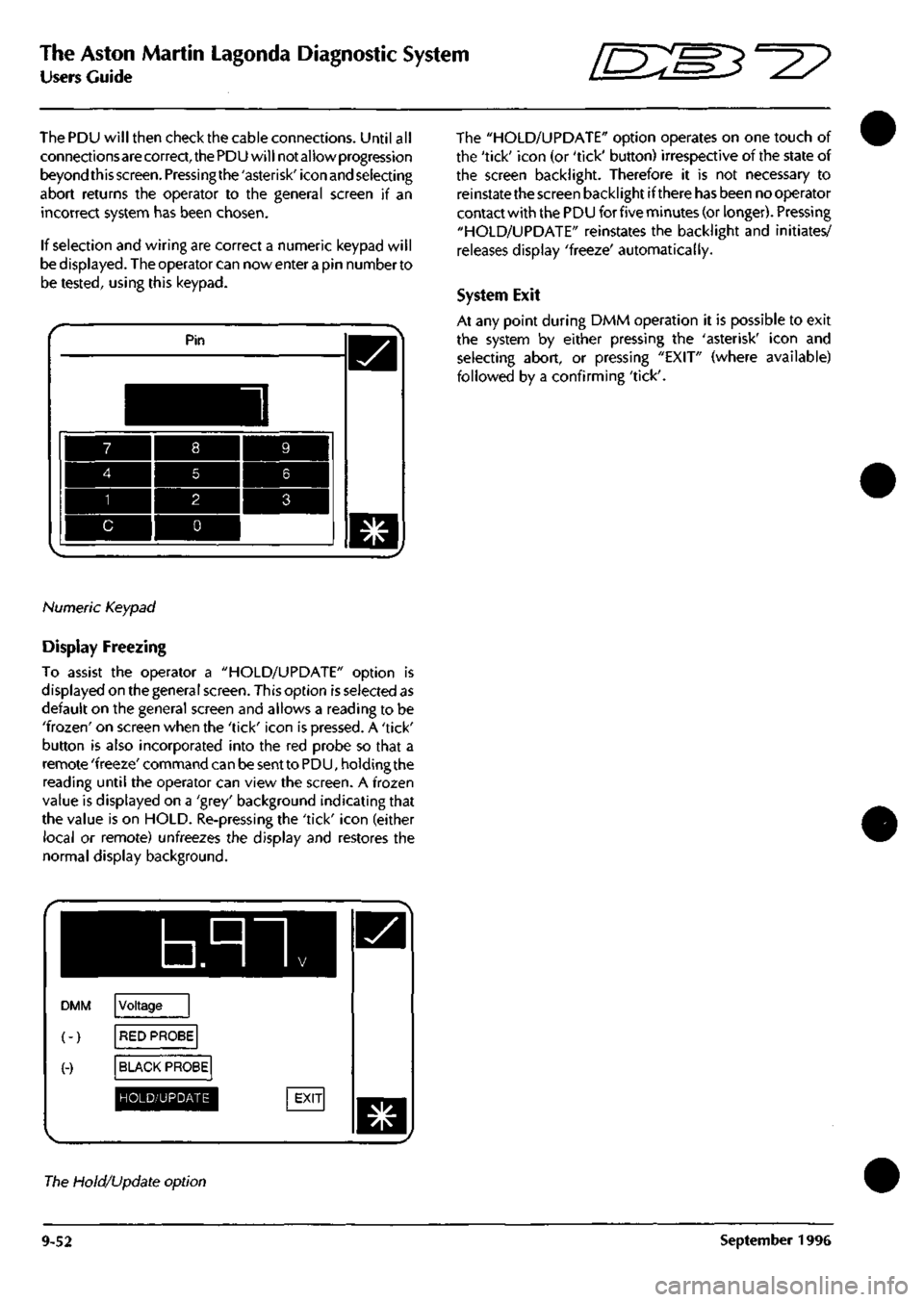

If selection and wiring are correct a numeric keypad will

be displayed. The operator can nowenterapin numberto

be tested, using this keypad.

Pin

Numeric Keypad

Display Freezing

To assist the operator a "HOLD/UPDATE" option is

displayed on the general screen. This option is selected as

default on the general screen and allows a reading to be

'frozen'

on screen when the 'tick' icon is pressed. A 'tick'

button is also incorporated into the red probe so that a

remote 'freeze' command can be sent to PDU, holding the

reading until the operator can view the screen. A frozen

value is displayed on a 'grey' background indicating that

the value is on HOLD. Re-pressing the 'tick' icon (either

local or remote) unfreezes the display and restores the

normal display background.

b.nn

DMM

(-)

(-)

Voltage

RED PROBE

BLACK PROBE

HOLD/UPDATE

The "HOLD/UPDATE" option operates on one touch of

the 'tick' icon (or 'tick' button) irrespective of the state of

the screen backlight. Therefore it is not necessary to

reinstate the screen backlight if there has been no operator

contact with the PDU for five minutes (or longer). Pressing

"HOLD/UPDATE" reinstates the backlight and initiates/

releases display 'freeze' automatically.

System Exit

At any point during DMM operation it is possible to exit

the system by either pressing the 'asterisk' icon and

selecting abort, or pressing "EXIT" (where available)

followed by a confirming 'tick'.

The Hold/Update option

9-52 September 1996

Page 404 of 421

^7

The Aston Martin Lagonda Diagnostic System

Users Guide

Diagnostic Trouble Codes

Introduction

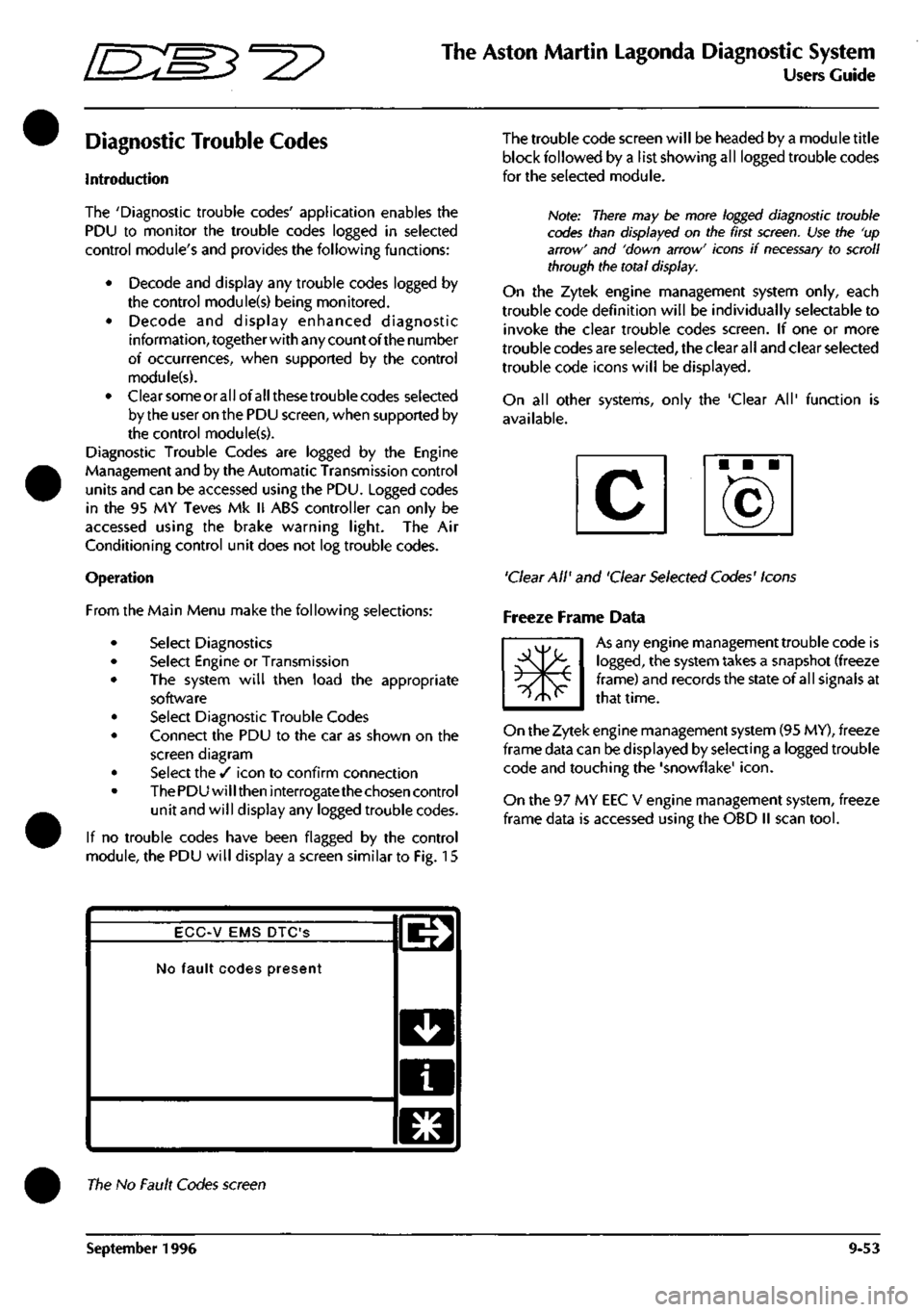

The 'Diagnostic trouble codes' application enables the

PDU to monitor the trouble codes logged in selected

control module's and provides the following functions:

• Decode and display any trouble codes logged by

the control module(s) being monitored.

• Decode and display enhanced diagnostic

information, together with any count of the number

of occurrences, when supported by the control

module(s).

• Clearsomeorallofallthesetroublecodes selected

by the user on the PDU screen, when supported by

the control module(s).

Diagnostic Trouble Codes are logged by the Engine

Management and by the Automatic Transmission control

units and can be accessed using the PDU. Logged codes

in the 95 MY Teves Mk II ABS controller can only be

accessed using the brake warning light. The Air

Conditioning control unit does not log trouble codes.

Operation

From the Main Menu make the following selections:

Select Diagnostics

Select Engine or Transmission

The system will then load the appropriate

software

Select Diagnostic Trouble Codes

Connect the PDU to the car as shown on the

screen diagram

Select the / icon to confirm connection

The PDU will then interrogate the chosen control

unit and will display any logged trouble codes.

If no trouble codes have been flagged by the control

module, the PDU will display a screen similar to Fig. 15

The trouble code screen will be headed by a module title

block followed by a list showing all logged trouble codes

for the seleaed module.

Note: There may be more logged diagnostic trouble

codes than displayed on the first

screen.

Use the 'up

arrow' and 'down arrow' icons if

necessary

to scroll

through the total display.

On the Zytek engine management system only, each

trouble code definition will be individually selectable to

invoke the clear trouble codes screen. If one or more

trouble codes are selected, the clear all and clear selected

trouble code icons will be displayed.

On all other systems, only the 'Clear All' function is

available.

'Clear All' and 'Clear Selected Codes' Icons

Freeze Frame Data

m*

As any engine management trouble code is

logged,

the system takes a snapshot (freeze

frame) and records the state of all signals at

that time.

On the Zytek engine management system (95 MY), freeze

frame data can be displayed by selecting a logged trouble

code and touching the 'snowflake'

icon.

On the 97 MY EEC V engine management system, freeze

frame data is accessed using the OBD II scan

tool.

ECC-V EMS DTC'S

No fault codes present

l^

D

a

El

The No Fault Codes screen

September 1996 9-53

Page 405 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide

•=2?

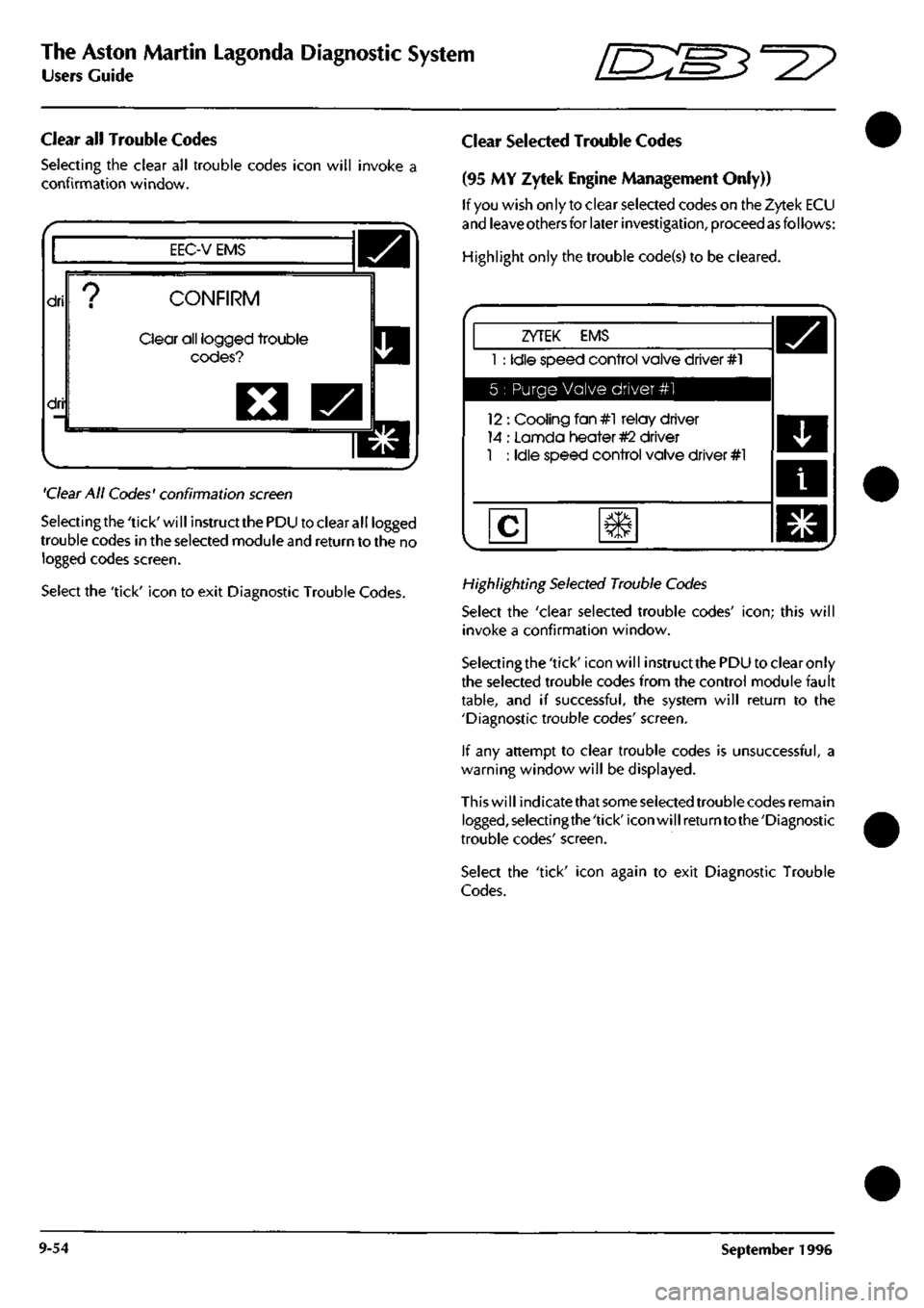

Clear all Trouble Codes

Selecting the clear all trouble codes icon will invoke a

confirmation window.

EEC-V EMS

dri

dri

CONFIRM

Clear all logged trouble

codes?

O

'Clear

All Codes' confirmation

screen

Selectingthe'tick'will instructthePDU to clear all logged

trouble codes in the selected module

and

return to the no

logged codes screen.

Select the 'tick' icon to exit Diagnostic Trouble Codes.

Clear Selected Trouble Codes

(95 MY Zytek Engine Management Only))

If

you

wish only to clear selected codes on the Zytek ECU

and

leave others

for later

investigation,

proceed

as

follows:

Highlight only the trouble code(s) to be cleared.

ZYTEK EMS

1 : Idle speed control valve driver #1

5 : Purge Valve driver #1

12 : Cooling fan#l relay driver

14 : Lannda heater

#2

driver

1 : Idle speed control valve driver #1

Highlighting

Selected

Trouble

Codes

Select the 'clear selected trouble codes'

icon;

this will

invoke a confirmation window.

Selectingthe 'tick' icon will instruct

the

PDU to clear only

the selected trouble codes from the control module fault

table,

and if successful, the system will return to the

'Diagnostic trouble codes' screen.

If any attempt to clear trouble codes is unsuccessful, a

warning window will be displayed.

This will indicatethat

some selected

trouble codes remain

logged,selectingthe'tick'iconwillreturntothe'Diagnostic

trouble codes' screen.

Select the 'tick' icon again to exit Diagnostic Trouble

Codes.

9-54 September 1996

Page 406 of 421

"^I?

The Aston Martin Lagonda Diagnostic System

Users Guide

Datalogger

Introduction

Datalogger is software produced to identify permanent or

intermittent faults on vehicle electronics. The objective of

Datalogger is to provide a view of the vehicle's electrical

behaviour, such that intermittent activity can be recorded

and interpreted quickly and accurately. Running on the

Portable Diagnostic Unit (PDU), the Datalogger

appi ication can captu

re

vehicle information in three ways.

• Serial communications direct from the control unit.

• Parallel communications using the Interface Adaptor.

• Direct signal monitoringusingthemeasurementprobes.

Serial Communication

Serial Communication is a two-wire communication link

between the PDU and most vehicle control modules

providingdigital measurements forconnected components.

The serial communication link allows the tester to

determine the current condition of components connected

to the control module, and to identify any history of faults.

On later vehicles, the PDU is connected to the vehicle

diagnostic sockets via the mu

Iti

Protocol Adaptor (MPA) to

gather serial data from the control modules.

Parallel Communication

The Vehicle Interface Adapter (VIA) provides an interface

between the PDU and the vehicle harnesses for the

acquisition of multiple analogue measurements. The VIA

is

connected between the relevantvehicle control module

and it'sharness connector. Thisallows the PDU to captu re

information from a multitude of channels entering the

control module. This vehicle interface is used with control

modules not equipped with a serial communication link

(Teves Mk II braking system and the air conditioning

system).

Measurement Probes

The measurement probes permit readings to be taken

directly from any connector on the vehicle.

Datalogger Applications

Datalogger may be used to interrogate the following DB7

systems:

• ABS braking system controller

• Engine Management Controller

• Air Conditioning Controller

• Automatic Transmission Controller

• Passive Anti Theft (97 MY)

• Security System (97 MY)

Using the Datalogger

Configure the vehicle to the normal operating conditions

for the system under test.

From the PDU main menu screen:

Highlight 'Diagnostics'.

Press the 'tick' icon to confirm the selection.

Enter the Transmission Type and confirm the selection.

Select the Vehicle Area to be tested and confirm the

selection.

The PDU tools screen should now be displayed.

Highlight 'Datalogger'.

Confirm the selection with the 'tick'

icon.

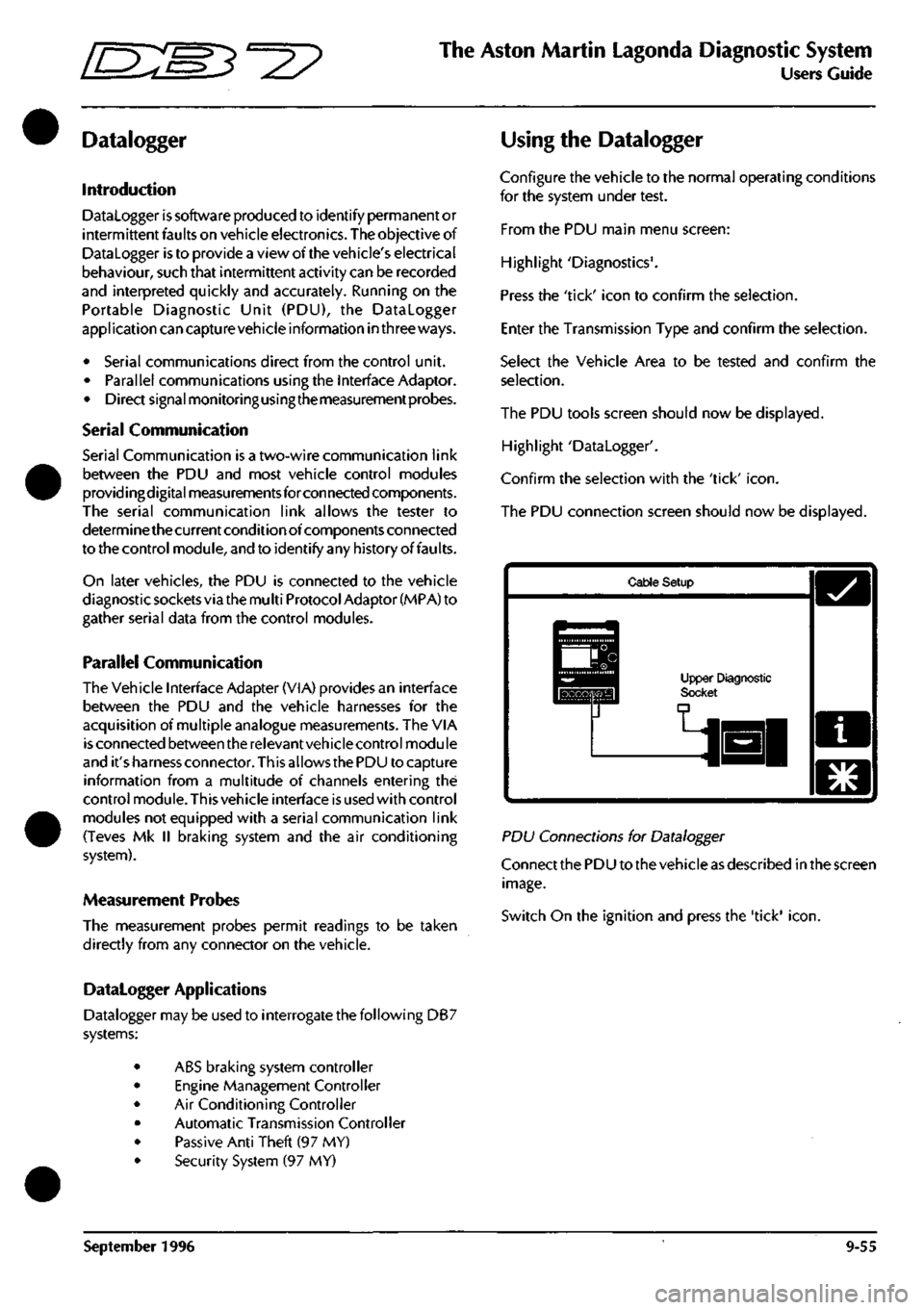

The PDU connection screen should now be displayed.

Cable Setup

Upper Diagnostic Socl

PD\J Connections for Datalogger

Connect the PDU to the vehicle as described in the screen

image.

Switch On the ignition and press the 'tick'

icon.

September 1996 9-55

Page 409 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide 5^^?

Only the data within the selected time period will be

stored.

A trigger is used to define the zero time point on

any waveform display. This is used to make it easier to

locate the actual point at which the fault occurred on the

waveform display. Triggers may take three forms.

1.

Manual Trigger

A manual trigger would be used in circumstances where

the technician can clearly identify the point when the fault

occurs and has access to the PDU at this point.

The trigger icon should be pressed on the waveform /

bargraph display (ortheon-road trigger icon) at the instant

the fault occurs. This will then become the zero point for

the waveform/bargraph display. The waveform/bargraph

display up to this point would have a negative form.

2.

Fault Code Trigger

The fault code trigger is used when the first indication of

a fault is normally by the appearance of a warning lamp

within the instrument pack. For some vehicle systems

Datalogger can trigger on specific fault codes, this type of

triggering is more precise than simply triggering on the

warning lamp.

This trigger

is

selected during the parameter customisation

process. To select a fault code to trigger 'on', set the fault

code (parameter) to record.

Asign the display order by touching the rectangle below

the Eye icon repeatedly until the desired display order

number is shown.

Press the rectangle in the trigger column.

Highlight the fault code parameter again and select the

magnifying glass

icon.

The trigger customisation screen

will be displayed.

Select the appropriate trigger style icon and select the tick

icon to confirm.

Press the Tick icon again to return to the main Datalogger

screen.

Select the Record icon to start data capture.

The unit will trigger when the fault code appears and will

set the zero time point of the waveform / bargraph display.

3. Specific Signal Trigger

It is possible to select a specific parameter or signal to

trigger Datalogger.

Triggering on specific signals is likely to be used when the

vehicle system has no on-board diagnostics or when

diagnostic information is not readily available at the time

the fault occurs, e.g. air-conditioning.

Thistypeoftriggershouldonly be used when it is known

that a particular signal has certain characteristics at the

time the fault occurs, e.g. one signal will always go from

12 Volts to ground, bringing on a warning lamp when a

particular fault occurs,

as

this is a known event, this signal

may be used to trigger the PDU.

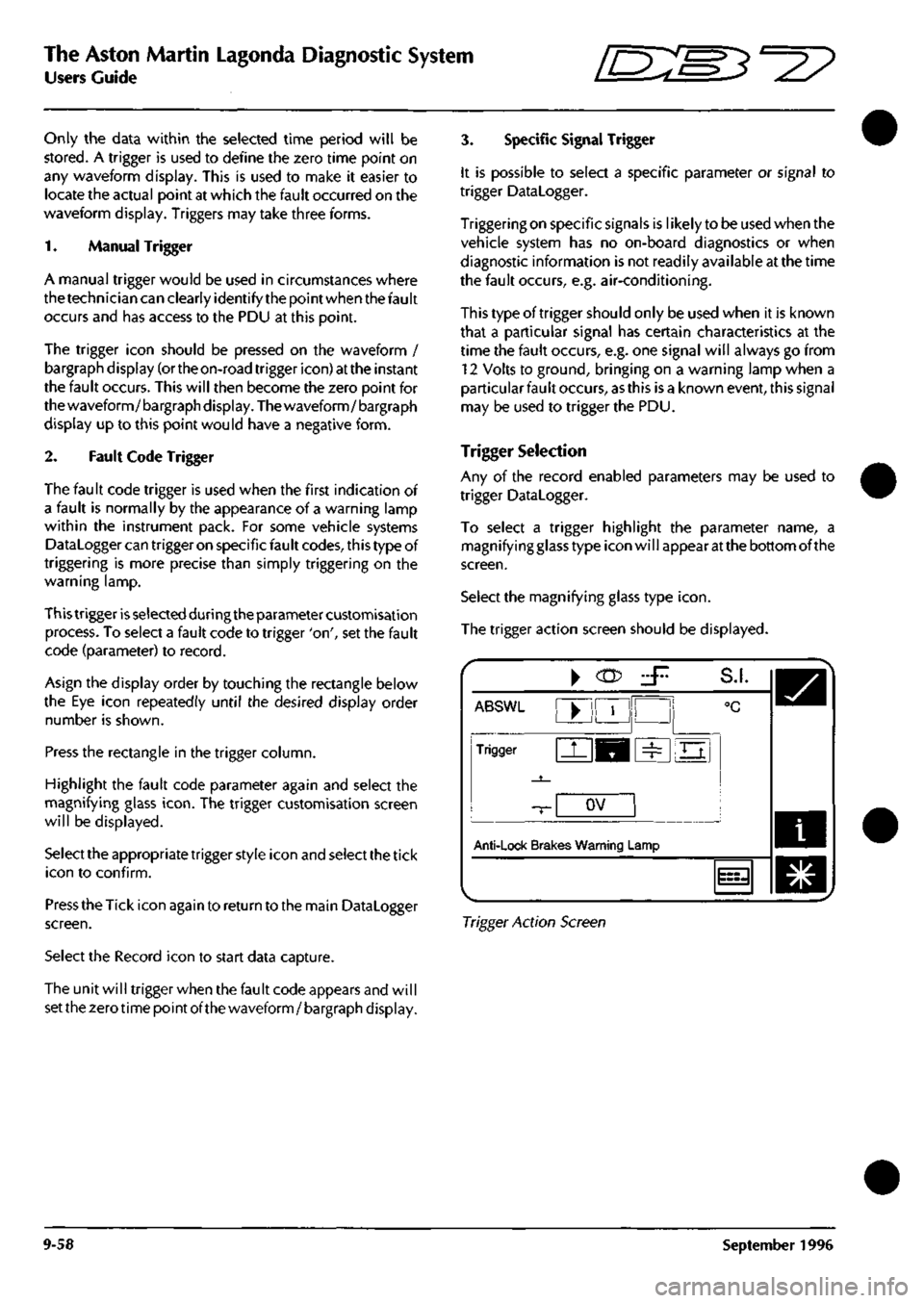

Trigger Selection

Any of the record enabled parameters may be used to

trigger Datalogger.

To select a trigger highlight the parameter name, a

magnifying glass type icon will appear at the bottom of the

screen.

Select the magnifying glass type

icon.

The trigger action screen should be displayed.

ABSWl

Trigger

-T-

Anti-lock Brak

^

^M

ov

es Warning

L

zF

!

=^

S.I.

°C

Ei

.amp

i

m,

Trigger Action Screen

9-58 September 1996

Page 410 of 421

^^?

The Aston Martin Lagonda Diagnostic System

Users Guide

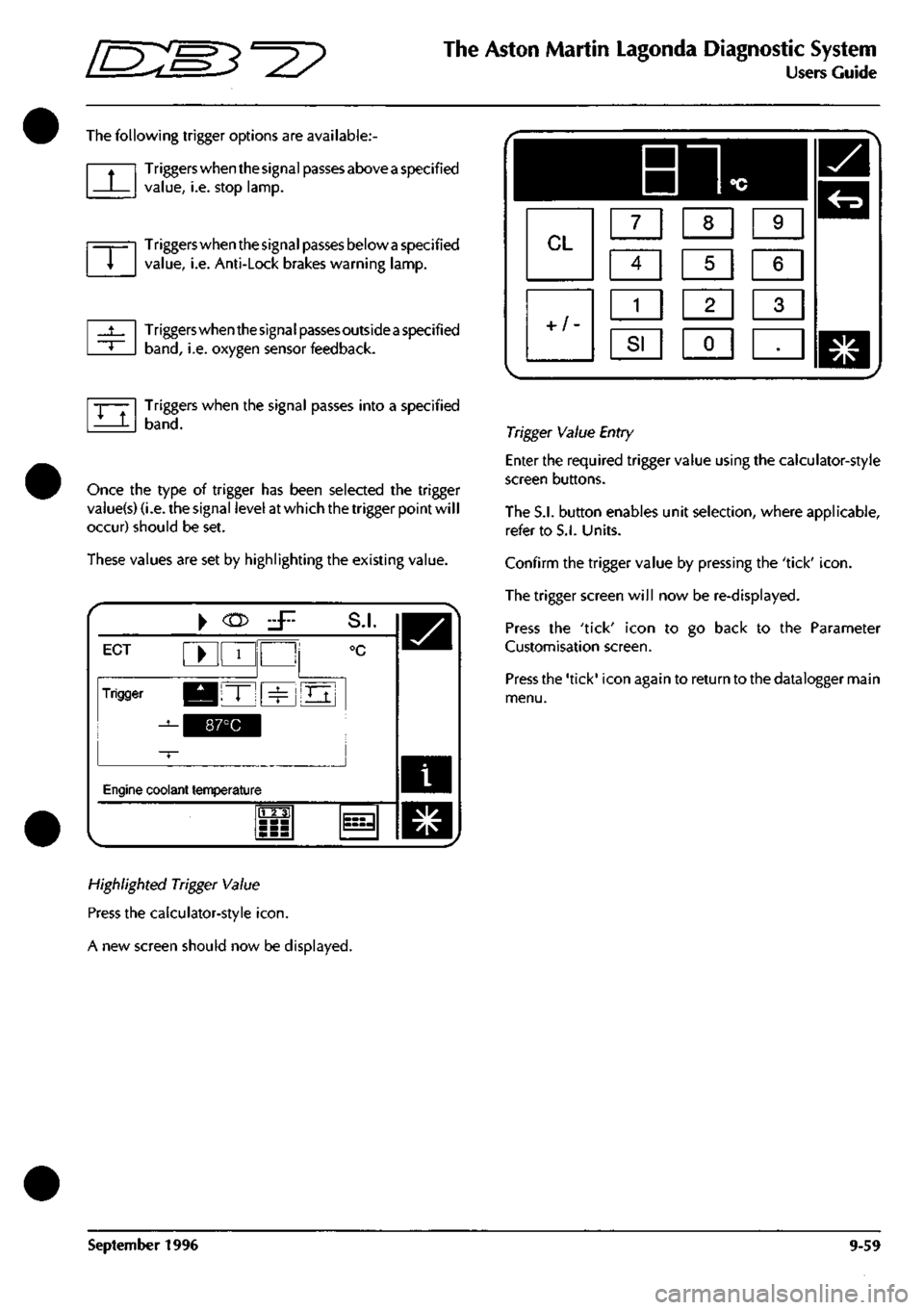

The following trigger options are available:

Triggers when the signal passes above

a

specified

value,

i.e. stop lamp.

Triggers when the signal passes below

a

specified

value,

i.e. Anti-Lock brakes warning lamp.

Triggers when the signa

I

passes outside

a

specified

band,

i.e. oxygen sensor feedback.

Triggers when the signal passes into a specified

band.

Once the type of trigger has been selected the trigger

vaiue(s) (i.e. the signal level at which the trigger point wil

I

occur) should be set.

These values are set by highlighting the existing value.

i

ECT ^ 1

Trigger KBIT" ^

^^^^1

S.I.

°c

Oj

Engine coolant temperature

m

^

Highlighted Trigger Value

Press the calculator-style

icon.

A new screen should now be displayed.

Trigger Value Entry

Enter the required trigger value using the calculator-style

screen buttons.

The S.I. button enables unit selection, where applicable,

refer to S.I. Units.

Confirm the trigger value by pressing the 'tick'

icon.

The trigger screen will now be re-displayed.

Press the 'tick' icon to go back to the Parameter

Customisation screen.

Press the 'tick' icon again to return to the datalogger main

menu.

September 1996 9-59

Page 413 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide ^2?

Split Cursor Icon

The split cursor icon spl its the vertical cursor into

two parts.

1^

VV

One permanent static cursor represented by

a

solid vertical

line in the waveform display, and one moveable cursor

represented by a dotted vertical line, this is moved by

applying finger pressure to the screen in the position the

cursor is required.

The digital display of the waveforms will now represent

the difference in levels between the two cursors and not

the absolute signal level as detailed earlier.

Re-scale Vertical Icon

Normally all of the waveforms are displayed

with the vertical axis representing the maximum

possible variation ofthesignal,

e.g.

battery voltage

0 to 16 V.

The re-scale icon causes the waveform to scale such that

the recorded variation determines the scale, this normally

enlarges the vertical scale.

The scaling operation can be performed on any of the

displayed waveforms by highlighting the parameter name

prior to the operation.

Once auto-scaling

has

taken place, further manual scaling

may be achieved by using the '+' and '-' system icons.

Waveform Display Number

This icon enables control of the number of

waveforms displayed on the screen at any one

MMV

MMV

time.

Pressing this icon causes the '+' and '-' system icons to

appear. Using these system icons increase or decrease the

number of displayed waveforms.

It should be noted that the more waveforms displayed the

poorer the detail becomes, therefore the number of

displayed waveforms should be kept to a minimum.

Horizontal Scale

-^ This icon performs the same function as the re-

scale vertical icon only for the horizontal axis.

By expanding the scale more detail will be available, thus

proving easier to analyse. However the amount of time

displayed on any one screen will be reduced.

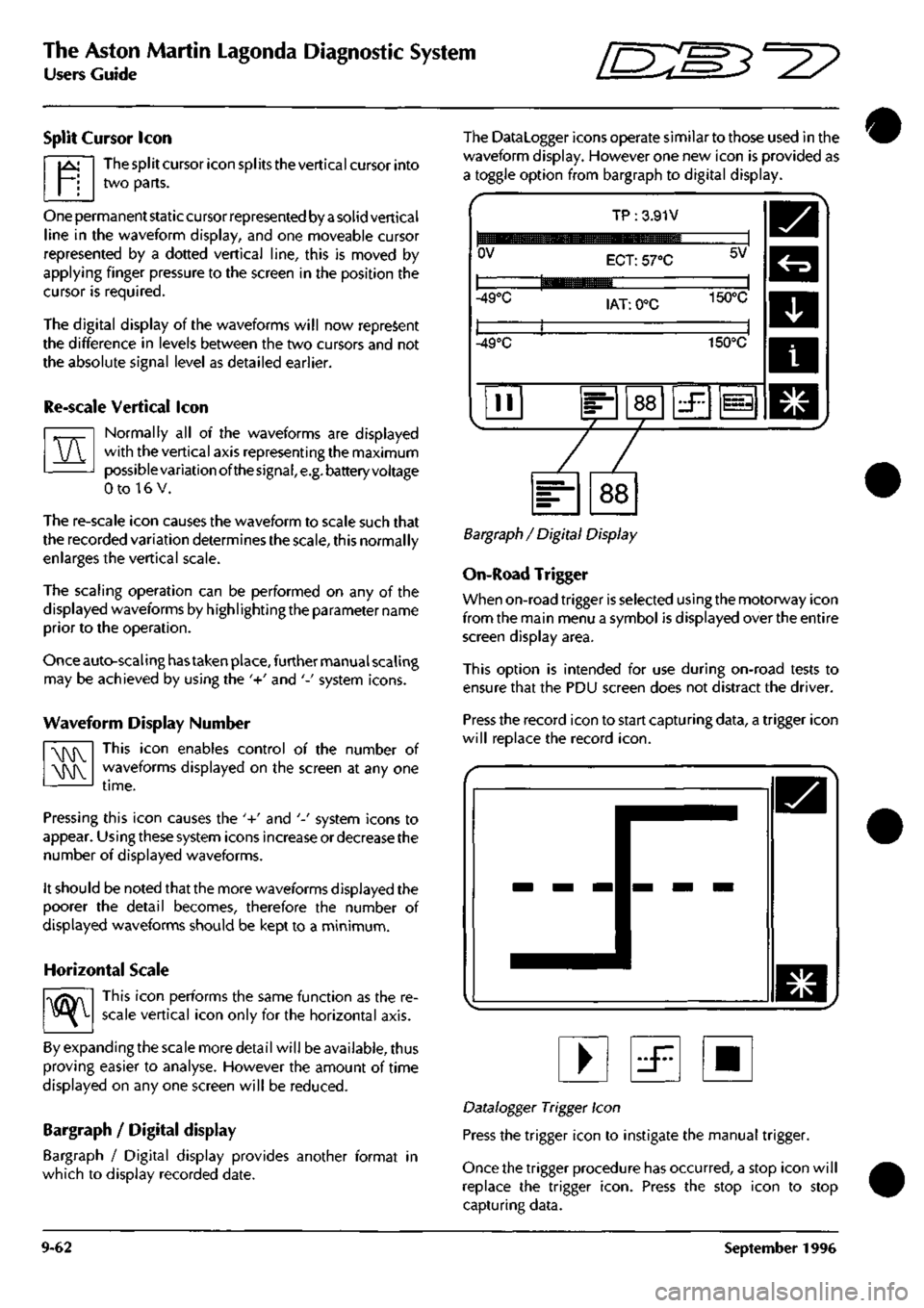

Bargraph / Digital display

Bargraph / Digital display provides another format in

which to display recorded date.

The Datalogger icons operate similar to those used in the

waveform display. However one new icon is provided as

a toggle option from bargraph to digital display.

OV

TP :3.91V

ECT: 57°C 5V

-49°C lAT: 0°C 150°C

-49°C 150°C

II 88 zF 1^

Bargraph / Digital Display

On-Road Trigger

When on-road trigger is selected using the motorway icon

from the main menu a symbol is displayed over the entire

screen display area.

This option is intended for use during on-road tests to

ensure that the PDU screen does not distract the driver.

Press the record icon to start capturing data, a trigger icon

will replace the record

icon.

• iF •

Datalogger Trigger Icon

Press the trigger icon to instigate the manual trigger.

Once the trigger procedure has occurred, a stop icon will

replace the trigger

icon.

Press the stop icon to stop

capturing data.

9-62 September 1996

Page 415 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide

ES^"^?

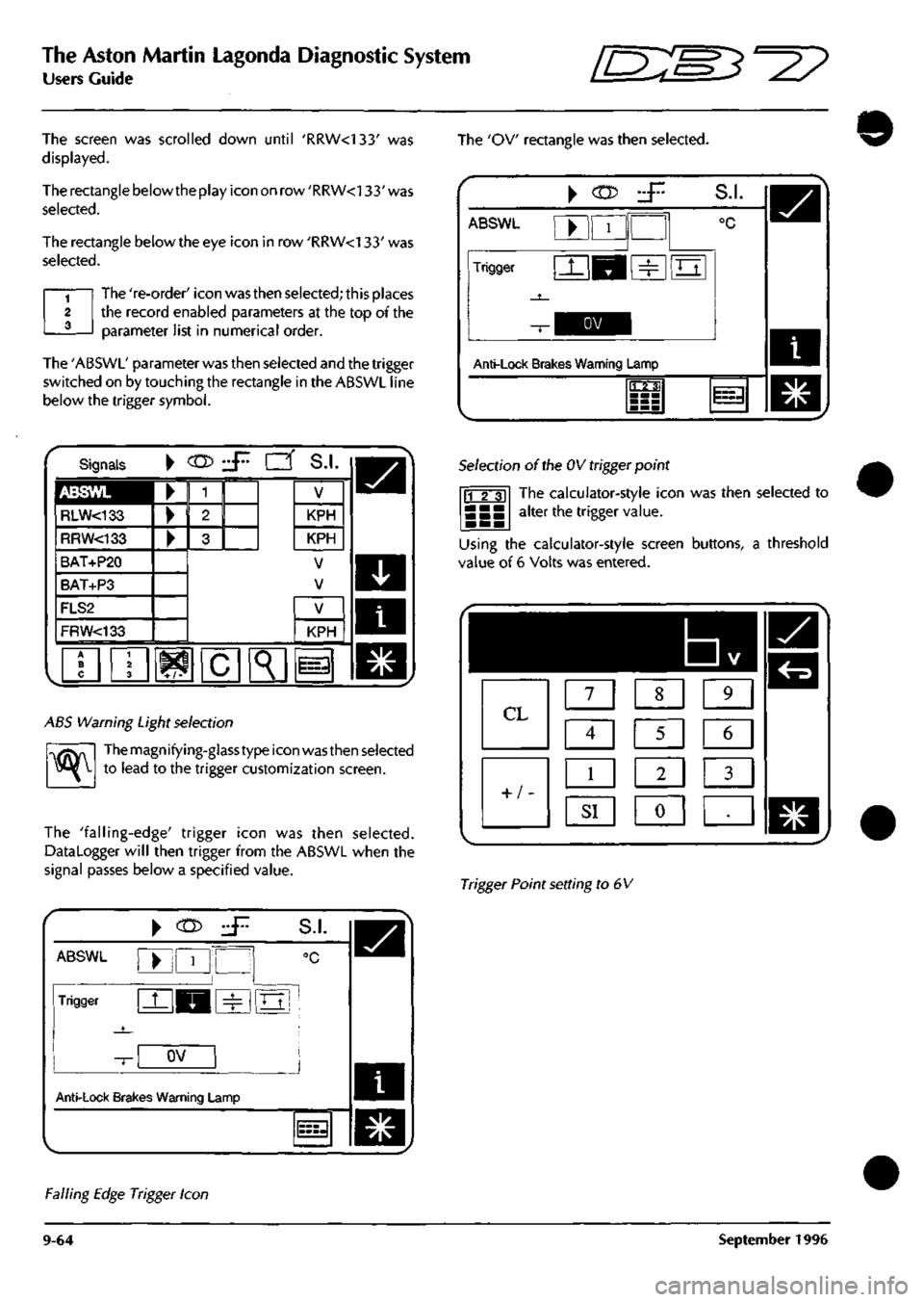

The screen was scrolled down until 'RRW<133' was

displayed.

The rectangle below the play icon on row 'RRW<133' was

selected.

The rectangle below the eye icon in row 'RRW<133' was

selected.

The 're-order' icon was then selected; this places

the record enabled parameters at the top of the

parameter list in numerical order.

The 'ABSWL' parameter was then selected and the trigger

switched on by touching the rectangle in the ABSWL line

below the trigger symbol.

The 'OV rectangle was then selected.

\

(n>

ABSWL

Trigger

S.I.

Anti-Lock Brakes Warning Lamp

1123;

11=3

Signals

ABSWL

RLW<133

RRW<133

BAT+P20

BAT+P3

FLS2

FRW<133

•

KPH

KPH

V

V

^K

KPH

i=

ABS Warning Light selection

^

Themagnifying-glasstype icon wasthen selected

to lead to the trigger customization screen.

The 'falling-edge' trigger icon was then selected.

DataLogger will then trigger from the ABSWL when the

signal passes below a specified value.

Selection of the OV trigger point

The calculator-style icon was then selected to

alter the trigger value. 11 2 31

Using the calculator-style screen buttons, a threshold

value of 6 Volts was entered.

1

7 1 1 8 1 1 9 1

Q

Q

5

1 6 1

LB m

1

^I 1 «J •

Trigger Point setting to 6V

ABSWL

Trigger

Anti-Lock Brak

^

(n>

•

1

'

^H

OV

es Warning L

.jr.

1

S.I.

°C

m

amp

J

l===-l

Falling Edge Trigger Icon

9-64 September 1996

Page 420 of 421

ThesAston Martin LagondanDiagriostic System

Users;

Guide-,^

User Self Test

^ -

The self-test function built into

the

PDU software enables

users

to

completely test the system

for

faulty rnodules and,

cables. By following the screen instructions, faulty system

components

can be

identified.

Procedure

Select User Self-Test from

the PDU

main menu.

The

self-

test software will load from

the CD.

The first screen shows

the

cable setup with

the PDU

connected

to the

base station. After confirming that

the

connections

are

correct,

the

self-test sequence begins.

The initial test

is of

the

PDU and

base station electronics

and takes slightly less than

2

minutes.

The user

is

then directed

to

connect

the

various external

elements of the system

in

turn and confirm the cable setup

at each stage.

As

each element

is

connected

and

tested,

the sequence will either direct that

the

next element

is

connected

or

will report

a

fault

in the

last element tested.

Using this procedure, any faulty element in the system will

be identified.

If the

self-test concludes with

no

fault

reported,

any

problem encountered must be in the vehicle

or

as a

result

of

incorrect

use.

The Asterisk

(*)

lcon?'fi ^^

G * s ^

When available, selecting

the

asterisk icon will bring

up

the

following menu

of

general facilities:

ic

•

•

*

•

• ~',"•'.

•

•

,

•., .,

Resume

Abort . ..

Status

• •

Setup ., , ,

Print Screen

Show trace : T'J

Print trace

D

•u

_ ,1

1

l»

.

*-«•

-

-•

,

'

•

Resume

Return

to the

screen from which

you

selected

the

asterisk

icon.

Abort

•

'•'•'"'

• '• "

'"'^''•'

"'-

' Return

to the PDU

Main Menu.

' ' ' ••'""

Self-Test Problems

If

the

self test software will

not

load

or if

unidentified

problems

are

encountered during

the

self-test,

go to the

problem solving procedure

in

the PDU installation guide.

Be prepared

to

record

any

problem codes which

are

reported during problem solving.

The

Genrad Service

Centre will require

the

problem code number

to

identify

the correct remedial action

and

replacement parts.

Status

Show

the

current software level

and the

application

currently loaded.

--«

^

^.« - ...

•

^f;;fc.i.*ir.

....-^i^cw'i*;*^--'. Print Screen

Send

the

current screen display

to the

printer

.iia*M--i^-Vj^W'JStS:'

.

Show Trace

••'- •

'B-T'^TS

o^

•._,

^,„„, ,' J

rbisplay'the current contents

of

the fracelmemorylDri

^

the screen

(Use the

Down

and

Up^ arrows

to

scroll

•,

through

the

display

if

more than

one

screenful). •

Ai..;:

. ; •

,\J-'!-MT.'

0'; I

Print Trace

•-l.---^,^

• ,\.

^,

,./j-,i:,

Q

:;

Send

the

current contents

of

the trace memory

to the

printer.

I

a-.-s.-™.*'.-jc^.'-v*

September 1996? 9-69,